Fabrication of Segments for ZnO-Based Tube Ceramic Targets by the Spark Plasma Sintering Method

Abstract

1. Introduction

2. Materials and Methods

3. Results

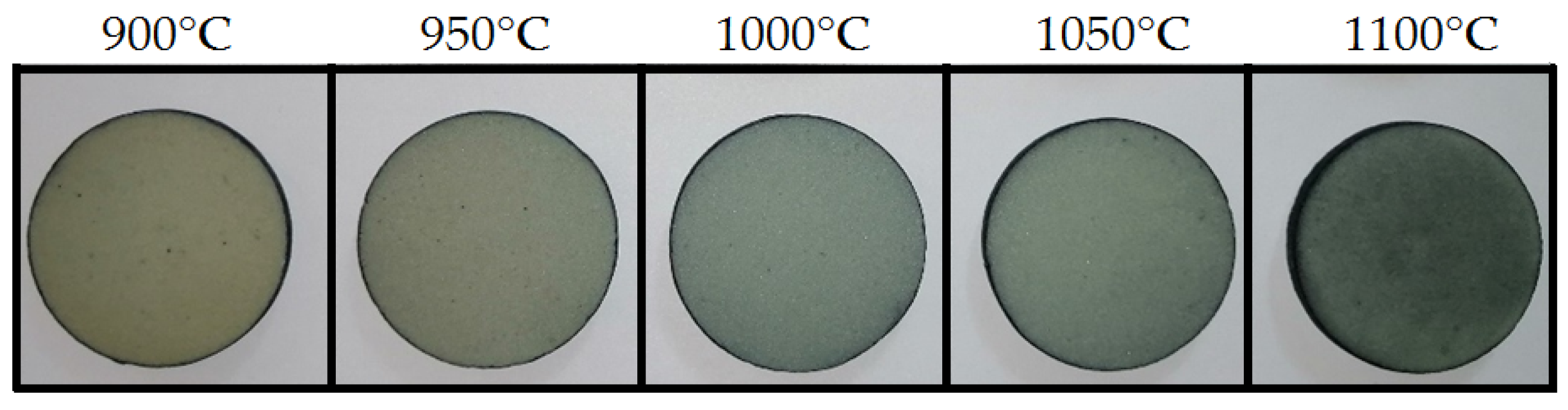

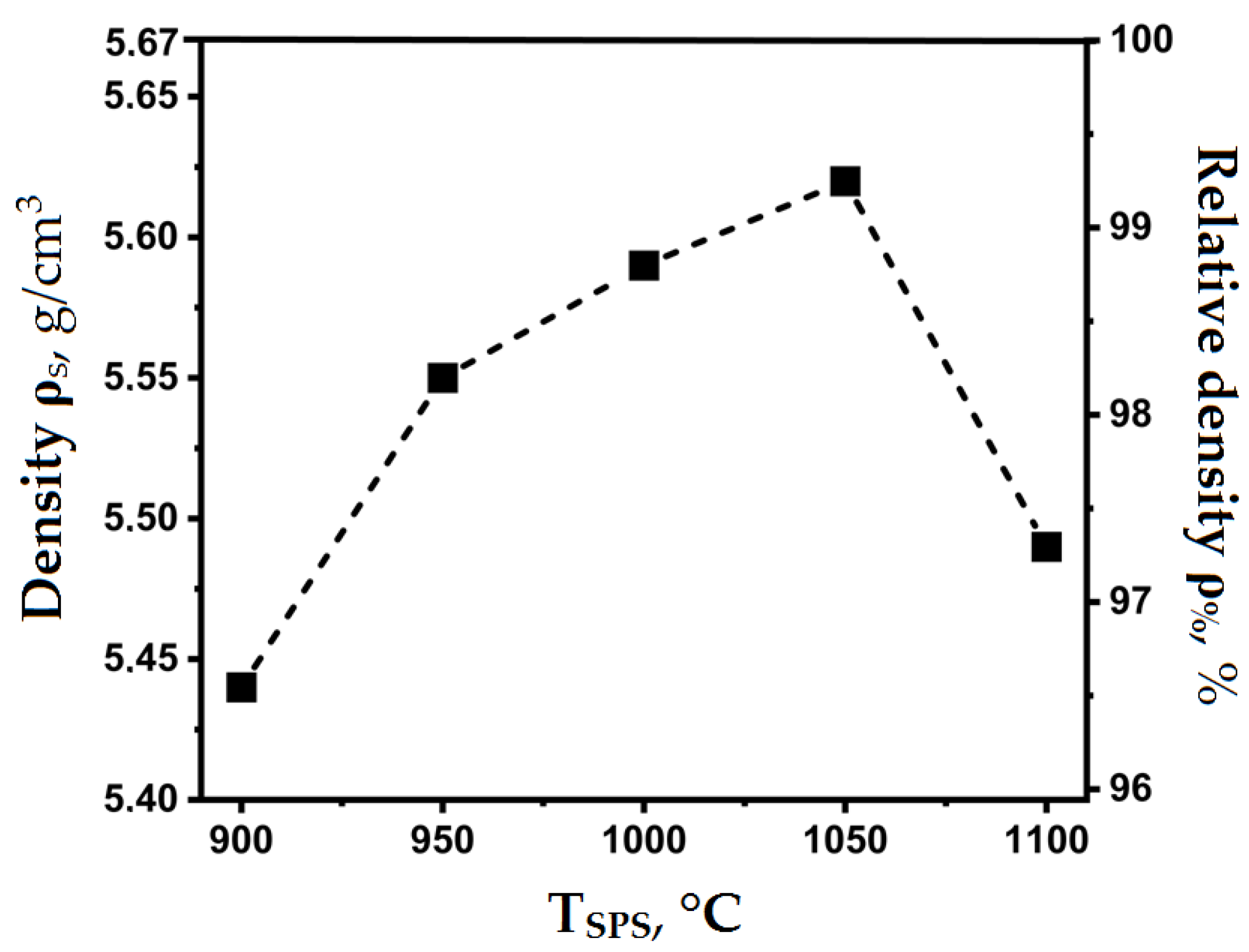

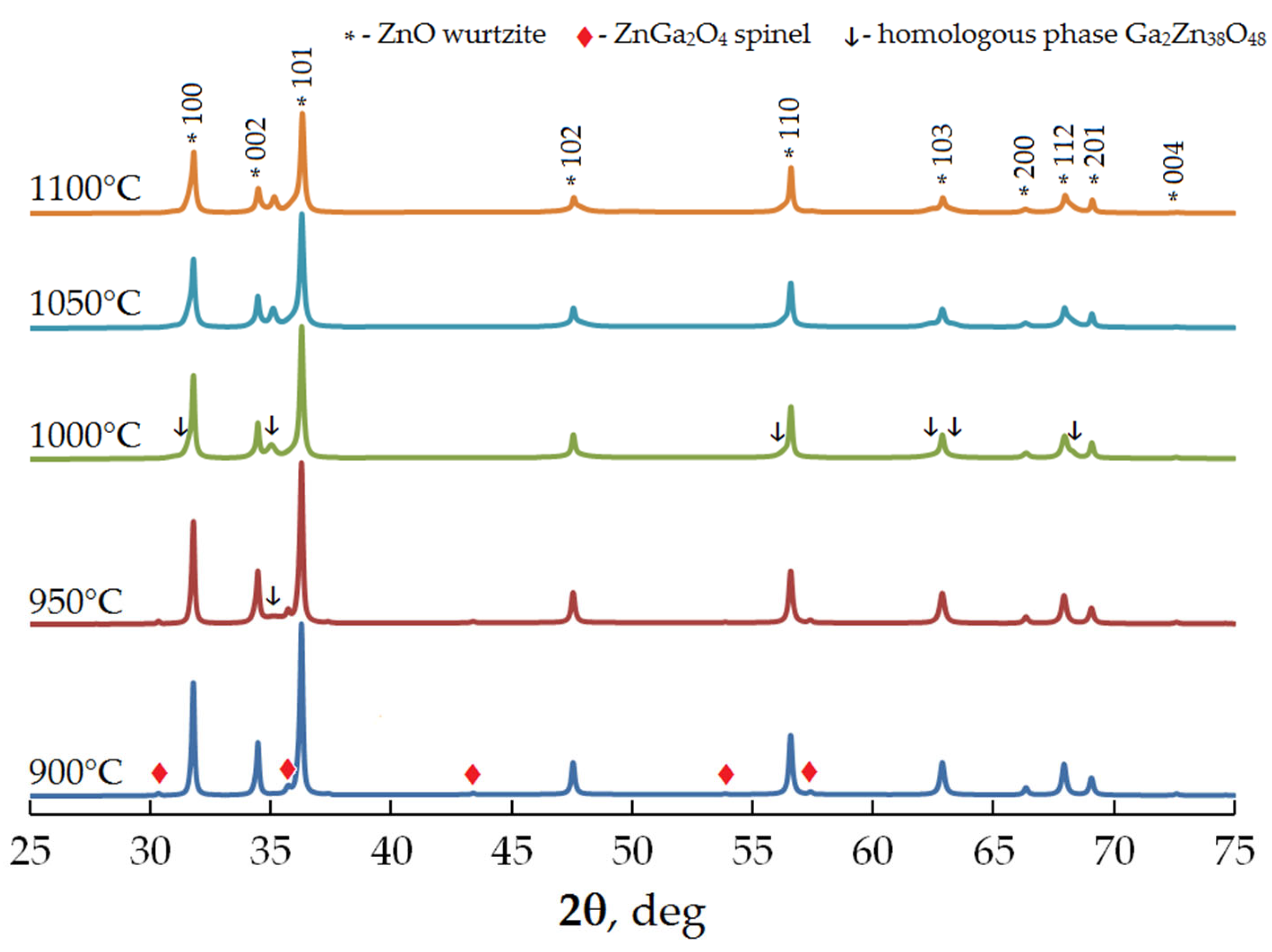

3.1. Optimization of the Temperature Regime of Spark Plasma Sintering of GZOB

