1. Introduction

Studies of radiation embrittlement associated with the processes of helium (He

2+) accumulation in the surface layer of lithium-containing ceramics are one of the important scientific areas of research in the field of studying the processes of radiation damage that occur in materials used as a basis for creating blanket materials for tritium breeding [

1,

2]. Interest in these types of studies—in particular, in the assessment of structural, thermal, and strength alterations in the near-surface layer of lithium-containing ceramics—is primarily due to the need to understand the destruction mechanisms associated with the accumulation of helium, which is a product of nuclear reactions of tritium multiplication

6Li + n →

4He +

3T [

3], the accumulation of which in the near-surface layer can result in deformation swelling of the structure and the emergence of metastable inclusions, the impact of which can lead to their embrittlement and destruction, which in turn will result in plasma contamination and a reduction in the stability of blanket materials [

4,

5,

6]. Moreover, the accumulation of helium, as a rule, occurs in the near-surface layer, despite the fact that nuclear reactions can occur in the entire volume of the blanket. Due to high mobility and low solubility, helium formed during nuclear reactions tends to leave the volume of ceramics, shifting to the surface, thereby forming gas-filled cavities in the near-surface layer, which arise due to the presence of pores in the structure of ceramics. Filling these pores with helium and its subsequent agglomeration can lead to the occurrence of mechanical deformation pressures on the pore walls, which, at high concentrations of implanted helium, can lead to deformation swelling of the surface layer, and, at critical concentrations, to partial opening or an explosive effect of the destruction of the gas-filled cavity.

One way to enhance resistance to gas swelling processes is to create two-phase ceramics by mixing two different lithium-containing components, which, in turn, results in heightened stability to degradation due to the creation of additional boundary effects associated with different phases [

7,

8,

9]. At the same time, the selection of components for obtaining two-phase ceramics is usually based on determining the most optimal parameters of component compatibility, including their thermophysical, strength, and structural parameters, the combination of which will not only increase the resistance to radiation-induced destruction and erosion of surface layers, but will also stabilize tritium production over a long period of operation of blanket materials [

10,

11]. Also, as an alternative method to increase the stability of lithium-containing ceramics against radiation-induced destruction, one can consider the method of adding stabilizing additives to the ceramics in the form of yttrium, magnesium, and aluminum oxides, which have found active use as stabilizers to increase the stability of ceramic structural materials used in conditions of elevated radiation backgrounds or those under direct exposure to ionizing radiation (in the case of using such ceramics as materials for the active zone or nuclear fuel) [

12,

13,

14]. The method to increase the stability to radiation damage by adding stabilizing additives is based on the possibility of obtaining structures of the substitution type (in the case when elements of oxide stabilizing additives replace elements of the main matrix of the material). Otherwise, the use of these additives leads to the formation of structures of the type of interstitial solutions, which, as in the case of two-phase ceramics, leads to the formation of additional interphase boundary effects, the presence of which helps to slow down migrating radiation defects in the structure of the damaged layer. Also, in several cases, the addition of stabilizing additives can result in heightened stability to radiation damage due to structural phase or polymorphic transformations, which, for example, in the case of zirconium ceramics, contribute to increased resistance to damage due to changes in packing density, as well as an increase in strength parameters during polymorphic transformations [

15,

16,

17].

Based on the above factors, the main objective of this study is to determine the effect of variation in the Li

2ZrO

3/MgLi

2ZrO

4 phase ratio in lithium-containing ceramics based on metazirconate obtained by mechanochemical solid-phase synthesis with the addition of magnesium oxide as a stabilizing dopant, at high concentrations of which the formation of the substitution phase MgLi

2ZrO

4 with a tetragonal type of crystal lattice occurs. A detailed study of the effect of variation in the phase composition of Li

2ZrO

3 with the addition of a variation in the concentration of the dopant was considered in [

18], where it was shown that, at low concentrations of the MgO dopant, stabilization of the main phase of Li

2ZrO

3 is observed, due to the effect of substitution of zirconium by magnesium. In addition, at concentrations above 0.1 M, the formation of the tetragonal MgLi

2ZrO

4 phase is observed, the weight contribution of which directly depends on the MgO dopant concentration. It was also shown that variation in the structural features and phase composition of ceramics leads to changes in both their strength (hardness and resistance to cracking under single compression) and their thermophysical parameters.

2. Methodology

Four types of lithium-containing ceramics with different MgO dopant concentrations were selected as samples for this study. The use of the dopant is due to the creation of a hardening effect due to the formation of interphase boundaries during the formation of two-phase ceramics, which occurs due to the partial substitution of lithium or zirconium ions in the Li

2ZrO

3 phase by magnesium ions, followed by its transformation into the MgLi

2ZrO

4 phase. The concentrations of the MgO dopant were chosen to be 0.10 M, 0.20 M, and 0.25 M, the addition of which yields two-phase ceramics of the Li

2ZrO

3/MgLi

2ZrO

4 type, with different ratios of the monoclinic (Li

2ZrO

3) and tetragonal (MgLi

2ZrO

4) phases [

18]. According to the data of [

18], when adding 0.1 M dopant to the ceramics, the weight contribution of the MgLi

2ZrO

4 phase is about 5.5 wt.%, while the dopant concentration growth to 0.2 and 0.25 M leads to a rise in the contribution of MgLi

2ZrO

4 to 38 and 50 wt.%, respectively. From the analysis of the phase composition of ceramics, it can be concluded that the addition of 0.25 M MgO leads to the formation of two-phase ceramics Li

2ZrO

3/MgLi

2ZrO

4 with an equally probable ratio of phases in the composition. The observed formation of the MgLi

2ZrO

4 phase with an increase in the concentration of magnesium oxide dopant in the composition of the initial mixtures is due to the processes of polymorphic phase transformations associated with the partial substitution of zirconium by magnesium, which leads to the initialization of monoclinic—Li

2ZrO

3 → tetragonal—MgLi

2ZrO

4-type processes, caused by thermal annealing of the samples, as well as mechanical grinding, a procedure used to mix the initial components of the ceramics. In this case, the formation of the MgLi

2ZrO

4 phase has a clearly expressed dependence on the dopant concentration, from which it follows that an elevation in the concentration of the MgO dopant results in the acceleration of the polymorphic transformation process, which causes the structural rearrangement of the monoclinic phase to change into a tetragonal one. Moreover, the formation of the MgLi

2ZrO

4 phase depending on various synthesis conditions was examined in detail in works [

19,

20], which formed the basis of the PDF-2 databases for this phase, and according to which the parameters and volume of the crystal lattice were refined.

