1. Introduction

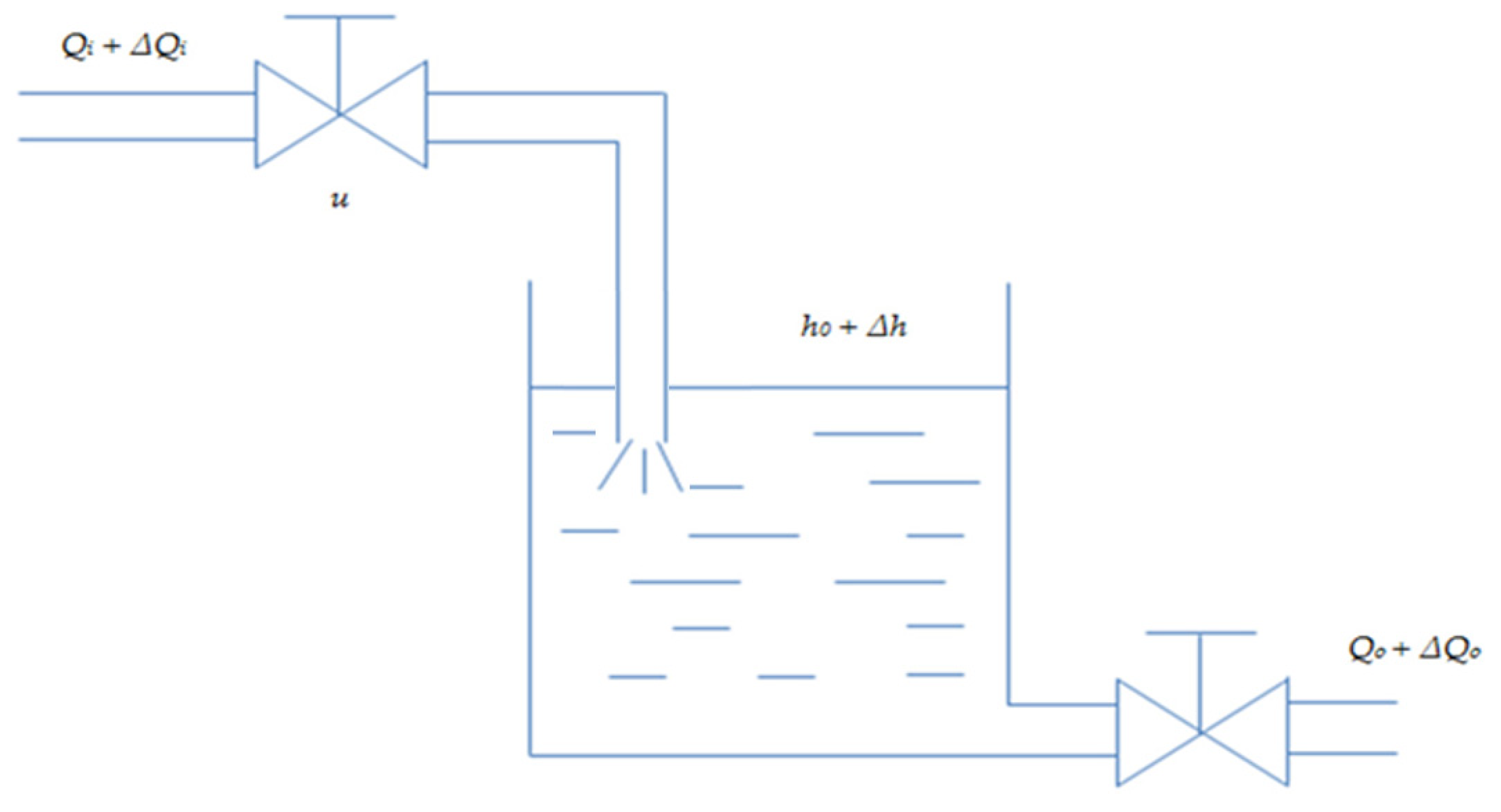

The level control of water tanks is a benchmark problem in the control field that can be used to assess the performance of a new control algorithm [

