1. Introduction

Owing to their high hardness, strength, and wear resistance, cemented carbides are widely used in the manufacturing of moulds and dyes for cold drawing and stamping, as well as in tool materials. Grinding technologies, as well as electroerosive and ultrasonic methods, dominate the processing methods for cemented carbide-based products. For a long time, there has been no alternative to this technology, although it has several disadvantages, such as high power consumption and relatively long machining times. In addition, the significant consumption of abrasives and diamond tools during the final grinding operations (to achieve surface roughness parameters Ra of 0.07–0.2 µm), as well as their low productivity, led to a significant increase in the cost of manufacturing products.

The search for high-performance methods for machining cemented carbides, including WC-Co system cemented carbides, has been stimulated by the appearance of composite and polycrystalline superhard cutting materials based on diamond (PCD; polycrystalline diamond) and cubic boron nitride (PCBN; polycrystalline cubic boron nitride). The possibility of machining cemented carbides using surface turning and milling has been investigated from a technological perspective for different aspects of the problem [

1,

2,

3,

4,

5,

6,

7]. In these studies, the influence of machining conditions, machined surface roughness on the cutting force, and temperature in the cutting zone were investigated. Additionally, the contact interaction characteristics of the tool with the workpiece were studied, and the wear resistance and serviceability of the cutting tool were evaluated. The machined alloys differed in both the degree of dispersion of the carbide components and the cobalt binder content (which varied from 10 to 25 wt.%). Notably, one of the main parameters in determining the accuracy and quality of dyes and moulds made of sintered tungsten carbides (with a high Co content of up to 25 wt.%), is the roughness of the mating surfaces. This aspect was previously studied [

2] using a face-centred configuration to optimise the cutting conditions.

Generally, a longer tool life and a better surface can be obtained when sintered tungsten carbides with a higher cobalt content are cut, preferably over 22 wt.% cobalt binders, because of the lower hardness of these materials [

3]. The tool wear on the flank face and the cutting temperature can be effectively reduced by using wet cutting. Another important observation in cemented carbide turning is that tool wear is not only caused by mechanical abrasion but also by adhesion. The presence of cobalt as a binder in both the tool material (PCD and PCBN) and the machined carbide promotes adhesive interactions in the cutting zone under certain machining conditions. The adhesive buildup on the front surface of the tool wear pads is most significant in the case of PCD [

7].

It is assumed that in carbide machining, it is necessary to minimise the adhesive–abrasive wear of cutting tools using PCBN tools. These cutting inserts should not contain adhesion components in their structure in relation to cobalt and should have increased hardness values. Our previous study showed that a PCBN composite with a low β-Si

3N

4 content (approximately 3% by volume) and without a Co agent can be effectively used to machine cemented tungsten carbide with a Co content of 15 wt.% [

4]. This material was called SN-PCBN (Si

3N

4-doped cBN-based composite). Sintering of SN-PCBN was carried out in a high-pressure toroidal apparatus at a pressure of 8.0 GPa and a temperature of 2250 °C for 60 s [

8]. During sintering, α-Si

3N

4 underwent a polymorphic transformation into β-Si

3N

4, forming a system of isolated inclusions in the cBN matrix, which was essentially an SN-PCBN structure. The functional role of silicon nitride during sintering and the effect of small β-Si

3N

4 inclusions on the properties of SN-PCBN have been comprehensively discussed in previous studies [

4,

8].

The most promising variation of PCBN, which can be used as a superhard tool material for the machining of sintered carbides, is binderless polycrystalline cubic boron nitride (BL-PCBN). Comparative tests were performed to characterise high-purity translucent BL-PCBN obtained using two methods: (1) conventional high-pressure, high-temperature sintering (HPHT-S) of cBN micropowders and (2) high-pressure, high-temperature direct conversion sintering (HPHT-DCS) of high-purity hexagonal graphite-like boron nitride (hBN) powders in the thermodynamic stability range of cBN [

9,

10,

11,

12,

13].

In particular, the dense, translucent bodies of PCBN were produced by the conventional HPHT-S process of cBN powder consolidation at 7.7 GPa above 2000 °C for 10 min without the addition of any sintering agent [

1]. Moreover, with the application of the HPHT-DCS method, the high-purity polycrystalline cBN sintered bodies were also synthesised [

11]. BL-PCBN samples were obtained at 7.7 GPa and 2150 °C for 15 min of thermobaric action using a modified high-pressure belt-type apparatus. Furthermore, the tests on the obtained BL-PCBN materials were carried out during the dry turning of cemented carbide with WC + 24 wt.% Co at a speed of 10 m/min, a depth of cut of 0.2 mm, and a feed rate of 0.1 mm/rev. No difference was found between the wear resistances of the samples obtained using either method during the machining tests [

1].

