3.1. Characterization of Initial Samples by Varying the Addition of Aluminum Nitride with Different Concentrations

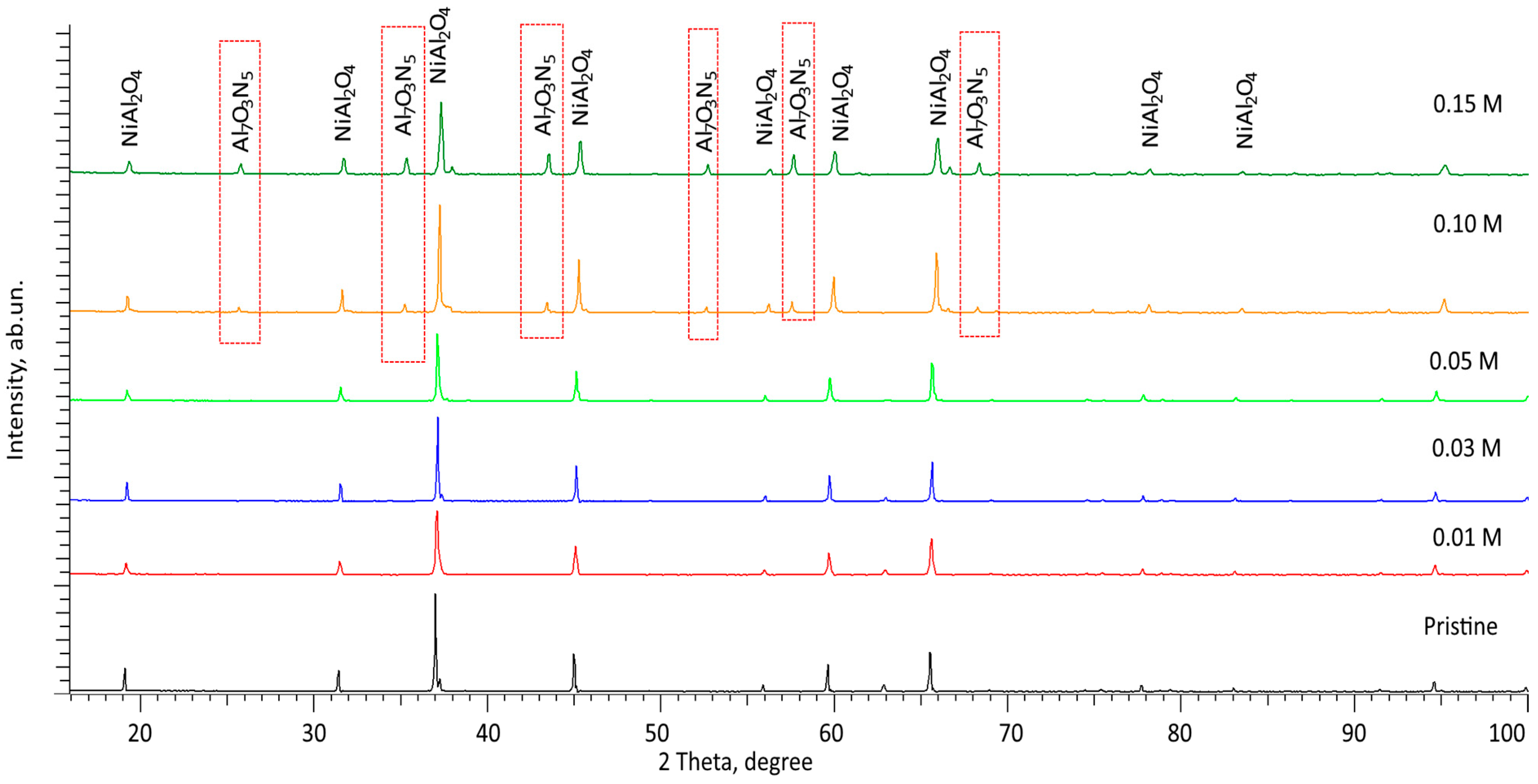

Figure 2 demonstrates the results of X-ray phase analysis of the ceramics under study depending on the concentration of the AlN component, reflecting alterations in the phase composition of the ceramics associated with the formation of impurity inclusions, the occurrence of which is due to an increase in the AlN concentration. The overall impression of the provided diffraction patterns highlights a significant level of structural order in the acquired samples. This is evident in the substantial disparity between the intensities of diffraction reflections and background radiation. Additionally, the analysis of the position and relative intensities of diffraction reflections in the examined samples is consistent with the cubic crystal structure characteristic of NiAl

2O

4, specifically belonging to the Fd-3m(227) spatial system (PDF-00-010-0339). Furthermore, with regard to the initial ceramic samples (without the addition of AlN), the diffraction patterns do not reveal any low-intensity reflections that would typically signify the presence of impurity inclusions in the form of unreacted initial component oxides. Conversely, the altered shape of diffraction reflections suggests the existence of factors within the structure that introduce distortions. These distortions manifest as reduced structural order and deviations in crystal lattice parameters from their reference values.

When incorporating AlN at concentrations ranging from 0.01 to 0.05 M, there was no evidence of the emergence of new diffraction reflections indicative of impurity inclusions in the resulting diffraction patterns. This observation can be attributed to the influence of the relatively low concentrations of AlN utilized during synthesis, which do not result in the formation of any impurities within the ceramic composition. It is important to note that an elevation in AlN concentration leads to the alignment of diffraction reflections, signifying an enhancement in their structural order and the mitigation of deformation distortions.

According to the obtained X-ray phase analysis data, at AlN concentrations of 0.10–0.15 M, the formation of the oxide-nitride phase Al7O3N8 (PDF-00-048-1580) occurs in the ceramic structure, the appearance of which is due to the processes of phase transformations between aluminum oxide and nitride at high temperatures. In this case, a variation in AlN concentration from 0.10 to 0.15 M results in an elevation in the contribution of this phase from 2.1 to 6.4 wt.%. The existence of this phase within concentrations of 0.10 to 0.15 M can be attributed to the heightened presence of aluminum nitride. When aluminum nitride interacts with aluminum and nickel oxides, it gives rise to a complex orthorhombic phase. The emergence of this phase can exert a notable influence on the alterations in the strength properties of the ceramics.

Using the acquired diffraction patterns, an evaluation of the structural parameters was conducted, along with an assessment of the degree of structural order. Changes in this factor indicate a reduction in deformation distortions within the crystal structure, which can be attributed to mechanochemical grinding processes and subsequent phase transformations during thermal sintering.

