Abstract

The research aimed at the composition optimization for diamond-SiC-Si composites. The effect of a porous diamond workpiece was studied on the properties (porosity, density, modulus of elasticity, phase composition) of the product of its siliconization with molten silicon. The lowest porosity and highest modulus of elasticity were observed in the case of using mixed matrices with the maximum size of diamond grains of 250/200 μm for siliconization. The best results in terms of the sound speed (16,600 m/s) and elasticity modulus (860 GPa) were achieved by microwave processing of a composite containing detonation nanodiamonds.

1. Introduction

Diamonds are known to possess exciting physical properties, including a high modulus of elasticity and speed of sound, the highest hardness, wear resistance, and thermal conductivity [1], which make them a promising material for structures subjected to extreme loads [2]. Unfortunately, both natural and synthetic diamond crystals are too small for use as structural materials. Furthermore, they have low crush and impact strength. The manufacture of products from diamond powders requires their sintering. However, heating of diamond leads to their graphitization (in an inert environment or in vacuum) or oxidation (in air), complicating the implementation of conventional technologies for their processing into useful materials. For such purposes, diamonds are compacted using a technique based on the preparation of compositions involving diamond grains in couple with non-diamond components.

The necessity of mass transfer at sintering results in transformations of metastable phases; i.e., diamond conversion into graphite at temperatures above 800 °C in an oxidizing environment or above 1600 °C in an inert environment [3,4,5,6]. Consequently, such materials with high diamond content can be obtained by high-pressure, high-temperature (HPHT) sintering technique [7,8], reaction sintering [9,10,11], or electrospark plasma sintering [12]. Particularly in reaction sintering, a diamond billet and non-diamond components are impregnated with liquid silicon at 1450–1650 °C in an inert atmosphere or in vacuum. The impregnation results in the formation of a composite comprising diamond and SiC, as well as the residual silicon deteriorating mechanical performances and corrosion resistance of the composites [13]. In addition to the considered reaction infiltration, these materials can be obtained using a reaction infiltration of silica vapor in vacuum [14,15].

The most advantageous combination of the composite properties and manufacturability was achieved for the diamond-SiC-Si composition obtained by infiltration of a porous diamond matrix with liquid silicon. This composition is formed as a result of binding the diamond grains due to the formation of reaction silicon carbide:

Si + C → SiC + Q

This approach provides multiphase composites including diamond, silicon carbide, some residual silicon, and possibly graphite formed due to a partial graphitization of diamond. Among these phases, diamond features the highest elasticity modulus, whereas the presence of silicon, and especially graphite, significantly deteriorates the mechanical performances of the material.

Although such compositions have been known for a long time, the most significant recent relevant publications are devoted to the study of the diamond-silicon interactions and processes at the phase boundary [9,10,16,17,18,19].

Evidently, the properties of such composites are evidently determined by the ratio between the phases (diamond, SiC, Si, graphite), as well as by the porosity. In turn, the resulting phase composition and porosity depend on the initial diamond powder dispersion. The prediction of the optimal particle size distribution of the diamond matrix before siliconization is impossible. Apparently, the elasticity modulus of the composite grows with the increase of the resulting diamond content. However, the absence or insufficient content of silicon carbide prevents the diamond grains being retained in the material. The use of coarse diamond grains with higher mechanical properties compared to fine diamond grains can be expected to improve the mechanical properties of the composites. On the other hand, a matrix comprising coarse diamond grains contains relatively large voids, causing a high porosity. Large and well-faceted single crystals usually feature a reduced reactivity. Consequently, more residual unreacted silicon will remain after their siliconization. The optimization of the granulometric composition of powders intended for sintering single-phase ceramics should be based on simple geometric factors including the selection of the grain size providing the maximum density; e.g., using the Fuller method. However, in this case, molten silicon not only fills the spaces between the diamond grains but also reacts with diamond, resulting in a decrease of diamond particle size and formation of an additional SiC phase. The result of this process is unpredictable in view of silicon’s different rates of reaction with diamonds of different dispersion. Thus, despite the fact that the dispersion of the initial diamond powders is decisive in achieving the best performances properties of the composite, the choice of granulometric composition is based on a certain research experience. For comparison, the properties of similar diamond-SiC-Si composites obtained without high-pressure application are summarized in Table 1.

Table 1.

Reference data on the properties of diamond-SiC-Si composites.

In Ref. [21], a sound speed of 12,578 m/s, elasticity modulus of 507 GPa, and density of 3.22 g/cm3 were achieved for a diamond-silicon carbide composite. The effect of diamond grain size (10 μm/50 μm) and temperature of impregnation with liquid silicon (1500 °C/1600 °C) upon the properties of resulting materials was studied and samples with an elasticity modulus of 525 GPa and density of 3.25 g/cm3 were obtained in [22]. The “ideal” composite in [19] features an elasticity modulus of 720 GPa and sound speed of 15,000 m/s. The best performances (sound speed of 15,500 m/s and elasticity modulus of 800 GPa) were achieved for the composite “Sceleton”® [20,26] samples containing 70% diamonds.

The aim of this study was the composition optimization of diamond-silicon carbide composites based on the study of the role of the initial diamond grains’ dispersion in the infiltration process, and consequently the effect on this factor on properties of the resulting composite.

2. Materials and Methods

To optimize the dispersion of the diamond-SiC-Si composition, both powders of certain grain sizes and polydisperse compositions were used. Synthetic diamond micropowders of the ASM (diamond synthetic micro powder GOST 9206-80) brand with dispersions of 3/2 µm, 7/5 µm, 10/7 µm, 14/10 µm, 28/20 µm, 50/40 µm, slip-powders of AS6 (diamond synthetic GOST 9206-80) brand with a dispersion of 100/80 µm, and grains of AC160 grade with a dispersion 250/200 µm (Intech Diamond Co., Moscow, Russia) were used as initial matrix materials. Generally, finer-grained materials are known to possess higher strength and hardness. It was expected that the use of nanodiamonds in the studied compositions would provide a positive effect on their properties. One of the goals of this study involved testing the possibility of replacing a finely dispersed diamond (ASM 10/7 μm) by a powder of detonation nanodiamonds (DND, sample 20 in Table 2). In this research, we used a powder of detonation nanodiamonds (DND) (Real-Dzerzhinsk, Ltd., Dzerzhinsk, Russia) obtained by blasting a mixture of trinitrotoluene with hexogen [27]. DND powder particles comprised nanosized grains (from 5 nm), agglomerated into particles of up to 2 µm (predominantly 0.2–0.8 µm) in size. The DND powder was finely crystalline with an imperfect structure and a block size (coherent scattering regions, CSR) of about 17 nm. Ash content (content of non-combustible impurities) was 0.8% wt. Similar to [27], the ash consisted of oxides, carbides, and salts of Fe, Ti, Cr, Cu, K, Ca, Si, Zn, and Pb. The applied DND nanopowders featured a low bulk density of 0.15–0.25 g/cm3.

Table 2.

Dispersion of the applied diamond matrices.

Based on the available set of grain sizes, the particle size distribution of polydisperse mixtures was calculated using the Main software according to the Fuller method to obtain a composition with the maximum density. The calculation results were used to choose the compositions for the performed experiments presented in Table 2 (samples 9–19). Since the DND powder had an average size of agglomerates of 0.2–0.8 μm, the fractional composition was changed towards an increase in the content of coarse- and medium-grain sizes compared to the basic composition of sample 19. The grain composition of sample 20 was corrected taking into account the previously established trends.

The selected powders were used to prepare porous blank samples, which were subsequently impregnated with molten silicon according to the procedure involving the following steps: mixing powders of different dispersion with silicon carbide grinding bodies; plasticizing the powder with polyethylene glycol, a PEG15 solution; granulation of the resulting mixture through a 0.5 mm sieve; disk molding at a pressure of 100 MPa; drying the prepared raw samples by heating up to 120 °C according to a preset program and holding for 5 h; siliconization of the samples by sintering, and impregnation with molten silicon in a vacuum. The resulting specimens were obtained in the form of cylinders with a diameter of 30 mm and height of 5 mm.

The speed of sound was measured by a resonance method using a ZVUK-130 (ZVUK, Ltd., Russia) installation. The elasticity (Young’s) modulus was calculated according to the equation

where V is the speed of sound and ρ is the material density.

E = ρV2,

The synthesized composites were characterized by measuring their density, hardness, and elasticity modulus, as well as by the study of their structure and phase composition.

The microstructure characterization and elemental analysis of the prepared samples were carried out using a Tescan Vega 3 SBH scanning electron microscope (SEM) with an AZtec X—Act attachment for X-ray microanalysis.

The phase composition and crystal structure of the samples were studied by X-ray diffraction (XRD) using a Rigaku Ultima IV diffractometer. The samples were taken according to the Braga-Brentano scheme using CuKα radiation in the range of 2θ angles from 20 to 120° with a step of 0.01° and detector movement speed of 5°/min. The collimation of the primary X-ray beam was carried out using ½° × 5 mm slits, as well as Soller slits with a divergence of 5° in the primary and diffracted beams. The operating mode of the X-ray tube was 40 kV/40 mA. The obtained images were interpreted using the Crystallographica Search-Match software with the identification of phases using the ICDD PDF database. A quantitative analysis of the phase composition was performed according to the Rietveld method using the Rigaku SmartLab Studio II software. The obtained data were used to calculate the X-ray density.