In this study, we compare the cutting efficiency of the two tool materials: SN-PCBN (obtained in a previous study [

4]) and BL-PCBN (obtained in this study by the HPHT-DCS method) when turning much harder sintered carbides with relatively low cobalt content (15 wt.%).

2. Materials and Methods

Commercially available fine polydisperse hBN powder (PJSC “Zaporozhabrasiv”, Zaporizhzhia, Ukraine) with particle size predominantly in the range of 5–12 μm has been used as the starting material. To reduce the O

2 and B

2O

3 impurities, the powder was subjected to high-temperature annealing in a pure nitrogen atmosphere at 2200 °C for 1 h, following a procedure similar to that described by Akaishi et al. [

9]. The samples intended for the HPHT-DCS experiment were prepared by pressing a powder in a steel mould to form round tablets.

A bulk density (d) of hBN tablets is determined not only by precursor compaction conditions but also by crystallomorphological features of particles in the initial powders. Typically, absolute density values lie between 1.7 and 2.1 g/cm3. It follows from these data that the porosity of pressed hBN tablets can be as ϕ ≅ 10–25%, since the X-ray density of hBN is 2.290 g/cm3. In particular, our samples are characterised by d = 2.06 g/cm3 and ϕ ≅ 10 %.

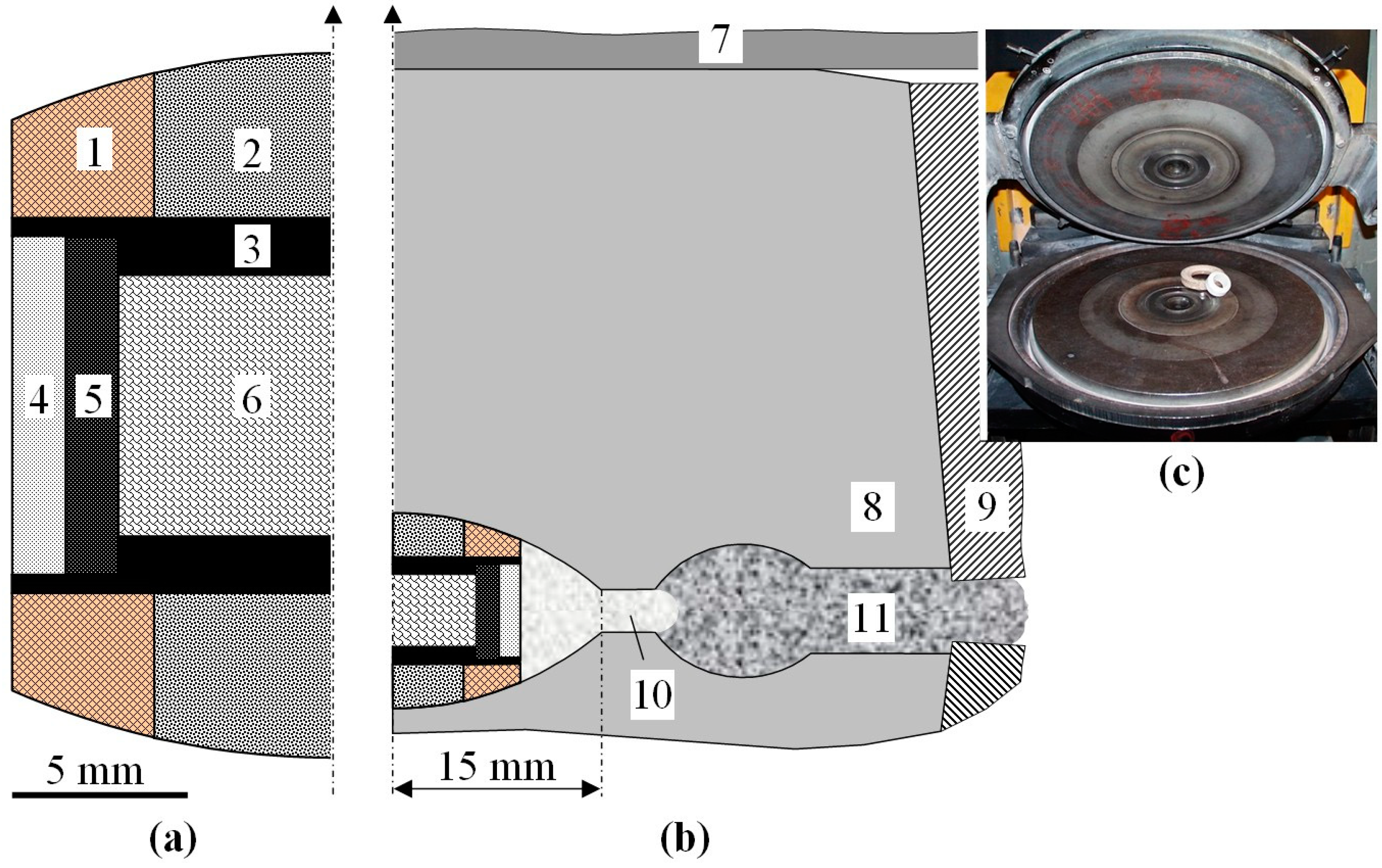

To obtain BL-PCBN by the HPHT-DCS method, a high-pressure, high-temperature toroid-type apparatus (HPA-T30) was used. The sectioned views of the high-pressure cell (HPC) assembly with the hBN sample in a central position are illustrated in

Figure 1.