Table 1 provides data on the crystal lattice parameters and volume, showcasing how they change in response to variations in the AlN concentration within the ceramic composition.

As is evident from the information presented in

Table 1, the introduction of AlN into NiAl

2O

4 ceramics results in a reduction in the crystal lattice parameters and its volume. The reduction in the crystal lattice parameters of the NiAl

2O

4 phase with the growing concentration of the AlN dopant is due to the effects of structural ordering associated with the ordering of the crystal lattice and its compaction. A decline in the crystal lattice parameters results in a decrease in its volume, which in turn directly affects the number of porous inclusions (density changes). At the same time, a rise in the structural ordering degree (a decrease in the parameters of the crystal lattice, as well as its volume) is due to a decrease in deformation distortions caused by the processes of mechanochemical grinding of samples. This reduction signifies an enhancement in the structural order of the ceramics and a decrease in deformation-related irregularities within the structure. Simultaneously, a substantial decline of more than four to six times in the structural ordering factor in samples where the presence of an Al

7O

3N

8 impurity phase was identified suggests that these ceramics exhibit minimal deformation distortions. This, in turn, contributes to their reinforcement and densification, leading to a reduction in the volume of the crystal lattice.

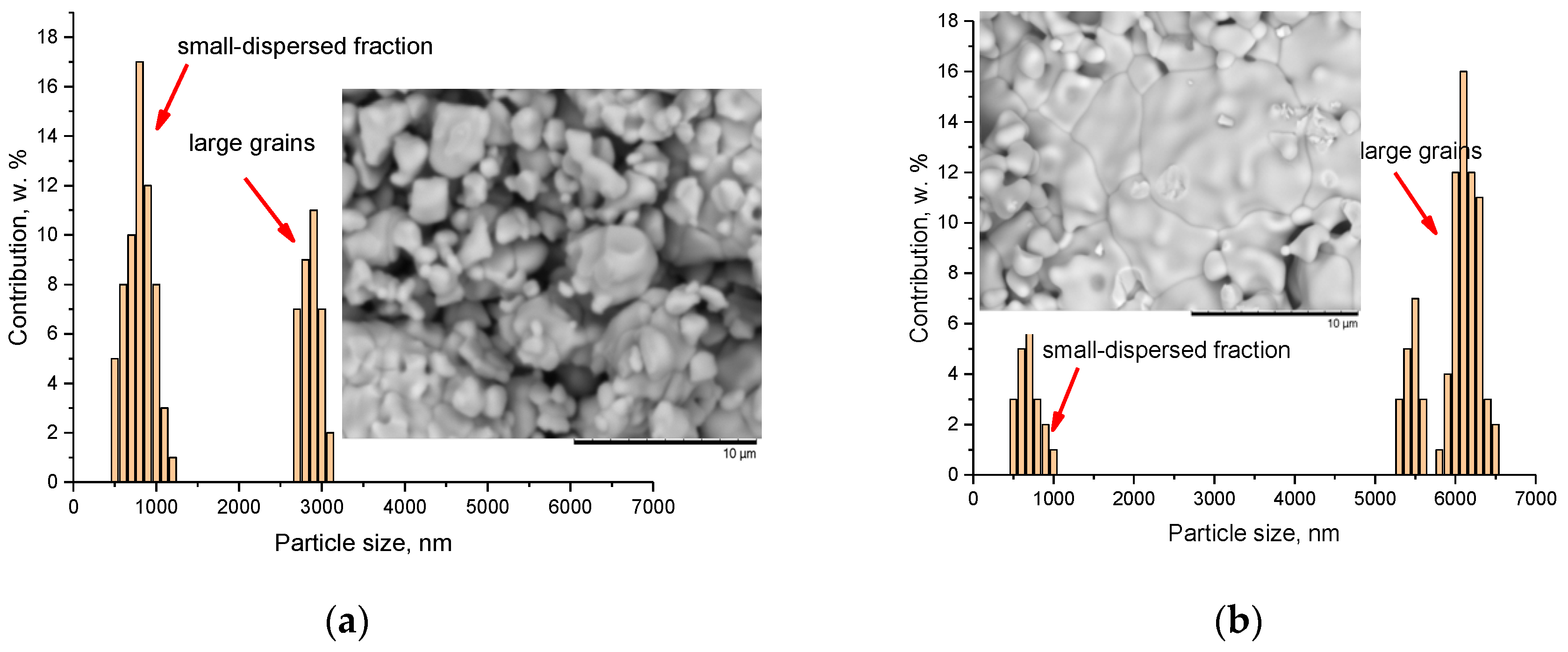

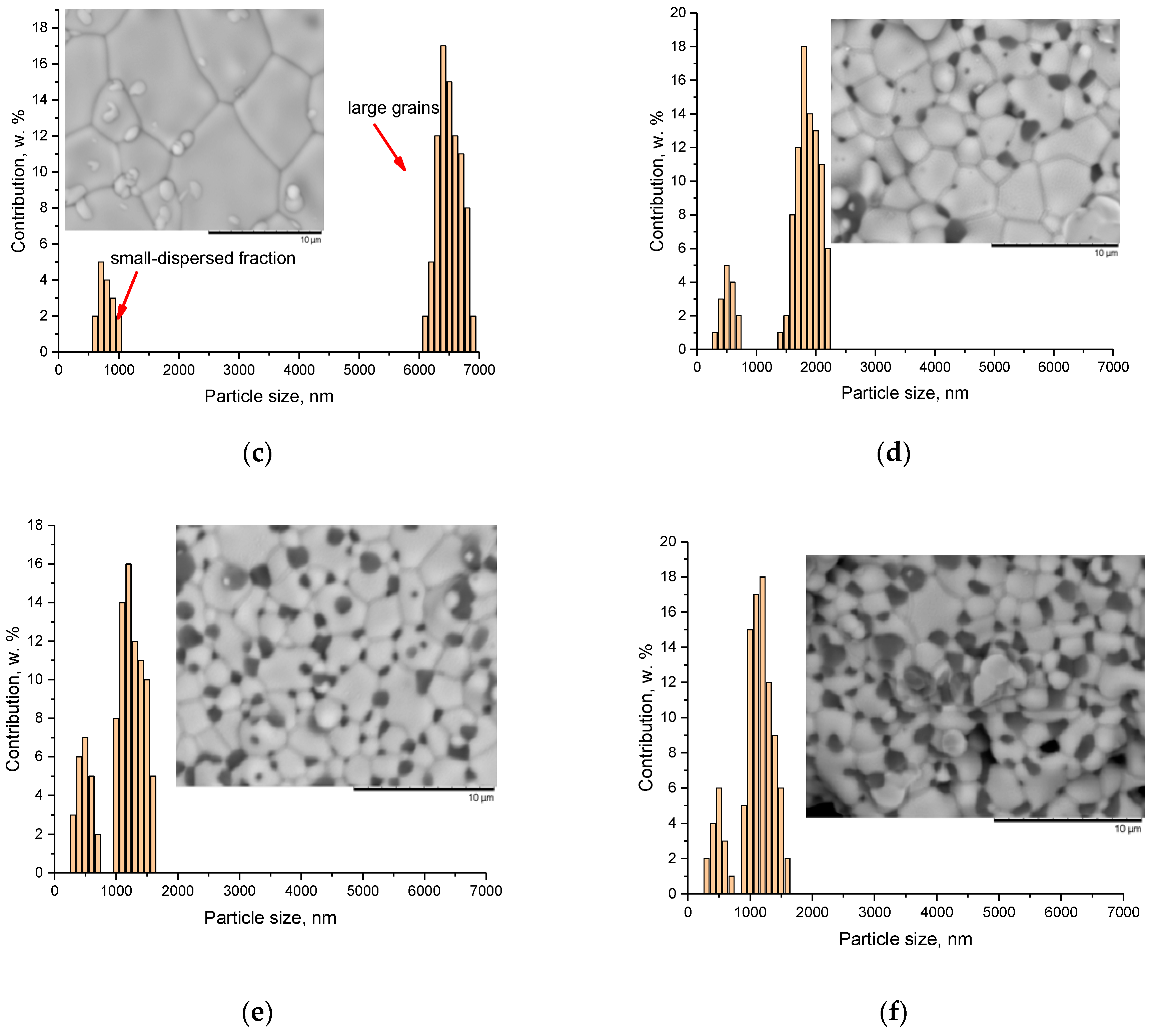

Figure 3 displays scanning electron microscopy (SEM) images depicting the morphology of ceramics. These images illustrate alterations in grain structure and their packing density as the composition varies.

Upon analyzing the obtained SEM images of ceramics with varying AlN content, the observed changes can be categorized into two distinctive stages. The initial stage is noticeable when AlN concentrations range from 0.01 to 0.03 M. In this range, an increase in AlN content leads to the development of a densely packed structure consisting of grains of irregular cubic or pentagonal shape. As the AlN concentration increases, the sizes of these grains diminish. In the second stage, not only do grain sizes decrease but there is also the emergence of inclusions possessing a distinct structure. The variation in color gradation within the images