Cermet Systems: Synthesis, Properties, and Applications

Abstract

:1. Introduction

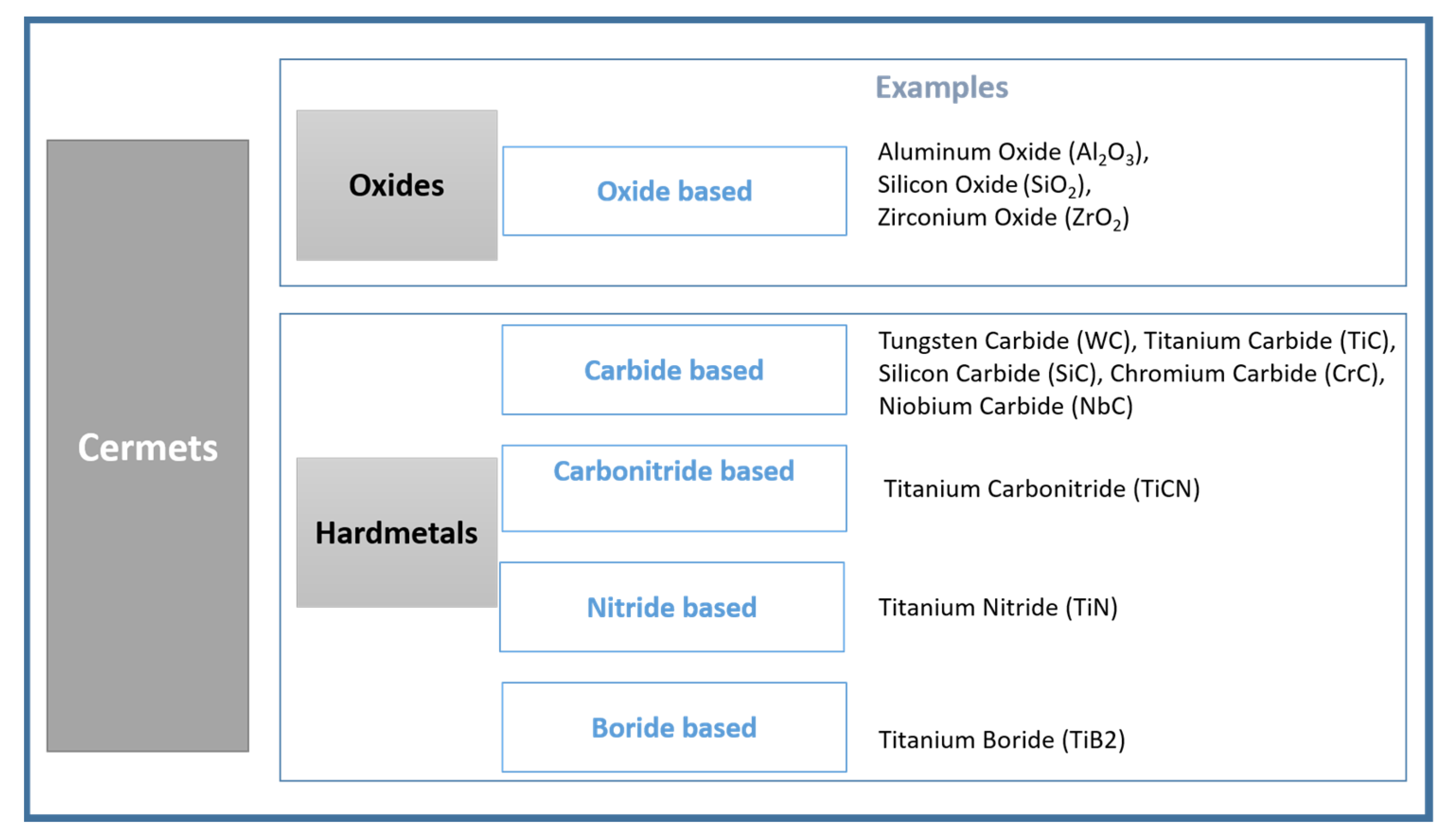

2. Cermet Systems

- WC-based cermets;

- TiC-based cermets;

- TiCN-based cermets;

- Alumina (Al2O3)-based cermets.

