Core Ontology for Describing Production Equipment According to Intelligent Production

Abstract

:1. Introduction

- To develop a core ontology that is focused on a particular type of production, includes generalized classes of processes and equipment, and is designed according to a standardized hierarchy;

- To verify the quality of the created ontology according to generally accepted criteria and based on the evaluation of the complexity and formality of the structure at the vocabulary level, taxonomy level, and non-taxonomy level.

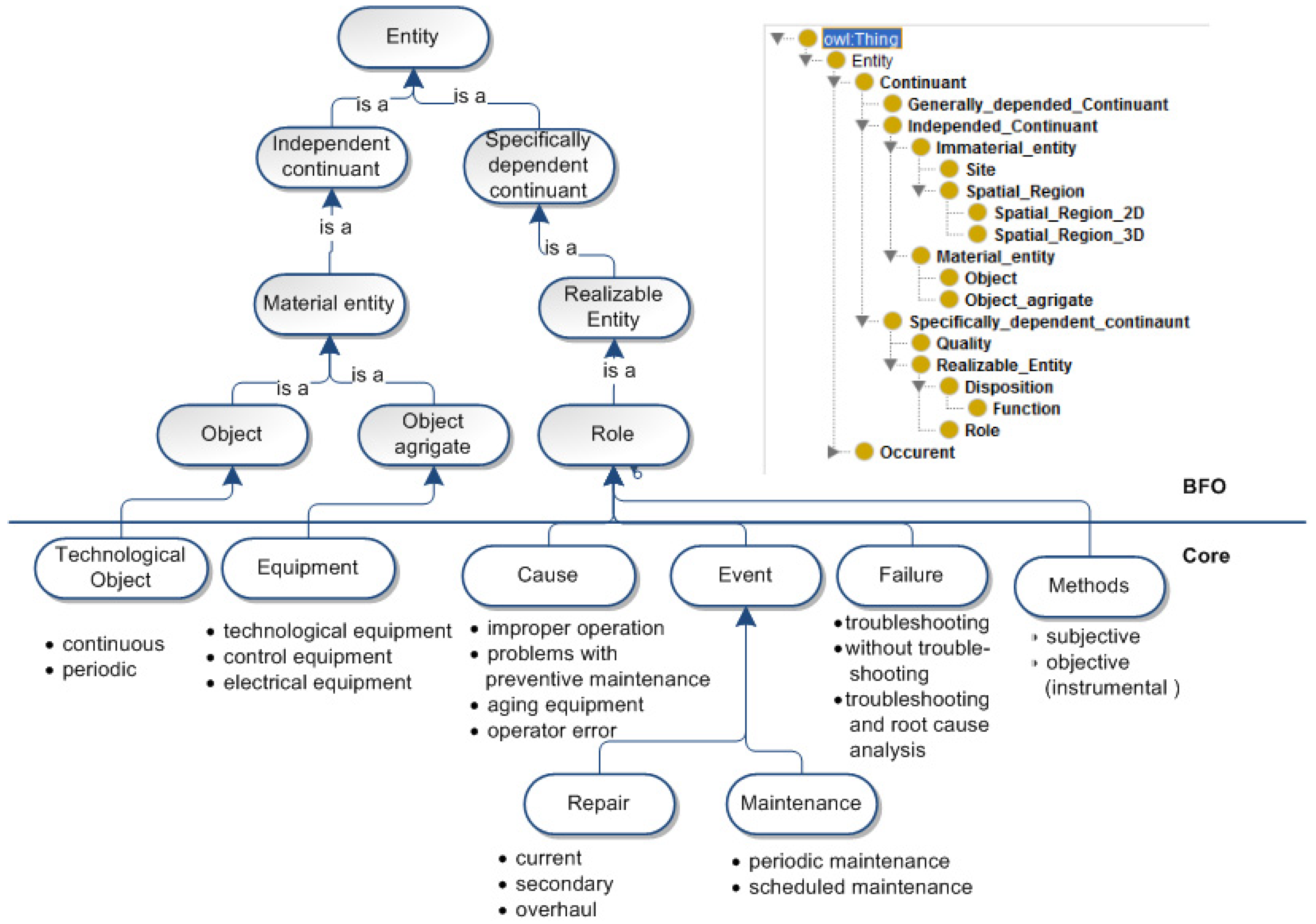

2. Place and Role of the Subject Domain Ontology in the Ontological System of Production

3. Materials and Methods

- BFO is popular—hundreds of ontologies claim to use it as a top-level ontology;

- It has a limited number of classes (terms), which is an advantage of top-level ontology. This indicates that it is understandable and easy to work with;

- It includes definition of higher-level concepts only, which makes it universally applicable to any subject area;

- It combines static and dynamic (temporal) parts in its composition;

- It is in the process of standardization;

- It is OWL-compatible.