indicates that these new inclusions possess a different phase composition. Simultaneously, the concentration of these inclusions rises proportionally with the increase in AlN content in the ceramic composition. It is noteworthy that these inclusions are situated at grain boundaries, thereby generating additional interphase boundary effects. The presence of these boundaries can contribute to the strengthening of ceramics. When comparing the findings from morphological studies concerning the formation of new inclusions at higher concentrations with the data from X-ray phase analysis, we can deduce the following conclusion. The emergence of these inclusions can likely be attributed to the formation of the Al

7O

3N

8 phase, which was detected in X-ray diffraction patterns of samples featuring an AlN concentration ranging from 0.10 to 0.15 M. It is noteworthy that the escalation in the contribution of this phase aligns well with the data estimating the quantity of these inclusions in the provided SEM images (the concentration of inclusions clearly rises according to the data in

Figure 3e,f). However, the absence of reflections indicative of the Al

7O

3N

8 phase in the X-ray diffraction patterns (as shown in

Figure 2), despite the observation of these inclusions in the morphological images (as seen in

Figure 3d), can be rationalized by the low concentration of these inclusions, which falls below the detection threshold of the X-ray method (detection limit less than 0.1 wt.%).

Thus, summing up the characterization of the ceramic samples under study with variations in the AlN component, the following conclusions can be drawn. Firstly, increasing the concentration from 0.01 to 0.05 M results in heightened structural order and densification of the ceramics, consequently leading to a reduction in grain size. Secondly, at concentrations of the AlN component above 0.05 M, according to X-ray diffraction data, the formation of an Al7O3N8 impurity phase is observed, the presence of which results in the formation of fine-grained ceramics with close-packed grains, at the boundaries of which impurity phase grains are formed. This phenomenon gives rise to the presence of interphase boundaries. Simultaneously, the reduction in grain size results in an elevated dislocation density and intergrain boundaries. These factors collectively contribute to enhanced resistance against external influences, including mechanical and radiation-related factors.