The dynamics of thermobaric action in toroidal-type HPA and the influence of its parameters on the evolution of structural changes and phase conversions in boron nitride have been studied earlier both in the processes of cBN powder sintering [

4] and in the study of polymorphic transformations of graphite-like hBN modification into diamond-like wurtzite wBN and cubic cBN [

13]. In the latter case, the complete solid-phase conversion stage is crucial for producing an ultra-fine-grain monophase BL-PCBN product with high hardness, as noted in references [

13,

14].

As it is known, the volume effect of hBN→cBN phase conversion is V = −34.4%. Total volume changes in the sample during the formation of BL-PCBN by the HPHT-DCS method are due to both the volume effect of the conversion and shrinkage as a result of the sintering of particles in the disperse system. HPHT-DCS (direct conversion sintering at high pressures and temperatures) means sintering at certain, rather high parameters of p,T-action, providing within a relatively short time not only sintering but simultaneously hBN→cBN conversion without the participation of any additives facilitating consolidation [

10,

15].

Detailed studies of the transformation kinetics or sintering shrinkage are extremely complicated due to the short duration of high-temperature exposure in toroidal-type HPA (several tens of seconds). The usual practice of isochronous processes is most obvious and convenient when optimising p,T-parameters of thermobaric action [

10]. We used the results of previous studies to justify the choice of conditions for obtaining ultra-fine-grain monophasic BL-PCBN products of high hardness, as demonstrated in

Figure 2.

The HPHT-DCS experimental procedure involved the placement of the hBN specimen (tablet) in direct contact with the graphite heater, which was then placed in the central part of the HPC assembly (

Figure 1). The internal and external gaskets were subsequently set between the anvils of the HPA-T30. Quasi-isostatic compression of the sample is caused by the axial convergence of the HPA anvils placed in the workspace of the hydraulic system of the DO-044 press (PJSC “Tyazhpressmash”, Ryazan, Russia).

An initial pressure of 8 ± 0.3 GPa in the cell at room temperature was set according to standard apparatus calibration. The temperature calibration, including a parabolic extrapolation up to 2300 °C, was acquired previously using a thermocouple technique with the Pt, 30% Rh–Pt, and 6% Rh wires. An absolute error of about ±50 °C is typical for setting the temperature in HPC higher than 2000 °C. A temperature of 2250 °C was used by us when implementing the PHT-DCS process. Note that some increase in pressure in cell volume is possible due to thermal expansion effects. A special correction, performed taking into account the shifts of the melting points for Ag and Pt [

16], shows that Δp can reach the values around 1 GPa at 2250 °C. The duration of p,T-action in our experiments did not exceed 40 s.

The morphology of the initial hBN powder and microstructure of the HPHT-sintered material were examined using a Zeiss EVO 50 XVP scanning electron microscope (SEM). The X-ray diffraction (XRD) analysis was conducted using the “DRON” system with a graphite monochromator and Cu Kα1 radiation. The densities of both the initial powder and sintered samples were determined by hydrostatic weighing.

Vickers hardness was measured using a routine tester (Falcon 509, Innovatest Europe BV, Maastricht, Netherlands) and an Axio Vision optical microscope. The hardness values correspond to the average of three identical tests for each sample. A dwell time of 10 s was used for indentation. Hardness calculations were performed according to standard procedures using the ratio HV = 1.854·P/D2, where P is the load and D is the diagonal length of the Vickers pyramid imprint.

The characterisation of the samples was based on the use of ultrasonic pulse testing methods in determining the modules of shear (G), Young (E), bulk elasticity (B), and Poisson’s ratio (ν) [

17].

