Thermomechanical Characterization of SiC/SiC Ceramic Matrix Composites in a Combustion Facility

Abstract

:1. Introduction

2. Experimental Procedure

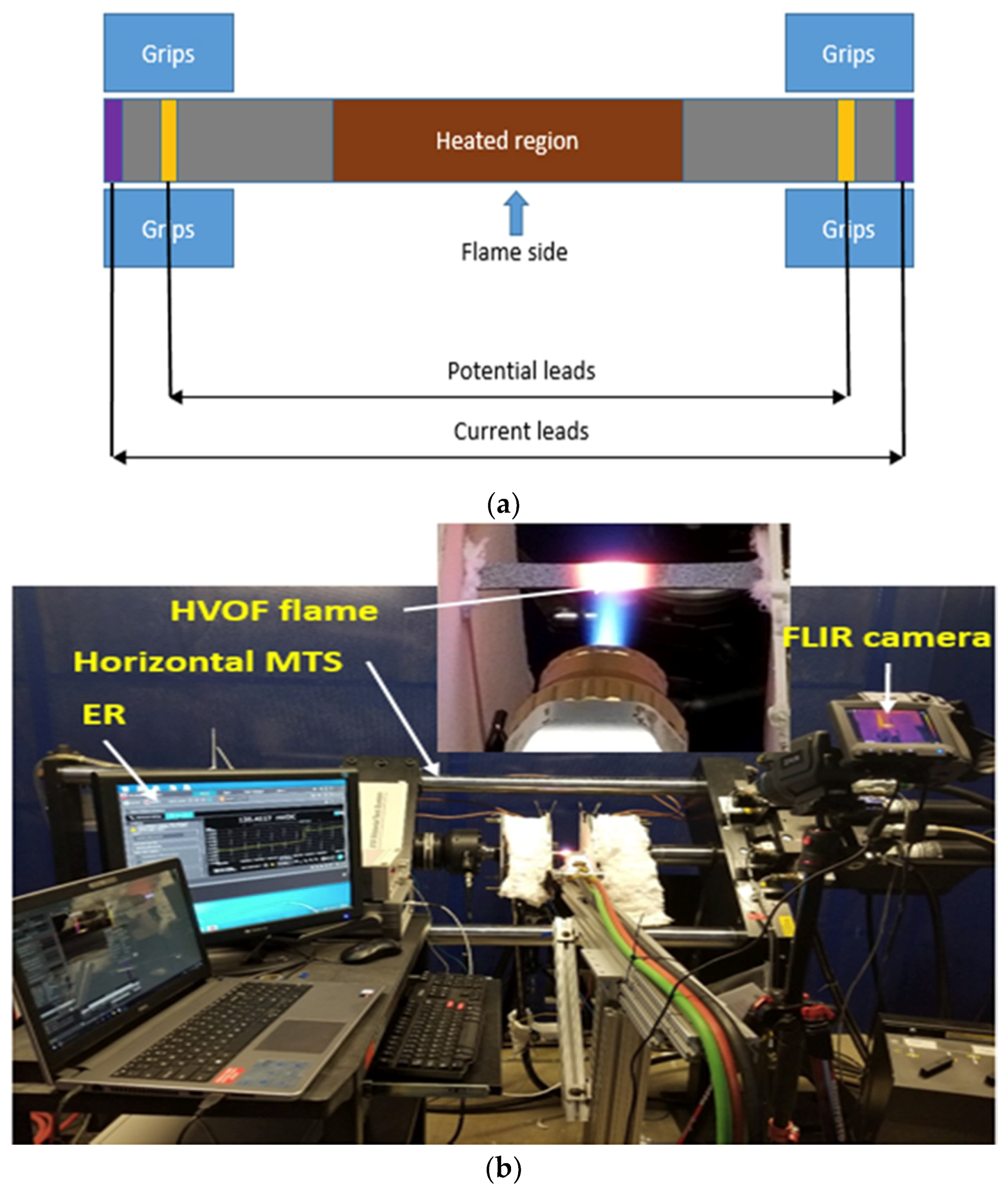

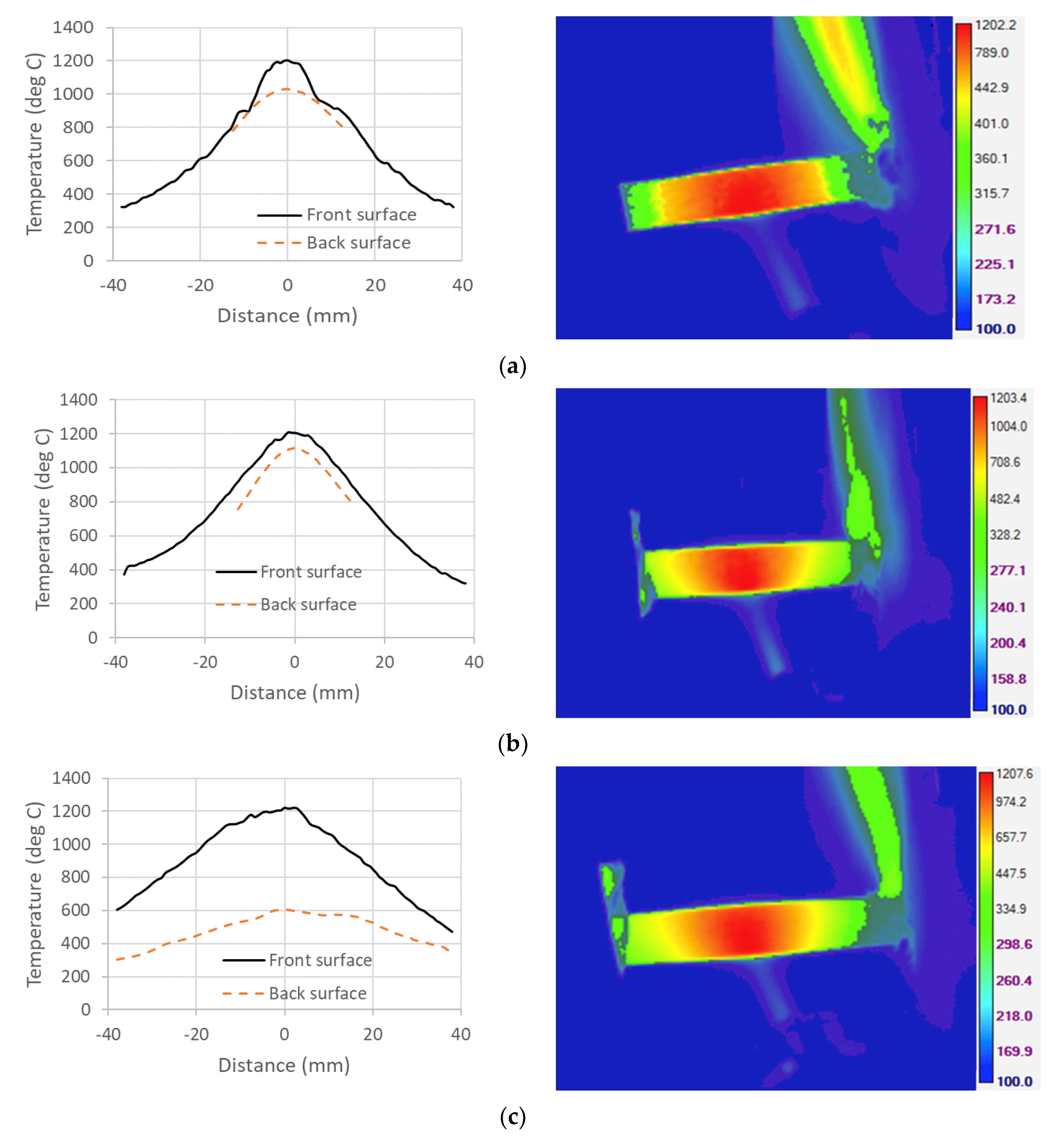

2.1. Burner Rig Facility

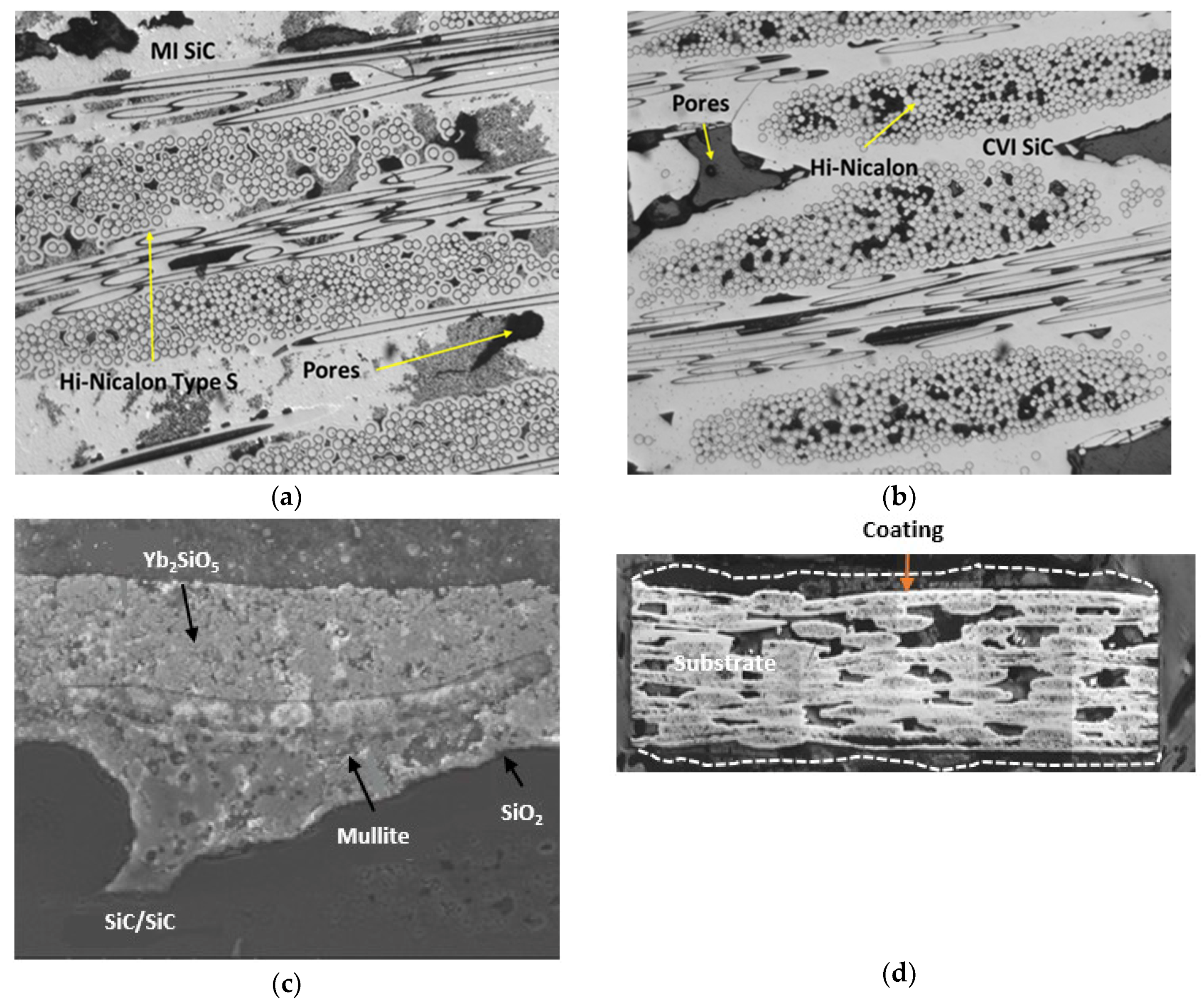

2.2. Materials Tested

2.3. Burner Rig Fatigue Test

2.4. Furnace Fatigue Test

3. Results and Discussion

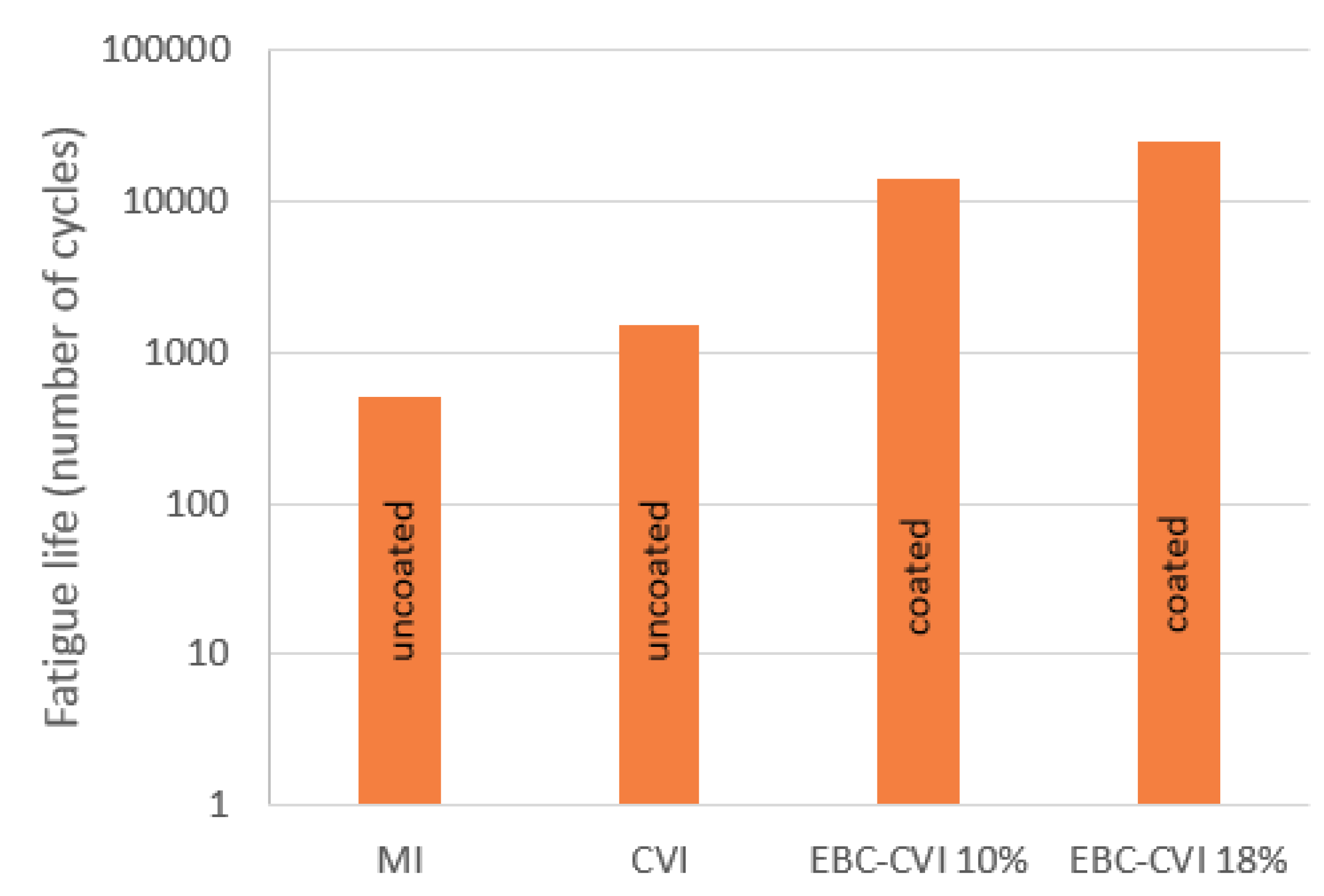

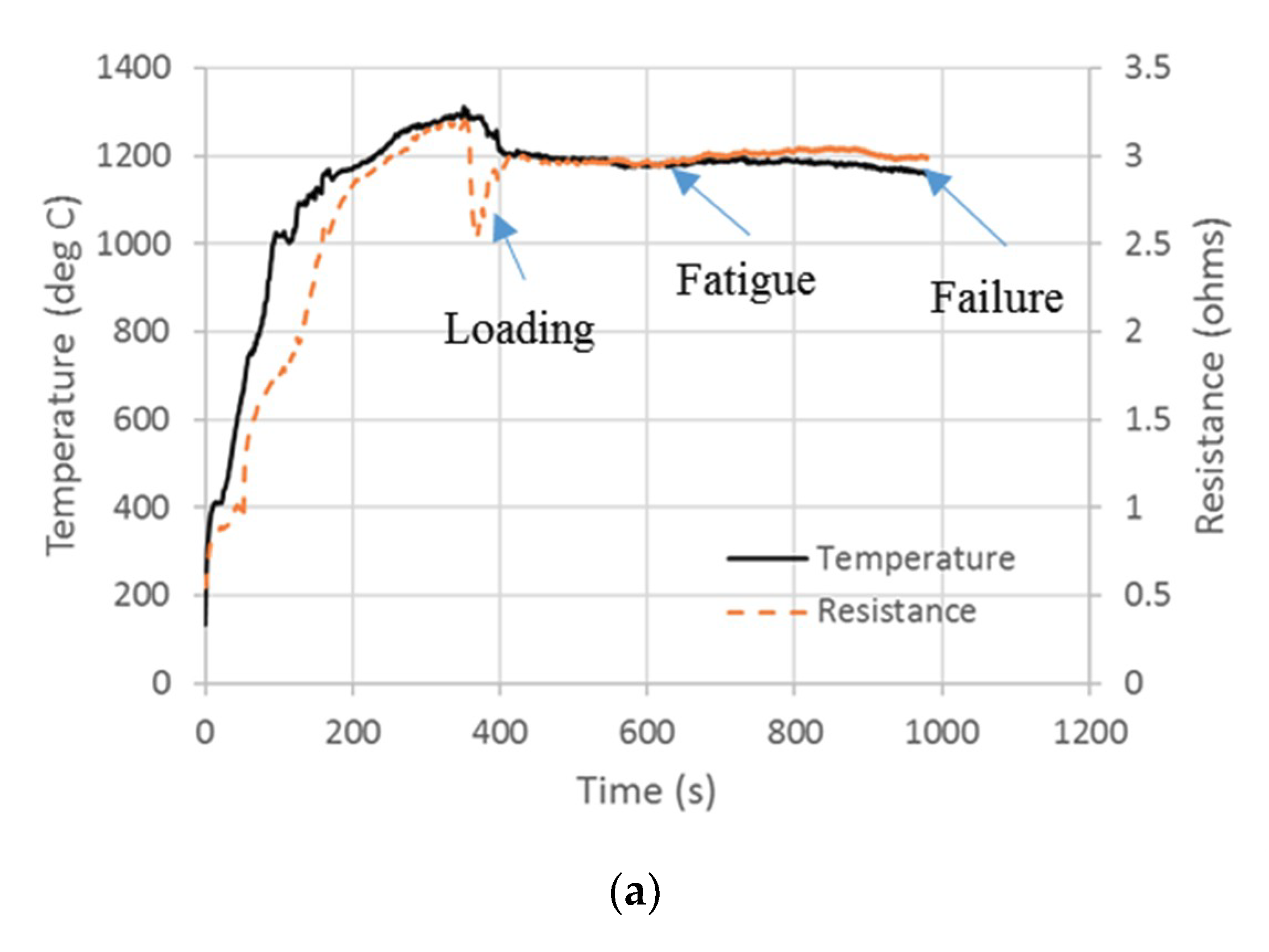

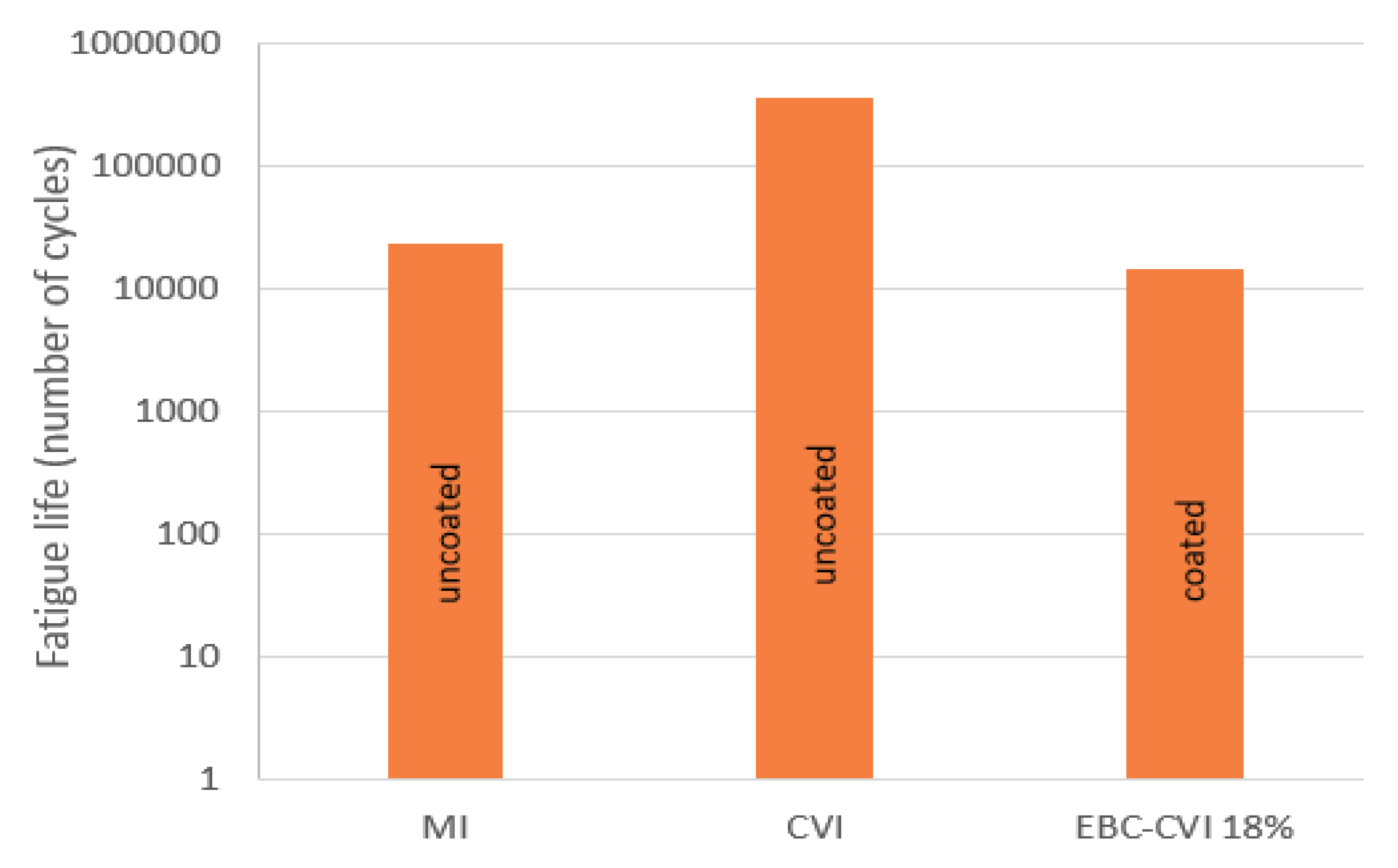

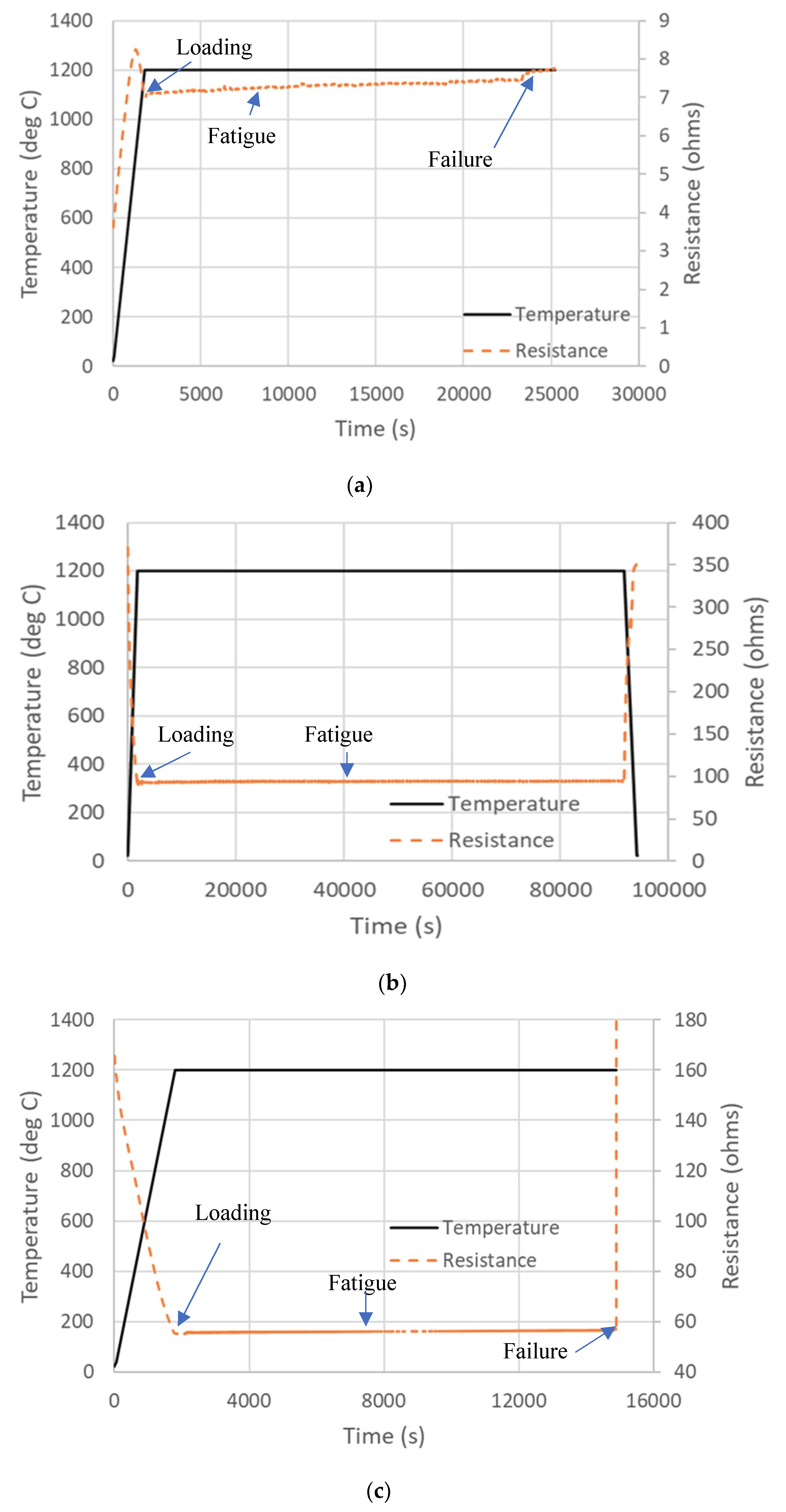

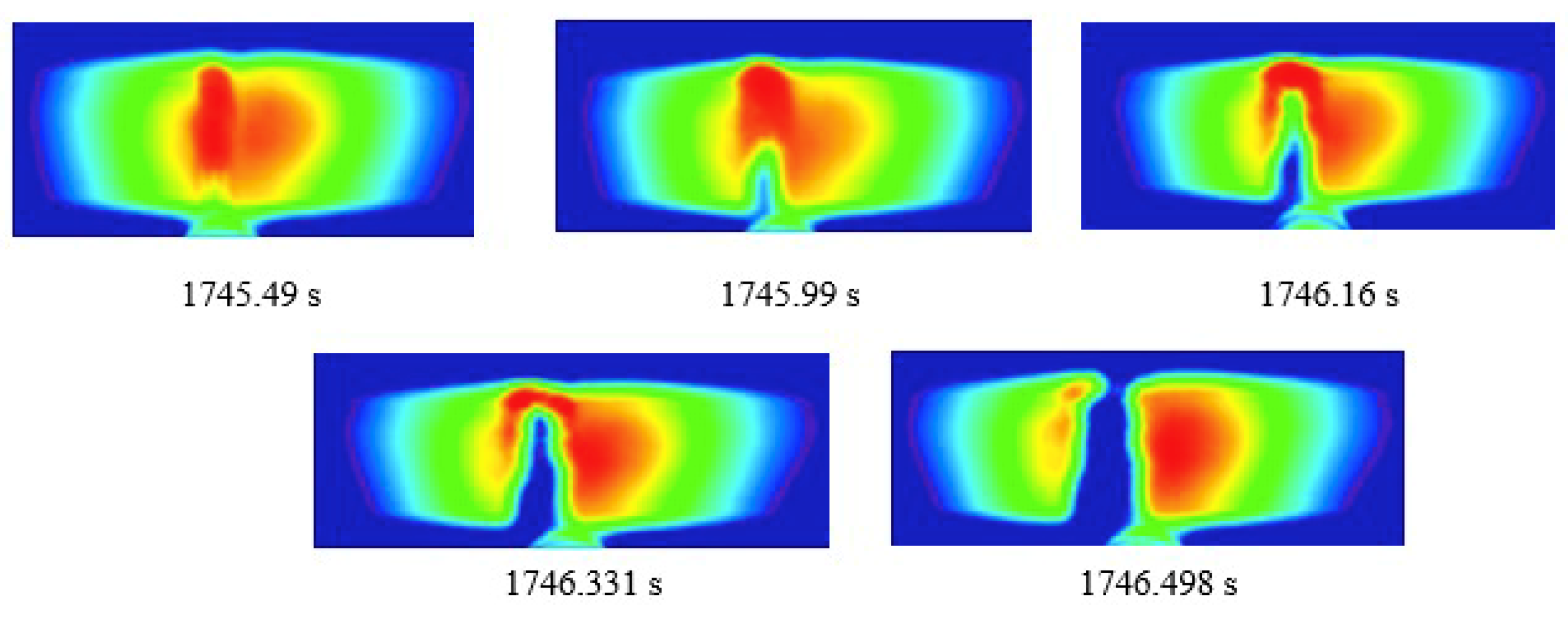

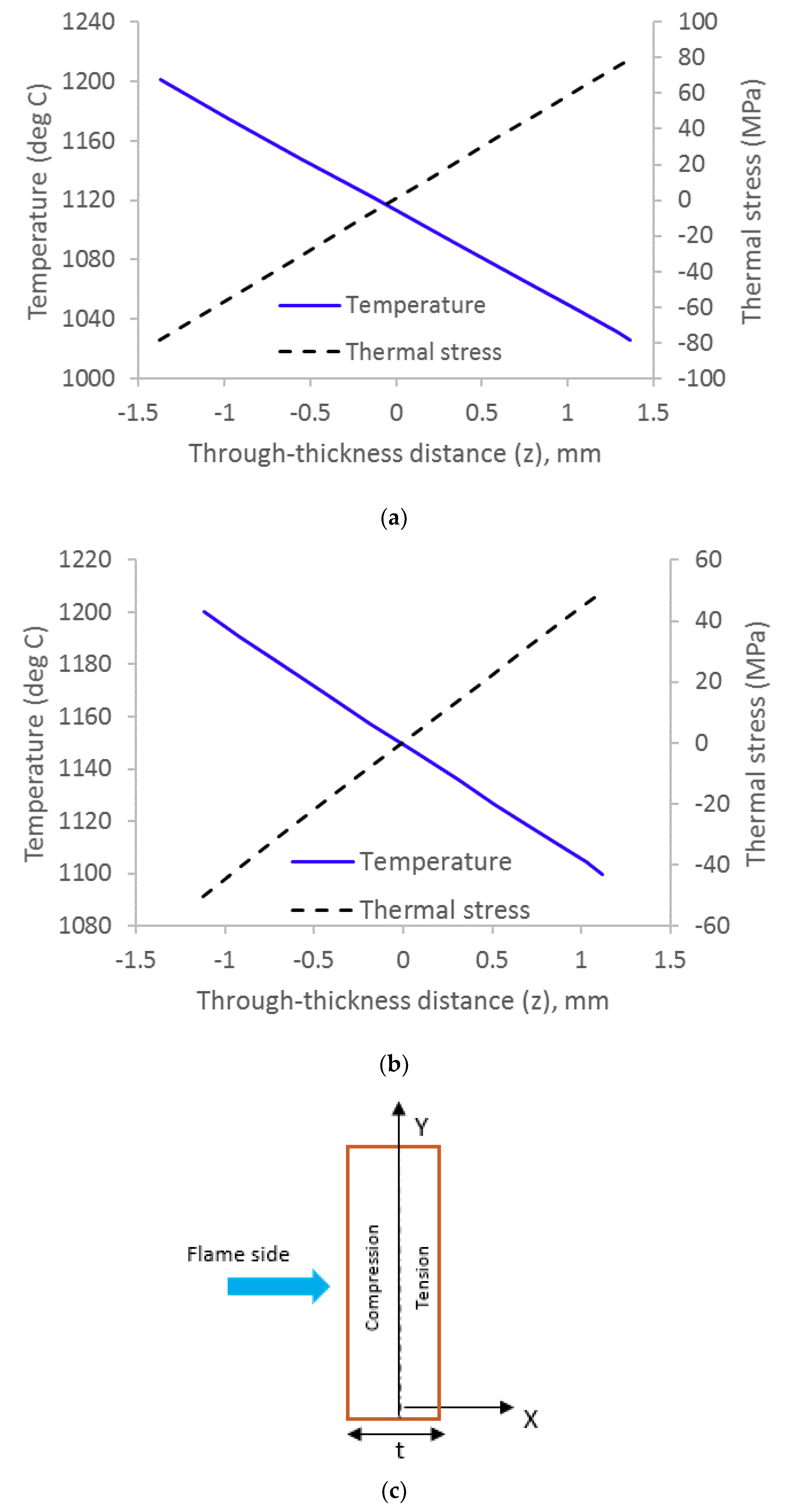

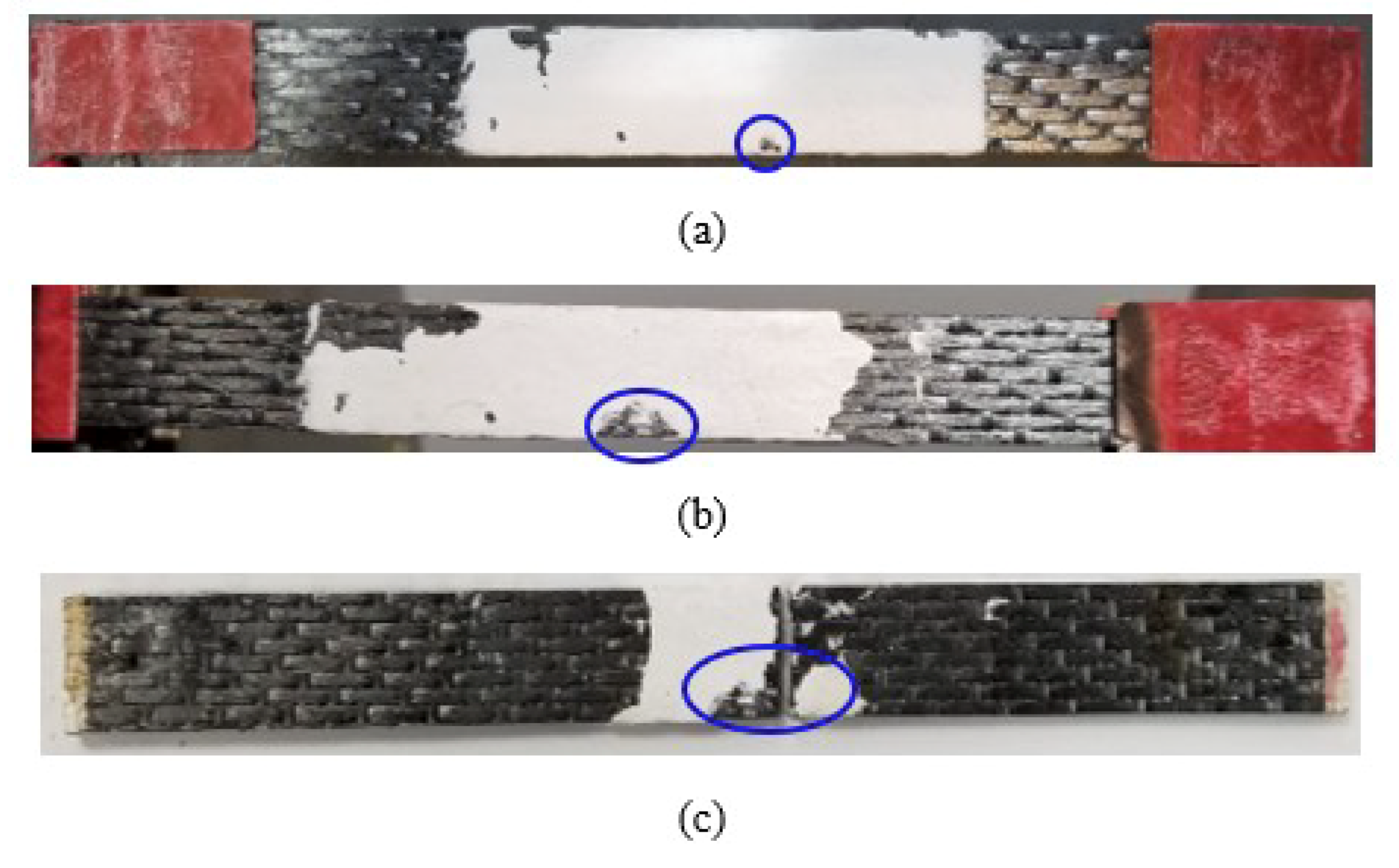

3.1. Burner Rig Fatigue Test Results

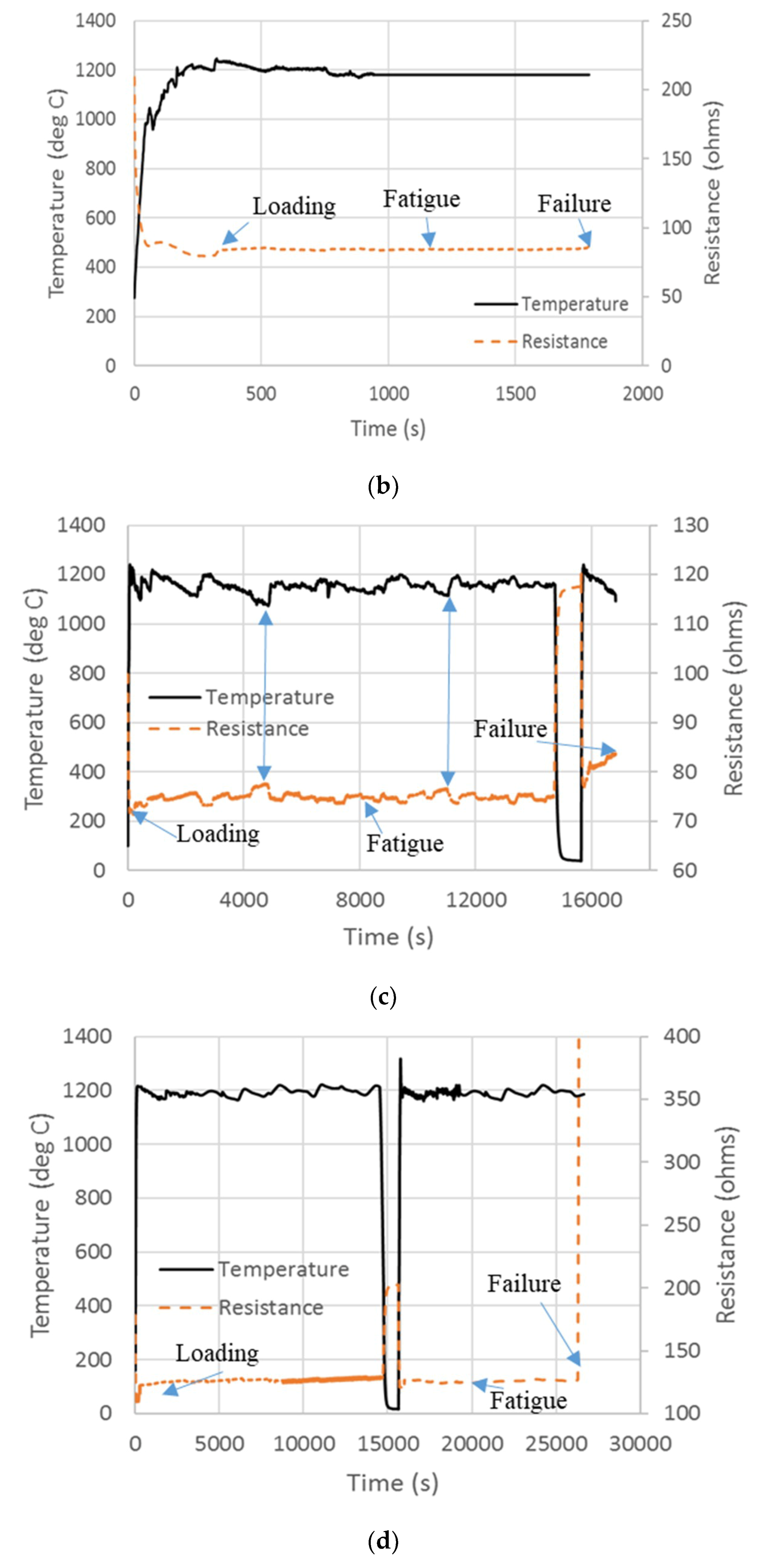

3.2. Furnace Testing

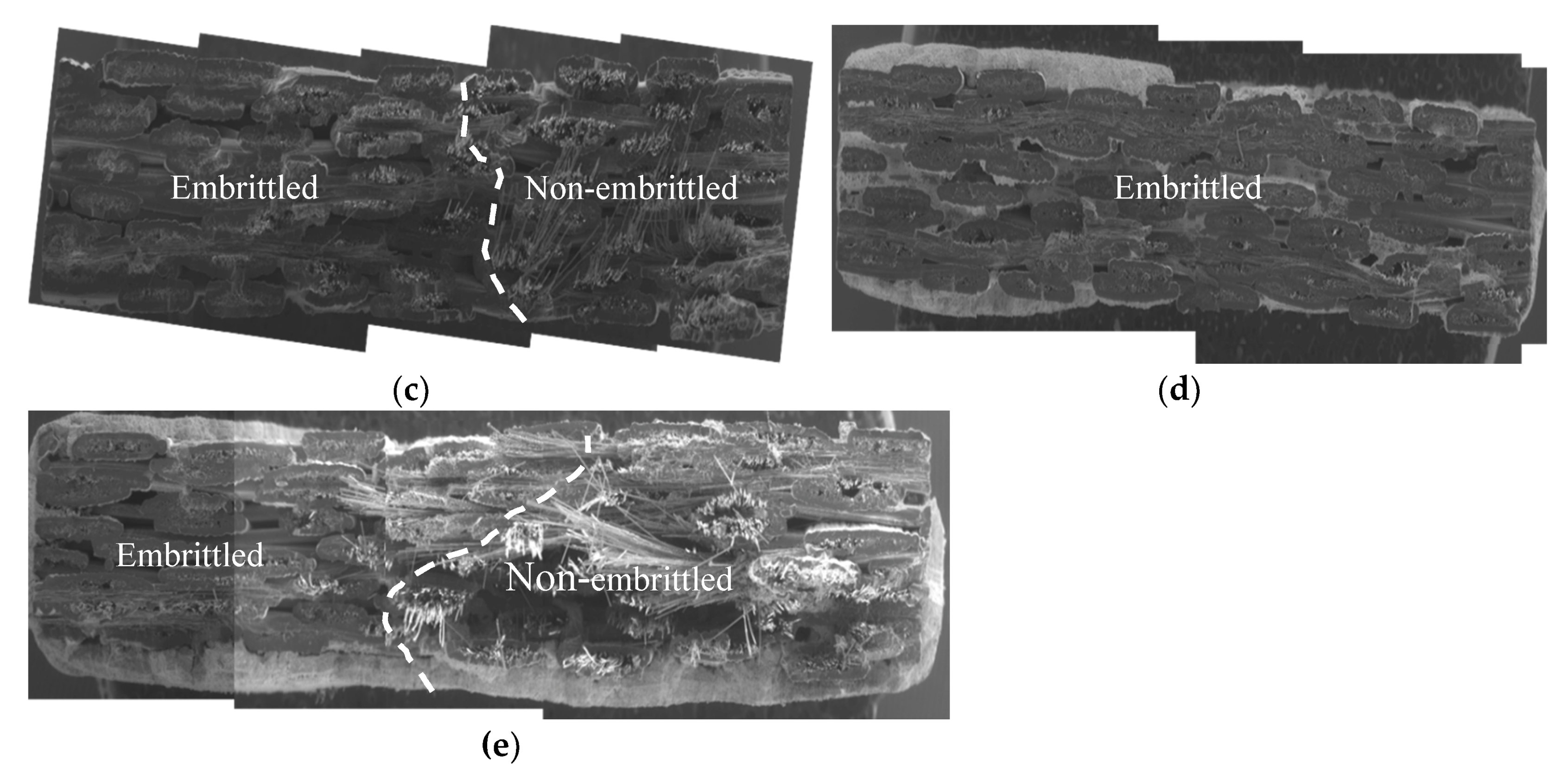

