1. Introduction

There is an increasing demand for reliable, adaptive, and decentralized control systems in new distributed renewable energy technologies. Among the most promising clean energy technologies is the fuel cell [

1,

2,

3,

4,

5,

6,

7], which directly converts chemical energy from hydrogen and oxygen into electrical energy through electrochemical reactions. The controller area network (CAN) bus is a serial communication protocol designed to facilitate reliable data exchange between electronic devices, particularly in automotive and industrial applications [

8,

9,

10,

11,

12]. Furthermore, the CAN protocol supports a transmission speed of up to 1 Mb/s, offering efficient bandwidth utilization along with built-in error checking and fault detection through Cyclic Redundancy Check (CRC) capabilities [

13,

14,

15,

16,

17]. Analysis of CAN bus signals is a crucial step in understanding the characteristics of this protocol-based communication. The CAN bus signals transmitted between two ESP32 controllers containing MCP2515 CAN modules were analyzed using a PC-based logic analyzer (LA) in the Zeroplus Studio V1.00.03 software package [

18,

19]. The monitoring and control system for stacked fuel cells employs one ESP32 module (“Write”) to transmit data triggered by an RFID switch, along with environmental information acquired from a DHT11 humidity and temperature sensor. Another ESP32 module (“Read”) receives the data, displays the results on an I2C-interfaced LCD screen, and controls actuators such as a cooling fan servo and an alert buzzer [

20,

21,

22,

23].

Mohammed, O.A.A. et al. [

24] developed an effective energy management strategy based on a model-free control method for regulating the DC-bus voltage in a hybrid fuel cell/battery/supercapacitor (FCHEV) electric vehicle system. Model-free technology is made very complicated by using this designed energy management strategy (EMS) featuring the Harr wavelet transform (HWT), an adaptive low-pass filter, and an interval type-2 fuzzy controller (IT2FC) for different power sources. It particularly requires a nonlinear disturbance observer (NDO) to overcome nonlinear problems through a novel adaptive model-free integral terminal sliding mode control (AMFITSMC) method.

This paper presents the simple design and implementation of a smart power output classification system that utilizes RFID-CAN-based access control to manage a bank of twenty individual 200 W fuel cell modules, yielding a total system output capacity of 4000 W (4 kW). With the aid of a decoding LA and the Zeroplus Studio software package, the CAN bus signals were analyzed to verify data integrity, timing accuracy, and the configured bit rate of 500 kbps.

2. Materials and Methods

In [

21], a similar concept featuring an integrated RFID interface for an enhanced CAN bus using an Arduino UNO microprocessor was presented; this paper presents 3D models of both the ESP32 controller containing an MCP2515 chip module—functioning as a commander node in the CAN bus system that transmits instructions from an RFID reader to control sensors—and the CAN bus slave node designed to drive the fan motor, warning buzzer, and LED indicators. These slave nodes represent individual fuel cell modules, each operating as an independent power generator in response to remote monitoring and control commands.

2.1. Tools and Materials for the Architecture of 20 Stacked Fuel Cells

The aim of this study is to develop control and monitoring functions for a fuel cell stack using the FC140-20 model (rated power: 200 W based on a CAN bus architecture that enables flexible and remote operation). In CAN bus-based systems, each node can independently send and receive data. The protocol employs a priority-based arbitration mechanism that ensures high-priority messages are transmitted first without disrupting other communications. Its reliability is further enhanced by built-in error detection methods such as Cyclic Redundancy Checking (CRC) and acknowledgment (ACK). A bill of materials (BOM), shown in

Table 1, lists the components that ensure the CAN bus’s suitability for critical applications in stacked fuel cell systems.

2.2. Control System Designed and Processing Method

The system employs two ESP32 NodeMCU boards to form a master–slave architecture. The master node collects data on temperature, pressure, and voltage and from RFID sensors; performs logic checks (e.g., overheat conditions, voltage drops, UID verification); and transmits control commands to the slave node via the CAN bus using a structured payload. The slave node continuously receives incoming CAN message frames, decodes them, and operates hardware actuators based on the received instructions. It also measures current using an AD8420 instrumentation amplifier in conjunction with a shunt resistor and supports feedback monitoring.

