Development and Research of New Hybrid Composites with Increased Requirements for Heat and Wear Resistance

Abstract

1. Introduction

Research Objectives

- -

- to justify the choice of developing new heat- and wear-resistant composite materials for the energy and oil and gas industries;

- -

- to justify the choice of equipment and technology for the formation of hybrid composite materials;

- -

- to assess the influence of the high-energy mechanical treatment (HMT) (mechanical alloying) of the powder compositions on the quality and mechanical properties of composites;

- -

- to study the structure of the powder compositions after the HMT, and to describe the mechanisms of interaction between the powder materials and the grinding media;

- -

- to study the structure and structural parameters of the composite materials;

- -

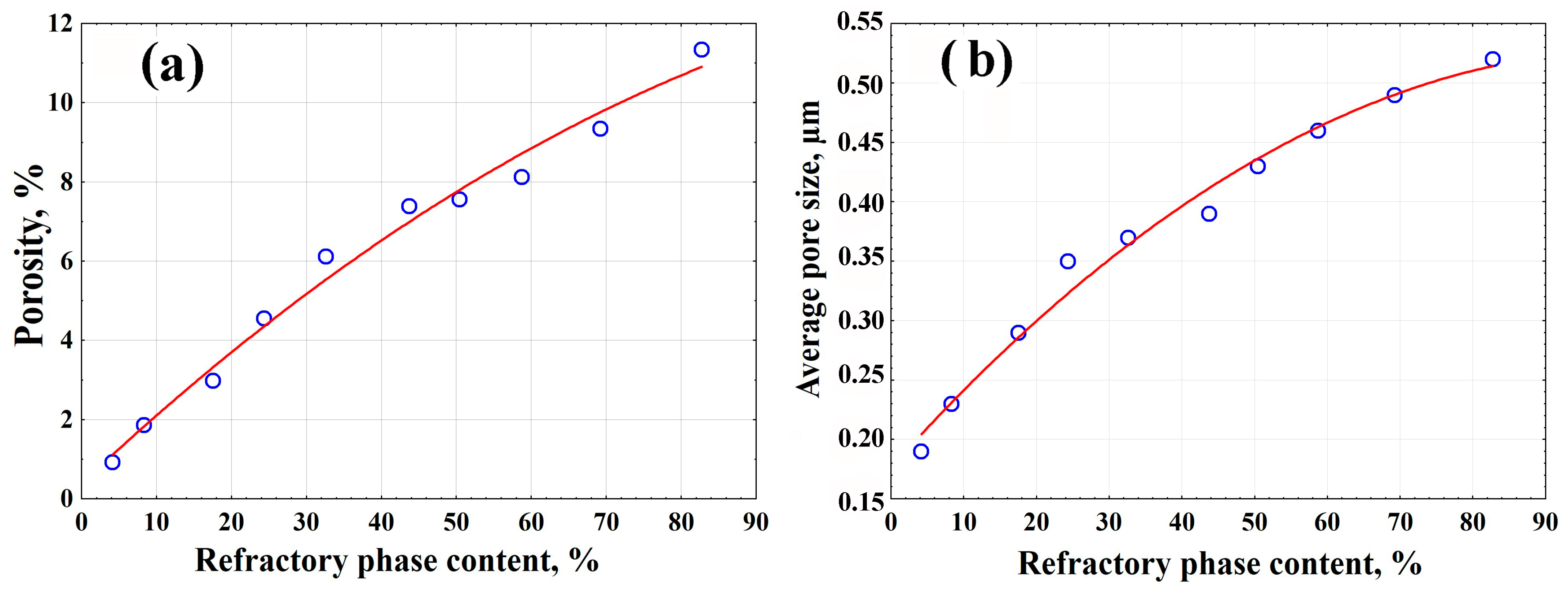

- to study and assess the density of the resulting composite materials (the effect of the content of the refractory ceramic phase on the porosity and average pore size of the composite layers);