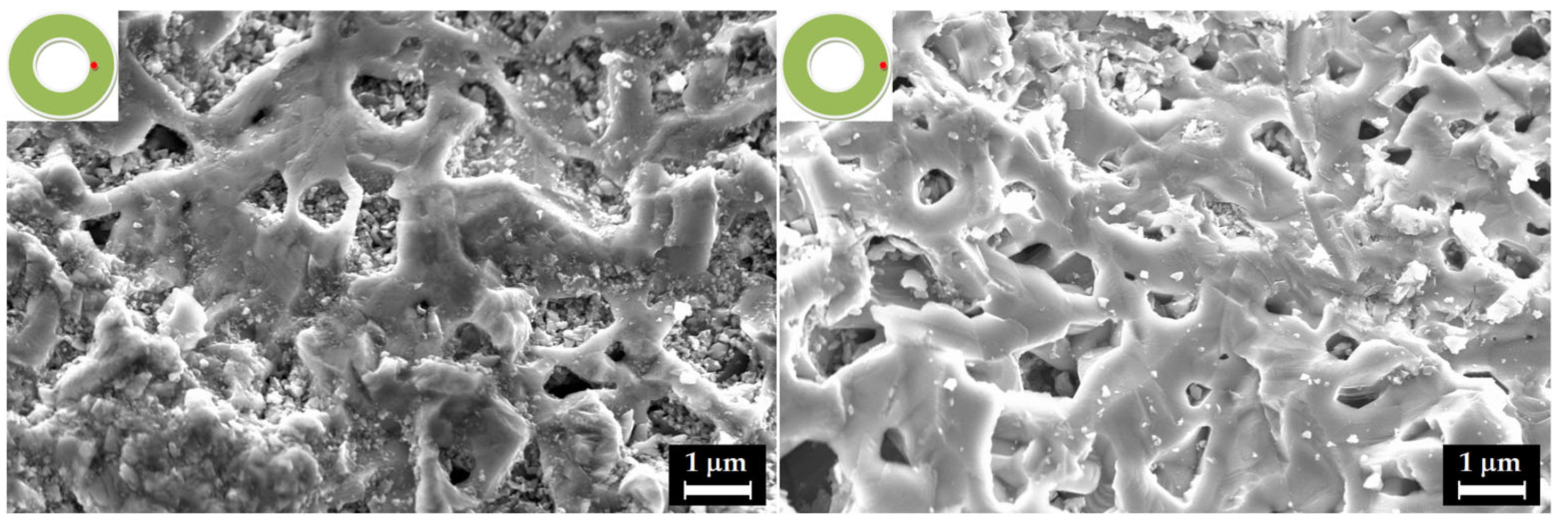

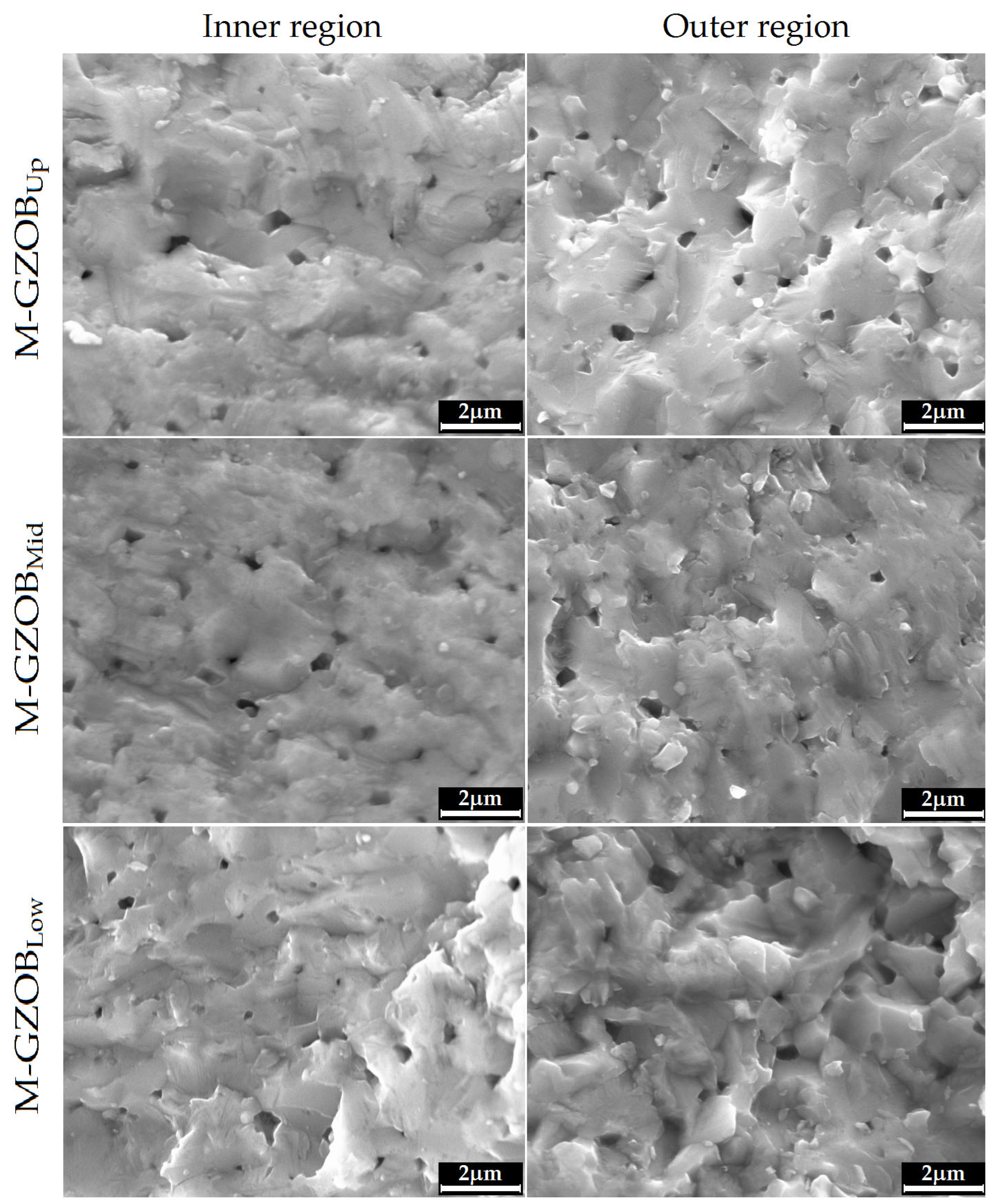

3.2. Optimization of the SPS Process for Hollow Cylindrical GZOB Ceramics

