Classification and Comparative Analysis of Acoustic Agglomeration Systems for Fine Particle Removal

Abstract

1. Introduction

2. Physical Principles of Acoustic Agglomeration

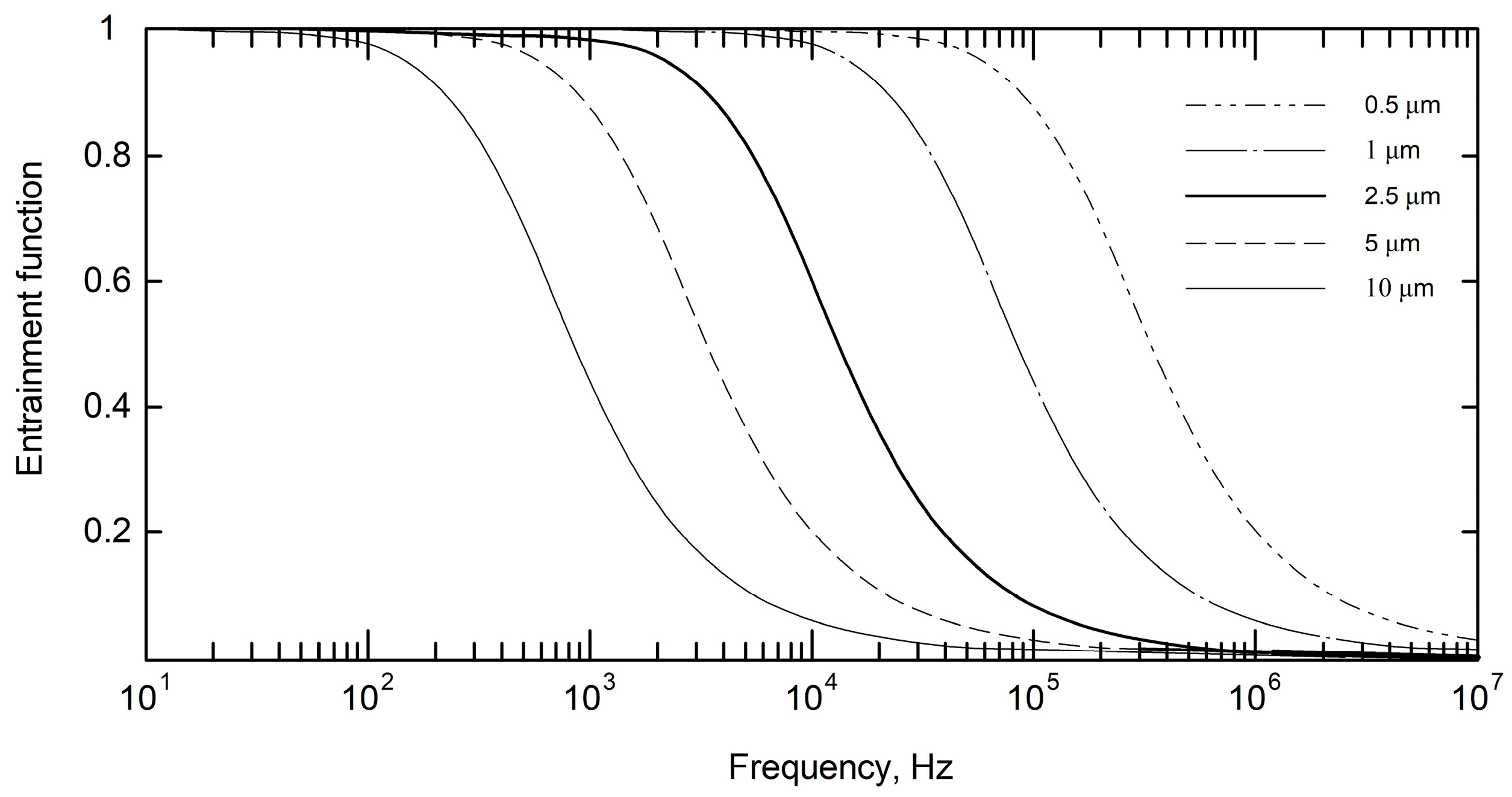

2.1. Frequency Dependence

2.2. Sound Pressure Level

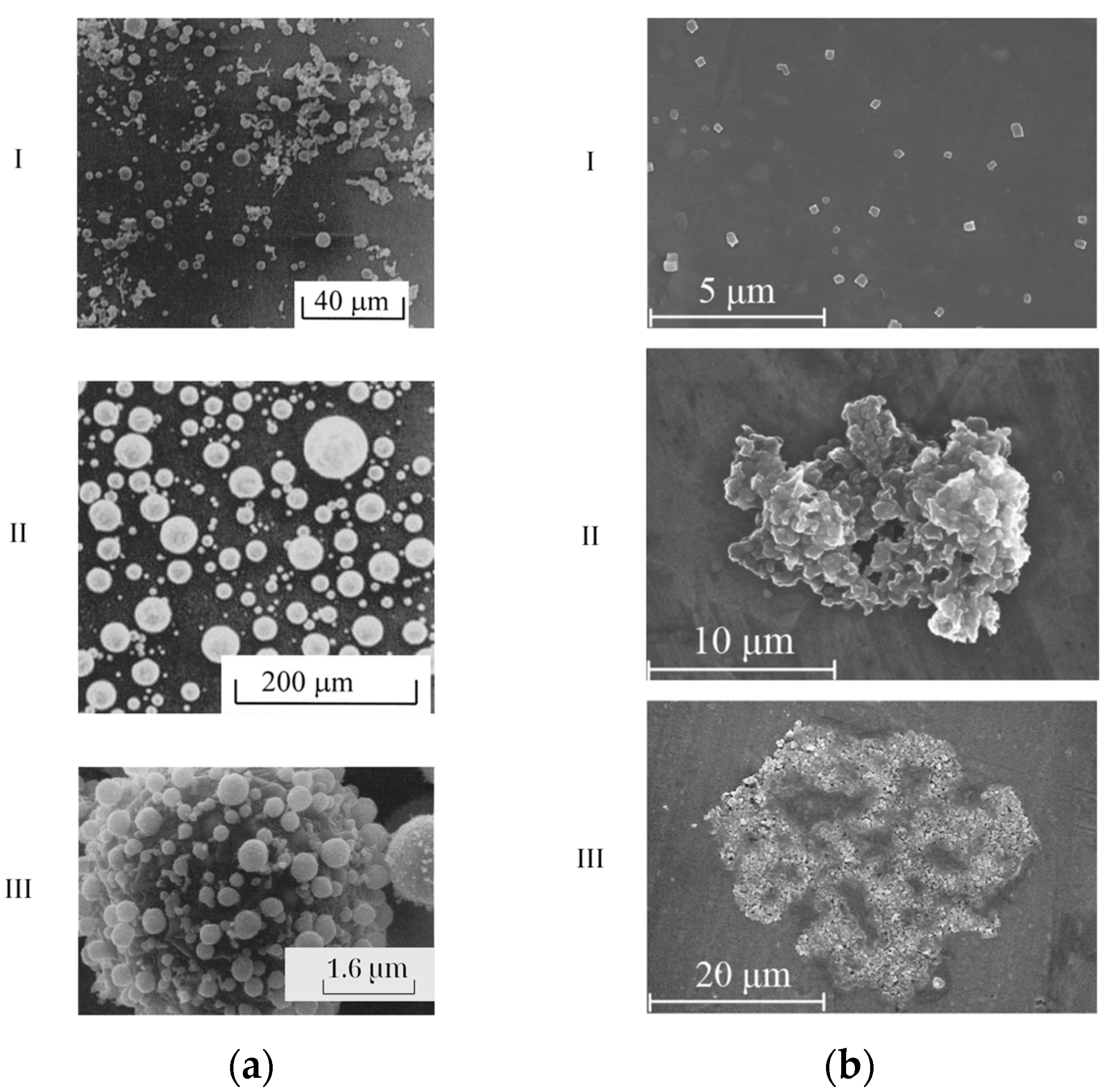

2.3. Particle Characteristics and Concentration

2.4. Influence of Ambient Conditions

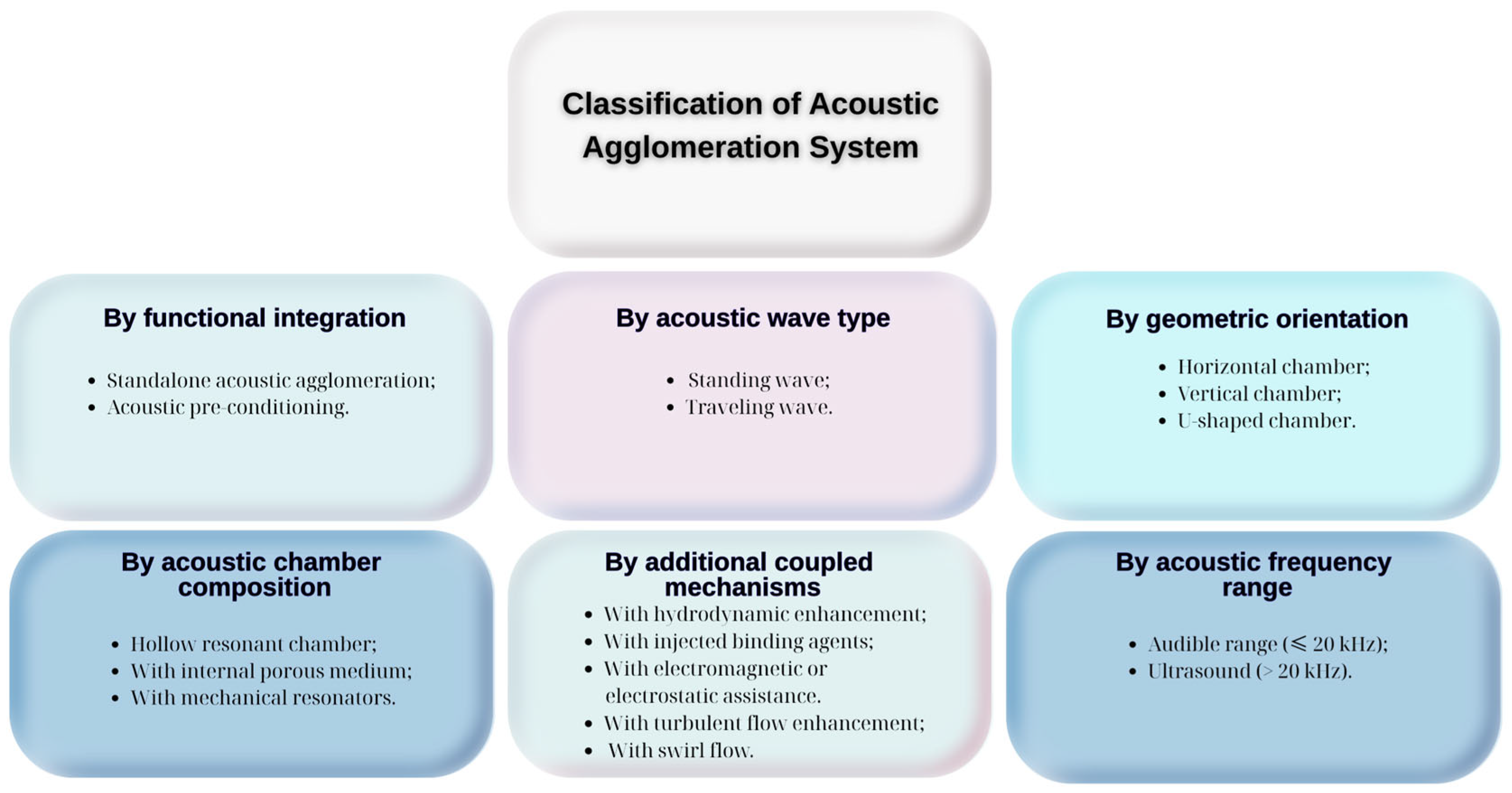

3. Classification of Acoustic Agglomeration Systems

3.1. Classification by Functional Integration

3.1.1. Standalone Acoustic Agglomeration

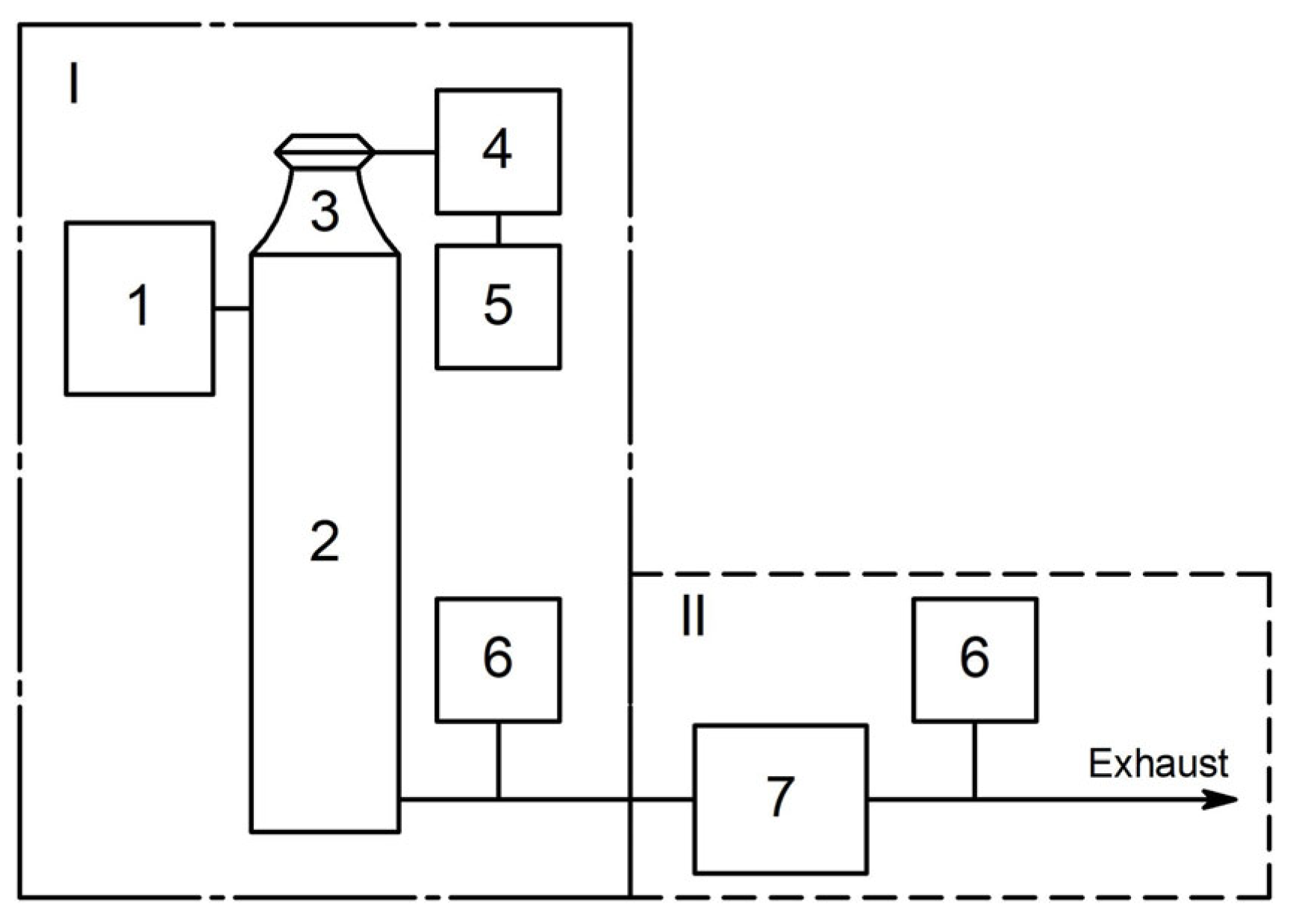

3.1.2. Acoustic Pre-Conditioning

3.2. Classification by Acoustic Wave Type

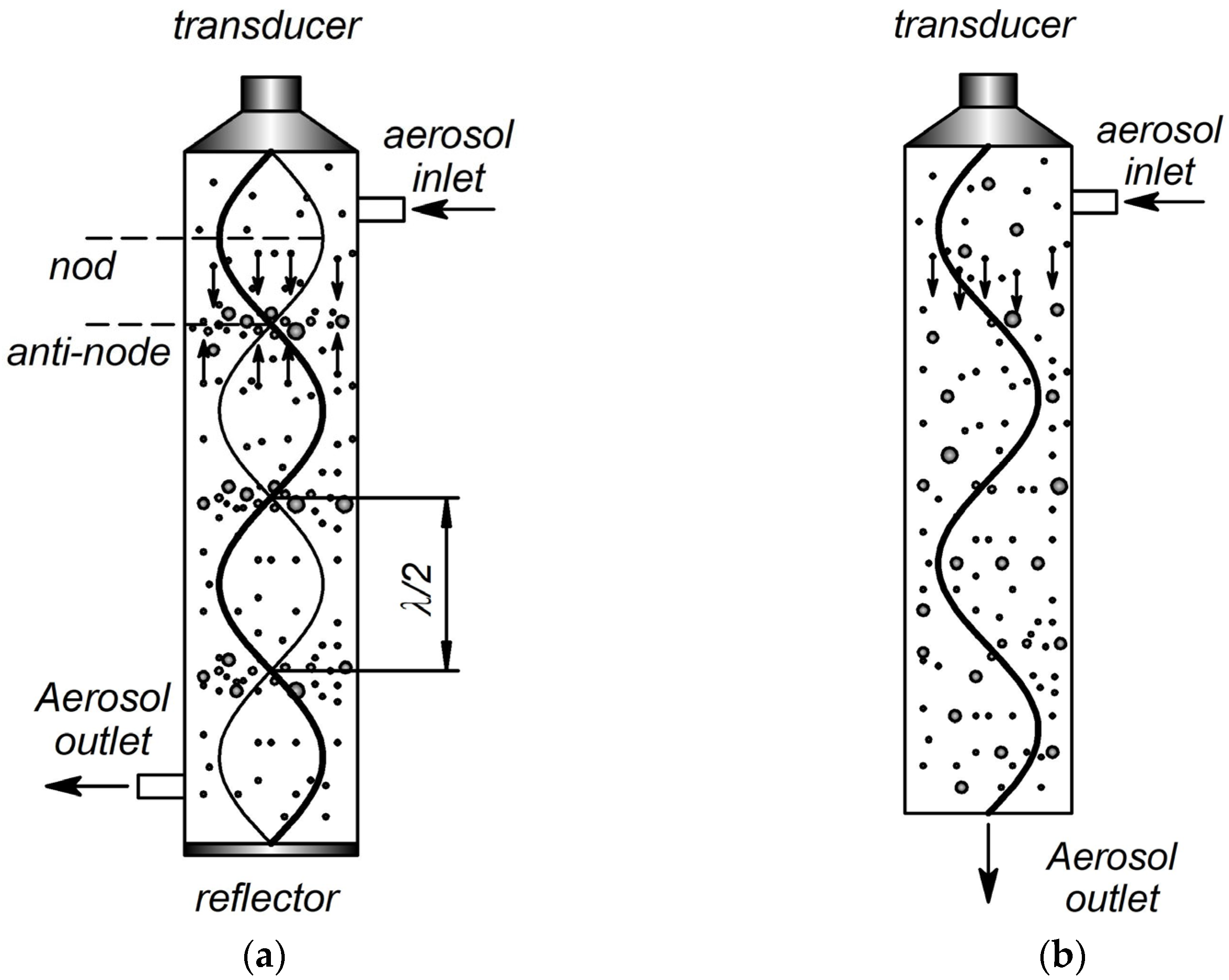

3.2.1. Standing Wave

3.2.2. Traveling Wave

3.3. Classification by Geometric Orientation

3.3.1. Horizontal Chamber

3.3.2. Vertical Chamber

3.3.3. U-Shaped Chamber

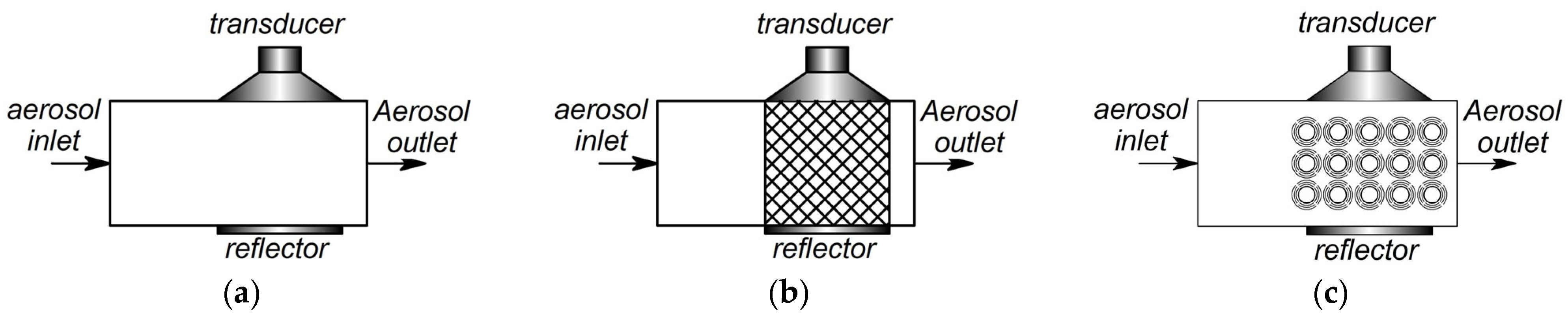

3.4. Classification by Acoustic Chamber Composition

3.4.1. Hollow Resonant Chamber

3.4.2. With Internal Porous Medium

3.4.3. With Mechanical Resonators

3.5. Classification by Additional Coupled Mechanisms (in the Acoustic Zone)

3.5.1. With Hydrodynamic Enhancement

3.5.2. With Injected Binding Agents

3.5.3. With Electromagnetic or Electrostatic Assistance

3.5.4. With Turbulent Flow Enhancement

3.5.5. With Swirl Flow

3.6. Classification by Acoustic Frequency Range

3.6.1. Audible Range

3.6.2. Ultrasound

4. Discussion

Scalability and Integration Issues

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAM | Acoustic Agglomeration Mechanism |

| ACMV | Air-Conditioning and Mechanical Ventilation |

| BY | Boundary Yield |

| CC | Combustion Chamber |

| CFD | Computational Fluid Dynamics |

| DOP | Dioctyl Phthalate |

