1. Introduction

Energy storage systems (ESSs) must to be efficient, reliable, and cost-effective to supply the requirements of microgrids (MGs) [

1,

2], electrical vehicles (EVs) [

3,

4,

5], and renewable energy applications [

6,

7], among others. These requirements have stimulated the emergence of hybrid energy storage systems (HESSs) characterized by the cooperative operation of two or more energy storage technologies [

8]. The main feature of an HESS is the complementary condition of the ESSs in terms of power and energy density [

8]; e.g., one or several ESSs should provide energy by hours or days, while other ESSs have to provide a high amount of instantaneous power with a discharge time in the order of seconds or minutes. These characteristics allow the HESS to be used for stabilization purposes, for example, when high power and fast response are required; in this case, the HESS should include supercapacitors (SC) or flywheels, as discussed in [

8]. Another application is the EV, where the HESS must have a high-energy capacity; therefore, batteries must be included [

4,

8,

9]. Moreover, other applications could profit from HESSs: integration of sources based on renewable energy [

7,

10], power quality improvement [

11,

12,

13,

14,

15], uninterrupted power supply (UPS), and public transport vehicles powered by electricity [

16]. Some commercial products provide HESS systems encapsulated as a single device; for example, CRE New Energy Technology offers a battery–ultracapacitor hybrid energy storage unit with high peak currents [

17], which is designed to be used as a battery replacement in buck-up units. The same company recently developed a new scalable hybrid supercapacitor–battery unit designed for industrial environments [

18], in particular for driving motors. However, these units have a close architecture, hence it is not possible to analyze the performance in battery protection, peak current regulation, or system stability.

Three major types of HESSs have been developed: passive, semi-active, and fully active [

19,

20]. Passive HESSs are highly efficient and cheap since they do not include power converters, but passive HESSs are uncontrolled systems whose behavior depends on the ESS parameters. In semi-active HESSs, an ESS is connected to the DC bus, while a DC/DC bidirectional converter interfaces the DC bus with other ESSs. This configuration offers a good trade-off between cost and performance. Finally, the fully active topology decouples all ESSs from the DC bus using power converters, thus achieving the maximum benefit from the ESSs but at the expense of complex controllers; moreover, this topology is expensive and has low efficiency in contrast with the other two HESS types.

There are multiple works reported in the literature dealing with HESS controllers. For example, in [

21] is reported a fully active HESS formed by a battery and an SC, which are interfaced with the DC bus using bidirectional boost converters. In that work, an equalization algorithm based on model predictive control (MPC) governs the converters, where the MPC considers the state of charge (SoC) of both battery and SC. Moreover, classical PI controllers regulate the voltage and current of the boost converters following a second-level droop control. Finally, that system is validated with simulation and experimental tests.

Another fully active HESS is reported in [

22], which is formed by a battery, an SC, and a fuel cell, connected to a DC bus. This HESS is regulated using a central super-twisting sliding mode control, where the current reference is given by an energy management unit based on fuzzy logic. The primary control is applied to an unidirectional boost converter and two bidirectional boost converters, and the controller performance is verified using Matlab/Simulink and hardware-in-the-loop (HIL) emulation on a C2000 Delfino. There is no experimental validation on a real power system.

Similar to [

22], the work reported in [

23] proposes a fully active HESS formed by three power sources: a battery, an SC, and a PV panel array. The interface with the DC bus is performed with a boost converter and two bidirectional boost converters, which are regulated using classical PI controllers. This HESS has a power management strategy designed to reduce the dynamic stress of the battery, provide a stable DC voltage, prevent a deep battery discharge, and enhance the overall efficiency of the system. The tuning process of these PI controllers is performed with different methods: pole placement, linear matrix inequalities (LMIs), particle swarm optimization (PSO), and genetic algorithm (GA). Then, the performances of the PI controllers, under several scenarios and with different tuning methods, are compared in Matlab/Simulink only.

Simulations and experimental comparisons of the three HESS types are reported in [

6]. The tested HESSs are formed by a PV panel, a battery, and an SC using bidirectional boost converters, where the primary controllers are classical PI, with reference currents obtained from a second-level power flow control.

Another HESS formed by batteries and lithium-ion capacitors (LiCs) is reported in [

24], where the semi-active configuration is used. In this case, the battery is connected to a DC bus, and the LiC current is controlled by a non-specified bidirectional DC/DC converter. A power flow controller in the second level sets the battery current, which is regulated using a classical PI acting on the power converter. Finally, the validation of this HESS is carried out using an advanced vehicle simulation platform.

Similar to the previous work, in [

25] is used a non-specified bidirectional DC/DC converter to form a semi-active HESS based on a battery and a supercapacitor. This HESS is controlled using a hysteresis control algorithm, where its reference is generated by an optimizer based on both fuzzy logic and model predictive controllers. Unfortunately, the dynamic performance of the controllers is not evaluated. Another hysteresis control for HESS is reported in [

26], where the battery SoC and the supercapacitor SoV (state of voltage) are used to control a bidirectional boost converter. This solution reduces the battery discharge percentage and improves the system’s efficiency by stabilizing the DC bus voltage.