1]. It is extensively used in many industrial fields. In particular, ocean vessels have a large number of liquid tanks, such as ballast tanks, oil tanks, fresh water tanks, and sludge tanks. They perform different services to guarantee safe navigation. Automatic control first originated from the needs of industrial processes. Since then, this technology has been developed for more than 70 years and has penetrated into every aspect of human life. However, in recent decades, the research on improving controller design has entered a bottleneck stage; there are hardly any new breakthroughs.

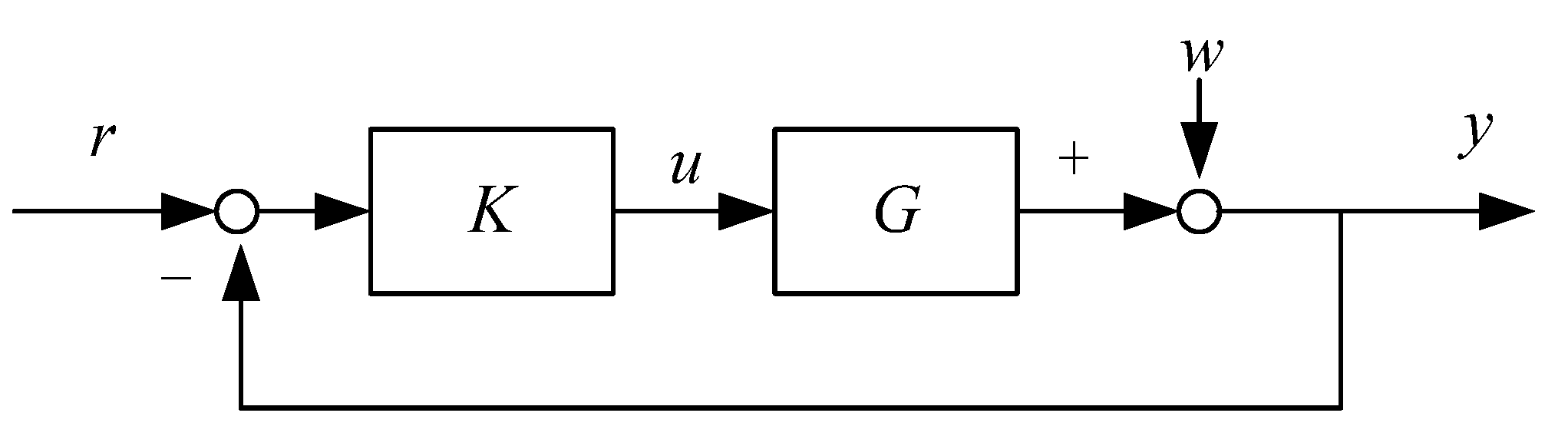

The development of control theory can be roughly divided into three stages: manual control, open-loop control and closed-loop control, and the closed-loop controls have transferred from process control to state control where the essence is still linear feedback [

2]. If we use formulas to denote the closed-loop control then

(where

represents the controller output,

represents the system error). The effectiveness of control law

is judged by whether the output will reach the set value when the system error occurs for a variety of reasons. Moreover, the conventional error feedback is linear feedback, which means

is feedback to the input of the controller either intact or filtered. Therefore, sometimes the control input is unnecessarily large. For this reason, several research studies attempted to use nonlinear feedback to replace linear feedback [

3,

4], that is

(

is a nonlinear function). Along the same lines, one can also adjust the control law output, which is called nonlinear decoration with

(where

is a nonlinear function) [

5,

6]. The nonlinear-decorated control can improve system performance; therefore, the relevant research is worth to be conducted.