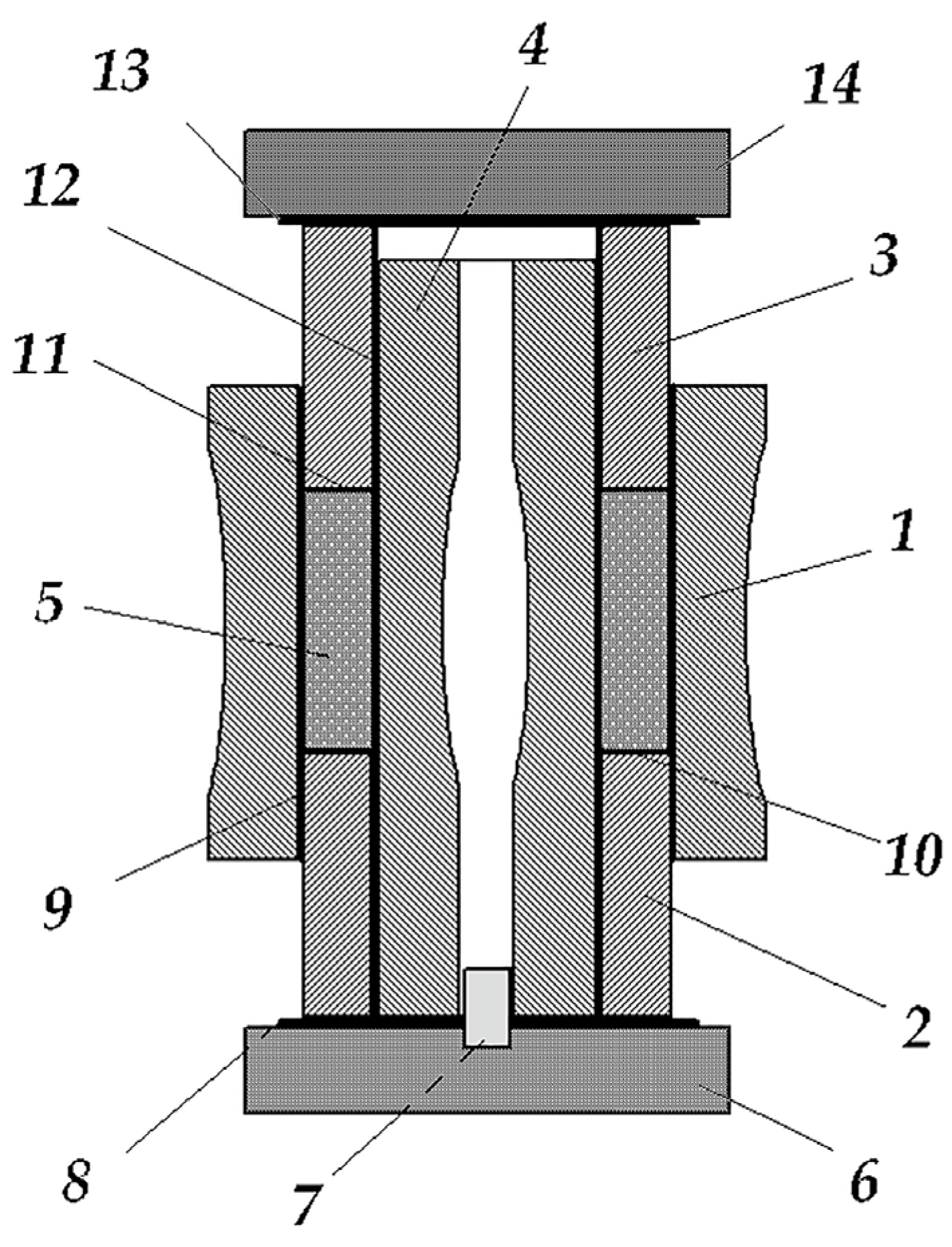

3.2.1. PS Development for SPS Forming of Hollow Cylindrical Ceramics

- The central graphite insert was made hollow in order to increase its electrical resistance and reduce its heat capacity;

- The outer side of the die and the inner side of the central insert were turned to get their special geometrical profiles.