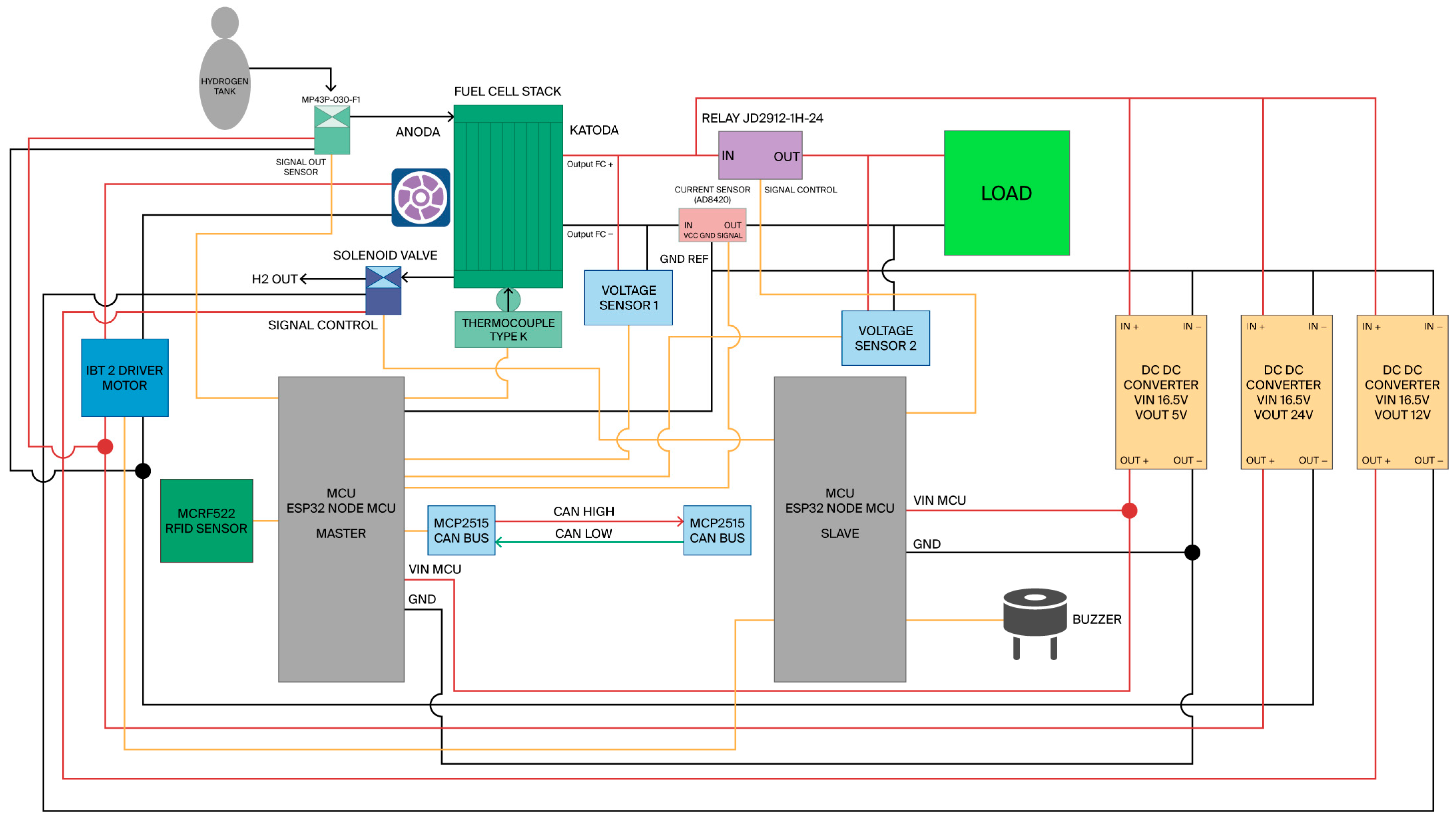

Replacing traditional control systems with multi-sensor monitoring technologies in fuel cell energy systems is the core focus of this study, driven by the demand for advanced networking techniques. As illustrated in

Figure 1, the proposed system incorporates multi-sensing communication strategies to integrate various electrical generation units within the fuel cell system [

21]. The CAN bus architecture manages and monitors fuel cell modules from the second (#2) to the twentieth (#20) unit, each equipped with an RFID sensor. These sensors detect two operational states: Lock (locked/active) and Unlock (unlocked/inactive). Based on the detected status, each node regulates its corresponding fuel cell via relay control. Communication is established using serial transmission via the CAN bus (MCP2515), through which RFID signals from the master controller (#1) are delivered to each fuel cell node (#2 to #20), ensuring coordinated and efficient system-wide operation. Each controlled unit—from the 2nd to the 20th fuel cell (represented as green circles)—functions as an actuator that receives RFID-based commands from the master unit (1st) via the CAN bus system. These nodes operate relay devices according to the received instructions. Additionally, each node transmits its operational parameters back to the master controller, enabling real-time monitoring and management, as illustrated in

Figure 2.

