Porous Functional Graded Bioceramics with Integrated Interface Textures

Abstract

:1. Introduction

2. Materials and Methods

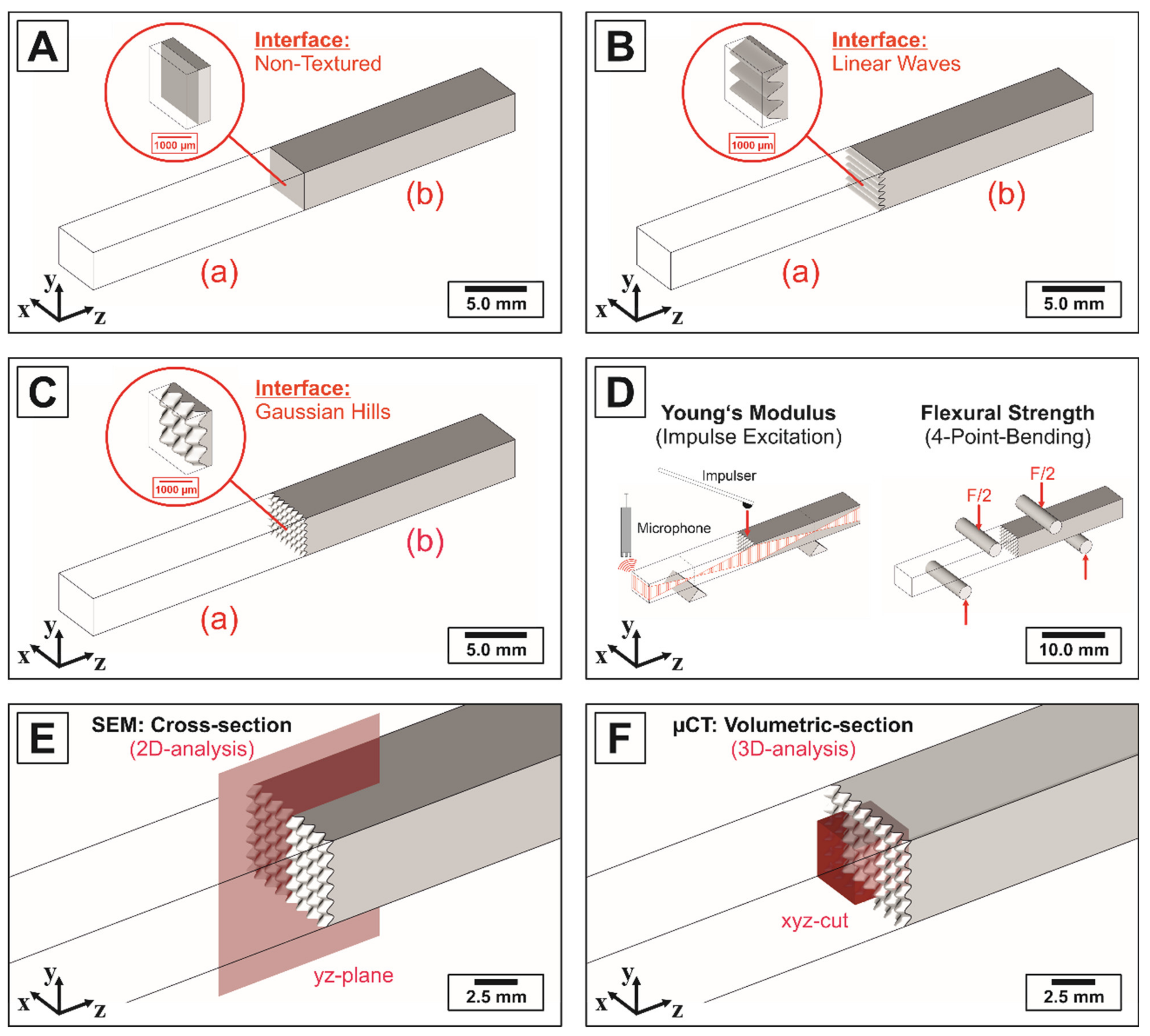

2.1. Fabrication of Porous Functional Graded Bioceramics with Integrated Interface Textures

- (A)

- (B)

- (C)

