Coded Control of a Sectional Electroelastic Engine for Nanomechatronics Systems

Abstract

:1. Introduction

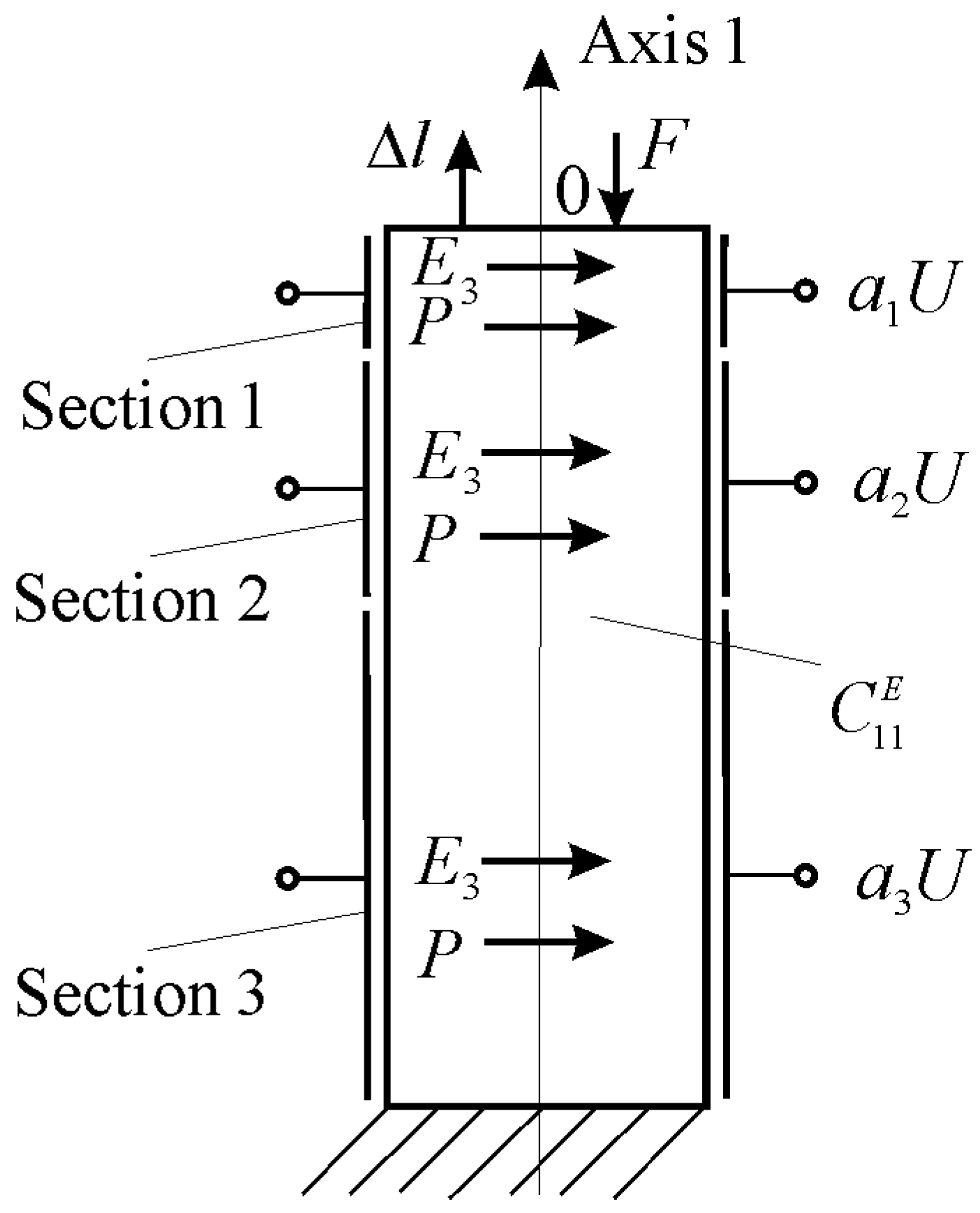

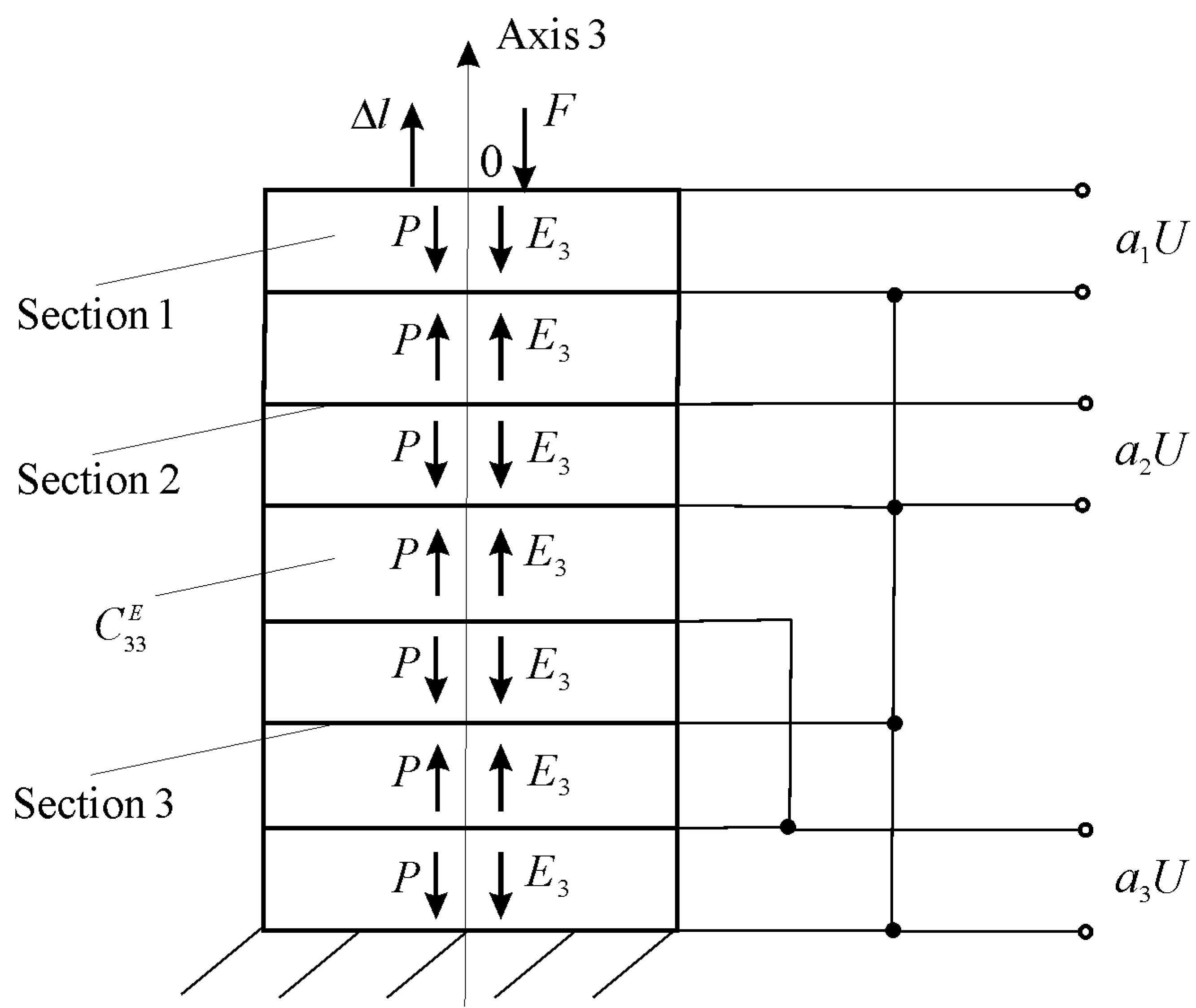

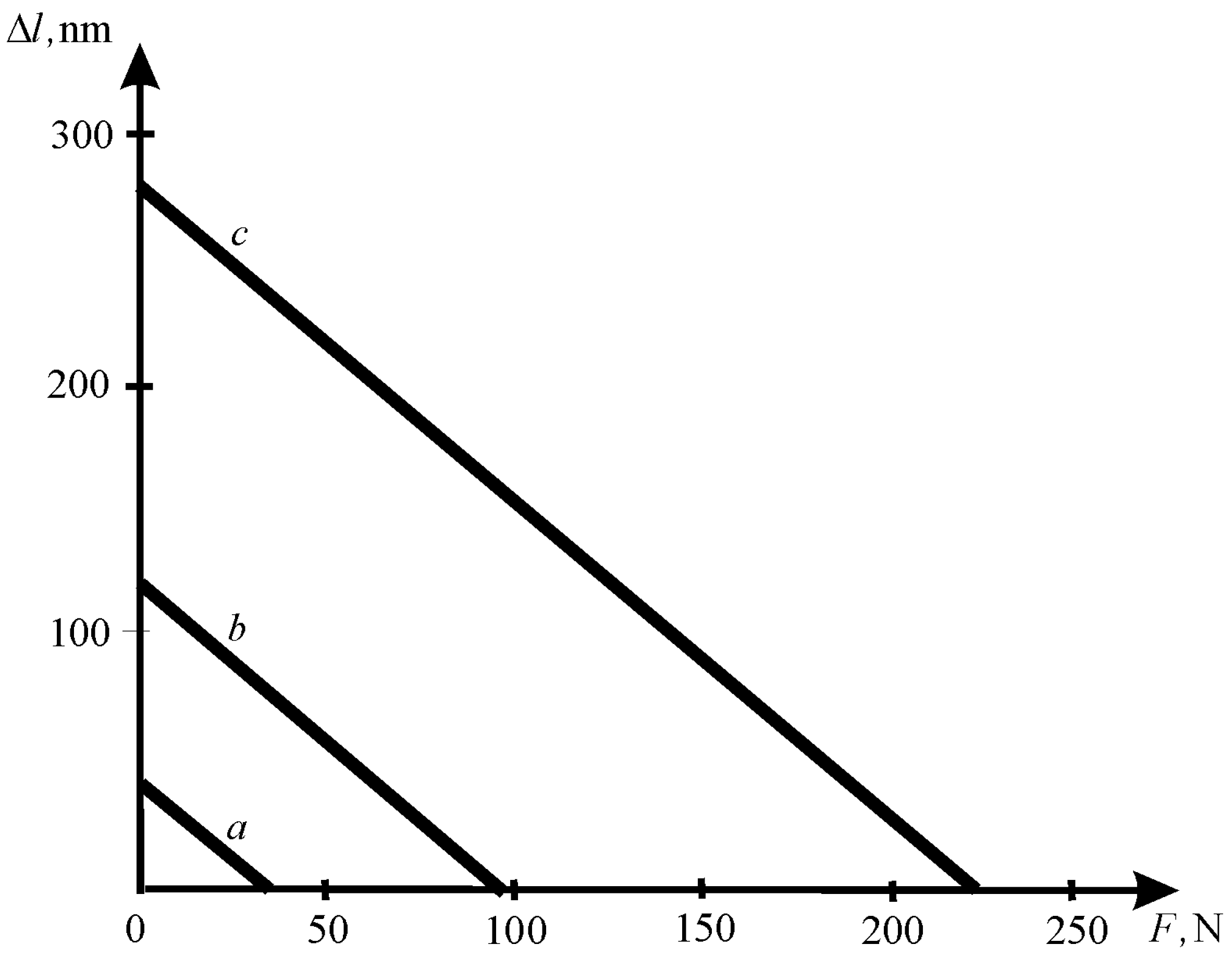

