Pixel Circuit Designs for Active Matrix Displays

Abstract

:1. Introduction

1.1. Display Technology

1.2. Driver Types

1.3. TFT Devices

1.3.1. a-Si TFT

1.3.2. LTPS TFT

1.3.3. Metal Oxide TFT

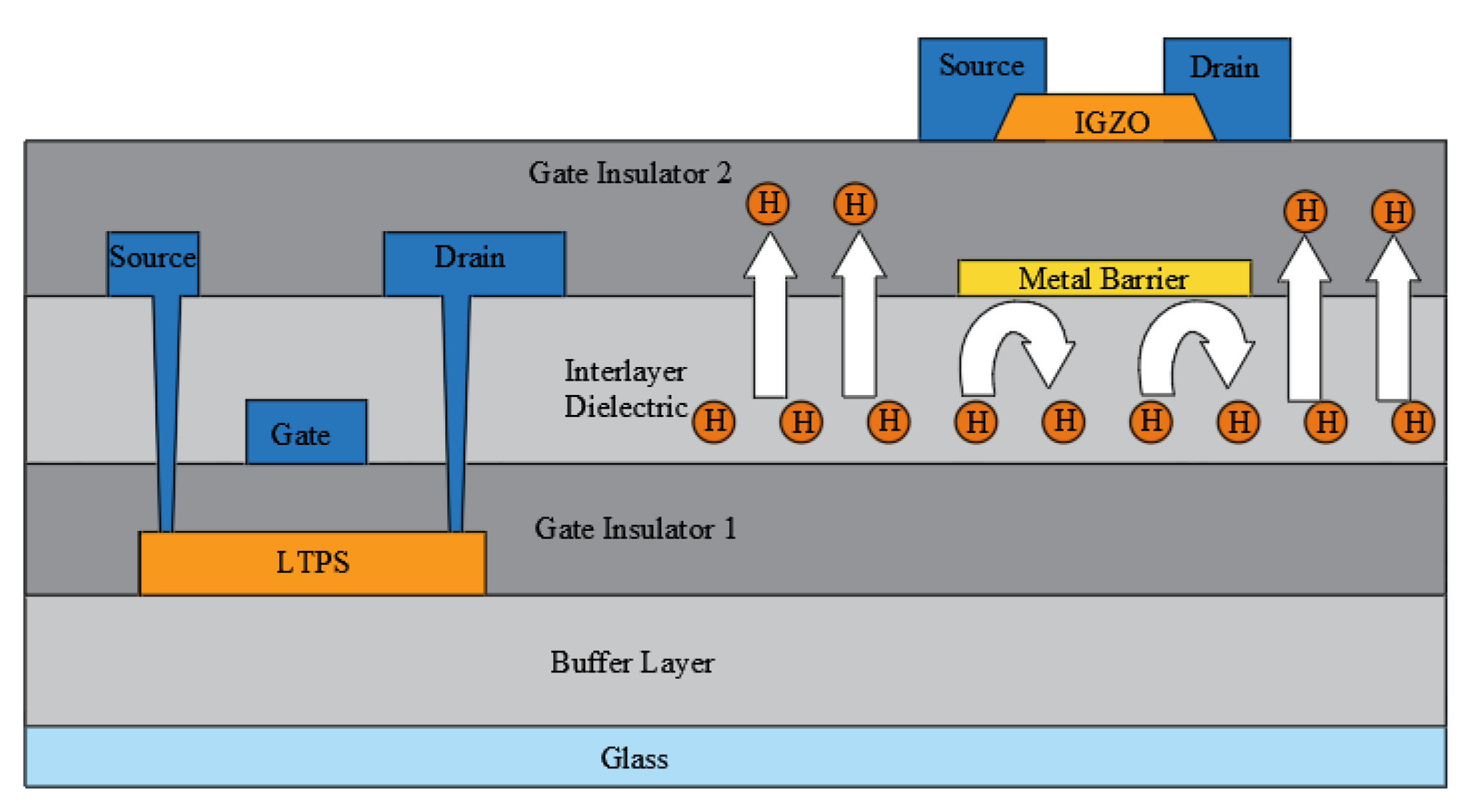

1.3.4. LTPO TFT

1.3.5. Double-Gate TFT

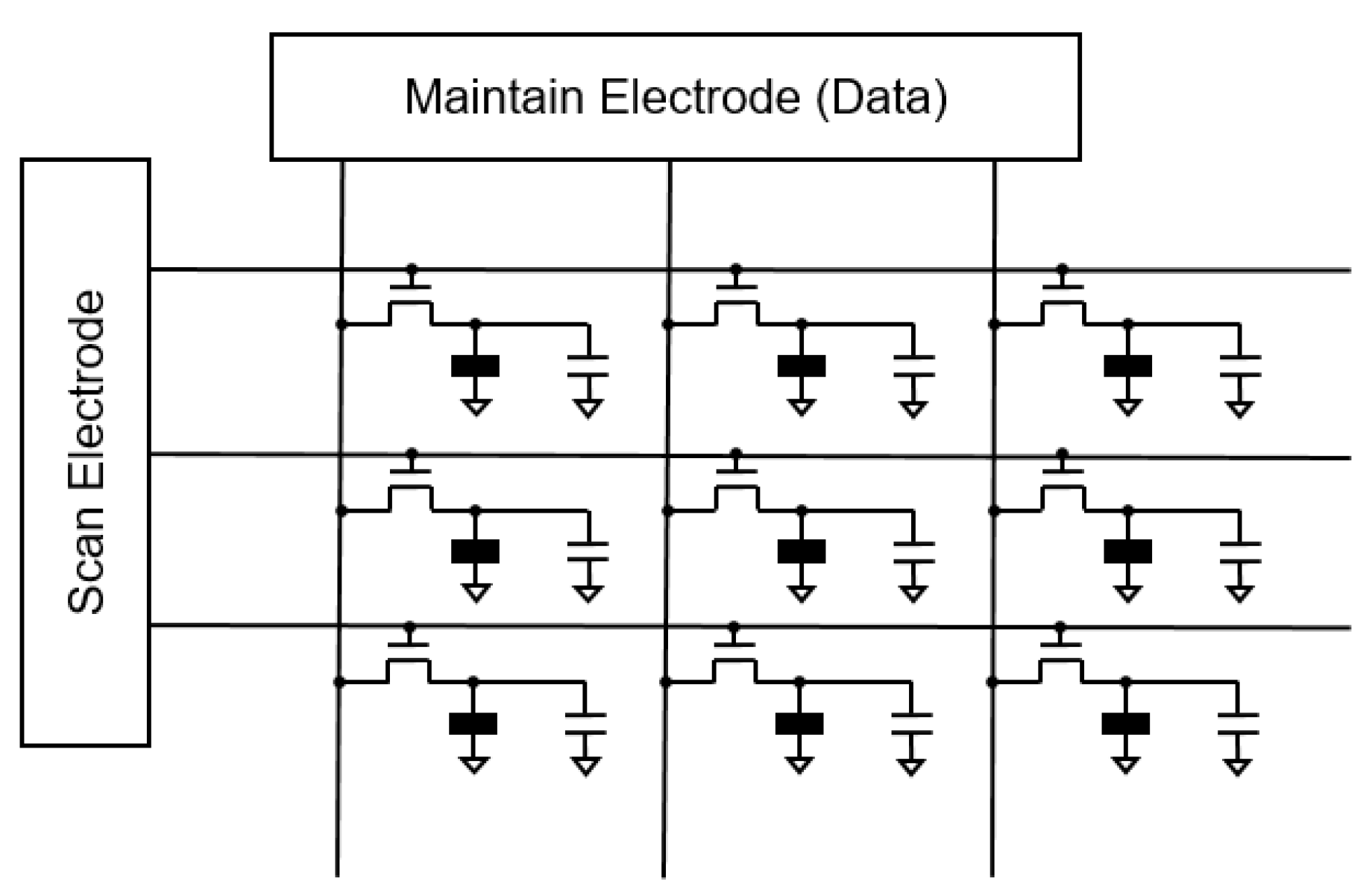