Typically, the HESS control strategy consists of distributing the power between the storage devices, and thus it is mainly an energy management system (EMS). A well-designed control strategy will use the complementary features of the ESS forming the HESS, allocating the low-frequency power demand to the device of high energy density. Similarly, the high-power density device must to attend the short-time peaks, i.e., the high-frequency power profile. There are multiple EMSs for HESSs reported in the literature, which can be divided into three main categories: rule-based control strategies, optimization-based control strategies, and intelligence-based control strategies [

27].

In summary, the previous literature review shows that bidirectional boost converters are commonly used in HESS systems to connect the supercapacitor with the battery or DC bus [

6,

21,

22,

23,

26]. This selection is based on the simplicity of the bidirectional boost topology; however, this topology introduces two major limitations: first, the supercapacitor voltage must be lower than the battery or DC bus voltage, which limits the commercial supercapacitors and batteries that can be used to form the HESS; and, second, the supercapacitor boost converter provides a discontinuous current to the battery, which introduces high-frequency current harmonics that could produce heating and damages. The literature revision also shows that classical PI controllers are widely used to regulate the supercapacitor converter [

6,

21,

23,

24], which must be designed around a particular operation condition. Therefore, such a solution makes it impossible to ensure the desired performance (and even global stability) in a wide operation range. Finally, several solutions are only tested with simulators or emulators [

22,

23,

24,

26], which prevents the evaluation of real operation conditions such as parasitic losses, bandwidth limitation, and inductor saturation, among others. This paper faces the previous drawbacks by designing a semi-active supercapacitor/battery hybrid energy storage system based on a bidirectional Sepic/Zeta DC/DC converter, which interfaces the SC and the battery/DC bus, as observed in

Figure 1. This connection enables the indirect control of the battery current, thus avoiding high-frequency transients to the battery. The main contributions of the the proposed solution are:

The power stage (Sepic/Zeta converter) has the advantage of connecting devices to the DC bus with any voltage condition (lower, equal, or higher than the ESS voltage).

The Sepic side of the converter is connected to the battery/DC bus, which guarantees a continuous current (non-pulsating waveform) and prevents high-frequency transients in the battery.

A gain-scheduling approach is used to design the proposed LQG-FF controller, which adapts the controller parameters to the system’s operating condition (step-down/step-up or unitary conversion ratio). This real-time adjustment makes the system highly adaptive and efficient, thus it provides a robust and flexible solution with the desired transient performance.

The rest of the paper is organized as follows.

Section 2 reports the power stage model, which is based on a bidirectional Sepic/Zeta converter. Then, a control-oriented model is obtained from the switched model, and it is validated against both the circuital and switched models through frequency response analysis. In

Section 3, a feedforward/optimal Linear Quadratic Gaussian (LQG-FF) controller, with adaptive parameters, is proposed. This controller ensures that the high-frequency component of the load current is provided by the supercapacitor, and hence the reference current of the Sepic/Zeta converter is calculated using a high-pass filter. Such a control approach guarantees that the battery will only deal with low-frequency current components.

Section 4 reports Matlab/Simulink simulations of the HESS in the three operation modes: step-up, step-down, and unitary gain; in the same way,

Section 5 analyzes the results of the experimental tests for the same application cases. The conclusions are presented in

Section 6.

3. Adaptive LQG-FF Current–Voltage Controller

The control of the proposed HESS has the main objective of avoiding high-frequency variations on the battery current () on any operation condition, i.e., in charge and discharge modes. Moreover, the controller must guarantee the stability conditions on the overall operation range; that is, under any voltage ratio between the battery and supercapacitor (i.e., buck mode, boost mode, or unitary gain).

Therefore, the controller must to impose a fast output current (

) in the converter to provide the fast variations of the bus current (

). The compensation is performed with a disturbance rejection controller, in particular a feed-forward controller. The system model given in Equation (

14) has matrices

and

that change in function of the operation point, and hence it is a system with variable parameters. Controlling this system over a wide operation range requires an adaptive algorithm; in this paper a feed-forward/optimal Linear Quadratic Gaussian (LQG) controller, with parameters adaptation, is designed. The general structure of the control strategy is shown in