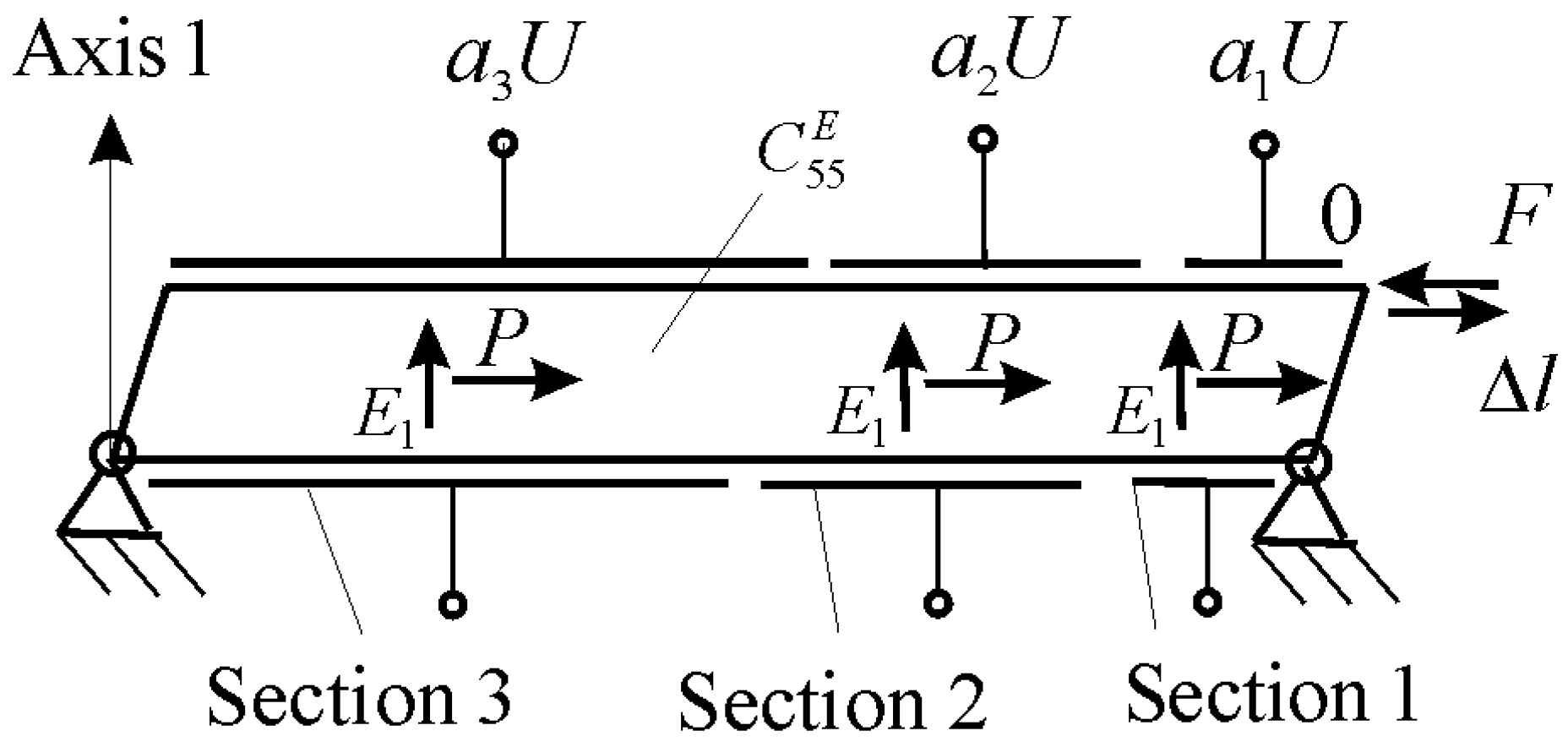

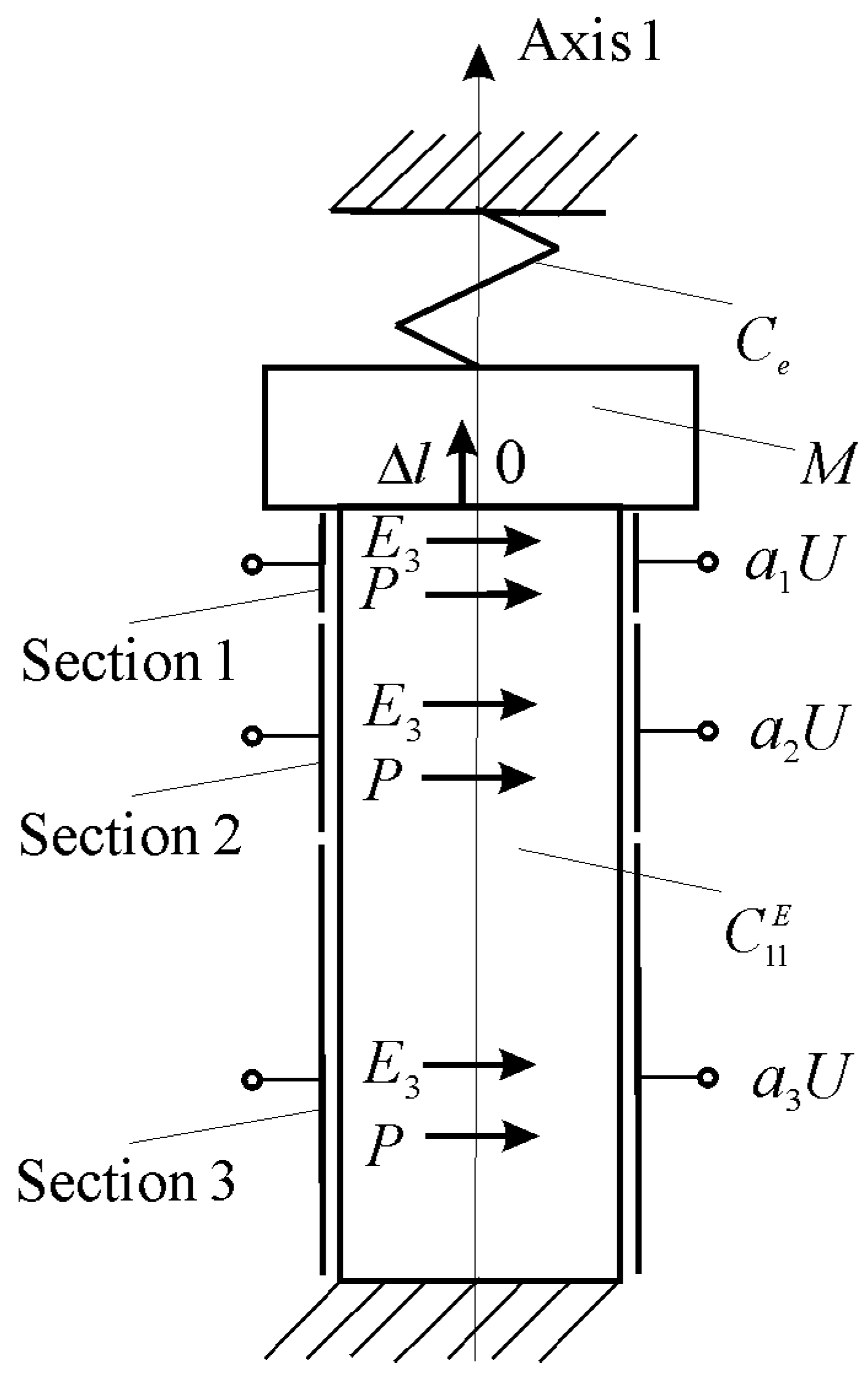

2. Mechanical and Adjustment Characteristics of a Sectional Electroelastic Engine

3. Transient Characteristic of a Sectional Electroelastic Engine at Elastic–Inertial Load

4. Results and Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schultz, J.; Ueda, J.; Asada, H. Cellular Actuators; Butterworth-Heinemann Publisher: Oxford, UK, 2017; p. 382. [Google Scholar]

- Afonin, S.M. Absolute stability conditions for a system controlling the deformation of an elecromagnetoelastic transduser. Dokl. Math. 2006, 74, 943–948. [Google Scholar] [CrossRef]

- Zhou, S.; Yao, Z. Design and optimization of a modal-independent linear ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 535–546. [Google Scholar] [CrossRef] [PubMed]

- Uchino, K. Piezoelectric Actuator and Ultrasonic Motors; Kluwer Academic Publishers: Boston, MA, USA, 1997; p. 347. [Google Scholar]