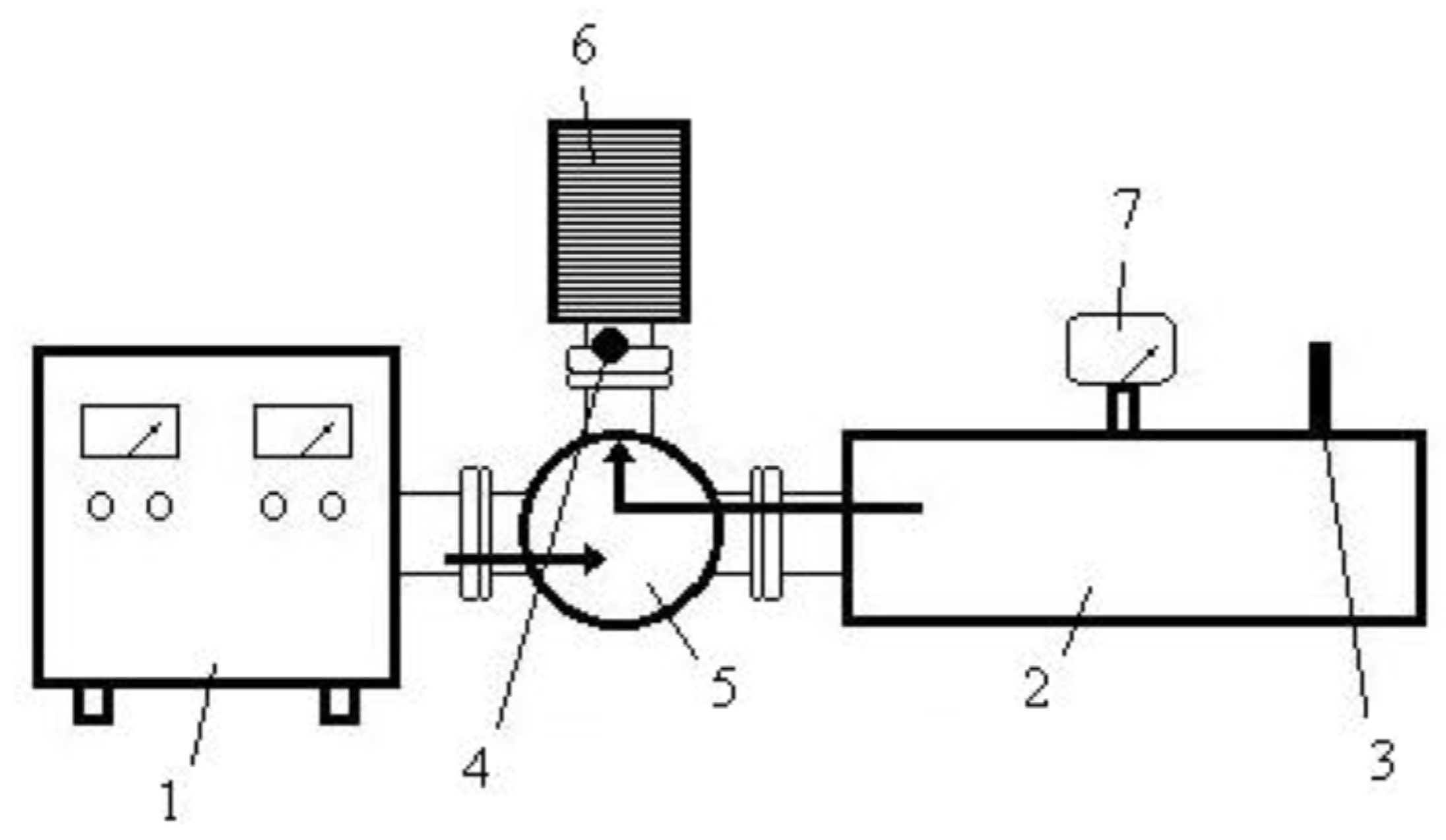

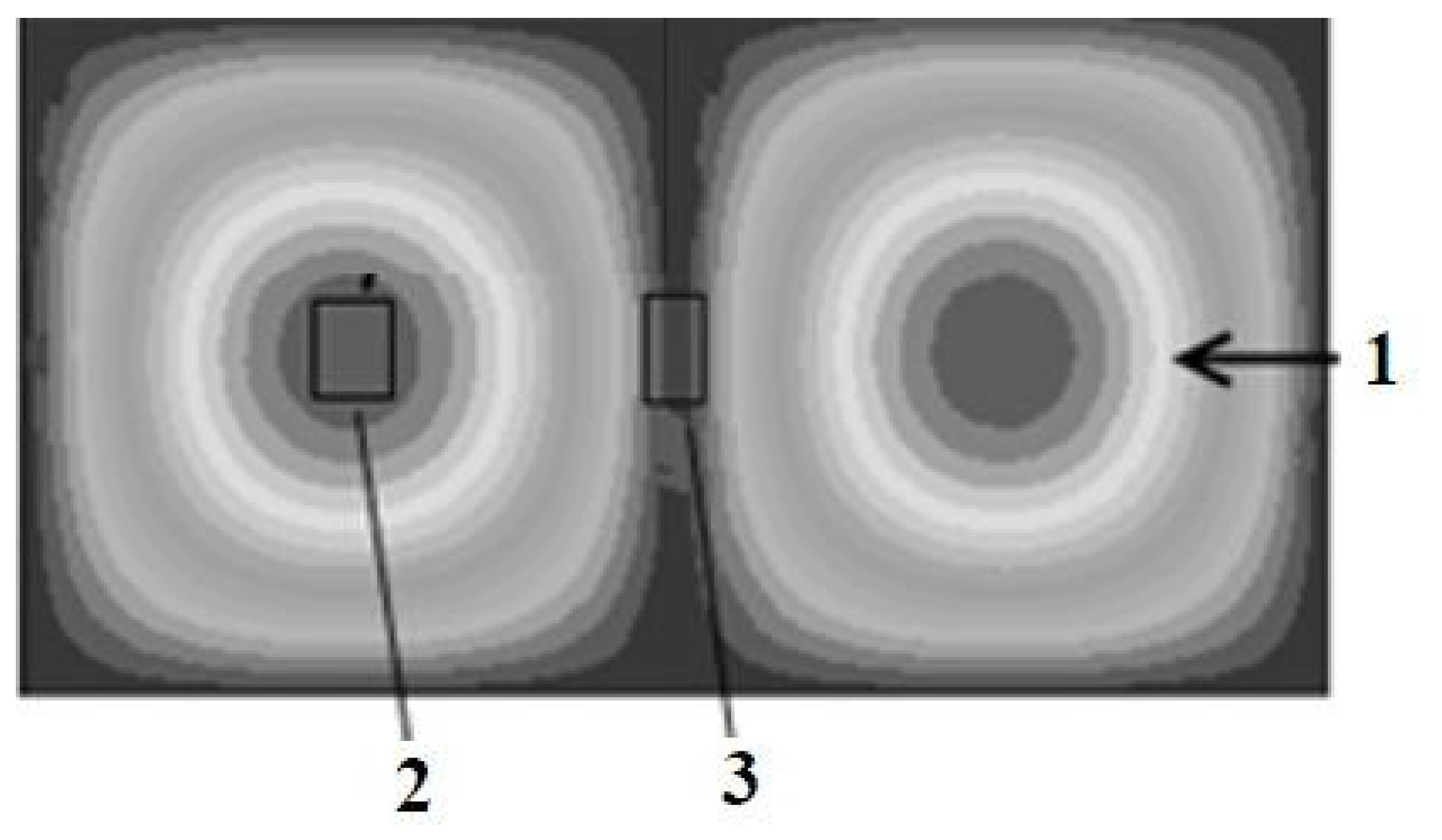

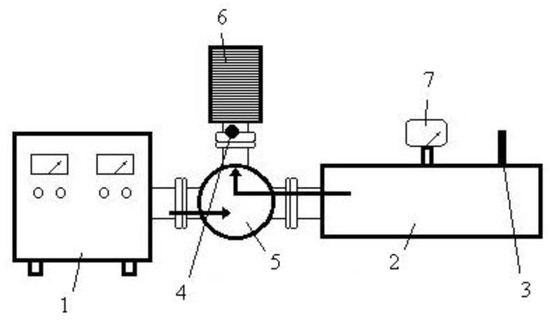

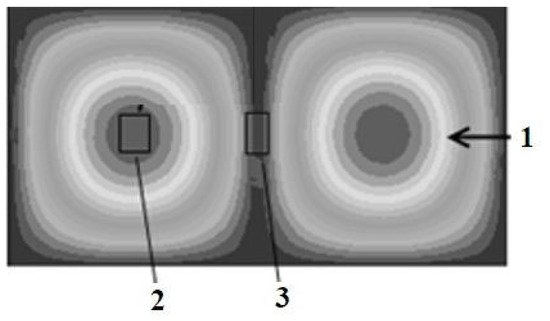

Microwave processing of non-magnetic materials in the electric field maximum is known to improve the target performances of ceramic samples (increase of density and electrical conductivity, decrease of porosity) [28]. Sample 20 was processed in a microwave installation with a single-mode waveguide-type chamber, including a 2.45 GHz magnetron (generating electromagnetic waves with the wavelengths λ = 12.3 cm), a circulator to protect the magnetron from a reflected electromagnetic wave, working chamber (45 mm × 90 mm × 170 mm), and resonance sensors. The side wall of the thermostat and waveguide contained a hole for permanent temperature control by a pyrometer and periodic temperature control by a thermo-couple. The microwave installation designed and assembled in our laboratory involved a resonance chamber based on a rectangular waveguide including a lower cross-section diaphragm from one end and a movable wall (plunger) from the opposite side. The energy was supplied along the longitudinal axis of the chamber. The resonance chamber was designed using the ANSYS software to provide the maximum coordination in the system generator-resonator load. The installation scheme is shown in Figure 1. The diaphragm was used to form a standing wave and a movable wall-plunger was installed to match the generator-chamber load system in terms of the quality factor. The sample was heated in a resonator chamber in an electric field (Figure 2, position 2) to the maximum possible temperature of 900 °C, followed by holding for 10 min.