3. Results

Another aim of the analysis was to examine the transmitted data to identify communication patterns. During digital signal monitoring, transmission errors or anomalies were detected in some of the sent data. Nevertheless, the results demonstrate that the analyzed CAN bus signals exhibited a high degree of consistency in data transmission, fully adhering to the specified protocol. This study provides in-depth insights into the performance of CAN bus communication and its advantages in microcontroller-based systems.

3.1. System Workflow

The workflow of this distributed control system is structured around a clearly defined master–slave model, in which each ESP32 NodeMCU module is assigned a specific role. The system operates through a real-time communication network over a CAN bus utilizing MCP2515 transceivers. The system’s operation is divided as follows.

3.1.1. Sensor Data Acquisition (Master Node)

The master ESP32 is responsible for acquiring all critical data from both the environment and the fuel cell system performs the following functions:

Measures stack temperature using a MAX6675 thermocouple module.

Monitors hydrogen input pressure via an analog MP43P pressure sensor.

Reads fuel-cell output voltage through a voltage divider circuit.

Detects user access by scanning RFID tags with an MFRC522 module.

All data acquisition is performed continuously in a timed loop to ensure a rapid response to any changes in the system state.

3.1.2. Control Logic and Decision-Making (Master Node)

After acquiring data, the master node processes the inputs according to predefined thresholds:

If the temperature exceeds 60 °C, cooling measures or hydrogen relief mechanisms are activated.

If the pressure falls below 0.49 bar, a low-fuel or leak condition is detected, and the system is prepared to issue an alert.

If the voltage exceeds 5 V, it indicates that the fuel cell is fully active and may require controlled output flow.

If a valid RFID user identifier (UID) is detected, the system or specific outputs are enabled accordingly.

Based on the logic evaluation, the master constructs a CAN frame comprising the following:

An identifier (ID) indicating the actuator or function to be triggered.

A payload indicating the desired state or value (e.g., ON/OFF, PWM value).

The message is then transmitted over the CAN Bus to the slave node.

3.1.3. Message Reception and Interpretation (Slave Node)

The slave ESP32 is configured to continuously receive incoming messages on the CAN bus. Upon message arrival, the following occurs:

The MCP2515 verifies the frame’s integrity using a Cyclic Redundancy Check (CRC).

If the frame is valid, it is forwarded to the ESP32 microcontroller for processing.

The ESP32 module decodes the ID and Payload, mapping them to specific actuators.

3.1.4. Actuator Execution (Slave Node)

Based on the received command, the slave node performs the corresponding hardware actions as described in

Table 2.