Reference [

7] explained the four typical working conditions of water level fluctuations in surge tanks, and a cascade load regulation method for optimal attenuation of water level fluctuation under superposition conditions was proposed. Reference [

8] discussed the design of PLC-based fractional-order controller for volume control of industry water tank; the purpose was to verify the stability and robustness of fractional-order discrete PID-feedback-loop for different approximation methods and approximation orders. Reference [

9] introduced the improved smith predictor and the improved inverse calculation method to design the controller of the conical tank level process and compared the energy utilization and performance of the actuator in a nonlinear process with traditional PI controller. In order to stabilize the well water level, Dariusz also designed another PI controller [

10]. The principle and algorithm of dynamic matrix predictive control are described in [

11]. Through the experimental analysis of different models of single, double and triple tanks, a classical double tank model was proposed, which was shown to have great efficiency improvement in the control process compared to the conventional model.

In addition, Reference [

12], using nonlinear ordinary differential equations described two mathematical models in order to research the adaptive control of nonlinear systems. Nonlinear robust controllers have also been widely used in other fields. However, all of the references mentioned above were in-depth studies based on different opinions and achieved some results about water tank control on the basis of distinctive control methods. Yet, there is little research based on the orientation of energy efficiency, leading to some prospective potential in this aspect.

On the basis of the references [

13,

14], the contributions of this paper are mainly twofold: (1) the condition of robust controller solution in reference [

14] is reproved by using

theory, and the condition of robust performance is relaxed from

to

; (2) the nonlinear feedback based on the arctangent function in [

13] is changed to the nonlinear decoration based on S function and the control performance is further improved.

3. Controller Design

In this study, the Lyapunov stability theory was applied to launch the stability analysis of the water tank feedback controller, which is designed based on the closed-loop-gain algorithm.

First, the state variable of the control system is interpreted as

,

Based on Formula (11), the inlet ratio of the water tank control system can be expressed as (12). At the same time, the parameters’ values are

. Combine with (2).

By combining Formulas (8) and (12), we obtain:

Then, by rearranging Formulas (11) and (13), the state equation of the controlled system can be written as

For Formula (14), the Lyapunov function of the system is interpreted as

where

represents a positive definite real symmetric matrix, and

.

Ignoring the external disturbance term

, then

According to the Lyapunov stability theory, the following function is needed to ensure the stability of the system at origin, for any interpreted positive definite real symmetric matrix.

Define positive definite real symmetric matrix, and make positive definite real symmetric matrix

as

Putting Formulas (14) and (18) into Formula (17), to obtain

To expand Formula (19) and obtain the solutions as

The following functions have to be met for maintaining the positive definiteness of matrix

By solving Function (21), we obtain

Thus, in the case of , if is ensured, then the controller will keep the balanced state at the origin.

For the purpose of verifying the robustness of the controller proposed by this study against external distraction, the external distraction term

is considered in Formula (9), and then the formula of Lyapunov function as shown in Formula (10), is [

14]

where

.

According to Young’s inequality, we can obtain

Then,

is a bounded interference term and

.

To define

, then

Formula (26), indicated that when state variable of the system , then .

For further discussing the robustness for the external distraction,

which is the performance index of gain robust is interpreted as

where

and

are positive and small, and the following theorem is obtained.

Theorem: in the controller design for the water tank level control system, as shown in Formula (14) by applying the closed-loop gain algorithm, and the parameter of controller satisfying the condition of , the state variable of the system ensures the whole controller uniform ultimate boundness and also achieves the performance index of gain robust , which is related to the controller parameter .

This theorem can be proved by integrating Formula (26) from

to

, to obtain

On the basis of the definition of, Formula (28) can be derived as

After discussing the bounds of

as shown in Formula (29),

can be stated as [

22]

The formula

is a requisite, for the purpose of keeping the negative definite of Formula (26), and then the range of controller parameters is derived according to Formula (30)

To summarize, based on the result of the Formula (27) about the performance index of gain robust and Formula (29), when the state variable of water tank control system satisfies the requirement of , if the parameter of the controller of closed-loop gain control law can meet , then the water tank control system shown in Formula (14) will obtain the performance index of gain robust , as shown in Formula (27), which is related to the parameter of controller parameter .