- -

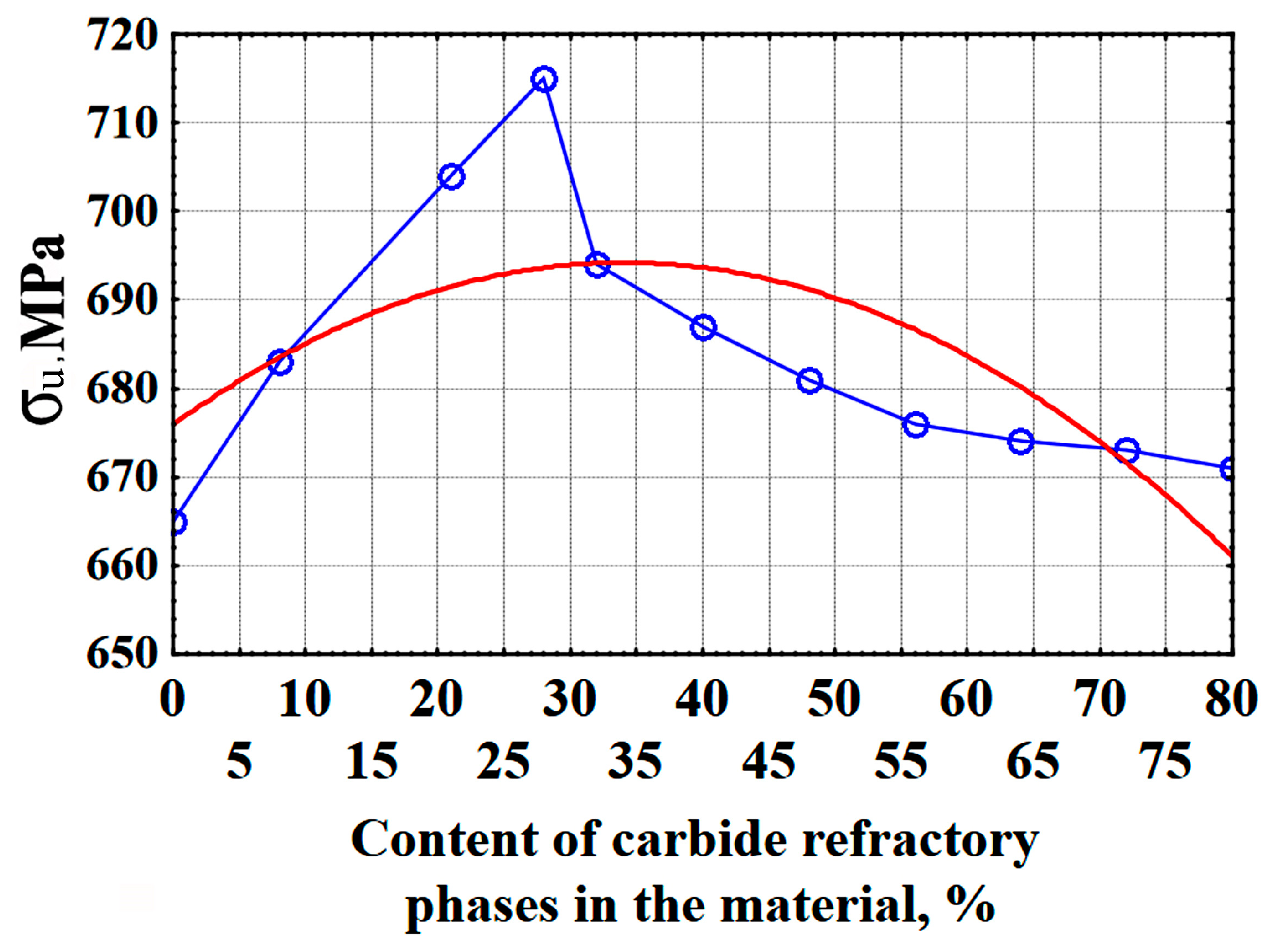

- to research and assess the mechanical properties of the composites (influence of the carbide phase content (HfC, TaC) in the composite layers on the flexural strength);

- -

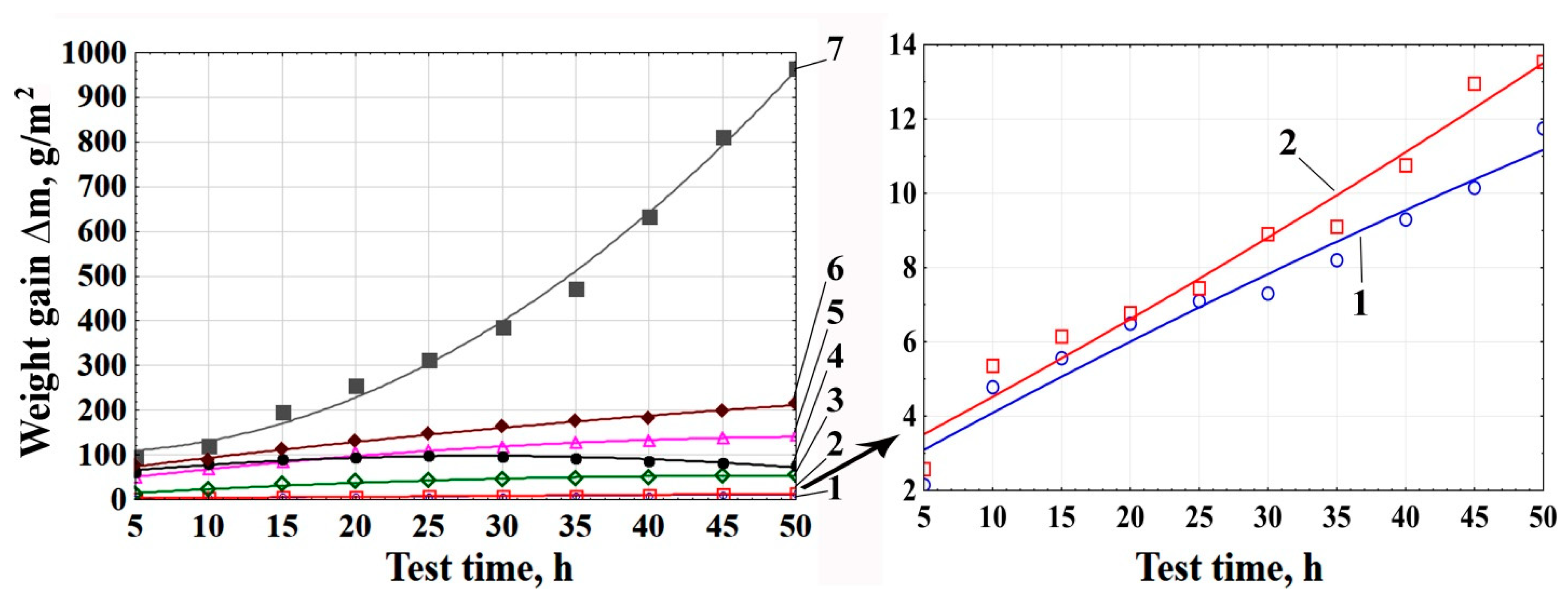

- to study the heat resistance of the developed composites (material 1 (Ni-HfC-Re-ZrO2-Y2O3-Gd2O3-Yb2O3-Al2O3), material 2 (HfC-Re-TaC-ZrO2-Y2O3-Gd2O3-Yb2O3-Al2O3)); to compare the heat resistance of the developed composites with previously known ones (Ni-Al2O3 (24% wt.); NiCrY-Al2O3 (10% wt.); NiCrAl-ZrO2 (37% wt.)); and to assess the influence of the carbide and oxide phases on the heat resistance of the composites;

- -

- to study the wear resistance of the developed composites and to compare the wear resistance of the developed composites with previously known heat-resistant composites (NiCrY-Al2O3 (10% wt.); NiCrAl-ZrO2 (37% wt.)).