Figure 1.

Scheme of the microwave installation. 1—Power supply unit and magnetron, 2—microwave chamber, 3—input microwave energy sensor, 4—reflected microwave energy sensor, 5—circulator, 6—load, 7—thermocouple.

Figure 2.

The distribution of fields in the resonator chamber of the microwave heating installation 1—Direction of supplied microwave energy, 2—maxima of electric field strength, 3—maxima of magnetic field strength.

3. Results and Discussion

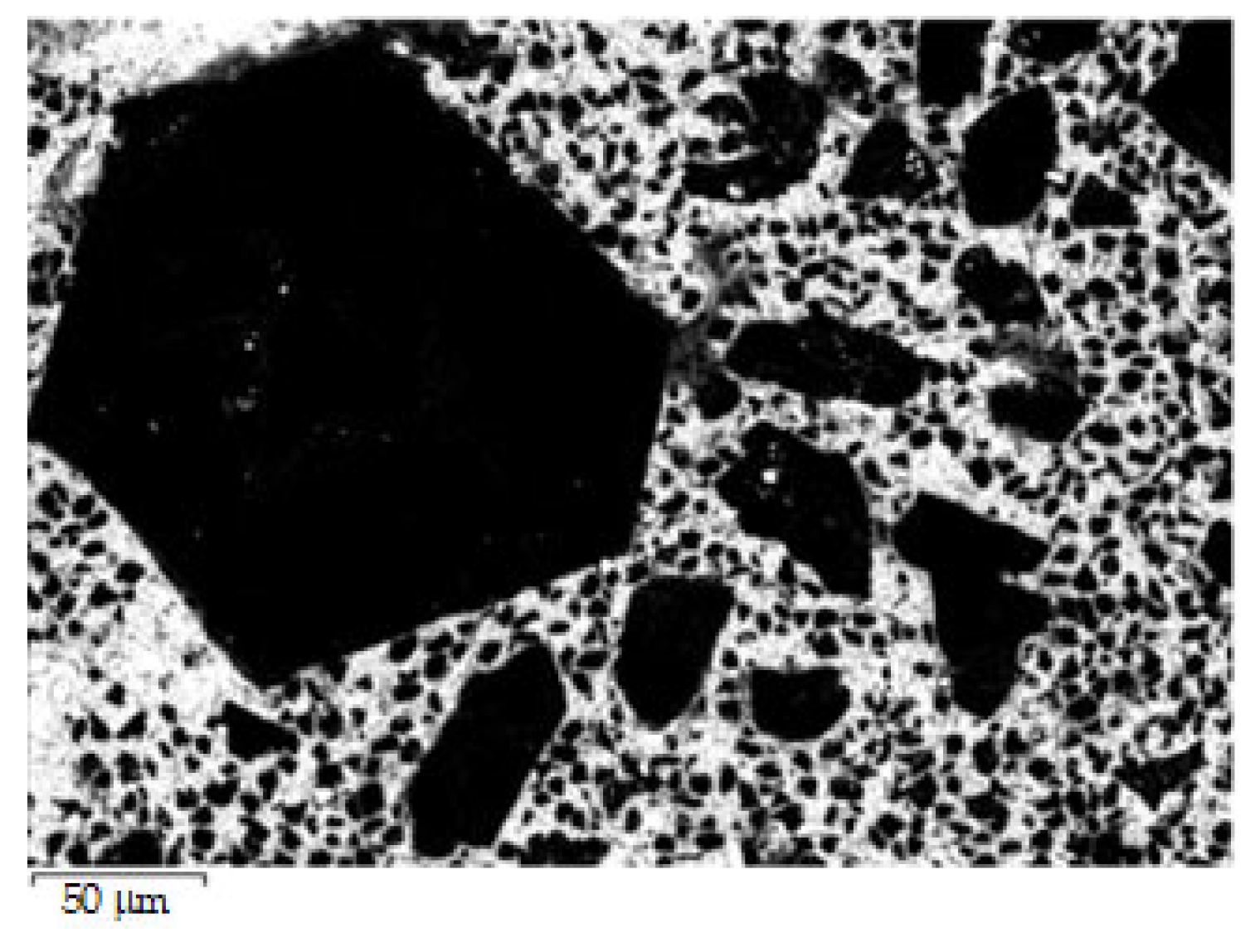

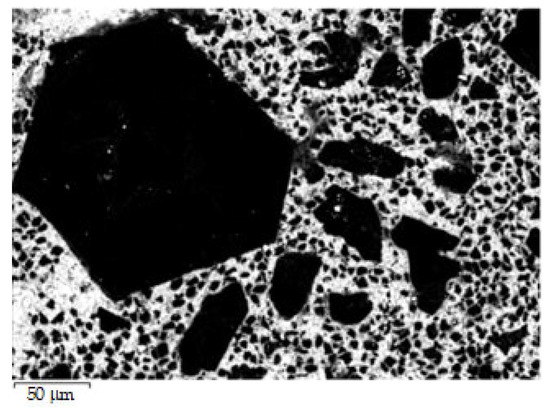

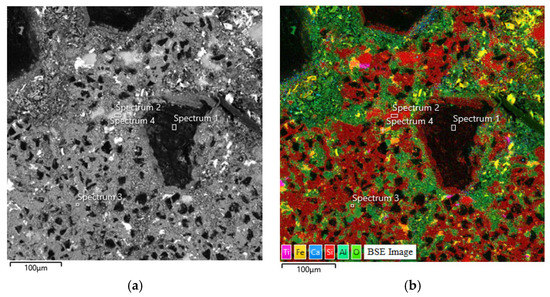

SEM characterization of the studied samples exemplarily presented in Figure 3 indicates that the prepared composites comprised a dispersed phase in the form of a set of diamond grains (black phase in SEM images) in a silicon carbide matrix (gray phase in SEM images).

Figure 3.

SEM image of sample 18 containing diamond grains of three different sizes.

The results of siliconization of various diamond matrices are summarized in Table 3 (numbers of the samples correspond to the numbers of diamond matrices in Table 2). The volume parts of pores and phases (diamond, SiC, Si, and graphite) were calculated on the basis of XRD data. Since the diamond matric impregnation with molten silicon proceeded via a free penetration of liquid silicon into the porous billet top down, in this study both top and bottom surfaces of the samples were characterized.

Table 3.

Properties of the composites prepared by siliconization of the diamond matrices.