| DSMC | Direct Simulation Monte Carlo |

| HEPA | High-Efficiency Particulate Air |

| HVAC | Heating, Ventilation, and Air Conditioning |

| MERV | Minimum Efficiency Reporting Value (Air Filter Rating) |

| PM | Particulate Matter |

| PM2.5 | Particulate Matter with Diameter ≤ 2.5 µm |

| SPL | Sound Pressure Level |

| TENG | Triboelectric Nanogenerator |

| WHO | World Health Organization |

Appendix A

| Reference | Particle Type | Particle Size and Distribution | Frequency (kHz) | Intensity (dB) | Results | Classification |

|---|---|---|---|---|---|---|

| Lai et al. [57] | – | Polydisperse, 10 µm | 6.858, 10.287, 20.574 | 70, 160 | Effective agglomeration of PM10 at ~10 kHz, 160 dB, and flow 0.1–0.3 m/s; potential to reduce energy use and pressure drop in ventilation systems | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber |

| Zhang et al. [71] | NaCl, balsa wood dust (preliminary) | Polydisperse, 0.25–10 µm | 0.836, 1.637, 2.510, 3.346, 4.183 | 108–116 | Prefiltration efficiency for 1.0 µm particles reached 61% without filter and 89% with MERV-6; system significantly improves capture of submicron particles | Acoustic pre-conditioning; standing wave; U-shaped chamber; hollow resonant chamber |

| Caperan et al. [29] | Glycol aerosol | Polydisperse, 0.5–1.5 µm, lognormal, geometric mean 0.8 µm | 10, 21 | 100–200 W (electric power) | Initial agglomeration rate increases proportionally to square of acoustic velocity amplitude; highest efficiency achieved with standing-wave field | Standalone acoustic agglomeration; traveling wave; horizontal chamber; hollow resonant chamber |

| Caperan et al. [49] | Fly ash | Polydisperse, dae ≈ 1.6 µm | 21 | 200 W (electric power) | Agglomeration rate K0 = 2.5 × 10−2 s−1, 3.3 times higher than Brownian agglomeration rate; fine fraction efficiently removed by acoustic field | Standalone acoustic agglomeration; standing wave; hollow resonant chamber |

