Digitalisation in the Context of Industry 4.0 and Industry 5.0: A Bibliometric Literature Review and Visualisation

Abstract

1. Introduction

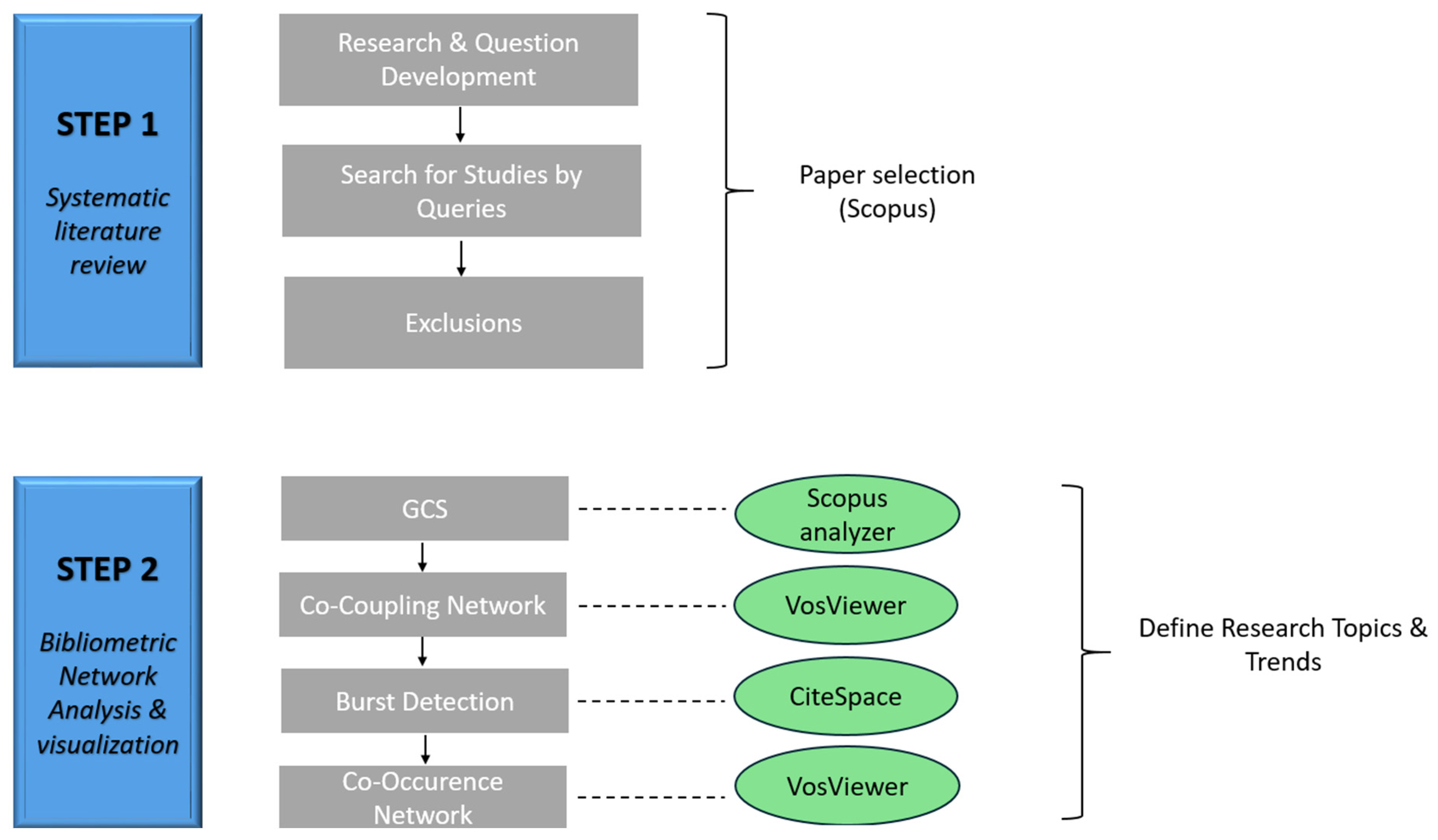

2. Materials and Methods

- Non-English language publications;

- Non-peer-reviewed materials (e.g., white papers, theses, editorials);

- Duplicate records.