2.2. Characterization

3. Results

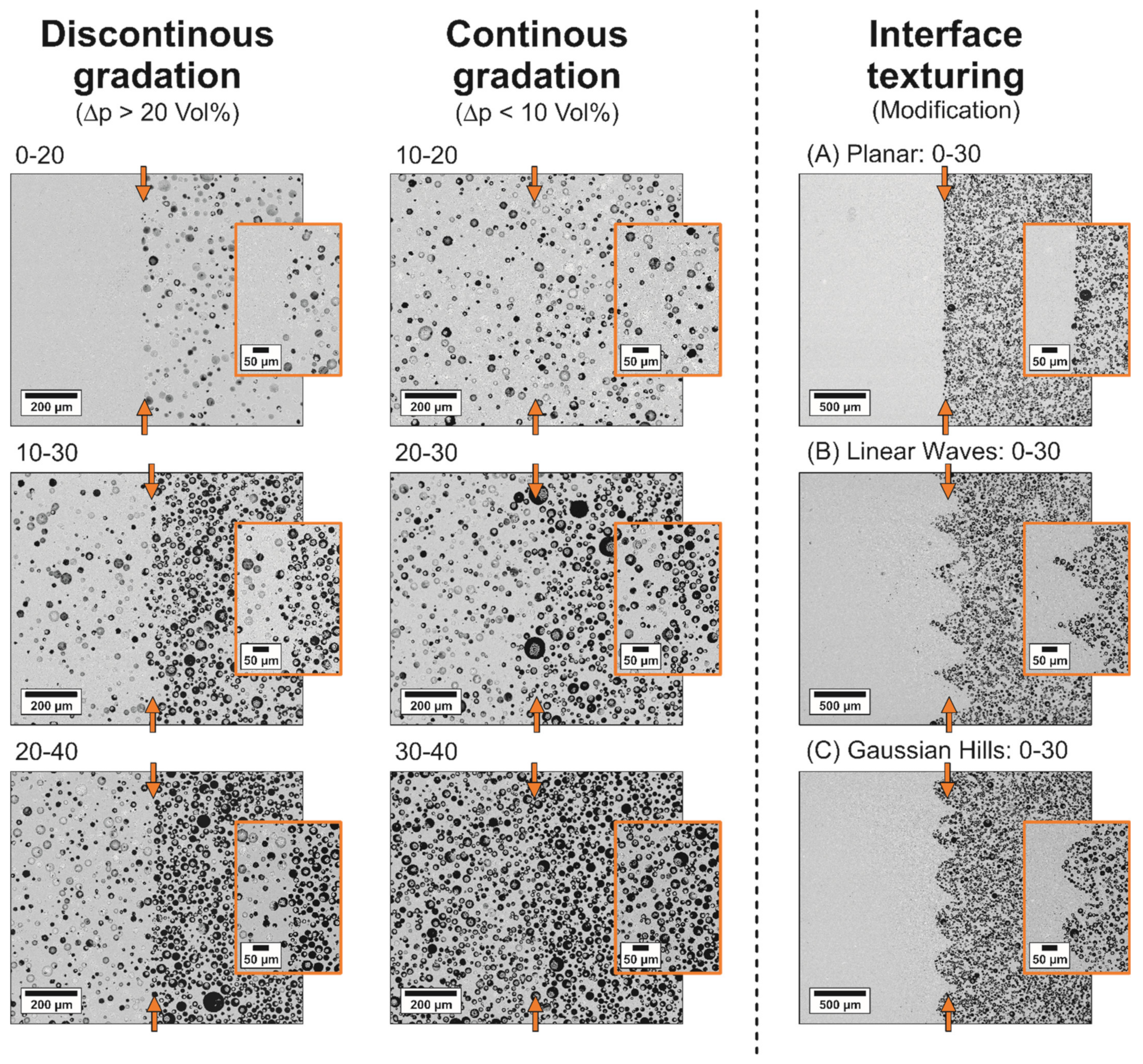

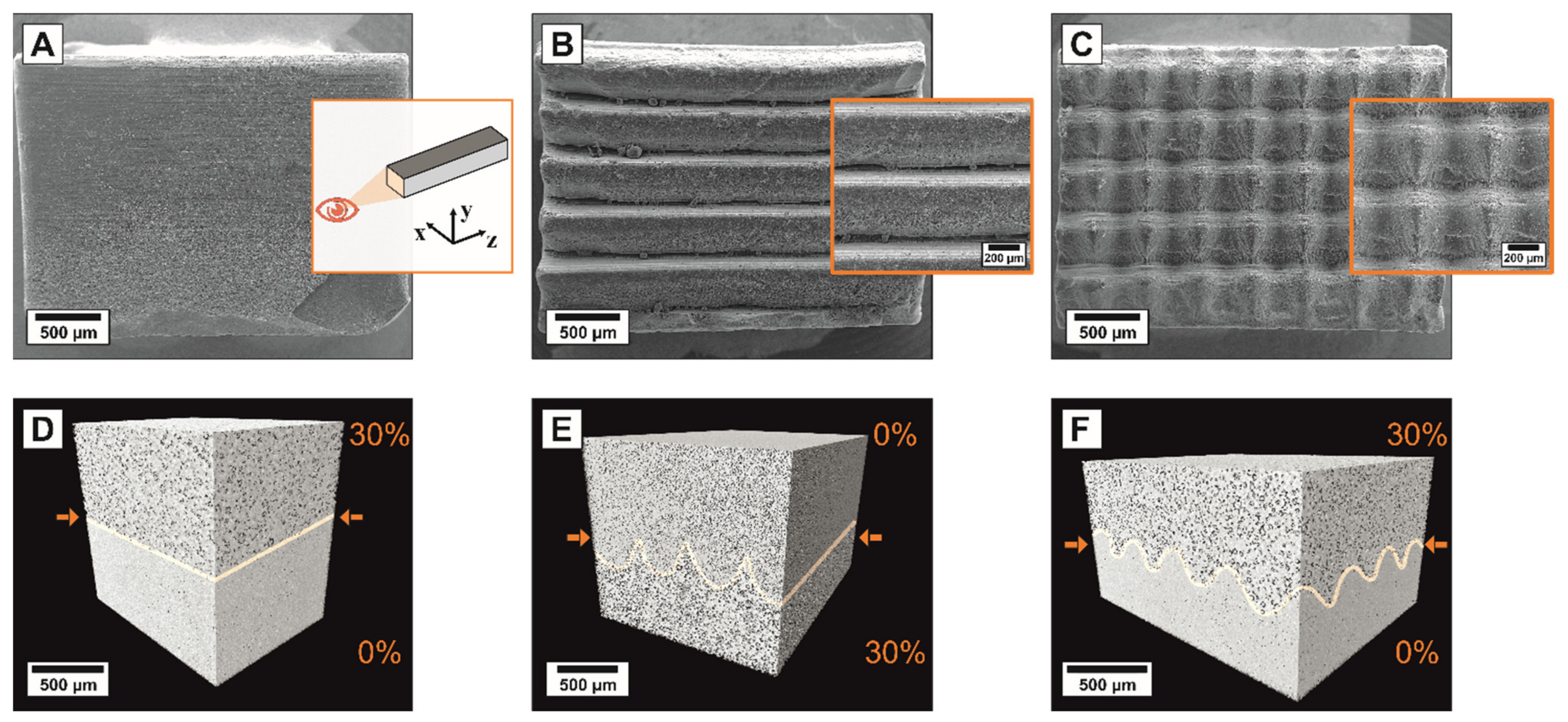

3.1. Microstructure of Porous FGCs with Integraded Interface Textures

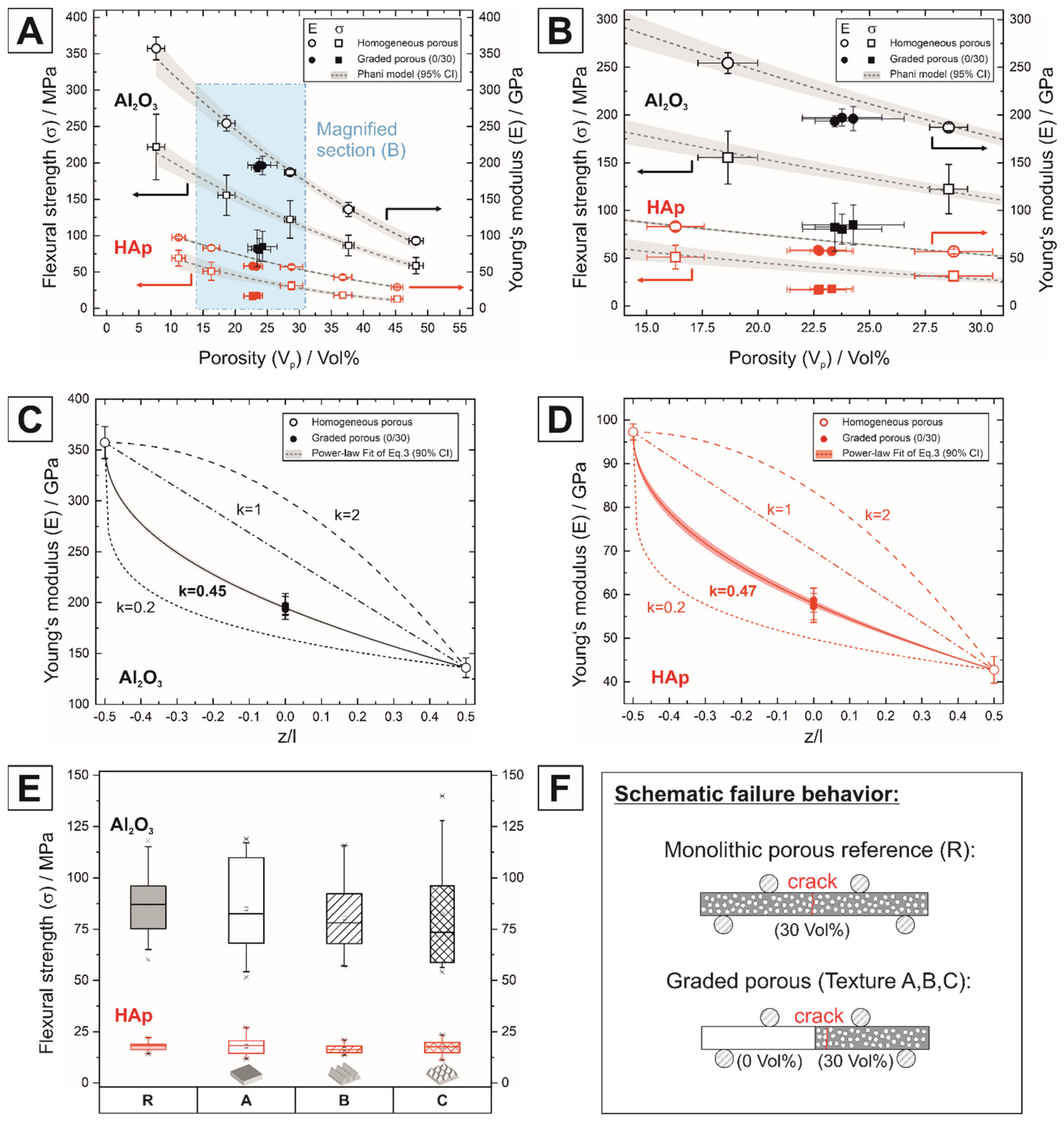

3.2. Mechanical Properties of Porous FGCs with Integrated Interface Textures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Giannoudis, P.V.; Dinopoulos, H.; Tsiridis, E. Bone substitutes: An update. Injury 2005, 36 (Suppl. 3), S20–S27. [Google Scholar] [CrossRef]

- White, A.A.; Best, S.M.; Kinloch, I.A. Hydroxyapatite? Carbon Nanotube Composites for Biomedical Applications: A Review. Int. J. Appl. Ceram. Technol. 2007, 4, 1–13. [Google Scholar] [CrossRef]