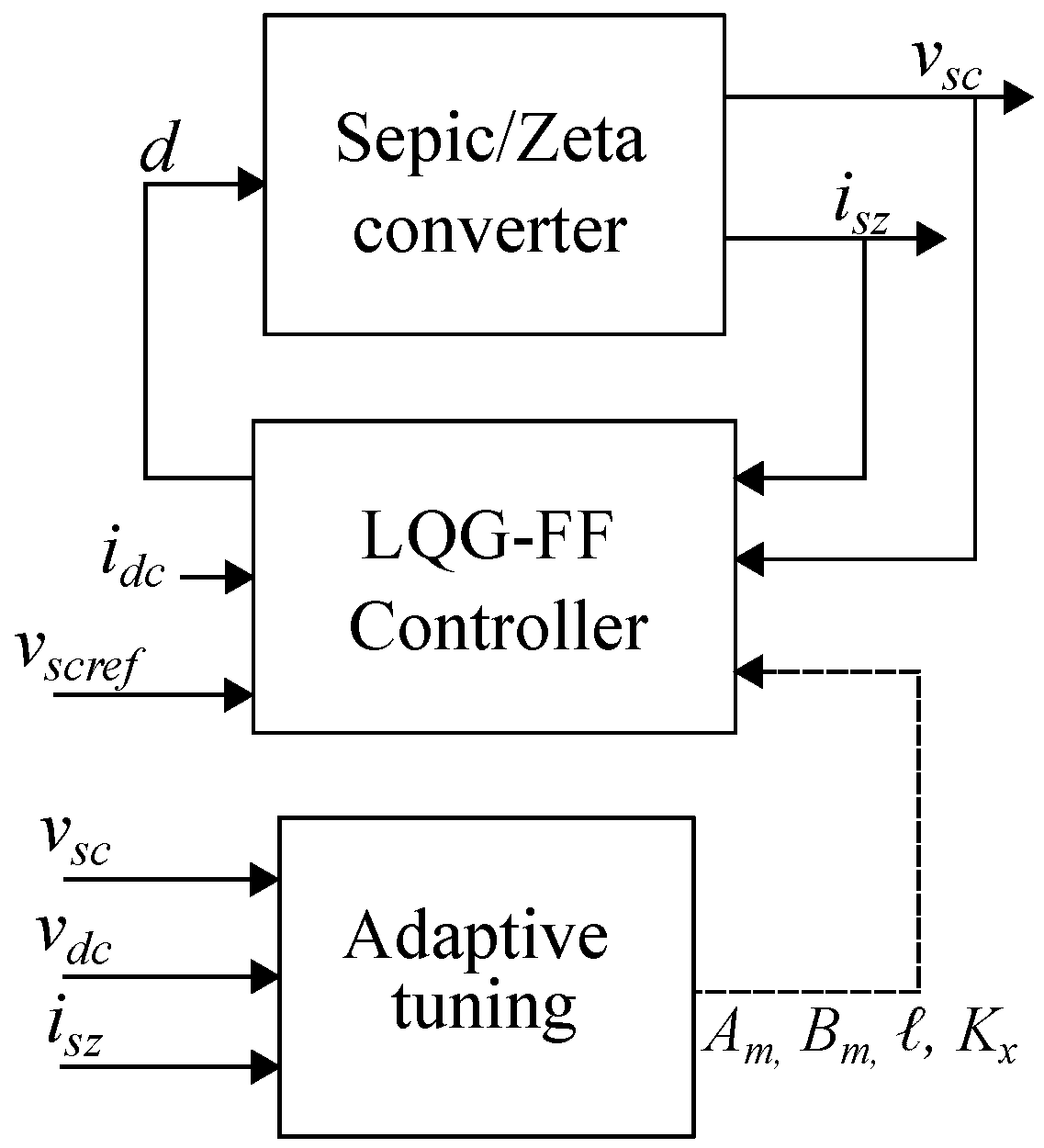

Figure 6, where high-frequency components of the load current (

) are sensed and feed back through a high-pass filter (HPF) block. Moreover, this structure has an inner loop to provide the high-frequency current components, and an external loop to regulate the DC bus voltage.

The control system design is divided into three stages. First, the design of the LQG controller; second, the design of an optimal observer to estimate the states; and, third, the design of the adaptive parameters function to adjust the controller to any operation point.

First, the optimal LQG approach was selected to track the current reference (generated by the HPF), to regulate the voltage (

) and to ensure stability conditions. The target of an optimal trajectory system is to design a controller that ensures a close tracking of a specified time-varying trajectory (

) [

28]. For the HESS model, the anticipative input signals (

d) and the non-anticipative disturbance input signals are used, which correspond to the high-frequency components of the load (bus) current (

). The control law for the optimal trajectory tracking consists of a feed-forward controller and a feedback controller, which are designed to minimize a performance index that includes penalties on the tracking errors (

z) and the control energy (

d):

In the previous expression,

is the extended state vector, which includes the error integral, named

. Then, the state feedback law (

K) is defined in Equation (

17), and the extended system is defined in Equation (

18).

Then, the optimal value for the control signal

is calculated using the Hamiltonian matrix [

29], as given in (

19).

Next, the

matrix must be solved from the Riccati differential equation given in (

21).

In addition, to ensure null steady-state errors, integrators are added to both output current and bus voltage errors.

On the other hand, to ensure a high reference tracking speed for the current loop, a feed-forward control is added, which ensures a fast action on the control signal d in response to changes on the bus current. In this way, the supercapacitor supplies the high-frequency variations of the DC bus, while the battery supports only the frequencies below the cutoff frequency of the high-pass filter.

In addition to the current control, an external cascade loop is added to regulate the supercapacitor voltage (). In this way, the state of charge of the supercapacitor, in steady-state, is regulated at a level that ensures the same capacity to deliver and absorb energy.

3.1. State Observer

A state observer was designed to reduce the number of sensing elements; in this application, it enables us to process the control strategy only measuring the current (

), as shown in

Figure 7. In addition, the observer needs the duty cycle (

d), which is known. The output of the observer is the vector of estimated states, which are the inductor currents and capacitor voltages; these were defined in Equations (

13) and (

14).