3.3. Microscopic Analysis

4. General Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brewer, D. HSR/EPM combustor materials development program. Mater. Sci. Eng. A 1999, 261, 284–291. [Google Scholar] [CrossRef]

- Lee, K.N.; Fox, D.S.; Bansal, N.P. Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. J. Eur. Ceram. Soc. 2005, 25, 1705–1715. [Google Scholar] [CrossRef]

- Bhatt, R.T.; Choi, S.R.; Cosgriff, L.M.; Fox, D.S.; Lee, K.N. Impact resistance of uncoated SiC/SiC composites. Mater. Sci. Eng. A 2008, 476, 20–28. [Google Scholar] [CrossRef]

- Opila, E.J.; Verrilli, M.J.; Robinson, R.C. Borosilicate Glass-Induced Fiber Degradation of SiC/BN/SiC Composites Exposed in Combustion Environments. Int. J. Appl. Ceram. Technol. 2016, 13, 434–442. [Google Scholar] [CrossRef]

- Zhu, D.; Choi, S.R.; Eldridge, J.I.; Lee, K.N.; Miller, R.A. Surface Cracking and Interface Reaction Associated Delamination Failure of Thermal and Environmental Barrier Coatings; NASA Technical Report; NASA: Washington, DC, USA, 2013.

- Lee, K.N. Key Durability Issues with Mullite-Based Environmental Barrier Coatings for Si-Based Ceramics. Gas Turbine Power 2000, 122, 632–636. [Google Scholar] [CrossRef]

- Zhu, D.; Lee, K.N.; Miller, R.A. Thermal gradient cyclic behavior of a thermal/environmental barrier coating system on sic/sic ceramic matrix composites. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Morscher, G.N. Tensile creep and rupture of 2D-woven SiC/SiC composites for high temperature applications. J. Eur. Ceram. Soc. 2010, 30, 2209–2221. [Google Scholar] [CrossRef]