3.2. Software Integrity of the Stacked Fuel Cell Specification

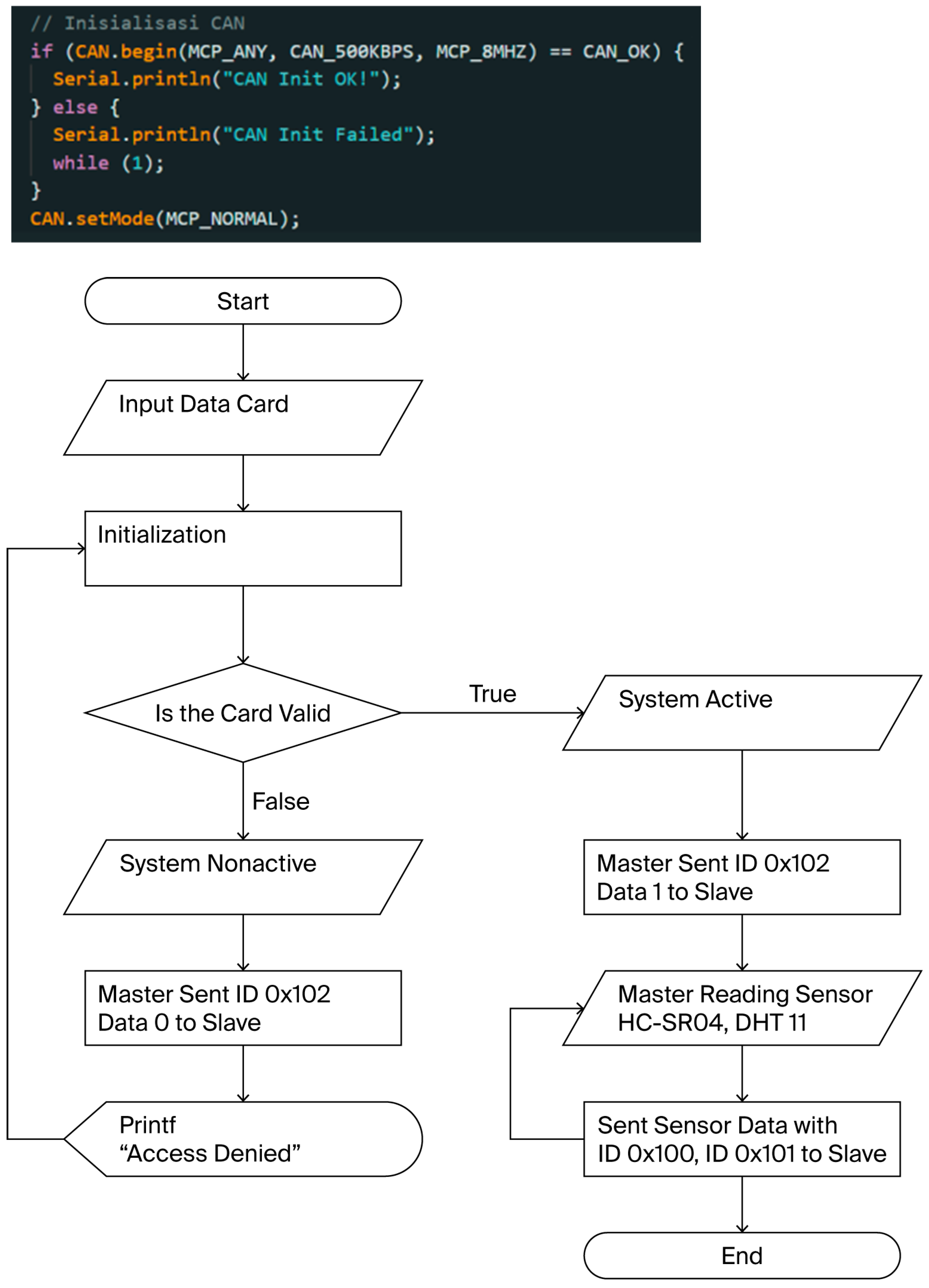

The flow chart in

Figure 3 illustrates the diagnostic programming implemented for troubleshooting hardware issues. Diagnostic routines are embedded in both the master and slave ESP32 NodeMCU firmware, developed in C++. The following code extract verifies the proper functioning of the MCP2515 CAN module:

This diagnostic function assists in detecting the MCP2515 CAN module and simplifies troubleshooting during operation. A logic analyzer was employed to inspect the CAN bus communication status at a bit rate of 500 kbps, where the probes (CAN_high and CAN_low wires) are parallel, connected to the two terminals of the socket on the MCP2515 CAN module. This ensures stable data transmission; the transmitted message frames include distance, temperature, and RFID authentication status information.