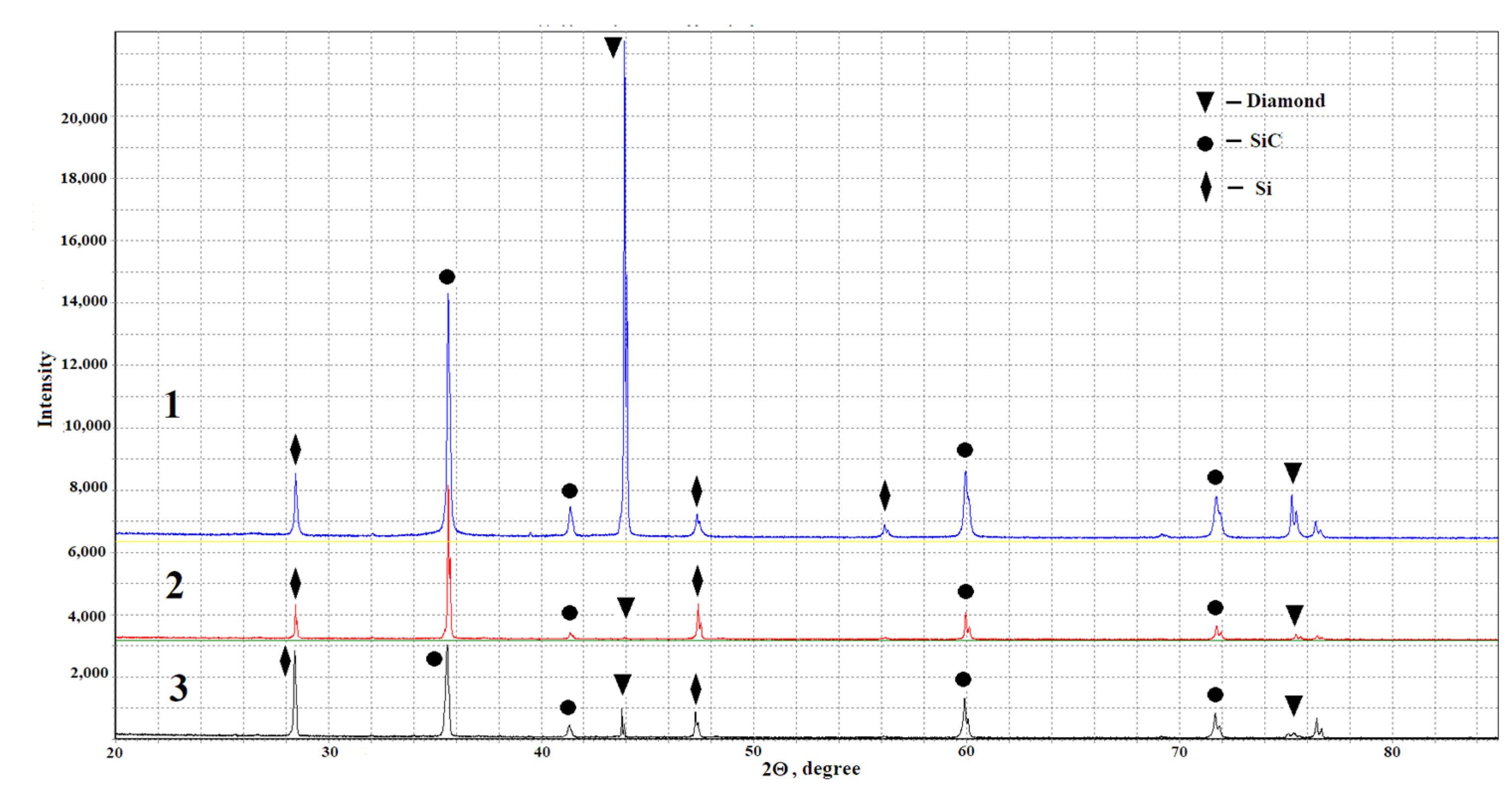

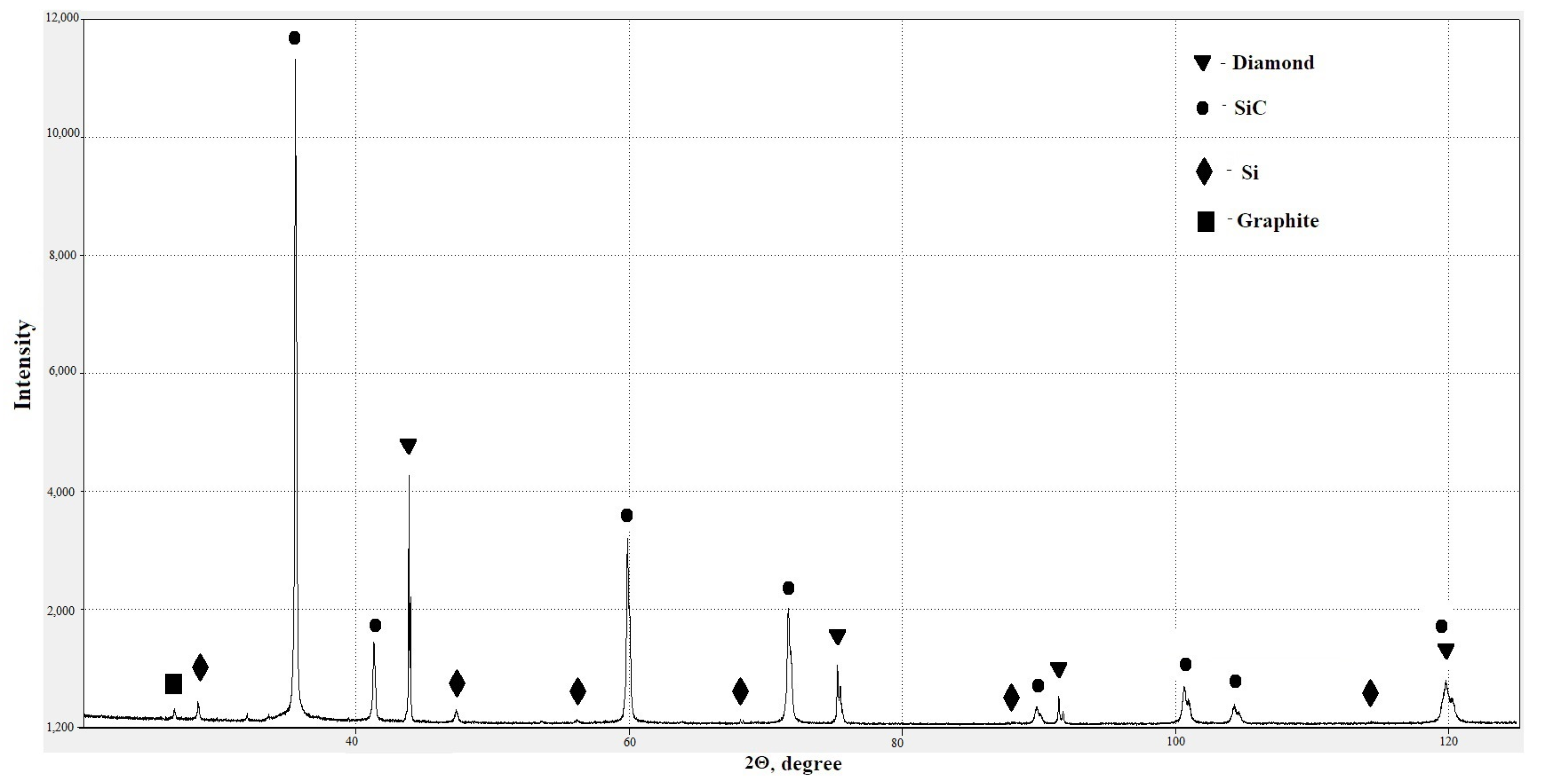

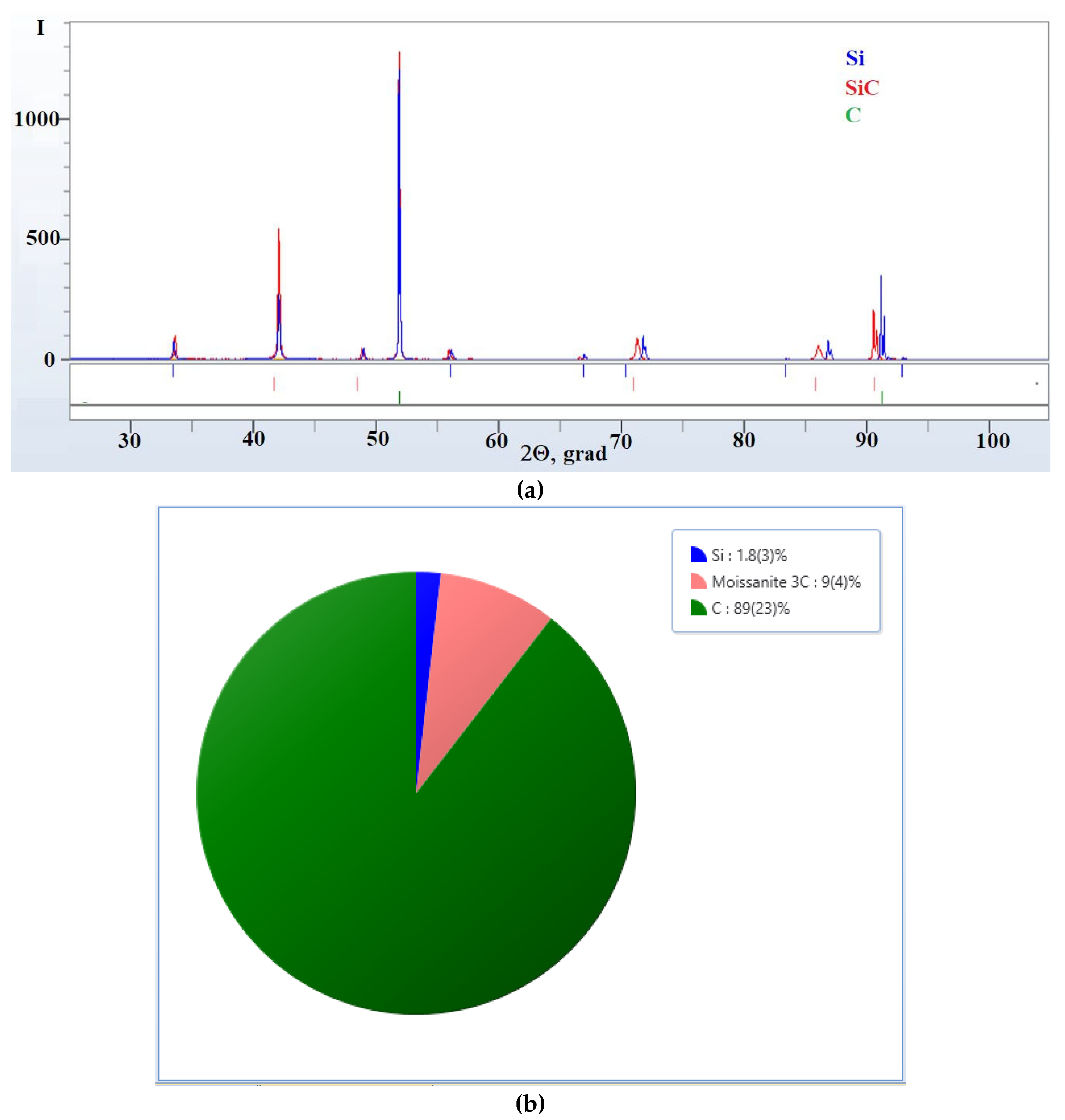

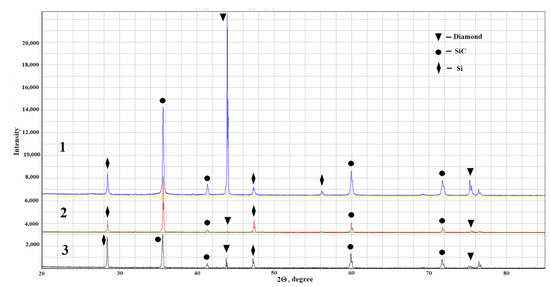

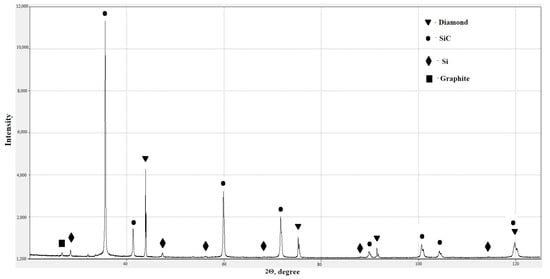

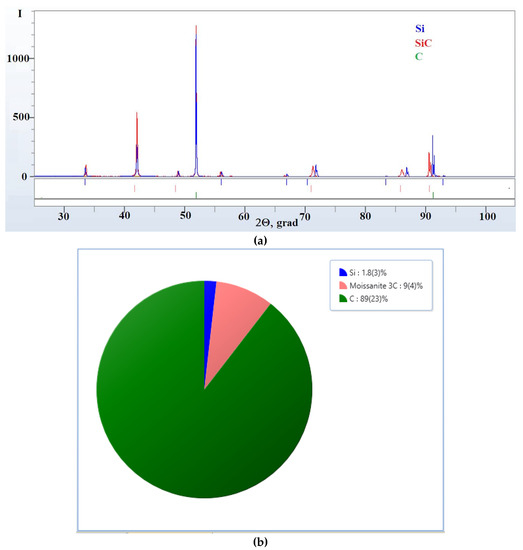

In complete accordance with the reference data, the studied samples contained three phases, including diamond, SiC, and Si. According to XRD profiles exemplarily presented in Figure 4, all the samples contained two prevailing phases; i.e., cubic silicon carbide (3C) and diamond, as well as residual silicon both on the upper surface of the samples from which the impregnation began, and on the lower (reverse) surface. X-ray spectra of the samples differed only in the height of the peaks of corresponding phases. Typical XRD spectra of the surfaces with high content of diamond, SiC, and Si are presented in Figure 4. It should be noted that sample 4 differs from other samples in the presence of trace amounts of graphite on the bottom surface (Figure 5).

Figure 4.

XRD spectra of diamond-SiC-Si composite surfaces with relatively high contents of (1) diamond (sample 7, bottom), (2) SiC (sample 19, top), and (3) Si (sample 8, top).