For the small-signal model obtained in Equations (

14) and (

15), and the feedback state law defined in (20) [

30], the linear state observer is formalized as follows:

where

y corresponds to

, as shown in

Figure 7.

In Equation (

22), the observer gain vector (

ℓ) defines the dynamic behavior of the error estimation, ensuring the observer convergence to the system states. This observer gain (

ℓ) is calculated solving an optimization problem to ensure two characteristics: the best estimation of the states, and minimizing the effect of measurement noise in

. Similarly to the feedback state vector (

K), the observer gain vector (

ℓ) in Equation (

24) is calculated by solving the Riccati differential equation given in (25) [

29]; here,

corresponds to the optimal error covariance matrix of the state observer, and

is a scalar to adjust the convergence speed of the observer states [

31].

3.2. Structure of the LQG Current–Voltage Controller

Figure 8 shows the designed control structure formed by the state observer, the state feedback, the internal current loop with feed-forward control, the filtering block (HPF), and finally the external voltage loop. In this diagram, the variables include both the stable state and small-signal responses provided by the previous dynamic model.

3.3. Adaptive Gain-Scheduling Parameters for the LQG-FF Controller

Due to the nonlinear characteristics of the Sepic converter, a method to adjust the controller parameters under any operation condition was designed. The adopted approach is named Gain-scheduling, which is a popular nonlinear technique widely used in aerospace and process control [

32]. This method requires the calculation of the state feedback vector and the observer parameters, solving offline the Riccati differential equation for each operating point (

and

combinations). Subsequently, intermediate operating values are calculated through a linear function; in this way, the variation of the state feedback vector and the observer gain vector are calculated; these functions must be implemented in a real-time control device.

The complete control structure, which includes the integration of the different control blocks previously described, is shown in

Figure 9. In this solution, the model parameters are adjusted depending on the operating point, thus updating matrices

,

,

ℓ,

; and four signals are measured: the currents

and

, and the voltages

and

.

A reduction in the SoC of a battery decreases the terminal’s voltage [

33]; similarly, the energy stored in the supercapacitor is calculated as

, and hence the supercapacitor SoC is also reduced when the voltage is decreased. Therefore, the adaptive gain-scheduling method used in this work ensures the correct parameters for any SoC and voltage condition in the battery and supercapacitor.

3.4. Selection of the Supercapacitor

The capacitance value is calculated to avoid high variations in the supercapacitor state of charge, which depends on the energy absorbed or delivered in the different operating conditions. The current of the supercapacitor corresponds to the high-frequency component of the DC bus current, which is represented by the following equation considering a step change on the DC bus current:

In Equation (

26),

represents the magnitude of the DC bus current perturbation, and

corresponds to the cut frequency (in Hz) of the filter HPF used in the controller. The time representation of (

26), obtained from the inverse Laplace transformation, is:

Equation (

28) reports the voltage variation in the supercapacitor caused by the previous current perturbation, where

corresponds to the stabilization time of the supercapacitor current for a unitary step perturbation in the bus current.

Then, solving Equation (

28) leads to the minimum value of

needed to ensure a maximum voltage deviation (

):

A security factor of

is introduced to take into account parametric tolerances in the electronic components and parasitic losses in the cables, among other unpredicted conditions, leading to the final supercapacitor selection range:

4. Design Example and Simulation Results

This section illustrates the design process of the proposed solution, where the performance of the proposed HESS is evaluated using detailed circuital simulations. The test-bed consists of a DC microgrid connected to a 12 V battery and a supercapacitor with a rated voltage of 16 V. This proof-of-concept HESS has a rated power of 40 W, where the Sepic/Zeta converter has a switching frequency kHz, with inductors H and an intermediate capacitor F. Finally, this design example considers load (bus) current transients up to 3 A, and hence the range is A.

The supercapacitor design is preformed using Equations (

29) and (

30) with a maximum bus current change

A. Moreover, the supercapacitor is designed to ensure a maximum voltage change of

and a cut frequency

Hz of the HPF, which results in a minimum value of the supercapacitor equal to

F. Due to the commercial availability and cost, the supercapacitor BMOD0058E016C02 [

34] is used, which has a capacitance equal to 58 F, thus fulfilling expression (

30).

Table 1 summarizes the parameters of this design example.

The matrices

and

of the space-state model are obtained offline by using Equation (

14). The parameters of these matrices are calculated for different operating points resulting from variations on the supercapacitor voltage (

). Then, the

K and

ℓ parameters of the controller are calculated using the LQR function from Matlab 2024b

® for all the space-state systems. For any other operating point, the adaptive gain-scheduling strategy determines the control parameters using a linear interpolation from the parameters previously calculated.