- Morscher, G.N.; Ojard, G.; Miller, R.; Gowayed, Y.; Santhosh, U.; Ahmed, J.; John, R. Tensile creep and fatigue of Sylramic-iBN melt-infiltrated SiC matrix composites: Retained properties, damage development, and failure mechanisms. Compos. Sci. Technol. 2008, 16, 3305–3313. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.B.; Christensena, D.T.; Chamberlain, A.L.; Lane, J.E.; Cook, T.S. Effect of frequency and environment on fatigue behavior of a CVI SiC/SiC ceramic matrix composite at 1200 °C. Compos. Sci. Technol. 2011, 71, 190–196. [Google Scholar] [CrossRef]

- Kim, T.T.; Mall, S.; Zawada, L.P. Fatigue characterization of a melt infiltrated woven Hi-NiC-S/BN/SiC ceramic matrix composite using a unique combustion facility. Ceram. Trans. 2009, 179, 103–116. [Google Scholar]

- Kim, T.T.; Mall, S.; Zawada, L.P.; Jefferson, G. Simultaneous fatigue and combustion exposure of SiC/SiC ceramic matrix composite. J. Compos. Mater. 2011, 44, 2991–3016. [Google Scholar] [CrossRef]

- Sabelkin, V.; Mall, S.; Cook, T.S.; Fish, J. Fatigue and creep behaviors of a SiC/SiC composite under combustion and laboratory environments. J. Compos. Mater. 2016, 50, 2145–2153. [Google Scholar] [CrossRef]

- Linus, U.J.T.O. A pervasive mode of oxidative degradation in a SiC-SiC composite. J. Am. Ceram. Soc 1999, 81, 2777–2784. [Google Scholar]

- Appleby, M.P.; Zhu, D.; Morscher, G.N. Mechanical properties and real-time damage evaluations of environmental barrier coated SiC/SiC CMCs subjected to tensile loading under thermal gradients. Surf. Coat. Technol. 2015, 284, 318–326. [Google Scholar] [CrossRef] [Green Version]

- Smith, C.E.; Morscher, G.N.; Xia, Z. Electrical resistance as a nondestructive Evaluation Technique for SiC/SiC Ceramic Matrix Composites under Creep-Rupture Loading. Int. J. Appl. Ceram. Technol. 2011, 8, 298–307. [Google Scholar] [CrossRef]

