Optimizing Bus Driver Scheduling: A Set Covering Approach for Reducing Transportation Costs

Abstract

1. Introduction

Our Contribution

2. Constructing Vehicle Schedules

- Information about the trips, including the departure and arrival times, the geographical locations of the departure and arrival stations, the type of vehicle needed, running distance, and category (local or regional).

- Vehicle types and related data, such as fuel type and range, running costs for normal and deadhead trips per km.

- Extra geographic information, including depot-specific characteristics, such as GPS coordinates, number of parking places, suitability for short- or long-term parking, and eligibility for breaks (the required distances and times between the geographic locations can be given or can be calculated from the GPS coordinates).

- Each trip must be assigned to a single vehicle.

- For vehicle shifts to be practical, they must adhere to the following:

- (a)

- Begin and conclude at the same depot.

- (b)

- Assignments must be completed without scheduling conflicts.

- Every depot’s capacity restrictions must be adhered to.

- Requirements for compatibility between depots and journeys must be met.

- Minimize the number of vehicles required.

- Minimize the total distance or duration of deadhead trips.

- Find an optimal (minimum) weighted sum of these costs.

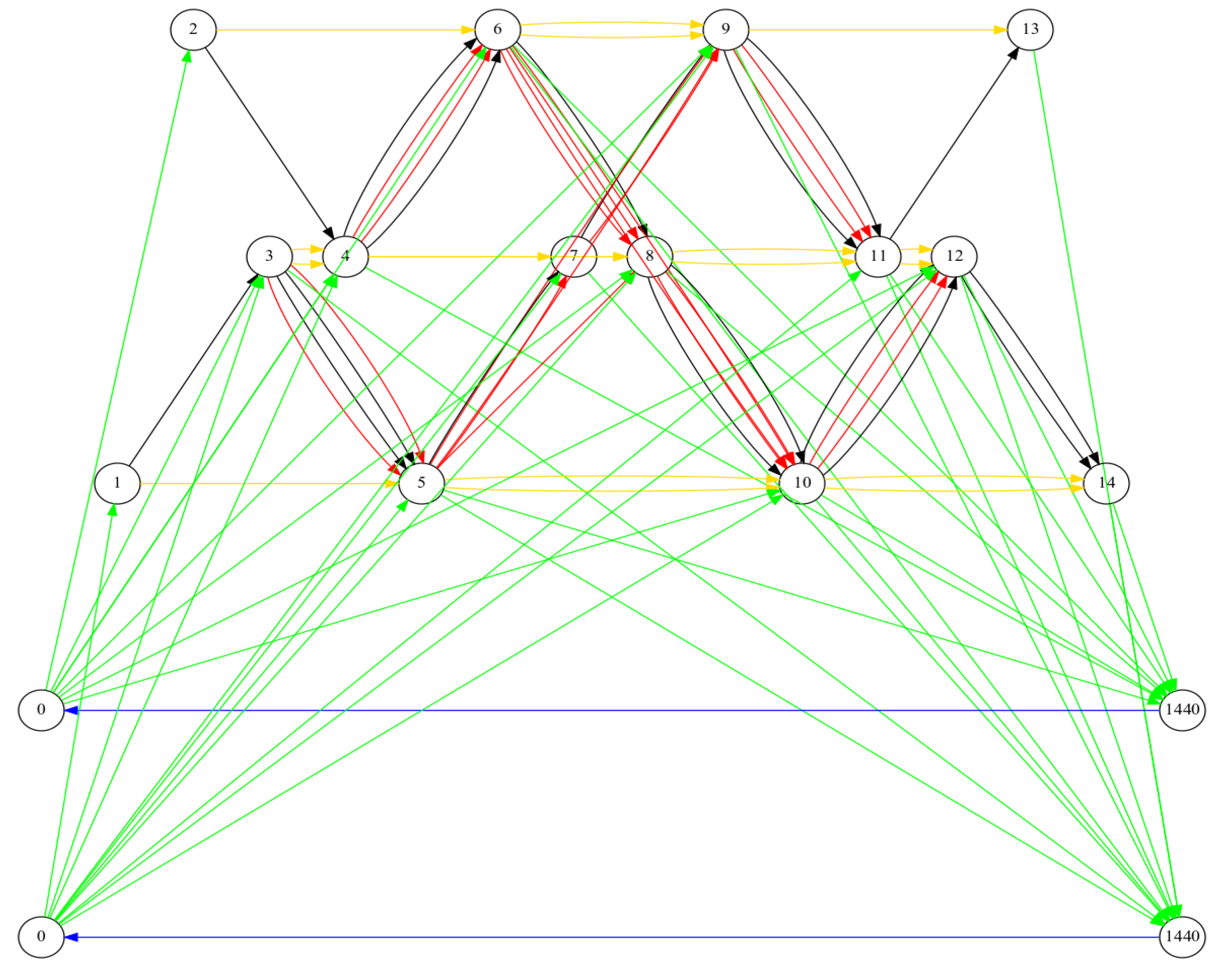

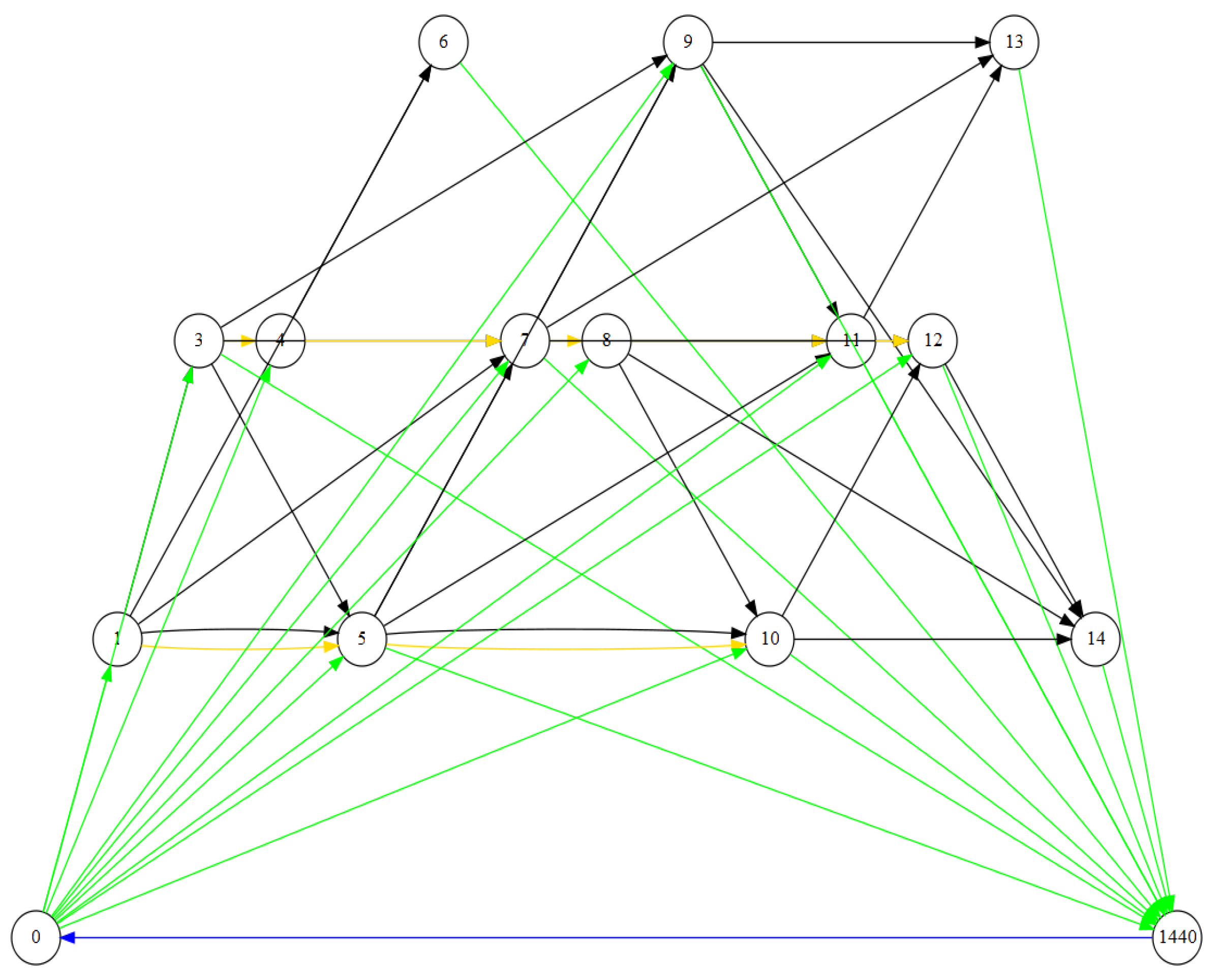

- The green edges represent deadhead trips to and from the depots.