3.3. Individual Unit Experimental Setup and Testing

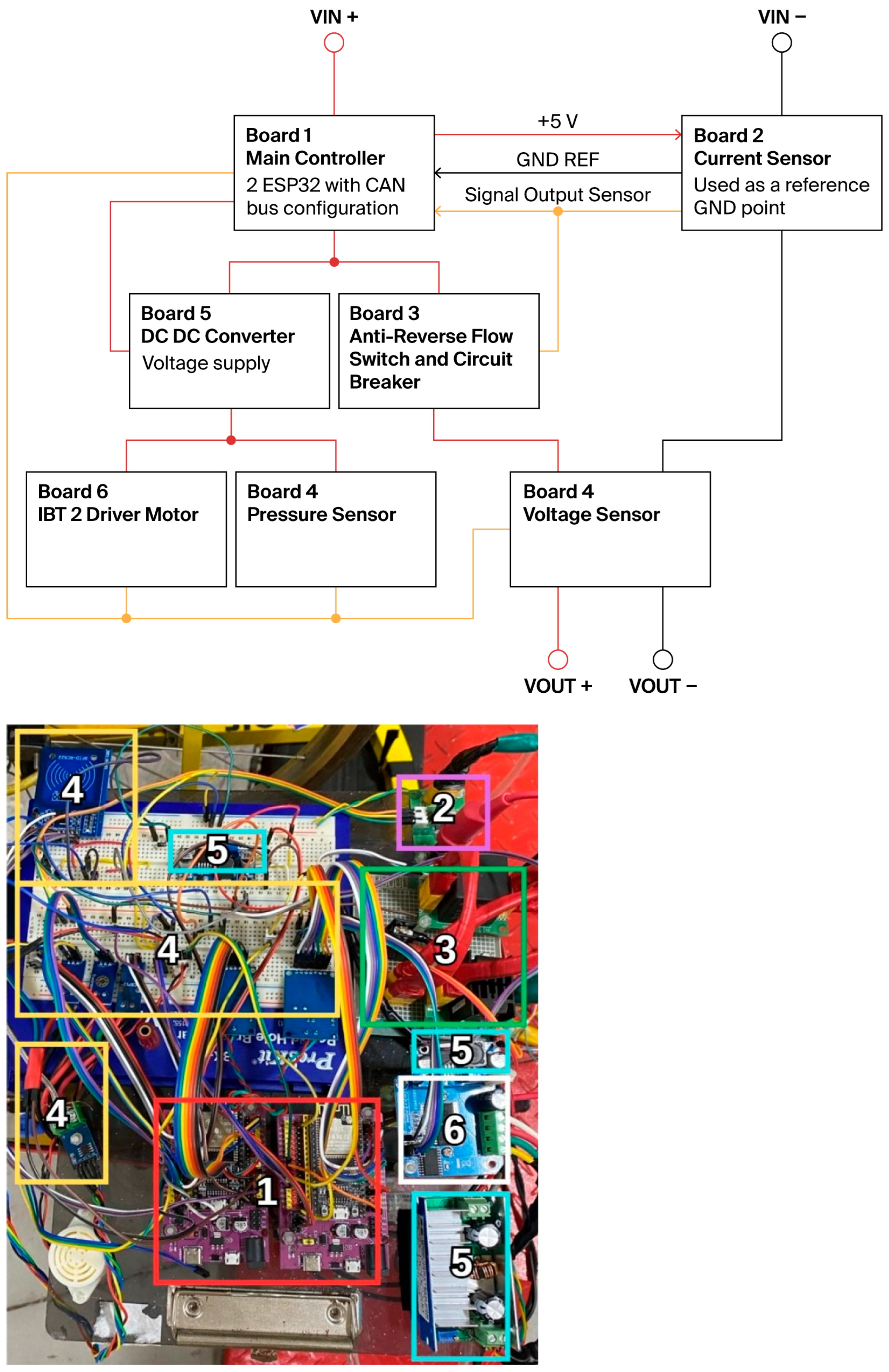

Prior to developing the complete CAN system for remote control and monitoring, individual unit experiments were conducted. Circuit diagrams of the master (commander) and follower (slave) nodes are shown in

Figure 4. The full control and monitoring functionality relies on the content of the CAN message frames, enabling the fuel cell stack to achieve its rated output power.

Each control node consists of two ESP32 NodeMCUs that communicate via MCP2515 CAN modules. The “ESP32 Write” (master) reads data from multiple sensors and interfaces, including an RC522 RFID sensor for authentication, an ultrasonic sensor for interference detection, a DHT11 sensor for fuel cell temperature and humidity monitoring, and an I2C LCD for displaying data or critical system information. The “ESP32 Read” (slave) receives CAN message frame data and controls output devices such as the LCD for warning messages, the cooling fan via servo control, the alert buzzer, and other actuators as needed. A block diagram and the practical experimental setup of the specific control and monitoring system are illustrated in

Figure 5.

To evaluate the functional performance and reliability of the proposed fuel cell control system, a series of targeted tests were carried out under simulated operational conditions. These tests assessed the accuracy of sensors, the responsiveness of actuators, the integrity of communication, and the overall system stability.

3.3.1. Sensor Validation

Temperature > 60 °C → Solenoid activated.

Pressure < 0.49 bar → Buzzer triggered.

Voltage > 5 V → Solenoid activated for 2 s.

Authorized RFID detected → Relay triggered.

3.3.2. CAN Communication Performance

3.3.3. Actuator Functionality

Solenoid and relay switched using 2N2222 NPN transistor drivers → Stable.

Buzzer responded with correct pulse pattern (three alerts) → Verified.

Fan speed controlled via PWM (optional) → Functional.

3.3.4. 2N2222 Transistor Switching

- ▪

Efficiently isolated GPIO from high-current devices.

- ▪

No overheating or saturation during testing.

- ▪

Flyback diodes prevented voltage spikes → Safe operation.

3.3.5. System Stability and Reliability

- ▪

Continuous operation for over 90 min without system faults.

- ▪

Closed-loop execution remained consistent and responsive.

- ▪

No false triggers or miscommunication observed → Robust.

The CAN bus protocol was analyzed using the Zeroplus Studio software package in conjunction with a PC-based logic analyzer. Captured and decoded messages confirmed the correctness of the signal structure (see References [

21,

22]), including details such as Message ID (260) and payload data (20, 181, 174, 118). Transmission time analysis indicated an average latency of 1.638 ms, which falls within the expected timing specifications.