- Bohner, M.; Le Santoni, B.G.; Döbelin, N. β-tricalcium phosphate for bone substitution: Synthesis and properties. Acta Biomater. 2020, 113, 23–41. [Google Scholar] [CrossRef]

- Bohner, M.; Baumgart, F. Theoretical model to determine the effects of geometrical factors on the resorption of calcium phosphate bone substitutes. Biomaterials 2004, 25, 3569–3582. [Google Scholar] [CrossRef] [PubMed]

- Deville, S.; Saiz, E.; Tomsia, A.P. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 5480–5489. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, D.-M. Influence of porosity and pore size on the compressive strength of porous hydroxyapatite ceramic. Ceram. Int. 1997, 23, 135–139. [Google Scholar] [CrossRef]

- Zhang, F.; Chang, J.; Lu, J.; Lin, K.; Ning, C. Bioinspired structure of bioceramics for bone regeneration in load-bearing sites. Acta Biomater. 2007, 3, 896–904. [Google Scholar] [CrossRef] [PubMed]

- Andersson, L.; Jones, A.C.; Knackstedt, M.A.; Bergström, L. Permeability, pore connectivity and critical pore throat control of expandable polymeric sphere templated macroporous alumina. Acta Mater. 2011, 59, 1239–1248. [Google Scholar] [CrossRef]