2. TFT-LCD Pixel Circuits

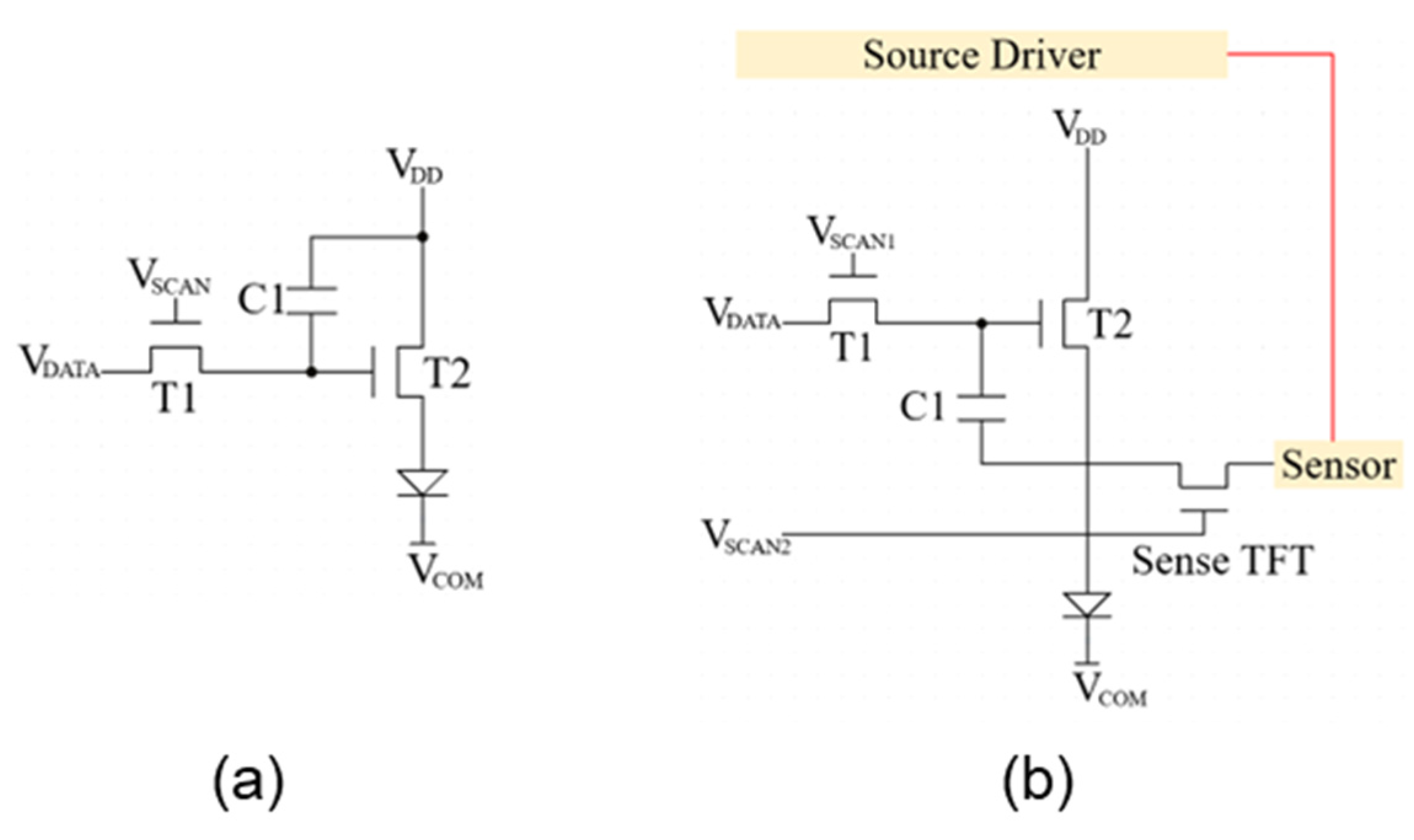

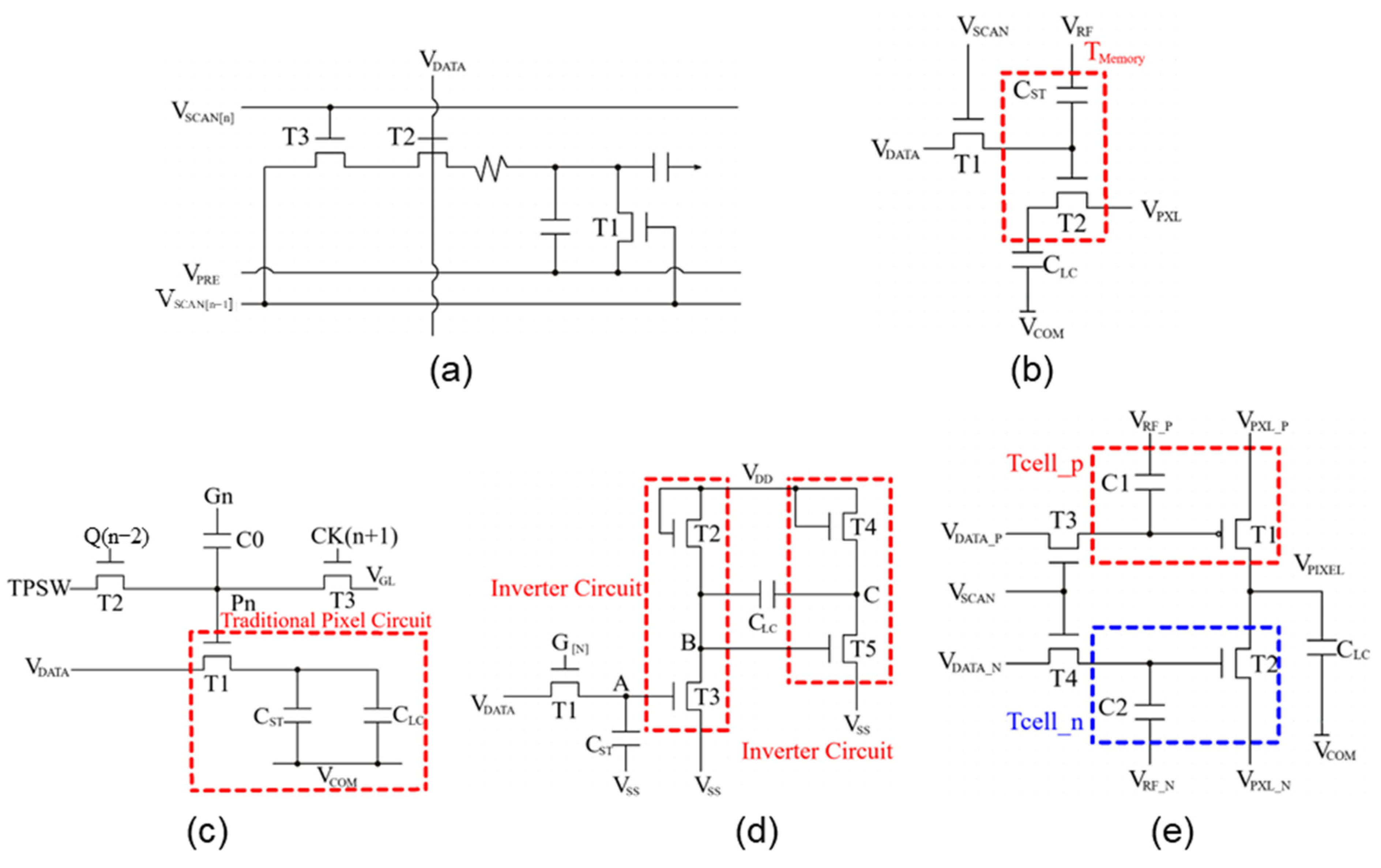

2.1. TFT-LCD Typical Pixel Circuits

2.2. TFT-LCD Novel Pixel Circuits

- LTPS TFT LCD pixel circuits

- 2.

- MO TFT LCD pixel circuits

- 3.

- LTPO TFT LCD pixel circuits

- 4.