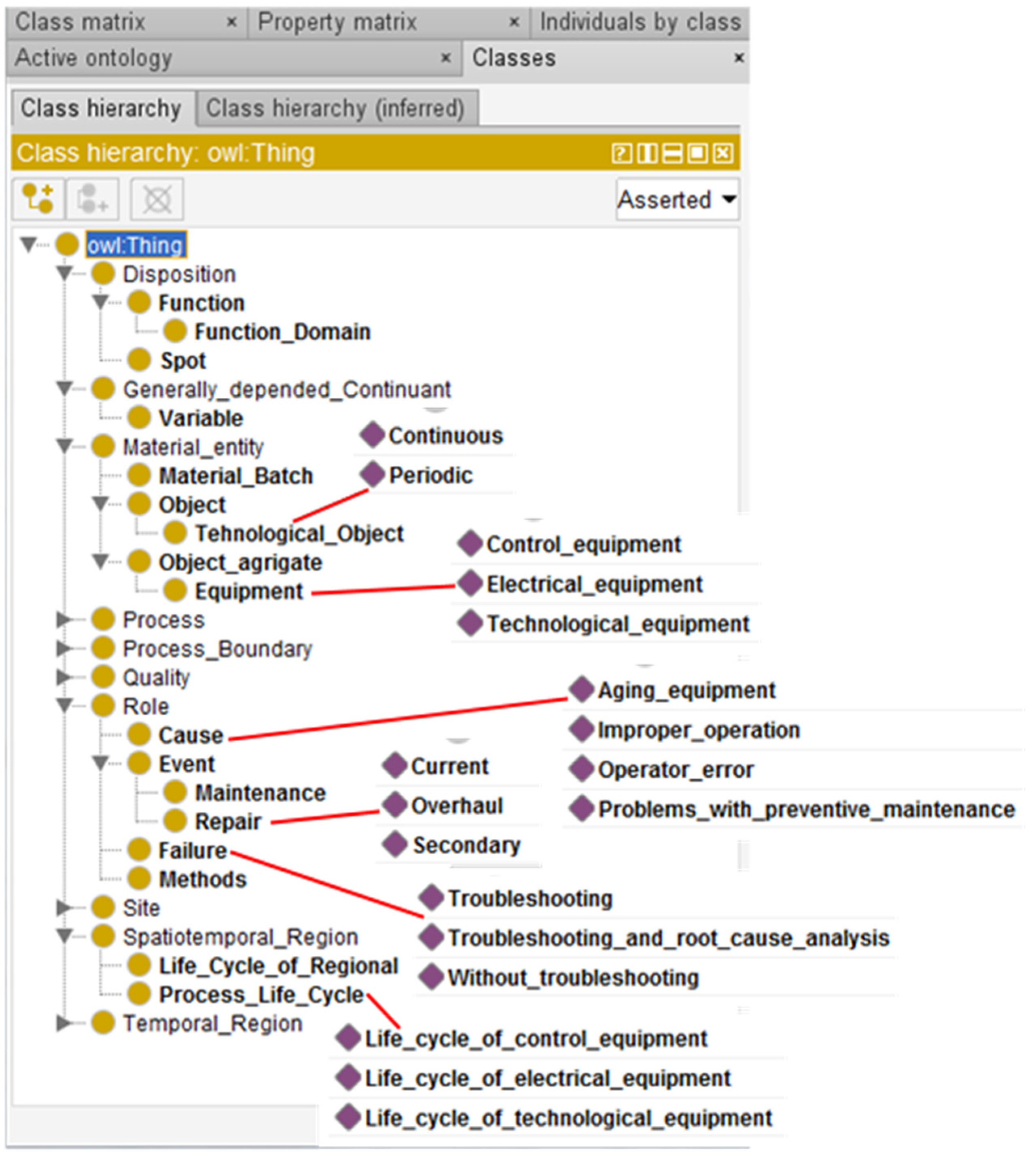

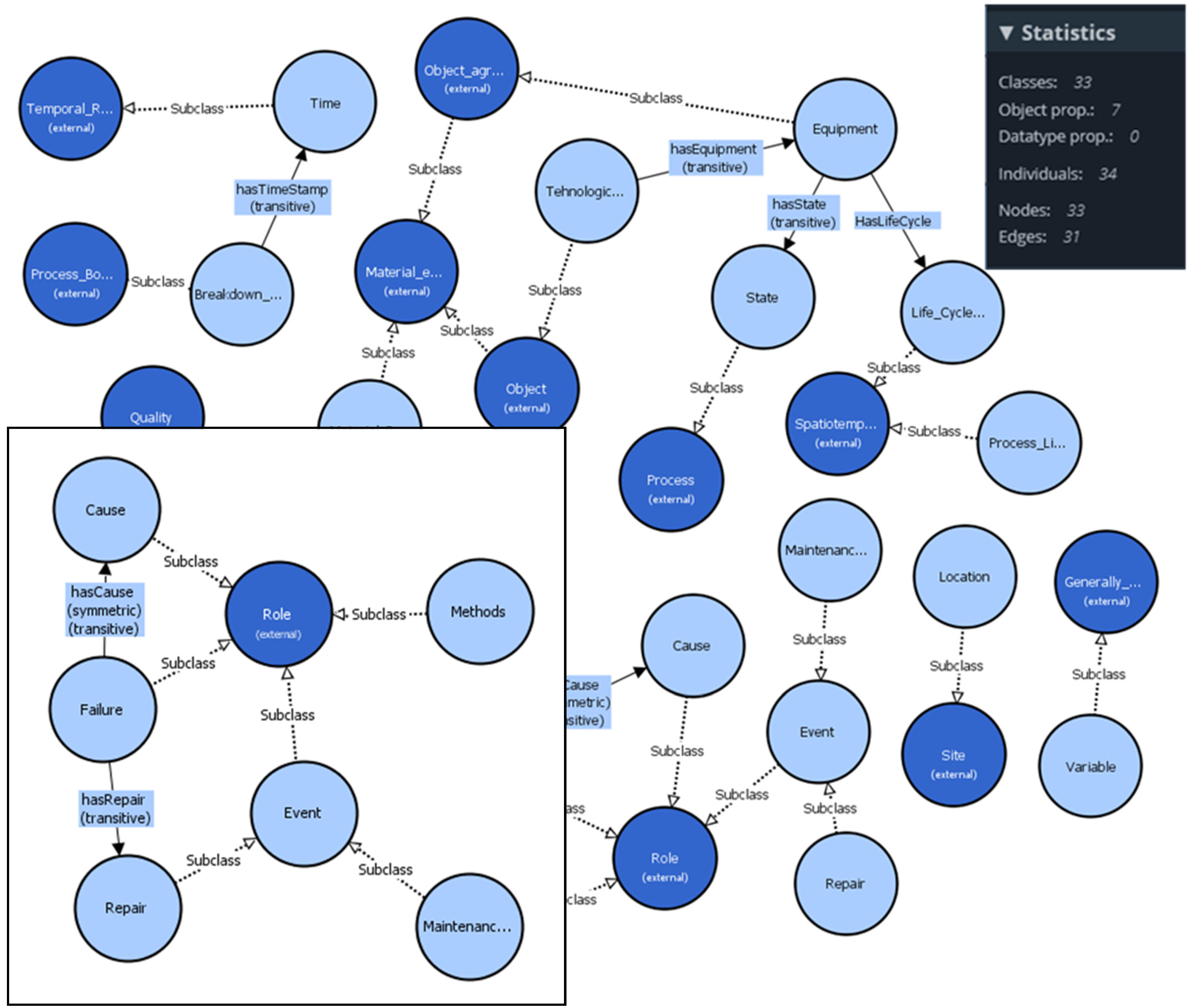

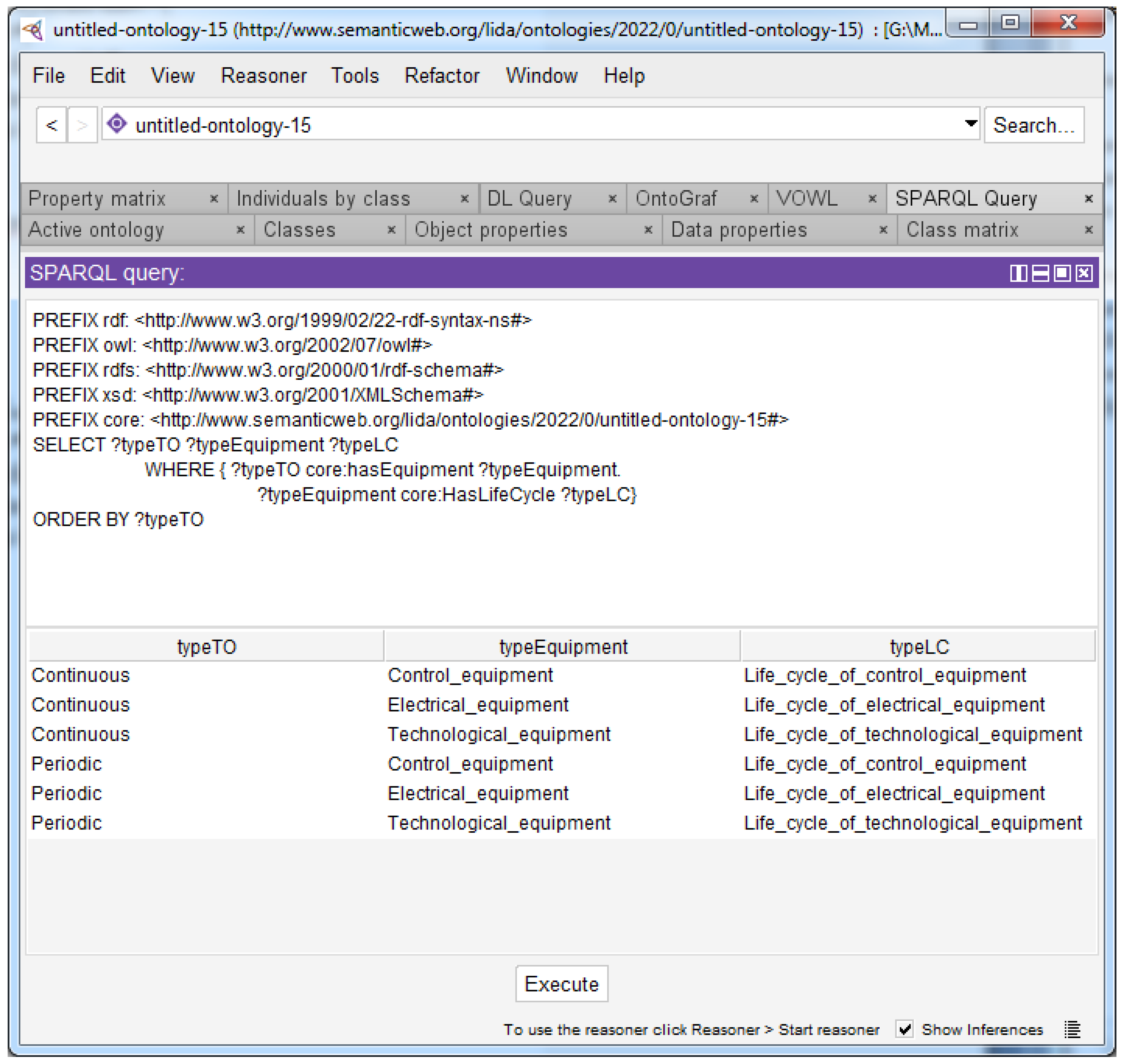

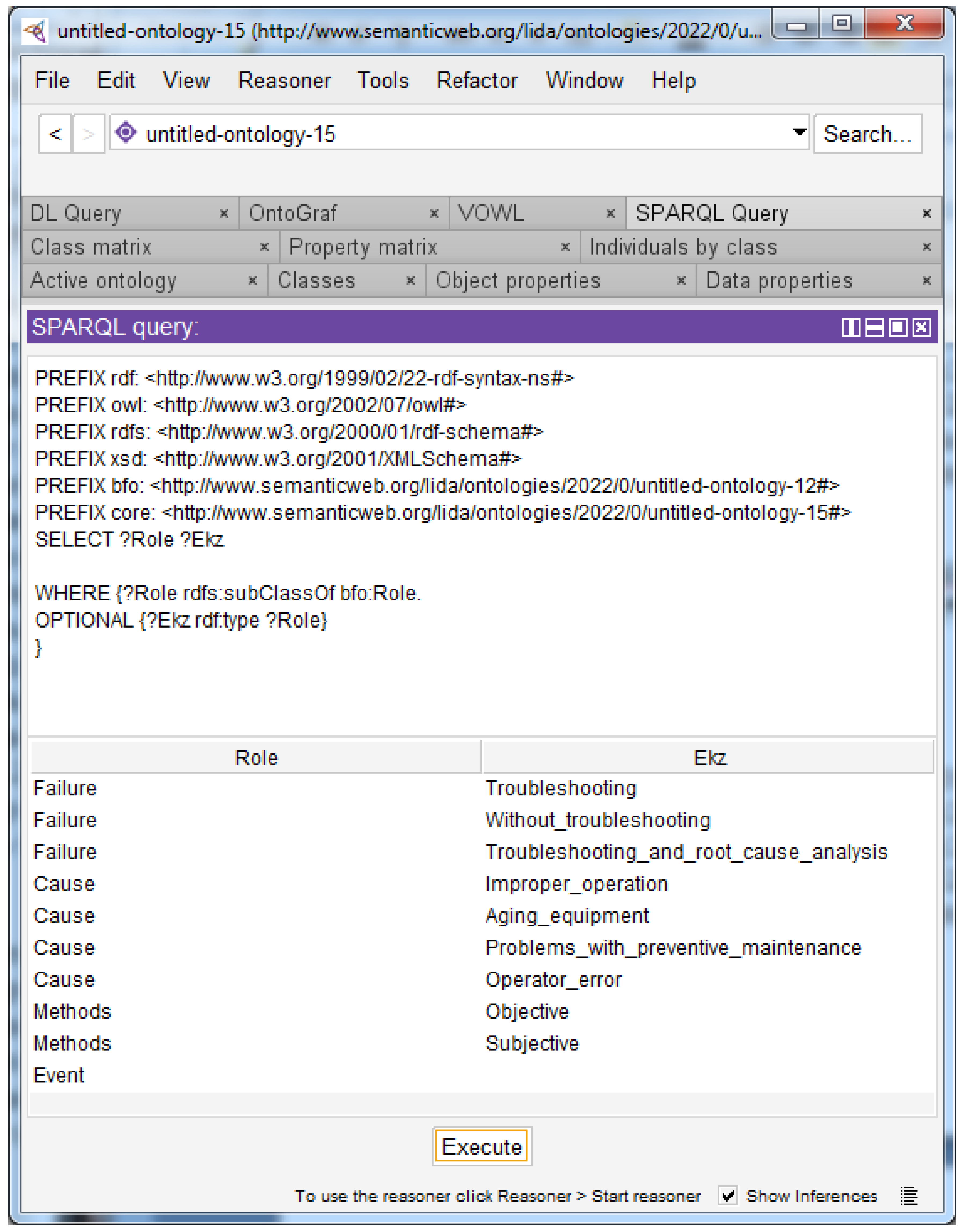

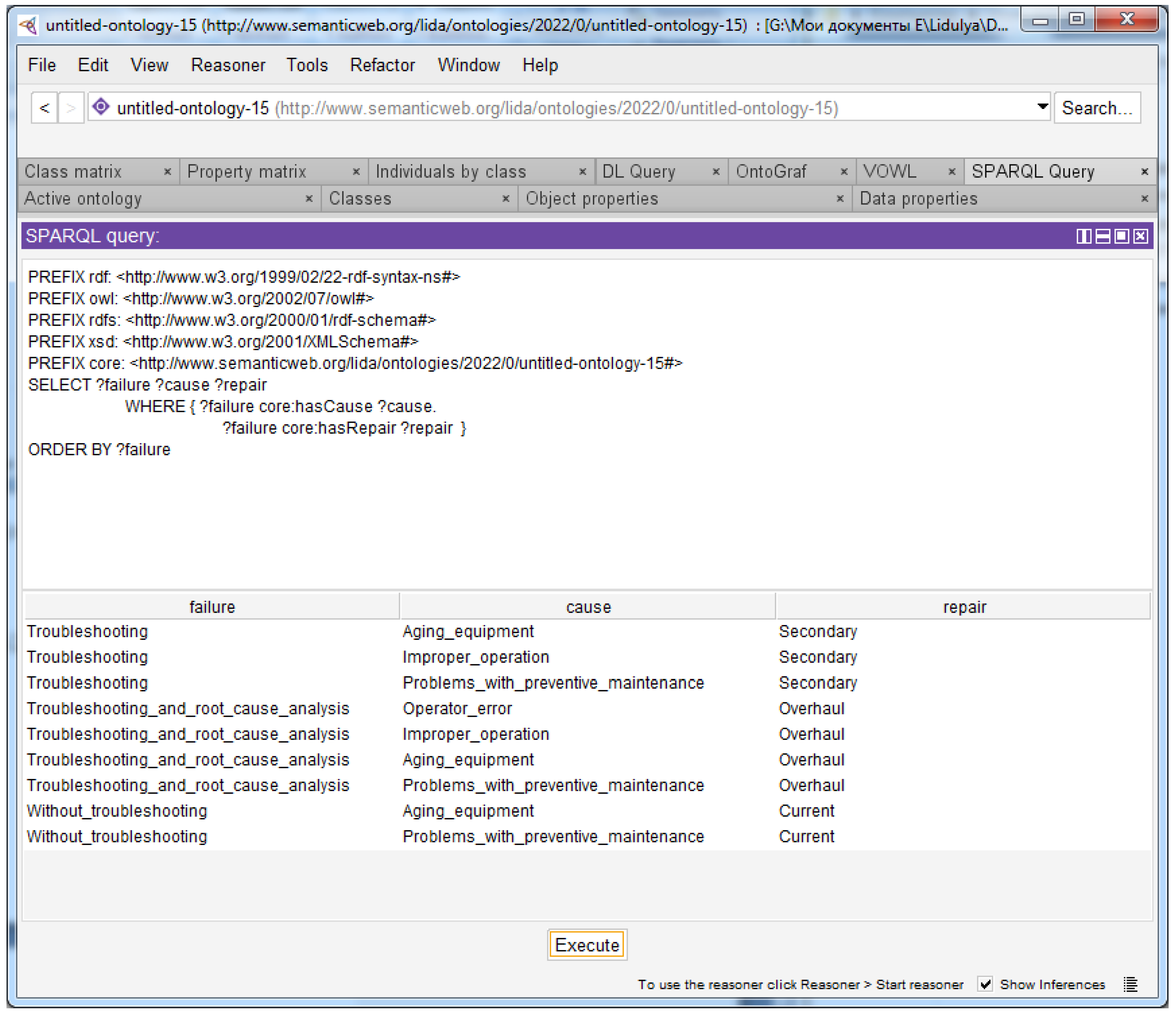

4. Experiment and Results

5. Conclusions

- -

- a single database of knowledge preservation, which stores information throughout the entire life cycle of the device;

- -

- a single knowledge base for modeling the subject area, which works on the usual historical database and establishes the necessary knowledge;

- -