Also, Li2ZrO3 ceramics with a monoclinic type of crystal lattice, obtained using a similar technology as that used for the ceramic samples with the addition of MgO dopant, were chosen as a comparison sample. The samples were synthesized using the mechanochemical solid-phase synthesis method, by mixing MgO, ZrO2, and LiClO4 × 3H2O in specified stoichiometric proportions, the chemical purity of which was approximately 99.95% (all chemical reagents were purchased from Sigma Aldrich, St. Louis, MO, USA). Solid-phase synthesis was carried out by mechanical grinding of the initial powders mixed in specified stoichiometric proportions in a PULVERISETTE 6 classic line planetary mill (Fritsch, Berlin, Germany) at a grinding speed of 400 rpm. The grinding was carried out to obtain a homogeneous mixture, which was subsequently subjected to thermal sintering in a muffle furnace at a temperature of 1300 °C for 8 h. After pressing, the samples were tablets with a diameter of 10 mm and a thickness of about 0.7–1 mm. To carry out the irradiation experiments, in order to avoid the effects of irradiation-induced structural changes contributing to the X-ray diffraction data of the samples, the samples were polished to thin them to a thickness of about 1 µm. To achieve this, the samples were filled with epoxy resin in a special form, after which, using polishing machines, they were thinned to a thickness of about 1 µm; moreover, the thickness of the sample was monitored using a thickness gauge. Once the required sample thickness was achieved, it was fixed on a special holder, which later served as a substrate for placing samples in the irradiation chamber, as well as for conducting experiments. The epoxy resin was removed from the sample by dissolution.

High-temperature irradiation with He

2+ ions was performed at the DC-60 heavy ion accelerator (Institute of Nuclear Physics, Astana branch, Astana, Kazakhstan) [

21,

22]. The choice of He

2+ ions was determined by the possibilities of conducting experiments on the simulation of the processes of helium accumulation in the near-surface layer of ceramics—promising materials for blankets used in the production and propagation of tritium. At the same time, as is known, the production of tritium is accompanied by the accumulation of not only tritium, but also helium, which is one of the main products of nuclear reactions of lithium with neutrons, which also requires detailed study due to the high mobility of helium, as well as its ability to agglomerate in voids. At the same time, irradiation with He

2+ ions, in particular, high-temperature irradiation with large doses, allows us to simulate the processes of not only the accumulation of implanted helium (as a rule, with irradiation fluences above 10

16 ion/cm

2, it is possible to obtain concentrations of implanted helium of the order of 1 at. % and higher), but also deformation processes in the structure of the damaged surface layer associated with the accumulation and subsequent agglomeration of helium, which can result in the partial embrittlement of the surface layer or its destruction due to the formation and subsequent growth of gas-filled inclusions in the form of blisters (gas-filled bubbles) [

23,

24]. The irradiation fluence of He

2+ ions was chosen to be from 10

15 to 10

18 cm

−2, and the irradiation temperature was chosen to be 1000 K, the choice of which was due to the possibilities of the simulation of the helium accumulation processes, comparable with those maximally close to the real operating conditions of this type of ceramics in the production of tritium. At the same time, the study of the near-surface layer in which the accumulation of implanted helium occurs is due to the migration processes of helium formed as a result of nuclear reactions of lithium with neutrons (in the case of real tritium production), which leads to the fact that helium, due to its mobility, tends to leave the volume of ceramics and rush to the surface, where the processes of filling the pores are initiated, the presence of which is due to the structural features of the ceramics, as well as the method of their production. As a result, accumulation occurs in a small near-surface layer with a thickness of about 300–500 nm, which, upon prolonged irradiation, is subject to deformation distortions, embrittlement, and partial amorphization (disordering due to the accumulation of many structural distortions).

The determination of the volumetric swelling of the crystalline structure of the damaged near-surface layer was carried out by comparative analysis of the changes in the crystal lattice volume of the samples before and after irradiation. In this case, diffraction patterns for determining structural changes caused by the accumulation of implanted helium in the near-surface layer, as well as the processes of deformation distortions associated with its accumulation, were obtained considering the thickness of the damaged layer. For this purpose, X-ray diffraction patterns were recorded in the Bragg-Brentano geometry at an X-ray power of 0.1 kW, which made it possible to obtain a diffraction pattern with a thickness of about 500 nm, corresponding to the thickness of the damaged ceramic layer. The X-ray diffraction patterns were measured in the angular range of 2θ = 25–75°, with a step of 0.03°, and the exposure time was 1 sec. The structural parameters were refined using the DiffracEVA v.4.2 software code; in addition, the phase composition was determined using the card values from the PDF-2 (2016) database.

The nature of deformation distortions depending on the irradiation fluence, as well as on the phase composition of the ceramics, was determined by comparing the change in the parameters of the crystal structure, the deformation distortion of which occurs as a result of the interaction of incident ions with the crystal structure. At the same time, according to the assessment of the values of ionization losses of incident low-energy He2+ ions, a change in structural features can occur due to athermal and ionization effects caused by the interaction of incident ions with electrons and nuclei of the target, due to the fact that the difference between the values of ionization losses is small, which determines the equally probable nature of the processes leading to structural changes.

The influence of radiation damage accumulation on the change in ceramic resistance to external mechanical effects was determined by measuring changes in the values of the hardness of the damaged area by depth using the nanoindentation method. The measurements were carried out on the lateral cleavage of the ceramics in order to establish the influence of structural changes caused by irradiation on the softening of the ceramics, as well as the possibility of the occurrence of diffusion processes of the migration of implanted helium in the near-surface layer, depending on the magnitude of atomic displacements (in terms of irradiation fluence).

The influence of the presence of phase inclusions in the form of the MgLi2ZrO4 phase on the resistance to changes in thermal parameters was determined by measuring the coefficient before and after irradiation using the longitudinal heat flow method. The measurements were carried out using a KIT-800 thermal conductivity meter. The calculation of the thermal conductivity coefficient, depending on the irradiation fluence, made it possible to determine the kinetics of the effect of radiation damage on the stability of heat transfer, as well as to determine the effect of volumetric swelling on the change in the value of heat loss associated with the destructive change in ceramics.