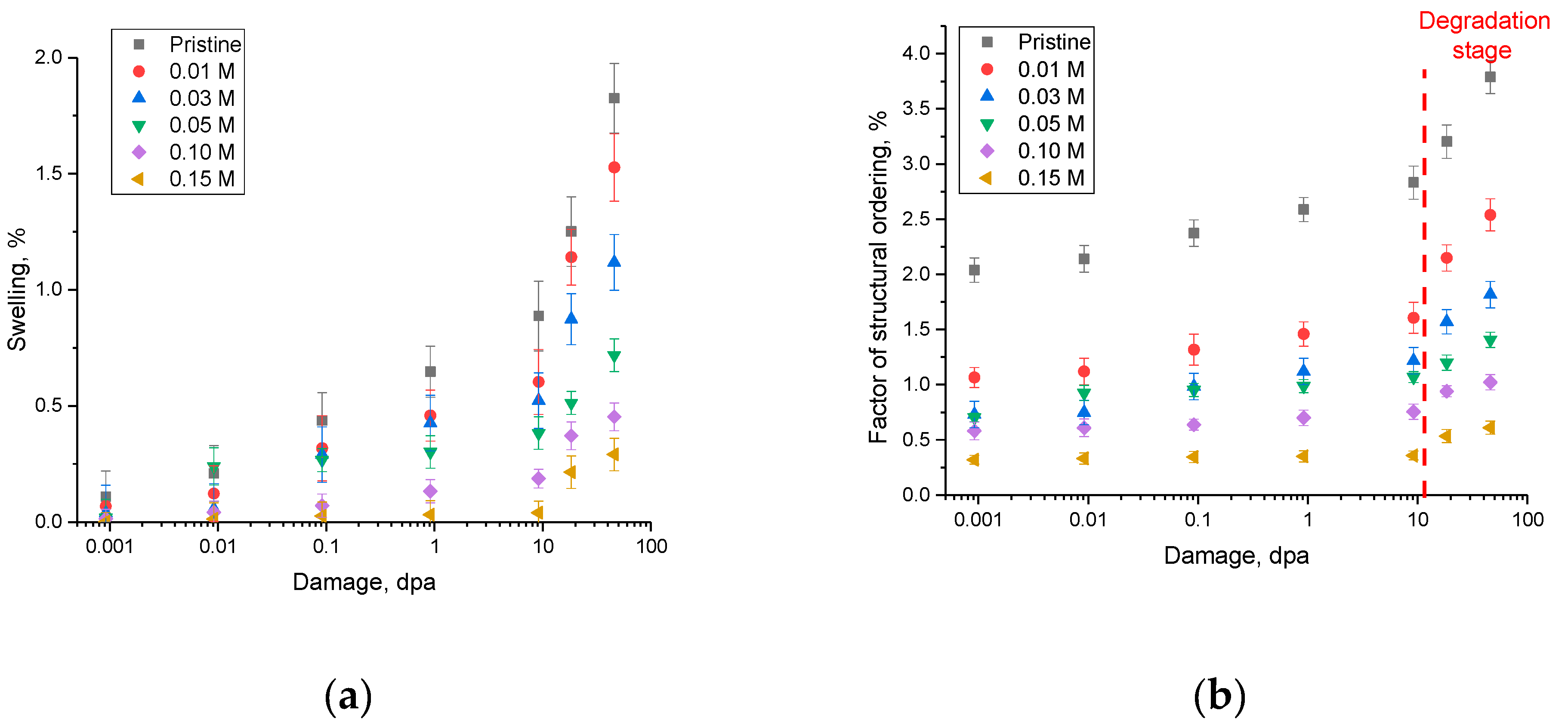

3.2. Evaluation of the Efficiency of Enhancing the Resistance to Structural Disorder and Swelling of NiAl2O4 Ceramics by Adding AlN to the Composition

One approach for assessing the resistance of ceramics to radiation-induced damage, linked to the accumulation of deformation distortions in the structure, involves monitoring the dynamic of alterations in structural parameters. This method entails ascertaining the structural characteristics (such as crystal lattice parameters or volume) for irradiated samples, contingent upon the irradiation fluence or the degree of accumulated atomic displacements, and subsequently comparing these values with those of the original samples. The outcomes of this comparative analysis enable the determination of the nature of structural changes connected to the accrual of radiation damage. Furthermore, it aids in gauging a material’s resistance to external influences, including the accumulation of structural distortions in cases where modifications have been made. Structural parameters for samples subjected to hydrogenation (irradiation with protons with different fluences) were determined based on the obtained X-ray diffraction patterns. The results of a comparative analysis of changes in structural parameters (changes in the crystal lattice volume and the factor of structural ordering) are presented in

Figure 4.

The swelling value was determined using the following calculation method. The swelling value was determined by calculating changes in the crystal lattice volumes of the studied samples in the initial state (depending on the concentration of the AlN dopant) and their changes as a result of hydrogenation processes under high-dose irradiation.

The structural disorder value was calculated based on changes in the structural order values (calculated for the initial values of the crystal lattice parameters) as a result of external influences (in this case, hydrogenation processes under high-dose irradiation).

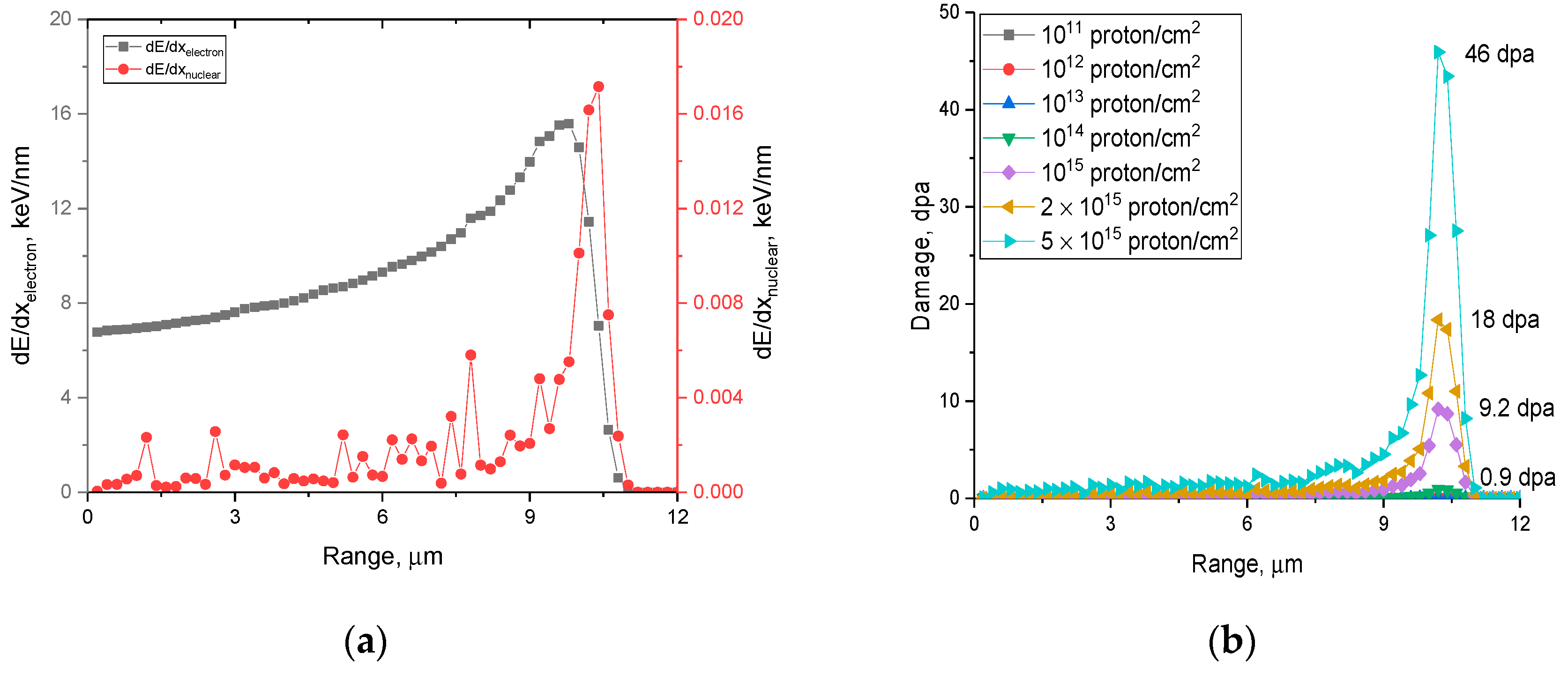

It is worth noting that the data obtained are presented depending on the magnitude of atomic displacements, calculated on the basis of data from the simulation of the interaction of incident protons with the crystal structure of ceramics. The choice of such a representation is due to the possibility of a comparative analysis of the observed structural changes, if necessary, with other types of radiation effects.