- Double-gate TFT LCD pixel circuits

3. OLED Pixel Circuits

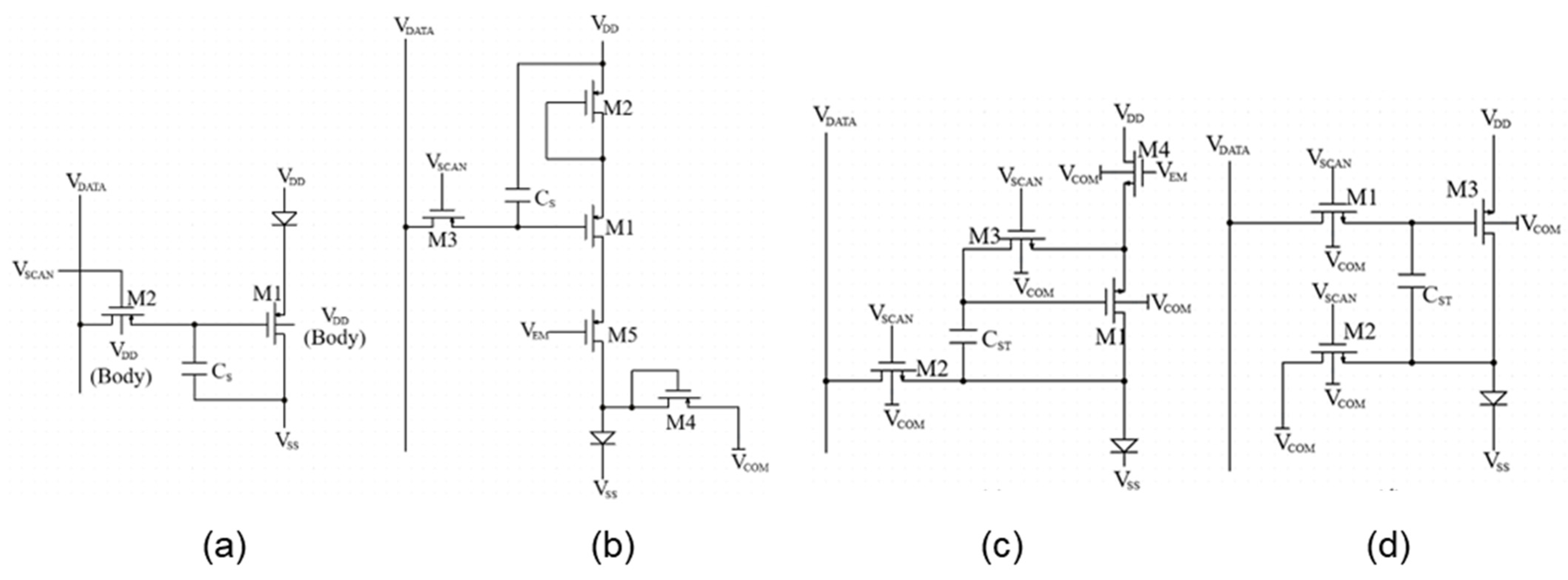

3.1. OLED Typical Pixel Circuits

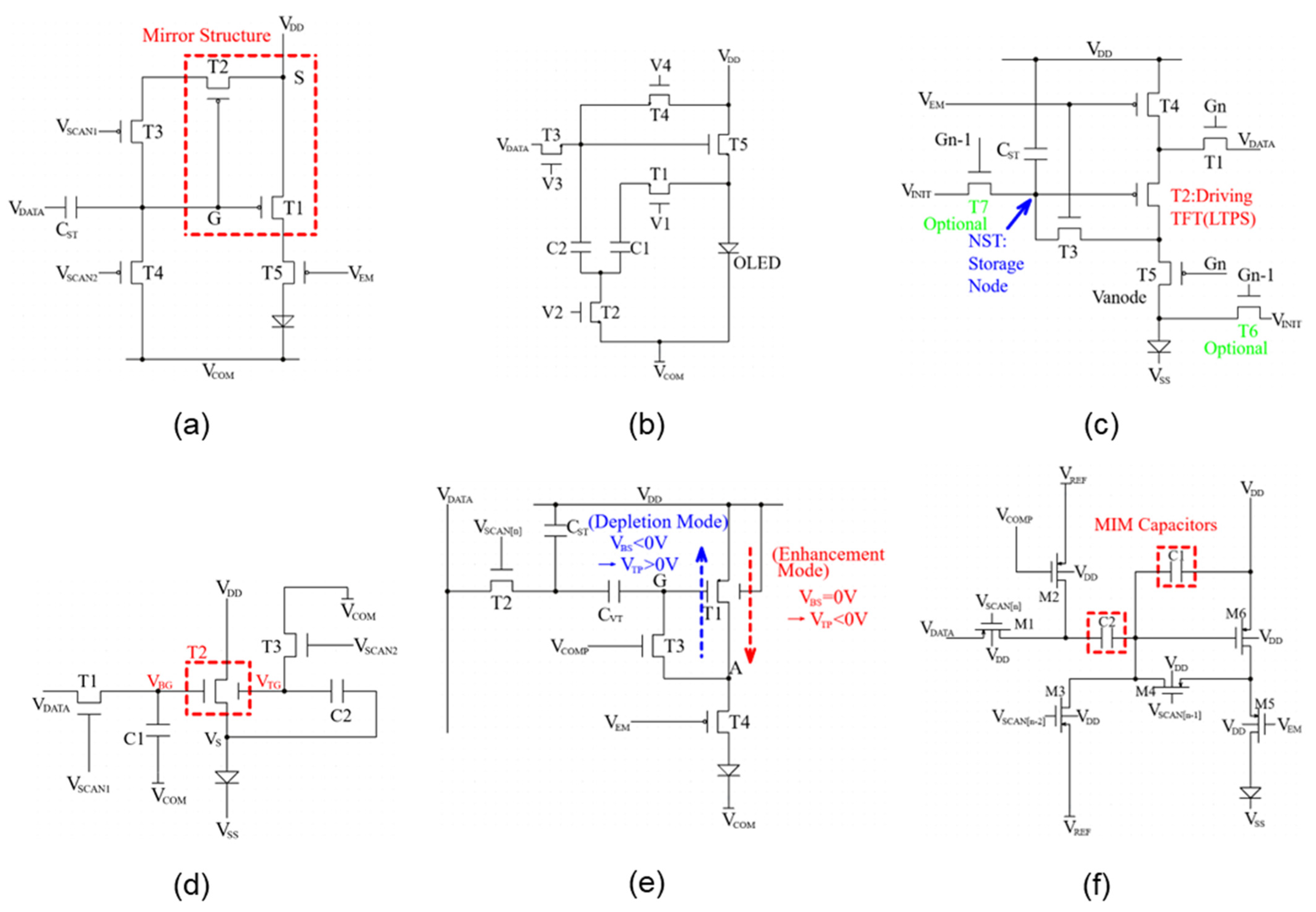

3.2. OLED Novel Pixel Circuits

3.2.1. LTPS TFT OLED Pixel Circuits

3.2.2. MO TFT OLED Pixel Circuits

3.2.3. LTPO TFT OLED Pixel Circuits

3.2.4. Double-Gate TFT OLED Pixel Circuits

| TFT-LCD and AM-OLED pixel circuit design issues and methods | |||

| Issue Category | Solutions | Examples of TFT-LCD | Examples of AM-OLED |

| Pixel charging | Improve TFT mobility, optimise driving waveforms | 3T1C [58] | / |

| Refresh rate and response time | High-speed TFT design, overdrive technology | 3T1C [58,59], 4T2C [61] | 6T2C [82], 7T1C [84], 3T2C [54], 4T2C [89] |

| Power consumption | Use low-power materials, dynamic power management | 3T2C [57], 5T2C [60] | 7T1C [84], 3T2C [54], 4T2C [89] |

| High resolution and high PPI | High-mobility TFT, new pixel structures | 4T2C [61] | 3T2C [54], 4T2C [89] |

| VTH shift | Internal compensation circuits (integrated compensation transistors and capacitors), use high-stability TFT materials | / | 5T1C [77], 5T2C [79], 7T1C [84], 3T2C [54] |

| Mobility variation | Mobility compensation circuits, improve manufacturing processes to enhance TFT uniformity | / | 5T1C [77] |