3. Results and Discussions

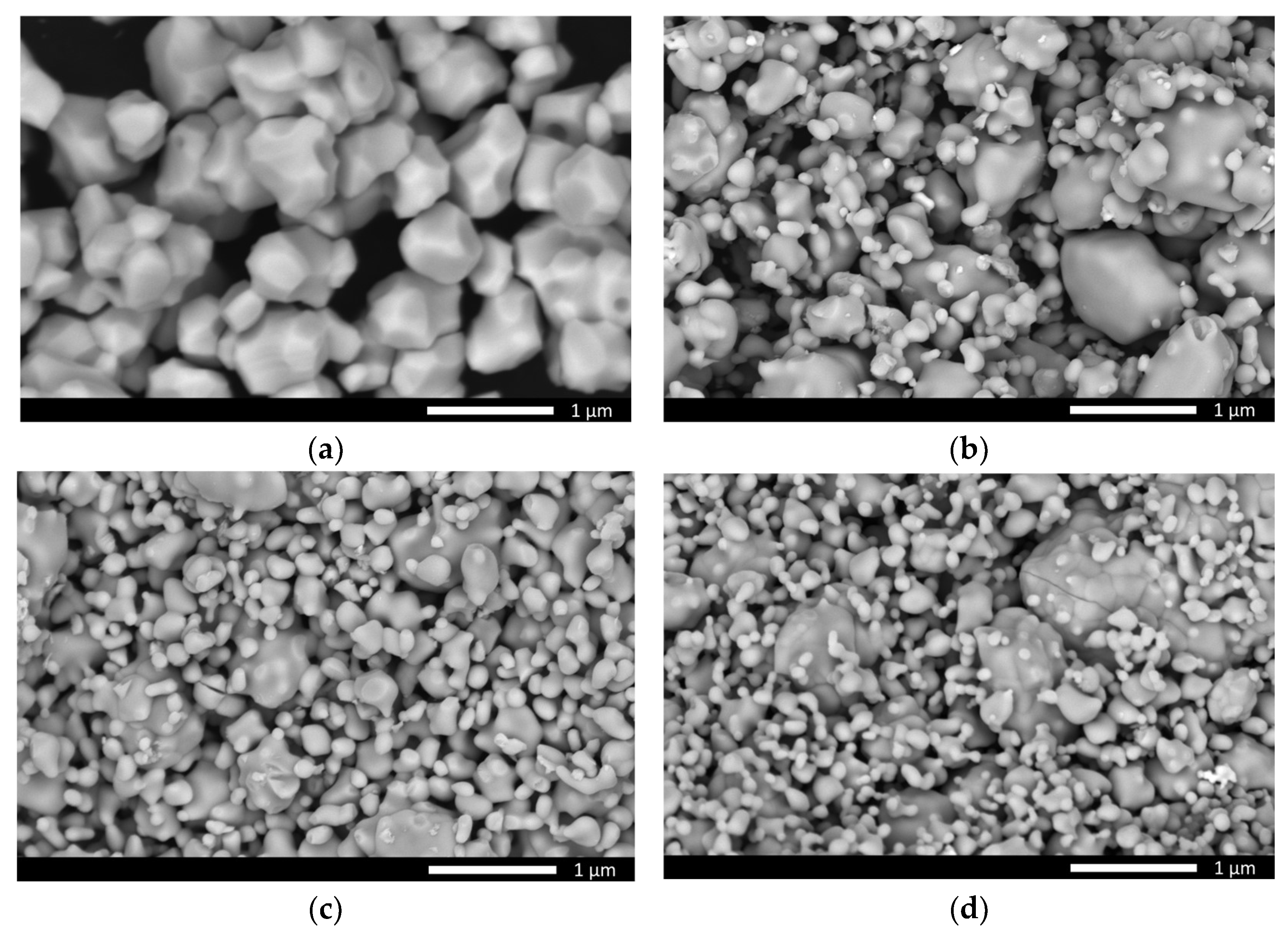

Figure 1 demonstrates the morphological features of the obtained ceramics depending on the variation of the component ratio in the initial mixtures. As can be seen from the data presented, an elevation in the MgO concentration in the composition of the ceramics leads to a rise in the finely dispersed fraction in the composition of the ceramics, as well as the formation of dendrite-like agglomerates, which are inclusions consisting of several particles connected along the edges. In this case, comparing the observed alterations in the morphology of the grains of Li

2ZrO

3 ceramics with the results of the dopant, it can be concluded that the formation of the MgLi

2ZrO

4 phase in the composition due to an alteration in the MgO dopant concentration leads to the formation of a finely dispersed fraction, the content of which grows with an elevation in the MgLi

2ZrO

4 phase contribution in the composition of the ceramics (according to the X-ray phase analysis data). It follows that the formation of two-phase ceramics can cause the effect of interphase hardening caused by differences in grain sizes, which leads to the formation of dispersion hardening associated with size effects.