3.2.2. Hollow Cylindrical GZOB Ceramics Produced Using the Standard and Modernized PSs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seyfert, U.; Heisig, U.; Teschner, G.; Strumpfel, J. 40 years of industrial magnetron sputtering in Europe. SVC Bull. Fall 2015, 2015, 22–26. [Google Scholar]

- Tietema, R. 4.21—Large-Scale Industrial Coating Applications and Systems. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; pp. 519–561. [Google Scholar] [CrossRef]

- Volker, L. Challenges in the industrial deposition of transparent conductive oxide materials by reactive magnetron sputtering from rotatable targets. Thin Solid Films 2017, 634, 149–154. [Google Scholar] [CrossRef]

- Medvedovski, E.; Szepesi, C.J.; Yankov, O.; Olsson, M.K. Rotary ITO Ceramic Sputtering Targets for Transparent Conductive Thin Films Coating. Am. Ceram. Soc. Bull. 2008, 87, 39–42. [Google Scholar]

- Sarkar, J. (Ed.) Chapter 4—Sputtering Target Manufacturing. In Sputtering Materials for VLSI and Thin Film Devices; William Andrew Publishing: Norwich, NY, USA, 2014; pp. 197–289. [Google Scholar] [CrossRef]

- Medvedovski, E.; Alvarez, N.; Yankov, O.; Olsson, M.K. Advanced indium-tin oxide ceramics for sputtering targets. Ceram. Int. 2008, 34, 1173–1182. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, W.; Song, D.; Ma, Q.; Zhang, L.; Zhang, H.; Ma, X.; Song, H. Comparative study of the sintering process and thin film sputtering of AZO, GZO and AGZO ceramics targets. Ceram. Int. 2014, 40, 12905–12915. [Google Scholar] [CrossRef]

- Kalvani, P.R.; Shapouri, S.; Jahangiri, A.R.; Jalili, Y.S. Microstructure evolution in high density AZO ceramic sputtering target fabricated via multistep sintering. Ceram. Int. 2020, 46, 5983–5992. [Google Scholar] [CrossRef]

- Mei, F.; Yuan, T.; Li, R.; Qin, K.; Huang, J. Improving the densification of indium tin oxide targets via secondary cold isostatic pressing and oxygen exchange treatments. Scr. Mater. 2018, 155, 109–113. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, H.; Xie, Y.; Miao, L.; Yao, W.; Zhang, F.; Wang, T.; Zhang, H. Characteristics of ultra-high density Al:ZnO sputtering targets prepared by hot isostatic pressing. Ceram. Int. 2018, 44, 5486–5491. [Google Scholar] [CrossRef]

- Lee, J.-R.; Chung, T.-J.; Yang, S.-H.; Hong, G.-S.; Oh, K.-S. Prevention of tapering in the tube-shaped sputtering target via initial heat treatment under external pressure. Ceram. Int. 2015, 41, 3677–3683. [Google Scholar] [CrossRef]

- Kelly, J.P.; Graeve, O.A. Spark Plasma Sintering as an Approach to Manufacture Bulk Materials: Feasibility and Cost Savings. JOM 2015, 67, 29–33. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Gao, L.; Li, Q.; Luan, W.; Kawaoka, H.; Sekino, T.; Niihara, K. Preparation and Electric Properties of Dense Nanocrystalline Zinc Oxide Ceramics. J. Am. Ceram. Soc. 2002, 85, 1016–1018. [Google Scholar] [CrossRef]

- Asvarov, A.S.; Muslimov, A.E.; Akhmedov, A.K.; Abduev, A.K.; Kanevsky, V.M. A Laboratory Apparatus for Spark Plasma Sintering of Ceramic and Composite Materials. Instrum. Exp. Tech. 2019, 62, 726–730. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Q.; Tian, T.; Zheng, L.; Barré, M.; Monot-Laffez, I.; Makowska-Janusik, M.; Li, G.; Kassiba, A.H. Defects and microstructure of highly conducting Al-doped ZnO ceramics obtained via spark plasma sintering. J. Eur. Ceram. Soc. 2020, 40, 5529–5534. [Google Scholar] [CrossRef]

- Sharma, S.; Bayikadi, R.; Swaminathan, P. Spark plasma sintering route to synthesize aluminium doped zinc oxide. RSC Adv. 2016, 6, 86586. [Google Scholar] [CrossRef]

- Takeuchi, T.; Ishida, T.; Ichikawa, K.; Miyamoto, S.; Kawahara, M.; Kageyama, H. Rapid preparation of indium tin oxide sputtering targets by spark plasma sintering. J. Mater. Sci. Lett. 2002, 21, 855–857. [Google Scholar] [CrossRef]