The general trend of changes in structural parameters indicates the formation of deformation distortions and residual tensile mechanical stresses in the structure of ceramics, since the change parameters are characteristic of a rise in the crystal lattice volume and the structural ordering factor grows with the accumulation of atomic displacements. In this case, the observed changes in structural parameters can be divided into two types: (1) small changes characteristic of atomic displacements of less than 1 dpa; and (2) a sharp deformation distortion of the crystal lattice at large values of atomic displacements. At the same time, the formation of the Al

7O

3N

8 impurity phase in the structure of ceramics results in a reduction of more than fivefold to sixfold in structural disorder compared to ceramic samples that do not contain AlN. The heightened resistance to structural deterioration in two-phase ceramics could be attributed to the presence of interphase boundaries. These boundaries serve to inhibit the degradation of the crystal structure arising from the accumulation of structural distortions associated with ionization effects [

33,

34]. It is important to highlight that the most significant structural alterations occur at irradiation fluences where substantial atomic displacements become the prevailing factor. This phenomenon signifies the impact of hydrogenation on the damaged layer, leading to its structural degradation due to deformations and residual mechanical stresses resulting from the interaction of incident particles with the crystalline structure. This interaction also involves the conversion of transferred kinetic energy into thermal energy within the crystalline structure [

35,

36].

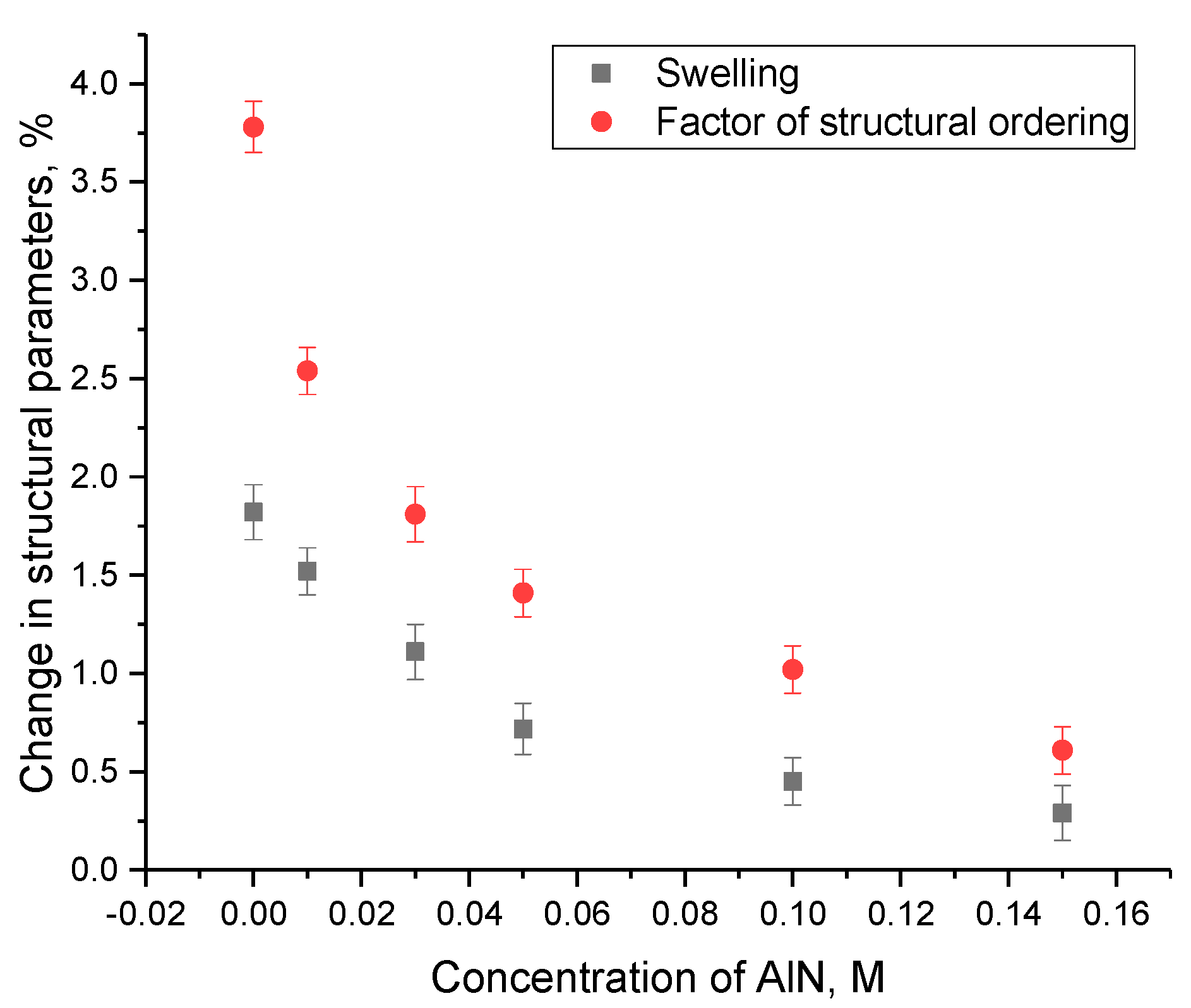

Figure 5 illustrates the outcomes of a comparative assessment of the extents of structural alterations recorded at maximum irradiation fluences, contingent upon the AlN concentration within the ceramic composition. These patterns exemplify the enhancement in ceramics’ stability in response to the inclusion of AlN when subjected to radiation-induced damage and hydrogenation processes that transpire during high-dose irradiation.