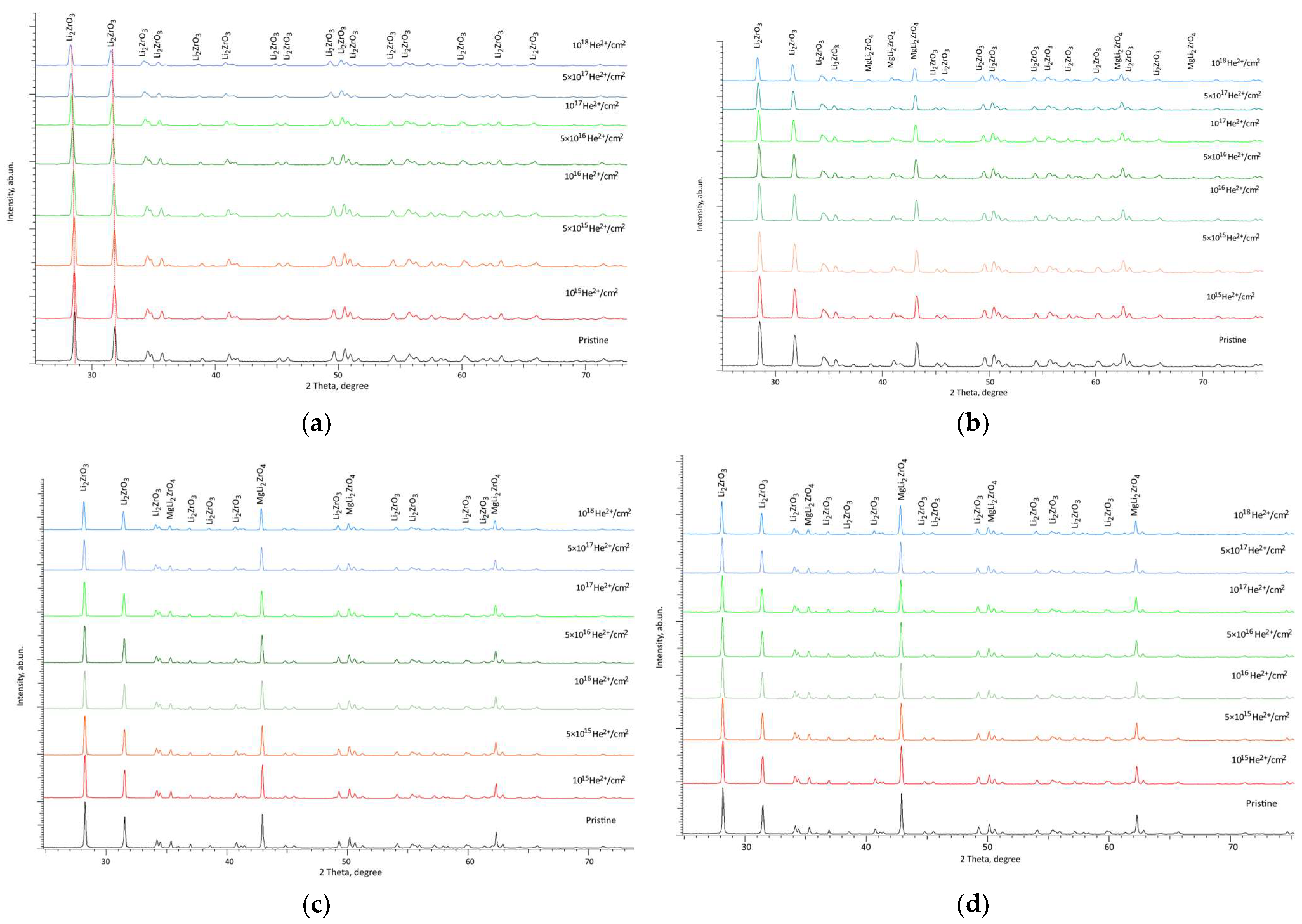

Figure 2 reveals the results of X-ray diffraction of the studied ceramic samples, reflecting changes in the structural parameters caused by the accumulation of deformation distortions in the crystal lattice during irradiation with He

2+ ions with different fluences. The general appearance of the presented dependences on the X-ray diffraction patterns indicates the absence of phase transformation processes, as evidenced by the absence of any manifestations of new diffraction reflections with variations in the irradiation fluence, alongside changes in the ratio of the observed phases at the irradiation fluence growth. The absence of such alterations indicates the sufficiently high resistance of the synthesized ceramics to the processes of phase polymorphic transformations caused by irradiation. At the same time, the nature of the observed changes in the diffraction patterns indicates the cumulative effect of structural distortions of a deformation nature, which have a clearly expressed nature characteristic of tensile deformation stresses. It should also be noted that a comparative analysis of the change in shape and position of the diffraction reflections of the initial Li

2ZrO

3 ceramic samples with the results obtained for ceramic samples with different MgO dopant concentrations showed the manifestation of a resistance to deformation distortions of the crystal structure for two-phase ceramics, which are expressed in less pronounced displacements of reflections, as well as distortions of their shape in the case of high-dose irradiation.

Figure 3 shows the dependences of the volume swelling of the crystalline structure of the surface layer of Li

2ZrO

3/MgLi

2ZrO

4 ceramics subjected to high-temperature irradiation with He

2+ ions with different irradiation fluences. The data are presented as a dependence of the change in the volume of the crystal lattice (Δ

V) on the magnitude of the atomic displacements (dpa), reflecting the effect of damage dose accumulation on the change in structural properties. The irradiation fluence was converted into atomic displacements according to the method proposed in [

25], considering the simulation results performed in the SRIM Pro 2013 software code [

26]. The general form of the presented dependence of the change in the Δ

V (dpa) value reflects the destructive nature of the change in the structure of the damaged layer, which is associated with the accumulation of defective inclusions and deformation distortions, causing a disordering of the crystal structure. Moreover, as is evident from the Δ

V (dpa) data presented on a logarithmic scale, the most pronounced structural changes are observed at atomic displacement values above 1 dpa, corresponding to a fluence above 10

17 ion/cm

2, which are expressed in the exponential growth of the Δ

V (dpa) value.

According to the presented data on the changes in ΔV (dpa), the most pronounced changes are observed for single-phase samples, the composition of which is characterized by the monoclinic phase of Li2ZrO3. For this type of ceramics, an increase in the value of atomic displacements above 1 dpa leads to an exponential growth in the deformation swelling of the crystal structure, the maximum value of which is about 7%, which indicates a strong swelling compared to the initial value, as well as structural distortions at irradiation fluences below 1017 ion/cm2 (with characteristic values of atomic displacements below 1 dpa), for which the ΔV (dpa) value is less than 1%. Such a strong difference in the ΔV (dpa) values at irradiation fluence growth can be explained by both the cumulative effect of structural deformations and the formation of complex defects of the VO—He type, the presence of which is due to the formation of vacancies as a result of deformation distortions of the crystal structure.

During the determination of changes in the value of the volumetric swelling of the crystalline structure of the near-surface layer of the studied Li2ZrO3/MgLi2ZrO4 ceramics contingent upon the dopant concentration, and, therefore, the phase transformations associated with them, it was determined that the formation of the MgLi2ZrO4 phase leads to a rise in stability to deformation swelling. At the same time, comparing the data of the ΔV (dpa) dependences for two-phase samples, one can conclude that the presence of interphase boundaries has a positive effect on the suppression of disordering effects caused by volumetric swelling. In this case, an elevation in the weight contribution of the MgLi2ZrO4 phase in the composition of ceramics leads to a decline in the general trend of changes in the ΔV (dpa) value, alongside a reduction in the maximum ΔV (dpa) value at a fluence of 1018 ion/cm2.

Analyzing the data presented on the changes in ΔV (dpa), one can conclude that, depending on the irradiation fluence (the value of atomic displacements), various processes that have a destructive effect on the near-surface layer predominate in the structure. At low irradiation fluences (below the critical point of 1017 ion/cm2), the main contribution to the structural changes is made by tensile deformation distortions, characteristic of the processes of collision and interaction by transferring kinetic energy and transforming it into the thermal energy of the incident ions with the crystal lattice. In this case, structural distortions occur due to ionization, the formation of vacancy, and point defects, the accumulation of which occurs due to a rise in the number of collisions with an elevation in the irradiation fluence. It should also be noted that the region of interaction of incident ions with the crystal lattice of the target material, as is known, is a region close to a cylindrical region arising along the trajectory of ion movement in the material, while the sizes of such regions can vary depending on the type and energy of ions.

It should also be noted that, at low radiation doses, in the case of high temperatures, the recombination of point defects can occur, which results in the partial healing of structural distortions caused by radiation damage. It is important to highlight that the formation of cluster defects of the oxygen vacancy combined with the helium (VO—He) type is usually controlled by the annihilation reaction, which directly depends on the interatomic distance, a rise in which results in annihilation effect reduction, which, consequently, leads to a growth in the concentration of clusters in the near-surface damaged layer.

In this case, the change in the interatomic distance in the case of irradiation is due to the accumulation of structural deformation distortions, the accumulation of which occurs with an increase in the irradiation fluence, and, in the case of low-energy ions, deformation distortions are associated with both ionization effects and athermal ones arising from collisions of incident ions with the crystal lattice. It should be noted that, due to the low energies of ions, the difference between the ionization losses of ions during collisions with electron shells and nuclei is minimal, which results in an equal contribution of both effects to the change in the structural features of the near-surface damaged layer of ceramics.