3. Results—Bibliometric Network Analyses and Visualisation

3.1. Time-Weighted Global Citation Score

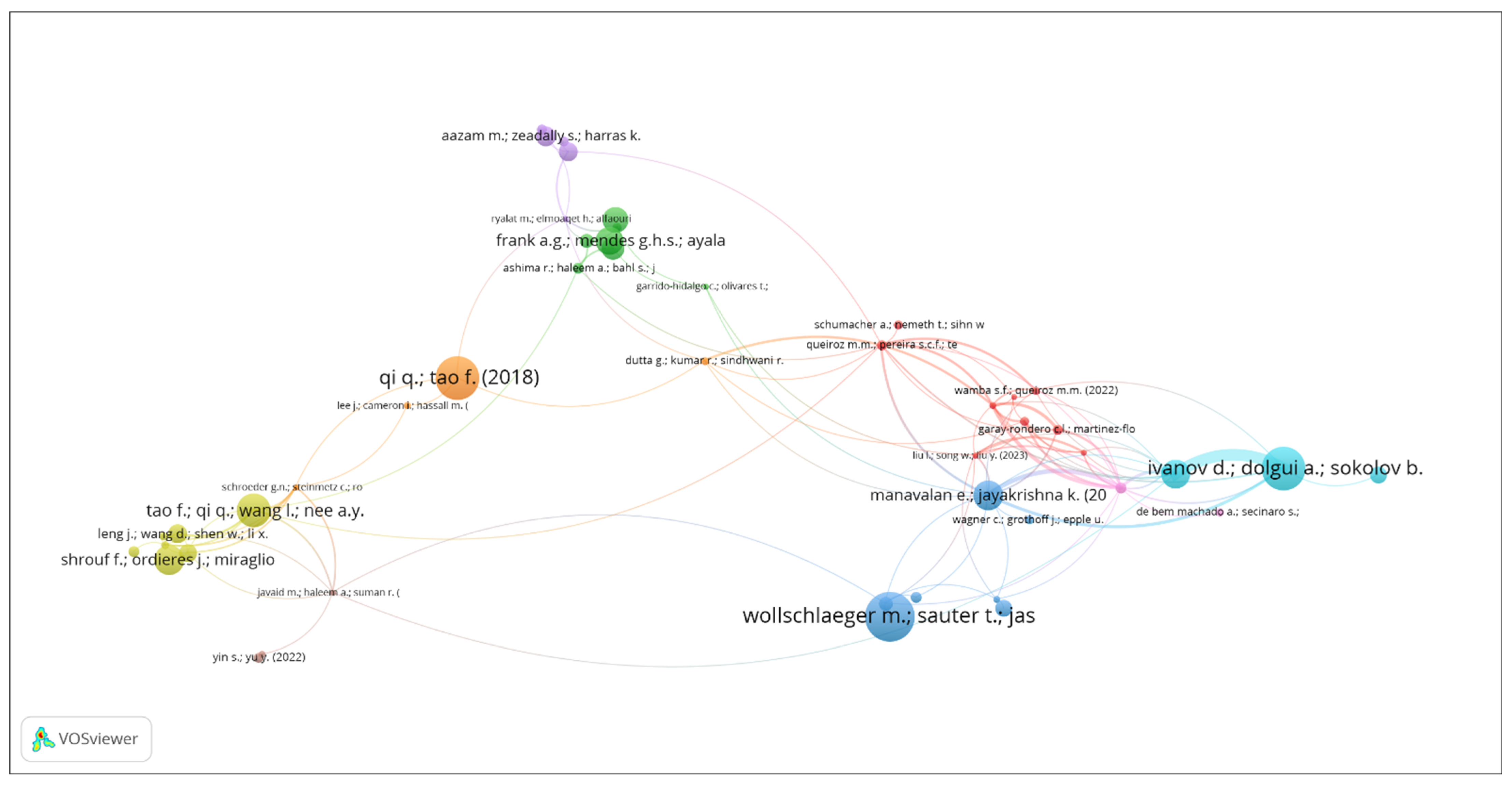

3.2. Co-Coupling Network (CCN) Analysis

| Clusters | Authors | References | Citations | Publish Year |

|---|---|---|---|---|

| 1 | Queiroz M.M.; Pereira S.C.F.; Telles R.; Machado M.C. | [53] | 236 | 2019 |

| Garay-Rondero C.L.; Martinez-Flores J.L.; Smith N.R.; Caballero Morales S.O.; Aldrette-Malacara A. | [54] | 236 | 2019 | |