3.2.5. Silicon-Based OLED Pixel Circuits

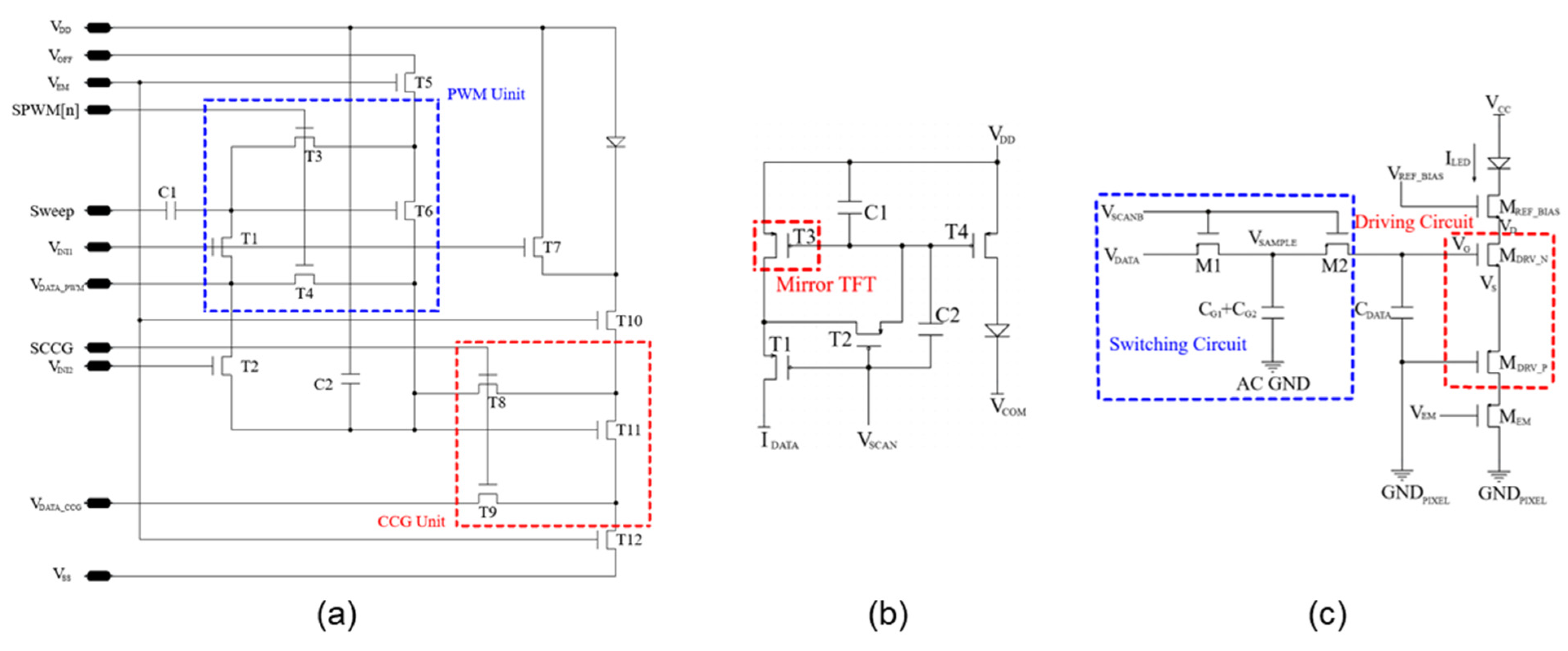

4. Micro-LED Circuit Design

TFT Micro-LED Pixel Circuits

- Silicon-based micro-LED pixel circuits

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, H.-W.; Lee, J.-H.; Lin, B.-Y.; Chen, S.; Wu, S.-T. Liquid Crystal Display and Organic Light-Emitting Diode Display: Present Status and Future Perspectives. Light. Sci. Appl. 2018, 7, 17168. [Google Scholar] [CrossRef] [PubMed]

- Parbrook, P.J.; Corbett, B.; Han, J.; Seong, T.; Amano, H. Micro-Light Emitting Diode: From Chips to Applications. Laser Photonics Rev. 2021, 15, 2000133. [Google Scholar] [CrossRef]

- Wang, I.-S. Dynamic Pixel Models for A-Si TFT-LCD and Their Implementation in SPICE. ETRI J. 2012, 34, 633–636. [Google Scholar] [CrossRef]

- Liu, B.; Chen, G.; Cai, X.; Yang, X.; Chen, B.; Zhu, C.; Li, J.; Tseng, C. P-55: Image Flicker Improvement in LTPS TFT-LCD with Low Frequency Driving. SID Symp. Dig. Tech. Pap. 2018, 49, 1403–1406. [Google Scholar] [CrossRef]

- Kim, D.; Kim, Y.; Lee, S.; Kang, M.S.; Kim, D.H.; Lee, H. High Resolution A-IGZO TFT Pixel Circuit for Compensating Threshold Voltage Shifts and OLED Degradations. IEEE J. Electron Devices Soc. 2017, 5, 372–377. [Google Scholar] [CrossRef]

- Sodhani, A.; Goswami, R.; Kandpal, K. Design of Pixel Circuit Using A-IGZO TFTs to Enhance Uniformity of AMOLED Displays by Threshold Voltage Compensation. Arab. J. Sci. Eng. 2021, 46, 9663–9672. [Google Scholar] [CrossRef]

- Bagheri, M.; Cheng, X.; Zhang, J.; Lee, S.; Ashtiani, S.; Nathan, A. Threshold Voltage Compensation Error in Voltage Programmed AMOLED Displays. J. Disp. Technol. 2016, 12, 658–664. [Google Scholar] [CrossRef]

- Jankovic, N.D.; Brajovic, V. Vth compensated AMOLED pixel employing dual-gate TFT driver. Electron. Lett. 2011, 47, 456–457. [Google Scholar] [CrossRef]

- Lih, J.-J.; Sung, C.-F.; Li, C.-H.; Hsiao, T.-H.; Lee, H.-H. Comparison of A-Si and Poly-Si for AMOLED Displays. J. Soc. Inf. Disp. 2004, 12, 367–371. [Google Scholar] [CrossRef]

- Li, Y.-L.; Liu, Y.-T. MicroLED Display: The next-Generation Display Technology. In Proceedings of the Advances in Display Technologies X, San Francisco, CA, USA, 26 February 2020; SPIE: Bellingham, WA, USA, 2000; Volume 11304, pp. 72–75. [Google Scholar]

- Zhou, L.; Zheng, H.; Zhang, S.H.; Li, H.D.; Zhang, G.; Zhang, S.Q.; Xu, W.; Xu, H.R.; Xiao, J.L.; Ning, H.L. Advances in Micro-LED Display and Its Driving Technology. Liq. Cryst. Disp. 2022, 37, 1395–1410. [Google Scholar]

- Anwar, A.R.; Sajjad, M.T.; Johar, M.A.; Hernández-Gutiérrez, C.A.; Usman, M.; Łepkowski, S.P. Recent Progress in Micro-LED-Based Display Technologies. Laser Photonics Rev. 2022, 16, 2100427. [Google Scholar] [CrossRef]

- Luo, Z.; Ding, Y.; Peng, F.; Wei, G.; Wang, Y.; Wu, S.-T. Ultracompact and High-Efficiency Liquid-Crystal-on-Silicon Light Engines for Augmented Reality Glasses. Opto-Electron. Adv. 2024, 7, 240039. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wu, Y.-R.; Kuo, H.-C.; Wong, M.S.; DenBaars, S.P.; Nakamura, S.; Pandey, A.; Mi, Z.; Tian, P.; Ohkawa, K.; et al. The Micro-LED Roadmap: Status Quo and Prospects. J. Phys. Photonics 2023, 5, 042502. [Google Scholar]

- Advances and Challenges in Microdisplays and Imaging Optics for Virtual Reality and Mixed Reality: Device. Available online: https://www.cell.com/device/abstract/S2666-9986(24)00234-5 (accessed on 20 March 2025).