- Petit, C.; Meille, S.; Maire, E.; Tadier, S.; Adrien, J. Mechanical behaviour of a β-TCP ceramic with a random porosity: Study of the fracture path with X-ray tomography. J. Eur. Ceram. Soc. 2016, 36, 3225–3233. [Google Scholar] [CrossRef]

- Ahn, M.-K.; Moon, Y.-W.; Maeng, W.-Y.; Koh, Y.-H.; Kim, H.-E. Calcium phosphate ceramics with continuously gradient macrochannels using three-dimensional extrusion of bilayered ceramic-camphene mixture/pure camphene feedrod. Ceram. Int. 2016, 42, 15603–15609. [Google Scholar] [CrossRef]

- Castillo, M.; Moore, J.J.; Schowengerdt, F.D.; Ayers, R.A.; Zhang, X.; Umakoshi, M.; Yi, H.C.; Guigne, J.Y. Effects of gravity on combustion synthesis of functionally graded biomaterials. Adv. Space Res. 2003, 32, 265–270. [Google Scholar] [CrossRef]

- Tampieri, A. Porosity-graded hydroxyapatite ceramics to replace natural bone. Biomaterials 2001, 22, 1365–1370. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempel, U.; Scharnweber, D.; Schulte, K. Functionally graded materials for biomedical applications. Mater. Sci. Eng. A 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Maca, K.; Dobsak, P.; Boccaccini, A. Fabrication of graded porous ceramics using alumina–carbon powder mixtures. Ceram. Int. 2001, 27, 577–584. [Google Scholar] [CrossRef]

- Ceron-Nicolat, B.; Wolff, F.; Dakkouri-Baldauf, A.; Fey, T.; Münstedt, H.; Greil, P. Graded Cellular Ceramics from Continuous Foam Extrusion. Adv. Eng. Mater. 2012, 14, 1097–1103. [Google Scholar] [CrossRef]

- Sobhani, S.; Allan, S.; Muhunthan, P.; Boigne, E.; Ihme, M. Additive Manufacturing of Tailored Macroporous Ceramic Structures for High-Temperature Applications. Adv. Eng. Mater. 2020, 22, 2000158. [Google Scholar] [CrossRef]

- Vijayavenkataraman, S.; Kuan, L.Y.; Lu, W.F. 3D-printed ceramic triply periodic minimal surface structures for design of functionally graded bone implants. Mater. Des. 2020, 191, 108602. [Google Scholar] [CrossRef]

- Zeschky, J.; Höfner, T.; Arnold, C.; Weißmann, R.; Bahloul-Hourlier, D.; Scheffler, M.; Greil, P. Polysilsesquioxane derived ceramic foams with gradient porosity. Acta Mater. 2005, 53, 927–937. [Google Scholar] [CrossRef]

- Lee, H.; Jang, T.-S.; Song, J.; Kim, H.-E.; Jung, H.-D. The Production of Porous Hydroxyapatite Scaffolds with Graded Porosity by Sequential Freeze-Casting. Materials 2017, 10, 367. [Google Scholar] [CrossRef]

- Lindner, M.; Bergmann, C.; Telle, R.; Fischer, H. Calcium phosphate scaffolds mimicking the gradient architecture of native long bones. J. Biomed. Mater. Res. A 2014, 102, 3677–3684. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, Q.; Wan, C. Preparation and evaluation of a biomimetic scaffold with porosity gradients in vitro. An. Acad. Bras. Cienc. 2012, 84, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Werner, J.; Linner-Krčmar, B.; Friess, W.; Greil, P. Mechanical properties and in vitro cell compatibility of hydroxyapatite ceramics with graded pore structure. Biomaterials 2002, 23, 4285–4294. [Google Scholar] [CrossRef]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Miao, X.; Sun, D. Graded/Gradient Porous Biomaterials. Materials 2010, 3, 26–47. [Google Scholar] [CrossRef] [Green Version]

- Petit, C.; Montanaro, L.; Palmero, P. Functionally graded ceramics for biomedical application: Concept, manufacturing, and properties. Int. J. Appl. Ceram. Technol. 2018, 15, 820–840. [Google Scholar] [CrossRef]

- Topateş, G. Al2O3 Ceramics with Graded Porosity Produced from Natural and Artificial Pore Formers. Politek. Derg. 2017, 22, 595–598. [Google Scholar] [CrossRef]