Volumetric swelling is caused by several factors, the key ones being the increase in the concentration of implanted helium ions in the near-surface layer, the accumulation of which leads to the deformation distortion of the crystal structure, and their subsequent agglomeration with vacancy defects and the formation of VO—He-type clusters leads to the filling of voids in the crystal structure. In this case, the implanted helium concentration growth, due to diffusion mechanisms and agglomeration, leads to the pores filled with helium creating additional deformation stress on the crystalline structure, thereby deforming the volume, which, in turn, leads to the displacement of the volume in the form of spherical cavities on the surface. It should also be noted that these cavities, as a rule, accumulate near to the grain boundaries, which, in turn, serve as so-called defect sinks, near which helium agglomeration occurs. At the same time, the presence of interphase boundaries associated with the formation of the MgLi2ZrO4 phase in the composition of ceramics leads to agglomeration processes becoming less pronounced, due to the large number of additional boundaries that create obstacles to the agglomeration of helium into larger inclusions.

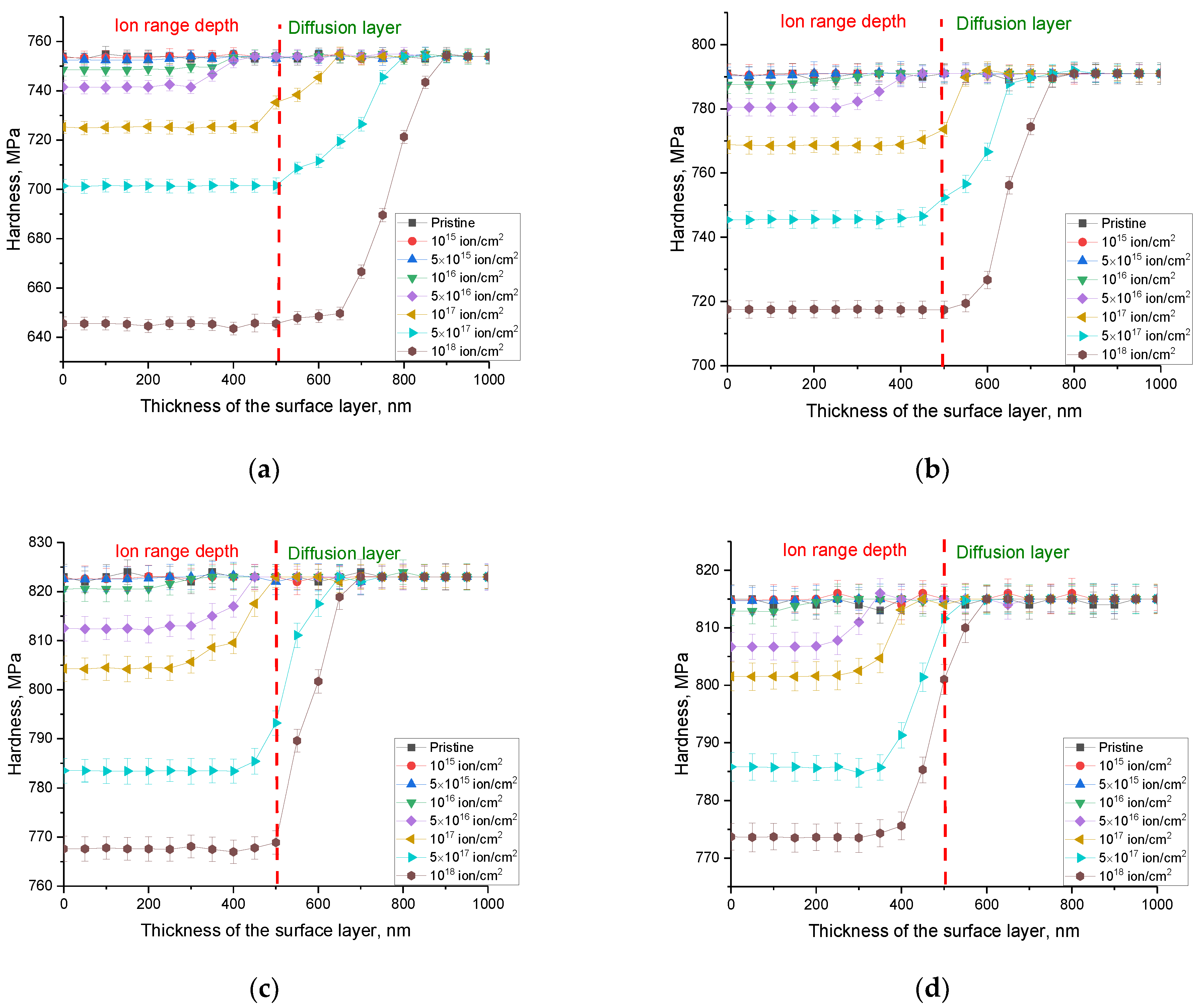

Figure 4 demonstrates the results of hardness measurements by depth in the near-surface layer, reflecting changes caused by deformation distortions resulting in softening. The data were obtained by hardness measurements using the method of nanoindentation of side chips with a step of 50 nm at a depth of about 1 μm, which, in total, exceeds by 2 times the layer thickness characteristic of the path of He

2+ ions (the path length is about 500 nm). The measured thickness growth is due to the possibility of the diffusion effect, which consists in the migration of implanted helium deep into the sample, due to the high mobility and low solubility of helium. As is known, helium agglomeration usually occurs in pores and voids, and the possibility of forming clusters of the V

O—He type under high-dose irradiation results in deformation swelling (see data in

Figure 1), which, as a consequence, can have an adverse effect not only on the structure of the damaged layer (corresponding to the trajectory of ion movement in the material), but also to a greater depth, due to the migration of point and vacancy defects in the material [

27].

It should be noted that the change in the phase composition of the studied ceramics, due to the rise in the contribution of the MgLi2ZrO4 phase, leads to an elevation in the hardness of the studied ceramic samples from 750–760 MPa to 810–825 MPa, which indicates a positive effect of changing the phase composition of ceramics on hardening (increase in hardness), which is due to the presence of interphase boundaries, an increase in the concentration of which leads to the creation of additional barriers of resistance to external mechanical influences, and as is evident from the general analysis of alterations in hardness and radiation-induced softening associated with the accumulation of structural distortions.