- a means of information support for management decision-making, which works with open ontological databases in the network and serves to present auxiliary information.

Author Contributions

Funding

Conflicts of Interest

References

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Gordon, A. Internet of Things-based Real-Time Production Logistics, Big Data-driven Decision-Making Processes, and Industrial Artificial Intelligence in Sustainable Cyber-Physical Manufacturing Systems. J. Self-Gov. Manag. Econ. 2021, 9, 61–73. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital twin shop-floor: A new shop-floor paradigm towards smart manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Hopkins, E.; Siekelova, A. Internet of Things Sensing Networks, Smart Manufacturing Big Data, and Digitized Mass Production in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2021, 16, 28–41. [Google Scholar] [CrossRef]

- Novak, A.; Bennett, D.; Kliestik, T. Product Decision-Making Information Systems, Real-Time Sensor Networks, and Artificial Intelligence-driven Big Data Analytics in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2021, 16, 62–72. [Google Scholar] [CrossRef]

- Smith, A.; Machova, V. Internet of Things-based Decision Support Systems, Industrial Big Data Analytics, and Autonomous Production Processes in Sustainable Smart Manufacturing. J. Self-Gov. Manag. Econ. 2021, 9, 21–34. [Google Scholar] [CrossRef]

- Griffin, K.; Krastev, V. Smart Traffic Planning and Analytics, Autonomous Mobility Technologies, and Algorithm-driven Sensing Devices in Urban Transportation Systems. Contemp. Read. Law Soc. Justice 2021, 13, 65–78. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Ghazal, R.; Malik, A.K.; Raza, B.; Qadeer, N.; Qamar, N.; Bhatia, S. Agent-Based Semantic Role Mining for Intelligent Access Control in Multi-Domain Collaborative Applications of Smart Cities. Sensors 2021, 21, 4253. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Jain, S. An intelligent knowledge treasure for military decision support. Int. J. Web-Based Learn. Teach. Technol. 2021, 14, 498–521. [Google Scholar] [CrossRef]