| Zhang et al. [70] | Ambient aerosol | Polydisperse, 0.3–3.0 µm | 0.795, 1.590, 2.385 | 104–123 | Filtration efficiency for PM2.5 increased with SPL, reaching up to 97.5% at 123 dB; highest efficiency observed under low airflow conditions | Acoustic pre-conditioning; standing wave; U-shaped chamber; with electromagnetic or electrostatic assistance |

| Gupta et al. [72] | Polystyrene particles | Polydisperse, 4–30 µm, spherical | 1103 | 20, 30 W (electric power) | Particle retention up to 60% during early phase, 35% at saturation, and 70–80% in aluminum mesh under optimal conditions | Standalone acoustic agglomeration; standing wave; horizontal chamber; with internal porous medium |

| Barrio-Zhang et al. [74] | Polystyrene | Monodisperse, 500 nm | 343 | 180 | Capture efficiency improved by up to 123 times in staggered configuration at low flow rate under 343 kHz and 180 dB | Acoustic pre-conditioning; standing wave; horizontal chamber; with internal porous medium |

| Kilikevičienė et al. [61] | Silica test dust (ISO 12103-1 A1) | Polydisperse, 0.3–10 µm | 0.5–3.0 | 129–135 | Reduction in particles <1 µm: 11.4–79.0%; increase in >2 µm particles: 14.3–331.7% depending on frequency | Acoustic pre-conditioning; horizontal chamber; standing wave |

| Zhang et al. [79] | Arizona dust, water droplets | Polydisperse, 0.006–10 µm (dust); D10 = 1.4 µm and D90 = 5.4 µm (droplets) | 21 | 133.4, 135.7, 136.9 | PM concentration reduced to 30% of original value with AA+DA; filtration efficiency increased by up to 57% compared to baseline | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber; with injected binding agents |