The analysis of the hardness measurements using the nanoindentation method by the depth of the damaged layer by measuring the hardness values on the side cleavage showed that an increase in the irradiation fluence above 1017 ion/cm2 results in the damaged layer thickness growth in the case of ceramics without the addition of a stabilizing additive, while the formation of inclusions in the form of the MgLi2ZrO4 phase, alongside the formation of two-phase ceramics, leads to a rise in the stability of hardness and a less pronounced increase in the damaged layer thickness. The observed changes indicate a positive effect of the presence of the MgLi2ZrO4 phase, not only on increasing the stability of strength parameters, but also on inhibiting the diffusion of helium in the near-surface layer.

In this case, as can be seen from the presented dependences of the change in hardness by depth, an increase in the irradiation fluence leads to an expansion of the damaged layer thickness, which, at fluences below 10

17 ion/cm

2, is about 350–450 nm, which corresponds to the depth of the He

2+ ion range in the near-surface layer of lithium-containing ceramics. An elevation in the irradiation fluence above 10

17 ion/cm

2, according to the results of the hardness change profiles by depth, results in the occurrence of a softening effect, not only in the damaged layer corresponding to the ion range depth, but also at a depth of more than 500 nm. It should also be noted that the observed changes in hardness with increasing fluence are observed not only in the form of a decrease in hardness, but also an increase in the thickness of the damaged layer, in which the hardness values differ significantly from the initial values. Such effects indicate the effect of diffusion of implanted ions deep into the ceramic material, which, in turn, creates deformation distortions, and, consequently, the emergence of softening areas. Moreover, these effects of diffusion and softening at a greater depth are most clearly observed for Li

2ZrO

3 ceramic samples without the addition of a dopant, i.e., without the presence of impurity phases in the form of MgLi

2ZrO

4, the concentration of which, as can be seen from the presented dependencies, has a clear effect on the resistance to diffusion of implanted ions. With an increase in the content of the MgLi

2ZrO

4 phase contribution in the ceramics, a decrease in the thickness of the diffusion layer is observed (in

Figure 4a–d, this region corresponds to the region to the right of the dotted red line), the change in which is clearly visible for samples irradiated with a maximum irradiation fluence of 10

18 ion/cm

2. Such an effect can be explained by the effects of interphase boundaries. An increase in concentration due to a change in the phase ratio leads to the creation of additional barriers that prevent both the migration of implanted helium and its agglomeration, due to containment at the boundaries.

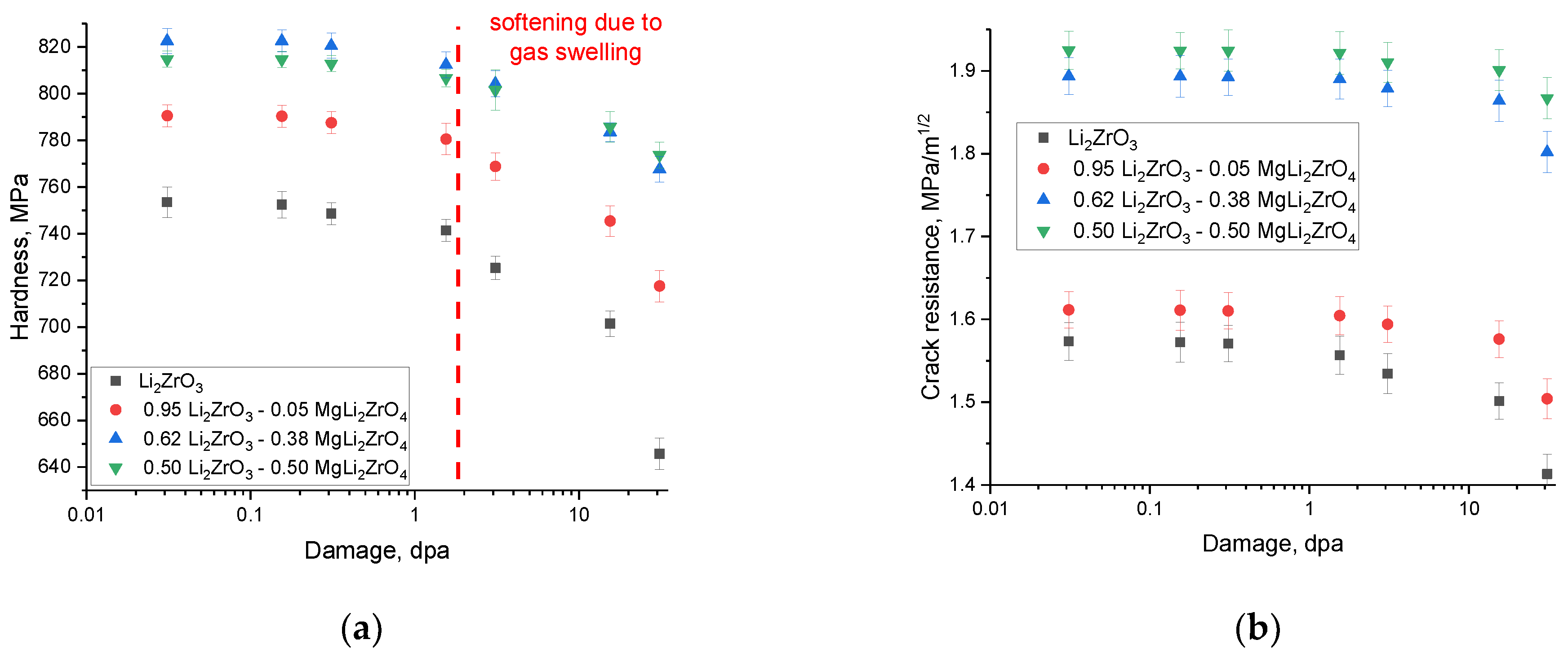

Figure 5a reveals the results of a comparative analysis of changes in hardness values at a depth of about 250–300 nm, reflecting the general trend of hardness reduction due to the accumulation of deformation distortions leading to the softening of the near-surface damaged layer. The general trend of changes has two characteristic sections that have a direct dependence on the value of atomic displacements (irradiation fluence), characterized by small changes (less than 1–3%, compared to the initial values) at values less than 1 dpa, and a sharp (close to exponential) decrease in hardness values with an increase in irradiation fluence, characteristic of those above 1 dpa. At the same time, in the case of small values of atomic displacements, the main trend of change is approximately equivalent for all four types of ceramics, while, in the case of large dpa values (more than 1 dpa), the trend of changes has a clearly expressed dependence on the phase composition of the ceramics. In this case, a rise in the contribution of the MgLi

2ZrO

4 phase, and, consequently, the number of interphase boundaries, leads to a decrease in the trend of hardness deterioration, which, as shown in

Figure 2, also leads to a decrease in the thickness of the diffuse layer under high-dose irradiation.