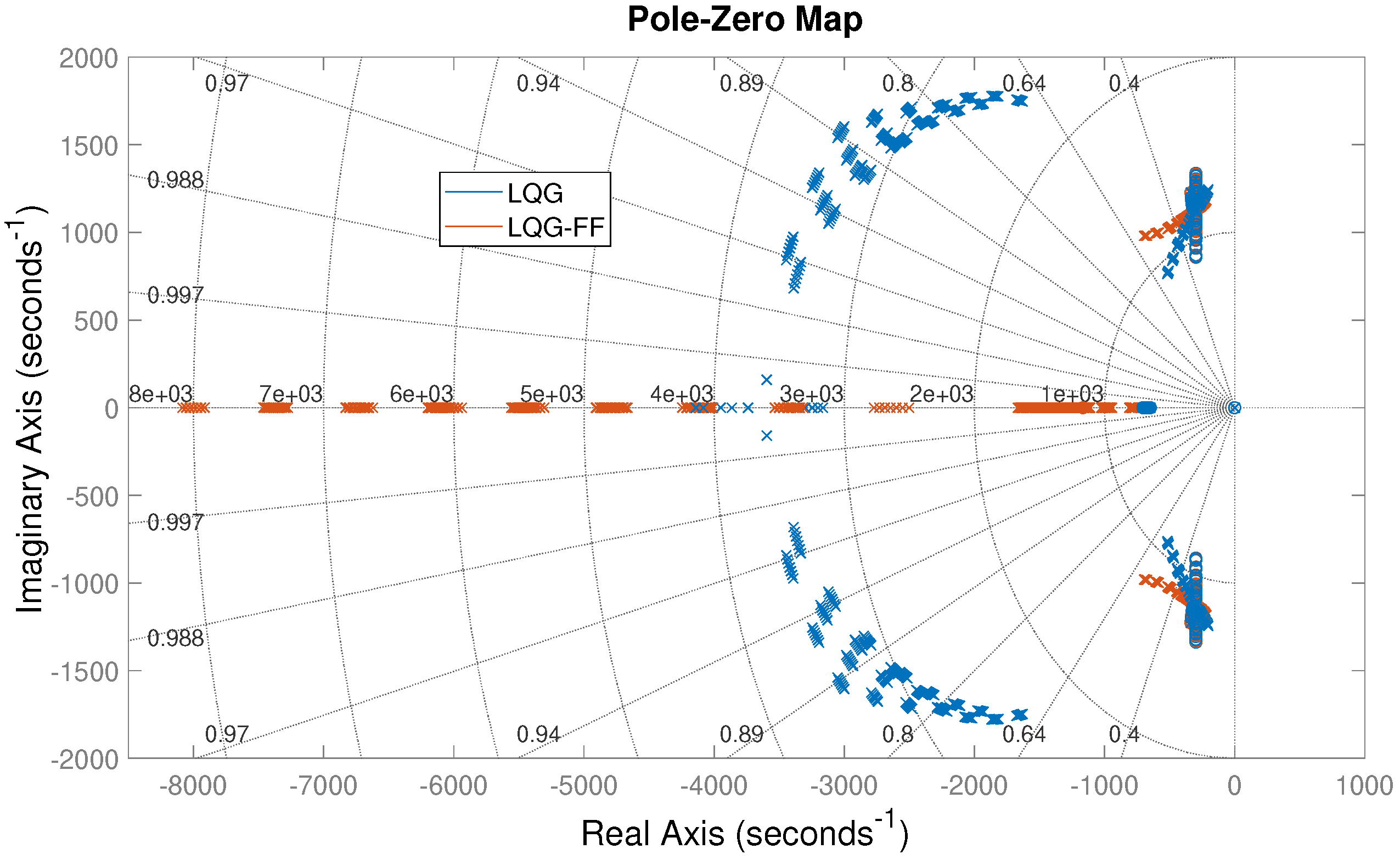

Figure 10 shows a pole-zero map to verify the close-loop stability of the system for different voltage (and SoC) conditions of both battery and supercapacitor. In this analysis, multiple operating points are simulated considering variations of 2 V for

and

, thus covering all the operation range. It is observed that the pole-zero points for all operating points are in the left side of the S-plane, which confirms the system stability.