- Hsiang, E.-L.; Yang, Z.; Yang, Q.; Lai, P.-C.; Lin, C.-L.; Wu, S.-T. AR/VR Light Engines: Perspectives and Challenges. Adv. Opt. Photonics 2022, 14, 783. [Google Scholar] [CrossRef]

- Yin, K.; Hsiang, E.-L.; Zou, J.; Li, Y.; Yang, Z.; Yang, Q.; Lai, P.-C.; Lin, C.-L.; Wu, S.-T. Advanced Liquid Crystal Devices for Augmented Reality and Virtual Reality Displays: Principles and Applications. Light. Sci. Appl. 2022, 11, 161. [Google Scholar] [CrossRef]

- Miao, W.-C.; Hsiao, F.-H.; Sheng, Y.; Lee, T.-Y.; Hong, Y.-H.; Tsai, C.-W.; Chen, H.-L.; Liu, Z.; Lin, C.-L.; Chung, R.-J.; et al. Microdisplays: Mini-LED, Micro-OLED, and Micro-LED. Adv. Opt. Mater. 2024, 12, 2300112. [Google Scholar] [CrossRef]

- Hara, Y.; Kikuchi, T.; Kitagawa, H.; Morinaga, J.; Ohgami, H.; Imai, H.; Daitoh, T.; Matsuo, T. IGZO-TFT Technology for Large-Screen 8K Display. J. Soc. Inf. Disp. 2018, 26, 169–177. [Google Scholar] [CrossRef]

- Bandari, V.K.; Schmidt, O.G. A Bright Future for Micro-LED Displays. Light. Sci. Appl. 2024, 13, 317. [Google Scholar] [CrossRef]

- Xu, H.; Liu, B.; Zheng, F.; Xiao, J.; Zhang, S.; Lu, L. A Compensation Pixel Circuit with High Bits Using PWM Method for AMLED. Energy Rep. 2023, 9, 194–199. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, X.; Chong, W.C.; Lau, K.M. Monolithically Integrated High-Resolution Full-Color GaN-on-Si Micro-LED Microdisplay. Photonics Res. PRJ 2023, 11, 109–120. [Google Scholar] [CrossRef]

- Wu, M.-C.; Chung, M.-C.; Wu, C.-Y. 3200 Ppi Matrix-Addressable Blue MicroLED Display. Micromachines 2022, 13, 1350. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.-H.; Lin, Y.-H.; Wu, M.-H.; Kuo, H.C.; Horng, R.-H. Current Confinement Effect on the Performance of Blue Light Micro-LEDs with 10 Μm Dimension. ACS Omega 2023, 8, 35351–35358. [Google Scholar] [CrossRef] [PubMed]

- Stewart, M.; Howell, R.S.; Pires, L.; Hatalis, M.K. Polysilicon TFT Technology for Active Matrix OLED Displays. IEEE Trans. Electron Devices 2001, 48, 845–851. [Google Scholar] [CrossRef]

- Wu, Y.-E.; Lee, M.-H.; Lin, Y.-C.; Kuo, C.; Lin, Y.-H.; Huang, W.-M. 41-1: Invited Paper: Active Matrix Mini-LED Backlights for 1000PPI VR LCD. Symp. Dig. Tech. Pap. 2019, 50, 562–565. [Google Scholar] [CrossRef]

- Koden, M. OLED Displays and Lighting, 1st ed.; Wiley: Hoboken, NJ, USA, 2016; ISBN 978-1-119-04045-3. [Google Scholar]

- Zhang, S.; Zheng, H.; Zhou, L.; Li, H.; Chen, Y.; Wei, C.; Wu, T.; Lv, W.; Zhang, G.; Zhang, S.; et al. Research Progress of Micro-LED Display Technology. Crystals 2023, 13, 1001. [Google Scholar] [CrossRef]

- Wager, J.F. Flat-Panel-Display Backplanes: LTPS or IGZO for AMLCDs or AMOLED Displays? Inf. Disp. 2014, 30, 26–29. [Google Scholar] [CrossRef]

- Wager, J.F. TFT Technology: Advancements and Opportunities for Improvement. Inf. Disp. 2020, 36, 9–13. [Google Scholar] [CrossRef]

- Sarma, K.R. Amorphous Silicon: Flexible Backplane and Display Application. In Flexible Electronics: Materials and Applications; Wong, W.S., Salleo, A., Eds.; Springer: Boston, MA, USA, 2009; pp. 75–106. ISBN 978-0-387-74363-9. [Google Scholar]

- Nodera, N.; Utsugi, S.; Ishida, S.; Takakura, R.; Matsushima, Y.; Michinaka, S.; Matsumoto, T.; Kobayashi, K.; Oketani, T. Novel LTPS Technology for Large Substrate. J. Soc. Inf. Disp. 2016, 24, 394–401. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Shih, L.-W.; Hung, C.-C.; Lai, P.-C.; Lin, T.-Y.; Liu, K.-H.; Wang, T.-H. Compensation Pixel Circuit to Improve Image Quality for Mobile AMOLED Displays. IEEE J. Solid-State Circuits 2019, 54, 489–500. [Google Scholar] [CrossRef]

- Fan, C.-L.; Chen, Y.-C.; Yang, C.-C.; Tsai, Y.-K.; Huang, B.-R. Novel LTPS-TFT Pixel Circuit with OLED Luminance Compensation for 3D AMOLED Displays. J. Disp. Technol. 2016, 12, 425–428. [Google Scholar] [CrossRef]

- Hosono, H. How We Made the IGZO Transistor. Nat. Electron. 2018, 1, 428. [Google Scholar] [CrossRef]

- Yin, X.; Deng, S.; Li, G.; Zhong, W.; Chen, R.; Li, G.; Yeung, F.S.Y.; Wong, M.; Kwok, H.S. Low Leakage Current Vertical Thin-Film Transistors with InSnO-Stabilized ZnO Channel. IEEE Electron Device Lett. 2020, 41, 248–251. [Google Scholar] [CrossRef]

- Park, J.H.; Seok, K.H.; Kim, H.Y.; Chae, H.J.; Lee, S.K.; Joo, S.K. A Novel Design of Quasi-Lightly Doped Drain Poly-Si Thin-Film Transistors for Suppression of Kink and Gate-Induced Drain Leakage Current. IEEE Electron Device Lett. 2015, 36, 351–353. [Google Scholar] [CrossRef]

- Kim, J.; Lee, H.; Jeong, M.; Bae, J.; Park, C.; Jang, J. Micro-LED Pixel Circuit Using Low-Temperature Poly-Si Oxide TFTs with Fast Rise and Fall Times of Pulse Width Modulation for Low Gray Expression. IEEE Electron Device Lett. 2023, 44, 1448–1451. [Google Scholar] [CrossRef]

- Zulqarnain, M.; Cantatore, E. Analog and Mixed Signal Circuit Design Techniques in Flexible Unipolar A-IGZO TFT Technology: Challenges and Recent Trends. IEEE Open J. Circuits Syst. 2021, 2, 743–756. [Google Scholar] [CrossRef]

- Chen, C.; Abe, K.; Kumomi, H.; Kanicki, J. A-InGaZnO Thin-Film Transistors for AMOLEDs: Electrical Stability and Pixel-Circuit Simulation. J. Soc. Inf. Disp. 2009, 17, 525. [Google Scholar] [CrossRef]

- Zhong, J.; Li, G.; Guo, R.; Ning, H.; Zhang, H.; Fang, Z.; Fu, X.; Wei, X.; Yao, R.; Peng, J. Bilayer Metal Oxide Channel Thin Film Transistor with Flat Interface Based on Smooth Transparent Nanopaper Substrate. IEEE Electron Device Lett. 2022, 43, 2113–2116. [Google Scholar] [CrossRef]

- Ning, H.; Zeng, X.; Zhang, H.; Zhang, X.; Yao, R.; Liu, X.; Luo, D.; Xu, Z.; Ye, Q.; Peng, J. Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature. Membranes 2021, 12, 29. [Google Scholar] [CrossRef]

- Liang, Z.; Wu, W.; Fu, X.; Ning, H.; Xu, W.; Xiong, X.; Qiu, T.; Luo, C.; Yao, R.; Peng, J. Flexible High-Entropy Poly(Vinyl Alcohol) Dielectric Films Were Prepared at a Low Temperature and Applied to an Indium Gallium Zinc Oxide Thin-Film Transistor. J. Phys. Chem. Lett. 2023, 14, 9245–9249. [Google Scholar] [CrossRef]

- Osawa H, Kim K W, Hung M C; et al. Displays with Silicon and Semiconducting Oxide Thin-Film Transistors. U.S. Patent 9,818,765, 14 November 2017.