| Zhao et al. [78] | Solid particles and liquid droplets | Not specified | 1–26 | 140, 148 | Agglomeration efficiency increased from 51.6% to 77.1% (140→148 dB) at 1.4 × 104 drops/cm3; from 68.2% to 85.6% at 2.4 × 104 drops/cm3 | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber; with injected binding agents |

| Sadighzadeh et al. [33] | Sulfuric acid mist | Polydisperse, 0.4–20 µm | 0.132, 0.245, 0.458, 0.852, 1.410, 3.530, 7.150 | 115, 135, 155, 165 | Removal efficiency reached 86% at 852 Hz and 165 dB; increased efficiency with higher inlet concentration and lower airflow | Standalone acoustic agglomeration; standing wave; horizontal chamber; hollow resonant chamber |

| Garbarienė et al. [58] | Diesel exhaust aerosol | Polydisperse, 10–470 nm | 21.3 | 144.1 | Particle concentration (10–70 nm) reduced by 21.7%, 100–180 nm by 8.2%; overall 11.0% reduction for NExBTL100 without EGR | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber |

| Ng et al. [42] | Arizona dust | Polydisperse, 0.25–32 µm | 6.4 | 140 | Filtration efficiency of MERV 11 increased from 73% to 83%, and MERV 13 from 88% to 92%; PM0.4–0.5 concentration reduced by 16% | Acoustic pre-conditioning; standing wave; horizontal chamber; with internal porous medium |

| Gallego Juárez et al. [50] | Coal combustion aerosol | Polydisperse, 0.005–30 µm | 10, 20 | 145–165 | Mass removal efficiency up to 37%; submicron number reduction up to 40%; better results at 20 kHz | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber; with electrostatic assistance |

| Sun et al. [76] | Fly ash | Polydisperse, 0.43–10 µm | 0.28–3.5 | 100–130 | Maximum agglomeration efficiency of 36.9% achieved at 1416 Hz, 128 dB, and 22.5 m/s jet velocity; mass median diameter increased from 2.47 µm to 6.48 µm | Standalone acoustic agglomeration; standing wave; horizontal chamber; hollow resonant chamber; with hydrodynamic enhancement |

| Liu et al. [63] | Organic waste combustion PM | Polydisperse, 0.009–2.5 µm | 21 | 150 | Filtration efficiency increased up to 22.4% at 30 °C; higher temperatures reduced efficiency; biomass > MSW > polypropylene | Acoustic pre-conditioning; standing wave; vertical chamber; hollow resonant chamber; with injected binding agents |

| Moldavsky et al. [52] | Arizona fine dust | Polydisperse, 0.19–>5 µm | 0.05, 0.1, 0.3, 0.5, 1.0 | 90–130 | Filter lifespan doubled at 300 Hz and 125 dB; extended 5–10× at 50–100 Hz and 125–130 dB; no reduction in filtration efficiency, reduced pressure drop | Acoustic pre-conditioning; standing wave; horizontal chamber; hollow resonant chamber |

| Amiri et al. [32] | Dioctyl phthalate (D.O.P.) aerosol | Polydisperse, 0.26–2 µm | 0.204, 0.550, 0.650, 0.749 | 140, 150, 155, 162 | Coagulation efficiency reached 83% at 749 Hz and 162 dB; effectiveness threshold observed at ≥155 dB | Acoustic pre-conditioning; standing wave; vertical chamber; hollow resonant chamber |

| Zhou et al. [30] | Fly ash | Polydisperse, 0.3–10 µm | 1.2, 1.4, 2.0, 2.2, 2.4 | 130–148 | Filtration efficiency of bag filter increased from 91.29% to 99.19%; ESP efficiency increased from 89.05% to 99.28% at 1400 Hz, 148 dB | Acoustic pre-conditioning; traveling wave; vertical chamber; hollow resonant chamber; with mechanical filters |

| Gupta & Feke [73] | Polystyrene | Polydisperse, 2–30 µm | 1103 | 50 W (electric power) | Filtration efficiency reached 80–90% after 1–2 min; optimal power 20–40 W; too high power (50 W) reduced efficiency due to acoustic streaming | Acoustic pre-conditioning; standing wave; rectangular chamber; with internal porous medium |

| Liu et al. [53] | Fly ash | Polydisperse, 0.03–10 µm | 0.2, 1.0, 1.4, 1.6, 1.8, 20 | 150 | Efficiency of 75.3% achieved at 1400 Hz, 148 dB, 5 s; high-frequency mode (20 kHz) reduced 0.2–0.25 µm particles by 10.38% | Standalone acoustic agglomeration; traveling wave; vertical chamber; hollow resonant chamber |

| Zhang et al. [77] | Fly ash | Polydisperse, 0.15–9.5 µm | 1.4 | 135, 141, 143 | Filtration efficiency increased from 63% (baseline) to 91% with XTG binder at 7.5 W | Acoustic pre-conditioning; traveling wave; vertical chamber; hollow resonant chamber; with injected binding agents |

| Noorpoor et al. [34] | D.O.P. droplets | Monodisperse and polydisperse, 260–3000 nm | 0.2, 0.65, 0.83 | 120–145 | Removal efficiency of 260 nm particles reached 93.35% at 830 Hz, 145 dB, and 10 L/min; dropped to 43.2% at 50 L/min | Standalone acoustic agglomeration; standing-wave field; vertical chamber; hollow resonant chamber |

| González et al. [35] | Glass spheres | Monodisperse, 8.0 ± 0.9 µm | 0.2–5 | – | Collisions observed only for qp < 0.5; 100% interaction for qp = 0.05–0.15 | Standalone acoustic agglomeration; standing wave; horizontal chamber; hollow resonant chamber |

| Lu et al. [36] | Fly ash | Polydisperse, 10–100 μm | 2.0 | 158 | Observed both agglomeration and breakup of particles; stable agglomerates for size ratio a = 0.73–1.37 at 10 μm | Standalone acoustic agglomeration; standing-wave field; horizontal chamber; hollow resonant chamber; without additional mechanisms |

| Gallego-Juárez et al. [41] | Fly ash | Polydisperse, <0.005–30 μm | 10, 20 | 165 | Mass concentration reduced up to 37%; number of particles reduced up to 40%, best at 20 kHz and SPL > 160 dB | Acoustic pre-conditioning; standing-wave field; horizontal chamber; hollow resonant chamber; with electrostatic assistance |

| Zhou et al. [65] | Fly ash | Polydisperse, 0.03–10 µm | 1.0, 1.2, 1.4, 1.6, 1.8, 2.0, 2.4 | 133–144 | At 1400 Hz, 142 dB: particle concentration reduced to 35% of initial; higher SPL and concentration increase efficiency | Acoustic pre-conditioning; vertical chamber; traveling-wave field; hollow resonant chamber |

| Yan et al. [80] | Fly ash | Polydisperse, 0.023–9.314 µm | 2 | 120–157 | Particle concentration reduced by 56.7% at 150 dB with SDS droplets; 73.3% efficiency at droplet conc. of 2 × 104 cm−3 | Acoustic pre-conditioning; standing-wave field; vertical chamber; with injected binding agents |

| Volk & Moroz [18] | Carbon black | Polydisperse, 0.01–1.0 µm | 1.3, 2, 3, 4, 5, 6 | 100, 110, 120 | Fraction of particles < 1 µm reduced from 96% to 40% at 3 kHz, 120 dB | Standalone acoustic agglomeration; traveling-wave field; horizontal chamber; hollow resonant chamber |

| Liu et al. [43] | Arizona dust | Polydisperse, 0.1–10 µm | 21 | 133, 136 | Filtration pressure drop reduced by 67.3%; filtration efficiency increased; filter lifetime extended by more than 50% | Acoustic pre-conditioning; standing-wave field; vertical chamber; hollow resonant chamber; with injected binding agents |

| Yan et al. [83] | Carbonaceous dust and silico-aluminate minerals | Polydisperse; 0.023–9.314 µm | 1.8 | 120, 130, 140, 150, 153, 158 | Efficiency increased from 10–23% (acoustic only) to 53–80% with vapor condensation at SPL = 150 dB, S = 1.2 | Acoustic pre-conditioning; standing-wave field; vertical chamber; hollow resonant chamber; with injected binding agents |

| Liu et al. [66] | Smoke particles | Polydisperse, 0.2–0.5 µm (exp); 0.01–1 µm (sim) | 0.8, 1.0, 1.2, 1.4, 1.6 | 131, 133, 135 (exp); 160 (sim) | Coagulation efficiency increased from 28.6% (acoustic only) and 50.6% (electric only) to 62% under combined field | Standalone acoustic agglomeration; with electromagnetic or electrostatic assistance; standing-wave field; traveling-wave field; horizontal chamber; hollow resonant chamber |