2. Materials and Research Methods

2.1. Materials

2.2. High Energy Machining

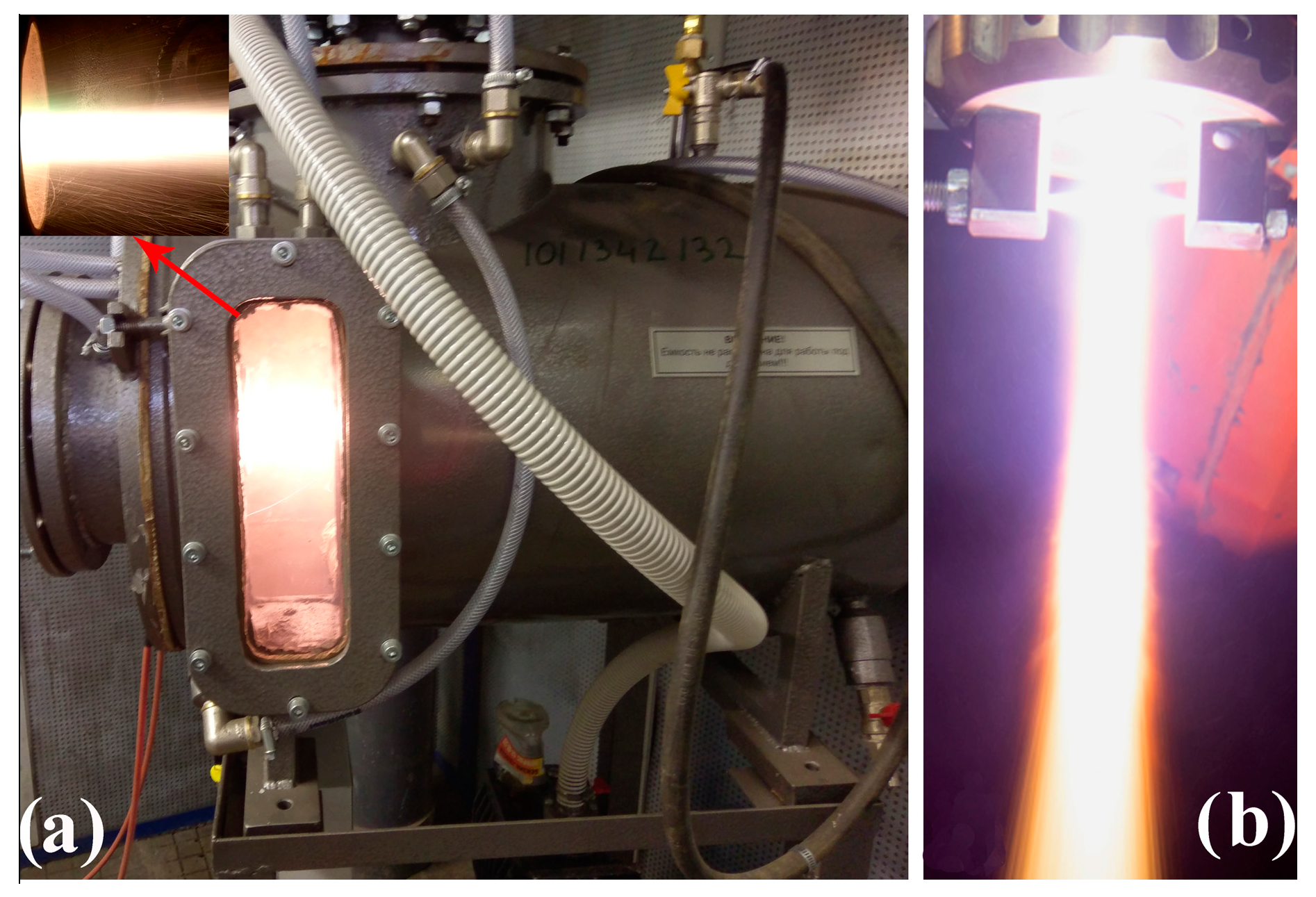

2.3. Formation of Layered Composites

2.4. Properties

3. Results and Discussion

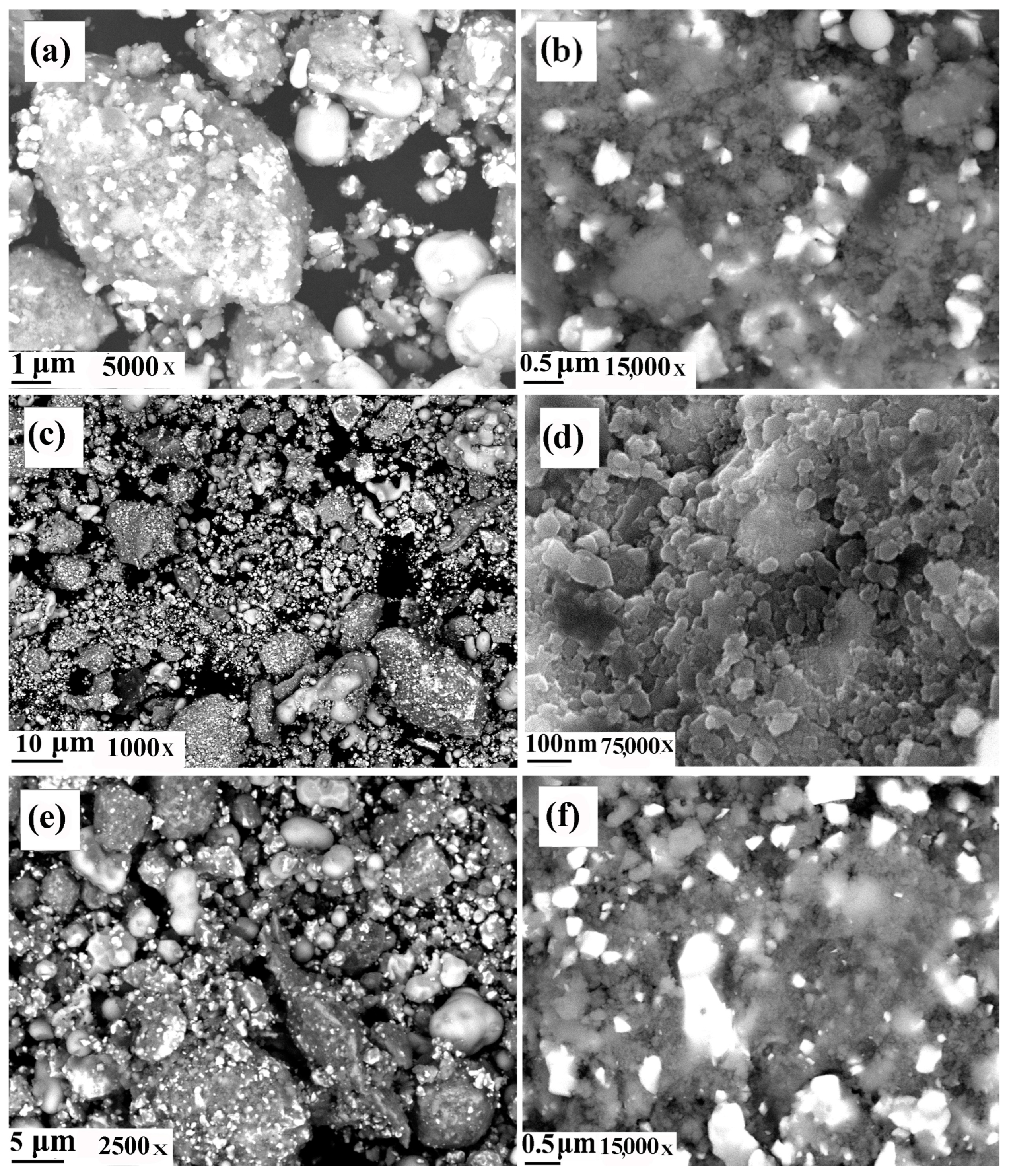

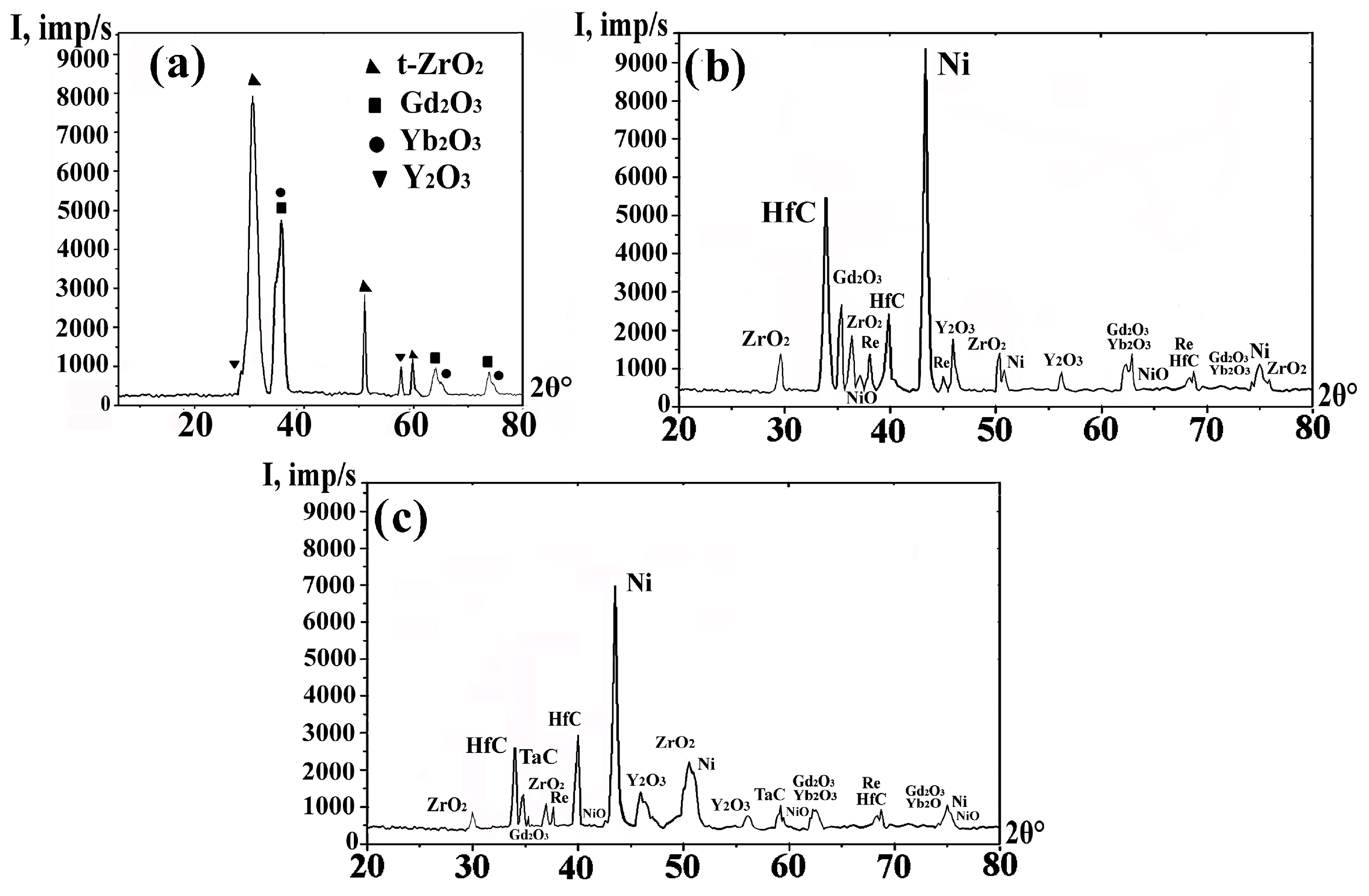

3.1. Study of the Powder Composition and Structure After HMT

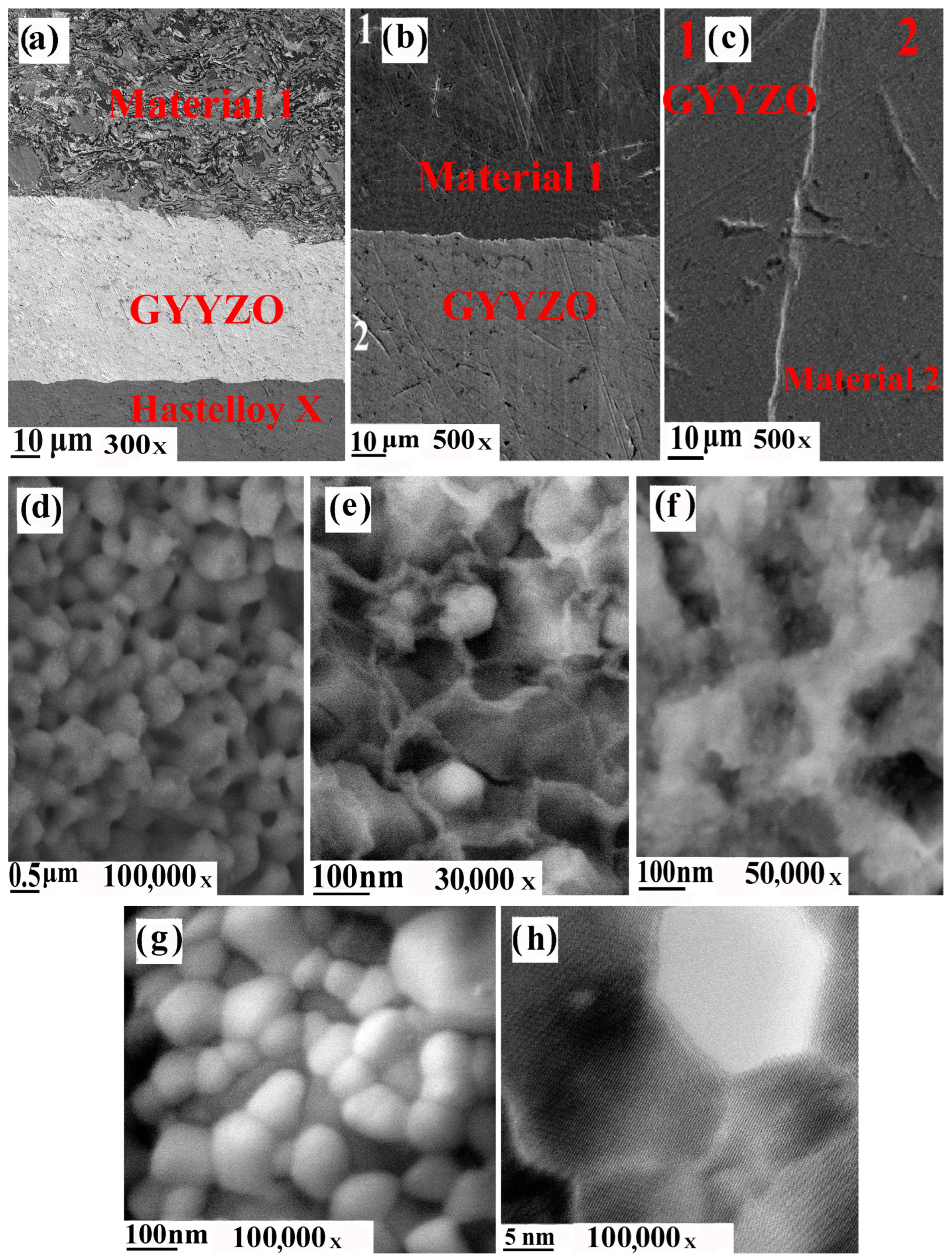

3.2. Structural Studies of Composites

3.3. Properties of Surface-Modified Layers of Hybrid Composites

3.3.1. Porosity

3.3.2. Microhardness

3.3.3. Mechanical Properties

3.3.4. Heat Resistance

3.3.5. Wear Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alkunte, S.; Fidan, I.; Naikwadi, V.; Gudavasov, S.; Ali, M.A.; Mahmudov, M.; Hasanov, S.; Cheepu, M. Advancements and Challenges in Additively Manufactured Functionally Graded Materials: A Comprehensive Review. J. Manuf. Mater. Process. 2024, 8, 23. [Google Scholar] [CrossRef]

- Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R.K.P. A Review on Functionally Gradient Materials (FGMs) and Their Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Xu, G.-M.; Chen, J.; Rusinov, P.; Zhang, C. Tribocorrosion behavior of TiZrHfNb-based refractory high-entropy alloys. Wear 2024, 536–537, 205158. [Google Scholar] [CrossRef]

- Rusinov, P.; Blednova, Z.; Rusinova, A.; Kurapov, G.; Semadeni, M. Development and Research of New Hybrid Composites in Order to Increase Reliability and Durability of Structural Elements. Metals 2023, 13, 1177. [Google Scholar] [CrossRef]

- Mehmood, M.A.; Shehzad, K.; Mujahid, M.; Bin Yaqub, T.; Godfrey, A.; Fernandes, F.; Muhammad, F.Z.; Yaqoob, K. Ceramic-reinforced HEA matrix composites exhibiting an excellent combination of mechanical properties. Sci. Rep. 2022, 12, 21486. [Google Scholar] [CrossRef]

- Medina, L.Z.; Riekehr, L.; Jansson, U. Phase formation in magnetron sputtered CrMnFeCoNi high entropy alloy. Surf. Coatings Technol. 2020, 403, 126323. [Google Scholar] [CrossRef]

- Akrami, S.; Edalati, P.; Fuji, M.; Edalati, K. High-entropy ceramics: Review of principles, production and applications. Mater. Sci. Eng. R Rep. 2021, 146, 100644. [Google Scholar] [CrossRef]

- Yang, L.; Shi, X.; Tian, X.; Wang, H.; Qi, L. Microstructure and corrosion behavior of ZrO2 coated carbon fiber reinforced magnesium matrix composites sprayed with different powder characteristics. Ceram. Int. 2022, 48, 30797–30806. [Google Scholar] [CrossRef]

- Sliem, M.H.; Fayyaz, O.; Shakoor, R.; Bagherifard, S.; Mansoor, B.; Abdullah, A.; Mohamed, A.M.A. The influence of different preparation methods on the erosion behavior of NiP-ZrO2 nanocomposite coating. Tribol. Int. 2022, 178, 108014. [Google Scholar] [CrossRef]

- Kim, S.; Kim, T.; Hong, E.; Jo, I.; Kim, J.; Lee, H. Phase Formation and Wear Resistance of Carbon-Doped TiZrN Nanocomposite Coatings by Laser Carburization. Metals 2021, 11, 590. [Google Scholar] [CrossRef]