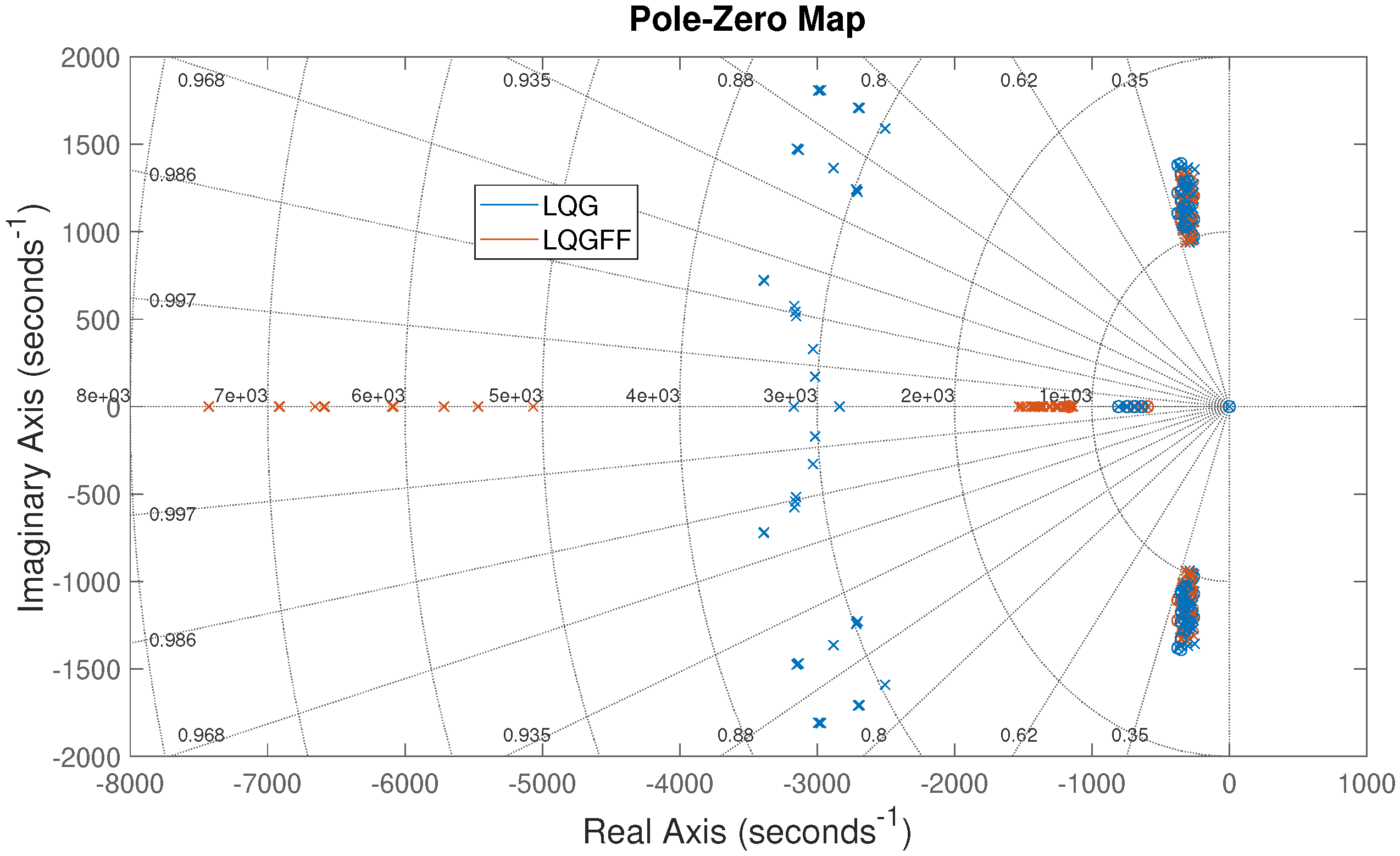

On the other hand,

Figure 11 shows the pole-zero map considering parametric variations on the converter elements, e.g., due to parametric tolerances. This analysis considers a tolerance of

for the inductors and

for the capacitors, and the results demonstrate that tolerances in the circuit components do not represent a risk for the system stability.

Then, the performance of both the HESS and the adaptive control system are evaluated in terms of current reference tracking and capacitor voltage regulation. The HESS is implemented using detailed circuital models in Simulink® from Matlab®. The main objective of the HESS is to provide the high-frequency current perturbations of the DC bus, which could be produced by power variations among loads and sources connected to the bus. In this way, the battery only provides the low-frequency current variations. Moreover, in real operation conditions, the supercapacitor voltage could be lower, equal to, or higher than the DC bus voltage, which implies that the power converter must operate in buck mode, boost mode, or at unitary gain. The following subsections report the simulation results in these different operating conditions.