4. Discussion

The software architecture of this fuel cell control system is based upon a robust master–slave model leveraging CAN bus communication, with a strong emphasis on modularity, data integrity, and real-time responsiveness. Two ESP32 NodeMCU units—configured as master and slave—communicate via MCP2515 CAN transceivers operating at a baud rate of 500 kbps. The master node is responsible for executing high-level control logic and acquiring sensor data and interfaces with the following critical components: a MAX6675 thermocouple (via SPI) for precise stack temperature measurement, an MP43P-030-F1 analog pressure sensor for hydrogen line pressure monitoring, a voltage divider circuit for measuring fuel-cell output voltage, and an MFRC522 RFID reader (via SPI) for user authentication through UID matching.

Within its main execution loop, the master node continuously monitors each connected sensor and evaluates the data against predefined threshold conditions. These include a stack temperature of over 60 °C, hydrogen pressure of below 0.49 bar, an output voltage over the designated operational limits, and successful authentication via a recognized RFID tag. Upon detecting any of these conditions, the master constructs a CAN frame comprising a unique 11-bit identifier (ID) and a corresponding data payload. A Cyclic Redundancy Check (CRC) code is automatically appended by the MCP2515 transceiver to ensure message integrity. This hardware-level CRC mechanism is essential for maintaining communication reliability within electrically noisy environments, ensuring that only complete and error-free messages are processed by the receiving slave node.

On the slave node, the ESP32 microcontroller is configured to continuously monitor the CAN bus for incoming frames. Upon message reception, the MCP2515 transceiver performs hardware-level CRC validation to ensure data integrity. If the frame is verified as error-free, it is decoded and dispatched to the corresponding actuator control routine. Based on the message ID and payload contents, the slave node performs one or more of the following operations:

Activates a 12 V solenoid valve for 2 s to purge or regulate hydrogen gas.

Drives a 24 V cooling fan using a PWM output scaled to match the real-time temperature level.

Triggers a relay when a valid UID is received from the master.

Activates a buzzer in a repeated tone pattern when the hydrogen pressure drops below 0.49 bar, serving as an alert mechanism.

Each actuator circuit—particularly those involving relays and solenoid valves that require a relatively high current—is not driven directly by the ESP32’s GPIO pins. Instead, these devices are controlled via 2N2222 NPN transistors configured as low-side switches. In this configuration, the transistor’s base is connected to an ESP32 GPIO pin through a current-limiting resistor (typically 1 kΩ). The emitter is connected to ground, and the collector is tied to the negative terminal of the relay or solenoid coil. The coil’s positive terminal is connected to an external power supply (+12 V or +24 V). When the ESP32 outputs a HIGH signal to the transistor base, it turns the transistor on, allowing current to flow through the collector–emitter path to ground, thereby energizing the coil. To suppress voltage spikes caused by inductive kickback when the coil is switched off, a flyback diode (e.g., 1N4007) is placed in parallel with the coil terminals. This switching architecture provides electrical isolation between the microcontroller and high-current components, protects the ESP32 from potential damage, and ensures reliable operation of inductive loads.

In parallel with actuator control, the slave node also monitors the fuel cell’s output current using a high-precision AD8420 instrumentation amplifier in combination with a 0.001 Ω shunt resistor. This configuration enables accurate differential analog current sensing, which can be utilized for system diagnostics, performance evaluation, or future integration of closed-loop control functionality.

This separation of responsibilities between the master (which handles sensing and decision-making) and the slave (which carries out physical actions) significantly enhances the system’s efficiency, modularity, and scalability. By distributing computational and control tasks across two nodes, the overall latency of the architecture is reduced, the processing load on individual microcontrollers is lowered, and future upgrades or expansions—such as the integration of telemetry modules, battery management systems, and an additional CAN node for data logging—are simplified.

Technical validation using a logic analyzer confirmed the accuracy and integrity of CAN communication. Captured frames demonstrated correct bit stuffing, identifier arbitration, and CRC generation, with no packet loss or data corruption observed during extended operation. The measured latency between event detection at the master node and actuator response at the slave node consistently remained below 250 ms, thereby satisfying real-time control requirements.

To perform a comparison, Xiong, S. et al. [

25] considered a fuel cell test system with fault identification. They focused on the design of a testing platform with a power greater than 1 kW, but did not include a small, flexible, stackable, and distributed fuel cell generator. In summary, this integrated architecture exemplifies best practices in embedded control design for stacked fuel cell generators, including the following:

Robust communication via CRC-verified CAN messages.

Safe and reliable actuator control using transistor-based drivers.

Real-time responsiveness and event handling.

Modular design ready for future enhancements.