- Xu, C.; Liu, H.; Yang, H.; Yang, L. A Green Biocompatible Fabrication of Highly Porous Functional Ceramics with High Strength and Controllable Pore Structures. J. Mater. Sci. Technol. 2016, 32, 729–732. [Google Scholar] [CrossRef]

- Hong, C.; Du, J.; Liang, J.; Zhang, X.; Han, J. Functionally graded porous ceramics with dense surface layer produced by freeze-casting. Ceram. Int. 2011, 37, 3717–3722. [Google Scholar] [CrossRef]

- Garcia-Tunon, E.; Barg, S.; Bell, R.; Weaver, J.V.M.; Walter, C.; Goyos, L.; Saiz, E. Designing smart particles for the assembly of complex macroscopic structures. Angew. Chem. Int. Ed. Engl. 2013, 52, 7805–7808. [Google Scholar] [CrossRef] [PubMed]

- García-Tuñón, E.; Machado, G.C.; Schneider, M.; Barg, S.; Bell, R.V.; Saiz, E. Complex ceramic architectures by directed assembly of ‘responsive’ particles. J. Eur. Ceram. Soc. 2017, 37, 199–211. [Google Scholar] [CrossRef]

- Scheithauer, U.; Kerber, F.; Füssel, A.; Holtzhausen, S.; Beckert, W.; Schwarzer, E.; Weingarten, S.; Michaelis, A. Alternative Process Routes to Manufacture Porous Ceramics-Opportunities and Challenges. Materials 2019, 12, 663. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Capasso, I.; Liguori, B.; Verdolotti, L.; Caputo, D.; Lavorgna, M.; Tervoort, E. Process strategy to fabricate a hierarchical porosity gradient in diatomite-based foams by 3D printing. Sci. Rep. 2020, 10, 612. [Google Scholar] [CrossRef]

- Hsu, Y.H.; Turner, I.G.; Miles, A.W. Fabrication of porous bioceramics with porosity gradients similar to the bimodal structure of cortical and cancellous bone. J. Mater. Sci. Mater. Med. 2007, 18, 2251–2256. [Google Scholar] [CrossRef] [PubMed]

- Biggemann, J.; Müller, P.; Köllner, D.; Simon, S.; Hoffmann, P.; Heik, P.; Lee, J.H.; Fey, T. Hierarchical Surface Texturing of Hydroxyapatite Ceramics: Influence on the Adhesive Bonding Strength of Polymeric Polycaprolactone. J. Funct. Biomater. 2020, 11, 73. [Google Scholar] [CrossRef]

- Biggemann, J.; Diepold, B.; Pezoldt, M.; Stumpf, M.; Greil, P.; Fey, T. Automated 3D assembly of periodic alumina-epoxy composite structures. J. Am. Ceram. Soc. 2018, 101, 3864–3873. [Google Scholar] [CrossRef]

- Biggemann, J.; Hoffmann, P.; Hristov, I.; Simon, S.; Müller, P.; Fey, T. Injection Molding of 3-3 Hydroxyapatite Composites. Materials 2020, 13, 1907. [Google Scholar] [CrossRef] [Green Version]

- European Commitee of Standardization. Advanced Technical Ceramics; Monolithic Ceramics; General and Textural Properties; Part 2: Determination of Density and Porosity; German Version DIN EN 623-2:1993-11; Beuth Verlag GmbH: Berlin, Germany, 1993. [Google Scholar]

- European Commitee of Standardization. Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 2: Determination of Young’s Modulus, Shear Modulus and Poisson’s Ratio; German Version EN 843-2:2006; Beuth Verlag GmbH: Berlin, Germany, 2006. [Google Scholar]

- European Commitee of Standardization. Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 1: Determination of Flexural Strength; German Version EN 843-1:2006; Beuth Verlag GmbH: Berlin, Germany, 2006. [Google Scholar]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Ohji, T.; Fukushima, M. Macro-porous ceramics: Processing and properties. Int. Mater. Rev. 2012, 57, 115–131. [Google Scholar] [CrossRef]

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing Routes to Macroporous Ceramics: A Review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Vakifahmetoglu, C.; Semerci, T.; Soraru, G.D. Closed porosity ceramics and glasses. J. Am. Ceram. Soc. 2020, 103, 2941–2969. [Google Scholar] [CrossRef]