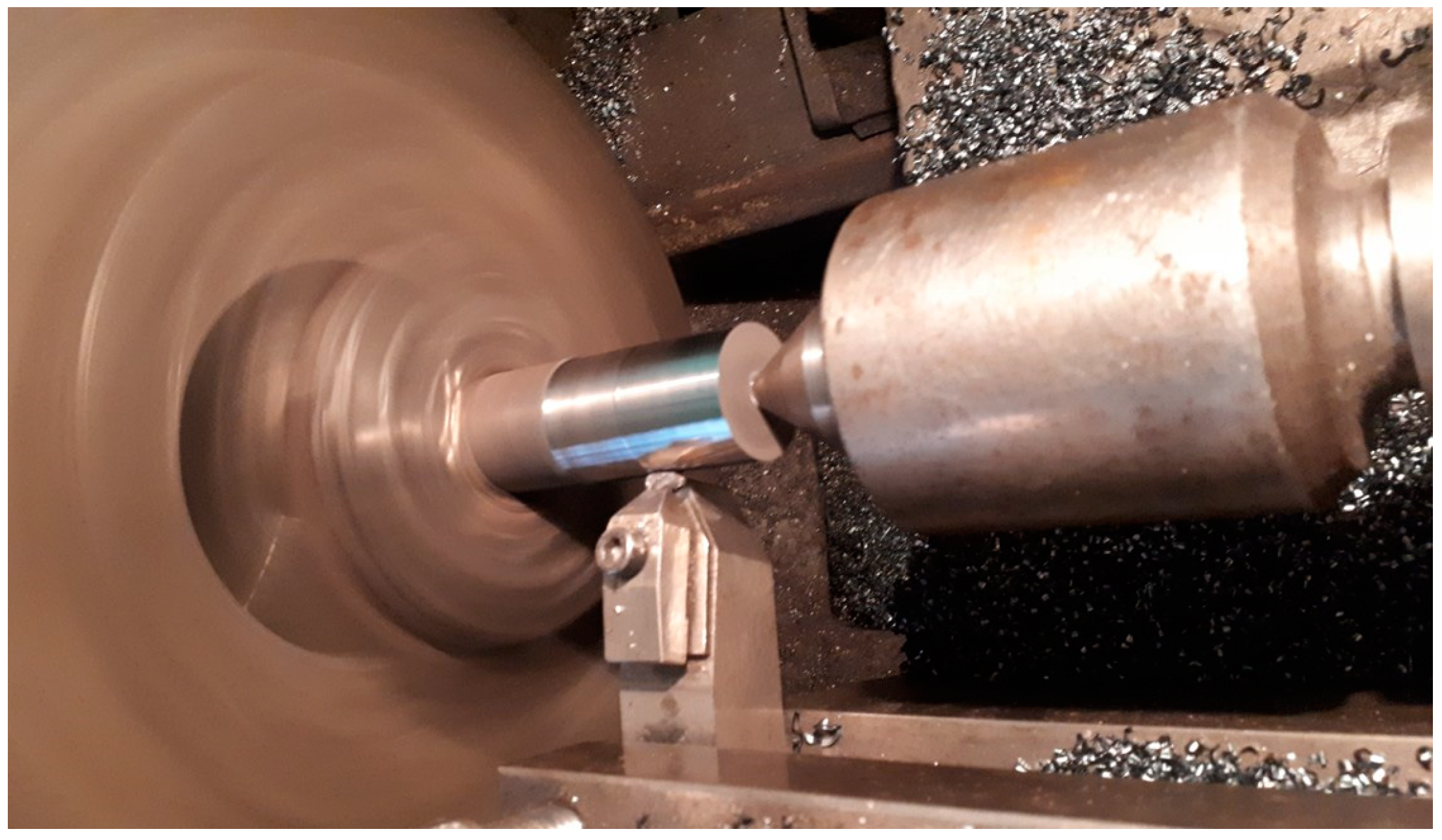

Finally, round cutting plates of standard size RNMN 09T300F [

18] (nominal dimensions: diameter 9.52 mm, thickness 3.97 mm) were manufactured to study the possibilities of BL-PCBN applications. The determination of the wear resistance of the obtained BL-PCBN plates was carried out during longitudinal continuous turning of bushings from cemented tungsten carbide with 15 wt.% cobalt content. Bushings with a diameter of 30 mm and length of 80 mm were machined on an FT-11 lathe ((

Figure 3).

The defective surface layer was removed from the samples to create the same conditions. The cutting plates were installed on a pass-through cutter with a mechanical attachment. The geometric parameters of the cutting part were as follows: rake angle γ = –10° and clearance angle α = 10°. The research was carried out at constant feed rates (f = 0.1 mm/rev) and cutting depth (ap = 0.2 mm). The depth of the cutting-edge wear was measured using a special instrumental microscope (SMT-2, Svitlovodsk, Ukraine).