- The red edges represent deadhead trips between the two stations.

- The yellow edges represent waiting.

- The black edges represent trips.

3. Constructing Driver Schedules

- Operating guidelines as limitations on driver scheduling

- The maximum number of hours that one can drive in a day;

- The laws governing the longest period that a driver may spend behind the wheel;

- The minimum amounts of time needed for rests, breaks, etc.

- Types of the events and shifts;

- Extra local regulations concerning breaks and the maximum number of working hours (per day).

- A driver cannot exceed 9 h of driving per day, with a maximum of two exceptions per week where it can be extended to 10 h.

- Breaks of at least 45 min must be taken after every 4.5 h of driving.

- A break can be divided into two periods, where the first is at least 15 min and the second is at least 30 min (which must be completed after 4.5 h of driving)

- Only specified areas (stations) are allowed for the minimum and maximum duration of breaks, which are 15 and 30 min long, respectively.

- The driver must take the first work break no later than five hours and fifty-nine minutes into the shift.

- If the driver works a shift for more than eight hours, a second break must start after working for 8 h and 59 min.

- If the shift exceeds nine hours, the driver must start a third break before nine hours and 59 min.

- A shift consists of three periods: the first six hours, the second two hours, and the third one hour. A break may only occur once during a period.

- The driver is exempt from taking a break if the rest period starts earlier and the shift is finished before the end of the period.

- If there is no two-hour or longer rest interval during the shift, there must be a minimum 12 h rest period after the shift. The rest period following the shift must be at least 9 h if there is at least a 2 h break during the shift. If this is not the case, the total length of the longest break during the shift plus the rest period following the shift must be at least 12 h.

- The driver must take a minimum of an 80 min break if their shift is broken into two parts. Short breaks are not allowed during a split shift. A shift must be classified as split if it has a minimum 80 min break. A split shift can have two or more components. In the latter scenario, there must be a minimum of 80 min of rest time between each of the next two shift halves; however, the total of these rest periods cannot exceed five hours.

- The driver has administrative time at the start and end of a shift. When a shift is split, there is an administrative period at the beginning and end of each part of the shift. They last about five minutes each. A driver change also has an administration period that lasts five minutes.

- There are certain paid events throughout a driver shift:

- A half-hour maintenance window for vehicles;

- A 10 min special administrative period.

These activities must be offered in blocks of at least five minutes (or in multiples of five).

- The shifts of the drivers are classified based on the duration of the trips. We refer to a shift as a long shift if it includes a trip of more than 50 km; otherwise, it is referred to as a short shift.

- After 4.5 h of nonstop driving during long shifts, drivers must take a work break of at least 45 min. There are two possible lengths for this break: the first should be at least 15 min, and the second should be at least 30 min. Each period may be extended, but the order cannot be altered.

- A maximum of nine hours may be spent driving on up to three days per week. There is a maximum driving limit of 56 h per week, which doubles to 90 h in two weeks.

- There is a minimum of 11 h of rest per 24 h. It can be split into two minimal periods: three hours and nine hours.

- The minimum weekly rest period is 45 h; this can be lowered to 36 h, but the three weeks that follow must make up for the lost time.

- Our method to solve the driver scheduling problem

- Vehicle schedules;

- Vehicle data;

- Driver data (driving license types, contract types);

- Geographical locations.

3.1. The Set Covering Formulation Used as the Mathematical Basis for Driver Scheduling

- T is the set of timetabled trips to be covered;

- D is the set of depots;

- Kd is the set of possible driver shifts from depot d;

- Kd(t) is the set of driver shifts covering trip t from depot d;

- is the cost of shift k from depot d;

- is the variable indicating if shift k from depot d is included in the solution or not.

- The algorithm of the solution

- Step 1 Generate all feasible workpieces from vehicle schedules to form an initial set of columns.

- Step 2 Using the current column set K, solve the relaxed master problem. Save the dual program’s information as well as the current lower bound.

- Step 3 Determine new columns with a negative reduced cost by solving the pricing problem for each depot. Add these new columns to the existing set.

- Step 4 Proceed to Step 2 if Step 3 contains new columns with negative reduced costs and the number of steps is less than a specified parameter.