As evident from the depicted trends in structural parameter changes following irradiation, ceramics devoid of AlN exhibited the highest susceptibility to structural degradation. In these ceramics, the decline in the structural ordering factor exceeded 1.5 times in comparison to the initial value, and the expansion of the crystal lattice at the maximum fluence reached nearly 2%. In contrast, similar metrics for two-phase ceramics samples (where the presence of an Al7O3N8 impurity phase was confirmed) remain below 0.5% (crystal lattice swelling) and less than 1% (deterioration of the structural ordering factor). Furthermore, for samples featuring AlN concentrations ranging from 0.01 to 0.10 M, a noticeable reduction in the degradation of structural parameters is observed. This reduction indicates an enhanced resistance to the destruction of the crystal lattice and a decrease in the effect of disorder arising from the accumulation of deformation distortions and residual tensile mechanical stresses (arising during the deformation of the crystal lattice).

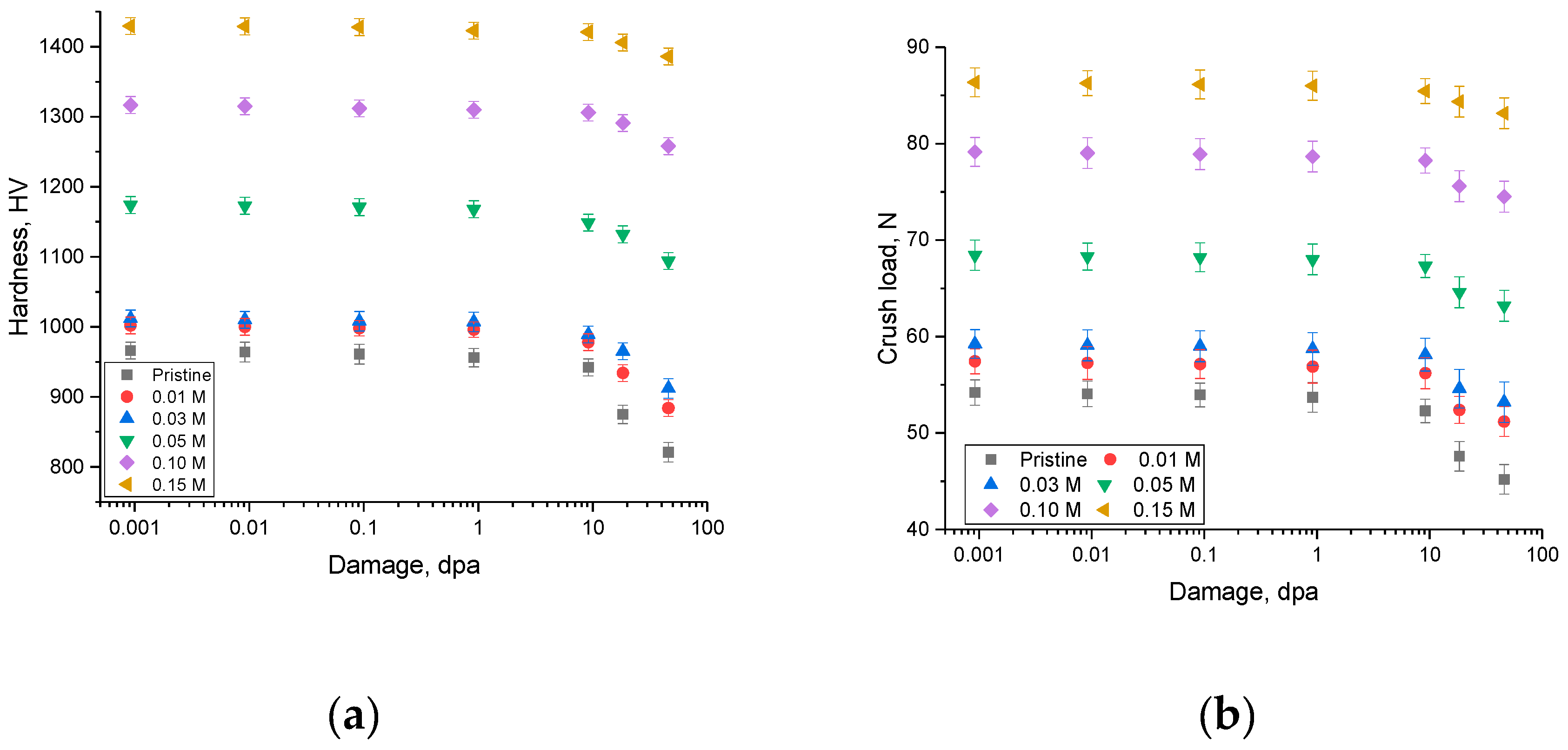

3.3. Assessment of the Irradiation Effect on Softening and Reduction of Strength and Thermophysical Parameters of NiAl2O4 Ceramics

Figure 6 displays the outcomes pertaining to alterations in hardness and resistance to cracking (maximum pressure threshold ceramics can endure during a single compression). These results reflect the degradation of ceramics’ strength properties in relation to the accumulation of atomic displacements (as fluence increases). Prior to examining the correlation between changes in the strength characteristics of irradiated samples, it is important to acknowledge the impact of the ceramics’ strengthening (manifested as an increase in hardness and maximum pressure) in response to variations in AlN concentration. Such a change in the strength characteristics of the ceramic samples under study depending on the change in the composition of the AlN concentration may be due to several factors. Firstly, the incorporation of AlN into the ceramic composition, as indicated by the X-ray diffraction analysis in

Figure 2 and the information in

Table 1, results in heightened structural order. This enhancement is accompanied by the densification of ceramics, subsequently leading to a reduction in residual deformation and structural distortions that originated during the synthesis and phase formation of the ceramics. This kind of structural ordering can result not only in strengthening but also in an elevated crack resistance when subjected to external pressure. This effect is clearly demonstrated in the obtained data, as presented in

Figure 6b. Secondly, as illustrated in

Figure 3 (providing information on the morphological characteristics of the studied ceramics), an increase in the concentration of the AlN additive in the ceramic composition results in a reduction in grain size. Additionally, it prompts the formation of a structure in which the intergranular space is occupied by grains of the Al

7O

3N

8 impurity phase (occurring at concentrations of 0.05–0.15 M). A reduction in grain size, coupled with the creation of these structures, gives rise to what is known as the dislocation strengthening effect. This effect involves an increase in dislocation density and the quantity of grain boundaries, and it is prominently evident in the alterations observed in the strength characteristics of the examined ceramics.