| Ghobakhloo M.; Iranmanesh M. | [55] | 200 | 2021 | |

| 2 | Frank A.G.; Mendes G.H.S.; Ayala N.F.; Ghezzi A. | [50] | 725 | 2019 |

| Aceto G.; Persico V.; Pescapé A. | [56] | 672 | 2020 | |

| Li Y.; Dai J.; Cui L. | [57] | 566 | 2020 | |

| 3 | Wollschlaeger M.; Sauter T.; Jasperneite J. | [44] | 1404 | 2017 |

| Manavalan E.; Jayakrishna K. | [49] | 775 | 2019 | |

| Özdemir V.; Hekim N. | [58] | 410 | 2018 | |

| 4 | Tao F.; Qi Q.; Wang L.; Nee A.Y.C. | [47] | 890 | 2019 |

| Shrouf F.; Ordieres J.; Miragliotta G. | [59] | 766 | 2014 | |

| Leng J.; wang d.; Shen W.; Li X.; Liu Q.; Chen X. | [27] | 458 | 2021 | |

| 5 | Aazam M.; Zeadally S.; Harras K.A. | [60] | 482 | 2018 |

| Nagy J.; Oláh J.; Erdei E.; Máté D.; Popp J. | [61] | 468 | 2018 | |

| Wang M.; Wang C.C.; Sepasgozar S.; Zlatanova S. | [62] | 228 | 2020 | |

| 6 | Ivanov D.; Dolgui A.; Sokolov B. | [42] | 1197 | 2019 |

| Ivanov D.; Dolgui A. | [43] | 744 | 2021 | |

| Ardito L.; Petruzzelli A.M.; Panniello U.; Garavelli A.C. | [63] | 411 | 2019 | |

| 7 | Qi Q.; Tao F. | [45] | 1204 | 2018 |

| Dutta G.; Kumar R.; Sindhwani R.; Singh R.K. | [64] | 177 | 2020 | |

| Lee J.; Cameron I.; Hassall M. | [65] | 147 | 2019 | |

| 8 | Yin S.; Yu Y. | [66] | 227 | 2022 |

| Wang B.; Zhou H.; Li X.; Yang G.; Zheng P.; Song C.; Yuan Y.; Wuest T.; Yang H.; Wang L. | [46] | 149 | 2024 | |