Figure 5.

XRD profile for the diamond-SiC-Si sample 4, bottom.

For the siliconization process, silicon was taken in excess, compared to the amount necessary to fill the porous blank sample. The study of the distribution of phases in the composite showed that the content of residual silicon grew with the increase of the diamond grains’ size in the initial porous sample. This trend was more prominent in the upper part of the sample, while on the lower plane of the samples, the silicon content did not exceed 11 vol%.

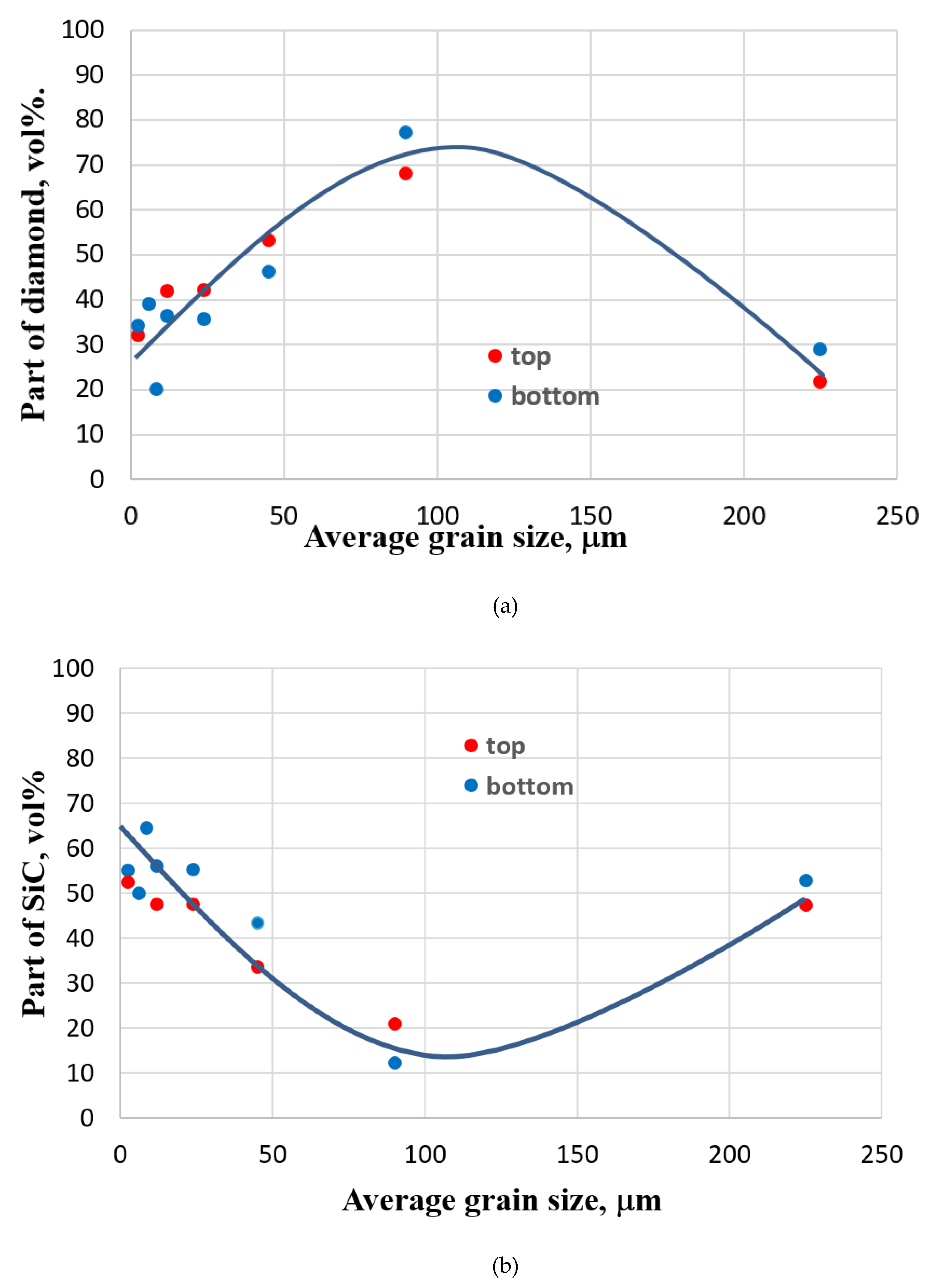

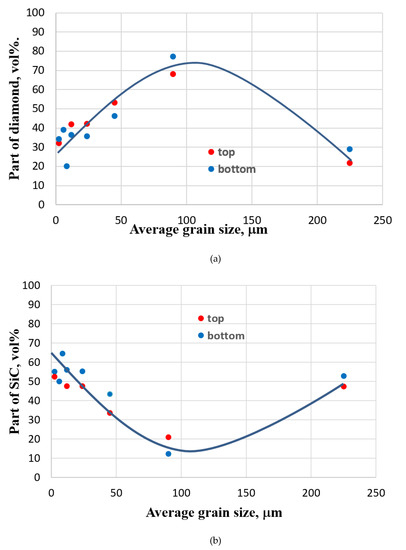

The parts of other phases in the composite, i.e., remaining diamond and silicon carbide formed by reaction (1), passed through an extremum depending on the initial size of the diamond grains in the blank sample (Figure 6).

Figure 6.

Percentage of diamond (a) and silicon carbide (b) in the siliconized composite prepared from single-double grain size powders (samples No. 1–14) as a function of the average grain size of the blank sample.