If the S function is applied to decorate the output

of the existing controller, then

Based on the Taylor series expansion, the Formula (33) can be obtain

When

is not too large, then

When , the above derivation is still valid.

The above proof is based on the reference [

14] using the

gain robustness performance index. In the actual simulation, it is found that the requirement

is conservative and the

robust theorem is used to re-prove.

According to Formulas (11) and (14), if the output matrix

is added, the sensitivity function

of the system can be obtained, followed by the complementary sensitivity function

of the system.

According to the system robustness theorem, Formula (37) can be obtained as

According to Formula (36), if you want to satisfy Formula (38), the damping coefficient of a second-order oscillation system requiring a complementary sensitivity function is greater than or equal to 1.

According to Young’s inequality, it can be obtained that

Therefore, Formula (39) is automatically satisfied; hence under the condition that the state variables of water tank level control system satisfy , as long as and , the robustness of the designed controller can be guaranteed, which is more relaxed than the original condition, and also consistent with the simulation results.

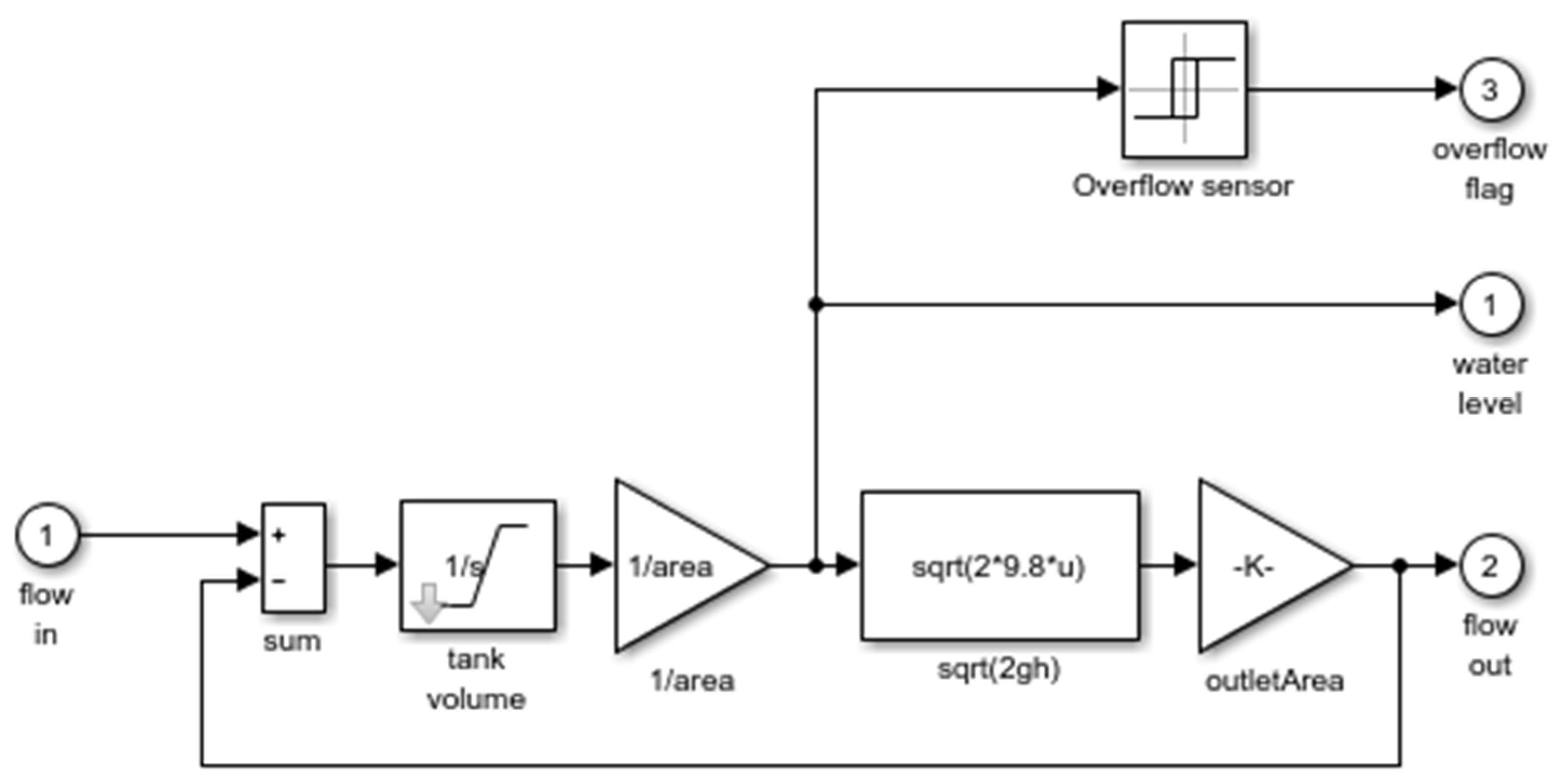

4. Simulation Experiments and Results

The Simulink toolbox of MATLAB (2016b) was used for the simulation experiment, and its diagrammatic drawing is shown in

Figure 5. Compared with the fuzzy controller proposed in reference [

18], the robust control proposed in reference [

17] has better robust stability and simplicity. However, the improved PD controller proposed in this study is a kind of S function nonlinear decorated control, aiming to achieve energy-saving performance based on the two controllers mentioned above.