| He et al. [84] | Fly ash | Polydisperse; 0.15–200 μm | 0.8, 1.2, 1.6, 2.0, 2.4 | 135, 139, 143 | Removal efficiency increased from 80.7% (ESP only) to 98.3% (combined field); D50 increased from 23.39 μm to 73.28 μm | Acoustic pre-conditioning; standing-wave field; vertical chamber; hollow resonant chamber; with electromagnetic or electrostatic assistance |

| Yuan et al. [56] | Cable fire smoke | Polydisperse, 0.3–10 µm | 1.5, 2, 4, 6 | 141–145 | Transmittance increased from 10% to 60% in 11 s at 1.5 kHz, 12 W; full smoke removal in ~180 s | Standalone acoustic agglomeration; standing-wave field; horizontal chamber; hollow resonant chamber |

| Kilikevičienė et al. [60] | Diesel exhaust particles | Polydisperse, 0.3–10 µm | 21.4, 33.8 | 139–141 | For D100: 44.3% reduction at 0.3 µm, 92.45% at 10 µm; for ROMEP: 6.0% reduction at 0.3 µm, 87.4% at 2 µm | Acoustic pre-conditioning; standing-wave field; horizontal chamber; hollow resonant chamber; with injected binding agents |

| Hoffmann et al. [91] | Fly ash; limestone; flue gas particles | Polydisperse; submicron to tens of microns | 0.044, 0.64–1.07, 1, 10, 19.6, 20, 21 | 140–165 | Particle mass shifted to >11 µm (23%) at 44 Hz; up to 70% reduction in micron particles at 10 kHz, 140–165 dB | Standalone acoustic agglomeration; standing-wave field; traveling-wave field; horizontal chamber; hollow resonant chamber |

| Mao et al. [82] | Cable fire smoke; water droplets | Polydisperse, 0.3–1 µm (smoke); 5–20 µm (droplets) | 1–6 | 137, 151 | Visibility threshold reached 30 s faster with droplets; same efficiency at 137 dB with droplets as 151 dB without | Standalone acoustic agglomeration; standing wave; vertical chamber; hollow resonant chamber; with injected binding agents |

| Komarov et al. [51] | Zn condensate | Polydisperse; 0.1–80 µm | 0.098, 0.210, 0.359, 0.459, 0.645, 0.991 | 142–160 | Particle size increased by 50%; number concentration decreased by 60%; mass concentration decreased by 40% at 160 dB | Standalone acoustic agglomeration; standing-wave field; vertical chamber; hollow resonant chamber |

| Guo et al. [81] | Water droplets, glycerin mist, cable fire smoke | Polydisperse; 0.3–25 µm | 15 | 143–150 | Transparency increased to 60% in 4–8 s depending on aerosol type | Standalone acoustic agglomeration; standing-wave field; vertical chamber; hollow resonant chamber |

| Sadighzadeh et al. [54] | Sulfuric acid mist | Polydisperse; 0.4–20 µm | 0.852 | 115, 135, 155, 165 | Removal efficiency increased from 22.75% to 78.69% with SPL increase | Acoustic pre-conditioning; standing-wave field; horizontal chamber; hollow resonant chamber |

| Knoop et al. [48] | Glass spheres | Polydisperse, 58–242 µm (primary), 1–3 mm (agglomerates) | 20 | — | Agglomerates fragmented under high-intensity ultrasound; fragmentation depends on primary size, humidity, and hydrophobicity | Standalone acoustic agglomeration; standing-wave field; vertical chamber; hollow resonant chamber |

| Li et al. [68] | Coal-fired ash | Polydisperse, 0.03–9.97 µm | 1.0–3.0 | 111–141 | Removal efficiency reached 70% at 1500 Hz, 141 dB, and 560 L/h cooling water flow | Acoustic pre-conditioning; standing-wave field; vertical chamber; with internal porous medium; with injected binding agents |

| Zhao et al. [67] | Coal dust | Polydisperse, 0.6–110 µm | 0.1–2.2 | 80–120 | Total dust concentration reduced from 18.25 to 9.5 mg/m3; sedimentation time reduced by 33.64%; respirable dust removal efficiency increased by 21.93% at 1300 Hz and 120 dB | Acoustic pre-conditioning; standing-wave field; horizontal chamber; hollow resonant chamber; with injected binding agents |

| Yang et al. [59] | Oil droplets | Polydisperse, 20–60% size increase depending on frequency | 1.3 | not specified | Drop diameter increased by ≈60% at 1300 Hz; aggregation enhanced at standing-wave antinodes | Acoustic pre-conditioning; standing-wave field; vertical chamber; hollow resonant chamber; with injected binding agents |

References

- Hao, Y.; Liu, Y.-M. The Influential Factors of Urban PM2.5 Concentrations in China: A Spatial Econometric Analysis. J. Clean. Prod. 2016, 112, 1443–1453. [Google Scholar] [CrossRef]

- New WHO Global Air Quality Guidelines Aim to Save Millions of Lives from Air Pollution. Available online: https://www.who.int/news/item/22-09-2021-new-who-global-air-quality-guidelines-aim-to-save-millions-of-lives-from-air-pollution (accessed on 3 May 2025).

- Air Quality in Europe 2022. Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2022/air-quality-in-europe-2022 (accessed on 3 May 2025).

- 2024 World Air Quality Report|IQAir. Available online: https://www.iqair.com/world-air-quality-report (accessed on 3 May 2025).

- Maghsoudi, M.; Mohammadi, N.; Soghi, M.; Sabet, M. Technological Trajectories in Circular Economy: Bridging Patent Analytics with Sustainable Development Goals. J. Environ. Manag. 2025, 379, 124752. [Google Scholar] [CrossRef]

- Yim, S.H.L.; Stettler, M.E.J.; Barrett, S.R.H. Air Quality and Public Health Impacts of UK Airports. Part II: Impacts and Policy Assessment. Atmos. Environ. 2013, 67, 184–192. [Google Scholar] [CrossRef]

- Querol, X.; Viana, M.; Alastuey, A.; Amato, F.; Moreno, T.; Castillo, S.; Pey, J.; De La Rosa, J.; Sánchez De La Campa, A.; Artíñano, B.; et al. Source Origin of Trace Elements in PM from Regional Background, Urban and Industrial Sites of Spain. Atmos. Environ. 2007, 41, 7219–7231. [Google Scholar] [CrossRef]

- Bollen, J.; Van Der Zwaan, B.; Brink, C.; Eerens, H. Local Air Pollution and Global Climate Change: A Combined Cost-Benefit Analysis. Resour. Energy Econ. 2009, 31, 161–181. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S. Highly Reusable Visible Light Active Hierarchical Porous WO3/SiO2 Monolith in Centimeter Length Scale for Enhanced Photocatalytic Degradation of Toxic Pollutants. Sep. Purif. Technol. 2020, 231, 115916. [Google Scholar] [CrossRef]

- Mednikov, E.P. Acoustic Coagulation and Precipitation of Aerosols; Consultants Bureau: New York, NY, USA, 1965. [Google Scholar]

- Ezzatneshan, E.; Vaseghnia, H. Dynamics of an Acoustically Driven Cavitation Bubble Cluster in the Vicinity of a Solid Surface. Phys. Fluids 2021, 33, 123311. [Google Scholar] [CrossRef]

- Wood, R.W.; Loomis, A.L. The Physical and Biological Effects of High-Frequency Sound-Waves of Great Intensity. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1927, 4, 417–436. [Google Scholar] [CrossRef]

- Patterson, H.S.; Cawood, W. Phenomena in a Sounding Tube. Nature 1931, 127, 667. [Google Scholar] [CrossRef]

- Da Costa Andrade, E.N. On the Groupings and General Behaviour of Solid Particles under the Influence of Air Vibrations in Tubes. Philos. Trans. R. Soc. Lond. Ser. A Contain. Pap. A Math. Or Phys. Character 1931, 230, 413–445. [Google Scholar] [CrossRef]

- Denser, H.W.; Neumann, E. Industrial Sonic Agglomeration and Collection Systems. Ind. Eng. Chem. 1949, 41, 2439–2442. [Google Scholar] [CrossRef]

- Fuchs, N.A.; Daisley, R.E.; Fuchs, M.; Davies, C.N.; Straumanis, M.E. The mechanics of aerosols. Physics Today 1965, 18, 73. [Google Scholar] [CrossRef]

- Moore, C.B.; Vonnegut, B.; Vrablik, E.A. Gushes of Rain and Hail After Lightning. J. Atmos. Sci. 1964, 21, 646–665. [Google Scholar] [CrossRef]

- Volk, M.; Hogg, R. Sonic Agglomeration: A Promising Ethod of Enhancing the Collection Efficiency of Electrostatic Precipitators. J. Acoust. Soc. Am. 1977, 61, 81–82. [Google Scholar] [CrossRef]

- Chou, K.H.; Lee, P.S.; Shaw, D.T. Aerosol Agglomeration in High-Intensity Acoustic Fields. J. Colloid Interface Sci. 1981, 83, 335–353. [Google Scholar] [CrossRef]