2.1. Tungsten Carbide (WC)-Based Cermets

2.2. Titanium Carbide (TiC) Based Cermets

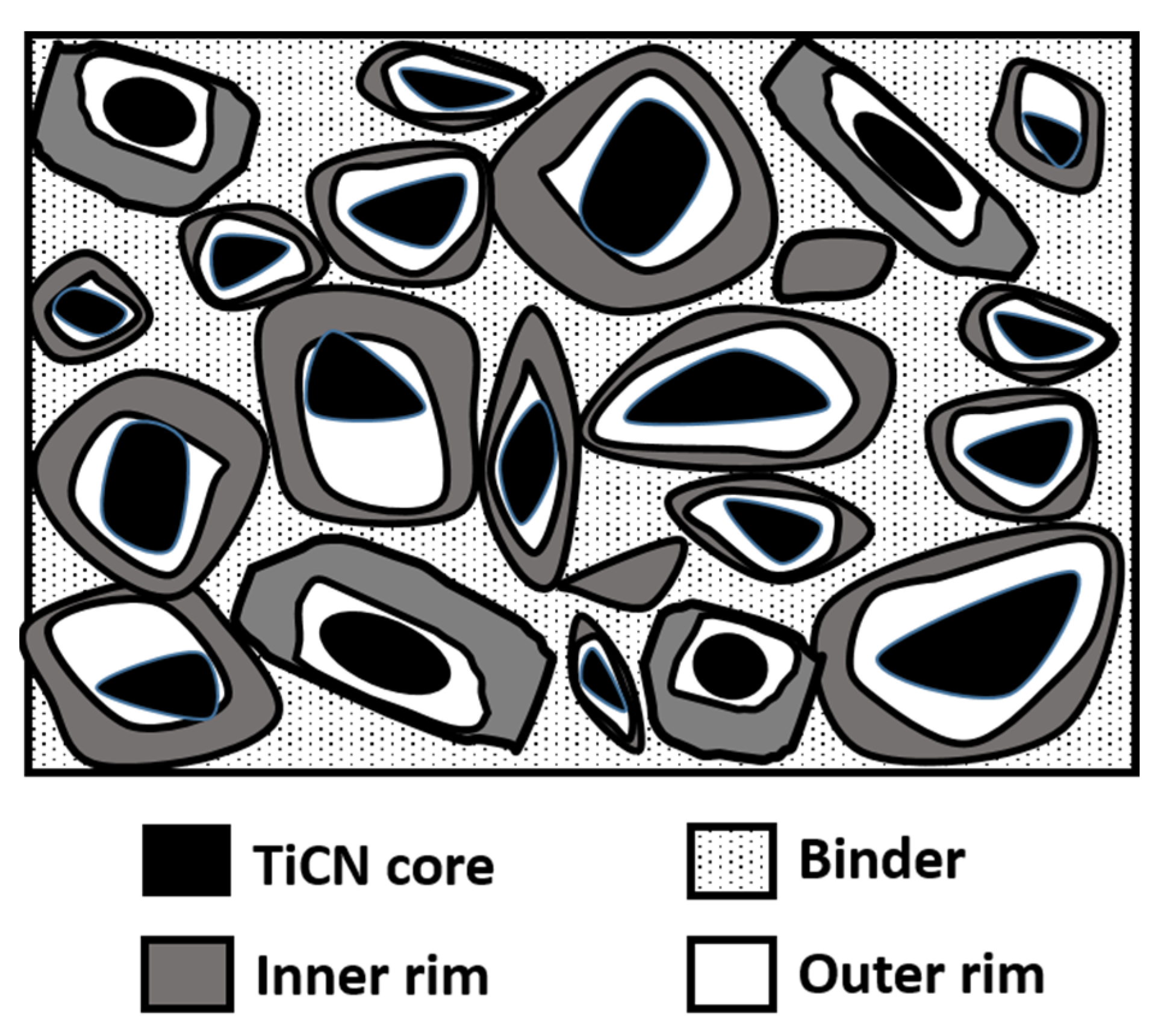

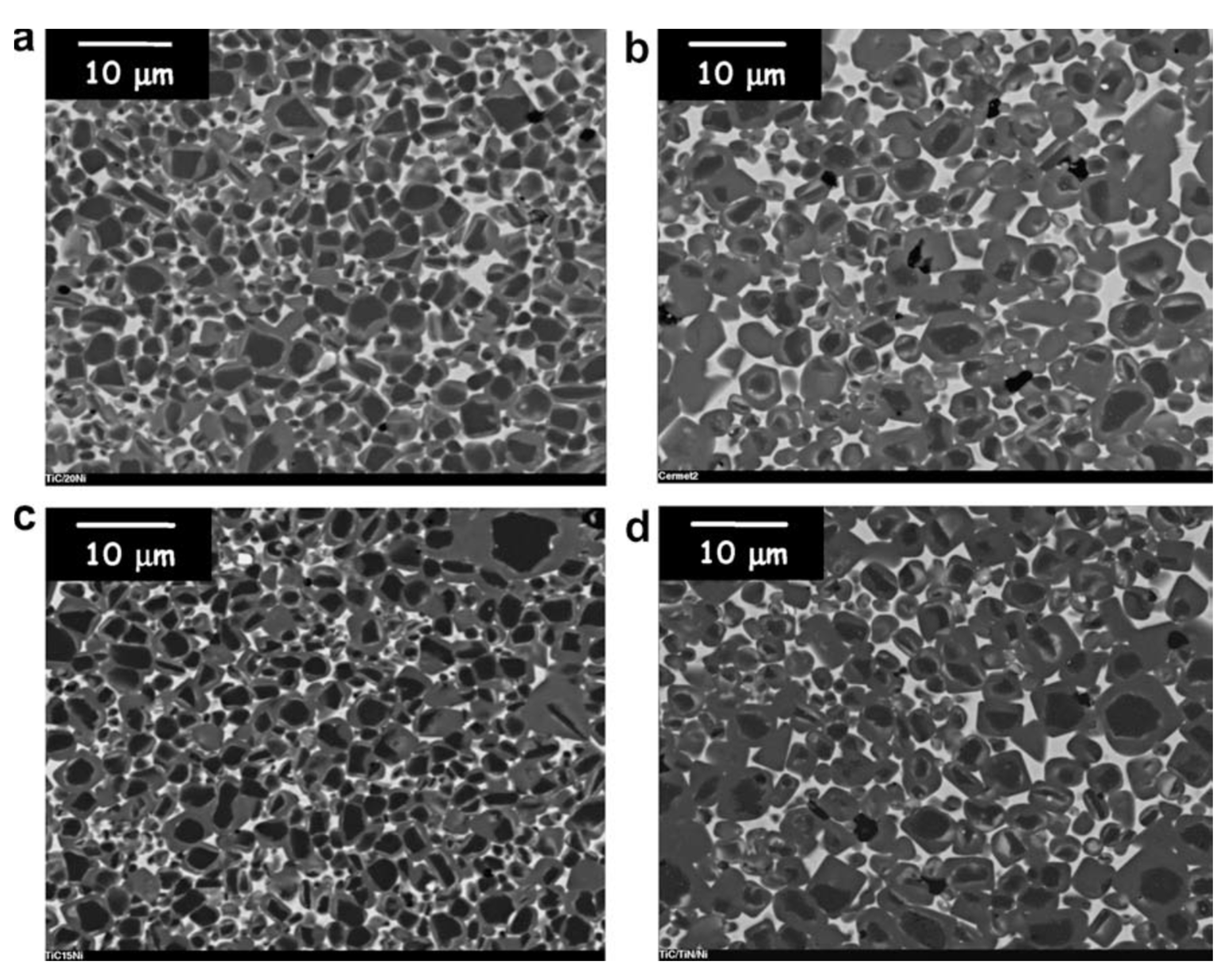

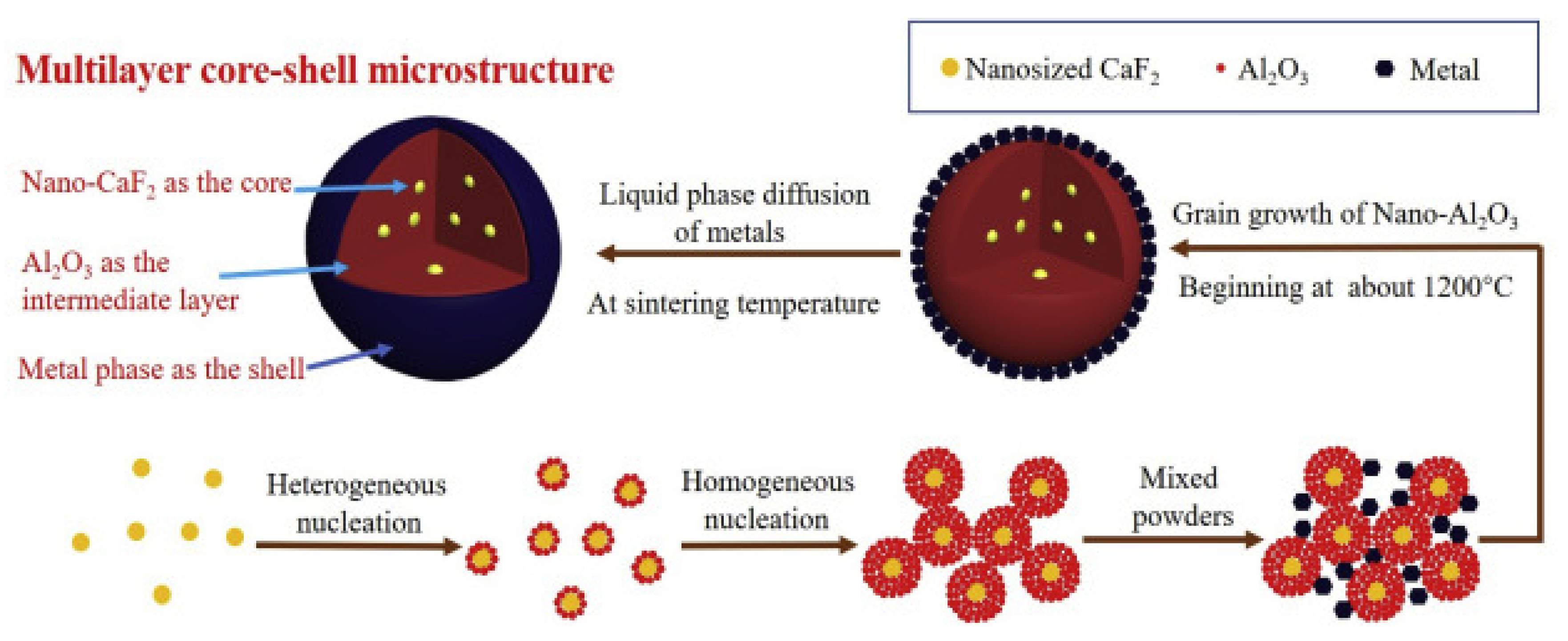

2.3. Titanium Carbonitride (TiCN)-Based Cermet

2.4. Aluminum Oxide (Al2O3)-Based Cermet Systems

- Improvement of DE by the peening effect of ceramic particles due to impact,

- The mechanical adherence of metallic particles due to asperities created by ceramic particles.

- Adherence of metallic particles to the oxide-free surface created by ceramic particle impact.