- Phani, K.K.; Niyogi, S.K. Young’s modulus of porous brittle solids. J. Mater. Sci. 1987, 22, 257–263. [Google Scholar] [CrossRef]

- Andersson, C.A. Derivation of the Exponential Relation for the Effect of Ellipsoidal Porosity on Elastic Modulus. J. Am. Ceram. Soc. 1996, 79, 2181–2184. [Google Scholar] [CrossRef]

- Pabst, W.; Gregorová, E. Young’s modulus of isotropic porous materials with spheroidal pores. J. Eur. Ceram. Soc. 2014, 34, 3195–3207. [Google Scholar] [CrossRef]

- Travitzky, N.; Windsheimer, H.; Fey, T.; Greil, P. Preceramic Paper-Derived Ceramics. J. Am. Ceram. Soc. 2008, 91, 3477–3492. [Google Scholar] [CrossRef]

- Louet, N.; Gonon, M.; Fantozzi, G. Influence of the amount of Na2O and SiO2 on the sintering behavior and on the microstructural evolution of a Bayer alumina powder. Ceram. Int. 2005, 31, 981–987. [Google Scholar] [CrossRef]

- Barros, M.D.; Rachadel, P.L.; Fredel, M.C.; Janssen, R.; Hotza, D. Mechanical Behaviour of Zirconia-Toughened Alumina Laminates with or without Y-PSZ Intermediate Layers. J. Ceram. Sci. Technol. 2017, 9, 69–78. [Google Scholar] [CrossRef]

- Akao, M.; Aoki, H.; Kato, K. Mechanical properties of sintered hydroxyapatite for prosthetic applications. J. Mater. Sci. 1981, 16, 809–812. [Google Scholar] [CrossRef]

- Orlovskii, V.P.; Komlev, V.S.; Barinov, S.M. Hydroxyapatite and Hydroxyapatite-Based Ceramics. Inorg. Mater. 2002, 38, 973–984. [Google Scholar] [CrossRef]

- Zaidi, M.; Joshi, K.K.; Shukla, A.; Cherinet, B. (Eds.) A review of the various modelling schemes of unidirectional functionally graded material structures; AIP Publishing: Jamshedpur, India, 2021. [Google Scholar]

- Daikh, A.A.; Zenkour, A.M. Effect of porosity on the bending analysis of various functionally graded sandwich plates. Mater. Res. Express 2019, 6, 65703. [Google Scholar] [CrossRef]

- Mota, A.F.; Loja, M.A.R. Mechanical Behavior of Porous Functionally Graded Nanocomposite Materials. C 2019, 5, 34. [Google Scholar] [CrossRef] [Green Version]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Z. Angew. Math. Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Voigt, W. Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. Phys. 1889, 274, 573–587. [Google Scholar] [CrossRef] [Green Version]

- Ridzwan, M.; Shuib, S.; Hassan, A.Y.; Shokri, A.A.; Ibrahim, M.N. Problem of Stress Shielding and Improvement to the Hip Implant Designs: A Review. J. Med Sci. 2007, 7, 460–467. [Google Scholar] [CrossRef] [Green Version]

- Greil, P. Advanced Engineering Ceramics. Adv. Mater. 2002, 14, 709. [Google Scholar] [CrossRef]

- Leguillon, D.; Tariolle, S.; Martin, E.; Chartier, T.; Besson, J.L. Prediction of crack deflection in porous/dense ceramic laminates. J. Eur. Ceram. Soc. 2006, 26, 343–349. [Google Scholar] [CrossRef]

- Reynaud, C.; Thévenot, F.; Chartier, T.; Besson, J.-L. Mechanical properties and mechanical behaviour of SiC dense-porous laminates. J. Eur. Ceram. Soc. 2005, 25, 589–597. [Google Scholar] [CrossRef]