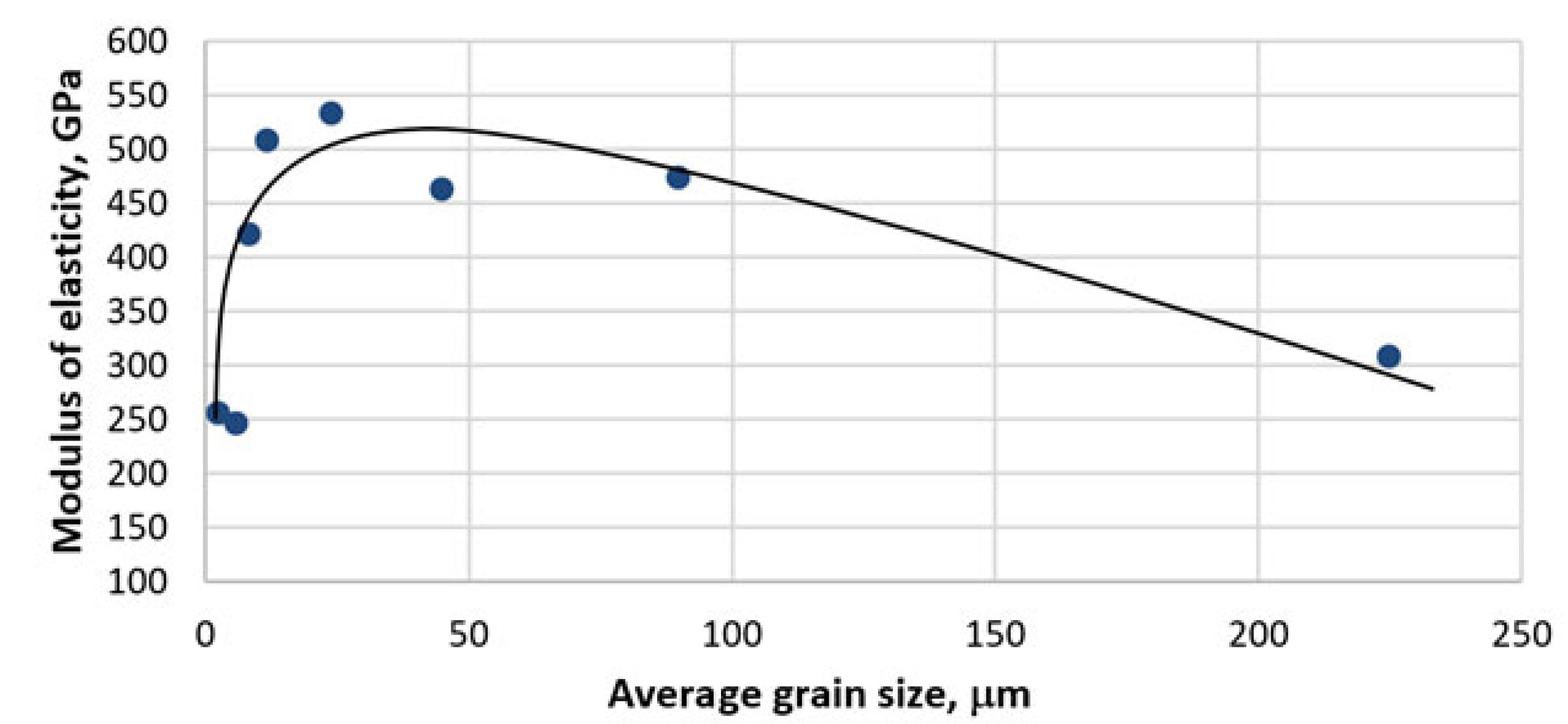

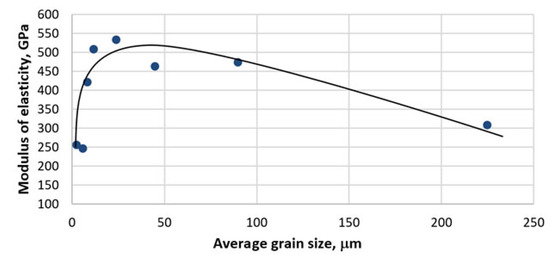

The composites obtained from powders with harrow grain size distribution featured extreme dependencies of density, porosity, sound speed, and elasticity modulus on the grain size (Figure 7). A drop in the speed of sound and modulus of elasticity were determined by the decrease in the density of the composites. A sharp decrease in density after siliconization of micropowders with a grain size of less than 20 μm was accompanied by the appearance of a large number of macrodefects in the samples, from cracks to cavities up to 5–10 mm in size.

Figure 7.

Elasticity modulus of siliconized samples prepared from narrow dispersion diamond grains as a function of the average grain size.

The observed phenomenon was attributed to the effect of the diamond dispersion on the rate of its interaction with the silicon melt. As shown by thermal studies, the temperature in the reaction (1) zone significantly exceeded the temperature in the furnace (1400 °C) and reached up to 1800–2000 °C. Since the siliconizing process took place in vacuum with a residual pressure of about 10−3 mm Hg, an increase in temperature led to boiling of the silicon melt and formation of craters and coarse cracks on the upper surface of the siliconized sample. In this case, the lower surface did not have such defects. Thus, adjustment of the dispersion (especially via the addition of micropowders) provided not only the optimal structure according to geometric factors, but also the control over the actual process temperature.

Calculations by the Fuller method showed that polydisperse mixtures featured a higher density and lower porosity compared to compacts prepared from fine-grained powders. In this research, the effect of more densely packed diamond matrix blanks on the results of siliconization was tested. For a mixture of powders including two fractions with the ratio between the size of fine and coarse grains of 1:10, the dependencies of density, porosity, sound velocity, and modulus of elasticity of the composite on the content of grains in the composition were also extreme.

Silicon samples containing 60% coarse and 40% fine grains had the highest density and modulus of elasticity, which was in good agreement with calculations for mechanical mixtures according to the Fuller method. This result confirms the non-shrinkage mechanism of sintering during siliconizing. At other equal parameters, the density and elasticity modulus of a composite containing two diamond grain fractions (size ratio 1:10) were higher for samples with a larger absolute size of diamond particles.

Interestingly, this extremum corresponded to a diamond size of 80–100 µm and did not coincide with the extreme values of physical properties (density and modulus of elasticity) observed in the region of 20–28 µm.

The best physical performances were probably achieved due to both a larger proportion of diamond (the phase with the highest density and modulus of elasticity) in the composition, and reduced porosity after siliconization. The porosity of the samples was calculated by comparison of the pycnometric density with the theoretical density calculated from the data of quantitative XRD analysis. The minimum porosity was found to correspond to siliconized compacts of powders with a grain size of 20–28 µm.