3. Synthesis of Cermets

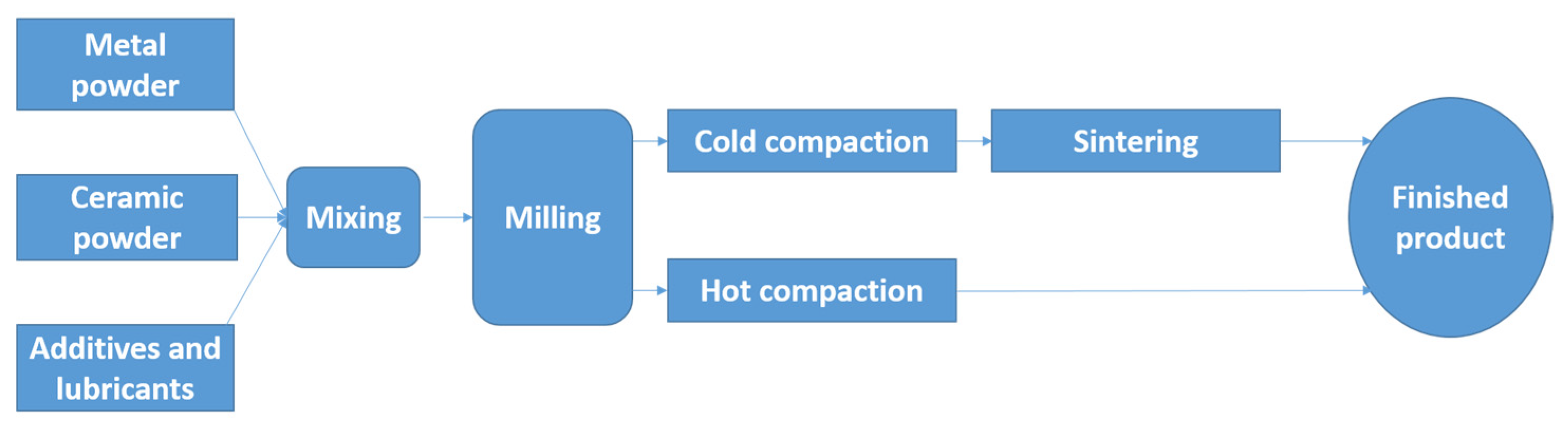

3.1. Powder Metallurgy (PM)

3.2. Reaction Synthesis (RS)

3.3. Thermal Spray (TS)

High-Velocity Oxygen Fuel (HVOF) Spraying

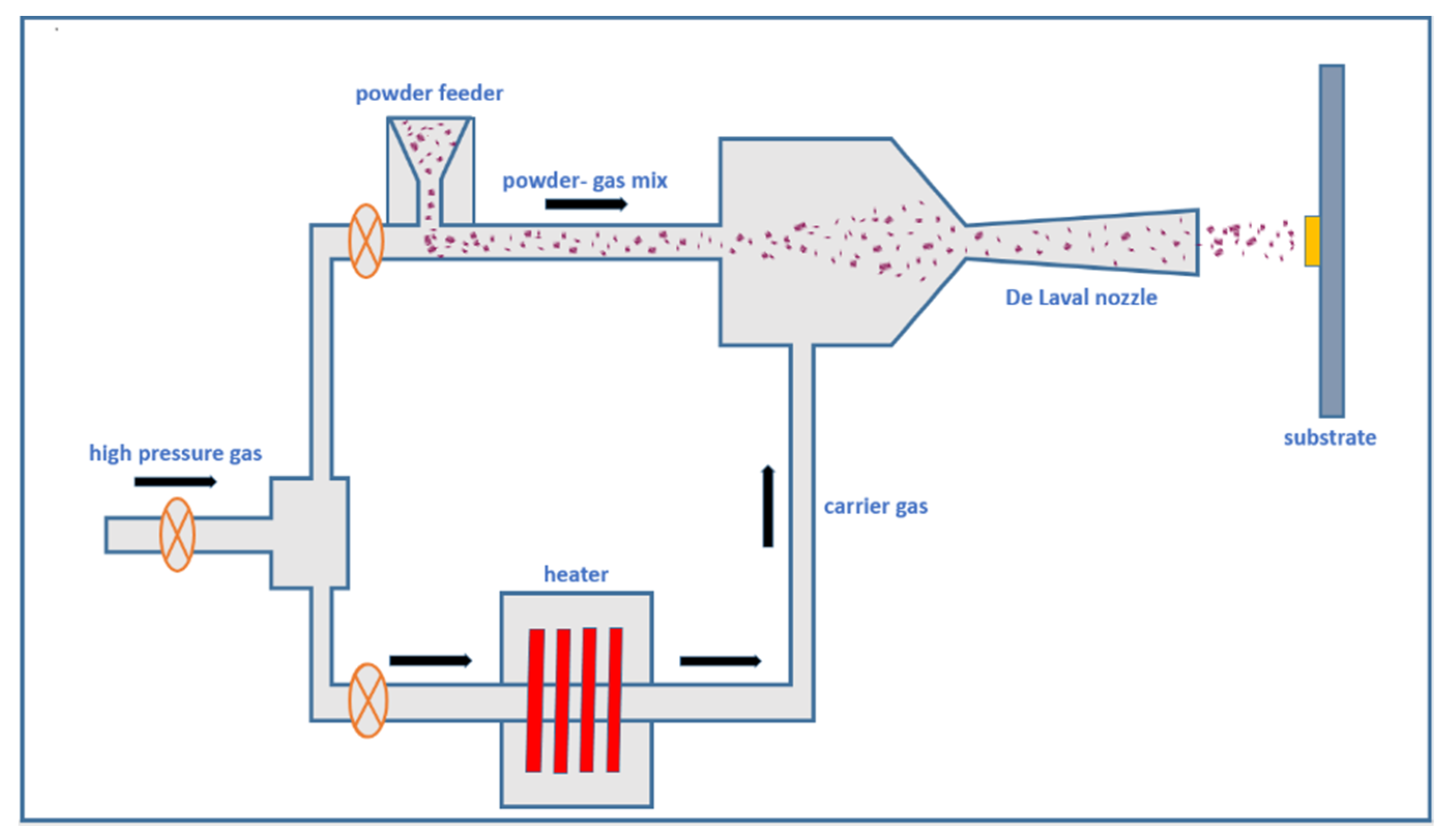

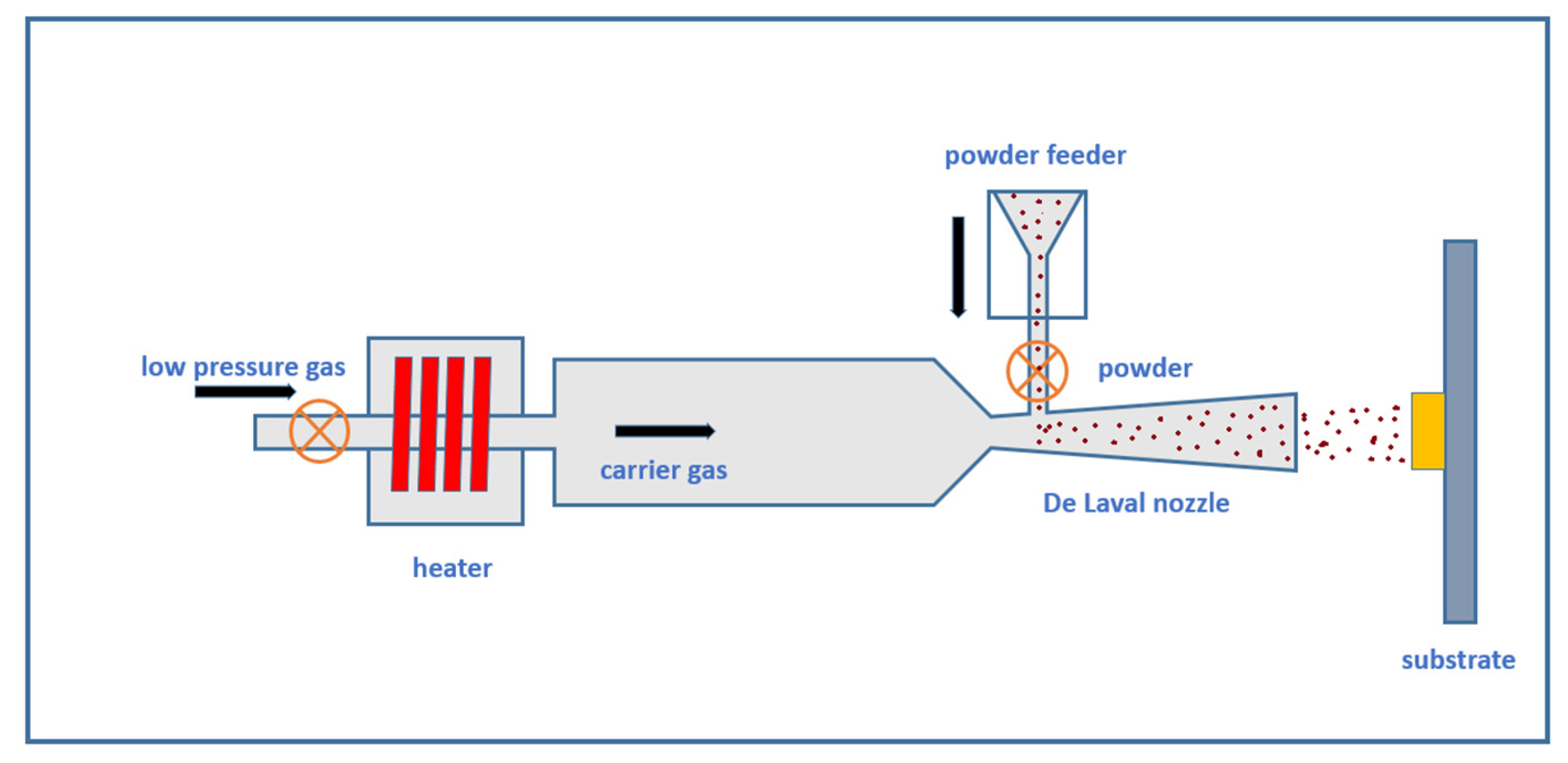

3.4. Cold Spray

3.5. Laser-Based Additively Manufactured Cermets

3.5.1. Selective Laser Melting (SLM)

3.5.2. Selective Laser Sintering (SLS)

3.5.3. Laser Engineered Net Shaping (LENS)

3.5.4. Binder Jet 3D Printing (BJ3DP) Technique

4. Microstructural Features of Cermets

5. Applications and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASI | Adiabatic Shear Instability |

| HPCS | High-Pressure Cold Spray |

| LPCS | Low-Pressure Cold Spray |

| HIP | Hot Isostatic Pressing |

| DIW | Direct Ink Writing |

| TICN | Titanium Carbonitride |

| SLS | Selective Laser Sintering |

| SLM | Selective Laser Melting |

| FDM | Fused Deposition Modeling |

| BJ3DP | Binder Jet 3D Printing |

| LENS | Laser Engineered Net Shaping |

| HVOF | High-Velocity Oxygen Fuel |

| WC | Tungsten Carbide |

| TIC | Titanium Carbide |

| DE | Deposition Efficiency |

References

- Steinitz, R. Cermets-New High-Temperature Materials. J. Jet Propuls. 1955, 25, 326–330. [Google Scholar] [CrossRef]

- Jesse, A. Bibliography on Cermets (1945–1971); Institut fuer Material und Festkoerperforschung: Karlsruhe, Germay, 1972. [Google Scholar]

- Boyer, H.E.; Gall, T.L. Metals Handbook; Desk Edition. 1985. Available online: https://www.osti.gov/biblio/5760918 (accessed on 25 April 2022).

- Petzow, G.; Claussen, N.; Exner, H.E. Aufbau und Eigenschaften von Cermets. Int. J. Mater. Res. 1968, 59, 170–179. [Google Scholar] [CrossRef]

- Mari, D. Cermets and Hardmetals☆. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2016; pp. 420–424. ISBN 978-0-12-819733-2. [Google Scholar]

- Ettmayer, P.; Kolaska, H.; Lengauer, W.; Dreyer, K. Ti(C,N) cermets—Metallurgy and properties. Int. J. Refract. Met. Hard Mater. 1995, 13, 343–351. [Google Scholar] [CrossRef]

- Zhang, S. Titanium carbonitride-based cermets: Processes and properties. Mater. Sci. Eng. A 1993, 163, 141–148. [Google Scholar] [CrossRef]

- Luo, X.; Chidambaram-Seshadri, R.; Yang, G.-J. Chapter 4-Micro-Nanostructured Cermet Coatings. In Advanced Nanomaterials and Coatings by Thermal Spray; Yang, G.-J., Suo, X., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 61–117. ISBN 978-0-12-813870-0. [Google Scholar]

- Akhtar, F.; Guo, S.J. Microstructure, mechanical and fretting wear properties of TiC-stainless steel composites. Mater. Charact. 2008, 59, 84–90. [Google Scholar] [CrossRef]

- Aramian, A.; Sadeghian, Z.; Prashanth, K.G.; Berto, F. In situ fabrication of TiC-NiCr cermets by selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 87, 105171. [Google Scholar] [CrossRef]

- Ettmayer, P.; Lengauer, W. The Story of Cermets. Powder Metall. Int. 1989, 21, 37–38. [Google Scholar]

- Topic, F.; Tsuda, K. History of Development of Cemented Carbides and Cermet Keiichi. SEI Tech. Rev. 2016, 82, 16–20. [Google Scholar]

- Roosaar, T.; Kübarsepp, J.; Klaasen, H.; Viljus, M. Wear Performance of TiC-Base Cermets. Medziagotyra 2008, 14, 238–241. [Google Scholar]

- Humenik, M.; Parikh, N. Cermets: I, Fundamental Concepts Related to Micro-structure and Physical Properties of Cermet Systems. J. Am. Ceram. Soc. 2006, 39, 60–63. [Google Scholar] [CrossRef]