- Chang, T.-K.; Lin, C.-W.; Chang, S. 39-3: Invited Paper: LTPO TFT Technology for AMOLEDs. Symp. Dig. Tech. Pap. 2019, 50, 545–548. [Google Scholar] [CrossRef]

- Chung, U.-J.; Choi, S.-C.; Noh, S.Y.; Kim, K.-T.; Moon, K.-J.; Kim, J.-H.; Park, K.-S.; Choi, H.-C.; Kang, I.-B. 15-1: Invited Paper: Manufacturing Technology of LTPO TFT. Symp. Dig. Tech. Pap. 2020, 51, 192–195. [Google Scholar] [CrossRef]

- Ye, J.-H.; Huang, C.-L.; Chen, M.-Y.; Hong, H.-Z.; Luo, J.-C.; Huang, K.-Y.; Peng, C.-T.; Chen, M.-S.; Huang, W.-M.; Wu, Y.-A. 12-4: Late-News Paper: Reliability Improvement of IGZO and LTPS Hybrid TFTs Array Technology. Symp. Dig. Tech. Pap. 2018, 49, 128–131. [Google Scholar] [CrossRef]

- Luo, C.; Yin, G.; Shu, Z.; Liu, G.; Ai, F. P-2: High-Performance LTPO TFT-LCD Using Metal as Hydrogen Barrier Layer. Symp. Dig. Tech. Pap. 2021, 52, 1063–1066. [Google Scholar] [CrossRef]

- Luo, F.C.; Chen, I.; Genovese, F.C. A Thin-Film Transistor for Flat Planel Displays. IEEE Trans. Electron Devices 1981, 28, 740–743. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, C.; Amegadez, P.S.K.; Ryu, G.-S.; Wei, H.; Balestra, F.; Ghibaudo, G.; Noh, Y.-Y. On the Origin of Improved Charge Transport in Double-Gate In–Ga–Zn–O Thin-Film Transistors: A Low-Frequency Noise Perspective. IEEE Electron Device Lett. 2015, 36, 1040–1043. [Google Scholar] [CrossRef]

- Chen, T.-L.; Huang, K.-C.; Lin, H.-Y.; Chou, C.H.; Lin, H.H.; Liu, C.W. Enhanced Current Drive of Double-Gate $\alpha$-IGZO Thin-Film Transistors. IEEE Electron Device Lett. 2013, 34, 417–419. [Google Scholar] [CrossRef]

- Shim, G.W.; Hong, W.; Cha, J.; Park, J.H.; Lee, K.J.; Choi, S. TFT Channel Materials for Display Applications: From Amorphous Silicon to Transition Metal Dichalcogenides. Adv. Mater. 2020, 32, 1907166. [Google Scholar] [CrossRef]

- Spijkman, M.; Myny, K.; Smits, E.C.P.; Heremans, P.; Blom, P.W.M.; De Leeuw, D.M. Dual-Gate Thin-Film Transistors, Integrated Circuits and Sensors. Adv. Mater. 2011, 23, 3231–3242. [Google Scholar] [CrossRef]

- Jeon, C.; Mativenga, M.; Geng, D.; Jang, J. AMOLED Pixel Circuit Using Dual Gate A-IGZO TFTs for Simple Scheme and High Speed V TH Extraction. SID Symp. Dig. Tech. Pap. 2016, 47, 65–68. [Google Scholar] [CrossRef]

- Chen, S.; Hsieh, I.C. Polysilicon TFT Technology Will Solve Problems of Mobility, Pixel Size, Cost, and Yield. Solid State Technol. 1996, 39, 113–118. [Google Scholar]

- Ma, R. Active Matrix for OLED Displays. In Handbook of Visual Display Technology; Chen, J., Cranton, W., Fihn, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1821–1841. ISBN 978-3-319-14345-3. [Google Scholar]

- Tai, Y.-H.; Chang, C.-Y.; Lin, C.-Y. Design and Simulation of the Pixel Circuit for a 6-in Full HD LTPS TFT LCD Based on the New Digital Driving Method. J. Disp. Technol. 2015, 11, 336–340. [Google Scholar] [CrossRef]

- Cao, H.; Tian, C.; Feng, J.; Cheng, H.; Guan, Y.; Liu, G. A Novel Design for a Pixel-Driver Circuit with Boost Function for UWFR Display. SID Symp. Dig. Tech. Pap. 2021, 52, 1085–1087. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Chen, F.-H.; Hung, C.-C.; Chen, B.-S. P-17: Novel Pixel Circuit with Inverter Structure Based on a-IGZO TFT for Blue-Phase Liquid Crystal Displays. SID Symp. Dig. Tech. Pap. 2018, 49, 1242–1245. [Google Scholar] [CrossRef]

- Jo, J.-H.; Lee, W.-R.; Chung, H.-J.; Lee, S.-W. A Self-Refreshing Memory-in-Pixel Comprising Low Temperature Poly-Silicon and Oxide TFTs for 3-Bit Liquid Crystal Displays. IEEE Electron Device Lett. 2021, 42, 839–842. [Google Scholar] [CrossRef]

- Jo, J.-H.; Jeong, W.-B.; Chung, H.-J.; Lee, S.-W. A Self-Refresh Memory-in-Pixel for Low-Power Reflective Liquid Crystal Displays. IEEE Electron Device Lett. 2023, 44, 48–51. [Google Scholar] [CrossRef]

- Wang, J.; Nie, C.; Dai, K.; Liao, Y. P-80: 4K Real 240Hz Technology in Large LCD-TFT TVs. SID Symp. Dig. Tech. Pap. 2024, 55, 1688–1690. [Google Scholar] [CrossRef]

- Kim, J.; Chung, H.-J.; Lee, S.-W. A Memory-in-Pixel Circuit for Low-Power Liquid Crystal Displays with Low Temperature Poly-Silicon and Oxide Thin Film Transistors. IEEE Electron Device Lett. 2019, 40, 1957–1960. [Google Scholar] [CrossRef]

- Kim, J.; Chung, H.-J.; Lee, S.-W. A Low-Power Pixel Circuit Comprising Low-Temperature Poly-Silicon and Oxide TFTs for Liquid Crystal Displays with Panel Self-Refresh Technology. IEEE Electron Device Lett. 2020, 41, 868–871. [Google Scholar] [CrossRef]

- Lin, C.-L.; Chang, W.-Y.; Hung, C.-C. Compensating Pixel Circuit Driving AMOLED Display with A-IGZO TFTs. IEEE Electron Device Lett. 2013, 34, 1166–1168. [Google Scholar] [CrossRef]

- Sohn, Y.; Moon, G.; Choi, K.; Kim, Y.; Park, K. Effects of TFT Mobility Variation in the Threshold Voltage Compensation Circuit of the OLED Display. J. Inf. Disp. 2017, 18, 25–30. [Google Scholar] [CrossRef]

- Mo, Y.G.; Kim, M.; Kang, C.K.; Jeong, J.H.; Park, Y.S.; Choi, C.G.; Kim, H.D.; Kim, S.S. 69.3: Amorphous Oxide TFT Backplane for Large Size AMOLED TVs. Symp. Dig. Tech. Pap. 2010, 41, 1037–1040. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.; Lee, H. A Novel P-Type LTPS TFT Pixel Circuit Compensating for Threshold Voltage and Mobility Variations. J. Disp. Technol. 2014, 10, 995–1000. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, H.; Xiao, W.; Liu, C.; Chen, J.; Guo, M.; Gao, H.; Liu, B.; Wu, W. Strategies for Applications of Oxide-Based Thin Film Transistors. Electronics 2022, 11, 960. [Google Scholar] [CrossRef]

- Shin, H.-J.; Choi, S.-H.; Kim, D.-M.; Han, S.-E.; Bae, S.-J.; Park, S.-K.; Kim, H.-S.; Oh, C.-H. 45-1: A Novel 88-inch 8K OLED Display for Premium Large-Size TVs. Symp. Dig. Tech. Pap. 2021, 52, 611–614. [Google Scholar] [CrossRef]

- Dawson, R.M.A.; Shen, Z.; Furst, D.A.; Connor, S.; Hsu, J.; Kane, M.G.; Stewart, R.G.; Ipri, A.; King, C.N.; Green, P.J.; et al. 4.2: Design Ofanlmproved Pixel Fora Polysilicon Active-Matrix Organic LED Display. Symp. Dig. Tech. Pap. 1998, 29, 11–14. [Google Scholar] [CrossRef]