- Morscher, G.N.; Baker, C.; Smith, C. Electrical Resistance of SiC Fiber Reinforced SiC/SiC Matrix Composites at Room Temperature during Tensile Testing. Int. J. Appl. Ceram. Technol. 2014, 11, 263–272. [Google Scholar] [CrossRef]

- Morscher, G.N.; Pujar, V.V. Melt-Infiltrated SIC composites for gas turbine engine applications. In Proceedings of the ASME Turbo Expo Land, Sea and Air 2004, Vienna, Austria, 14–17 June 2004. [Google Scholar]

- Zhou, J.; Chase, G.G.; Almansour, A.; Morscher, G.N.; Harder, B.; Fox, D. EBC Slurry Infiltrated Matrix/Coatings for Woven SiC/SiC Composites. Ceram. Eng. Sci. Proc. 2018, 38, 137–145. [Google Scholar]

- Smith, C.E. Monitoring Damage Accumulation in SiC/SiC Ceramic Matrix Composites Using Electrical Resistance. Master’s Thesis, The University of Akron, Akron, OH, USA, 2009. [Google Scholar]

- Smith, C.E.; Morscher, G.N.; Xia, Z.H. Monitoring damage accumulation in ceramic matrix composites using electrical resistivity. Scr. Mater. 2008, 59, 463–466. [Google Scholar] [CrossRef] [Green Version]

- Morscher, G.N.; Smith, C.E.; Maillet, E.; Baker, C.; Mansour, R. Electrical resistance monitoring of damage and crack growth in advanced SiC-based ceramic composites. Am. Ceram. Soc. Bull. 2014, 93, 28–31. [Google Scholar]

- Smith, C.E. Electrical Resistance Changes of Melt Infiltrated Sic/Sic Subject to Long-Term Tensile Loading at Elevated Temperatures. Ph.D. Thesis, The University of Akron, Akron, OH, USA, 2016. [Google Scholar]

- Available online: http://www.coiceramics.com/nicalonfiber.html (accessed on 9 June 2019).