General trends in changes in strength characteristics depending on the magnitude of atomic displacements can be divided into two clearly defined zones. The first zone is characterized by the absence of significant changes in strength parameters and is typical for fluences of 1011–1014 proton/cm2, characteristic of atomic displacement values of less than 1 dpa. The absence of visible changes in this case is due to the high resistance of ceramics to mechanical influences, due to both high strength characteristics and small structural changes caused by the accumulation of deformation distortions during irradiation. The second zone is typical for atomic displacement values greater than 1 dpa, which is characterized by a decrease in strength characteristics; however, the trends of changes depending on the concentration of AlN in the composition of ceramics are different. These differences consist of a decrease in the change in these values of hardness and maximum pressure for the samples depending on the increase in AlN concentration. In this case, such changes can be explained both by the effect of dislocation strengthening (most pronounced for samples containing impurity inclusions in the form of Al7O3N8) and by the initial values of structural ordering.

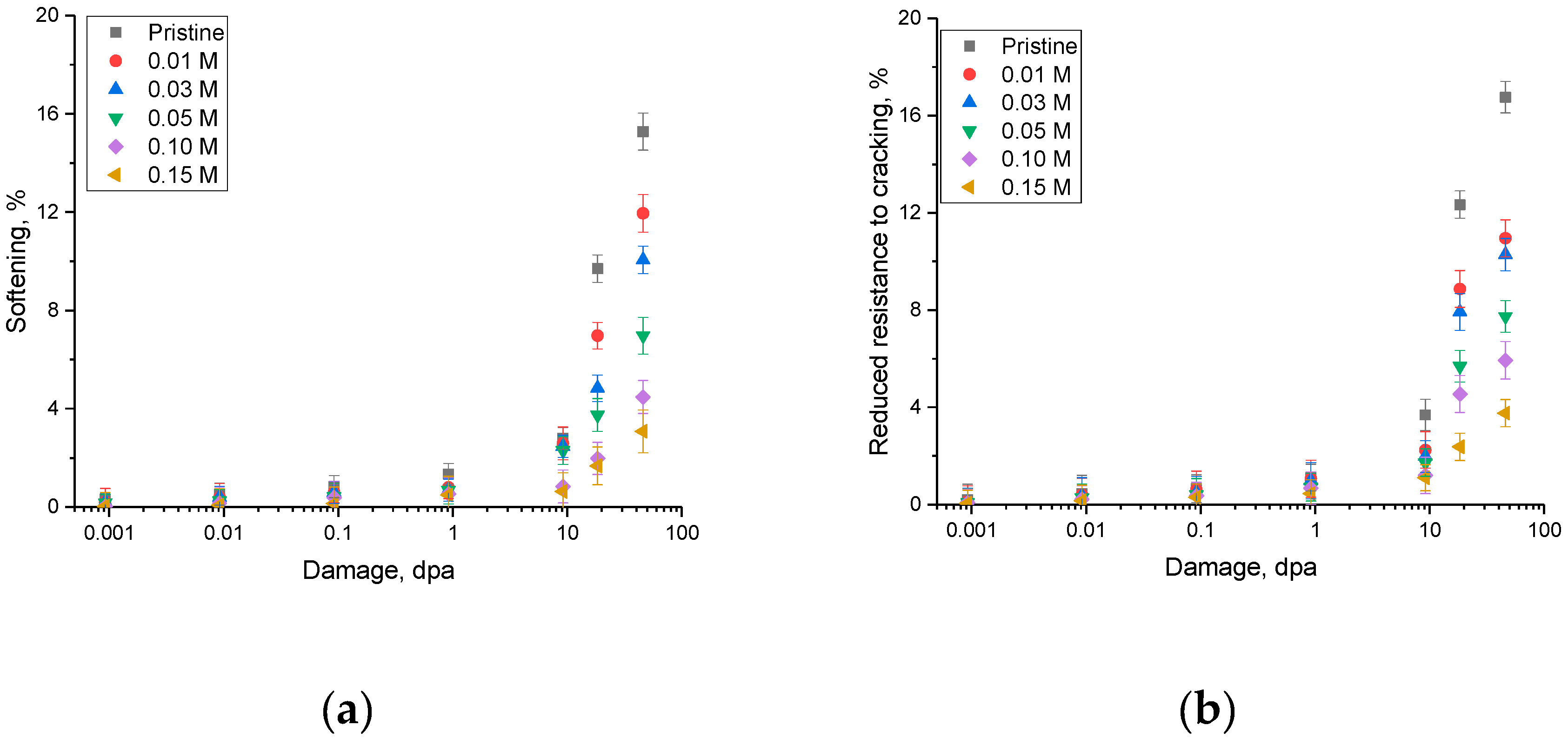

The outcomes demonstrating alterations in the strength properties, which signify a weakening and reduced resistance to cracking, of the studied ceramics based on accumulated radiation damage are depicted in

Figure 7. The overall presentation of the acquired data suggests a two-stage pattern in the evolution of ceramics’ resistance to external factors, encompassing the accumulation of structural distortions and deformation inclusions within the damaged layer. The variations in the concentration of these factors directly influence the deterioration of the strength parameters.

As can be seen from the presented data, the most pronounced changes in strength parameters associated with hardness degradation and a decrease in crack resistance are observed in samples of NiAl2O4 ceramics that do not contain AlN. At the same time, the maximum value of degradation of strength properties was more than 15% at the maximum irradiation fluence. Meanwhile, the reduction in strength parameters for samples in which the formation of an Al7O3N8 impurity phase was observed amounted to less than 3–4% at the maximum irradiation fluence. This is notably more than three to five times lower than the corresponding values for ceramics that lack impurity inclusions (i.e., those without the addition of AlN to the composition). The findings concerning alterations in strength characteristics highlight a favorable impact stemming from the presence of impurity inclusions in the form of the Al7O3N8 phase within the ceramic composition. This effect extends beyond strengthening and also encompasses an increase in resistance to the degradation of strength properties resulting from the accumulation of radiation damage and hydrogenation processes.