- Shojaie-Bahaabad, M.; Bozorg, M.; Najafizadeh, M.; Cavaliere, P. Ultra high temperature ceramic coatings in thermal protection systems (TPS). Ceram. Int. 2024, 50, 9937–9951. [Google Scholar] [CrossRef]

- Pakseresht, A.; Mosas, K.K.A. Ceramic Coatings for High-Temperature Environments. In From Thermal Barrier to Environmental Barrier Applications; Springer: Cham, Switzerland, 2024; p. 491. [Google Scholar] [CrossRef]

- Ch, J.R.; Vetrivendan, E.; Madhura, B.; Ningshen, S. A review of ceramic coatings for high temperature uranium melting applications. J. Nucl. Mater. 2020, 540, 152354. [Google Scholar] [CrossRef]

- Devarajan, D.K.; Rangasamy, B.; Mosas, K.K.A. State-of-the-Art Developments in Advanced Hard Ceramic Coatings Using PVD Techniques for High-Temperature Tribological Applications. Ceramics 2023, 6, 301–329. [Google Scholar] [CrossRef]

- Ni, D.; Cheng, Y.; Zhang, J.; Liu, J.-X.; Zou, J.; Chen, B.; Wu, H.; Li, H.; Dong, S.; Han, J.; et al. Advances in ultra-high temperature ceramics, composites, and coatings. J. Adv. Ceram. 2022, 11, 1–56. [Google Scholar] [CrossRef]

- Sako, E.Y.; Orsolini, H.D.; Moreira, M.; de Meo, C.E.; Pelissari, P.I.B.G.B.; Salvini, V.R.; Pandolfelli, V.C. Review: Thermal ceramic coatings as energy saving alternatives for high temperature processes. Int. J. Appl. Ceram. Technol. 2020, 17, 2492–2508. [Google Scholar] [CrossRef]

- Gulyaev, I.; Kuzmin, V.; Kornienko, E.; Vyalova, A.; Tyryshkin, P.; Sergachev, D.; Vashchenko, S. Plasma spraying of thermal barrier coatings using YSZ powders. Mater. Today Proc. 2019, 19, 2134–2138. [Google Scholar] [CrossRef]

- Tisnado, J.O.Z.; Bondareva, O.; Hristova, V. Structure degradation of the plasma spray thermal barrier coating on the blade during operation. Lett. Mater. 2019, 9, 228–233. [Google Scholar] [CrossRef]

- He, J.; Liu, J.; Zhao, H.; Qin, Y.; Fan, J. High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings. Coatings 2024, 14, 109. [Google Scholar] [CrossRef]

- Wang, S.; Chen, S.; Liu, M.; Huang, Q.; Liu, Z.; Li, X.; Xu, S. The Effect of Plasma Spray Parameters on the Quality of Al-Ni Coatings. Coatings 2023, 13, 2063. [Google Scholar] [CrossRef]

- Jude, S.; Jappes, J.W.; Adamkhan, M. Thermal barrier coatings for high-temperature application on superalloy substrates—A review. Mater. Today Proc. 2022, 60, 1670–1675. [Google Scholar] [CrossRef]

- Barwinska, I.; Kopec, M.; Kukla, D.; Senderowski, C.; Kowalewski, Z.L. Thermal Barrier Coatings for High-Temperature Performance of Nickel-Based Superalloys: A Synthetic Review. Coatings 2023, 13, 769. [Google Scholar] [CrossRef]

- Vagge, S.; Ghogare, S. Thermal barrier coatings: Review. Mater. Today Proc. 2022, 56, 1201–1216. [Google Scholar] [CrossRef]

- Narita, T.; Kato, Y.; Narita, T.; Ara, M. Advances in Diffusion Barrier Coatings for High-Temperature Applications. High Temp. Corros. Mater. 2023, 100, 399–411. [Google Scholar] [CrossRef]

- Sahith, M.S.; Giridhara, G.; Suresh Kumar, R. Development and analysis of thermal barrier coatings on gas turbine blades—A Review. Mater. Today Proc. 2018, 5, 2746–2751. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, D.; Xie, J.; Xu, S.; Huang, H.; Li, J.; Hou, H.; Wu, J. Application of zirconia thermal barrier coating on the surface of pulling-straightening roller. Int. J. Heat Technol. 2017, 35, 765–772. [Google Scholar] [CrossRef]

- Smialek, J.L.; Jacobson, N.S.; Gleeson, B.; Hovis, D.B.; Heuer, A.H. Oxygen Permeability and Grain-Boundary Diffusion Applied to Alumina Scales; National Aeronautics and Space Administration John, H. Glenn Re-search Center at Lewis Field: Cleveland, OH, USA, 2013; Volume 217855, pp. 1–34. [Google Scholar]

- Nakagawa, T.; Nishimura, H.; Sakaguchi, I.; Shibata, N.; Matsunaga, K.; Yamamoto, T.; Ikuhara, Y. Grain Boundary Character Dependence of Oxygen Grain Boundary Diffusion in α-Al2O3 Bicrystals. Scr. Mater. 2011, 65, 544–547. [Google Scholar] [CrossRef]

- Elements of Metallurgy and Engineering Alloys; Campbell, F.C., Ed.; ASM International: Materials Park, OH, USA, 2008. [Google Scholar]

- Knittel, S.; Mathieu, S.; Vilasi, M. The oxidation behaviour of uniaxial hot pressed MoSi2 in air from 400 to 1400 °C. Intermetallics 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Sazonova, M.V.; Ban’kovskaya, I.B.; Kolovertnov, D.V. Thermal Stability of Composites and Coatings Based on MoSi2–B–Al2O3 When Heated in Air to 1600 °C. Refract. Ind. Ceram. 2022, 62, 668–671. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, T.; Fu, B.; Li, G.; Liu, Q.; Li, Y. Microstructure and Properties of Cold Sprayed NiCrAl Coating on AZ91D Magnesium Alloy. Coatings 2021, 11, 193. [Google Scholar] [CrossRef]

- Yancheshmeh, D.A.; Esmailian, M.; Shirvani, K. Microstructural and oxidation behavior of Nisingle bondCrsingle bondAl super alloy containing hafnium at high temperature. Int. J. Hydrogen Energy 2018, 43, 5365–5373. [Google Scholar] [CrossRef]