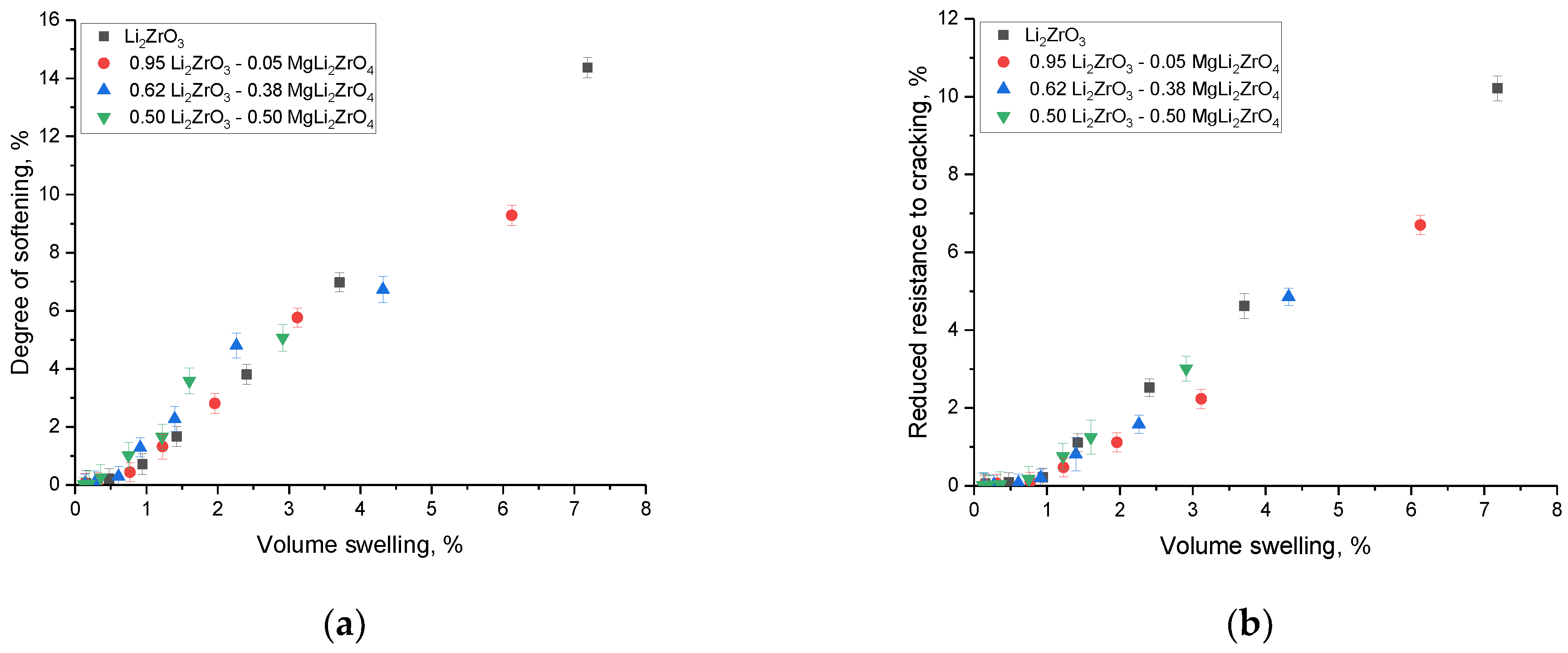

The presented data on changes in crack resistance values in

Figure 5b have similar trends of alterations as those of the changes in hardness; however, in the case of two ceramics in which the contents of the MgLi

2ZrO

4 phase are 38 and 50%, smaller changes in crack resistance are observed under high-dose irradiation (more than 1 dpa), which indicates a positive strengthening effect and an increase in the resistance to cracking due to interphase boundaries.

Figure 6 reveals the comparative analysis results of changes in the strength parameters (hardness and crack resistance) from the value of volumetric structural swelling caused by changes in the structural parameters with an increase in irradiation fluence (atomic displacement values). These changes in the degree of softening (hardness reduction) and crack resistance (crack resistance reduction) were determined by comparing the hardness and crack resistance values of the irradiated samples and the original samples that were not irradiated. These values of the softening degree are reflected in percentage ratio in order to determine the critical conditions under which the maximum degradation of the damaged layer occurs. The general form of the presented data reflects a direct relationship between the structural degradation degree, expressed in the change in the crystal lattice volume associated with deformation distortion, and the deterioration of strength parameters. At the same time, the variation of the phase composition of ceramics due to the growth in the contribution of the MgLi

2ZrO

4 phase results in the degradation resistance growth of both structural parameters and strength characteristics.

Figure 7a demonstrates the results of the change in the thermal conductivity coefficient of the studied ceramics contingent upon the phase composition of the samples irradiated with He

2+ ions with different fluences. The data are presented as dependencies of the changes in the thermal conductivity coefficient on the value of atomic displacements, the accumulation of which leads to the destructive disordering of the crystal structure (see data in

Figure 3). The general view of the presented data on the change in the thermal conductivity coefficient has two distinct trends associated with the effects of structural distortions, the changes of which are caused by the accumulation of deformation distortions, as well as an increase in the concentration of implanted ions in the damaged layer under high-dose irradiation. At the same time, the most significant changes in the values of the thermal conductivity coefficient are observed for atomic displacements of more than 1 dpa, which correspond to fluences above 10

17 ion/cm

2, from which it can be concluded that the key factor influencing the change in the thermophysical parameters is the effects of the accumulation of implanted helium in the structure filling the voids, as well as the associated processes of formation of clusters of the V

O—He type. In this case, the observed alterations in thermal conductivity are in good agreement with the observed changes in the value of volumetric structural swelling, the increase of which indicates a reduction in the damaged layer disordering degree. In this regard, the observed reduction in the thermal conductivity coefficient at high irradiation fluences (above 10

17 ion/cm

2) is due to a growth in the number of scattering centers that prevent phonon mechanisms of heat transfer in the structure of ceramics, which leads to a decrease in the rate of heat transfer and, as a consequence, an increase in heat loss, which affect the decrease in the thermal conductivity coefficient.

Figure 7b presents the data of a comparative analysis of changes in the thermal conductivity coefficient and volumetric structural swelling of irradiated samples, indicating the relationship between structural degradation and the thermophysical parameters of the studied ceramics, as well as an increase in the stability of the thermophysical properties of ceramics due to a change in the phase composition of the ceramics. At the same time, the presented data clearly show a direct relationship between the emerging effects of the structural degradation associated with the accumulation of implanted He

2+ ions in the near-surface layer, which has a negative effect on the degradation of the thermophysical parameters. However, structural distortions associated with deformation distortions arising as a result of ionization and athermal processes have a less pronounced effect on the change in thermal conductivity, due to the fact that the main mechanism of heat transfer due to phonon scattering is disrupted by inclusions in the form of disordered regions or gas-filled cavities, the formation of which occurs during high-dose irradiation.