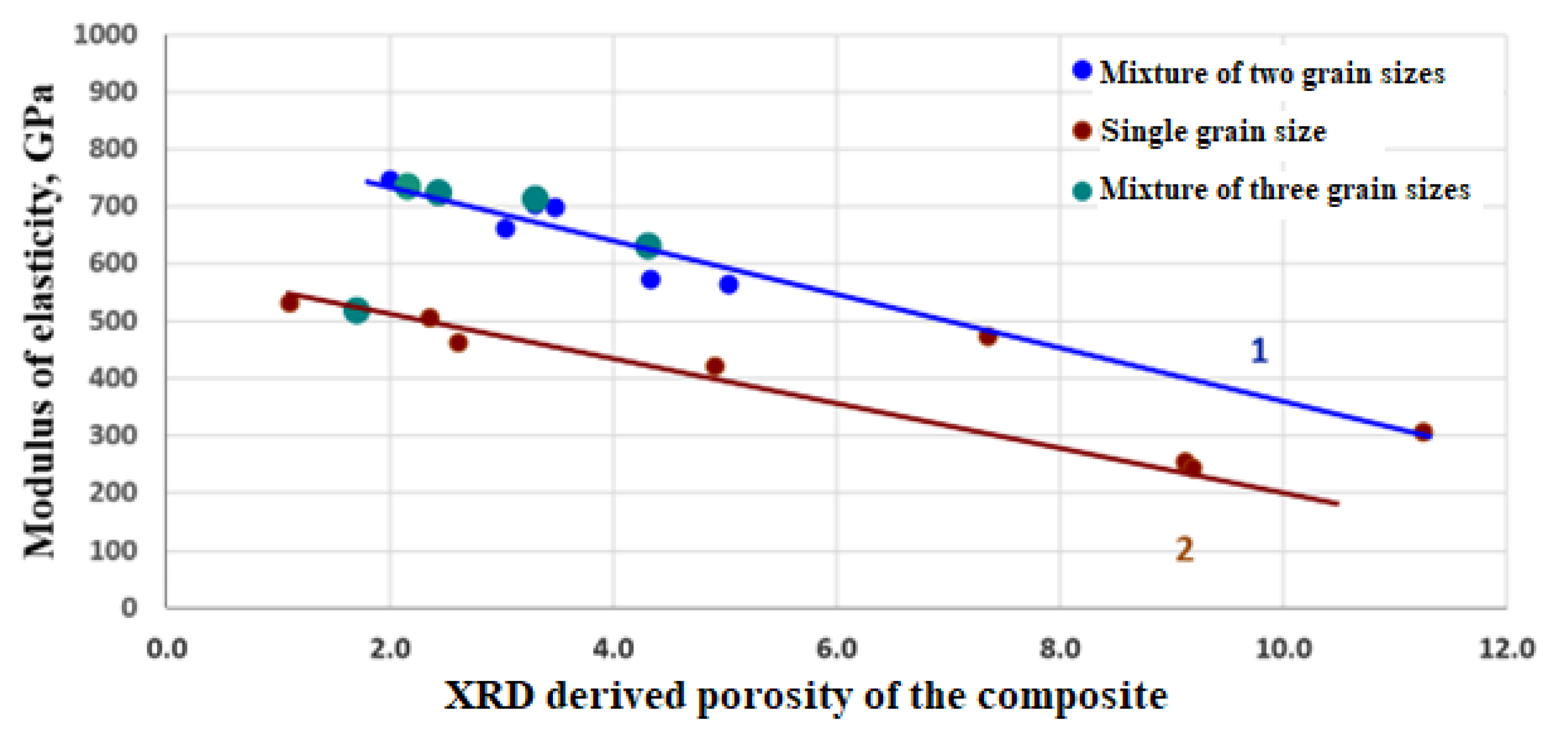

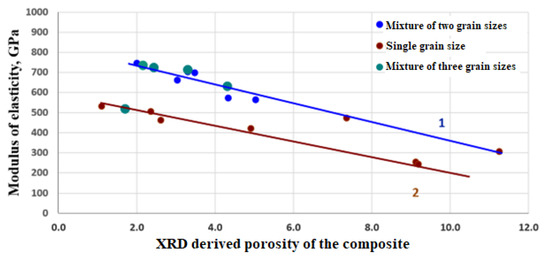

In compositions containing diamond grains of two different sizes, the maximum content of diamond in couple with minimum content of silicon carbide and silicon phases were observed for mixtures with the ratio of 50:50. The highest elasticity modulus was also shifted relating to the maximum of the diamond content, probably due to the contribution of porosity to the mechanical characteristics of the material. Generally, there was a positive correlation between the elasticity modulus and the part of the diamond phase in the composite (Figure 8). However, the composite porosity had a greater influence on the modulus of elasticity. Obviously, an increase in the elastic modulus corresponded to a decrease in porosity of the composite, but in this case the experimental data were arranged along two almost parallel correlation lines (Figure 8). The analysis of this phenomenon showed that data for matrices comprising a mixture of two and three grain sizes with a diamond grain size of at least 10/80 µm and a matrix of narrow grain sizes of more than 80 µm fell on one straight line of correlation. The second straight line of correlation included the results for all narrow grain sizes less than 80 µm and polydisperse mixtures containing micropowders with a grain size of 3/2 µm.

Figure 8.

Elasticity modulus of the composites as a function of their porosity.

In siliconized compositions containing three diamond grain sizes featuring the maximum package density according to the Fuller method, a significant phase composition gradient along the compressed sample height was found. It can be concluded that for the uniform passage of the molten silicon front through the porous diamond matrix, a certain pore size and a moderate rate of chemical interaction were required. The presence of a third grain size, especially fine grain, led to a rapid formation of silicon carbide and “plugging” of the channels responsible for the complete penetration of molten silicon into the depth of the workpiece. In all compositions containing a mixture of three grain sizes (samples 15–19), a low average diamond content was observed.

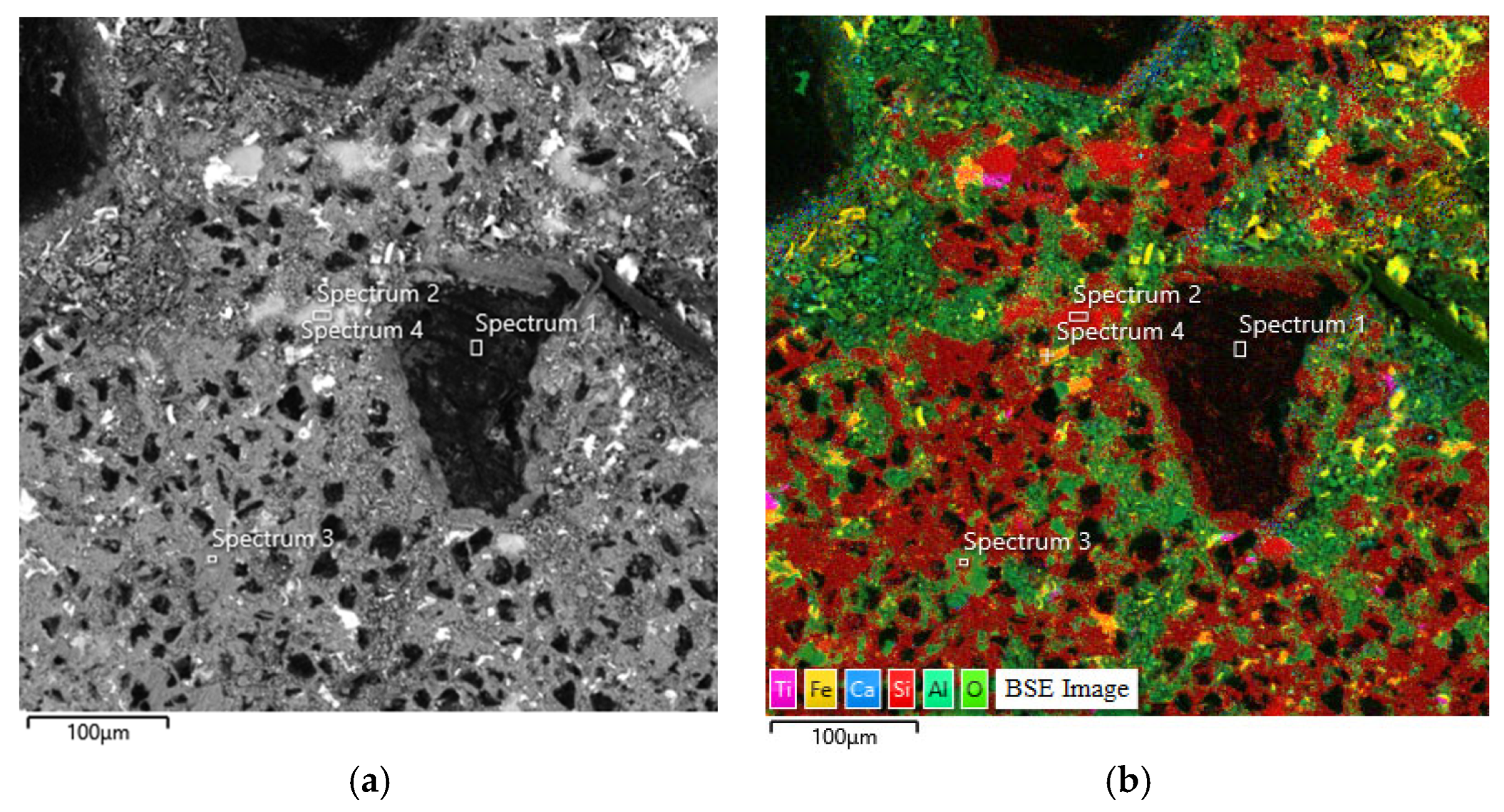

The analysis of the structure of sample 20 (Figure 9) showed that the addition of DND to the composition led to a strong increase of oxygen content in the material (up to 16.2%, spectrum area 2 in Figure 9). The comparison of the properties of samples 20 and 19 revealed that replacement of the diamond micropowder by a detonation nanodiamond did not cause a change in density and porosity of the resulting composite equal to 3.26 g/cm3 and 2.34%, respectively. XRD data and phase content calculation by the Rietveld method showed that the proportion of residual silicon was only about 1.8 wt% (2.5 vol%) (Figure 10). Since the proportion of diamond was almost 89.2 wt% (82.7 vol%), the speed of sound in the material slightly increased to 13,200 m/s and consequently the modulus of elasticity increased to 552 GPa.

Figure 9.

SEM image (a) and distribution of elements (b) in the sample No. 20.

Figure 10.

XRD profile (a) and phase contents (b) determined according to the Rietveld method for sample 20.

The performed microwave treatment resulted in a significant increase in the speed of sound in the composite up to 16,600 m/s, and growth of its modulus of elasticity up to 860 GPa, although no significant changes in the density and porosity were observed. The mechanism of the considered effects will be studied and reported in our further research.

4. Conclusions

An obvious relationship was observed among the mechanical properties and phase composition of diamond-silicon carbide-silicon composites. The elasticity modulus of the composites evidently grew with the increase of diamond content, but mechanical properties were also significantly affected by the porosity. The most advantageous combination of minimum porosity, maximum diamond, and minimum silicon content was achieved by the optimization of the grain size of the initial powdered components. This optimization could not be based only on geometric factors in respect to the closest package of grains with several different sizes. The composite structuring proceeded without shrinkage of spaces between the largest diamond particles, which were filled as a result of chemical processes with silicon carbide. In the case of too large pores in the initial billet, the resulting composite lacked silicon carbide, leading to an excessive porosity and consequently a reduced elasticity modulus, as observed in sample 8. In contrast, a very tight initial package with too small pores could not provide high enough target properties of the composite because siliconization resulted in closing of such pores, preventing the liquid silicon from penetrating, as observed in samples 9, 13, 14, and 19. The rate of silicon melt interaction with diamond depended on the size and surface condition of diamond particles. An excessive content of small diamond grains in the initial billet led to a significant temperature growth, causing silicon evaporation. This process resulted in the increase of porosity and the formation of cracks and craters on the top surface of the samples, yielding evaporated silicon (samples 1–4).