3. Results and Discussion

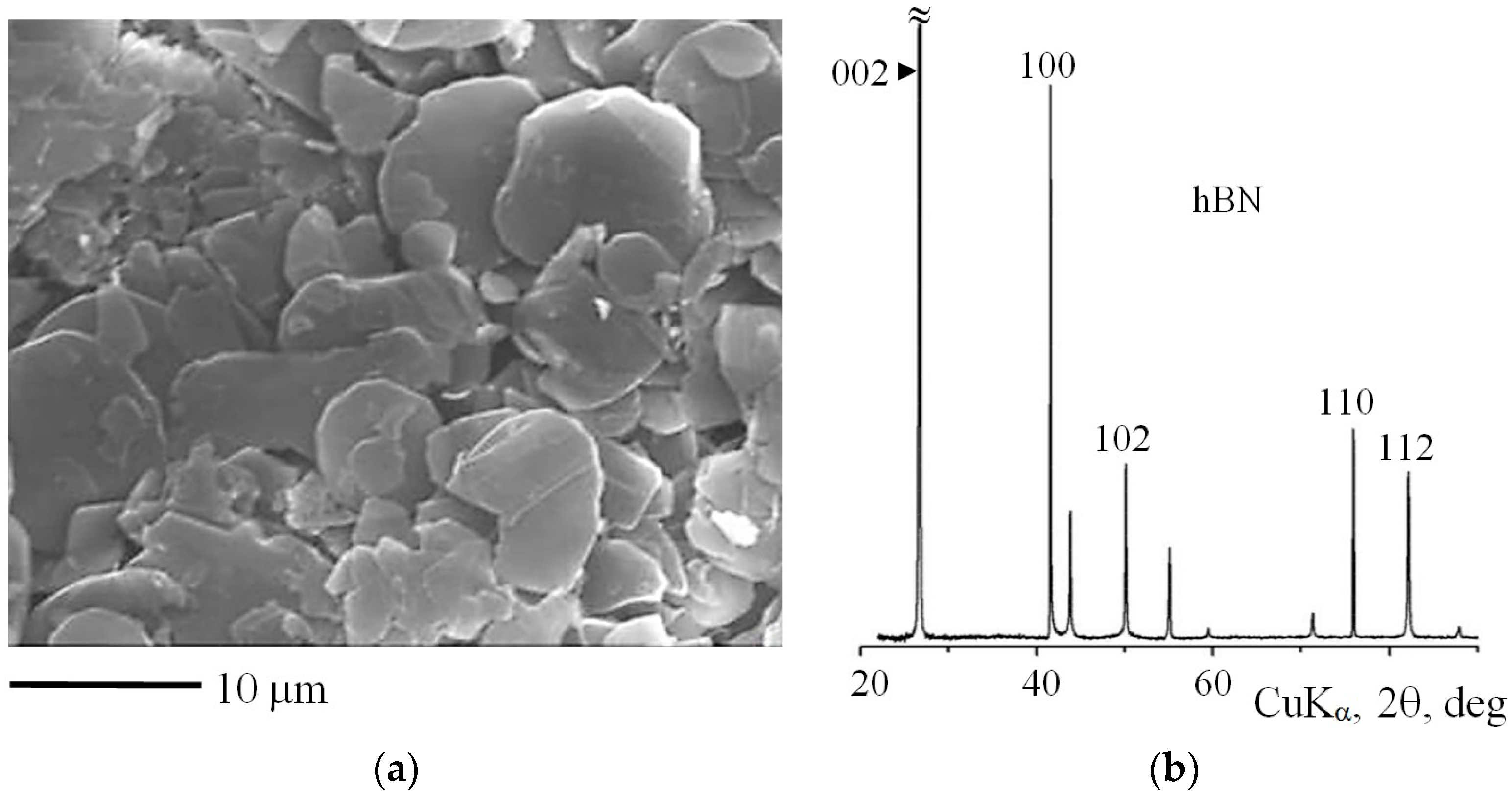

First, the morphology of the starting boron nitride powders was investigated. The hBN precursor particles have a scaly, rounded shape (lamellar habit,

Figure 4a). It was presumed that the special chemical and high-temperature treatment of the powders (according to the manufacturer’s information [

19]) determined the shape. The X-ray density of the hBN precursor powder was found to be 2.279 g/cm

3.

The XRD pattern consisted exclusively of reflections of the graphite-like modification (

Figure 4b). The absence of noticeable blurring of XRD peaks indicates a high level of ordering in the three-dimensional structure and a low concentration of turbostratic defects (β ≤ 2.6%) [

20]. The hBN crystal lattice constants were determined to be a = b = 0.25041(1) nm and c = 0.66551(5) nm (space group: P6

3/mmc). The unit cell volume was 36.1595 Å

3.

