Fabrication of Reaction-Bonded Boron Carbide-Based Composites by Binder Jetting 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Characterization

3. Results

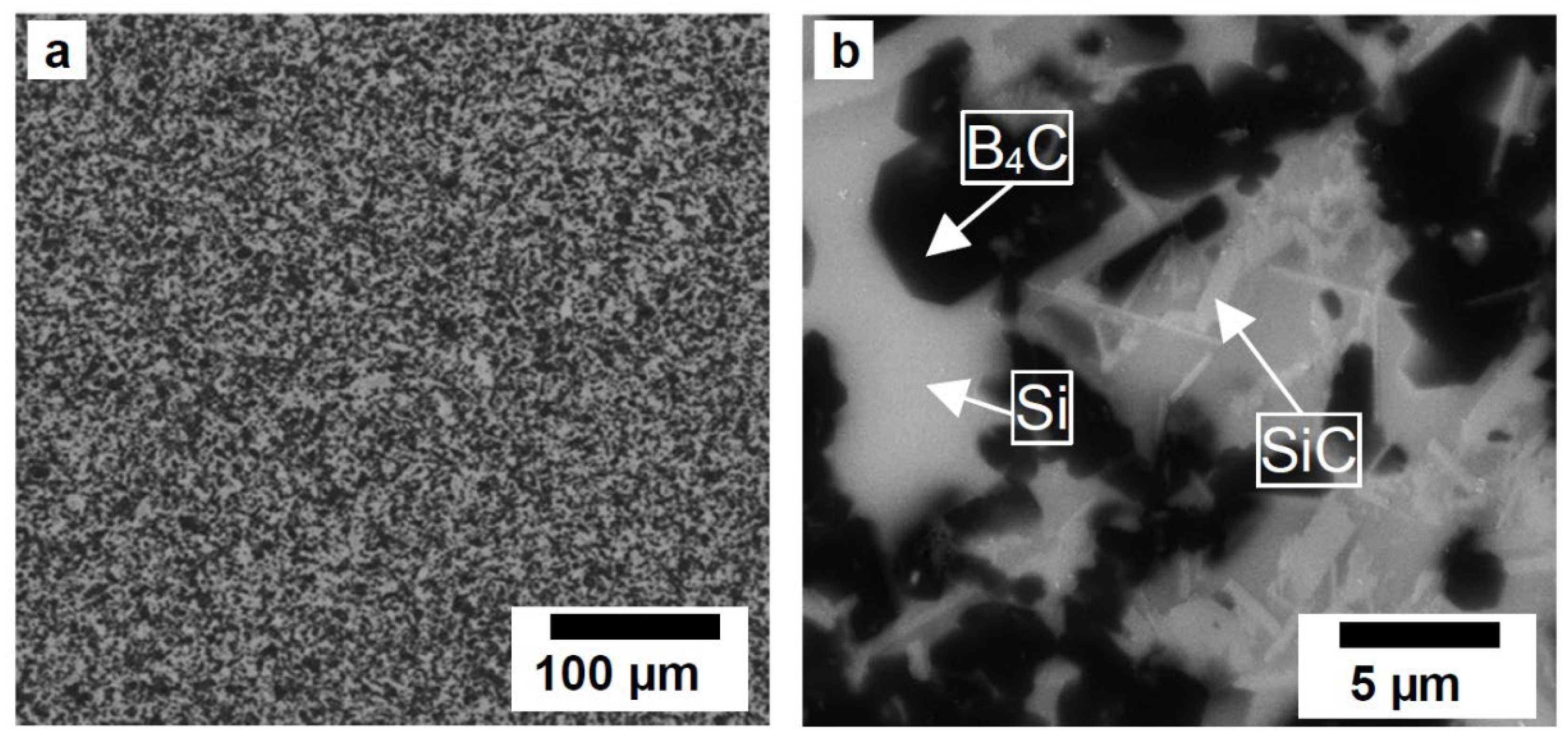

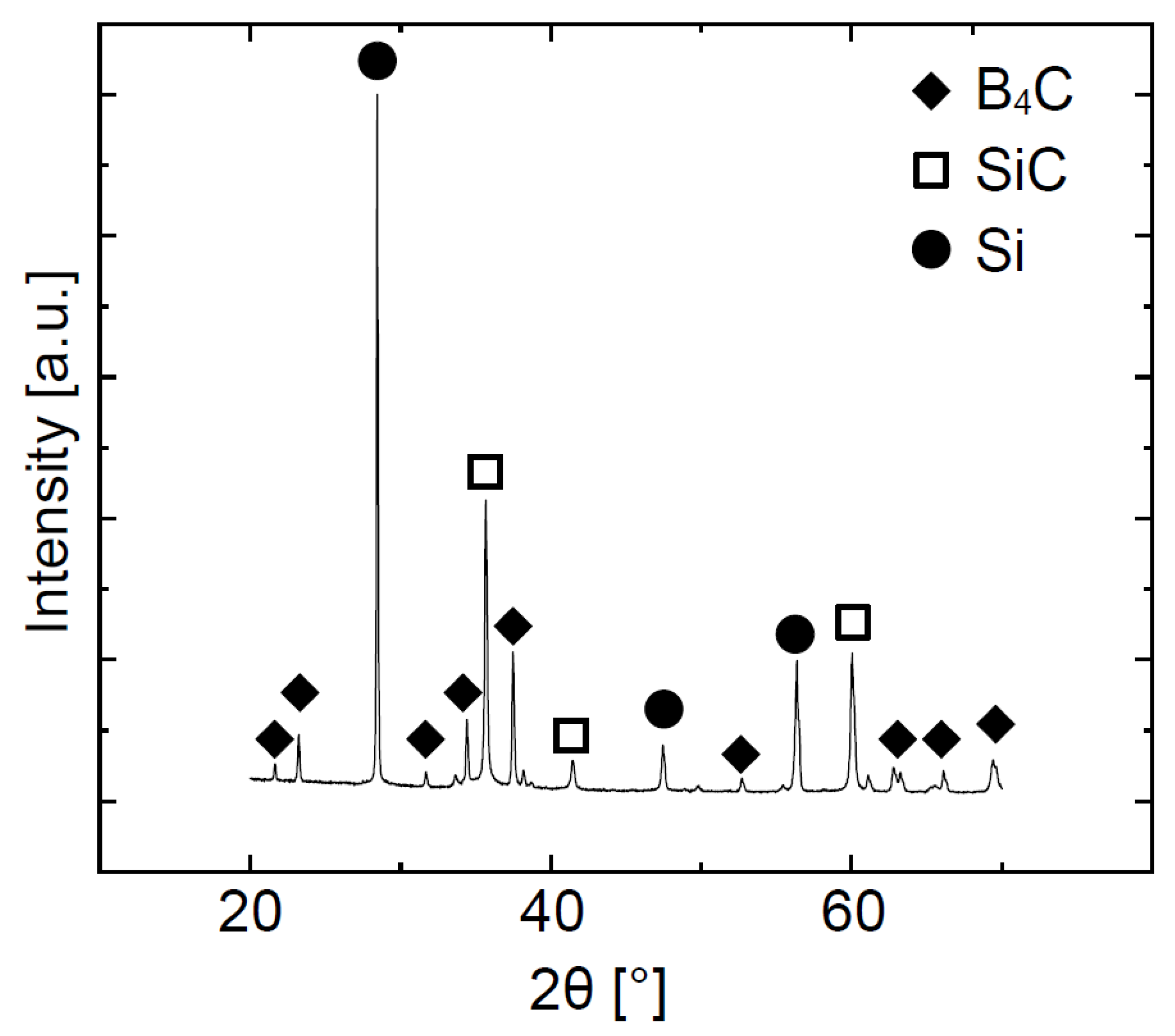

3.1. Raw Materials

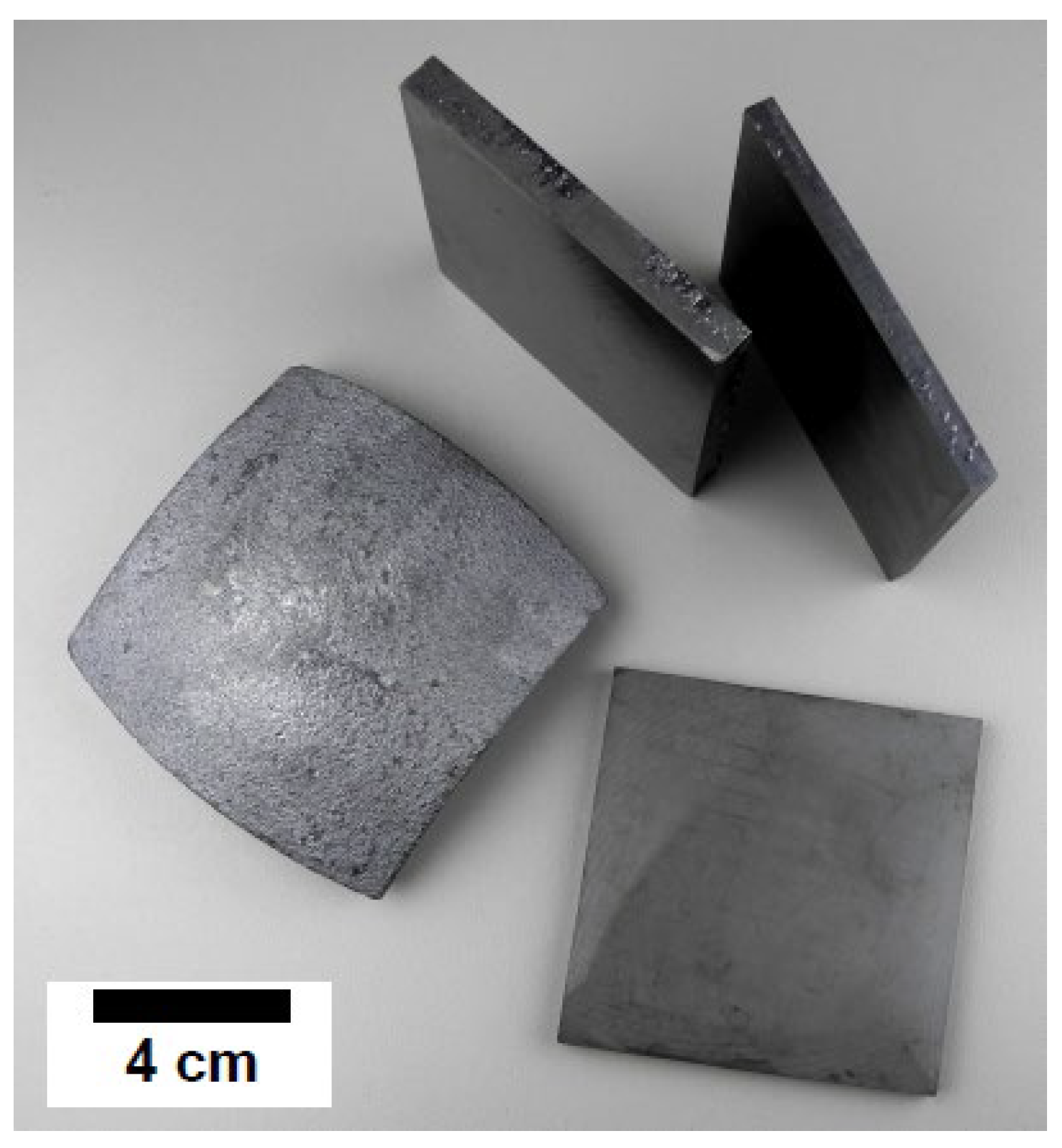

3.2. Properties of Reaction-Bonded B4C-SiC-Si

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thévenot, F. Boron carbide—A comprehensive review. J. Eur. Ceram. Soc. 1990, 6, 205–225. [Google Scholar] [CrossRef]