- Davis, J.B.; Kristoffersson, A.; Carlström, E.; Clegg, W.J. Fabrication and Crack Deflection in Ceramic Laminates with Porous Interlayers. J. Am. Ceram. Soc. 2000, 83, 2369–2374. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Horsewell, A. Crack Growth along Interfaces in Porous Ceramic Layers. J. Am. Ceram. Soc. 2001, 84, 2051–2059. [Google Scholar] [CrossRef]

| Hydroxyapatite (HAp) | |||

| Homogeneous Porous Ceramics (from Ref. [36]) | |||

| Pore former Content/Vol% | Porosity (Φp)/Vol% | Young’s Modulus (E)/GPa | Flexural strength (σf)/MPa |

| 0 | 11.2 ± 1.0 | 97.3 ± 1.9 | 69.0 ± 10.9 |

| 10 | 16.3 ± 1.3 | 83.1 ± 3.9 | 51.1 ± 12.5 |

| 20 | 28.8 ± 1.7 | 57.0 ± 2.5 | 31.4 ± 5.6 |

| 30 | 36.8 ± 1.4 | 42.8 ± 3.1 | 18.1 ± 2.3 |

| 40 | 45.2 ± 0.9 | 29.1 ± 0.9 | 13.0 ± 3.0 |

| Phani model: | E0 = 131, b = 2.49 (R² = 0.999) | σ0 = 104, b = 3.69 (R² = 0.982) | |

| Porous Functional Graded Ceramics (porous FGCs, this work) | |||

| Porosity pairing/Texture Type | Porosity (Φp)/Vol% | Young’s Modulus (E)/GPa | Flexural strength (σf)/MPa |

| 0–30/Planar (A) | 23.3 ± 1.0 | 57.2 ± 3.0 | 17.9 ± 4.2 |

| 0–30/Waves (B) | 22.7 ± 1.3 | 58.7 ± 2.8 | 16.5 ± 1.8 |

| 0–30/Hills (C) | 22.7 ± 1.5 | 57.6 ± 3.9 | 17.5 ± 3.5 |

| Power-law (Equation (3)) | k = 0.47 (R² = 0.999) | ||

| Alumina (Al2O3) | |||

| Homogeneous Porous Ceramics (this work) | |||

| Pore former content/Vol% | Porosity (Φp)/Vol% | Young’s Modulus (E)/GPa | Flexural strength (σf)/MPa |

| 0 | 7.7 ± 1.3 | 357.3 ± 15.7 | 221.9 ± 45.1 |

| 10 | 18.6 ± 1.3 | 254.4 ± 10.8 | 155.5 ± 27.8 |

| 20 | 28.6 ± 0.9 | 187.1 ± 3.6 | 122.3 ± 25.8 |

| 30 | 37.7 ± 0.9 | 136.0 ± 9.6 | 86.5 ± 14.1 |

| 40 | 48.2 ± 1.1 | 93.0 ± 4.8 | 58.8 ± 11.1 |

| Phani model: | E0 = 415, b = 2.34 (R² = 0.995) | σ0 = 256, b = 2.27 (R² = 0.995) | |

| Porous Functional Graded Ceramics (Porous FGCs, this work) | |||

| Porosity Pairing /Texture Type | Porosity (Φp)/Vol% | Young’s Modulus (E)/GPa | Flexural Strength (σf)/MPa |

| 0–30/Planar (A) | 24.3 ± 2.3 | 196.2 ± 12.7 | 84.9 ± 20.7 |

| 0–30/Waves (B) | 23.8 ± 1.8 | 197.2 ± 8.9 | 80.3 ± 15.7 |

| 0–30/Hills (C) | 23.4 ± 0.9 | 193.4 ± 5.8 | 82.4 ± 25.2 |

| Power-law (Equation (3)) | k = 0.45 (R² = 0.999) | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biggemann, J.; Köllner, D.; Simon, S.; Heik, P.; Hoffmann, P.; Fey, T. Porous Functional Graded Bioceramics with Integrated Interface Textures. Ceramics 2021, 4, 681-695. https://doi.org/10.3390/ceramics4040048

Biggemann J, Köllner D, Simon S, Heik P, Hoffmann P, Fey T. Porous Functional Graded Bioceramics with Integrated Interface Textures. Ceramics. 2021; 4(4):681-695. https://doi.org/10.3390/ceramics4040048

Chicago/Turabian StyleBiggemann, Jonas, David Köllner, Swantje Simon, Paula Heik, Patrizia Hoffmann, and Tobias Fey. 2021. "Porous Functional Graded Bioceramics with Integrated Interface Textures" Ceramics 4, no. 4: 681-695. https://doi.org/10.3390/ceramics4040048

APA StyleBiggemann, J., Köllner, D., Simon, S., Heik, P., Hoffmann, P., & Fey, T. (2021). Porous Functional Graded Bioceramics with Integrated Interface Textures. Ceramics, 4(4), 681-695. https://doi.org/10.3390/ceramics4040048