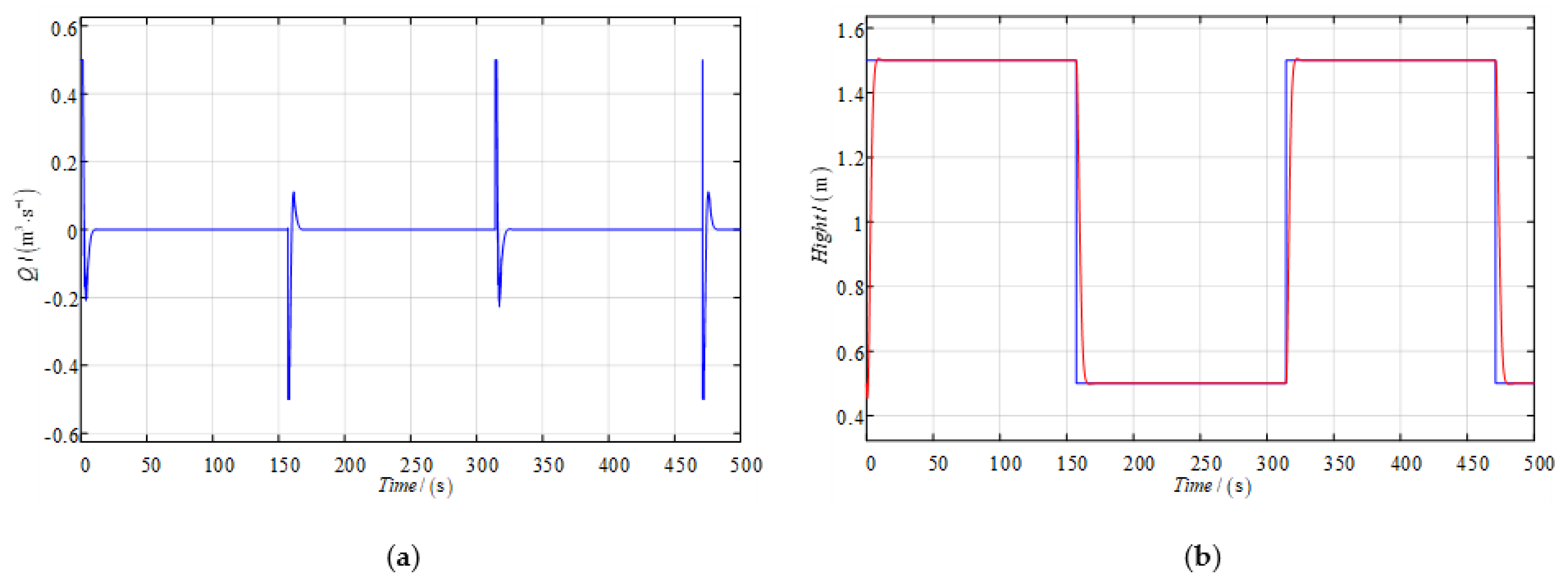

The input signal is a square wave with amplitude changing from

to

. The Formula (2) in this study was applied to design a PD controller. When the max inlet ratio of the tank is ensured at

due to the effect of nonlinear decorated robust PD control, the mean control input is

. The simulation results are displayed in

Figure 6. There are no overshoot and quick tracking achieved. Considering the complicated nonlinear model that is used in the simulation experiments while the controller is designed according to the simplified linear model, the system robustness is also guaranteed. (In