- Heimann, R.B. Classic and Advanced Ceramics; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2010; ISBN 9783527325177. [Google Scholar]

- Hogan, J.D.; Farbaniec, L.; Mallick, D.; Domnich, V.; Kuwelkar, K.; Sano, T.; McCauley, J.W.; Ramesh, K.T. Fragmentation of an advanced ceramic under ballistic impact: Mechanisms and microstructure. Int. J. Impact Eng. 2017, 102, 47–54. [Google Scholar] [CrossRef]

- Victor, G.; Pipon, Y.; Moncoffre, N.; Bérerd, N.; Esnouf, C.; Douillard, T.; Gentils, A. In situ TEM observations of ion irradiation damage in boron carbide. J. Eur. Ceram. Soc. 2019, 39, 726–734. [Google Scholar] [CrossRef]

- Sikalidis, C. Advances in Ceramics—Characterization, Raw Materials, Processing, Properties, Degradation and Healing; InTech: London, UK, 2011; ISBN 978-953-307-504-4. [Google Scholar]

- Sonber, J.K.; Limaye, P.K.; Murthy, T.; Sairam, K.; Nagaraj, A.; Soni, N.L.; Patel, R.J.; Chakravartty, J.K. Tribological properties of boron carbide in sliding against WC ball. Int. J. Refract. Met. Hard Mater. 2015, 51, 110–117. [Google Scholar] [CrossRef]