As such, the system is well-suited for real-world deployment in hydrogen energy platforms, electric vehicle subsystems, and advanced academic research involving embedded distributed systems.

5. Conclusions and Future Work

The individual unit experiment demonstrated that the CAN bus with an RFID interface effectively supports multiple sensors and actuators, exhibiting high reliability at a bit rate of 500 kbps. This proposed configuration enables stable and efficient communication within a complex system of up to 20 stacked fuel cells or more, each rated at 200 W, ensuring rapid and accurate data transfer while minimizing interference and latency. The logic analyzer, integrated in the Zeroplus Studio software package, offers comprehensive insights into the performance of the CAN bus, facilitating debugging and optimization through real-time signal monitoring and analysis. The system incorporates critical sensors—including a MAX6675 thermocouple, an MP43P pressure sensor, a voltage measurement circuit, and an RFID authentication module—alongside various actuators such as solenoid valves, relays, buzzers, and cooling fans. Its architecture is based on a clear master–slave model, where the master handles real-time environmental sensing and decision-making, while the slave executes low-latency actuator commands. Communication between nodes is reliably managed via CAN frames with hardware-based CRC validation, ensuring data integrity even in electrically noisy environments.

Finally, the concept of multi-node expansion offers potential for more complex configurations, enabling broader and more distributed communication among numerous devices through extended RFID or wireless-interfaced CAN bus setups. In this paper, only one unit of a new fuel cell controller was studied, but from two up to twenty stacked fuel cells operating via the RFID (access)-CAN (control) mechanism can be assessed in future work. This approach provides enhanced scalability, flexibility, and applicability in fields such as industrial automation, autonomous vehicles, and smart green power grids.

Author Contributions

Conceptualization, F.-L.W. and C.-H.C.; methodology, F.-L.W. and C.-H.C.; software, K.K.P.P. and C.-H.C.; validation, C.-H.C., F.-L.W. and C.-P.W.; formal analysis, C.-H.C. and F.-L.W.; investigation, C.-H.C. and F.-L.W.; resources, F.-L.W. and C.-P.W.; data curation, K.K.P.P. and C.-P.W.; writing—original draft preparation, C.-P.W. and K.K.P.P.; writing—review and editing, F.-L.W., C.-H.C. and C.-P.W.; visualization, C.-H.C. and K.K.P.P.; supervision, C.-H.C.; project administration, C.-H.C.; funding acquisition, F.-L.W. and C.-H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Taiwan Society of Professional Development in Vehicles, grant number TSPDV 20250415, and we greatly appreciate this funding.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

This paper is an expanded version of the 2025 IEEE 5th International Conference on Electronic Communications, Internet of Things and Big Data (2025iceib.asia-conf). The conference paper can be reached at the DOI addres 10.3390/engproc2025108020.

Conflicts of Interest

Author Chu-PoWen was employed by the company YAMAHA Motor R&D Taiwan Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Shen, Y.; Zhou, J.; Zhang, J.; Yi, F.; Wang, G.; Pan, C.; Guo, W.; Shu, X. Research on Energy Management of Hydrogen Fuel Cell Bus Based on Deep Reinforcement Learning Considering Velocity Control. Sustainability 2023, 15, 12488. [Google Scholar] [CrossRef]

- Savran, E.; Karpat, E.; Karpat, F. Fuel Cell Electric Vehicle Hydrogen Consumption and Battery Cycle Optimization Using Bald Eagle Search Algorithm. Appl. Sci. 2024, 14, 7744. [Google Scholar] [CrossRef]

- Quan, R.; Zhang, J.; Feng, Z. Remote Fault Diagnosis for the Powertrain System of Fuel Cell Vehicles Based on Random Forest Optimized with a Genetic Algorithm. Sensors 2024, 24, 1138. [Google Scholar] [CrossRef]

- Dotzauer, N.A. Dynamic Modeling of Fuel Cells for Applications in Aviation. Eng. Proc. 2025, 90, 68. [Google Scholar] [CrossRef]

- Wang, Z.; He, R.; Hu, D.; Lu, D. Energy Management Strategy for Fuel Cell Vehicles Based on Deep Transfer Reinforcement Learning. Energies 2025, 18, 2192. [Google Scholar] [CrossRef]

- Wang, X.; Ji, J.; Li, J.; Zhao, Z.; Ni, H.; Zhu, Y. Review and Outlook of Fuel Cell Power Systems for Commercial Vehicles, Buses, and Heavy Trucks. Sustainability 2025, 17, 6170. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Y. Genetic Algorithm-Based Energy Management Strategy for Fuel Cell Hybrid Electric Vehicles. World Electr. Veh. J. 2025, 16, 467. [Google Scholar] [CrossRef]