- Bhagat, R.B.; Conway, J.C.; Amateau, M.F.; Brezler, R.A. Tribological performance evaluation of tungsten carbide-based cermets and development of a fracture mechanics wear model. Wear 1996, 201, 233–243. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Popovich, V.; Matos, M.; Senos, A.M.R.; Vieira, M.T. Carbide phases formed in WC–M (M=Fe/Ni/Cr) systems. Ceram. Int. 2009, 35, 369–372. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chang, M.-H.; Huang, K.-T. Study on the sintered characteristics and properties of nanostructured WC–15 wt% (Fe–Ni–Co) and WC–15 wt% Co hard metal alloys. J. Alloys Compd. 2015, 649, 89–95. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, B.-H.; He, K.; Jing, H.; Bai, Z.; Chen, W.; Zhang, W.-W. Mechanical properties and microstructure of WC-Fe-Ni-Co cemented carbides prepared by vacuum sintering. Vacuum 2017, 143, 271–282. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Delbari, S.A.; Shahedi Asl, M.; Le, Q.V.; Jang, H.W.; Shokouhimehr, M.; Mohammadi, M.; Sabahi Namini, A. A novel TiC-based composite co-strengthened with AlN particulates and graphene nano-platelets. Int. J. Refract. Met. Hard Mater. 2020, 92, 105331. [Google Scholar] [CrossRef]

- Huang, S.G.; Vleugels, J.; Mohrbacher, H.; Woydt, M. NbC grain growth control and mechanical properties of Ni bonded NbC cermets prepared by vacuum liquid phase sintering. Int. J. Refract. Met. Hard Mater. 2018, 72, 63–70. [Google Scholar] [CrossRef]

- Farag, S.; Konyashin, I.; Ries, B. The influence of grain growth inhibitors on the microstructure and properties of submicron, ultrafine and nano-structured hardmetals—A review. Int. J. Refract. Met. Hard Mater. 2018, 77, 12–30. [Google Scholar] [CrossRef]

- Aleksandrov Fabijanić, T.; Jakovljević, S.; Franz, M.; Jeren, I. Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen. Metals 2016, 6, 198. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.G.; Liu, R.L.; Li, L.; Van der Biest, O.; Vleugels, J. NbC as grain growth inhibitor and carbide in WC–Co hardmetals. Int. J. Refract. Met. Hard Mater. 2008, 26, 389–395. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, X.; Yang, Z.; Li, Y.; He, G.; Li, J. Preparation of WC/CoCrFeNiAl0.2 high-entropy-alloy composites by high-gravity combustion synthesis. Int. J. Miner. Metall. Mater. 2020, 27, 244–251. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, W.; Li, T.; Zhang, M.; Liu, B.; Liu, Y.; Wang, L.; Hu, S. Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding. Surf. Coat. Technol. 2020, 385, 125326. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, G.; Liu, B.; Wang, J.; Han, L.; Liu, Y. Microstructures and wear behaviour of (FeCoCrNi)1-x(WC)x high entropy alloy composites. Int. J. Refract. Met. Hard Mater. 2018, 75, 56–62. [Google Scholar] [CrossRef]

- Li, W.G.; Wu, Q.L. Effect of Ni Addition on In Situ WC-Cr3C2 Cermet Coating by Laser Controlled Reactive Synthesisuse. Adv. Mater. Res. 2010, 123–125, 43–46. [Google Scholar] [CrossRef]

- Liu, G.; Guo, S.; Li, J.; Chen, K.; Fan, D. Fabrication of hard cermets by in-situ synthesis and infiltration of metal melts into WC powder compacts. J. Asian Ceram. Soc. 2017, 5, 418–421. [Google Scholar] [CrossRef] [Green Version]

- Cramer, C.L.; Preston, A.D.; Ma, K.; Nandwana, P. In-situ metal binder-phase formation to make WC-FeNi Cermets with spark plasma sintering from WC, Fe, Ni, and carbon powders. Int. J. Refract. Met. Hard Mater. 2020, 88, 105204. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Y.; Zuo, L.; Zhang, Y.; Qi, Y.; Gao, K. The effect of volume fraction of WC particles on wear behavior of in-situ WC/Fe composites by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2017, 69, 196–208. [Google Scholar] [CrossRef]