| Javaid M.; Haleem A.; Suman R. | [67] | 127 | 2023 |

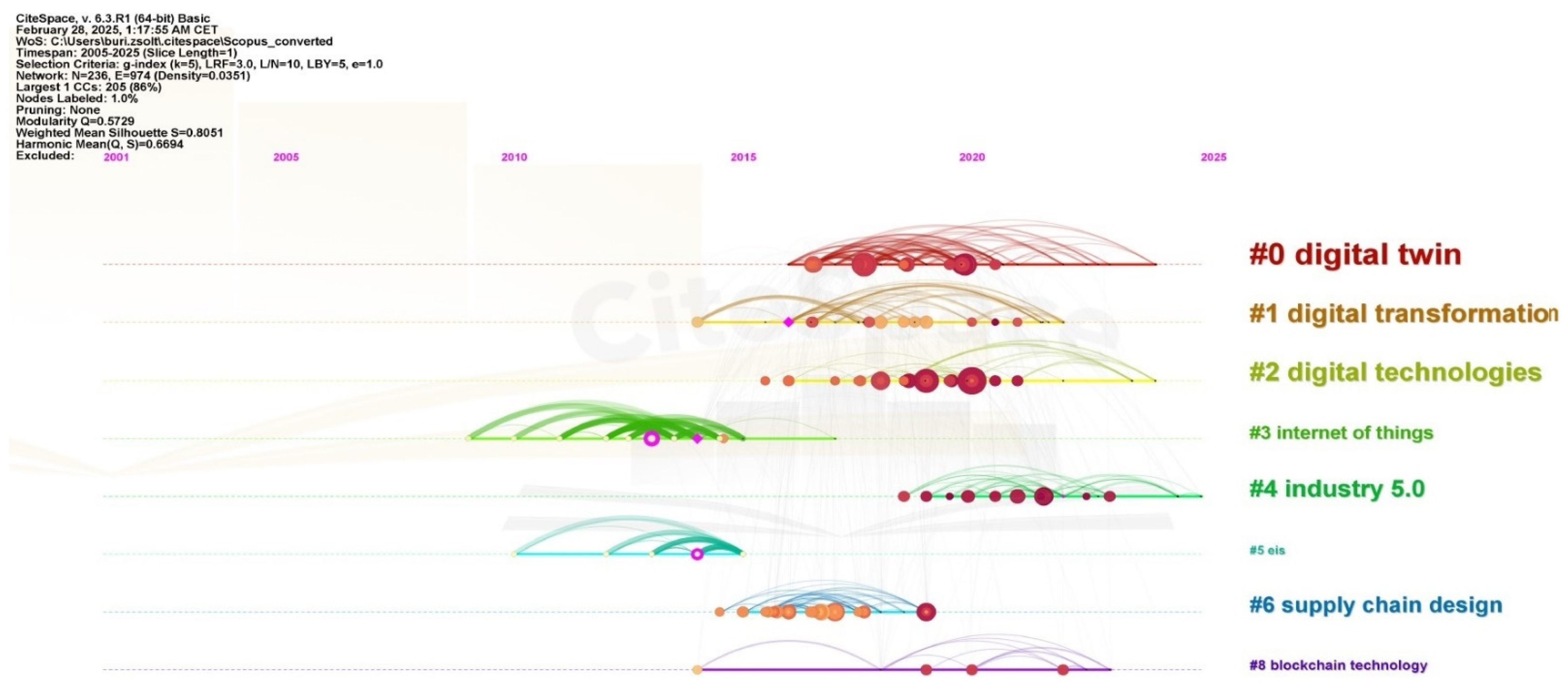

3.3. Results of Burt Detection Analysis (BDA)

3.4. Co-Occurrence Network of Keywords (CONK) Analysis

4. Discussion and Conclusions

- Sector-specific case studies examining the application of blockchain to improve supply chain resilience in the context of Industry 5.0.

- Empirical evaluation of human–digital twin collaboration in a real manufacturing environment in terms of efficiency, adaptability, and operator well-being.

- Longitudinal analyses tracking the adoption curve of collaborative robotics in sustainable production systems, identifying enabling factors or barriers related to technology, economics, and labor.

- Interdisciplinary frameworks integrating politics, ethics, and technology that provide actionable guidelines for planning and managing Industry 5.0.

- Addressing the ethical and social implications of human–digital twins and AI-driven collaboration. Key issues include privacy, autonomy, accountability, bias, and the evolving role of humans in industrial environments, which represent one of the core tensions in the Industry 5.0 paradigm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABM | Agent-Based Modeling |

| AI | Artificial Intelligence |

| BDA | Burst Detection Analysis |

| BNAV | Bibliometric Network Analysis and Visualisation |

| CCN | Co-Coupling Network (Analysis) |

| CLSCs | Closed-Loop Supply Chains |

| CONK | Co-Occurrence Network of Keywords |

| CPS | Cyber-Physical Systems |

| DES | Discrete Event Simulation |

| DGIP | Digital Green Innovation Performance |

| DSC | Digital Supply Chain |

| DSC-T | Digital Supply Chain Twin |

| DSCCs | Digital Supply Chain Capabilities |

| DT | Digital Twin |

| DTaaS | Digital Twin as a Service |

| GCS | Global Citation Score |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| LCA | Life Cycle Assessment |

| QoE | Quality of Experience |

| QoER | Quality of Experience Ratio |

| SD-IIoT | Software-Defined Industrial Internet of Things |

| SLR | Systematic Literature Review |

| SSC | Sustainable Supply Chain |

| TSN | Time-Sensitive Network |

| fsQCA | Fuzzy-Set Qualitative Comparative Analysis |

References

- Gordon, R. The Rise and Fall of American Growth: The US Standard of Living Since the Civil War; Princeton University Press: Princeton, NJ, USA, 2017; ISBN 1400888956. [Google Scholar]

- Drath, R.; Horch, A. Industrie 4.0: Hit or hype? [industry forum]. IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Schweichhart, K. Reference Architectural Model Industrie 4.0 (RAMI 4.0). An Introduction. 2016. Available online: https://ec.europa.eu/futurium/en/system/files/ged/a2-schweichhart-reference_architectural_model_industrie_4.0_rami_4.0.pdf (accessed on 23 August 2025).

- Cañas, H.; Mula, J.; Díaz-Madroñero, M.; Campuzano-Bolarín, F. Implementing industry 4.0 principles. Comput. Ind. Eng. 2021, 158, 107379. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Oks, S.J.; Jalowski, M.; Lechner, M.; Mirschberger, S.; Merklein, M.; Vogel-Heuser, B.; Möslein, K.M. Cyber-physical systems in the context of industry 4.0: A review, categorization and outlook. Inf. Syst. Front. 2024, 26, 1731–1772. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the perspective of automation and supervision systems: Definitions, architectures and recent trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Tiwari, M.K.; Bidanda, B.; Geunes, J.; Fernandes, K.; Dolgui, A. Supply chain digitisation and management. Int. J. Prod. Res. 2024, 62, 2918–2926. [Google Scholar] [CrossRef]

- Filz, M.-A.; Bosse, J.P.; Herrmann, C. Digitalization platform for data-driven quality management in multi-stage manufacturing systems. J. Intell. Manuf. 2024, 35, 2699–2718. [Google Scholar] [CrossRef]

- Hu, Y.; Jia, Q.; Yao, Y.; Lee, Y.; Lee, M.; Wang, C.; Zhou, X.; Xie, R.; Yu, F.R. Industrial internet of things intelligence empowering smart manufacturing: A literature review. IEEE Internet Things J. 2024, 11, 19143–19167. [Google Scholar] [CrossRef]