- Akhmedov, A.; Abduev, A.; Murliev, E.; Asvarov, A.; Muslimov, A.; Kanevsky, V. The ZnO-In2O3 Oxide System as a Material for Low-Temperature Deposition of Transparent Electrodes. Materials 2021, 14, 6859. [Google Scholar] [CrossRef]

- Ma, N.; Li, J.-F.; Zhang, B.P.; Lin, Y.H.; Ren, L.R.; Chen, G.F. Microstructure and thermoelectric properties of Zn1−xAlxO ceramics fabricated by spark plasma sintering. J. Phys. Chem. Solids 2010, 71, 1344–1349. [Google Scholar] [CrossRef]

- Kunikata, T.; Kato, T.; Shiratori, D.; Kantuptim, P.; Nakauchi, D.; Kawaguchi, N.; Yanagida, T. Annealing Temperature Dependence of Scintillation Properties of Ga-doped ZnO Translucent Ceramics. Sens. Mater. 2023, 35, 491–497. [Google Scholar] [CrossRef]

- Giuntini, D.; Raethel, J.; Herrmann, M.; Michaelis, A.; Haines, C.D.; Olevsky, E.A. Spark plasma sintering novel tooling design: Temperature uniformization during consolidation of silicon nitride powder. J. Ceram. Soc. Jpn. 2016, 124, 403–414. [Google Scholar] [CrossRef]

- Abduev, A.K.; Akhmedov, A.K.; Asvarov, A.S. The structural and electrical properties of Ga-doped ZnO and Ga, B-codoped ZnO thin films: The effects of additional boron impurity. Sol. Energy Mater. Sol. Cells 2007, 91, 258–260. [Google Scholar] [CrossRef]

- Abduev, A.K.; Asvarov, A.S.; Akhmedov, A.K.; Kamilov, I.K. Ceramic Target, Film Consisting of Zinc Oxide, Gallium and Boron, and Method for Preparing the Film. U.S. Patent 20,080,283,802, 20 November 2008. [Google Scholar]

- Pretorius, F.; Focke, W.W.; Androsch, R.; Du Toit, E. Estimating binary liquid composition from density and refractive index measurements: A comprehensive review of mixing rules. J. Mol. Liq. 2021, 332, 115893. [Google Scholar] [CrossRef]

- Colibaba, G.V.; Rusnac, D.; Fedorov, V.; Petrenko, P.; Monaico, E.V. Low-temperature sintering of highly conductive ZnO:Ga:Cl ceramics by means of chemical vapor transport. J. Eur. Ceram. Soc. 2021, 41, 443–450. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, M.; Zhang, H.; Zheng, Z.; Wang, Z.; Cheng, H.; Wang, P.; Liu, Y.; Huang, B. Fabrication of ZnO Ceramics with Defects by Spark Plasma Sintering Method and Investigations of Their Photoelectrochemical Properties. Nanomaterials 2021, 11, 2506. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.P.; Jeng, G.R. Properties of aluminum doped zinc oxide materials and sputtering thin films. J. Alloys Compd. 2009, 468, 343–349. [Google Scholar] [CrossRef]

- Jayathilake, D.S.Y.; Peiris, T.A.N.; Sagu, J.S.; Potter, D.B.; Wijayantha, K.G.U.; Carmalt, C.J.; Southee, D.J. Microwave-Assisted Synthesis and Processing of Al-Doped, Ga-Doped, and Al, Ga Codoped ZnO for the Pursuit of Optimal Conductivity for Transparent Conducting Film Fabrication. ACS Sustain. Chem. Eng. 2017, 5, 4820–4829. [Google Scholar] [CrossRef]

- Jood, P.; Peleckis, G.; Wang, X.; Dou, S. Effect of gallium doping and ball milling process on the thermoelectric performance of n-type ZnO. J. Mater. Res. 2012, 27, 2278–2285. [Google Scholar] [CrossRef]

- Asvarov, A.S.; Abduev, A.K.; Akhmedov, A.K.; Muslimov, A.E.; Kanevsky, V.M. On the Synthesis of ZnO: Al Ceramics by the Slip Casting Method. J. Surf. Investig. 2022, 16, 997–1002. [Google Scholar] [CrossRef]