Figure 6b, the blue line represents the set level and the red line represents the simulated level).

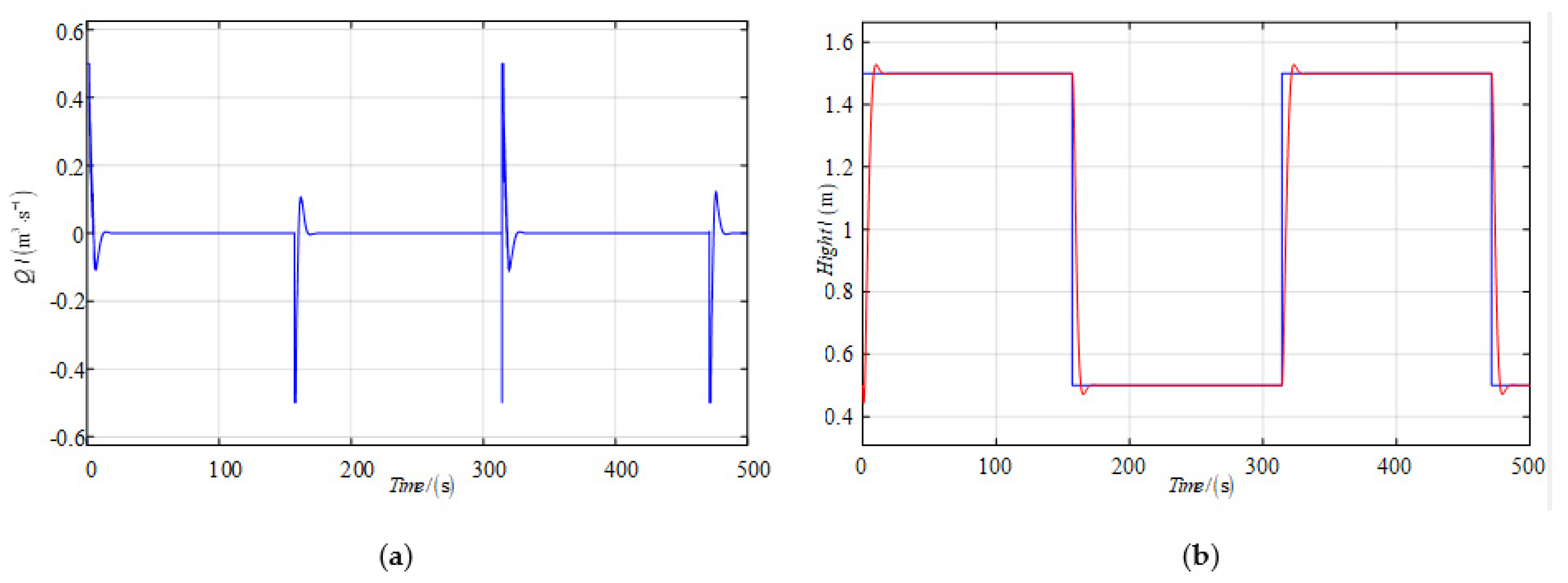

As displayed in

Figure 7, which shows the effect of nonlinear feedback, its mean control input is

. The control input of the improved algorithm is reduced by 9.6%, compared to the nonlinear-decorated control and the nonlinear feedback control. The purpose of saving energy by applying the S-function-decorated control is then obtained.