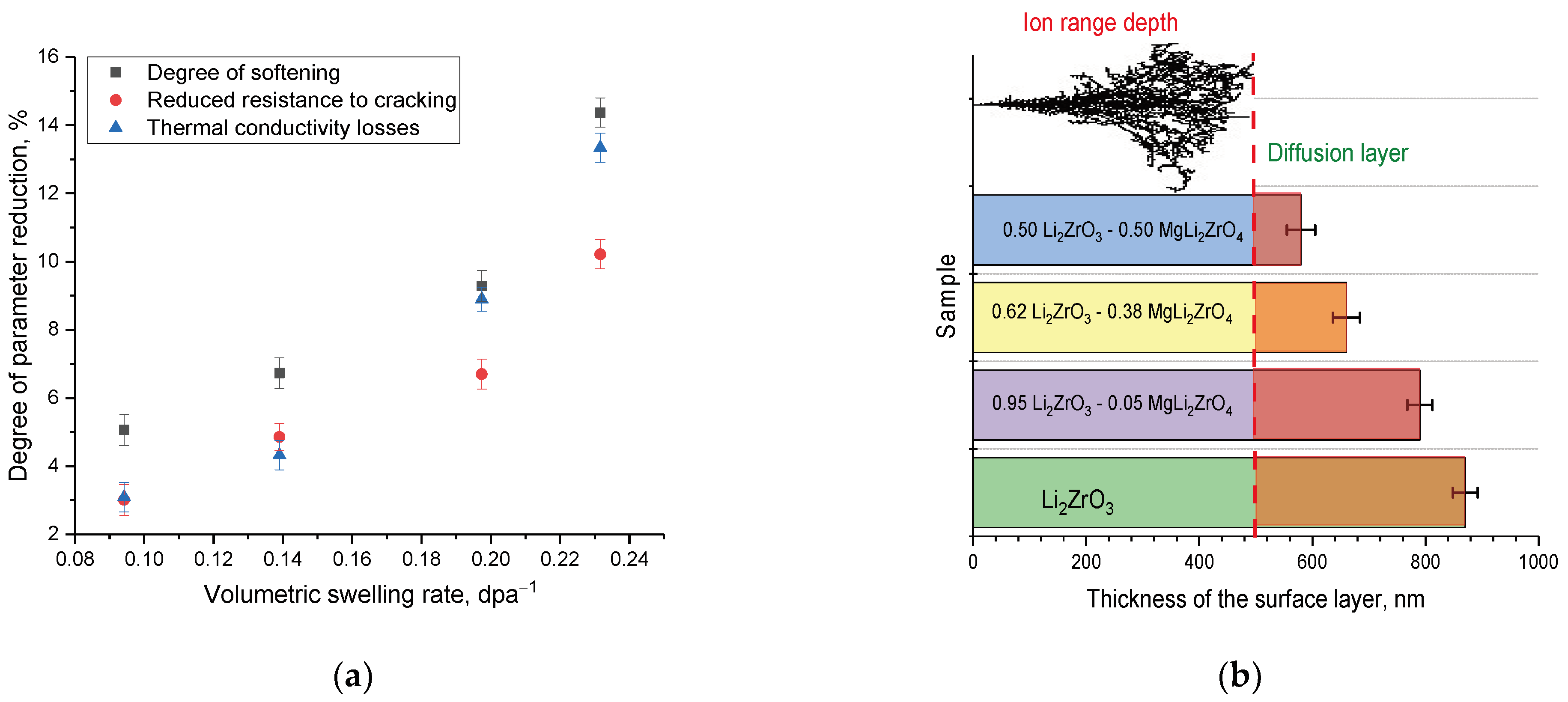

Figure 8a reveals the data comparing alterations in the values of softening (reduction in hardness), crack resistance (reduction in resistance to cracking), and thermal conductivity contingent upon the rate of volumetric-radiation-induced deformation swelling of the damaged layer. This rate was calculated based on a comparison of the data of alterations in the volume of the crystal structure before and after irradiation at the maximum value of atomic displacements (in the case of maximum irradiation fluence). According to the data presented, a direct relationship is visible between changes in the strength and thermal parameters and the degree of structural disorder. At the same time, an elevation in the phase ratio in the composition (due to an increase in the MgLi

2ZrO

4 phase with an increase in the MgO dopant) leads to a decline in the rate of volumetric-radiation-induced deformation swelling by more than 1.5–2.5 times, which indicates the restraint of structural degradation, and, as a consequence, smaller changes in the strength and thermal parameters due to an increase in interphase boundaries, the presence of which provides additional sinks for point and vacancy defects, and also restrains the migration and diffusion of implanted helium in the structure. It is important to highlight that the greatest changes among the studied parameters are observed for the hardness of the damaged layer, while the crack resistance parameters change less at the maximum irradiation fluence. This difference can be explained by the presence of interphase boundaries, which also have an additional restraining effect on the resistance to the propagation of microcracks under external mechanical influences. At the same time, an elevation in the Li

2ZrO

3/MgLi

2ZrO

4 phase ratio due to a rise in the contribution of MgLi

2ZrO

4 results in greater crack resistance in comparison with single-phase Li

2ZrO

3 ceramics.

Figure 8b illustrates the results of a comparative analysis of the thickness of the damaged layer with modified hardness parameters (according to the measurements of the nanoindentation method) for the studied ceramics depending on the phase composition. As can be seen from the data presented, in the case of Li

2ZrO

3 ceramics, at the maximum irradiation fluence (10

18 ion/cm

2), the total thickness of the damaged layer (layer with modified hardness parameters by depth when measured by the nanoindentation method) is about 830–850 nm, which is more than 1.5 times greater than the layer thickness characteristic of the maximum ion path depth in the ceramics. This effect can be explained by the diffusion of the implanted ions, which, in the case of high temperatures, is more pronounced due to the thermal expansion of the crystal lattice, alongside more pronounced structural deformation due to the synergistic effect of thermal expansion and deformation distortion, resulting in the destabilization of the damaged layer. The formation of inclusions in the composition of ceramics in the form of the MgLi

2ZrO

4 phase, according to the assessment of the damaged layer thickness, results in diffusion layer thickness reduction, which, for 0.5 Li

2ZrO

3—0.5 MgLi

2ZrO

4 ceramics, is no more than 100 nm, which is more than 3–3.5 times less than the thickness of the diffusion layer of damage for single-phase Li

2ZrO

3 ceramics.

The observed effects of inhibiting the diffusion of point and vacancy defects into the depth, as well as V

O—He-type clusters, due to a change in the phase ratio, are in good agreement with the results of studies [

28,

29,

30], which revealed that the presence of structural changes associated with the presence of superlattices, alongside interphase boundaries, results in the inhibition of defect migration in the damaged layer.