- Tiwary, R.; Reethof, G. Hydrodynamic Interaction of Spherical Aerosol Particles in a High Intensity Acoustic Field. J. Sound Vib. 1986, 108, 33–49. [Google Scholar] [CrossRef]

- Song, L.; Koopmann, G.H.; Hoffmann, T.L. An Improved Theoretical Model of Acoustic Agglomeration. J. Vib. Acoust. 1994, 116, 208–214. [Google Scholar] [CrossRef]

- González, I.; Gallego, J.A.; Hoffmann, T.L. Precise Measurements of Particle Entrainment in a Standing-Wave Acoustic Field between 20 and 3500 Hz. J. Aerosol Sci. 2000, 31, 1461–1468. [Google Scholar] [CrossRef]

- González-Gómez, I.; Hoffmann, T.L.; Gallego-Juárez, J.A. Theory and Calculation of Sound Induced Particle Interactions of Viscous Origin. Acta Acust. United Acust. 2000, 86, 784–797. [Google Scholar]

- Dong, S.; Lipkens, B.; Cameron, T.M. The Effects of Orthokinetic Collision, Acoustic Wake, and Gravity on Acoustic Agglomeration of Polydisperse Aerosols. J. Aerosol Sci. 2006, 37, 540–553. [Google Scholar] [CrossRef]

- Shi, Y.; Wei, J.; Bai, W.; Zhao, Z.; Ayantobo, O.O.; Wang, G. Theoretical Analysis of Acoustic and Turbulent Agglomeration of Droplet Aerosols. Adv. Powder Technol. 2023, 34, 104145. [Google Scholar] [CrossRef]

- Danilov, S.D.; Mironov, M.A. Mean Force on a Small Sphere in a Sound Field in a Viscous Fluid. J. Acoust. Soc. Am. 2000, 107, 143–153. [Google Scholar] [CrossRef] [PubMed]

- Zu, K.; Yao, Y.; Cai, M.; Zhao, F.; Cheng, D.L. Modeling and Experimental Study on Acoustic Agglomeration for Dust Particle Removal. J. Aerosol Sci. 2017, 114, 62–76. [Google Scholar] [CrossRef]

- Liu, P.; Shang, X.; Tan, M.W.; Shi, D.; Zhang, X.; Liu, G.; Lim, S.H.; Yin, H.; Wan, M.P.; Lisak, G.; et al. Rapid and Versatile Numerical Simulations of Acoustic Agglomeration by the Fixed Pivot-Based Population Balance Modeling. Powder Technol. 2025, 456, 120821. [Google Scholar] [CrossRef]

- Capéran, P.; Somers, J.; Richter, K.; Fourcaudot, S. Acoustic Agglomeration of a Glycol Fog Aerosol: Influence of Particle Concentration and Intensity of the Sound Field at Two Frequencies. J. Aerosol Sci. 1995, 26, 595–612. [Google Scholar] [CrossRef]

- Zhou, D.; Luo, Z.; Jiang, J.; Chen, H.; Lu, M.; Fang, M. Experimental Study on Improving the Efficiency of Dust Removers by Using Acoustic Agglomeration as Pretreatment. Powder Technol. 2016, 289, 52–59. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, L.; Wang, J.; Hu, E. Improving Acoustic Agglomeration Efficiency by Addition of Sprayed Liquid Droplets. Powder Technol. 2017, 317, 181–188. [Google Scholar] [CrossRef]

- Amiri, M.; Sadighzadeh, A.; Falamaki, C. Experimental Parametric Study of Frequency and Sound Pressure Level on the Acoustic Coagulation and Precipitation of PM2.5 Aerosols. Aerosol Air Qual. Res. 2016, 16, 3012–3025. [Google Scholar] [CrossRef]

- Sadighzadeh, A.; Mohammadpour, H.; Omidi, L.; Jafari, M.J. Application of Acoustic Agglomeration for Removing Sulfuric Acid Mist from Air Stream. Sustain. Environ. Res. 2018, 28, 20–24. [Google Scholar] [CrossRef]

- Noorpoor, A.R.; Sadighzadeh, A.; Habibnejad, H. Influence of Acoustic Waves on Deposition and Coagulation of Fine Particles. Int. J. Environ. Res. 2013, 7, 131–138. [Google Scholar]

- González, I.; Gallego, J.A.; Riera, E. Influence of the Acoustic Entrainment on Aerosol Particle Interactions: Experimental Balance of the Hydrodynamic. In Proceedings of the Forum Acusticum Sevilla 2002, Sevilla, Spain, 16 September 2002. [Google Scholar]

- Lu, M.; Fang, M.; He, M.; Liu, S.; Luo, Z. Insights into Agglomeration and Separation of Fly-Ash Particles in a Sound Wave Field. RSC Adv. 2019, 9, 5224–5233. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.; Tang, L.-J.; Cheng, L.; Wang, G.-Q.; Li, F.-F. Interaction between Strong Sound Waves and Cloud Droplets: Cloud Chamber Experiment. Appl. Acoust. 2021, 176, 107891. [Google Scholar] [CrossRef]

- Fan, F.; Yang, X.; Kim, C.N. Direct Simulation of Inhalable Particle Motion and Collision in a Standing Wave Field. J. Mech. Sci. Technol. 2013, 27, 1707–1712. [Google Scholar] [CrossRef]

- Liu, J.; Li, X. A Computational Investigation of Particle Acoustic Agglomeration in a Resonance Tube. Powder Technol. 2020, 374, 82–94. [Google Scholar] [CrossRef]

- Rodríguez Maroto, J.J.; Gómez Moreno, F.J.; Martín Espigares, M.; Gallego, J.A.; Riera, E.; Elvira, L.; Rodríguez, G.; Vázquez, F.; Hoffmann, T.L.; Montoya, F. Acoustic Preconditioning of Coal Combustion Fumes for Enhancement of Electrostatic Precipitator Performance: II. Performance Evaluation. In Coal Science and Technology; Elsevier: Amsterdam, The Netherlands, 1995; Volume 24, pp. 1903–1906. ISBN 978-0-444-82227-7. [Google Scholar]

- Gallego, J.A.; Riera, E.; Rodríguez, G.; Gálvez, J.C.; Hoffmann, T.L.; Vázquez, F.; Rodríguez Maroto, J.J.; Gómez Moreno, F.J.; Martín Espigares, M.; Acha, M.; et al. Pilot Scale Acoustic Preconditioning of Coal Combustion Fumes to Enhance Electrostatic Precipitator Performance. High Temp. Gas Clean. 1996, 3, 60–68. [Google Scholar]

- Ng, B.F.; Xiong, J.W.; Wan, M.P. Application of Acoustic Agglomeration to Enhance Air Filtration Efficiency in Air-Conditioning and Mechanical Ventilation (ACMV) Systems. PLoS ONE 2017, 12, e0178851. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, X.; Liu, G.; Hao Lim, S.; Pun Wan, M.; Lisak, G.; Feng Ng, B. Ultrasonic Aerosol Agglomeration: Manipulation of Particle Deposition and Its Impact on Air Filter Pressure Drop. Ultrason. Sonochem. 2024, 103, 106774. [Google Scholar] [CrossRef]

- King, L.V. On the Acoustic Radiation Pressure on Spheres. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1934, 147, 212–240. [Google Scholar] [CrossRef]

- Bruus, H. Acoustofluidics 7: The Acoustic Radiation Force on Small Particles. Lab. Chip 2012, 12, 1014–1021. [Google Scholar] [CrossRef]

- Settnes, M.; Bruus, H. Forces Acting on a Small Particle in an Acoustical Field in a Viscous Fluid. Phys. Rev. E 2012, 85, 016327. [Google Scholar] [CrossRef] [PubMed]

- Markauskas, D.; Maknickas, A.; Kačianauskas, R. Simulation of Acoustic Particle Agglomeration in Poly-Dispersed Aerosols. Procedia Eng. 2015, 102, 1218–1225. [Google Scholar] [CrossRef]

- Knoop, C.; Todorova, Z.; Tomas, J.; Fritsching, U. Agglomerate Fragmentation in High-Intensity Acoustic Standing Wave Fields. Powder Technol. 2016, 291, 214–222. [Google Scholar] [CrossRef]

- Capéran, P.; Somers, J.; Richter, K. Acoustic Agglomeration of Redispersed Flyash. J. Aerosol Sci. 1995, 26, S275–S276. [Google Scholar] [CrossRef]

- GallegoJuárez, J.A.; RieraFranco de Sarabia, E.; RodríguezCorral, G. Application of Acoustic Agglomeration to Reduce Fine Particle Emissions from Coal Combustion Plants. Environ. Sci. Technol. 1999, 33, 3843–3849. [Google Scholar] [CrossRef]

- Komarov, S.V.; Yamamoto, T.; Uda, T.; Hirasawa, M. Acoustically Controlled Behavior of Dust Particles in High Temperature Gas Atmosphere. ISIJ Int. 2004, 44, 275–284. [Google Scholar] [CrossRef]