- Step 5 Solve the IP problem and build an integer solution with the current column set.

| Algorithm 1 Generate workpieces from a vehicle schedule. |

|

| Algorithm 2 Solve a set partition problem for each vehicle schedule by a greedy heuristic to obtain the initial driver shifts |

|

- The maximum working time;

- The maximum shift duration;

- The maximum number of workpieces;

- The maximum driving time.

3.2. Computational Results

- Minimum length of the workpieces: 30 min;

- Maximum length of the workpieces: 300 min;

- Minimum number of trips per workpiece: 1;

- Maximum number of trips per workpiece: not limited;

- Maximum number of workpieces per shift: 3;

- Maximum working time and shift duration: 720 min;

- Maximum driving time: 540 min.

- INS: Initial number of driver shifts, i.e., columns;

- FNS: The final number of driver shifts after solving the integer model;

- IOV: Initial value of the objective function;

- FROV: Final value of the objective function for the relaxed problem;

- FIOV: Final value of the objective function for the integer problem;

- RG%: Relative gap.

| Problem | Number of Trips | Number of Vehicles | Number of Drivers | Number of CG Iterations | Time (minutes) |

|---|---|---|---|---|---|

| #1 | 830 | 99 | 225 | 104 | 2 |

| #2 | 902 | 107 | 229 | 143 | 3 |

| #3 | 900 | 105 | 229 | 155 | 3 |

| #4 | 951 | 104 | 201 | 188 | 6 |

| #5 | 1465 | 175 | 292 | 286 | 30 |

| #6 | 1467 | 175 | 297 | 272 | 29 |

| #7 | 1483 | 174 | 298 | 223 | 21 |

| Problem | Depot 1 | |||||

|---|---|---|---|---|---|---|

| INS | FNS | IOV | FROV | FIOV | RG% | |

| #1 | 76 | 58 | 781,674 | 603,116 | 603,116 | 0 |

| #2 | 60 | 36 | 632,574 | 360,320.601 | 377,021 | 4.42 |

| #3 | 60 | 36 | 632,574 | 360,320.601 | 377,021 | 4.42 |

| #4 | 69 | 43 | 727,607 | 419,176.834 | 445,501 | 5.91 |

| #5 | 93 | 49 | 951,707 | 496,062.845 | 507,398 | 2.23 |

| #6 | 93 | 57 | 973,703 | 574,549.559 | 590,071 | 2.63 |

| #7 | 90 | 52 | 943,671 | 531,940.470 | 538,806 | 1.27 |

| Problem | Depot 2 | |||||

|---|---|---|---|---|---|---|

| INS | FNS | IOV | FROV | FIOV | RG% | |

| #1 | 227 | 158 | 2,405,062 | 1,658,725.778 | 1,676,210 | 1.04 |

| #2 | 190 | 119 | 2,032,993 | 1,228,429.196 | 1,254,494 | 2.07 |

| #3 | 190 | 122 | 2,043,245 | 1,267,100.875 | 1,285,449 | 1.42 |

| #4 | 209 | 119 | 2,258,083 | 1,245,889.563 | 1,271,081 | 1.98 |

| #5 | 322 | 194 | 3,450,365 | 2,014,750.609 | 2,050,696 | 1.75 |

| #6 | 321 | 192 | 3,434,485 | 2,003,882.411 | 2,038,130 | 1.68 |

| #7 | 326 | 195 | 3,485,790 | 2,035,322.634 | 2,060,903 | 1.24 |

| Problem | Depot 3 | |||||

|---|---|---|---|---|---|---|

| INS | FNS | IOV | FROV | FIOV | RG% | |

| #1 | 11 | 9 | 105,632 | 95,177 | 95,177 | 0 |

| #2 | 75 | 74 | 910,375 | 895,845 | 895,845 | 0 |

| #3 | 72 | 71 | 910,375 | 851,249 | 851,249 | 0 |

| #4 | 39 | 39 | 474,073 | 474,073 | 474,073 | 0 |

| #5 | 49 | 49 | 613,759 | 613,441 | 613,441 | 0 |

| #6 | 48 | 48 | 603,821 | 603,503 | 603,503 | 0 |

| #7 | 55 | 51 | 671,171 | 627,329 | 627,329 | 0 |

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Desaulniers, G.; Hickman, M.D. Public Transit. In Handbook in OR & MS; Barnhart, C., Laporte, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; Volume 14. [Google Scholar] [CrossRef]