- Alvarez -Ruiz, D.T.; Azough, F.; Hernandez-Maldonado, D.; Kepaptsoglou, D.M.; Ramasse, Q.M.; Day, S.J.; Svec, P.; Svec, P.S.; Freer, R. Utilising unit-cell twinning operators to reduce lattice thermal conductivity in modular structures: Structure and thermoelectric properties of Ga2O3(ZnO)9. J. Alloys Compd. 2018, 762, 892–900. [Google Scholar] [CrossRef]

- Chernenko, K.A.; Gorokhova, E.I.; Eronko, S.B.; Sandulenko, A.V.; Venevtsev, I.D.; Wieczorek, H. Structural, Optical, and Luminescent Properties of ZnO:Ga and ZnO:In Ceramics. IEEE Trans. Nucl. Sci. 2018, 65, 2196–2202. [Google Scholar] [CrossRef]

- Pham, A.T.T.; Luu, T.A.; Pham, N.K.; Ta, H.K.T.; Nguyen, T.H.; Van Hoang, D.; Phan, T.B. Multi-scale defects in ZnO thermoelectric ceramic materials co-doped with In and Ga. Ceram. Int. 2020, 46, 10748–10758. [Google Scholar] [CrossRef]

- Wu, M.-W.; Lai, P.-H.; Hong, C.-H.; Chou, F.-C. The sintering behavior, microstructure, and electrical properties of gallium-doped zinc oxide ceramic targets. J. Eur. Ceram. Soc. 2014, 34, 3715–3722. [Google Scholar] [CrossRef]

- Michiue, Y.; Mori, T. Identification of a secondary phase Ga2O3(ZnO)m in Ga-doped ZnO thermoelectric materials by a (3 + 1)-dimensional superspace model. J. Appl. Cryst. 2018, 51, 924–927. [Google Scholar] [CrossRef]

- Michiue, Y.; Kimizuka, N.; Kanke, Y. Structure of Ga2O3(ZnO)6: A member of the homologous series Ga2O3(ZnO)m. Acta Cryst. 2008, B64, 521–526. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Ruiz, D.T.; Azough, F.; Slater, T.; Day, S.J.; Freer, R. The effect of nano-twins on the thermoelectric properties of Ga2O3(ZnO)m (m = 9, 11, 13 and 15) homologous compounds. J. Eur. Ceram. Soc. 2020, 40, 5549–5558. [Google Scholar] [CrossRef]

| Sample | Samples after Cutting | ||

|---|---|---|---|

| S-GZOB | 96.7% | S-GZOBUp | 97.8% |

| S-GZOBMid | 94.9% | ||

| S-GZOBLow | 97.4% | ||

| M-GZOB | 98.8% | M-GZOBUp | 98.9% |

| M-GZOBMid | 99.0% | ||

| M-GZOBLow | 98.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhmedov, A.K.; Asvarov, A.S.; Makhmudov, S.S.; Kanevsky, V.M. Fabrication of Segments for ZnO-Based Tube Ceramic Targets by the Spark Plasma Sintering Method. Ceramics 2023, 6, 1302-1313. https://doi.org/10.3390/ceramics6030080

Akhmedov AK, Asvarov AS, Makhmudov SS, Kanevsky VM. Fabrication of Segments for ZnO-Based Tube Ceramic Targets by the Spark Plasma Sintering Method. Ceramics. 2023; 6(3):1302-1313. https://doi.org/10.3390/ceramics6030080

Chicago/Turabian StyleAkhmedov, Akhmed K., Abil Sh. Asvarov, Soslan Sh. Makhmudov, and Vladimir M. Kanevsky. 2023. "Fabrication of Segments for ZnO-Based Tube Ceramic Targets by the Spark Plasma Sintering Method" Ceramics 6, no. 3: 1302-1313. https://doi.org/10.3390/ceramics6030080

APA StyleAkhmedov, A. K., Asvarov, A. S., Makhmudov, S. S., & Kanevsky, V. M. (2023). Fabrication of Segments for ZnO-Based Tube Ceramic Targets by the Spark Plasma Sintering Method. Ceramics, 6(3), 1302-1313. https://doi.org/10.3390/ceramics6030080