- Moldavsky, L.; Fichman, M.; Gutfinger, C. Enhancing the Performance of Fibrous Filters by Means of Acoustic Waves. J. Aerosol Sci. 2006, 37, 528–539. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Zhang, G.; Zhou, J.; Cen, K. Frequency Comparative Study of Coal-Fired Fly Ash Acoustic Agglomeration. J. Environ. Sci. 2011, 23, 1845–1851. [Google Scholar] [CrossRef] [PubMed]

- Sadighzadeh, A.; Jafari, M.J.; Omidi, L.; Mohammadpour, H. An Experimental Study on the Use of Acoustic Fields at High Sound Pressure Levels for the Removal of Sulfuric Acid Mist from the Air Stream. Iran Occup. Health 2016, 13, 80–87. [Google Scholar]

- Luo, X.; Cao, J.; Gong, H.; Yan, H.; He, L. Phase Separation Technology Based on Ultrasonic Standing Waves: A Review. Ultrason. Sonochem. 2018, 48, 287–298. [Google Scholar] [CrossRef]

- Yuan, D.; Zhang, G.; Lin, C.; Lv, H.; Zhang, K.; Lin, F.; Gu, H. Fast Elimination of Cable Fire Smoke in Underground Tunnels Using Acoustic Agglomeration Technology. Tunn. Undergr. Space Technol. 2021, 117, 104154. [Google Scholar] [CrossRef]

- Lai, S.K.; Zhang, Y.; Yu, J.C.W.; Li, Y. A New Approach for an Induced Coagulation of Particulate Matter through Thermo-Acoustic Agglomeration. In Proceedings of the 2020 International Congress on Noise Control Engineering, Seoul, Republic of Korea, 23–26 August 2020; Korean Society of Noise and Vibration Engineering: Seoul, Republic of Korea, 2020. [Google Scholar]

- Garbarienė, I.; Dudoitis, V.; Ulevičius, V.; Plauškaitė-Šukienė, K.; Kilikevičius, A.; Matijošius, J.; Rimkus, A.; Kilikevičienė, K.; Vainorius, D.; Maknickas, A.; et al. Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust. Symmetry 2021, 13, 1200. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, Q.; Wang, Y.; Chen, H.; Zhang, Y.; Qiao, M.; Zhou, Y.; Zhu, N. Agglomeration of Oil Droplets Assisted by Low-Frequency Sonic Pretreatment. Powder Technol. 2023, 428, 118860. [Google Scholar] [CrossRef]

- Kilikevičienė, K.; Chlebnikovas, A.; Matijošius, J.; Kilikevičius, A. Investigation of the Acoustic Agglomeration on Ultrafine Particles Chamber Built into the Exhaust System of an Internal Combustion Engine from Renewable Fuel Mixture and Diesel. Heliyon 2023, 9, e16737. [Google Scholar] [CrossRef] [PubMed]

- Kilikevičienė, K.; Kačianauskas, R.; Rimša, V.; Kilikevičius, A. Agglomeration of Particulate Matter in Chimneys Using Acoustic Flow. Heliyon 2024, 10, e25306. [Google Scholar] [CrossRef]

- Luo, P.; Deng, Z.; Zhang, Z.; Shen, G.; Zhang, S. Research on Enhanced Mass Transfer Using Audible Acoustic Agglomeration Technology. Int. Commun. Heat Mass Transf. 2024, 156, 107721. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Liu, P.; Lim, S.H.; Wan, M.P.; Ng, B.F.; Lisak, G. Enhanced Particulate Matter Removal from Flue Gas of Organic Solid Waste through Acoustic Agglomeration. Sep. Purif. Technol. 2025, 360, 131244. [Google Scholar] [CrossRef]

- Johnson, K.A.; Vormohr, H.R.; Doinikov, A.A.; Bouakaz, A.; Shields, C.W.; López, G.P.; Dayton, P.A. Experimental Verification of Theoretical Equations for Acoustic Radiation Force on Compressible Spherical Particles in Traveling Waves. Phys. Rev. E 2016, 93, 053109. [Google Scholar] [CrossRef]

- Zhou, D.; Luo, Z.; Fang, M.; Xu, H.; Jiang, J.; Ning, Y.; Shi, Z. Preliminary Experimental Study of Acoustic Agglomeration of Coal-Fired Fine Particles. Procedia Eng. 2015, 102, 1261–1270. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, C.; Zhang, L.; Ding, H.; Huang, H.; Xu, F.; Bu, S.; Jin, H.; Xu, W. Experimental and Numerical Study on the Acoustic Coagulation of Charged Particles. Powder Technol. 2022, 410, 117780. [Google Scholar] [CrossRef]

- Zhao, B.; Xiao, P.; Li, S.; Liu, X.; Lin, H.; Yan, D.; Chen, Z.; Chen, L. Study on the Influence Pattern and Efficiency Enhanced Mechanism of Acoustic–Chemical Spray Dust Reduction. Sci. Total Environ. 2023, 900, 165913. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Wang, E.; Wang, Q.; Husnain, N.; Li, D.; Fareed, S. Improving the Removal of Inhalable Particles by Combining Flue Gas Condensation and Acoustic Agglomeration. J. Clean. Prod. 2020, 261, 121270. [Google Scholar] [CrossRef]

- Korobiichuk, I.; Shybetskyi, V.; Kalinina, M.; Rzeplinska-Rykala, K. Simulation of Ultrasonic Vibration Propagation Through Resonators for Acoustic Coagulation Intensification. In Automation 2023: Key Challenges in Automation, Robotics and Measurement Techniques; Lecture Notes in Networks and Systems; Springer Nature: Cham, Switzerland, 2023; pp. 165–172. ISBN 978-3-031-25843-5. [Google Scholar]

- Zhang, Y.; Lai, S.-K.; Wang, C.; Ho, K.-F.; Wang, C.H. Acoustic Energy Boosts Air Purification: A Novel Sound-Wave Drive TENG for Filterless Particulate Capturing. Nano Energy 2025, 135, 110674. [Google Scholar] [CrossRef]

- Zhang, Y.T.; Lai, S.K.; Yu, J.C.W.; Guo, H.; Lim, C.W. A Novel U-Shaped Acoustic-Manipulated Design to Enhance the Performance of Low-Efficiency Filters for Sub-Micron Particles. Powder Technol. 2021, 392, 412–423. [Google Scholar] [CrossRef]

- Gupta, S.; Feke, D.L. Acoustically Driven Collection of Suspended Particles within Porous Media. Ultrasonics 1997, 35, 131–139. [Google Scholar] [CrossRef]

- Gupta, S.; Feke, D.L. Filtration of Particulate Suspensions in Acoustically Driven Porous Media. AIChE J. 1998, 44, 1005–1014. [Google Scholar] [CrossRef]

- Barrio-Zhang, A.; Anandan, S.; Deolia, A.; Wagner, R.; Warsinger, D.M.; Ardekani, A.M. Acoustically Enhanced Porous Media Enables Dramatic Improvements in Filtration Performance. Sep. Purif. Technol. 2024, 342, 126972. [Google Scholar] [CrossRef]

- Shybetskyi, V.; Kalinina, M.; Semeniuk, S.; Khyzhna, D. Ultrasonic Pre-treatment for Enhanced Air Filtration in Pharmaceutical Cleanrooms. In «Biotechnology of the 21st Century»: Materials of the 19th International Scientific and Practical Conference; Igor Sikorsky Kyiv Polytechnic Institute: Kyiv, Ukraine, 2025. [Google Scholar]

- Sun, D.; Zhang, X.; Fang, L. Coupling Effect of Gas Jet and Acoustic Wave on Inhalable Particle Agglomeration. J. Aerosol Sci. 2013, 66, 12–23. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, T.; Zhang, L.; Wang, J.; Chi, Z.; Hu, E. Improving Acoustic Agglomeration Efficiency of Coal-Fired Fly-Ash Particles by Addition of Liquid Binders. Chem. Eng. J. 2018, 334, 891–899. [Google Scholar] [CrossRef]

- Zhao, H.; Fan, F.; Su, J.; Hu, X.; Su, M. An Improved DSMC Method for Acoustic Agglomeration of Solid Particles Assisted by Spray Droplets. Int. J. Multiph. Flow 2024, 176, 104829. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, P.; Liu, G.; Lim, S.H.; Wan, M.P.; Lisak, G.; Ng, B.F. An Efficient Strategy to Enhance Air Filtration through the Synergistic Effects of Ultrasonics and Seed Particles. Sep. Purif. Technol. 2025, 353, 128600. [Google Scholar] [CrossRef]