- Ibarra-Rojas, O.J.; Delgado, F.; Giesen, R.; Muñoz, J.C. Planning, operation, and control of bus transport systems: A literature review. Transp. Res. Part B Methodol. 2015, 77, 38–75. [Google Scholar] [CrossRef]

- Ferro, G.; Minciardi, R.; Parodi, L.; Robba, M. Optimization of Electric-Vehicle Charging. Scheduling and Planning Problems. In Advances in Industrial Control; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Perumal, S.S.G.; Lusby, R.M.; Larsen, J. Electric bus planning & scheduling: A review of related problems and methodologies. Eur. J. Oper. Res. 2022, 301, 395–413. [Google Scholar] [CrossRef]

- Van Kooten Niekerk, M.E.; van den Akker, J.M.; Hoogeveen, J.A. Scheduling electric vehicles. Public Transp. 2017, 9, 155–176. [Google Scholar] [CrossRef]

- Pasha, J.; Li, B.; Elmi, Z.; Fathollahi-Fard, A.M.; Lau, Y.; Roshani, A.; Kawasaki, T.; Dulebenets, M.A. Electric vehicle scheduling: State of the art, critical challenges, and future research opportunities. J. Ind. Inf. Integr. 2024, 38, 100561. [Google Scholar] [CrossRef]

- Yao, E.; Liu, T.; Lu, T.; Yang, Y. Optimization of electric vehicle scheduling with multiple vehicle types in public transport. Sustain. Cities Soc. 2020, 52, 101862. [Google Scholar] [CrossRef]

- Békési, J.; Brodnik, A.; Pash, D.; Krész, M. An integrated framework for bus logistic management: Case studies. In Logistik Management; Physica-Verlag: Heidelberg, Germany, 2009; pp. 389–411. [Google Scholar]

- Dávid, B.; Krész, M. Application Oriented Variable Fixing Methods for the Multiple Depot Vehicle Scheduling Problem. Acta Cybern. 2013, 21, 53–73. [Google Scholar] [CrossRef]

- Bodin, L.; Golden, B.; Assad, A.; Ball, M. Routing and Scheduling of Vehicles and Crews: The State of the Art. Comput. Oper. Res. 1983, 10, 63–211. [Google Scholar]

- Kliewer, N.; Mellouli, T.; Suhl, L. A time-space network based exact optimization model for multi-depot bus scheduling. Eur. J. Oper. Res. 2006, 175, 1616–1627. [Google Scholar] [CrossRef]

- Löbel, A. Optimal Vehicle Scheduling in Public Transit. Ph.D. Thesis, Technische Universitaet, Berlin, Germany, 1997. [Google Scholar]

- Ercsey, Z.; Kovács, Z. Multicommodity network flow model of a human resource allocation problem considering time periods. Cent. Eur. J. Oper. Res. 2024, 32, 1041–1059. [Google Scholar] [CrossRef]

- Hadjar, A.; Marcotte, O.; Soumis, F. A Branch-and-Cut Algorithm for the Multiple Depot Vehicle Scheduling Problem. Oper. Res. 2006, 54, 130–149. [Google Scholar] [CrossRef]

- Ribeiro, C.C.; Soumis, F. A Column Generation Approach to the Multiple-Depot Vehicle Scheduling Problem. Oper. Res. 1994, 42, 41–52. [Google Scholar] [CrossRef]

- Bunte, S.; Kliewer, N. An overview on vehicle scheduling models. J. Public Transp. 2009, 1, 299–317. [Google Scholar] [CrossRef]

- Balogh, J.; Békési, J.; Galambos, G.; Krész, M. Model and Algorithm for a Vehicle Scheduling Problem with Refueling. In Proceedings of the 9th Workshop on Models and Algorithms for Planning and Scheduling Problems, Abbey Rolduc, The Netherlands, 29 June–3 July 2009; pp. 229–231. [Google Scholar]

- Tóth, A.; Krész, M. An efficient solution approach for real-world driver scheduling problems in urban bus transportation. Cent. Eur. J. Oper. Res. 2013, 21 (Suppl. S1), 75–94. [Google Scholar] [CrossRef]

- Falkner, J.C.; Ryan, D.M. EXPRESS: Set partitioning for bus crew scheduling in Christchurch. In Computer-Aided Transit Scheduling; Desrochers, M., Rousseau, J.-M., Eds.; Lecture Notes in Economics and Mathematical Systems; Springer: Berlin, Germany, 1992. [Google Scholar]