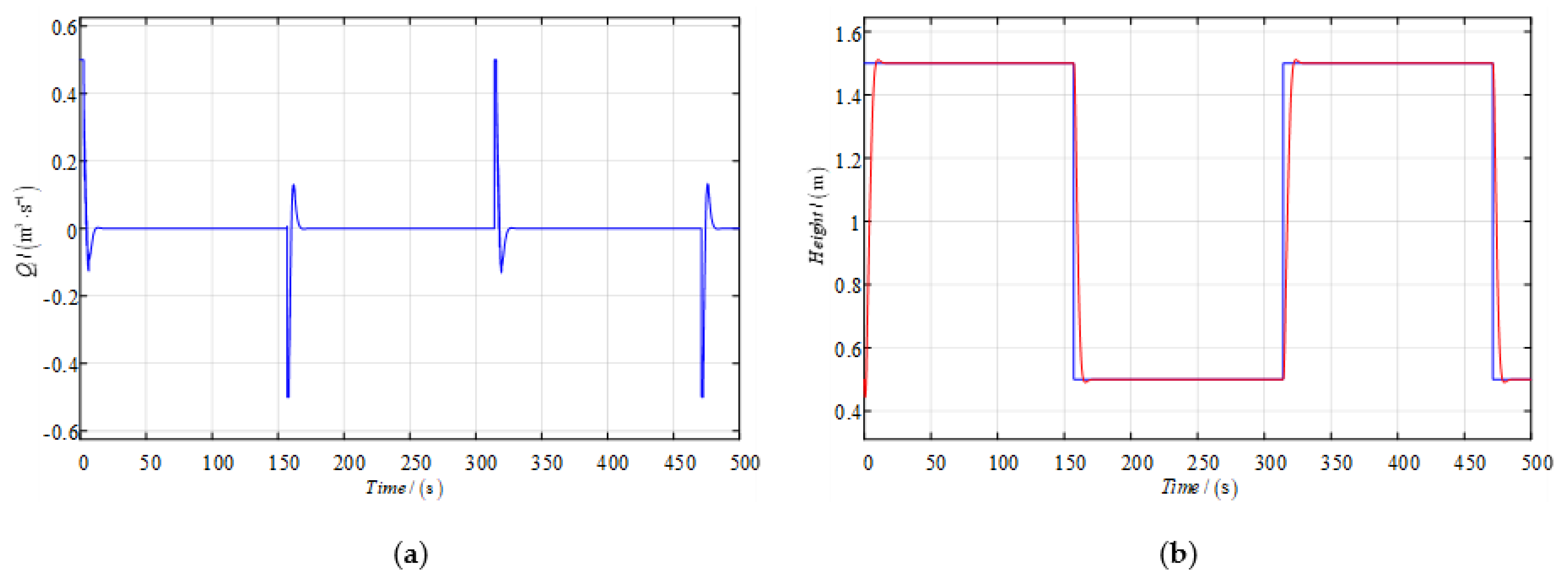

The mean control input of nonlinear decorated robust control is

if the inlet ratio is decreased from

to

, as shown in

Figure 8. The control output of the level is almost unchanged with satisfactory robustness.