- Ghasali, E.; Shahmorad, A.; Orooji, Y.; Faraji, A.; Asadian, K.; Alizadeh, M.; Ebadzadeh, T. Effects of vanadium and titanium addition on the densification, microstructure and mechanical properties of WC-Co cermets. Ceram. Int. 2021, 47, 14270–14279. [Google Scholar] [CrossRef]

- Wentzel, E.J.; Allen, C. The erosion-corrosion resistance of tungsten-carbide hard metals. Int. J. Refract. Met. Hard Mater. 1997, 15, 81–87. [Google Scholar] [CrossRef]

- Aw, P.K.; Tan, A.L.K.; Tan, T.P.; Qiu, J. Corrosion resistance of tungsten carbide based cermet coatings deposited by High Velocity Oxy-Fuel spray process. Thin Solid Films 2008, 516, 5710–5715. [Google Scholar] [CrossRef]

- Lin, N.; He, Y.; Zou, J. Enhanced mechanical properties and oxidation resistance of tungsten carbide-cobalt cemented carbides with aluminum nitride additions. Ceram. Int. 2017, 43, 6603–6606. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-C.; Shon, I.-J.; Yoon, J.-K.; Doh, J.-M.; Munir, Z.A. Rapid sintering of ultrafine WC–Ni cermets. Int. J. Refract. Met. Hard Mater. 2006, 24, 427–431. [Google Scholar] [CrossRef]

- Chen, C.-S.; Yang, C.-C.; Chai, H.-Y.; Yeh, J.-W.; Chau, J.L.H. Novel cermet material of WC/multi-element alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 200–204. [Google Scholar] [CrossRef]

- Kubarsepp, J.; Reshetnyak, H.; Annuka, H. Characterization of the serviceability of steel-bonded hardmetals. Int. J. Refract. Met. Hard Mater. 1993, 12, 341–348. [Google Scholar] [CrossRef]

- Kübarsepp, J.; Klaasen, H.; Pirso, J. Behavior of TiC-based Cermets in Different Wear Conditions. Wear 2001, 249, 229–234. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, G.Q. Sintering of Ti(C,N)-Based Cermets: The Role of Compaction. Mater. Manuf. Process. 1995, 10, 773–783. [Google Scholar] [CrossRef]

- Hussainova, I. Effect of microstructure on the erosive wear of titanium carbide-based cermets. Wear 2003, 255, 121–128. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Syarif, J.; Daud, A.R. Development and application of tool wear: A review of the characterization of TiC-based cermets with different binders. Chem. Eng. J. 2014, 255, 445–452. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, X.; Xiao, X.; Zhao, H. Effect of Co and Ni Contents on the Sintering Behavior, Microstructure Evolution, and Mechanical Properties of (Ti,M)C-Based Cermets. JOM 2021, 73, 3403–3410. [Google Scholar] [CrossRef]

- Liu, N.; Chen, M.; Xu, Y.; Zhou, J. Minshi Wettability and Bonding between Ni and Th_C, N with Multiple Carbide Additions. 2005. [Google Scholar]

- Han, C.; Den, C.; Zhao, D.; Hu, K. Milling performance of TiC–Ni cermet tools toughened by TiN nanoparticles. Int. J. Refract. Met. Hard Mater. 2012, 30, 12–15. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Wang, J.; Hong, C. Effect of Fe on the phases and microstructure of TiC–Fe cermets by combustion synthesis/quasi-isostatic pressing. Mater. Sci. Eng. A 2004, 381, 92–97. [Google Scholar] [CrossRef]

- Arenas, F.; Rondón, C.; Sepúlveda, R. Friction and tribological behavior of (Ti, V)C–Co cermets. J. Mater. Process. Technol. 2003, 143–144, 822–826. [Google Scholar] [CrossRef]

- Cardinal, S.; Malchère, A.; Garnier, V.; Fantozzi, G. Microstructure and mechanical properties of TiC–TiN based cermets for tools application. Int. J. Refract. Met. Hard Mater. 2009, 27, 521–527. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Daud, A.R. Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet—A review. Mater. Des. 2015, 67, 95–106. [Google Scholar] [CrossRef]

- Gaier, M.; Lin, H.-T.; Farhat, Z.N.; Plucknett, K.P. Precipitation hardenable TiC-Steel cermets. Wear 2021, 477, 203804. [Google Scholar] [CrossRef]

- Peng, Y.; Miao, H.; Peng, Z. Development of TiCN-based cermets: Mechanical properties and wear mechanism. Int. J. Refract. Met. Hard Mater. 2013, 39, 78–89. [Google Scholar] [CrossRef]

- Li, C.; Yi, M.; Wei, G.; Chen, Z.; Xiao, G.; Zhang, J.; Zhou, T.; Wu, G.; Xu, C. Effect of multilayer core-shell microstructure on mechanical properties of Ti(C,N) based self-lubricating cermet materials. J. Alloys Compd. 2020, 817, 153197. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Shen, B.; Cao, D. The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC0.7N0.3 cermet. Mater. Des. 2007, 28, 1689–1694. [Google Scholar] [CrossRef]

- Jun, W.; Ying, L.; Ping, Z.; Jiancai, P.; Jinwen, Y.; Minjing, T. Effect of WC on the microstructure and mechanical properties in the Ti (C0.7N0.3)–xWC–Mo2C–(Co, Ni) system. Int. J. Refract. Met. Hard Mater. 2009, 27, 9–13. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, W.; Xiong, W.; Zhou, Y. Effect of Mo and Mo2C on the microstructure and properties of the cermets based on Ti (C, N). Acta Metall. Sin. Engl. Lett. 2008, 21, 211–219. [Google Scholar] [CrossRef]

- Park, D.; Lee, Y.; Kang, S. Effect of carbides on the microstructure and properties of Ti (C, N)-based ceramics. J. Am. Ceram. Soc. 1999, 82, 3150–3154. [Google Scholar] [CrossRef]

- Wan, W.; Xiong, J.; Yang, M.; Guo, Z.; Dong, G.; Yi, C. Effects of Cr3C2 addition on the corrosion behavior of Ti (C, N)-based cermets. Int. J. Refract. Met. Hard Mater. 2012, 31, 179–186. [Google Scholar] [CrossRef]

- Ghasali, E.; Orooji, Y.; Tahamtan, H.; Asadian, K.; Alizadeh, M.; Ebadzadeh, T. The effects of metallic additives on the microstructure and mechanical properties of WC-Co cermets prepared by microwave sintering. Ceram. Int. 2020, 46, 29199–29206. [Google Scholar] [CrossRef]

- Tewari, A.; Basu, B.; Bordia, R.K. Model for fretting wear of brittle ceramics. Acta Mater. 2009, 57, 2080–2087. [Google Scholar] [CrossRef]

- Kumar, B.M.; Basu, B. Fretting wear properties of TiCN-Ni cermets: Influence of load and secondary carbide addition. Metall. Mater. Trans. A 2008, 39, 539–550. [Google Scholar] [CrossRef]

- Kumar, B.M.; Basu, B. Mechanisms of material removal during high temperature fretting of TiCN–Ni based cermets. Int. J. Refract. Met. Hard Mater. 2008, 26, 504–513. [Google Scholar] [CrossRef]

- Sarkar, D.; Ahn, S.; Kang, S.; Basu, B. Fretting Wear of TiCN-Ni Cermet: Influence of secondary Carbide Content; National Resources Canada: Ottawa, ON, Canada, 2003.