- Ismaila, K.; Muharama, A.; Pratama, M. Design of CAN bus for research applications purpose hybrid electric vehicle using ARM microcontroller. Energy Procedia 2015, 68, 288–296. [Google Scholar]

- Oladimeji, D.; Rasheed, A.; Varol, C.; Baza, M.; Alshahrani, H.; Baz, A. CAN Attack: Assessing Vulnerabilities within Controller Area Network. Sensors 2023, 23, 8223. [Google Scholar] [CrossRef]

- Fang, S.; Zhang, G.; Li, Y.; Li, J. Windowed Hamming Distance-Based Intrusion Detection for the CAN Bus. Appl. Sci. 2024, 14, 2805. [Google Scholar] [CrossRef]

- Agbli, K.S.; Hilairet, M.; Gustin, F. Real-Time Control Based on a CAN-Bus of Hybrid Electrical Systems. Energies 2020, 13, 4502. [Google Scholar] [CrossRef]

- Wagh, A.S.; Joshi, S.D. Design and Implementation of CAN Communication System for Automotive Application Using HIL. Int. J. Curr. Eng. Sci. Res. 2015, 2, 114–118. [Google Scholar]

- CAN Specification, Version 2.0; Postfach 30 02 40, D-70442 Stuttgart; Robert Bosch GmbH: Gerlingen, Germany, 1991.

- Robert Boys. CAN Primer: Creating Your Own Network: ARM® Keil™ MDK™ Toolkit Featuring Simulator, Serial Wire Viewer and ETM Trace—For the STMicroelectronics STM32F4 Cortex™-M4; Arm Limited: Cambridge, UK, 2012; Available online: https://www.keil.com/download/files/canprimer_v2.pdf (accessed on 10 January 2022).

- Texas Instrument. Introduction to the Controller Area Network (CAN), SLOA101B—August 2002—Revised May 2016; Texas Instrument: Dallas, TX, USA, 2016; Available online: https://www.ti.com/lit/an/sloa101b/sloa101b.pdf?ts=1758177123185&ref_url=https%253A%252F%252Fwww.google.com%252F (accessed on 15 September 2020).

- Conal Watterson. Controller Area Network (CAN) Implementation Guide; Analog Devices, Inc.: Wilmington, MA, USA, 2017. [Google Scholar]

- Saini, R.; Islam, R. Reconfigurable CAN Intrusion Detection and Response System. Electronics 2024, 13, 2672. [Google Scholar] [CrossRef]

- Zeroplus Technology. CAN Bus Signal Analysis Using Zeroplus Logic Analyzer, Application Notes; Zeroplus Technology: New Taipei City, Taiwan, 2020. [Google Scholar]

- Microchip Technology. CAN Bus Analyzer User’s Guide; Microchip Technology Inc.: Chandler, AZ, USA, 2019. [Google Scholar]

- Marei, M.I.; Samborsky, S.J.; Lambert, S.B.; Salama, M.M.A. On the Characterization of Ultracapacitor Banks Used for HEVs. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, VPPC 06, Windsor, UK, 6–8 September 2006; pp. 1–6. [Google Scholar]

- Wen, F.-L.; Chan, C.-H.; Wen, C.-P. Integration of RFID Interface for Enhanced CAN Bus. Eng. Proc. 2025, 108, 20. [Google Scholar] [CrossRef]

- Chan, C.-H.; Wen, F.-L.; Wen, S.-J. Design and Implementation of a CAN-based Monitoring and Control System with Arduino UNO and Logic Analyzer. In Proceedings of the 2025 IEEE 5th International Conference on Electronic Communications, Internet of Things and Big Data (IEEE ICEIB 2025), New Taipei City, Taiwan, 25–27 April 2025; Volume 108, p. 44. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Huang, R.-D.; Chuang, C.-W. Novel Integration Approach for In-Situ Monitoring of Temperature in Micro-direct Methanol Fuel Cell. Jpn. J. Appl. Phys. 2007, 46, 6911–6914. [Google Scholar] [CrossRef]

- Mohammed, O.A.A.; Peng, L.; Hamid, G.H.A.; Ishag, A.M.; Abdalla, M.A.A. Effective Energy Management Strategy with Model-Free DC-Bus Voltage Control for Fuel Cell/Battery/Supercapacitor Hybrid Electric Vehicle System. Machines 2023, 11, 944. [Google Scholar] [CrossRef]

- Xiong, S.; Wu, Z.; Cheng, J. Design of a Fuel Cell Test System with Fault Identification. Electronics 2023, 12, 3365. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).