- Zhang, S.; Ouyang, P.; Yan, H.; Si, L. Study on Microstructure and Oxidation Resistance Mechanism of Y-Modified NiCrAlY Coating Prepared by Pack Cementation. Coatings 2023, 13, 63. [Google Scholar] [CrossRef]

- Fu, G.; Wei, L.; Zhang, X.; Cui, Y.; Yu, B.; Lv, C.; Wang, Y.; Ye, S. Migration and enrichment of chromium and silicon element in glass coating at high temperature. J. Non-Cryst. Solids 2018, 492, 18–26. [Google Scholar] [CrossRef]

- Han, F.; Chen, Y.; Liu, Y.; Yang, X.; Che, S.; Zhang, Y.; Huo, J.; Gao, M.; Wang, J.-Q. High temperature oxidation behaviors of Ir-Ni-Ta-(B) metallic glass. Corros. Sci. 2022, 205, 110420. [Google Scholar] [CrossRef]

- Li, W.; Chen, K.; Liu, L.; Yang, Y.; Zhu, S. Effect of SiO2–Al2O3 Glass Composite Coating on the Oxidation Behavior of Ti60 Alloy. Materials 2020, 13, 5085. [Google Scholar] [CrossRef] [PubMed]

- Hoche, H.; Pusch, C.; Riedel, R.; Fasel, C.; Klein, A. Properties of SiCN coatings for high temperature applications—Comparison of RF-, DC- and HPPMS-sputtering. Surf. Coatings Technol. 2010, 205, S21–S27. [Google Scholar] [CrossRef]

- Rusinov, P.; Blednova, Z.; Rusinova, A.; Kurapov, G.; Semadeni, M. Development, Synthesis and Research of Multifunctional Composite Materials to Increase the Strength, Reliability, and Durability of Units in Various Industries; Nova Science Publishers: Hauppauge, NY, USA, 2023; Volumes 67, Chapter 4, pp. 191–229. [Google Scholar]

- Yi, J.; Miao, Q.; Liang, W.; Ding, Z.; Qi, Y.; Lin, H.; Huang, C.; Li, Y. A study for pre-processing of Nb diffusion in Nb-N layer by double-glow plasma alloying. J. Alloys Compd. 2020, 820, 153121. [Google Scholar] [CrossRef]

- Chandrasekaran, A.; van de Kruijs, R.W.; Sturm, J.M.; Bijkerk, F. Nb Texture Evolution and Interdiffusion in Nb/Si-Layered Systems. ACS Appl. Mater. Interfaces 2021, 13, 31260–31270. [Google Scholar] [CrossRef] [PubMed]

- Ma, D.-D.; Xue, Y.-P.; Gao, J.; Ma, Y.; Yu, S.-W.; Wang, Y.-S.; Xue, C.; Hei, H.-J.; Tang, B. Effect of Ta diffusion layer on the adhesion properties of diamond coating on WC-Co substrate. Appl. Surf. Sci. 2020, 527, 146727. [Google Scholar] [CrossRef]

- Xu, G.; Cai, J.; Wang, R.; Xu, A.; Hu, Y.; Liu, J.; Suo, J. Effect of Transition Metal Layer on Bending and Interfacial Properties of W/TiN/Ta-Laminated Composite. Materials 2023, 16, 2434. [Google Scholar] [CrossRef]

- Liu, G.; Shen, Z.; He, L.; Mu, R.; Huang, G. LaYZrO/YSZ double ceramic layer thermal barrier coatings by EB-PVD: Thermal performance, morphology and failure behavior. Materialia 2022, 27, 101661. [Google Scholar] [CrossRef]

- Ai, L.; Wang, X.; Yang, M.; Lei, Y.; Zhu, Y. Effects of Top Ceramic Layers with an Ultrathin Dense Layer on the Thermal–Physical Properties of Thermal Barrier Coatings. Coatings 2023, 13, 1929. [Google Scholar] [CrossRef]

- Amer, M.; Curry, N.; Hayat, Q.; Sharma, R.; Janik, V.; Zhang, X.; Nottingham, J.; Bai, M. Cracking Behavior of Gd2Zr2O7/YSZ Multi-Layered Thermal Barrier Coatings Deposited by Suspension Plasma Spray. Coatings 2023, 13, 107. [Google Scholar] [CrossRef]

- Kang, Y.; Bai, Y.; Wang, Y.; Su, X. Degradation and failure of a novel double-layer LC/YSZ thermal barrier coating in a burner rig corrosion test. Mater. High Temp. 2024, 41, 343–356. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Fu, Y.; Hu, D.; Meng, J.; Li, T. Ablation behavior of HfC coating with different thickness for carbon/carbon composites at ultra-high temperature. J. Eur. Ceram. Soc. 2020, 41, 1769–1778. [Google Scholar] [CrossRef]

- Das, S.; Sozal, M.S.I.; Li, W.; John, D. Ultra-High-Temperature Ceramic Coatings ZrC, ZrB2, HfC, and HfB2. In Ceramic Coatings for High-Temperature Environments, Engineering Materials; Pakseresht, A., Amirtharaj Mosas, K.K., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Kim, H.S.; Kang, B.R.; Choi, S.M. Microstructure and Mechanical Properties of Vacuum Plasma Sprayed HfC, TiC, and HfC/TiC Ultra-High-Temperature Ceramic Coatings. Materials 2020, 13, 124. [Google Scholar] [CrossRef]

- Smith, C.J.; Ross, M.A.; De Leon, N.; Weinberger, C.R.; Thompson, G.B. Ultra-high temperature deformation in TaC and HfC. J. Eur. Ceram. Soc. 2018, 38, 5319–5332. [Google Scholar] [CrossRef]

- Xiao, L.; Yesong, C.; Pan, K.; Jia, F.; Xin, Y.; Qizhong, H. Effect of TaC on high temperature ablative resistance of SiC coatings. Mater. Sci. Eng. Powder Metall. 2023, 28, 120–128. [Google Scholar] [CrossRef]