- Hayun, S.; Rittel, D.; Frage, N.; Dariel, M.P. Static and dynamic mechanical properties of infiltrated B4C–Si composites. Mater. Sci. Eng. A 2008, 487, 405–409. [Google Scholar] [CrossRef]

- Sairam, K.; Sonber, J.K.; Murthy, T.; Subramanian, C.; Fotedar, R.K.; Nanekar, P.; Hubli, R.C. Influence of spark plasma sintering parameters on densification and mechanical properties of boron carbide. Int. J. Refract. Met. Hard Mater. 2014, 42, 185–192. [Google Scholar] [CrossRef]

- Sonber, J.K.; Murthy, T.S.R.C.; Subramanian, C.; Fotedar, R.K.; Hubli, R.C.; Suri, A.K. Synthesis, Densification and Characterization of Boron Carbide. Trans. Indian Ceram. Soc. 2013, 72, 100–107. [Google Scholar] [CrossRef]

- Popper, P.; Davies, D.G.S. The preparation and properties of self-bonded silicon carbide. Powder Metall. 1961, 4, 113–127. [Google Scholar] [CrossRef]

- Savio, S.G.; Rao, A.S.; Reddy, P.R.S.; Madhu, V. Microstructure and ballistic performance of hot pressed & reaction bonded boron carbides against an armour piercing projectile. Adv. Appl. Ceram. 2019, 118, 264–273. [Google Scholar] [CrossRef]

- Dariel, M.P.; Frage, N. Reaction bonded boron carbide: Recent developments. Adv. Appl. Ceram. 2012, 111, 301–310. [Google Scholar] [CrossRef]

- Lv, X.; Ye, F.; Cheng, L.; Fan, S.; Liu, Y. Binder jetting of ceramics: Powders, binders, printing parameters, equipment, and post-treatment. Ceram. Int. 2019, 45, 12609–12624. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Mariani, M.; Beltrami, R.; Brusa, P.; Galassi, C.; Ardito, R.; Lecis, N. 3D printing of fine alumina powders by binder jetting. J. Eur. Ceram. Soc. 2021, 41, 5307–5315. [Google Scholar] [CrossRef]

- Tappa, K.; Jammalamadaka, U. Novel Biomaterials Used in Medical 3D Printing Techniques. J. Funct. Biomater. 2018, 9, 17. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Cramer, C.L.; Elliott, A.M.; Kiggans, J.O.; Haberl, B.; Anderson, D.C. Processing of complex-shaped collimators made via binder jet additive manufacturing of B4C and pressureless melt infiltration of Al. Mater. Des. 2019, 180, 107956. [Google Scholar] [CrossRef]

- Fleisher, A.; Zolotaryov, D.; Kovalevsky, A.; Muller-Kamskii, G.; Eshed, E.; Kazakin, M.; Popov, V.V. Reaction bonding of silicon carbides by Binder Jet 3D-Printing, phenolic resin binder impregnation and capillary liquid silicon infiltration. Ceram. Int. 2019, 45, 18023–18029. [Google Scholar] [CrossRef]

- Oh, J.-W.; Park, J.; Nahm, S.; Choi, H. SiC-Si composite part fabrication via SiC powder binder jetting additive manufacturing and molten-Si infiltration. Int. J. Refract. Met. Hard Mater. 2021, 101, 105686. [Google Scholar] [CrossRef]

- Aroati, S.; Cafri, M.; Dilman, H.; Dariel, M.P.; Frage, N. Preparation of reaction bonded silicon carbide (RBSC) using boron carbide as an alternative source of carbon. J. Eur. Ceram. Soc. 2011, 31, 841–845. [Google Scholar] [CrossRef]

- Winkel, A.; Meszaros, R.; Reinsch, S.; Müller, R.; Travitzky, N.; Fey, T.; Greil, P.; Wondraczek, L. Sintering of 3D-Printed Glass/HAp Composites. J. Am. Ceram. Soc. 2012, 95, 3387–3393. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Travitzky, N.; Zimmermann, K.; Melcher, R.; Greil, P. From Polysaccharides to Sisic Composites by 3D Printing. In Advances in Ceramic Matrix Composites XI.; Bansal, N.P., Singh, J.P., Kriven, W.M., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 37–45. ISBN 9781118407844. [Google Scholar]

- Fu, Z.; Schlier, L.; Travitzky, N.; Greil, P. Three-dimensional printing of SiSiC lattice truss structures. Mater. Sci. Eng. A 2013, 560, 851–856. [Google Scholar] [CrossRef]