- Puchianu, C.M.; Bautu, E. Conceptual and ontological modeling of in-vehicle life-logging software systems. Procedia Comput. Sci. 2020, 176, 2635–2644. [Google Scholar] [CrossRef]

- SAC. Alignment Report for Reference Architectural Model for Industrie 4.0/Intelligent Manufacturing System Architecture; Federal Ministry of Economic Affairs and Energy: Berlin, Germany, 2018; 35p, Available online: https://www.dke.de/resource/blob/1711304/2e4d62811e90ee7aad10eeb6fdeb33d2/alignment-report-for-reference-architectural-model-for-industrie-4-0-data.pdf (accessed on 27 September 2022).

- Han, S. A review of smart manufacturing reference models based on the skeleton meta-model. J. Comput. Des. Eng. 2020, 7, 323–336. [Google Scholar] [CrossRef]

- Lutska, N.M.; Zaiets, N.A.; Vlasenko, L.O.; Shtepa, V.M.; Savchuk, O.V. Forecasting the Efficiency of the Control System of the Technological Object on the Basis of Neural Networks. In Proceedings of the IEEE 20th International Conference on Modern Electrical and Energy Systems (MEES), Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar] [CrossRef]

- Zaiets, N.A.; Savchuk, O.V.; Shtepa, V.M.; Lutska, N.M.; Vlasenko, L.O. The synthesis of strategies for the efficient performance of sophisticated technological complexes based on the cognitive simulation modelling. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 2, 110–117. [Google Scholar] [CrossRef]

- Zaiets, N.; Vlasenko, L.; Lutska, N.; Usenko, S. System Modeling for Construction of the Diagnostic Subsystem of the Integrated Automated Control System for the Technological Complex of Food Industries. In Proceedings of the 2019 5th International Conference on Mechatronics and Robotics Engineering (ICMRE 2019), Rome, Italy, 16–19 February 2019; pp. 93–98. [Google Scholar] [CrossRef]

- Korobiichuk, I.; Ladanyuk, A.; Vlasenko, L.; Zaiets, N. Modern Development Technologies and Investigation of Food Production Technological Complex Automated Systems. In Proceedings of the 2nd International Conference on Mechatronics Systems and Control Engineering ICMSCE 2018, Amsterdam, The Netherlands, 21–23 February 2018; pp. 52–56, ISBN 978-1-4503-6365-5. [Google Scholar] [CrossRef]

- Taberko, V.; Ivaniuk, D.; Shunkevich, D.; Pupena, O. Ontological Approach for Standards Development Within Industry 4.0. In Proceedings of the International Conference on Open Semantic Technologies for Intelligent Systems, OSTIS 2020: Open Semantic Technologies for Intelligent System, Minsk, Belarus, 19–22 February 2020; pp. 64–80. [Google Scholar]

- Smith, B. Basic Formal Ontology 2.0. Specification and User’s Guide. 2015. Available online: https://ncorwiki.buffalo.edu/index.php/Basic_Formal_Ontology_2.0 (accessed on 27 September 2022).

- Giustozzi, F.; Saunier, J.; Zanni-merk, C. Context modeling for industry 4.0: An ontology-based proposal. Procedia Comput. Sci. 2018, 126, 675–684. [Google Scholar] [CrossRef]

- Kitamura, Y.; Mizoguchi, R. An ontological analysis of fault process and category of faults. In Proceedings of the Tenth International Workshop on Principles of Diagnosis (DX-99), Loch Awe, Scotland, 25 March 1999; pp. 118–128. [Google Scholar]

- Dendani-Hadiby, N.; Khadir, M.T. A case based reasoning system based on domain ontology for fault diagnosis of steam turbines. Int. J. Hybrid Inf. Technol. 2012, 5, 89–104. [Google Scholar]

- Bernaras, A.; Laresgoiti, I.; Bartolome, N.; Corera, J. An ontology for fault diagnosis in electrical networks. In Proceedings of the International Conference on Intelligent System Application to Power Systems, Orlando, FL, USA, 28 January–2 February l996; pp. 199–203. [CrossRef]