- Smith, C.E.; Xia, Z.; Morscher, G.N. Electrical Resistance of SiC/SiC Ceramic Matrix Composites for Damage Detection and Life-Prediction; BiblioGov: Washington, DC, USA, 2019. [Google Scholar]

- Yun, H.M.; DiCarlo, J.A.; Ogbuji, L.T.; Chen, Y.L. Tensile Behavior of As-Fabricated and Burner Rig Exposed SiC/SiC Composites with Hi-Nicalon Type-S Fibers. Ceram. Eng. Sci. Proc. 2002, 23. [Google Scholar] [CrossRef]

- Takeda, M.; Urano, A.; Sakamoto, J.; Imai, Y. Microstructure and oxidative degradation behavior of silicon carbide fiber Hi-Nicalon type S. J. Nucl. Mater. 1998, 258, 1594–1599. [Google Scholar] [CrossRef]

- Yun, H.M.; Goldsby, J.C.; DiCarlo, J.A. Effects of Thermal Treatment on Tensile Creep and Stress-Rupture Behavior of Hi-Nicalon SiC Fibers. Ceram. Eng. Sci. Proc. 2008, 16, 987–996. [Google Scholar]

- Yun, H.M.; DiCarlo, J.A. Thermomechanical Behavior of Advanced SiC Fiber Multifilament Tows. In Proceedings of the 20th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures, Cocoa Beach, FL, USA, 7–11 January 1996. [Google Scholar]

- Ruggles-Wrenn, M.; Boucher, N.; Przybyla, C. Fatigue of three advanced SiC/SiC ceramic matrix composites at 1200 °C in air and in steam. Int. J. Appl. Ceram. Technol. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Morscher, G.N.; Hurst, J.; Brewer, D. Intermediate-temperature stress rupture of a woven Hi-Nicalon, BN-interphase, SiC-matrix composite in air. J. Am. Ceram. Soc. 2000, 83, 1441–1449. [Google Scholar] [CrossRef]

- Appleby. High Temperature Damage Characterization of Ceramic Composites and Protective Coatings. Ph.D. Thesis, The University of Akron, Akron, OH, USA, 2016. [Google Scholar]

- Corman, G.S.; Luthra, K.L. Silicon melt-infiltrated ceramic composites (HiPerComp). In Handbook of Ceramics Composites; Bansal, N.P., Ed.; Kluwer Academic: New York, NY, USA, 2005; pp. 99–115. [Google Scholar]

- Lamon, J. Chemical Vapor Infiltrated SiC/SiC composites (CVI SiC/SiC). In Handbook of Ceramics Composites; Bansal, N.P., Ed.; Kluwer Academic: New York, NY, USA, 2005; pp. 55–76. [Google Scholar]

- Available online: https://www.grc.nasa.gov/www/CEAWeb/ (accessed on 9 June 2019).

- Opila, E.J.; Hann, R.E., Jr. Paralinear oxidation of CVD SiC in watervapor. J. Am. Ceram. Soc. 1997, 80, 197–205. [Google Scholar] [CrossRef]

| Material | Length (mm) | Average Width (mm) | Average Thickness (mm) | Porosity | Test Condition |

|---|---|---|---|---|---|

| MI | 152 | 10.74 ± 0.01 | 2.92 ± 0.01 | - | Furnace/burner rig |

| CVI | 152 | 12.74 ± 0.01 | 2.25 ± 0.04 | 10% | Furnace/burner rig |

| EBC-CVI | 152 | 13.03 | 2.59 | 10% | Burner rig |

| EBC-CVI | 152 | 13.09 ± 0.06 | 2.63 ± 0.04 | 18% | Furnace/burner rig |

| Specimen | Ultimate Tensile Strength (UTS) MPa | Modulus (E) GPa | 1 Proportional Limit MPa |

|---|---|---|---|

| MI | 263 | 219 | 123 |

| CVI 2 | - | 200 | 110 |

| Parameter | Condition |

|---|---|

| Stress | 100 MPa |

| Frequency | 1 Hz |

| Stress ratio | 0.1 |

| Temperature | 1200 °C |

| Specimen orientation | 45° |

| Velocity | ~650 m/s |

| 1 Equivalence ratio | ~0.83 |

| CMC Constituent | Electrical Resistivity (Ω-cm) |

|---|---|

| CVI SiC | 100–10,000 [17,23] |

| Si | 0.0001–1000 [17,23] |

| Hi-Nicalon | 3 [23,24] |

| Hi-Nicalon Type S | 0.1 [23] |

| Specimen | Room Temperature (RT) ER (Ω) | Resistivity (Ω-mm) | ER @ 1200 °C before Loading (Ω) | RT ER after 4H (Ω) | ER before Failure @ 1200 °C (Ω) |

|---|---|---|---|---|---|

| MI | 0.524 | 0.16 | 2.9 | - | 3.0 |

| CVI | 208 | 61.8 | 84 | - | 92 |

| CVI-EBC 10% | 114 | 34.1 | 74 | 121 | 83 |

| CVI-EBC 18% | 179 | 55.5 | 125 | 199 | 130 |

| Specimen | RT ER (Ω) | Resistivity (Ω-mm) | ER @ 1200 °C before Loading (Ω) | ER before Failure @ 1200 °C |

|---|---|---|---|---|

| MI | 3.6 | 1.07 | 7.1 | 7.77 |

| CVI | 370 | 79.99 | 92 | *NA |

| EBC-CVI 18% | 165 | 47.41 | 55 | 58 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panakarajupally, R.P.; Presby, M.J.; Manigandan, K.; Zhou, J.; Chase, G.G.; Morscher, G.N. Thermomechanical Characterization of SiC/SiC Ceramic Matrix Composites in a Combustion Facility. Ceramics 2019, 2, 407-425. https://doi.org/10.3390/ceramics2020032

Panakarajupally RP, Presby MJ, Manigandan K, Zhou J, Chase GG, Morscher GN. Thermomechanical Characterization of SiC/SiC Ceramic Matrix Composites in a Combustion Facility. Ceramics. 2019; 2(2):407-425. https://doi.org/10.3390/ceramics2020032

Chicago/Turabian StylePanakarajupally, Ragav P., Michael J. Presby, K. Manigandan, Jianyu Zhou, George G. Chase, and Gregory N. Morscher. 2019. "Thermomechanical Characterization of SiC/SiC Ceramic Matrix Composites in a Combustion Facility" Ceramics 2, no. 2: 407-425. https://doi.org/10.3390/ceramics2020032

APA StylePanakarajupally, R. P., Presby, M. J., Manigandan, K., Zhou, J., Chase, G. G., & Morscher, G. N. (2019). Thermomechanical Characterization of SiC/SiC Ceramic Matrix Composites in a Combustion Facility. Ceramics, 2(2), 407-425. https://doi.org/10.3390/ceramics2020032