- Gallab, M.; Bouloiz, H.; Kebe, S.A.; Tkiouat, M. Opportunities and challenges of the industry 4.0 in industrial companies: A survey on Moroccan firms. J. Ind. Bus. Econ. 2021, 48, 413–439. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Sinha, A.K. Digital economy to improve the culture of industry 4.0: A study on features, implementation and challenges. Green Technol. Sustain. 2024, 2, 100083. [Google Scholar] [CrossRef]

- Han, L.; Hou, H.; Bi, Z.; Yang, J.; Zheng, X. Functional requirements and supply chain digitalization in industry 4.0. Inf. Syst. Front. 2024, 26, 2273–2285. [Google Scholar] [CrossRef]

- Admass, W.S.; Munaye, Y.Y.; Diro, A.A. Cyber security: State of the art, challenges and future directions. Cyber Secur. Appl. 2024, 2, 100031. [Google Scholar] [CrossRef]

- Shabur, M.A. A comprehensive review on the impact of Industry 4.0 on the development of a sustainable environment. Discov. Sustain. 2024, 5, 97. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mohammad, I.; Ming-Lang, T.; Andrius, G.; Alessandro, S.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Gallab, M.; Di Nardo, M.; Naciri, L. Navigating contemporary challenges and future prospects in digital industry evolution. Discov. Appl. Sci. 2024, 6, 259. [Google Scholar] [CrossRef]

- Pizoń, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203. [Google Scholar] [CrossRef]

- Damaševičius, R.; Vasiljevas, M.; Narbutaitė, L.; Blažauskas, T. Exploring the impact of collaborative robots on human–machine cooperation in the era of Industry 5.0. In Modern Technologies and Tools Supporting the Development of Industry 5.0; Taylor & Francis: Abingdon, UK, 2024; pp. 149–178. ISBN 9781003489269. [Google Scholar]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The expanding role of artificial intelligence in collaborative robots for industrial applications: A systematic review of recent works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative robots and industrial revolution 4.0 (IR 4.0). In Proceedings of the 2020 International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020; pp. 1–5. [Google Scholar] [CrossRef]

- He, Q.; Li, L.; Li, D.; Peng, T.; Zhang, X.; Cai, Y.; Zhang, X.; Tang, R. From digital human modeling to human digital twin: Framework and perspectives in human factors. Chin. J. Mech. Eng. 2024, 37, 9. [Google Scholar] [CrossRef]

- Yin, S.; Liu, L.; Mahmood, T. New trends in sustainable development for industry 5.0: Digital green innovation economy. Green Low-Carbon Econ. 2024, 2, 269–276. [Google Scholar] [CrossRef]

- Payer, R.C.; Quelhas, O.L.G.; Bergiante, N.C.R. Framework to supporting monitoring the circular economy in the context of industry 5.0: A proposal considering circularity indicators, digital transformation, and sustainability. J. Clean. Prod. 2024, 466, 142850. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 digital manufacturing to Industry 5.0 digital society: A roadmap toward human-centric, sustainable, and resilient production. Inf. Syst. Front. 2024, 1–33. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, H.; Yang, G.; Li, X.; Yang, H. Human digital twin (HDT) driven human-cyber-physical systems: Key technologies and applications. Chin. J. Mech. Eng. 2022, 35, 11. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Cherubini, A.; Passama, R.; Crosnier, A.; Lasnier, A.; Fraisse, P. Collaborative manufacturing with physical human–robot interaction. Robot. Comput.-Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Khan, A. Digital sustainability: Dimension exploration and scale development. Acta Psychol. 2025, 256, 105028. [Google Scholar] [CrossRef]

- Feroz, A.K.; Zo, H.; Chiravuri, A. Digital transformation and environmental sustainability: A review and research agenda. Sustainability 2021, 13, 1530. [Google Scholar] [CrossRef]

- Powell, K.; Peterson, S. Coverage and Quality: A Comparison of Web of Science and Scopus Databases for Reporting Faculty Nursing Publication Metrics. Nursing Outlook 2017, 65, 572–578. [Google Scholar] [CrossRef]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; López-Cózar, E.D. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Informetr. 2018, 12, 1160–1177. [Google Scholar] [CrossRef]

- Bornmann, L.; Haunschild, R. Citation score normalized by cited references (CSNCR): The introduction of a new citation impact indicator. J. Informetr. 2016, 10, 875–887. [Google Scholar] [CrossRef]

- Li, H.; Wu, M.; Wang, Y.; Zeng, A. Bibliographic coupling networks reveal the advantage of diversification in scientific projects. J. Informetr. 2022, 16, 101321. [Google Scholar] [CrossRef]