- Chung, H.; Kim, Y.-W.; Oh, C.; Kwon, O.-K.; Choi, S.-M. Organic Light Emitting Device Pixel Circuit and Driving Method Therefor. U.S. Patent 7,414,599, 19 August 2008. [Google Scholar]

- Lee, J.-H.; Nam, W.-J.; Jung, S.-H.; Han, M.-K. A New Current Scaling Pixel Circuit for AMOLED. IEEE Electron Device Lett. 2004, 25, 280–282. [Google Scholar] [CrossRef]

- Nathan, A.; Chaji, G.R.; Ashtiani, S.J. Driving Schemes for A-Si and LTPS AMOLED Displays. J. Disp. Technol. JDT 2005, 1, 267. [Google Scholar]

- Lee, G.-H.; Kim, S.-K.; Son, Y.-S.; Jeon, J.-Y.; Jeon, Y.-J.; Cho, G.-H. P-45: A Fast Driving Circuit for AMOLED Displays Using Current Feedback. SID Symp. Dig. 2006, 37, 363. [Google Scholar] [CrossRef]

- Lin, C.-L.; Hung, C.-C.; Chen, P.-S.; Lai, P.-C.; Cheng, M.-H. New Voltage-Programmed AMOLED Pixel Circuit to Compensate for Nonuniform Electrical Characteristics of LTPS TFTs and Voltage Drop in Power Line. IEEE Trans. Electron Devices 2014, 61, 2454–2458. [Google Scholar] [CrossRef]

- Chu, H.; Wei, N.; Yu, B.; Zhao, H.; Li, Y.; Wang, X.; He, H. A Mirrored 5T1C OLED Pixel Circuit for Compensating Characteristics Variations and Voltage Drop. Microelectron. J. 2023, 131, 105645. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Chang, J.-H.; Chen, S.-C.; Tsai, C.-L.; Koa, J.-L.; Cheng, M.-H.; Shih, L.-W.; Hsu, W.-C. Leakage-Prevention Mechanism to Maintain Driving Capability of Compensation Pixel Circuit for Low Frame Rate AMOLED Displays. IEEE Trans. Electron Devices 2021, 68, 2313–2319. [Google Scholar] [CrossRef]

- Singh, A.; Goswami, M.; Kandpal, K. Design of a Voltage-programmed V. TH Compensating Pixel Circuit for AMOLED Displays Using Diode-connected a-IGZO TFT. IET Circuits Devices Syst. 2020, 14, 876–880. [Google Scholar] [CrossRef]

- Song, E.; Nam, H. Novel Voltage Programming N-Channel TFT Pixel Circuit for Low Power and High Performance AMOLED Displays. Displays 2014, 35, 118–125. [Google Scholar] [CrossRef]

- Vosniadis, P.; Siskos, S. A New Threshold-Voltage Compensation Technique of IGZO and LTPS for AMOLED Display Pixel Circuit. In Proceedings of the 2017 Panhellenic Conference on Electronics and Telecommunications (PACET), Xanthi, Greece, 17–18 November 2017; pp. 1–4. [Google Scholar]

- Xie, Y.; Chen, P.; Cai, K.; Jia, S.; Yang, C.; Jian, H.; Weng, J. IGZO-TFT Pixel Circuits Compensating Threshold Voltage and Mobility Variations in AMOLED Displays. SID Symp. Dig. Tech. Pap. 2021, 52, 1100–1103. [Google Scholar] [CrossRef]

- Kim, J.C.; Lee, I.S.; Kim, H.T.; An, J.B.; Kim, J.S.; Yoo, J.S.; Hwang, H.W.; Choi, H.C.; Ha, Y.M.; Kim, H.J. A Novel LTPO AMOLED Pixel Circuit and Driving Scheme for Variable Refresh Rate. J. Inf. Disp. 2023, 24, 283–298. [Google Scholar] [CrossRef]

- Luo, H.; Wang, S.; Kang, J.; Wang, Y.; Zhao, J.; Tsong, T.; Lu, P.; Gupta, A.; Hu, W.; Wu, H.; et al. 24-3: Complementary LTPO Technology, Pixel Circuits and Integrated Gate Drivers for AMOLED Displays Supporting Variable Refresh Rates. Symp. Dig. Tech. Pap. 2020, 51, 351–354. [Google Scholar] [CrossRef]

- Luo, H.; Wellenius, P.; Lunardi, L.; Muth, J.F. Transparent IGZO-Based Logic Gates. IEEE Electron Device Lett. 2012, 33, 673–675. [Google Scholar] [CrossRef]

- Kang, D.H.; Kang, I.; Ryu, S.H.; Jang, J. Self-Aligned Coplanar a-IGZO TFTs and Application to High-Speed Circuits. IEEE Electron Device Lett. 2011, 32, 1385–1387. [Google Scholar] [CrossRef]

- He, X.; Xiao, X.; Deng, W.; Wang, L.; Wang, L.; Chi, S.; Shao, Y.; Chan, M.; Zhang, S. Characteristics of Double-Gate a-IGZO TFT. In Proceedings of the 2014 12th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT), Guilin, China, 28–31 October 2014; pp. 1–3. [Google Scholar]

- Li, X.; Geng, D.; Mativenga, M.; Jang, J. High-Speed Dual-Gate a-IGZO TFT-Based Circuits with Top-Gate Offset Structure. IEEE Electron Device Lett. 2014, 35, 461–463. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.; Yang, J.; Moon, K.; Lee, S.; Jeon, J.; Kim, Y.; Choi, S.; Chung, U.; Park, K.; et al. Organic Light-emitting Diode Display Pixel Circuit Employing Double-gate Low-temperature poly-Si Thin-film Transistor and Metal-oxide Thin-film Transistors. J. Soc. Inf. Disp. 2020, 28, 1003–1011. [Google Scholar] [CrossRef]

- Bae, J.; Nam, H. Body-Effect-Free OLED-on-Silicon Pixel Circuit Based on Capacitive Division to Extend Data Voltage Range. Electronics 2021, 10, 2351. [Google Scholar] [CrossRef]

- Mai, H. Pixel Design and Characterization of High-Performance Tandem OLED Microdisplays; University of Edinburgh: Edinburgh, UK, 2019. [Google Scholar]

- Kim, H.; Kwak, B.-C.; Lim, H.-S.; Kwon, O.-K. Pixel Circuit for Organic Light-Emitting Diode-on-Silicon Microdisplays Using the Source Follower Structure. Jpn. J. Appl. Phys. 2010, 49, 03CD05. [Google Scholar] [CrossRef]

- Kwak, B.-C.; Lim, H.-S.; Kwon, O.-K. Organic Light-Emitting Diode-on-Silicon Pixel Circuit Using the Source Follower Structure with Active Load for Microdisplays. Jpn. J. Appl. Phys. 2011, 50, 03CC05. [Google Scholar] [CrossRef]

- Hong, S.-W.; Kwak, B.-C.; Na, J.-S.; Hong, S.-K.; Kwon, O.-K. Simple Pixel Circuits for High Resolution and High Image Quality Organic Light Emitting Diode-on-Silicon Microdisplays with Wide Data Voltage Range. J. Soc. Inf. Disp. 2016, 24, 110–116. [Google Scholar] [CrossRef]

- Na, J.-S.; Hong, S.-K.; Kwon, O.-K. A 4410-Ppi Resolution Pixel Circuit for High Luminance Uniformity of OLEDoS Microdisplays. IEEE J. Electron Devices Soc. 2019, 7, 1026–1032. [Google Scholar] [CrossRef]

- Seong, J.; Jang, J.; Lee, J.; Lee, M. CMOS Backplane Pixel Circuit with Leakage and Voltage Drop Compensation for an Micro-LED Display Achieving 5000 PPI or Higher. IEEE Access 2020, 8, 49467–49476. [Google Scholar] [CrossRef]