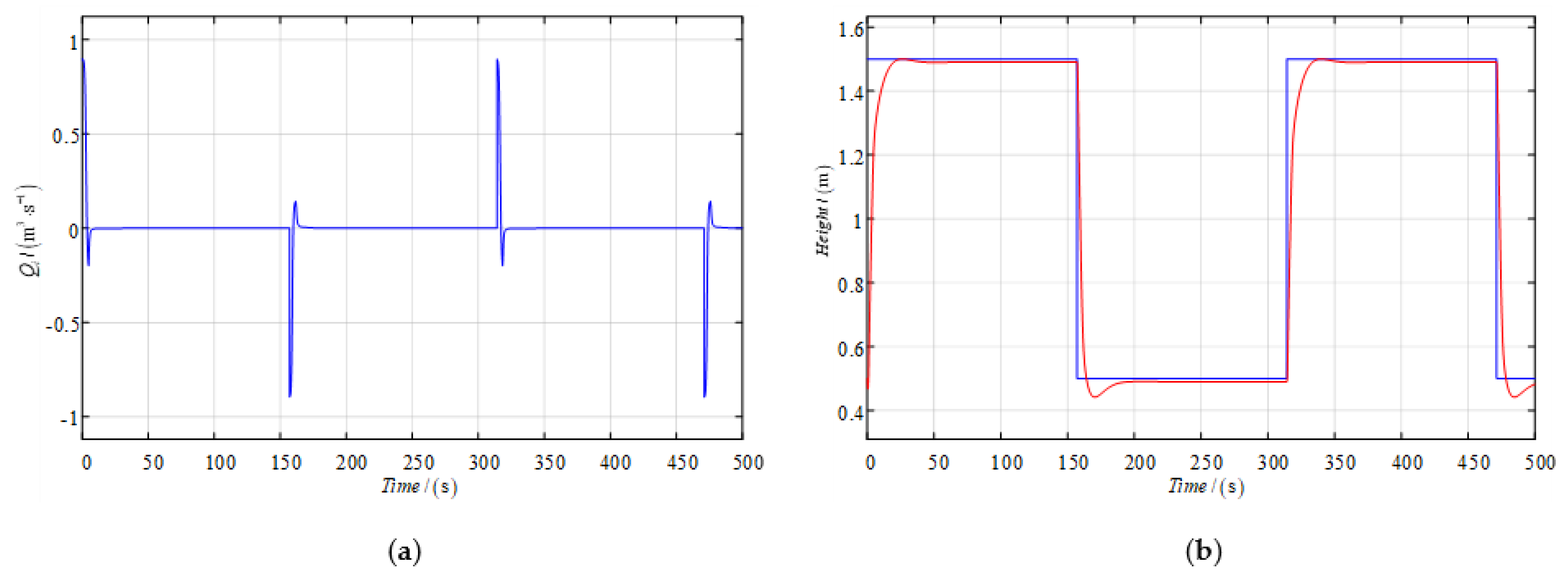

The effect of nonlinear feedback is shown in

Figure 9, its mean control input is

when the inlet ratio is reduced from

to

. Compared with the nonlinear-decorated control and the nonlinear feedback control with a limited inlet ratio, the control input of the improved algorithm is reduced by 4.4%.

The performance of linear feedback fuzzy control is displayed in

Figure 10, the mean control input is

, and the effect of linear feedback fuzzy control is displayed in

Figure 11 when the limit of inlet ratio is

, with the mean control input as

. The mean control input of nonlinear-decorated robust control is reduced by 26.1%, compared with the linear feedback fuzzy control. The purpose of energy-saving is met. Further, the fuzzy control has a slight overshoot.

The comprehensive control performance index

of (42) is used to evaluate the above three kinds of control algorithms.

is a function that controls input energy and output error, and the smaller the value is, the better.

Table 1 presents a quantitative comparison of the control simulation results mentioned above, and studies the efficiency of the proposed algorithm. It is worth nothing that the response performance specification

of the nonlinear-decorated robust method is decreased by 13.0% and 26.3%, respectively, in contrast to the nonlinear feedback and the fuzzy controller. When the model has some perturbation (the max inlet ratio is changed), the control performance is also satisfactory with good robustness.