- Bakkum, D.J.; Radivojevic, M.; Frey, U.; Franke, F.; Hierlemann, A.; Takahashi, H. Parameters for burst detection. Front. Comput. Neurosci. 2014, 7, 193. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xie, J.; Hou, W.; Tu, X.; Xu, J.; Song, F.; Wang, Z.; Lu, Z. Mapping the knowledge structure of research on patient adherence: Knowledge domain visualization based co-word analysis and social network analysis. PLoS ONE 2012, 7, e34497. [Google Scholar] [CrossRef] [PubMed]

- Su, H.-N.; Lee, P.-C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Chen, C. Science mapping: A systematic review of the literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Bornmann, L.; Marx, W. Methods for the generation of normalized citation impact scores in bibliometrics: Which method best reflects the judgements of experts? J. Informetr. 2015, 9, 408–418. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control. 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The future of industrial communication: Automation networks in the era of the internet of things and industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, H.; Li, X.; Yang, G.; Zheng, P.; Song, C.; Yuan, Y.; Wuest, T.; Yang, H.; Wang, L. Human Digital Twin in the context of Industry 5.0. Robot. Comput.-Integr. Manuf. 2024, 85, 102626. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Majid, M.; Habib, S.; Javed, A.R.; Rizwan, M.; Srivastava, G.; Gadekallu, T.R.; Lin, J.C.-W. Applications of wireless sensor networks and internet of things frameworks in the industry revolution 4.0: A systematic literature review. Sensors 2022, 22, 2087. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Arruda, H.; Silva, E.R.; Lessa, M.; Proença, D., Jr.; Bartholo, R. VOSviewer and bibliometrix. J. Med. Libr. Assoc. 2022, 110, 392–395. [Google Scholar] [CrossRef]

- Orduña-Malea, E.; Costas, R. Link-based approach to study scientific software usage: The case of VOSviewer. Scientometrics 2021, 126, 8153–8186. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Pereira, S.C.F.; Telles, R.; Machado, M.C. Industry 4.0 and digital supply chain capabilities: A framework for understanding digitalisation challenges and opportunities. Benchmarking: Int. J. 2021, 28, 1761–1782. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Morales, S.O.C.; Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M. Digital transformation success under Industry 4.0: A strategic guideline for manufacturing SMEs. J. Manuf. Technol. Manag. 2021, 32, 1533–1556. [Google Scholar] [CrossRef]

- Aceto, G.; Persico, V.; Pescapé, A. Industry 4.0 and health: Internet of things, big data, and cloud computing for healthcare 4.0. J. Ind. Inf. Integr. 2020, 18, 100129. [Google Scholar] [CrossRef]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Özdemir, V.; Hekim, N. Birth of industry 5.0: Making sense of big data with artificial intelligence,“the internet of things” and next-generation technology policy. Omics: J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar] [CrossRef]

- Aazam, M.; Zeadally, S.; Harras, K.A. Deploying fog computing in industrial internet of things and industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 4674–4682. [Google Scholar] [CrossRef]

- Nagy, J.; Oláh, J.; Erdei, E.; Máté, D.; Popp, J. The role and impact of Industry 4.0 and the internet of things on the business strategy of the value chain—The case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in off-site construction: Current status and future direction towards industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2018, 25, 323–346. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Digital transformation priorities of India’s discrete manufacturing SMEs–a conceptual study in perspective of Industry 4.0. Compet. Rev. Int. Bus. J. 2020, 30, 289–314. [Google Scholar] [CrossRef]

- Lee, J.; Cameron, I.; Hassall, M. Improving process safety: What roles for Digitalization and Industry 4.0? Process Saf. Environ. Prot. 2019, 132, 325–339. [Google Scholar] [CrossRef]

- Yin, S.; Yu, Y. An adoption-implementation framework of digital green knowledge to improve the performance of digital green innovation practices for industry 5.0. J. Clean. Prod. 2022, 363, 132608. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Suman, R. Digital twin applications toward industry 4.0: A review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Baiyere, A.; Salmela, H.; Tapanainen, T. Digital transformation and the new logics of business process management. Eur. J. Inf. Syst. 2020, 29, 238–259. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Pfeiffer, S. The vision of “Industrie 4.0” in the making—A case of future told, tamed, and traded. Nanoethics 2017, 11, 107–121. [Google Scholar] [CrossRef] [PubMed]

- Grabowska, S.; Saniuk, S.; Gajdzik, B. Industry 5.0: Improving humanization and sustainability of Industry 4.0. Scientometrics 2022, 127, 3117–3144. [Google Scholar] [CrossRef] [PubMed]