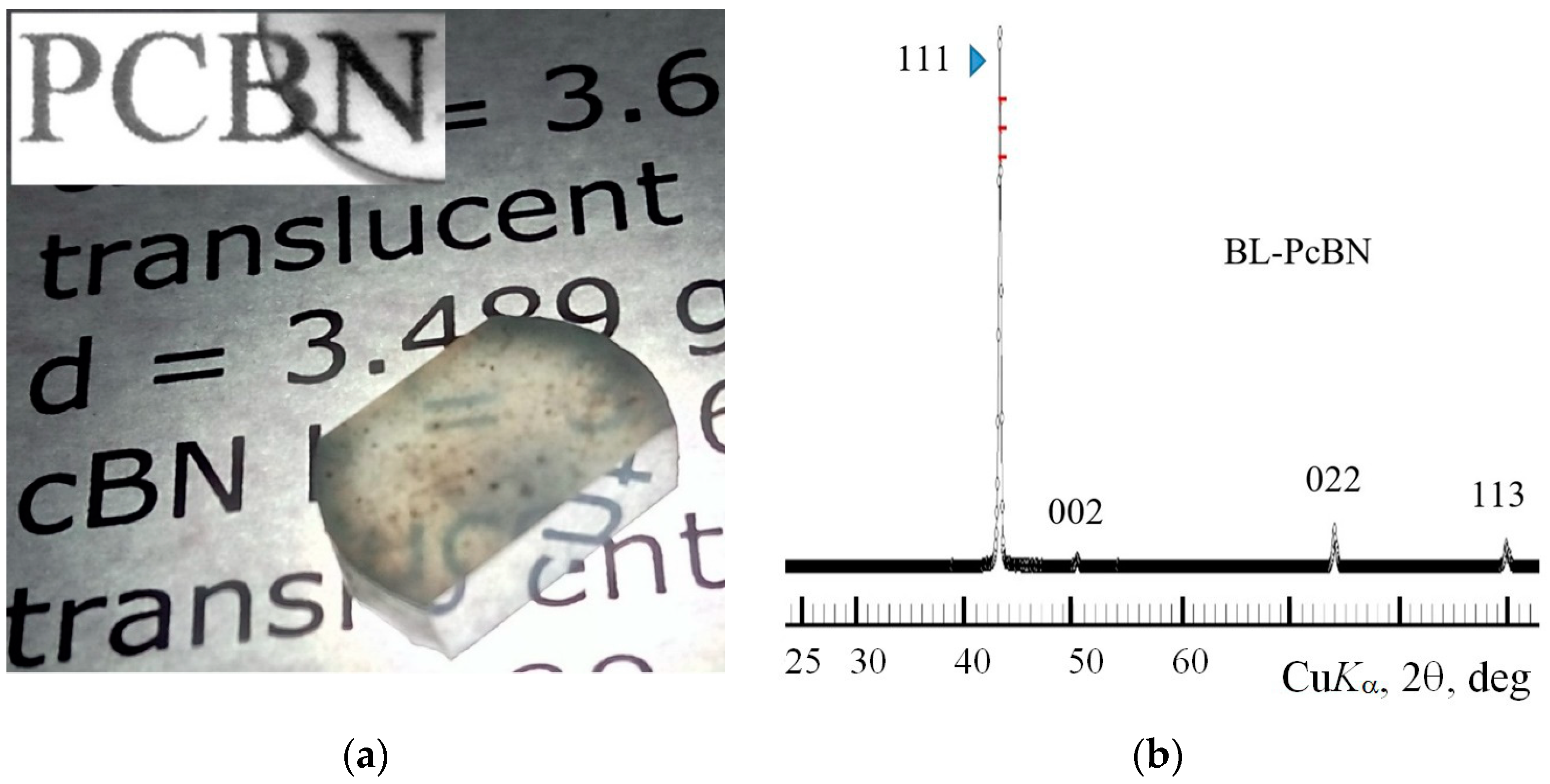

XRD phase analysis of the sintered material clearly demonstrated that the initial hBN powder underwent a complete transformation into the cubic modification (BL-PCBN) after HPHT-DCS at 2250 °C, 8 GPa, and 40 s (

Figure 5).

The microstructural characteristics of the BL-PCBN sample (

Table 1) were determined from the XRD peaks using harmonic analysis and half-width approximation [

21].

As can be seen from the data obtained, extremely small sizes of coherent scattering regions of around 37.2 nm are detected in the BL-PCBN sample. The significantly enhanced (111) reflection in the XRD pattern indicates a strong axial [111] texture of polycrystalline BL-PCBN. Notably, the texture axis is normal to the base surface of the sample. The intensity of the (022) reflection must be approximately 30% of that of the maximum intensity of the (111) reflection for complete isotropy [

22]. In contrast, the observed intensity of the (022) line was only 7.8% (

Figure 4b). When the diffraction was performed with the sample orthogonal to the prism plane, the (111) reflections were attenuated, and the (022) reflection was enhanced by up to 41%.