4.1. Tracking of the Current Reference

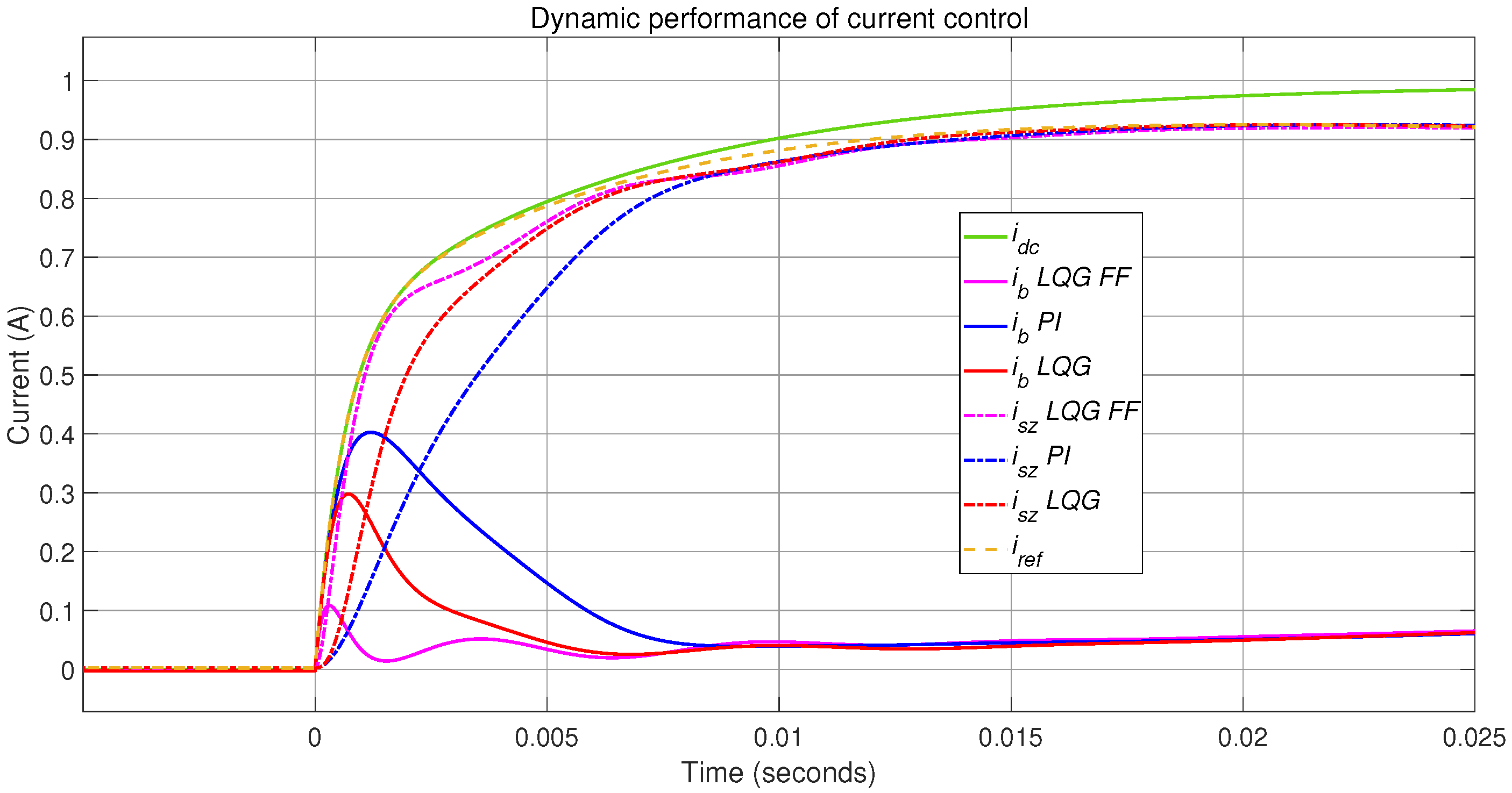

The current reference tracking evaluates the ability of the HESS to provide the high-frequency transients using the supercapacitor. In addition to the adaptive LQG-feed-forward controller (LQG-FF) proposed in this paper, this test also includes two traditional control strategies for comparison purposes: the classical PI controller widely adopted in literature for this same application, and the classical LQG controller.

The tests consider step perturbations on the DC bus current (

) from 0 A to 1 A. In these conditions, the battery voltage (

) is equal to 12 V, and three levels of supercapacitor voltage (

) are considered: 9 V (buck mode), 12 V (unitary gain), and 15 V (boost mode). The results are shown in

Figure 12 (boost mode),

Figure 13 (unitary gain) and

Figure 14 (buck mode). In these simulations, the proposed LQG-FF controller exhibits the faster tracking of the reference (

) (yellow/dashed line), thus imposing an output current profile (

) (magenta/dashed line) close to the desired waveform (

). In addition, the transitory peak occurring in the battery current (magenta/solid line) is the lowest one in comparison with the other control systems, where the classical PI controller exhibits the worst performance in terms of maximum overshoot and reference tracking. This is expected since the parameters of the proposed LQG-FF controller are adapted in real time to ensure the tracking of the high-frequency reference, and hence lower oscillations in the battery current occur. The classical controllers (PI and LQG) were designed for a particular condition in the middle of the operation range, and hence these controllers were not adapted during the transient conditions.

The Root-Mean-Square-Error (RMSE) between

and

is calculated during the transitory response to be used as a performance indicator. The RMSE for the three controllers are shown in

Table 2, where different operating points are tested. In this test, the proposed LQG-FF controller provides the best performance in the complete range of

, and the PI controller exhibits the worst behavior. The last two columns of the table show the error comparison between the proposed LQG-FF solution and the two classical approaches, where the LQG-FF controller provides a fraction of the error introduced by the other two solutions.

The controller’s performances for longer profiles were evaluated considering a load current that forces both charge (

) and discharge (

) conditions. The tests results are reported in

Figure 15,

Figure 16 and

Figure 17, where the DC bus current (

) is presented in green color. The bus current starts at 0 A, and after 4 s the DC bus current is increased to 1 A, and thus the battery enters discharging mode (

A) and the supercapacitor provides the fast current transient to the DC bus using

. At 10 s, the DC bus current is decreased to 0 A, and in this case the supercapacitor absorbs the negative current transient. At 16 s, the DC bus current is changed to

A, and hence the battery enters charging mode (

A) and the supercapacitor absorbs the negative current transient. Finally, the test ends by driving the DC bus current to zero, which sets the battery into stand-by mode (

A). For all bus current perturbations, the battery current reaches the stable condition after 1 s with null steady-stable error. In addition, the test confirm that the supercapacitor provides or absorbs the high-frequency transients, thus ensuring low stress for the battery.