A crucial consideration in assessing the viability of ceramics for use in fuel cells is their thermophysical properties and their capacity to maintain stability in the face of external factors, including processes of degradation and hydrogenation during operation. A decrease in thermal conductivity characteristics can potentially result in detrimental outcomes, including effects linked to the inhibition of phonon heat transfer, given the dielectric nature of ceramics. An elevation in the inhibition of phonons involved in heat transfer, as a consequence of increased collisions with deformation inclusions, can lead to the development of localized areas of overheating. This, in turn, can bring about a destructive reduction in heat transfer efficiency, which would have an adverse impact on the ceramics’ operational performance.

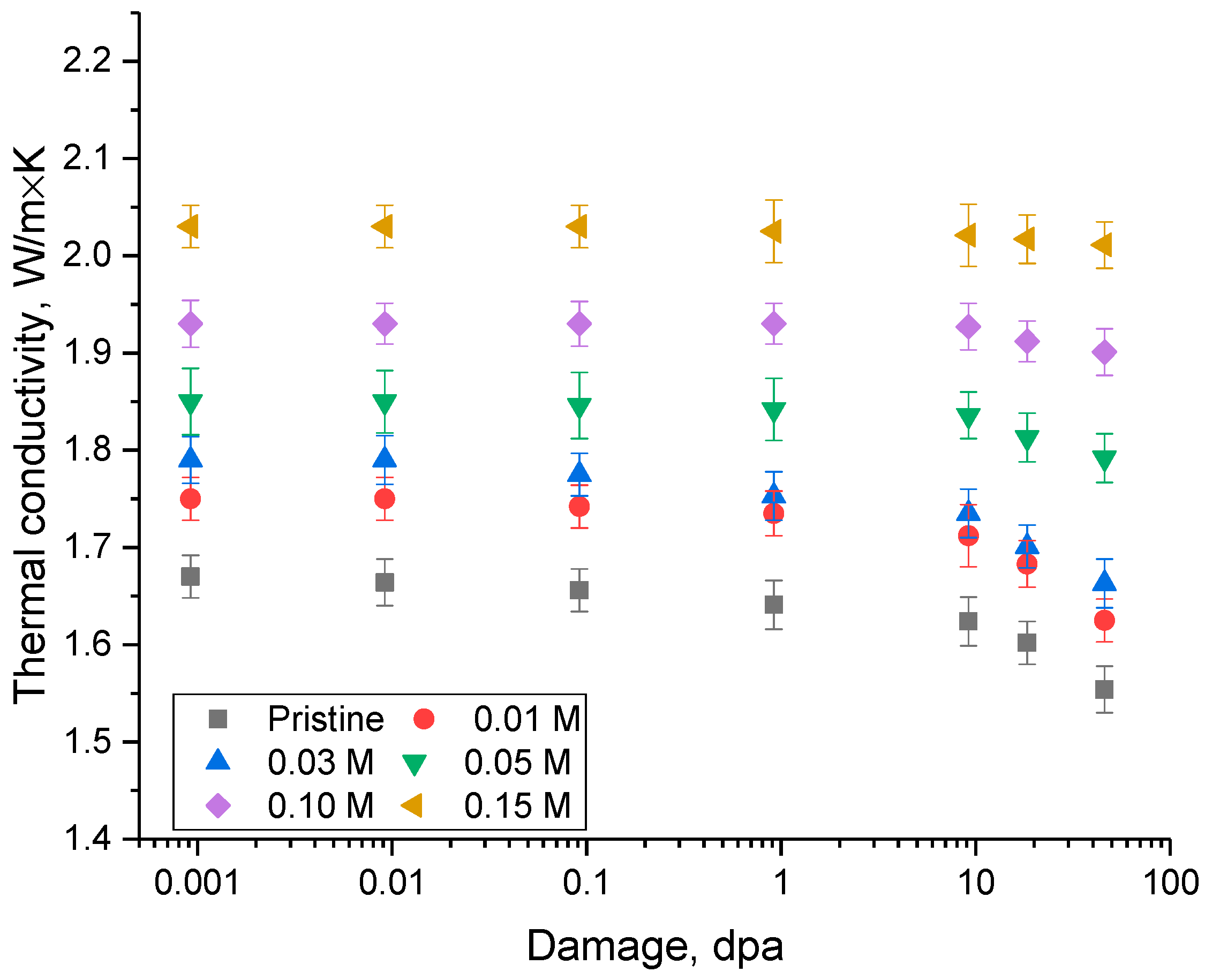

Figure 8 provides an illustration of the evaluation of variations in the thermal conductivity coefficient, which serves as an indicator of heat transfer within ceramics. The changes observed in irradiated samples suggest a degradation in heat transfer processes and the emergence of supplementary heat losses within the structure of damaged ceramics. An examination of the thermophysical characteristics of the initial ceramic samples in relation to the increment in AlN concentration within the composition reveals a favorable trend toward enhancing thermal conductivity. These alterations in thermal conductivity in the context of dielectric ceramics are inherently linked to the extent of structural ordering. In this context, the enhancement of the crystal structure resulting from increased ordering of the crystal lattice and greater compaction as the AlN concentration rises results in a thermal conductivity increase of over 5–10% for AlN dopant concentrations between 0.01 and 0.05 M. Additionally, the presence of the Al

7O

3N

8 impurity phase within the composition significantly enhances thermal conductivity by more than 15–20% when compared to the undoped samples.

As can be seen from the presented data on alterations in the thermal conductivity coefficient of irradiated samples, the most significant manifestations of deterioration in thermophysical parameters appear in the case when the magnitude of deformation distortions corresponds to atomic displacements of more than 5 dpa (at fluences above 1014 proton/cm2). In this case, the deterioration of thermal conductivity is due to the accumulation of deformation distortions in the structure and the formation of regions of disorder, the presence of which results in the appearance of additional scattering centers for phonons, which leads to the deterioration of thermal conductivity. It is important to highlight that in the case of ceramics that contain impurity inclusions that prevent severe destruction of the crystal structure (see data on the results of assessing changes in structural parameters), the decline in the thermal conductivity coefficient is less than 1% even in cases of high irradiation doses. Moreover, for ceramics without the addition of AlN in the ceramic composition, the decrease in the thermal conductivity coefficient at maximum irradiation fluence is more than 7%. Furthermore, it is important to emphasize that the structural ordering observed in the samples at low AlN concentrations within the ceramic composition results in heightened stability of the thermophysical parameters. Notably, the reduction in the thermal conductivity coefficient, in comparison to the variations in strength characteristics, is considerably smaller (more than two times). This suggests that hydrogenation processes exert a more pronounced effect on alterations in strength characteristics compared to their impact on thermophysical parameters.