The appearance of the texture can be associated with the stacking texture of the initial hBN sample (tablet) before its conversion into cBN. The structural aspect of the crystal-oriented hBN→cBN solid-phase conversion has been previously studied [

23]. At such transformation, one of the tetrahedral planes of each cBN crystallite is predominantly oriented parallel to the basal surface of the initial sample, whereas the other three planes exhibit random azimuthal rotations. Thus, this surface is composed of a mosaic of the highest reticular density grids and, respectively, of greatest hardness. The ultra-fragmented state of crystallites will further increase the hardness and mechanical properties in general (‘grain boundary strengthening’), as is known from the results of a number of previous works [

13,

14].

The density and elastic properties of SN-PCBN sintered with the addition of 3 wt.% of Si

3N

4 [

4] and BL-PCBN (this study) were not significantly different. However, the hardnesses of the materials differed strongly (

Table 2). The hardness of SN-PCBN was relatively low (HV

5 = 34.8 GPa). This level of hardness is consistent with that typically observed for HPHT-sintered cBN materials, especially with coarse-grained structures.

The Vickers hardness of BL-PCDN was initially measured using a load of 9.8 N. However, this load was insufficient because the indentations left by the indenter were barely visible on the sample surface. According to data [

24], the calculated hardness of polycrystalline translucent cBN (similar material) decreased from 54 to 49 GPa as the load increased to 39 N and then remained constant for values above this load. We increased the load to 49 N and examined the Vickers indentation traces in detail, analysing its images by differential interference contrast technique (Axio Vision optics). An average hardness value for BL-PCBN under consideration was found to be 63.4 ± 1.7 GPa.

The translucency of the BL-PCBN obtained is assumed to testify about the full completion of the hBN-cBN conversion. This is confirmed by the results of X-ray studies (

Figure 5). It is also obvious that for wide-band cBN, light transmission without noticeable scattering is possible in non-porous, ultra-fine-grain structures in which crystallite sizes are outside the range of the visible spectrum. An accumulated experience shows that BL-PCBN and similar materials produced by the direct conversion sintering method have, as a rule, a complicated multilevel microstructure with crystallite sizes less than about 350 nm [

9,

24]. An important feature of HPHT-DCS technology is that the formation of the fine-grained PCBN takes place at 7.5–10.5 GPa in a rather narrow temperature range, which was found to be 2250–2350 °C (

Figure 2). At temperatures more than 2400 °C, the undesirable process of grain growth is intensively developed. During recrystallisation, the microstructural defects (stacking faults, twins, and dislocations, including in the grain boundary), are eliminated to reduce the internal energy of the structure. The new grains are typically large, much larger than the original ones. Therefore, the hardness is reduced since the defects increasing hardness are eliminated by the recrystallisation [

9,

13,

14].

Given the increased hardness of BL-PCBN, there is no compelling reason to investigate its performance in turning typical iron-carbon alloys, because even ordinary cBN-based cutting tools exhibit a lifetime longer than 60 min during the cutting of such alloys. Therefore, we decided to test our samples using the WC-Co alloy, which is extremely difficult to cut into a workpiece material. Many cBN-based composites have not been effectively applied in the processing of cemented carbide materials. We prepared cutting inserts of the standard size (RNMN 09T300F) using both BL-PCBN (obtained in this study) and SN-PCBN (obtained in a previous study [

4]) to compare their wear behaviour and cutting performance during turning.

The flank wear of both BL-PCBN and SN-PCBN inserts exhibits an almost linear increase with cutting speed during the turning of WC-15Co hard alloy. However, the wear values for the BL-PCBN inserts are significantly lower, as illustrated in

Figure 6.