- Smith, B.M.; Wren, A. A bus crew scheduling system using a set covering formulation. Transp. Res. 1988, 22, 97–108. [Google Scholar] [CrossRef]

- Dias, T.G.; de Sousa, J.P.; Cunha, J.F. Genetic algorithms for the bus driver scheduling problem: A case study. J. Oper. Res. Soc. 2002, 53, 324–335. [Google Scholar] [CrossRef]

- Kwan, R.S.K.; Kwan, A.S.K.; Wren, A.S.K. Evolutionary Driver Scheduling with Relief Chains. Evol. Comput. 2001, 9, 445–460. [Google Scholar] [CrossRef]

- Wren, A.; Fores, S.; Kwan, A.S.K.; Kwan, R.S.K.; Parker, M.E.; Proll, L. A flexible system for scheduling drivers. J. Sched. 2003, 6, 437–455. [Google Scholar] [CrossRef]

- Li, J. A Self-Adjusting Algorithm for Driver Scheduling. J. Heuristics 2005, 11, 351–367. [Google Scholar] [CrossRef]

- Ernst, A.T.; Jiang, H.; Krishnamoorthy, M.; Sier, D. Staff scheduling and rostering: A review of applications, methods and models. Eur. J. Oper. Res. 2004, 153, 3–27. [Google Scholar] [CrossRef]

- Gintner, V.; Kliewer, N.; Suhl, L. A Crew Scheduling Approach for Public Transit Enhanced with Aspects from Vehicle Scheduling. In Lecture Notes in Economics and Mathematical Systems 600, Computer-Aided Systems in Public Transport; Hickman, M., Mirchandani, P., Voss, S., Eds.; Springer: Heidelberg, Germany, 2008; pp. 25–42. [Google Scholar]

- Mesquita, M.; Moz, M.; Paias, A.; Paixao, J.; Pato, M.; Respício, A. A new model for the integrated vehicle-crew-rostering problem and a computational study on rosters. J. Sched. 2011, 14, 319–334. [Google Scholar] [CrossRef]

- Steinzen, I. Topics in Integrated Vehicle and Crew Scheduling in Public Transit. Ph.D. Thesis, University of Paderborn, Paderborn, Germany, 2007. [Google Scholar]

- Weider, S. Integration of Vehicle and Duty Scheduling in Public Transport. Ph.D. Thesis, TU Berlin, Berlin, Germany, 1997. [Google Scholar]

- Horváth, M.; Kis, T. Computing strong lower and upper bounds for the integrated multiple-depot vehicle and crew scheduling problem with branch-and-price. Cent. Eur. J. Oper. Res. 2019, 27, 39–67. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, Z.; Cao, Z.; Lu, Z. Optimal Bus Bridging Schedule with Transfer Passenger Demand during Disruptions of Urban Rail Transit. J. Transp. Eng. Part A Syst. 2021, 147, 04021071. [Google Scholar] [CrossRef]

- Teng, J.; Chen, T.; Fan, W. Integrated Approach to Vehicle Scheduling and Bus Timetabling for an Electric Bus Line. J. Transp. Eng. Part A Syst. 2020, 146, 04019073. [Google Scholar] [CrossRef]

- Mo, D.Y.; Lam, H.Y.; Xu, W.; Ho, G.T.S. Design of Flexible Vehicle Scheduling Systems for Sustainable Paratransit Services. Sustainability 2020, 12, 5594. [Google Scholar] [CrossRef]

- Steinzen, I.; Gintner, V.; Suhl, L.; Kliewer, N. A Time-Space Network Approach for the Integrated Vehicle- and Crew-Scheduling Problem with Multiple Depots. Transp. Sci. 2010, 44, 367–382. [Google Scholar] [CrossRef]

- Yin, W.; Hu, W.; Yan, X.; Peng, B.; Yang, X. A time-space network-based model for transportation service optimization of China Railway Express. High-Speed Railw. 2024, 2, 153–163. [Google Scholar] [CrossRef]

- Jiang, Y.; Bian, B.; Zheng, B.; Chu, J. A time space network optimization model for integrated fresh fruit harvest and distribution considering maturity. Comput. Ind. Eng. 2024, 190, 110029. [Google Scholar] [CrossRef]