- Meng, J.; Lu, J.; Wang, J.; Yang, S. Tribological behavior of TiCN-based cermets at elevated temperatures. Mater. Sci. Eng. A 2006, 418, 68–76. [Google Scholar] [CrossRef]

- Zheng, Z.; Lv, J.; Lou, M.; Xu, K.; Chen, L.; Zhang, J.; Chang, K. Mechanical and tribological properties of WC incorporated Ti (C, N)-based cermets. Ceram. Int. 2021, 48, 10086–10095. [Google Scholar] [CrossRef]

- Wang, Z.; Wan, W.; Wang, J.; Fan, K.; Li, Y.; Xiong, J.; Du, H. Carburization and wear behavior of self-lubricating Ti (C, N)-based cermets with various secondary carbides. Ceram. Int. 2021, 47, 26678–26691. [Google Scholar] [CrossRef]

- Verma, V.; Kumar, B.M. Effects of binders (Ni-Co) and Ternary Carbide (TaC) on Friction and Wear Behavior of Ti (CN) Based Cermets. Ceram. Trans. 2017, 263, 353–364. [Google Scholar]

- Ruys, A.J. Alumina Ceramics: Biomedical and Clinical Applications; Woodhead Publishing: Sawston, UK, 2018; ISBN 0-08-102443-6. [Google Scholar]

- Sova, A.; Papyrin, A.; Smurov, I. Influence of ceramic powder size on process of cermet coating formation by cold spray. J. Therm. Spray Technol. 2009, 18, 633. [Google Scholar] [CrossRef]

- Miranda-Hernandez, J.G.; La Torre, D.; Diaz, S.; Rocha-Rangel, E. Synthesis, microstructural analysis and mechanical properties of alumina-matrix cermets. Epa.-J. Silic. Based Compos. Mater. 2010, 2010, 1. [Google Scholar] [CrossRef]

- Irissou, E.; Legoux, J.-G.; Arsenault, B. Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties. J. Therm. Spray Technol. 2007, 16, 661–668. [Google Scholar] [CrossRef]

- Fernandez, R.; Jodoin, B. Cold Spray Aluminum–Alumina Cermet Coatings: Effect of Alumina Content. J. Therm. Spray Technol. 2018, 27, 603–623. [Google Scholar] [CrossRef]

- German, R.M. Sintering Theory and Practice; Wiley: Hoboken, NJ, USA, 1996; ISBN 0-471-05786-X. [Google Scholar]

- Exner, H.E. An Introduction To The Development And Effects Of Voids In Sintered Materials. J. Microsc. 1979, 116, 25–37. [Google Scholar] [CrossRef]

- Jones, R.; Szweda, A.; Petrak, D. Polymer derived ceramic matrix composites. Compos. Part Appl. Sci. Manuf. 1999, 30, 569–575. [Google Scholar] [CrossRef]

- Wen, Q.; Qu, F.; Yu, Z.; Graczyk-Zajac, M.; Xiong, X.; Riedel, R. Si-based polymer-derived ceramics for energy conversion and storage. J. Adv. Ceram. 2022, 11, 197–246. [Google Scholar] [CrossRef]

- Kumar, A.P.; Raj, R.; Kailas, S.V. A novel in-situ polymer derived nano ceramic MMC by friction stir processing. Mater. Des. 2015, 85, 626–634. [Google Scholar] [CrossRef]

- Newkirk, M.S.; Lesher, H.D.; White, D.R.; Kennedy, C.R.; Urquhart, A.W.; Claar, T.D. Preparation of LanxideTM Ceramic Matrix Composites: Matrix Formation by the Directed Oxidation of Molten Metals. In Proceedings of the 11th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings, Cocoa Beach, FL, USA, 18–23 January 1987; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1987; pp. 879–885, ISBN 978-0-470-32040-2. [Google Scholar]

- Janssen, R.; Scheppokat, S.; Claussen, N. Tailor-made ceramic-based components—Advantages by reactive processing and advanced shaping techniques. J. Eur. Ceram. Soc. 2008, 28, 1369–1379. [Google Scholar] [CrossRef]

- Travitzky, N.; Fu, Z.; Knyazeva, A.; Janssen, R.; Nekludov, D.; Yin, X.; Greil, P. Reactive Synthesis of Ceramic-Metal Composites. Adv. Eng. Mater. 2018, 20, 1800324. [Google Scholar] [CrossRef]

- Nagelberg, A.S. Observations on the role of Mg and Si in the directed oxidation of Al–Mg–Si alloys. J. Mater. Res. 1992, 7, 265–268. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, H.; Wang, H.; Chen, Q.; Bai, X.; Zhao, X.; Fang, Y.; Xu, H.; Li, Q. In situ Ti (C, N)-based cermets by reactive hot pressing: Reaction process, densification behavior and mechanical properties. Ceram. Int. 2019, 45, 1363–1369. [Google Scholar] [CrossRef]

- LaSalvia, J.C.; Kim, D.K.; Meyers, M.A. Effect of Mo on microstructure and mechanical properties of TiC—Ni-based cermets produced by combustion synthesis—impact forging technique. Mater. Sci. Eng. A 1996, 206, 71–80. [Google Scholar] [CrossRef]

- Berger, L.-M. Application of hardmetals as thermal spray coatings. Int. J. Refract. Met. Hard Mater. 2015, 49, 350–364. [Google Scholar] [CrossRef]

- Schorr, B.S.; Stein, K.J.; Marder, A.R. Characterization of thermal spray coatings. Mater. Charact. 1999, 42, 93–100. [Google Scholar] [CrossRef]

- Czupryński, A. Flame spraying of aluminum coatings reinforced with particles of carbonaceous materials as an alternative for laser cladding technologies. Materials 2019, 12, 3467. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reiners, G.; Kreye, H.; Schwetzke, R. Properties and Characterization of Thermal Spray Coatings; ASM International: Almere, The Netherlands, 1998; pp. 629–634. [Google Scholar]

- Exner, H.; Gurland, J. A review of parameters influencing some mechanical properties of tungsten carbide–cobalt alloys. Powder Metall. 1970, 13, 13–31. [Google Scholar] [CrossRef]

- Gärtner, F.; Stoltenhoff, T.; Schmidt, T.; Kreye, H. The cold spray process and its potential for industrial applications. J. Therm. Spray Technol. 2006, 15, 223–232. [Google Scholar] [CrossRef]

- Williamson, E.H.; Gee, M.; Robertson, D.; Watts, J.F.; Whiting, M.J.; Yeomans, J.A. A comparative study of the wear performance of hard coatings for nuclear applications. Wear 2022, 488–489, 204124. [Google Scholar] [CrossRef]

- Ahmed, R.; Hadfield, M. Mechanisms of fatigue failure in thermal spray coatings. J. Therm. Spray Technol. 2002, 11, 333–349. [Google Scholar] [CrossRef]

- Nerz, J.; Kushner, B.; Rotolico, A.; Yazici, R. Effects of Deposition Methods on the Physical Properties of Tungsten Carbide-12 wt% Cobalt Thermal Spray Coatings. Prot. Coat. Process. Charact. 1990, 133–143. [Google Scholar]

- Kamnis, S.; Gu, S. Study of in-flight and impact dynamics of nonspherical particles from HVOF guns. J. Therm. Spray Technol. 2010, 19, 31–41. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.Q.; Shui, Z.R. Hot erosion behavior of carbide–metal composite coatings. J. Mater. Process. Technol. 2003, 143, 87–92. [Google Scholar] [CrossRef]

- Maiti, A.; Mukhopadhyay, N.; Raman, R. Effect of adding WC powder to the feedstock of WC–Co–Cr based HVOF coating and its impact on erosion and abrasion resistance. Surf. Coat. Technol. 2007, 201, 7781–7788. [Google Scholar] [CrossRef]

- Kumar, P.; Sidhu, B.S. Characterization and High-Temperature Erosion Behaviour of HVOF Thermal Spray Cermet Coatings. J. Mater. Eng. Perform. 2016, 25, 250–258. [Google Scholar] [CrossRef]

- Wood, R.J. Tribology of thermal sprayed WC–Co coatings. Int. J. Refract. Met. Hard Mater. 2010, 28, 82–94. [Google Scholar] [CrossRef]

- Wayne, S.F.; Sampath, S. Structure/property relationships in sintered and thermally sprayed WC-Co. J. Therm. Spray Technol. 1992, 1, 307–315. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Tokarev, A. Structure of aluminum powder coatings prepared by cold gasdynamic spraying. Met. Sci. Heat Treat. 1996, 38, 136–139. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; Tong, C.; DeRosset, W.S.; Helfritch, D.J. Analysis of the impact velocity of powder particles in the cold-gas dynamic-spray process. Mater. Sci. Eng.-Struct. Mater. Prop. Microstruct. Process. 2004, 368, 222–230. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Coleman, A.; Murray, K.; Kearns, M.; Vuoristo, P. High pressure cold sprayed (HPCS) and low pressure cold sprayed (LPCS) coatings prepared from OFHC Cu feedstock: Overview from powder characteristics to coating properties. J. Therm. Spray Technol. 2012, 21, 1065–1075. [Google Scholar] [CrossRef]

- Villafuerte, J. Current and future applications of cold spray technology. Met. Finish. 2010, 108, 37–39. [Google Scholar] [CrossRef]

- Wang, Q.; Spencer, K.; Birbilis, N.; Zhang, M.-X. The influence of ceramic particles on bond strength of cold spray composite coatings on AZ91 alloy substrate. Surf. Coat. Technol. 2010, 205, 50–56. [Google Scholar] [CrossRef]