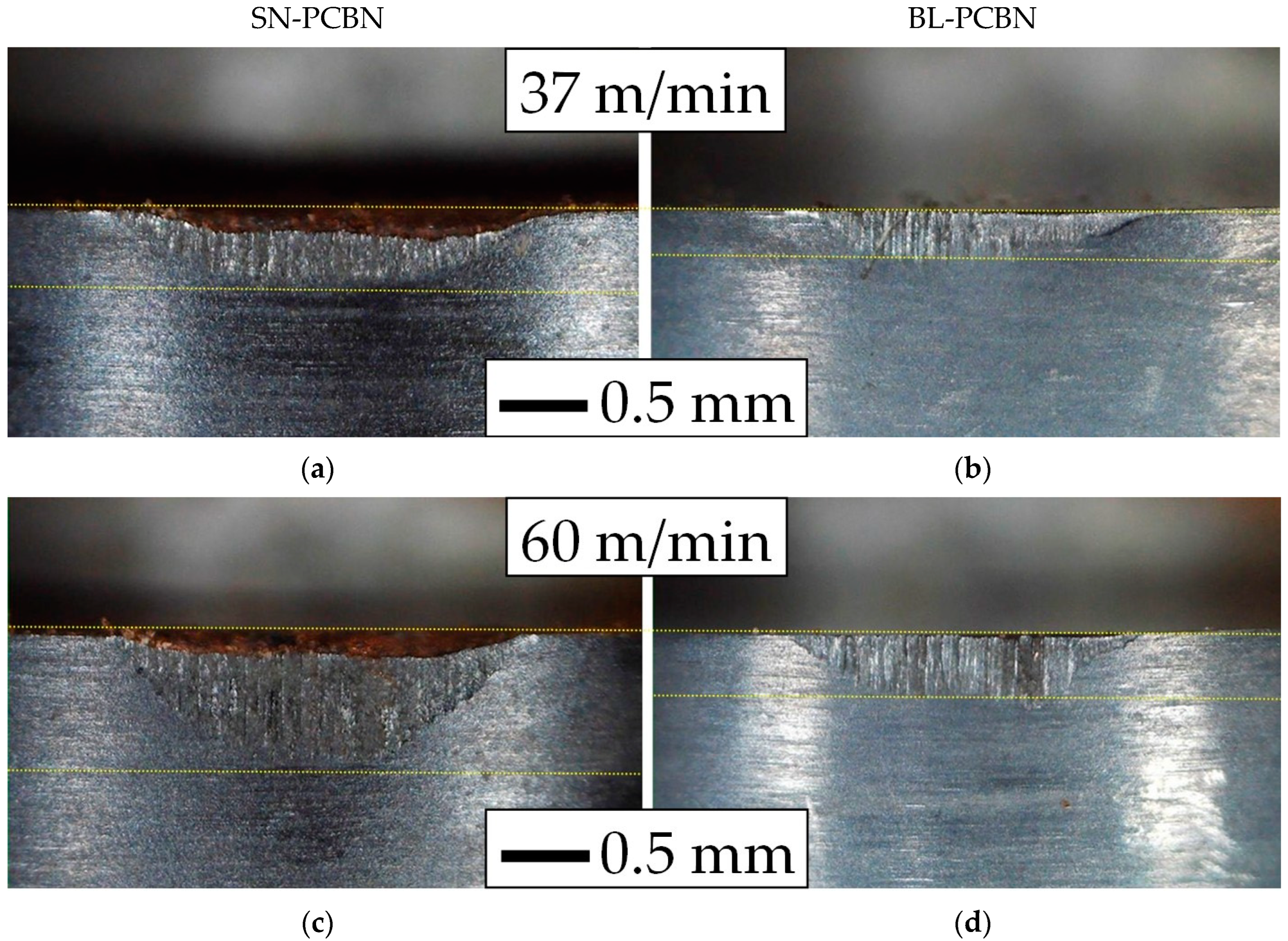

Turning at speeds up to 30 m/min resulted in gradual and uniform wear of the both BL-PCBN and SN-PCBN cutting inserts, characterised by the formation of a wear chamfer exclusively on the flank face. As the cutting speed increased to 37 m/min and subsequently to 60 m/min, significant degradation of the cutting edges was observed. Concurrently, crater wear developed on the rake surface of SN-PCBN (

Figure 7a,c), accompanied by an increase in the wear chamfer on the flank face. Such a pattern indicates a higher wear intensity of reference material at elevated cutting speeds.

Crater wear was not observed for BL-PCBN (

Figure 7b,d). This behaviour can be attributed to the enhanced abrasive resistance of the rake surface of the insert, which results from the absence of any additives in the structure of BL-PCBN and its exceptionally high hardness. The wear resistance of the BL-PCBN tool was 1.5–1.9 times higher than that of the reference SN-PCBN tool. It is extremely difficult to draw a conclusion about the relationship between the abrasive and adhesive types of wear mechanism of BL-PCBN based on the type of cutting edges after turning cemented carbide. In the same way, it can be assumed that the predominant wear mechanism in the present tests during the turning of cemented carbides by BL-PCBN is abrasive. This confirms the extremely low level of crater wear on the insert of BL-PCBN (

Figure 7b,d).

The turning performance of the BL-PCBN inserts, defined as the volume of workpiece material removed per time unit (Q) depending on the cutting speed, is presented in

Table 3.

The results of the WC-15Co hard alloy turning test show that at a cutting length of 75 m, a critical flank wear width of 0.4 mm was observed at a cutting speed of 37 m/min for the SN-PCBN tool, while the BL-PCBN tool reached the same wear threshold at a higher cutting speed of 60 m/min. Furthermore, the turning performance of the BL-PCBN inserts was significantly enhanced, achieving a material removal rate that was 1.6 times greater than that of the SN-PCBN reference tool (

Figure 8).

The results of the tool wear and performance investigations indicate the potential of using BL-PCBN in the high-speed machining of cemented carbide components.