- Dehghan, S.; Sattarpanah Karganroudi, S.; Echchakoui, S.; Barka, N. The Integration of Additive Manufacturing into Industry 4.0 and Industry 5.0: A Bibliometric Analysis (Trends, Opportunities, and Challenges). Machines 2025, 13, 62. [Google Scholar] [CrossRef]

- Islam, M.T.; Sepanloo, K.; Woo, S.; Woo, S.H.; Son, Y.-J. A review of the industry 4.0 to 5.0 transition: Exploring the intersection, challenges, and opportunities of technology and Human–Machine collaboration. Machines 2025, 13, 267. [Google Scholar] [CrossRef]

- Murtaza, A.A.; Saher, A.; Zafar, M.H.; Moosavi, S.K.R.; Aftab, M.F.; Sanfilippo, F. Paradigm shift for predictive maintenance and condition monitoring from Industry 4.0 to Industry 5.0: A systematic review, challenges and case study. Results Eng. 2024, 24, 102935. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The digital twin: Realizing the cyber-physical production system for industry 4.0. Procedia Cirp 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Gallab, M.; Ahidar, I.; Zrira, N.; Ngote, N. Towards a Digital Predictive Maintenance (DPM): Healthcare Case Study. Procedia Comput. Sci. 2024, 232, 3183–3194. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Industry 4.0 and the supply chain digitalisation: A blockchain diffusion perspective. Prod. Plan. Control. 2022, 33, 193–210. [Google Scholar] [CrossRef]

- Zhang, K.; Zhu, Y.; Maharjan, S.; Zhang, Y. Edge intelligence and blockchain empowered 5G beyond for the industrial Internet of Things. IEEE Netw. 2019, 33, 12–19. [Google Scholar] [CrossRef]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S.; Pelusi, D.; Ghosh, U.; Nayak, J. Industrial Internet of Things and its applications in industry 4.0: State of the art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Shu, Z.; Li, D.; Wang, S.; Imran, M.; Vasilakos, A.V. Software-defined industrial internet of things in the context of industry 4.0. IEEE Sens. J. 2016, 16, 7373–7380. [Google Scholar] [CrossRef]

- Rani, S.; Jining, D.; Shoukat, K.; Shoukat, M.U.; Nawaz, S.A. A human–machine interaction mechanism: Additive manufacturing for Industry 5.0—Design and management. Sustainability 2024, 16, 4158. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Change 2022, 176, 121448. [Google Scholar] [CrossRef]

- Roman, E.-A.; Stere, A.-S.; Roșca, E.; Radu, A.-V.; Codroiu, D.; Anamaria, I. State of the Art of Digital Twins in Improving Supply Chain Resilience. Logistics 2025, 9, 22. [Google Scholar] [CrossRef]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is industry 5.0 a human-centred approach? A systematic review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Alnaser, A.A.; Maxi, M.; Elmousalami, H. AI-powered digital twins and internet of things for smart cities and sustainable building environment. Appl. Sci. 2024, 14, 12056. [Google Scholar] [CrossRef]

- Qu, C.; Kim, E. Reviewing the Roles of AI-Integrated Technologies in Sustainable Supply Chain Management: Research Propositions and a Framework for Future Directions. Sustainability 2024, 16, 6186. [Google Scholar] [CrossRef]

- Spleth, P.; Korbel, J.J.; Zarnekow, R. Sustainability Effects of Digital Twins: A Review. In Proceedings of the Pacific-Asia Conference on Information Systems, Ho Chi Minh City 2024, Ho Chi Minh City, Vietnam, 1–5 July 2024. [Google Scholar]

- Potnis, T.; Lau, Y.-Y.; Yip, T.L. Roles of blockchain technology in supply chain capability and flexibility. Sustainability 2023, 15, 7460. [Google Scholar] [CrossRef]

- Wang, M.; Yang, Y. An empirical analysis of the supply chain flexibility using blockchain technology. Front. Psychol. 2022, 13, 1004007. [Google Scholar] [CrossRef]

- Modoni, G.E.; Sacco, M. A human digital-twin-based framework driving human centricity towards industry 5.0. Sensors 2023, 23, 6054. [Google Scholar] [CrossRef]

- Li, L.; Duan, L. Human centric innovation at the heart of industry 5.0–exploring research challenges and opportunities. Int. J. Prod. Res. 2025, 1–33. [Google Scholar] [CrossRef]

- Kagermann, H. Change through digitization—Value creation in the age of Industry 4.0. In Management of Permanent Change; Springer: Berlin/Heidelberg, Germany, 2014; pp. 23–45. [Google Scholar] [CrossRef]