- Yan, J.; Chen, L.; Li, Z. Removal of Fine Particles from Coal Combustion in the Combined Effect of Acoustic Agglomeration and Seed Droplets with Wetting Agent. Fuel 2016, 165, 316–323. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, G.; Li, Y.; Gu, H.; Yuan, D.; Liu, M. Study on Aerosol Agglomeration Using the Airborne Ultrasonic Transducer. Particuology 2023, 82, 157–165. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, G.; Gu, H.; Yuan, D.; Liu, M. Experimental Study of Acoustic Agglomeration Coupled with Water Droplets on Eliminating Cable Fire Smoke. Powder Technol. 2022, 412, 117977. [Google Scholar] [CrossRef]

- Yan, J.; Chen, L.; Yang, L. Combined Effect of Acoustic Agglomeration and Vapor Condensation on Fine Particles Removal. Chem. Eng. J. 2016, 290, 319–327. [Google Scholar] [CrossRef]

- He, M.; Luo, Z.; Lu, M.; Liu, S.; Fang, M. Effects of Acoustic and Pulse Corona Discharge Coupling Field on Agglomeration and Removal of Coal-Fired Fine Particles. Aerosol Air Qual. Res. 2019, 19, 2585–2596. [Google Scholar] [CrossRef]

- Wang, M. Laboratory Investigation on Acoustic Agglomeration in Turbulence and Field Exploration on Acoustic Impact in Artificial Rainfall Technology. Ph.D. Thesis, University of Hong Kong, Hong Kong SAR, China, 2022. [Google Scholar]

- Lee, P.S.; Cheng, M.T.; Shaw, D.T. The Influence of Hydrodynamic Turbulence on Acoustic Turbulent Agglomeration. Aerosol Sci. Technol. 1982, 1, 47–58. [Google Scholar] [CrossRef]

- Khmelev, V.N.; Shalunov, A.V.; Nesterov, V.A. Improving the Separation Efficient of Particles Smaller than 2.5 Micrometer by Combining Ultrasonic Agglomeration and Swirling Flow Techniques. PLoS ONE 2020, 15, e0239593. [Google Scholar] [CrossRef]

- Khmelev, V.N.; Shalunov, A.V.; Nesterov, V.A.; Terentiev, S.A. Influence of Acoustic Streams on the Efficiency of Ultrasonic Particle Agglomeration. Appl. Sci. 2024, 14, 559. [Google Scholar] [CrossRef]

- Rahimi, M.; Movahedirad, S.; Shahhosseini, S. CFD Study of the Flow Pattern in an Ultrasonic Horn Reactor: Introducing a Realistic Vibrating Boundary Condition. Ultrason. Sonochem. 2017, 35, 359–374. [Google Scholar] [CrossRef]

- Yun, H.; Seo, J.H.; Yang, J. Development of Particle Filters for Portable Air Purifiers by Combining Melt-Blown and Polytetrafluoroethylene to Improve Durability and Performance. Indoor Air 2024, 2024, 5055615. [Google Scholar] [CrossRef]

- Hoffmann, T.L. Environmental Implications of Acoustic Aerosol Agglomeration. Ultrasonics 2000, 38, 353–357. [Google Scholar] [CrossRef] [PubMed]

| Particle Size Range | Most Effective Construction |

|---|---|

| ≤0.5 µm | Vertical chamber + standing wave + porous medium Vertical chamber + standing wave + injected droplets Horizontal chamber + ultrasound + hollow resonator Vertical chamber + ultrasound + long exposure |

| 0.5–1 µm | Horizontal chamber + standing wave + hollow chamber Vertical chamber + standing wave + aerosol with binders Vertical chamber + porous medium + acoustic pre-conditioning Vertical chamber + ultrasound + seed particles |

| 1–3 µm | Horizontal chamber + traveling wave + no filter Vertical chamber + standing wave + orthokinetic mechanism Horizontal chamber + standing wave + turbulence |

| 3–10 µm | Horizontal chamber + traveling wave + dry flow Vertical chamber + standing wave + large binder particles Horizontal chamber + low-frequency acoustic field |

| Subcategory | Advantages | Limitations | Typical Use Cases |

|---|---|---|---|

| Classification by functional integration | |||

| Standalone acoustic agglomeration | Operates independently without filtration; flexible for lab and pilot-scale systems. | Requires high acoustic intensity; limited by agglomerate removal efficiency. | Aerosol coagulation studies; dry gas purification without filter elements. |

| Acoustic pre-conditioning | Enhances performance of downstream filters; reduces particle load and extends filter life. | Cannot operate as standalone system; dependent on integration with filters. | HVAC systems; ESP pretreatment; multistage filtration lines. |

| Classification by acoustic wave type | |||

| Standing wave | Creates stable trapping zones for particles; high control of spatial distribution. | Requires precise geometry and alignment; sensitive to flow disturbances. | Laboratory setups; stationary ducts; resonance-based agglomerators. |

| Traveling wave | Supports continuous displacement and agglomeration in flow direction. | Lower trapping force compared to standing waves; needs careful damping. | Moving gas streams; inline reactors; flow-through coagulation chambers. |

| Classification by geometric orientation | |||

| Horizontal chamber | Easier integration into ducts and industrial lines; supports wide flow regimes. | May require flow straighteners or diffusers for wave stability. | Industrial exhaust; ESP inlets; dry gas cleaning. |

| Vertical chamber | Supports gravitational sedimentation; compact footprint. | Flow rate must be controlled to avoid particle re-entrainment. | Pilot-scale agglomerators; stack-mounted treatment units. |

| U-shaped chamber | Increases residence time via recirculation; fits compact geometries. | More complex wave tuning and interaction at bends. | Portable purifiers; integrated pretreatment modules. |

| Classification by acoustic chamber composition | |||

| Hollow resonant chamber | Simplifies construction and modeling; maintains acoustic quality. | Limited field modulation options; no interaction with physical media. | Base setups for acoustic chambers. |

| With internal porous medium | Supports capture and deposition after agglomeration; enhances flow resistance control. | Risk of clogging; acoustic field distortion near obstacles. | Hybrid acoustic–filter units; airflow filtration elements. |

| With mechanical resonators | Improves field uniformity and resonance targeting; enhances trapping precision. | Requires custom tuning; structurally complex. | Compact and high-precision agglomeration systems. |

| Classification by additional coupled mechanisms (in the acoustic zone) | |||

| With hydrodynamic enhancement | Jet mixing increases collisions and agglomeration efficiency. | Sensitive to jet velocity and orientation. | Dust control in ducts with active flow injection. |

| With injected binding agents | Liquid bridges improve capture rate for fine particles. | Requires droplet control; risk of residue or coalescence. | Fire smoke, vapor co-removal; hybrid agglomeration systems. |

| With electromagnetic or electrostatic assistance | Synergistic interaction enhances agglomeration; supports lower SPLs. | Integration complexity; field interference risks. | Electroacoustic collectors; fine dust pretreatment. |

| With turbulent flow enhancement | Enhances particle collision via inertial clustering; effective for submicron particles in dynamic flows. | Less control over particle paths; may disrupt standing-wave structure | Exhaust treatment with acoustic nozzles; aerosol agglomeration in gas jets |

| With swirl flow | Promotes particle accumulation in vortex zones; enables efficient agglomeration at low concentrations. | Complex chamber geometry; swirl may entrain particles too strongly | Compact and high-precision agglomeration systems; fine aerosol agglomeration. |

| Classification by acoustic frequency range | |||

| Audible range (≤20 kHz) | Lower equipment cost; deeper penetration in dense aerosols. | Less effective on submicron particles; audible noise generation. | Coarse and fine aerosol agglomeration; low-frequency acoustic research. |

| Ultrasound (>20 kHz) | Effective for ultrafine particles; compact transducer designs. | Higher energy demand; attenuation in large volumes. | Fine aerosol agglomeration. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shybetsky, V.; Korobiichuk, I.; Kalinina, M.; Nowicki, M.; Shopova, Z.; Khyzhna, D. Classification and Comparative Analysis of Acoustic Agglomeration Systems for Fine Particle Removal. Appl. Syst. Innov. 2025, 8, 116. https://doi.org/10.3390/asi8040116

Shybetsky V, Korobiichuk I, Kalinina M, Nowicki M, Shopova Z, Khyzhna D. Classification and Comparative Analysis of Acoustic Agglomeration Systems for Fine Particle Removal. Applied System Innovation. 2025; 8(4):116. https://doi.org/10.3390/asi8040116

Chicago/Turabian StyleShybetsky, Vladyslav, Igor Korobiichuk, Myroslava Kalinina, Michał Nowicki, Zlata Shopova, and Daryna Khyzhna. 2025. "Classification and Comparative Analysis of Acoustic Agglomeration Systems for Fine Particle Removal" Applied System Innovation 8, no. 4: 116. https://doi.org/10.3390/asi8040116

APA StyleShybetsky, V., Korobiichuk, I., Kalinina, M., Nowicki, M., Shopova, Z., & Khyzhna, D. (2025). Classification and Comparative Analysis of Acoustic Agglomeration Systems for Fine Particle Removal. Applied System Innovation, 8(4), 116. https://doi.org/10.3390/asi8040116