- Kimura, M.; Nishinohara, D.; Nishiyori, T.; Suzuki, D.; Sawamura, S.; Kato, M. Pulse-Width Modulation with Current Uniformization for AM-OLED Micro-Displays on Si LSI Chips. J. Soc. Inf. Disp. 2019, 27, 402–408. [Google Scholar] [CrossRef]

- Kim, J.-H.; Shin, S.; Kang, K.; Jung, C.; Jung, Y.; Shigeta, T.; Park, S.-Y.; Lee, H.S.; Min, J.; Oh, J.; et al. 15-1: PWM Pixel Circuit with LTPS TFTs for Micro-LED Displays. Symp. Dig. Tech. Pap. 2019, 50, 192–195. [Google Scholar] [CrossRef]

- Zhao, B.; Xiao, J.; Liu, Q.; Liu, B.; Hu, L.; Peng, J. A Novel Compensation Pixel Circuit for High Bits of AM Mini/Micro-LED Based on PWM Method. Energy Rep. 2021, 7, 343–348. [Google Scholar] [CrossRef]

- Hong, Y.-H.; Jung, E.K.; Hong, S.; Kim, Y.-S. 61-2: A Novel Micro-LED Pixel Circuit Using N-type LTPS TFT with Pulse Width Modulation Driving. Symp. Dig. Tech. Pap. 2021, 52, 868–871. [Google Scholar] [CrossRef]

- Lin, Y.-Z.; Liu, C.; Zhang, J.-H.; Yuan, Y.-K.; Cai, W.; Zhou, L.; Xu, M.; Wang, L.; Wu, W.-J.; Peng, J.-B. Active-Matrix Micro-LED Display Driven by Metal Oxide TFTs Using Digital PWM Method. IEEE Trans. Electron Devices 2021, 68, 5656–5661. [Google Scholar] [CrossRef]

- Zou, P.-A.; Xu, Y.-G.; Liu, C.; Zhang, L.-R.; Zhang, J.-H.; Yuan, Y.-K.; Cai, W.; Han, S.-H.; Zhou, L.; Xu, M.; et al. A New Analog PWM Pixel Circuit with Metal Oxide TFTs for Micro-LED Displays. IEEE Trans. Electron Devices 2022, 69, 4306–4311. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Z.; Kwok, H.-S. Current Driving Active Matrix Micro-LED Display. SID Symp. Dig. Tech. Pap. 2018, 49, 272–275. [Google Scholar] [CrossRef]

- Xiao, J.; Huo, W.; Yuan, D.; Liang, C.; Lai, G.; Li, J.; Xu, H.; Li, S.; Zhang, S. A New Pixel Circuit for Micro-Light Emitting Diode Displays with Pulse Hybrid Modulation Driving and Compensation. IEEE J. Electron Devices Soc. 2024, 12, 1–6. [Google Scholar] [CrossRef]

- Kim, S.S.; Kim, J.S.; Kim, J.H.; Lee, K.R.; Lee, J.M. Led Driving Circuit and Driving Method Thereof. 2023. [Google Scholar]

- Ji, X.; Wang, F.; Zhou, H.; Wang, K.; Yin, L.; Zhang, J. 3400 PPI Active-Matrix Monolithic Blue and Green Micro-LED Display. IEEE Trans. Electron Devices 2023, 70, 4689–4693. [Google Scholar] [CrossRef]

- Kursun, V.; Friedman, E.G. Multi-Voltage CMOS Circuit Design; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-470-01024-2. [Google Scholar]

- Zhang, X.; Yin, L.; Ren, K.; Zhang, J. Research on Simulation Design of MOS Driver for Micro-LED. Electronics 2022, 11, 2044. [Google Scholar] [CrossRef]

- Lee, P.-Y.L.; Li, S.H.; Hung, T.Y.; Yang, Y.-W.; Li, S.-H.; Sun, J.-J.; Lin, C.-W.D.; Lu, C.-W.; Fang, Y.-H.; Kuo, W.-H.; et al. A 10-Bit 1280 × 720 Micro-LED Display Driver with 2-Transistor Pixel Circuits and Current-Mode Pulse Width Modulation. IEEE Solid-State Circuits Lett. 2022, 5, 134–137. [Google Scholar] [CrossRef]

- Cheng, S.-S.; Chao, P.C.-P. A New SRAM-Embedded Pixel Circuit That Modulates Accurately Gray Level for PWM-Driven Micro-LED Displays. IEEE Solid-State Circuits Lett. 2023, 6, 157–160. [Google Scholar] [CrossRef]

| Category | Display Type | Panel Size (Inches) | Substrate | PPI (Pixels per Inch) | Technical Difficulties |

|---|---|---|---|---|---|

| Direct-view displays | AM-LCD | 5–85 | Glass | 300–600 | Backlighting, response speed |

| AM-OLED | 400–800 | Lifetime, screen burn-in | |||

| AM-LED | 2000–7000 | Massive transfer, full colour | |||

| Projection near-eye displays | High-resolution density LCD | 0.5–2.5 | Glass/ Silicon | 800–2000 | Flickering, small aperture ratio |

| LCoS (liquid crystal on silicon) | 0.3–2.5 | Silicon | 2000–5000 | Edge field effect, voltage swing limit | |

| Silicon-based OLED | 0.4–1.5 | Silicon | 3000–5644 | Manufacturing yield and lifetime | |

| Silicon-based LED | 0.4–1.5 | Silicon | 2000–7000 | Huge transfers, efficiency degradation, and current congestion |

| TFT | a-Si TFT | LTPS TFT | MO TFT |

|---|---|---|---|

| Microstructure | Amorphous | Polycrystalline | Amorphous |

| Max process temperature (°C) | 330 | 500 | 350 |

| Cost | Low | High | Low |

| Mobility (cm2/Vs) | 0.1–1 | 50–100 | 10–30 |

| PPI | Low | High | High |

| Threshold voltage (VTH) uniformity | Good | Worse | Good |

| VTH stability | Worse | Good | Better |

| Logic power | Worse | Better | Good |

| Application | LCD | LCD OLED Micro-LED | LCD OLED Micro-LED |

| Feature | Glass Substrate (TFT) | Silicon Substrate (CMOS) |

|---|---|---|

| Substrate characteristics | Low cost Easy to achieve large sizes Low carrier mobility | High cost High integration High carrier mobility |

| Circuit complexity | Limited circuit design High demand for compensation circuits | Flexible circuit design Easy integration of compensation circuits |

| Compatible driving techniques | Suitable for PWM (easy to implement) Difficult to implement PAM Limited implementation of PHM | Suitable for PAM (high-precision control) Easy to implement PWM (high refresh rate) Easy to implement PHM (high dynamic range) |

| Power consumption | High | Low |

| Manufacturing process | Compatible with existing TFT-LCD processes Lower difficulty in mass transfer | Requires high-precision CMOS processes High difficulty in mass transfer |

| Cost | Low | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, D.-M.; Zheng, H.; Tan, C.-H.; Zhang, S.; Li, H.-D.; Zhou, L.; Chen, Y.; Wei, C.; Xu, M.; Wang, L.; et al. Pixel Circuit Designs for Active Matrix Displays. Appl. Syst. Innov. 2025, 8, 46. https://doi.org/10.3390/asi8020046

Wei D-M, Zheng H, Tan C-H, Zhang S, Li H-D, Zhou L, Chen Y, Wei C, Xu M, Wang L, et al. Pixel Circuit Designs for Active Matrix Displays. Applied System Innovation. 2025; 8(2):46. https://doi.org/10.3390/asi8020046

Chicago/Turabian StyleWei, Dan-Mei, Hua Zheng, Chun-Hua Tan, Shenghao Zhang, Hua-Dan Li, Lv Zhou, Yuanrui Chen, Chenchen Wei, Miao Xu, Lei Wang, and et al. 2025. "Pixel Circuit Designs for Active Matrix Displays" Applied System Innovation 8, no. 2: 46. https://doi.org/10.3390/asi8020046

APA StyleWei, D.-M., Zheng, H., Tan, C.-H., Zhang, S., Li, H.-D., Zhou, L., Chen, Y., Wei, C., Xu, M., Wang, L., Wu, W.-J., Ning, H., & Jia, B. (2025). Pixel Circuit Designs for Active Matrix Displays. Applied System Innovation, 8(2), 46. https://doi.org/10.3390/asi8020046