The simulations demonstrate the correct behavior of both the HESS and control system, where the supercapacitor provides or absorbs the high-frequency current transients of the DC bus. The simulations also show the correct adaptability of the control system to changes on the voltages (buck, boost, unitary gain), and at different operating conditions of the battery (charge, discharge, stand-by), hence ensuring the stability of the system and avoiding the saturation of the duty cycle in the power converter.

4.2. Voltage Regulation

In any HESS, the supercapacitor is submitted to charge and discharging conditions. However, the supercapacitor charge (which is estimated from its voltage) must be limited and regulated to ensure the capability of providing and absorbing high-frequency transients. In fact, the

profiles reported in

Figure 15,

Figure 16 and

Figure 17 show variations due to the bus current perturbations. This voltage variation is better observed in the simulation of

Figure 18, where consecutive DC bus current perturbations are applied to demand energy from the supercapacitor: the bus current (

) starts from

A, increasing in 1 A each 4 s to reach 3 A. This test shows the need of a voltage controller for

; otherwise, the supercapacitor voltage decreases as it delivers energy to support the positive high-frequency transients. On the other hand, if negative high-frequency transients are consecutively applied,

will reach an overvoltage condition, which could damage the supercapacitor.

Therefore, the external voltage loop is activated for the following tests, which consider the same persistent current profile used in the previous simulation of

Figure 18. The simulations including the external voltage loop are reported in

Figure 19,

Figure 20 and

Figure 21, where the control of the supercapacitor voltage is evaluated at operating points equal to 9 V, 12 V, and 15 V, respectively.

The new simulation results, reported in

Figure 19,

Figure 20 and

Figure 21, show the correct regulation of the supercapacitor voltage (

) (and SoC), which in all cases exhibits a null steady-state error. The transient response in

has the same dynamic behavior as the duty cycle, which is forced to provide the current transient provided by the supercapacitor. Finally, the adaptive gain-scheduling strategy adjusts the controller parameters to ensure the same dynamic performance in all the operating points, and at the same time prevent the duty cycle saturation.

In conclusion, the simulations reported in this section confirm the correct operation of the proposed HESS and control system. In particular, the HESS ensures that high-frequency transients are provided by the supercapacitor, while low-frequency transients are provided by the battery, thus reducing battery stress. In addition, the supercapacitor voltage is controlled, thus regulating the SoC, to ensure the HESS capability to provide or absorb load transients.

6. Conclusions

In this work a semi-active hybrid energy storage system (HESS) formed by a battery, a supercapacitor, and controlled Sepic/Zeta converter is proposed. The HESS is able to reduce the battery degradation since the supercapacitor is forced to absorb or deliver the high-frequency current perturbations present in the DC bus. Considering that batteries and supercapacitors can exhibit wide voltage variations in charging or discharging modes, it is demonstrated that the proposed control for the Sepic/Zeta converter is suitable to operate in a wide operating range, which means under different relationships between the supercapacitor and battery voltages.

On the other hand, the proposed control strategy allows fast tracking of the high-frequency bus current components due to the incorporation of a feed-forward loop. In this way, fast changes in battery power are avoided, which can reduce the degradation of the batteries in the long run. In addition, the adaptive gain-scheduling control strategy ensures the desired performance under different voltage relationships between the battery and the supercapacitor (buck, boost, Unitary Gain). Moreover, the charging, discharging, and stand-by modes of the battery are correctly managed by the HESS. An important consequence of the supercapacitor voltage regulation is that unwanted state-of-charge conditions can be avoided; in this way, the capacitor voltage can be defined in such a way that the HESS always has the same capacity to deliver or absorb energy. The evaluation of this adaptability was performed with variations up to 67% of the nominal range, obtaining much better RMSE values for the reference tracking: between 60% and 76% lower in comparison with the classical LQG controller, and between 66% and 88% lower in comparison with the classical PI controller.

The experimental results confirm the advantages of the proposed adaptive control system over classical PI and LQG strategies. In this context, the proposed feed-forward control loop increases the speed of the reference tracking, and thus considerable attenuation in high-frequency variations of the battery current is provided. These experiments were performed for a wide variation range (67% of the nominal value), achieving a much better absorption of the high-frequency components in comparison with the classical LQG (up to 68% lower RMSE) and PI (up to 84% lower RMSE) controllers.

In conclusion, the proposed solution supports the battery operation by filtering the high-frequency components of the load current to prevent damage. In addition, the operation of this solution is transparent to the energy management system interacting with the battery, and hence no modification to the microgrid management system is needed. Finally, the experimental results demonstrate the viability of implementing the proposed control strategy using commercial and low-cost processing platforms.

An additional advantage of the proposed open architecture based on the Zeta/Sepic converter is the possibility to replace the battery or the supercapacitor without replacing the other one; hence, it reduces the disposal problem in comparison with commercial closed architectures where the complete HESS device must be replaced in the case of a single ESS failure. A future work will study the replacement frequency of both the battery and supercapacitor based on the operation time of the HESS, also analyzing the disposal or repurposing options for both ESSs.

Finally, the modularity of the proposed architecture enables us to combine multiple batteries, supercapacitors, and Zeta/Sepic converters to provide the power level needed in any application, only requiring us to divide the current reference (provided by the HP filter) by the number of the supercapacitors. This improvement will be developed in a future work to increase the power range of the target applications.