- Peng, F.; Fan, X.; Wang, P.; Sheng, M. A Time-Space Network-Based Optimization Method for Scheduling Depot Drivers. Sustainability 2022, 14, 14431. [Google Scholar] [CrossRef]

- Qu, Z.; He, S. A Time-Space Network Model Based on a Train Diagram for Predicting and Controlling the Traffic Congestion in a Station Caused by an Emergency. Symmetry 2019, 11, 780. [Google Scholar] [CrossRef]

- Balogh, J.; Békési, J. Driver scheduling for vehicle schedules using a set covering approach: A case study. In Proceedings of the 10th International Conference on Applied Informatics, Eger, Hungary, 30 January–1 February 2014; pp. 219–229. [Google Scholar] [CrossRef]

- Desrochers, M.; Soumis, F. A column generation approach to the urban transit crew scheduling problem. Transp. Sci. 1989, 23, 1–65. [Google Scholar] [CrossRef]

- Chvatal, V. A greedy heuristic for the set-covering problem. Math. Oper. Res. 1979, 4, 233–235. [Google Scholar] [CrossRef]

- Irnich, S. Resource extension functions: Properties, inversion, and generalization to segments. OR Spectr. 2008, 30, 113–148. [Google Scholar] [CrossRef]

- Huisman, D. Integrated and Dynamic Vehicle and Crew Scheduling. Ph.D. Thesis, Tinbergen Institute, Erasmus University, Rotterdam, The Netherlands, 2004. [Google Scholar]

- Huisman, D.; Freling, R.; Wagelmans, A.P.M. Multiple-Depot Integrated Vehicle and Crew Scheduling. Transp. Sci. 2005, 39, 491–502. [Google Scholar] [CrossRef]

| Edge Type | Cost | Resources (Length is Measured in Time) | |||

|---|---|---|---|---|---|

|

Working time |

Shift Duration |

Driving Time |

Number of Workpieces | ||

| Pull-in | Fixed value | Length | Length | Length | 0 |

| Pull-out | 0 | Length | Length | Length | 0 |

| Workpiece | Length * Unit cost | Length | Length | Length | 1 |

| Waiting | 0 | 0 | Length | 0 | 0 |

| Problem | Number of Vehicles | Number of Driver Shifts | Total |

|---|---|---|---|

| #1 | 19 | 37 | 56 |

| #2 | 21 | 38 | 59 |

| #3 | 18 | 33 | 51 |

| #4 | 17 | 32 | 49 |

| #5 | 20 | 37 | 57 |

| #6 | 16 | 32 | 48 |

| #7 | 18 | 33 | 51 |

| #8 | 20 | 38 | 58 |

| #9 | 23 | 42 | 65 |

| #10 | 12 | 24 | 36 |

| Averages | 18.4 | 34.6 | 53 |

| Problem | Number of Vehicles | Number of Driver Shifts | Total |

|---|---|---|---|

| #1 | 34 | 68 | 102 |

| #2 | 35 | 66 | 101 |

| #3 | 34 | 62 | 96 |

| #4 | 29 | 55 | 84 |

| #5 | 35 | 66 | 101 |

| #6 | 29 | 57 | 86 |

| #7 | 32 | 60 | 92 |

| #8 | 36 | 69 | 105 |

| #9 | 43 | 77 | 120 |

| #10 | 22 | 45 | 67 |

| Averages | 32.9 | 62.5 | 95.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Árgilán, V.S.; Békési, J. Optimizing Bus Driver Scheduling: A Set Covering Approach for Reducing Transportation Costs. Appl. Syst. Innov. 2025, 8, 122. https://doi.org/10.3390/asi8050122

Árgilán VS, Békési J. Optimizing Bus Driver Scheduling: A Set Covering Approach for Reducing Transportation Costs. Applied System Innovation. 2025; 8(5):122. https://doi.org/10.3390/asi8050122

Chicago/Turabian StyleÁrgilán, Viktor Sándor, and József Békési. 2025. "Optimizing Bus Driver Scheduling: A Set Covering Approach for Reducing Transportation Costs" Applied System Innovation 8, no. 5: 122. https://doi.org/10.3390/asi8050122

APA StyleÁrgilán, V. S., & Békési, J. (2025). Optimizing Bus Driver Scheduling: A Set Covering Approach for Reducing Transportation Costs. Applied System Innovation, 8(5), 122. https://doi.org/10.3390/asi8050122