- Aldwell, B.; Yin, S.; McDonnell, K.A.; Trimble, D.; Hussain, T.; Lupoi, R. A novel method for metal–diamond composite coating deposition with cold spray and formation mechanism. Scr. Mater. 2016, 115, 10–13. [Google Scholar] [CrossRef]

- Monette, Z.; Kasar, A.K.; Daroonparvar, M.; Menezes, P.L. Supersonic particle deposition as an additive technology: Methods, challenges, and applications. Int. J. Adv. Manuf. Technol. 2020, 106, 2079–2099. [Google Scholar] [CrossRef]

- Wang, Y.; Normand, B.; Mary, N.; Yu, M.; Liao, H. Effects of ceramic particle size on microstructure and the corrosion behavior of cold sprayed SiCp/Al 5056 composite coatings. Surf. Coat. Technol. 2017, 315, 314–325. [Google Scholar] [CrossRef]

- Lima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural characteristics of cold-sprayed nanostructured WC-Co coatings. Thin Solid Films 2002, 416, 129–135. [Google Scholar] [CrossRef]

- Maev, R.; Leshchynsky, V. Air Gas Dynamic Spraying of Powder Mixtures: Theory and Application. J. Therm. Spray Technol. 2006, 15, 198–205. [Google Scholar] [CrossRef]

- Shockley, J.M.; Descartes, S.; Vo, P.; Irissou, E.; Chromik, R. The influence of Al2O3 particle morphology on the coating formation and dry sliding wear behavior of cold sprayed Al-Al2O3 composites. Surf. Coat. Technol. 2015, 57, 324–333. [Google Scholar] [CrossRef]

- Shkodkin, A.; Kashirin, A.; Klyuev, O.; Buzdygar, T. Metal particle deposition stimulation by surface abrasive treatment in gas dynamic spraying. J. Therm. Spray Technol. 2006, 15, 382–386. [Google Scholar] [CrossRef]

- Xie, Y.; Planche, M.-P.; Raoelison, R.; Hervé, P.; Suo, X.; He, P.; Liao, H. Investigation on the influence of particle preheating temperature on bonding of cold-sprayed nickel coatings. Surf. Coat. Technol. 2017, 318, 99–105. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; DeRosset, W.S.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Poza, P.; Garrido-Maneiro, M.Á. Cold-sprayed coatings: Microstructure, mechanical properties, and wear behaviour. Prog. Mater. Sci. 2022, 123, 100839. [Google Scholar] [CrossRef]

- Dosta, S.; Couto, M.; Guilemany, J.M. Cold spray deposition of a WC-25Co cermet onto Al7075-T6 and carbon steel substrates. Acta Mater. 2013, 61, 643–652. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruthl, J. Additive Manufacturing of Ceramics: A Review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar] [CrossRef]

- Manufacturing in the Age of Instinct|Read the Report. Available online: https://www.genpact.com/form/manufacturing (accessed on 11 January 2022).

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Chaparro-Garnica, C.Y.; Jordá-Faus, P.; Bailón-García, E.; Ocampo-Pérez, R.; Aguilar-Madera, C.G.; Davó-Quiñonero, A.; Lozano-Castelló, D.; Bueno-López, A. Customizable Heterogeneous Catalysts: Nonchanneled Advanced Monolithic Supports Manufactured by 3D-Printing for Improved Active Phase Coating Performance. ACS Appl. Mater. Interfaces 2020, 12, 54573–54584. [Google Scholar] [CrossRef] [PubMed]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Simchi, A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features. Mater. Sci. Eng. A 2006, 428, 148–158. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Lavernia, E.J.; Schoenung, J.M. Processing and Microstructure of WC-CO Cermets by Laser Engineering Net Shaping. In Proceedings of the 2008 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10 September 2008. [Google Scholar]

- Enneti, R.K.; Prough, K.C. Wear properties of sintered WC-12% Co processed via Binder Jet 3D Printing (BJ3DP). Int. J. Refract. Met. Hard Mater. 2019, 78, 228–232. [Google Scholar] [CrossRef]

- Lengauer, W.; Duretek, I.; Fürst, M.; Schwarz, V.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C.; et al. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. Hard Mater. 2019, 82, 141–149. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, Z.; Chen, C.; Yang, W. Additive manufacturing of WC-20Co components by 3D gel-printing. J. Refract. Met. Hard Mater. 2018, 70, 215–223. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsev, I. Microstructure and properties of intermetallic composite coatings fabricated by selective laser melting of Ti–SiC powder mixtures. Intermetallics 2014, 46, 147–155. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.; Matovic, B. Dense and near-net-shape fabrication of Si3N4 ceramics. Mater. Sci. Eng. A 2009, 500, 130–149. [Google Scholar] [CrossRef]

- Regenfuss, P.; Streek, A.; Ullmann, F.; Kühn, C.; Hartwig, L. Laser micro sintering of ceramic materials, part 2. Interceram 2008, 57, 6–9. [Google Scholar]

- Deckers, J.; Meyers, S.; Kruth, J.P.; Vleugels, J. Direct Selective Laser Sintering/Melting of High Density Alumina Powder Layers at Elevated Temperatures. Phys. Procedia 2014, 56, 117–124. [Google Scholar] [CrossRef] [Green Version]

- Khmyrov, R.S.; Safronov, V.A.; Gusarov, A.V. Synthesis of Nanostructured WC-Co Hardmetal by Selective Laser Melting. Procedia IUTAM 2017, 23, 114–119. [Google Scholar] [CrossRef]

- Grigoriev, S.; Tarasova, T.; Gusarov, A.; Khmyrov, R.; Egorov, S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials 2019, 12, 3425. [Google Scholar] [CrossRef] [Green Version]

- Campanelli, S.L.; Contuzzi, N.; Posa, P.; Angelastro, A. Printability and Microstructure of Selective Laser Melting of WC/Co/Cr Powder. Materials 2019, 12, 2397. [Google Scholar] [CrossRef] [Green Version]

- Domashenkov, A.; Borbély, A.; Smurov, I. Structural modifications of WC/Co nanophased and conventional powders processed by selective laser melting. Mater. Manuf. Process. 2017, 32, 93–100. [Google Scholar] [CrossRef]

- Das, S.; Fuesting, T.P.; Danyo, G.; Brown, L.E.; Beaman, J.J.; Bourell, D.L. Direct laser fabrication of superalloy cermet abrasive turbine blade tips. Mater. Des. 2000, 21, 63–73. [Google Scholar] [CrossRef]

- Kumar, S. Manufacturing of WC–Co moulds using SLS machine. J. Mater. Process. Technol. 2009, 209, 3840–3848. [Google Scholar] [CrossRef]

- Kumar, S.; Kruth, J.-P.; Froyen, L. Wear behaviour of SLS WC-Co composites. In Proceedings of the 2008 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10 September 2008. [Google Scholar]

- Kumar, S.; Czekanski, A. Optimization of parameters for SLS of WC-Co. Rapid Prototyp. J. 2017, 23, 1202–1211. [Google Scholar] [CrossRef]

- Xiong, Y.; Kim, M.; Seo, O.; Schoenung, J.M.; Kang, S. (Ti,W)C–Ni cermets by laser engineered net shaping. Powder Metall. 2010, 53, 41–46. [Google Scholar] [CrossRef]

- Reyes, M.; Neville, A. Degradation mechanisms of Co-based alloy and WC metal–matrix composites for drilling tools offshore. Wear 2003, 255, 1143–1156. [Google Scholar] [CrossRef]

- Cramer, C.L.; Nandwana, P.; Lowden, R.A.; Elliott, A.M. Infiltration studies of additive manufacture of WC with Co using binder jetting and pressureless melt method. Addit. Manuf. 2019, 28, 333–343. [Google Scholar] [CrossRef]

- Gee, M.G.; Roebuck, B.; Lindahl, P.; Andren, H.O. Constituent phase nanoindentation of WC/Co and Ti (C, N) hard metals. Mater. Sci. Eng. A 1996, 209, 128–136. [Google Scholar] [CrossRef]

- Haijun, Y.; Ying, L.; Yongzhong, J. Effect of secondary carbides addition on the microstructure and mechanical properties of (Ti, W, Mo, V)(C, N)-based cerments. Int. J. Refract. Met. Hard Mater. 2011, 29, 586–590. [Google Scholar]

- Zhang, H.Q.; Liu, N.; Song, R.Y.; Liu, Z.W.; Cai, W. Effect of Ni-Co on the properties of ultra-fine grade Ti (C, N)-based cermets. Cem. Carbide 2008, 25, 214–217. [Google Scholar]