- Kumar, S.; Mondal, S.; Kumar, A.; Ranjan, A.; Prasad, N.E. Chemical Vapor Deposition of TaC/SiC on Graphite Tube and Its Ablation and Microstructure Studies. Coatings 2017, 7, 101. [Google Scholar] [CrossRef]

- Liu, X.-L.; Dai, Y.; Wang, Z.-J.; Wu, J. Research progress on tantalum carbide coatings on carbon materials. New Carbon Mater. 2021, 36, 1049–1061. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Sung, J.-H. Microstructure and Mechanical Properties of Hastelloy X Fabricated Using Directed Energy Deposition. Metals 2023, 13, 885. [Google Scholar] [CrossRef]

- Liu, M.; Zeng, Q.; Hua, Y.; Zheng, W.; Wu, Y.; Jin, Y.; Li, Y.; Wang, J.; Zhang, K. High-Temperature Tensile Properties of Hastelloy X Produced by Laser Powder Bed Fusion with Different Heat Treatments. Metals 2022, 12, 1435. [Google Scholar] [CrossRef]

- Wang, H.; Wu, H.; Liu, Y.; Qiu, W.; Deng, H.; Zhou, L.; Chen, L. Oxidation Behavior of Hastelloy X Alloy Fabricated by Selective Laser Melting and Subsequent Hot Isostatic Pressing Treatment. Adv. Eng. Mater. 2022, 24, 2200369. [Google Scholar] [CrossRef]

- Baranowski, M.; Senkara, J. Mechanical Properties of Structural Components in Hastelloy X Joints Brazed with Ni-Pd-Cr-B-Si Alloy. Materials 2023, 16, 1115. [Google Scholar] [CrossRef]

- Gao, P.-H.; Zeng, S.-C.; Jin, C.; Zhang, B.; Chen, B.-Y.; Yang, Z.; Guo, Y.-C.; Liang, M.-X.; Li, J.-P.; Li, Q.-P.; et al. Effect of Gd2O3 Addition on the Microstructure and Properties of Gd2O3-Yb2O3-Y2O3-ZrO2 (GYYZO) Ceramics. Materials 2021, 14, 7470. [Google Scholar] [CrossRef] [PubMed]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Guo, J.; Xiao, C.; Gao, J.; Li, G.; Wu, H.; Chen, L.; Qian, L. Interplay between counter-surface chemistry and mechanical activation in mechanochemical removal of N-faced GaN surface in humid ambient. Tribol. Int. 2021, 159, 107004. [Google Scholar] [CrossRef]

- Fourmont, A.; Le Gallet, S.; Hoummada, K.; Descoins, M.; Desgranges, C.; Politano, O.; Baras, F. Effects of mechanical activation on chemical homogeneity and contamination level in dual-phase AlCoCrFeNi high entropy alloy. Mater. Chem. Phys. 2021, 272, 125000. [Google Scholar] [CrossRef]

- Kajdas, C. Mechanical Activation of Chemical Process. Mater. Sci. Appl. 2015, 6, 60–67. [Google Scholar] [CrossRef]

- Nandihalli, N.; Mori, T.; Kleinke, H. Effect of addition of SiC and Al2O3 refractories on Kapitza resistance of antimonide-telluride. AIP Adv. 2018, 8, 095009. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, K. Microstructural and mechanical properties of thermal barrier coating at 1400 °C treatment. Theor. Appl. Mech. Lett. 2014, 4, 021008. [Google Scholar] [CrossRef]

- Ternero, F.; Rosa, L.G.; Urban, P.; Montes, J.M.; Cuevas, F.G. Influence of the Total Porosity on the Properties of Sintered Materials—A Review. Metals 2021, 11, 730. [Google Scholar] [CrossRef]

| Material | Ni | Mo | Cr | Fe | W | Co | Mn | HfC | Re | Si | TaC | ZrO2 | Y2O3 | Cu | Gd2O3 | Yb2O3 | Ti | Al | Al2O3 | Ta | Hf |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy X | 43.3 | 9.5 | 21.8 | 20.1 | 0.7 | 1.9 | 0.8 | - | - | 0.9 | - | - | - | 0.4 | - | - | 0.2 | 0.4 | - | - | - |

| Rene N6 | 57.4 | 1.4 | 4.2 | - | 6 | 12.5 | - | - | 5.4 | - | - | - | - | - | - | - | - | 5.75 | - | 7.2 | 0.15 |

| Gd2O3-Yb2O3-Y2O3-ZrO2 (GYYZO) | - | - | - | - | - | - | - | - | - | - | - | 53 | 5 | - | 35 | 7 | - | - | - | - | - |

| Material 1 | 30 | - | - | - | - | - | - | 20 | 4 | - | - | 8 | 7 | - | 9 | 6 | - | - | 16 | - | - |

| Material 2 | 30 | - | - | - | - | - | - | 16 | 3 | - | 12 | 6 | 5 | - | 8 | 5 | - | - | 15 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rusinov, P.; Zhang, C.; Sereda, P.; Rusinova, A.; Kurapov, G.; Semadeni, M. Development and Research of New Hybrid Composites with Increased Requirements for Heat and Wear Resistance. Ceramics 2025, 8, 8. https://doi.org/10.3390/ceramics8010008

Rusinov P, Zhang C, Sereda P, Rusinova A, Kurapov G, Semadeni M. Development and Research of New Hybrid Composites with Increased Requirements for Heat and Wear Resistance. Ceramics. 2025; 8(1):8. https://doi.org/10.3390/ceramics8010008

Chicago/Turabian StyleRusinov, Peter, Chao Zhang, Polina Sereda, Anastasia Rusinova, George Kurapov, and Maxim Semadeni. 2025. "Development and Research of New Hybrid Composites with Increased Requirements for Heat and Wear Resistance" Ceramics 8, no. 1: 8. https://doi.org/10.3390/ceramics8010008

APA StyleRusinov, P., Zhang, C., Sereda, P., Rusinova, A., Kurapov, G., & Semadeni, M. (2025). Development and Research of New Hybrid Composites with Increased Requirements for Heat and Wear Resistance. Ceramics, 8(1), 8. https://doi.org/10.3390/ceramics8010008