- Zong, Z.; Guan, Y. AI-driven intelligent data analytics and predictive analysis in Industry 4.0: Transforming knowledge, innovation, and efficiency. J. Knowl. Econ. 2025, 16, 864–903. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control. 2022, 33, 1573–1590. [Google Scholar] [CrossRef]

- Falekas, G.; Karlis, A. Digital twin in electrical machine control and predictive maintenance: State-of-the-art and future prospects. Energies 2021, 14, 5933. [Google Scholar] [CrossRef]

- Gallab, M.; Bouloiz, H.; Alaoui, Y.L.; Tkiouat, M. Risk Assessment of Maintenance activities using Fuzzy Logic. Procedia Comput. Sci. 2019, 148, 226–235. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Zrelli, I.; Kayikci, Y.; Hassoun, A. The research landscape of industry 5.0: A scientific mapping based on bibliometric and topic modeling techniques. Flex. Serv. Manuf. J. 2024, 37, 1–48. [Google Scholar] [CrossRef]

| Research Question | Bibliometric Technique(s) | Purpose |

|---|---|---|

| RQ1—How is the transition from Industry 4.0 to Industry 5.0 reshaping human–machine interaction, and what supporting role does digitalisation play in this process? | Keyword co-occurrence analysis; temporal trend analysis | Identify key terms, their relationships, and how the thematic focus on human–machine collaboration has shifted towards human-centric objectives. |

| RQ2—How do digital twins and artificial intelligence impact the development of Industry 5.0 and contribute to the creation of a sustainable industry? | Co-citation network analysis; thematic clustering | Map the intellectual structure of AI and digital twin research and reveal how these technologies are linked to sustainability-related themes. |

| RQ3—How will the introduction of blockchain technology impact the digitization and resiliency of supply chains? | Bibliographic coupling; cluster analysis | Identify recent research on blockchain in supply chains and examine its connections to flexibility and decentralised coordination. |

| Title | Year | Cited by | References | Time-Weighted GCS |

|---|---|---|---|---|

| 2019 | 1197 | [42] | 200 |

| 2021 | 743 | [43] | 186 |

| 2017 | 1404 | [44] | 176 |

| 2018 | 1204 | [45] | 172 |

| 2024 | 149 | [46] | 149 |

| 2019 | 890 | [47] | 148 |

| 2022 | 403 | [48] | 134 |

| 2019 | 775 | [49] | 129 |

| 2019 | 725 | [50] | 121 |

| 2021 | 458 | [27] | 115 |

| Research Question | Key Results | Source and Method |

|---|---|---|

| RQ1—How is the transition from Industry 4.0 to Industry 5.0 reshaping human–machine interaction, and what supporting role does digitalisation play in this process? | Human–machine interaction and collaborative robotics have been present since Industry 4.0, but are increasingly reoriented towards human-centric objectives in Industry 5.0. | Derived from keyword co-occurrence analysis and temporal trend analysis in the Section 3, showing a shift in term associations over time. |

| RQ2—How do digital twins and artificial intelligence impact the development of Industry 5.0 and contribute to the creation of a sustainable industry? | Strong linkages between AI, digital twins, and sustainability-related concepts indicate a recent shift in research focus towards environmental and social objectives. | Identified through co-citation network analysis and thematic clustering, where sustainability terms co-occurred with AI/digital twin clusters. |

| RQ3—How will the introduction of blockchain technology impact the digitization and resiliency of supply chains? | Blockchain’s role has evolved from improving transparency to enabling flexibility and decentralised coordination in supply chains. | Based on bibliographic coupling and cluster analysis, revealing emerging research clusters on supply chain resilience and decentralised systems. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buri, Z.; T. Kiss, J. Digitalisation in the Context of Industry 4.0 and Industry 5.0: A Bibliometric Literature Review and Visualisation. Appl. Syst. Innov. 2025, 8, 137. https://doi.org/10.3390/asi8050137

Buri Z, T. Kiss J. Digitalisation in the Context of Industry 4.0 and Industry 5.0: A Bibliometric Literature Review and Visualisation. Applied System Innovation. 2025; 8(5):137. https://doi.org/10.3390/asi8050137

Chicago/Turabian StyleBuri, Zsolt, and Judit T. Kiss. 2025. "Digitalisation in the Context of Industry 4.0 and Industry 5.0: A Bibliometric Literature Review and Visualisation" Applied System Innovation 8, no. 5: 137. https://doi.org/10.3390/asi8050137

APA StyleBuri, Z., & T. Kiss, J. (2025). Digitalisation in the Context of Industry 4.0 and Industry 5.0: A Bibliometric Literature Review and Visualisation. Applied System Innovation, 8(5), 137. https://doi.org/10.3390/asi8050137