- Jin, Z.; Liu, N.; Zhan, B.; Li, Q. Influence of WC Content on Microstructure and Mechanical Properties of Ultrafine Ti (C, N)-based Cermet. Carbide 2010, 27, 269–273. [Google Scholar]

- He, C.; Xia, Z.; Wang, Y.; Zhao, B.; Tang, Q.; Mao, C.; Yu, M. Study of Ti (C, N)-based metal ceramic. Rare Met. 1999, 1, 4–12. [Google Scholar]

- Dai, H.Y.; Li, J.F.; Zhai, F.X.; Cheng, X.R.; Wang, Y.B. Effect of molybdenum on the microstructure and mechanical properties of TiC-Fe cermets. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2012; Volume 557, pp. 205–208. [Google Scholar]

- Ning, L.; Yong, J.; Qingrong, L. Effect of chemical composition on the fracture toughness of Ti (C, N) based cermets. PM Technol. China 1999, 17, 269–272. [Google Scholar]

- Shangzhi, X.; Huiping, W.; Shuzhu, Z. The influence of TiN content on properties of Ti (CN) solid solution. Mater. Sci. Eng. A 1996, 209, 294–297. [Google Scholar] [CrossRef]

- Guo, Z.; Xiong, J.; Yang, M.; Wang, J.; Sun, L.; Wu, Y.; Chen, J.; Xiong, S. Microstructure and properties of Ti(C,N)–Mo2C–Fe cermets. Int. J. Refract. Met. Hard Mater. 2009, 27, 781–783. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, J.; Zhang, X.; Tang, S. Properties of titanium carbonitride matrix cermets. Int. J. Refract. Met. Hard Mater. 2006, 24, 236–239. [Google Scholar] [CrossRef]

- Andrén, H.-O. Microstructure Development During Sintering and Heat Treatment of Cemented Carbides and Cermets. Mater. Chem. Phys. 2001, 67, 209–213. [Google Scholar] [CrossRef]

- Yu, H.; Zheng, Y.; Liu, W.; Zheng, J.; Xiong, W. Effect of V content on the microstructure and mechanical properties of Mo2FeB2 based cermets. Mater. Des. 1980–2015 2010, 31, 2680–2683. [Google Scholar] [CrossRef]

- Jeon, E.; Joardar, J.; Kang, S. Microstructure and tribo-mechanical properties of ultrafine Ti (CN) cermets. Int. J. Refract. Met. Hard Mater. 2002, 20, 207–211. [Google Scholar] [CrossRef]

- Russias, J.; Cardinal, S.; Aguni, Y.; Fantozzi, G.; Bienvenu, K.; Fontaine, J. Influence of titanium nitride addition on the microstructure and mechanical properties of TiC-based cermets. Int. J. Refract. Met. Hard Mater. 2005, 23, 358–362. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, N.; Chen, Q. Wear properties of nano TiN modified cermet cutters. Mater. Mech. Eng. 2002, 26, 28. [Google Scholar]

- Xu, Q.; Zhang, X.; Qu, W.; Han, J. Progress in research on cermets. Cem. Carbide 2002, 19, 221–225. [Google Scholar]

- Xiong, J.; Guo, Z.; Yang, M.; Xiong, S.; Chen, J.; Wu, Y.; Wen, B.; Cao, D. Effect of ultra-fine TiC0.5N0.5 on the microstructure and properties of gradient cemented carbide. J. Mater. Process. Technol. 2009, 209, 5293–5299. [Google Scholar] [CrossRef]

- Velasco, F.; Isabel, R.; Antón, N.; Martínez, M.; Torralba, J. TiCN—high speed steel composites: Sinterability and properties. Compos. Part Appl. Sci. Manuf. 2002, 33, 819–827. [Google Scholar] [CrossRef]

- Montimer, B.; Lancaster, J. Extending the life of aerospace dry bearings by the use of hard smooth counterfaces. Wear 1988, 121, 289–305. [Google Scholar] [CrossRef]

- Hu, H.; Cheng, Y.; Yin, Z.; Zhang, Y.; Lu, T. Mechanical properties and microstructure of Ti(C, N) based cermet cutting tool materials fabricated by microwave sintering. Ceram. Int. 2015, 41, 15017–15023. [Google Scholar] [CrossRef]

- Yamasaki, Y.; Nishi, M.; Takagi, K. Development of very high strength Mo2NiB2 complex boride base hard alloy. J. Solid State Chem. 2004, 177, 551–555. [Google Scholar] [CrossRef]

- Takagi, K. Development and application of high strength ternary boride base cermets. J. Solid State Chem. 2006, 179, 2809–2818. [Google Scholar] [CrossRef]

- John, M.; Menezes, P.L. Self-Lubricating Materials for Extreme Condition Applications. Materials 2021, 14, 5588. [Google Scholar] [CrossRef]

- Liu, J.; Ye, J.; Xiong, J.; Guo, Z.; Yang, T.; Wan, W.; Liu, Q. Formation of self-lubricant surface layer on the Ti(C, N)-based cermets. Vacuum 2017, 143, 225–228. [Google Scholar] [CrossRef]

- Liu, Z. Elevated temperature diffusion self-lubricating mechanisms of a novel cermet sinter with orderly micro-pores. Wear 2007, 262, 600–606. [Google Scholar] [CrossRef]

- Simchi, A.; Danninger, H. Effects of porosity on delamination wear behaviour of sintered plain iron. Powder Metall. 2004, 47, 73–80. [Google Scholar] [CrossRef]

| Binder (Weight %) | Synthesis Route | Properties | Reference |

|---|---|---|---|

| Co 5% + (V, Ti) 5% | Ultrafast microwave heating | Improved mechanical properties (Bending strength- 981 ± 10 MPa, Hardness- 24.7 ± 0.1 GPa Fracture toughness- 8.6 ± 0.1) | [31] |

| Ni (10%), Ni+ Cr+ Co (10%) | Powder metallurgy | No effect on erosion resistance Improved erosion resistance | [32] |

| Ni (17%), Co (17%) | High-velocity oxy-fuel process | Better corrosion resistance with Ni binder compared to Co binder | [33] |

| Ni (10%) | High-frequency induction heated sintering | Higher hardness compared to conventional route along with comparable toughness (HV 1810 kg/mm2) | [35] |

| Al0.5CoCrCuFeNi (20%) | Powder metallurgy | Improved hardness and fracture toughness compared to traditional WC-Co system | [36] |

| Cermet System | Microhardness (kgf·mm−2) | Strength (MPa) | Thermal Conductivity (W/m°C) |

|---|---|---|---|

| TiC-based | 500 | 1050 | 24.7 |

| TiCN-based | 600 | 1360 | 42.3 |

| Secondary Carbide | Composition | Hardness | Bending Strength (MPa) | Toughness (MPa. m1/2) | Reference |

|---|---|---|---|---|---|

| WC | 15 wt.% | 93.4 HRA | 1500 | - | [53] |

| 20 wt.% | 91.6 HRA | 2100 | - | [54] | |

| 10 wt.% | 91.2 HRA | 1800 | - | [54] | |

| Mo2C | 5 wt.% | - | 1580–1820 | 17.9–18.4 | [55] |

| 10 wt.% | 93.5 HRA | ~1300 | - | [53] | |

| NbC | 3 mol.% | 1631–1835 HV | 700–1100 | 3.5–5.5 | [56] |

| TaC (Tantalum Carbide) | 7 wt.% | 93.0 HRA | - | 1580 | [53] |

| Cr2C2 | 7 wt.% | 93.5 HRA | - | 1490 | [57] |

| VC | 1 wt.% | 1749 HV | - | 1204.6 | [58] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jose, S.A.; John, M.; Menezes, P.L. Cermet Systems: Synthesis, Properties, and Applications. Ceramics 2022, 5, 210-236. https://doi.org/10.3390/ceramics5020018

Jose SA, John M, Menezes PL. Cermet Systems: Synthesis, Properties, and Applications. Ceramics. 2022; 5(2):210-236. https://doi.org/10.3390/ceramics5020018

Chicago/Turabian StyleJose, Subin Antony, Merbin John, and Pradeep L. Menezes. 2022. "Cermet Systems: Synthesis, Properties, and Applications" Ceramics 5, no. 2: 210-236. https://doi.org/10.3390/ceramics5020018

APA StyleJose, S. A., John, M., & Menezes, P. L. (2022). Cermet Systems: Synthesis, Properties, and Applications. Ceramics, 5(2), 210-236. https://doi.org/10.3390/ceramics5020018