The siliconization of mixed matrices with a maximum diamond grain size of 250/200 μm provided composites with the lowest porosity (less than 2.5%) and highest modulus of elasticity. The best elasticity modulus and sound speed (16,600 m/s and 860 GPa, respectively), which exceeded the performances of all the existing materials (Table 1), were achieved upon microwave processing of the composites containing detonation nanodiamonds.

The obtained composites can be used for the manufacture of plain bearings, grinding media, armored ceramics, and highly loaded elements in mechanical engineering.

Author Contributions

Conceptualization S.P.B. and M.M.S.; methodology, S.P.B.; validation, S.P.B., A.S.D., S.N.P., N.A.K. and M.M.S.; formal analysis, S.P.B., M.M.S.; investigation, S.P.B., A.S.D., S.N.P. and N.A.K.; resources, S.N.P. and M.M.S.; writing—original draft preparation, S.P.B.; writing—review and editing, S.P.B., A.S.D., N.A.K. and M.M.S.; visualization, S.P.B., A.S.D. and N.A.K.; supervision, S.P.B. and M.M.S.; funding acquisition, M.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

The research is supported by the Russian Science Foundation, grant No. 20-13-00054.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Micrographs of ceramic samples were obtained at the Center for Collective Use of the NRC “Kurchatov Institute”—CRISM “Prometey”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bruzhkin, A. High-Pressure synthesized materials: A chest of treasure andhints. High Press. Res. 2007, 27, 333–351. [Google Scholar] [CrossRef]

- Shul’zhenko, A.A.; Bakulya, V.N. (Eds.) Synthesis of Diamond and Similar Materials; Inst. Sverkhtverd. Mater. im. V. N. Bakulya: Kiev, Ukraine, 2003. [Google Scholar]

- Pantea, C.; Qian, J.; Voronin, G.A.; Zerda, T.W. High pressure study ofgraphitization of diamond crystals. J. Appl. Phys. 2002, 91, 1957–1962. [Google Scholar] [CrossRef]

- Seal, M. Graphitization of diamond. Nature 1960, 185, 522–523. [Google Scholar] [CrossRef]

- James, T.; James, A.P.F. Study of the transformation of diamond to graphite. Proc. R. Soc. Lond. Ser. A Math. 1964, 277, 260–269. [Google Scholar]

- Khmelnitsky, R.; Gippius, A. Transformation of diamond to graphite under heattreatment at low pressure. Phase Transit. 2014, 87, 175–192. [Google Scholar] [CrossRef]

- Ko, Y.S.; Tsurumi, T.; Fukunaga, O.; Yano, T. High pressure sintering of diamond-SiC composite. J. Mater. Sci. 2001, 36, 469–475. [Google Scholar] [CrossRef]

- Ekimov, E.A.; Gavriliuk, A.G.; Palosz, B.; Gierlotka, S.; Dluzewski, P.; Tatianin, E.; Kluev, Y.; Naletov, A.M.; Presz, A. High-pressure, high-temperature synthesis ofSiC-diamond nanocrystalline ceramics. Appl. Phys. Lett. 2000, 77, 954–956. [Google Scholar] [CrossRef]

- Herrmann, M.; Matthey, B.; Höhn, S.; Kinski, I.; Rafaja, D.; Michaelis, A. Diamond-ceramics composites—New materials for a wide range of challenging applications. J. Eur. Ceram. Soc. 2012, 32, 1915–1923. [Google Scholar] [CrossRef]

- Mlungwane, K.; Herrmann, M.; Sigalas, I. The low-pressure infiltration of diamond by silicon to form diamond–silicon carbide composites. J. Eur. Ceram. Soc. 2008, 28, 321–326. [Google Scholar] [CrossRef]

- Gordeev, S.; Zhukov, S.; Danchukova, L.; Ekström, T. Method of Manufacturing a Diamond–Silicon Carbide–Silicon Composite and a Composite Produced by This Method. U.S. Patent 709 747, 25 September 2002. [Google Scholar]

- He, Z.; Katsui, H.; Goto, T. High-Hardness Diamond Composite Consolidated by Spark Plasma Sintering. J. Am. Ceram. Soc. 2016, 99, 1862–1865. [Google Scholar] [CrossRef]

- Herrmann, M.; Kluge, E.; Rödel, C.; McKie, A.; van Staden, F. Corrosion behaviour of silicon carbide–diamond composite materials in aqueous solutions. J. Eur.Ceram. Soc. 2014, 10, 2143–2151. [Google Scholar] [CrossRef]

- Yang, Z.; He, X.; Wu, M.; Zhang, L.; Ma, A.; Liu, R.; Hu, H.; Zhang, Y.; Qu, X. Fabrication of diamond/SiC composites by Si-vapor vacuum reactive infiltration. Ceram. Int. 2013, 3, 3399–3403. [Google Scholar] [CrossRef]

- Yang, Z.; He, X.; Wu, M.; Zhang, L.; Ma, A.; Liu, R.; Hu, H.; Zhang, Y.; Qu, X. Infiltration mechanism of diamond/SiC composites fabricated by Si-vapor vacuum reactive infiltration process. J. Eur. Ceram. Soc. 2013, 4, 869–878. [Google Scholar] [CrossRef]

- Gordeev, S.K. Advanced diamond based composites for engineering applications. In Diamond Based Composites; Kluwer: Dordrecht, The Netherlands, 1997; pp. 1–11. [Google Scholar]

- Zhuk, A.E. Zakonomernosti obrazovaniya SiC v almazosoderzachey compozicei pri nizcich davleniyach (Patterns of SiC formation in a diamond-containing composition at low pressures). In Metalloobrabotka. Mashinostroenie (Vestnik BNTU Metallurgy. Metalworking. Mechanical Engineering); Vestnik BNTU Metallurgiya: Impopo, South Africa, 2007; Volume 4, pp. 27–31. [Google Scholar]

- Park, J.S.; Sinclair, R.; Rowcliffe, D.; Stern, M.; Davidson, H. Orientation relationship in diamond and silicon carbide composites. Diam. Relat. Mater. 2007, 16, 562–565. [Google Scholar] [CrossRef]

- Shevchenko, V.Y.; Perevislov, S.N. Reaction–diffusion mechanism of synthesis in the dia-mond–silicon carbide system. Russ. J. Inorg. Chem. 2021, 8, 1107–1114. [Google Scholar] [CrossRef]

- Gordeev, S.K.; Korchagina, S.B.; Zapevalov, V.E.; Parshin, V.V.; Serov, E.A. Diamond–Silicon Carbide Composite as a Promising Material for Microelectronics and High-Power Electronics. Radiophys. Quantum Electron. 2022, 65, 434–441. [Google Scholar] [CrossRef]

- Pittari, J.; Subhash, G.; Trachet, A.; Zheng, J.; Halls, V.; Karandikar, P. The Rate-Dependent Response of Pressureless-Sintered and Reaction-bonded Silicon Carbide-Based Ceramics. Int. J. Appl. Ceram. Technol. 2014, 12, E207–E216. [Google Scholar] [CrossRef]

- Matthey, B.; Höhn, S.; Wolfrum, A.-K.; Mühle, U.; Motylenko, M.; Rafaja, D.; Herrmann, M. Microstructural investigation of diamond-SiC composites produced by pressureless silicon infiltration. J. Eur. Ceram. Soc. 2017, 37, 1917–1928. [Google Scholar] [CrossRef]

- Voronin, G.A.; Zerda, T.W.; Gubicza, J.; Ungár, T.; Dub, S.N. Properties of nanostructured diamond-silicon carbide composites sintered by high pressure infiltration technique. J. Mater. Res. 2004, 19, 2703–2707. [Google Scholar] [CrossRef]

- Matthey, B.; Kunze, S.; Hörner, M.; Blug, B.; van Geldern, M.; Michaelis, A.; Herrmann, M. SiC-bonded diamond materials produced by pressureless silicon infiltration. J. Mater. Res. 2017, 32, 3362–3371. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Wang, C.; Nan, B.; Zhao, Z.; Cheng, L.; Zhang, L. Microstructure and properties of diamond/SiC composites via hot molding forming and CVI densifying. Adv. Eng. Mater. 2019, 21, 1800640. [Google Scholar] [CrossRef]

- Shaboldo, O.P.; Gordeev, S.K.; Vikhman, V.B.; Trubin, D.A. Materials and Technologies of New Generation for Perspective Products of Aviation and Space Equipment. In Proceedings of the 5th Russian Science and Technology Conference, Moscow, Russia, 19 July 2021; pp. 8–22. [Google Scholar]

- Dolmatov, V.Y. Detonation synthesis ultradispersed diamonds: Properties and applications. Russ. Chem. Rev. 2001, 70, 607–626. [Google Scholar] [CrossRef]

- Madhan, M.; Prabhakaran, G. Microwave versus conventional sintering: Microstructure and mechanical properties of Al2O3–SiC ceramic composites. Boletín Soc. Española Cerámica Vidr. 2018, 58, 125–134. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).