- Wang, D.; Tang, W.H.; Wu, Q.H. Ontology-based fault diagnosis for power transformers. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 26 July 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Melik-Merkumians, M.; Zoitl, A.; Moser, T. Ontology-based fault diagnosis for industrial control applications. In Proceedings of the 2010 IEEE 15th Conference on Emerging Technologies & Factory Automation (ETFA 2010), Bilbao, Spain, 13–16 September 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Hieb, J.; Graham, J.; Guan, J. An ontology for identifying cyber intrusion induced faults in process control systems. In International Conference on Critical Infrastructure Protection; Springer: Berlin/Heidelberg, Germany, 2009; pp. 125–138. [Google Scholar]

- Zaiets, N.; Shtepa, V.; Pavlov, P.; Elperin, I.; Hachkovska, M. Development of a resource-process approach to increasing the efficiency of electrical equipment for food production. East. -Eur. J. Enterp. Technol. 2019, 4, 59–65. [Google Scholar] [CrossRef] [Green Version]

- Guarino, N. Formal ontology in information Systems. In Proceedings of the First International Conference (FOIS’98), Trento, Italy, 6–8 June 1998; IOIS Press: Amsterdam, The Netherlands. [Google Scholar]

- Cummings, J. DCO: A Mid Level Generic Data Collection Ontology. Ph.D. Thesis, University of Guelph, Guelph, ON, Canada, 2017. [Google Scholar] [CrossRef]

- Gómez-Pérez, A. Ontology Evaluation. In Handbook on Ontologies. International Handbooks on Information Systems; Staab, S., Studer, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Zakaria, N.H.; Hassan, R.; Othman, R.M.; Asmuni, H. Maturity-Based Analysis of Lightweight Ontology from the Aspect of Extensibility, Reusability and Evolutionary. Int. J. Adv. Soft Comput. Appl. 2015, 7, 55–74. [Google Scholar]

- Obrst, L.; Ceusters, W.; Mani, I.; Ray, S.; Smith, B. The evaluation of ontologies. In Semantic Web; Springer: Boston, MA, USA, 2007; pp. 139–158. [Google Scholar]

- Parsia, B.; Matentzoglu, N.; Gonçalves, R.S.; Glimm, B.; Steigmiller, A. The OWL Reasoner Evaluation (ORE) 2015 CompetitionReport. J. Autom. Reason. 2017, 59, 455–482. [Google Scholar] [CrossRef] [PubMed]

- Core Ontology Vocabulary. Available online: https://lov.linkeddata.es/dataset/lov/vocabs?&tag=Industry&page=1 (accessed on 27 September 2022).

| Relation | Description |

|---|---|

| hasCause | It relates breakdowns to their causes. |

| hasEquipment | It is used for objects that may contain other objects. For example, a technological object may contain technological devices, automation equipment and electrical devices. |

| hasLifeCycle | Each individual has a life cycle. |

| hasRepair | It relates breakdowns to repairs. |

| hasSpot | It relates breakdowns to the device, the device to its location on the process layout. This will allow a universal way to save search time in the ontology. |

| hasState | It is used for objects that can be in different states. For example, the equipment can be in the following states: working, not working, in need of repair |

| hasTimeStamp | It relates the time value to some data of measurements and events and include some unit of time. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlasenko, L.; Lutska, N.; Zaiets, N.; Korobiichuk, I.; Hrybkov, S. Core Ontology for Describing Production Equipment According to Intelligent Production. Appl. Syst. Innov. 2022, 5, 98. https://doi.org/10.3390/asi5050098

Vlasenko L, Lutska N, Zaiets N, Korobiichuk I, Hrybkov S. Core Ontology for Describing Production Equipment According to Intelligent Production. Applied System Innovation. 2022; 5(5):98. https://doi.org/10.3390/asi5050098

Chicago/Turabian StyleVlasenko, Lidiia, Nataliia Lutska, Nataliia Zaiets, Igor Korobiichuk, and Serhii Hrybkov. 2022. "Core Ontology for Describing Production Equipment According to Intelligent Production" Applied System Innovation 5, no. 5: 98. https://doi.org/10.3390/asi5050098

APA StyleVlasenko, L., Lutska, N., Zaiets, N., Korobiichuk, I., & Hrybkov, S. (2022). Core Ontology for Describing Production Equipment According to Intelligent Production. Applied System Innovation, 5(5), 98. https://doi.org/10.3390/asi5050098