- Schlier, L.; Zhang, W.; Travitzky, N.; Greil, P.; Cypris, J.; Weclas, M. Macro-Cellular Silicon carbide Reactors for Nonstationary Combustion Under Piston Engine-Like Conditions. Int. J. Appl. Ceram. Technol. 2011, 8, 1237–1245. [Google Scholar] [CrossRef]

- Nazarchuk, T.N.; Mekhanoshina, L.N. The oxidation of boron carbide. Powder Metall. Met. Ceram 1964, 3, 123–126. [Google Scholar] [CrossRef]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron Carbide: Structure, Properties, and Stability under Stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Greil, P. Biomorphous ceramics from lignocellulosics. J. Eur. Ceram. Soc. 2001, 21, 105–118. [Google Scholar] [CrossRef]

- Hayun, S.; Weizmann, A.; Dariel, M.P.; Frage, N. Microstructural evolution during the infiltration of boron carbide with molten silicon. J. Eur. Ceram. Soc. 2010, 30, 1007–1014. [Google Scholar] [CrossRef]

- Karandikar, P.G.; Evans, G.; Wong, S.; Aghajanian, M.K.; Sennett, M. A Review of Ceramics for Armor Applications. In Advances in Ceramic Armor IV; Ohji, T., Wereszczak, A., Franks, L.P., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; pp. 163–175. ISBN 9780470456286. [Google Scholar]

- Suri, A.K.; Subramanian, C.; Sonber, J.K.; Murthy, T.S.R.C. Synthesis and consolidation of boron carbide: A review. Int. Mater. Rev. 2010, 55, 4–40. [Google Scholar] [CrossRef]

- Li, X.; Jiang, D.; Zhang, J.; Zhu, Y.; Chen, Z.; Huang, Z. Reaction-Bonded B 4 C with High Hardness. Int. J. Appl. Ceram. Technol. 2016, 13, 584–592. [Google Scholar] [CrossRef]

- Wahl, L.; Cicconi, M.R.; Weichelt, M.; de Ligny, D.; Travitzky, N. Residual-stress-induced crack formation in robocasted multi-material ceramics: Stress considerations and crack prevention. J. Eur. Ceram. Soc. 2022, 43, 217–223. [Google Scholar] [CrossRef]

| Binder Content in the Starting Powder Mixture | Phase Composition B4C/Si/SiC [vol.%] | True Density after Si Infiltration [g/cm3] | Young’s Modulus [GPa] | Hardness HV5 [GPa] | Bending Strength σ0 [MPa] |

|---|---|---|---|---|---|

| 10.0 vol.% | 57.1/28.2/14.7 | 2.58 ± 0.21 | 339 ± 25 | 18.6 ± 1.1 | 372 ± 74 |

| 18.6 vol.% | 59.1/15.3/25.6 | 2.62 ± 0.25 | 343 ± 10 | 20.9 ± 2.6 | 392 ± 52 |

| 22.5 vol.% | 56.6/12.3/31.1 | 2.68 ± 0.32 | 361 ± 39 | 21.1 ± 1.9 | 300 ± 47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wahl, L.; Schmiedeke, S.; Knorr, M.; Schneider, I.; Travitzky, N. Fabrication of Reaction-Bonded Boron Carbide-Based Composites by Binder Jetting 3D Printing. Ceramics 2022, 5, 1167-1173. https://doi.org/10.3390/ceramics5040082

Wahl L, Schmiedeke S, Knorr M, Schneider I, Travitzky N. Fabrication of Reaction-Bonded Boron Carbide-Based Composites by Binder Jetting 3D Printing. Ceramics. 2022; 5(4):1167-1173. https://doi.org/10.3390/ceramics5040082

Chicago/Turabian StyleWahl, Larissa, Samuel Schmiedeke, Moritz Knorr, Ines Schneider, and Nahum Travitzky. 2022. "Fabrication of Reaction-Bonded Boron Carbide-Based Composites by Binder Jetting 3D Printing" Ceramics 5, no. 4: 1167-1173. https://doi.org/10.3390/ceramics5040082

APA StyleWahl, L., Schmiedeke, S., Knorr, M., Schneider, I., & Travitzky, N. (2022). Fabrication of Reaction-Bonded Boron Carbide-Based Composites by Binder Jetting 3D Printing. Ceramics, 5(4), 1167-1173. https://doi.org/10.3390/ceramics5040082