- Ueda, J.; Secord, T.; Asada, H.H. Large effective-strain piezoelectric actuators using nested cellular architecture with exponential strain amplification mechanisms. IEEE/ASME Trans. Mechatron. 2010, 15, 770–782. [Google Scholar] [CrossRef]

- Sherrit, S.; Jones, C.; Aldrich, J.; Blodget, C.; Bao, X.; Badescu, M.; Bar-Cohen, Y. Multilayer piezoelectric stack actuator characterization. Proc. SPIE—Int. Soc. Opt. Eng. 2008, 6929, 692909. [Google Scholar] [CrossRef]

- Uchino, K. Multilayer technologies for piezoceramic materials. In Advanced Piezoelectric Materials: Science and Technology; Uchino, K., Ed.; Woodhead Publishing in Materials: Cambridge, UK, 2017; Chapter 11; pp. 423–451. [Google Scholar] [CrossRef]

- Afonin, S.M. Block diagrams of a multilayer piezoelectric motor for nano- and microdisplacements based on the transverse piezoeffect. J. Comput. Syst. Sci. Int. 2015, 54, 424–439. [Google Scholar] [CrossRef]

- Afonin, S.M. Structural parametric model of a piezoelectric nanodisplacement transduser. Dokl. Phys. 2008, 53, 137–143. [Google Scholar] [CrossRef]

- Afonin, S.M. Solution of the wave equation for the control of an elecromagnetoelastic transduser. Dokl. Math. 2006, 73, 307–313. [Google Scholar] [CrossRef]

- Cady, W.G. Piezoelectricity: An Introduction to the Theory and Applications of Electromechancial Phenomena in Crystals; McGraw-Hill Book Company: New York, NY, USA; London, UK, 1946; p. 80. [Google Scholar]

- Mason, W.P. Methods and devices. In Physical Acoustics: Principles and Methods; Mason, W., Ed.; Academic Press: New York, NY, USA, 1964; Volume 1, Part A; p. 515. [Google Scholar]

- Zwillinger, D. Handbook of Differential Equations; Academic Press: Boston, MA, USA, 1989; p. 673. [Google Scholar]

- Afonin, S.M. Structural-parametric model and transfer functions of electroelastic actuator for nano- and microdisplacement. In Piezoelectrics and Nanomaterials: Fundamentals, Developments and Applications; Parinov, I.A., Ed.; Nova Science: New York, NY, USA, 2015; Chapter 9; pp. 225–242. [Google Scholar]

- Afonin, S.M. A structural-parametric model of electroelastic actuator for nano- and microdisplacement of mechatronic system. In Advances in Nanotechnology; Bartul, Z., Trenor, J., Eds.; Nova Science: New York, NY, USA, 2017; Volume 19, Chapter 8; pp. 259–284. [Google Scholar]

- Afonin, S.M. Nano- and micro-scale piezomotors. Russ. Eng. Res. 2012, 32, 519–522. [Google Scholar] [CrossRef]

- Afonin, S.M. Elastic compliances and mechanical and adjusting characteristics of composite piezoelectric transducers. Mech. Solids 2007, 42, 43–49. [Google Scholar] [CrossRef]

- Afonin, S.M. Static and dynamic characteristics of a multi-layer electroelastic solid. Mech. Solids 2009, 44, 935–950. [Google Scholar] [CrossRef]

- Afonin, S.M. Static and dynamic characteristics of multilayered electromagnetoelastic transducer of nano- and micrometric movements. J. Comput. Syst. Sci. Int. 2010, 49, 73–85. [Google Scholar] [CrossRef]

- Afonin, S.M. Structural-parametric model electromagnetoelastic actuator nanodisplacement for mechatronics. Int. J. Phys. 2017, 5, 9–15. [Google Scholar] [CrossRef]

- Afonin, S.M. Structural-parametric model multilayer electromagnetoelastic actuator for nanomechatronics. Int. J. Phys. 2019, 7, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Afonin, S.M. Structural-parametric model of electromagnetoelastic actuator for nanomechanics. Actuators 2018, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Afonin, S.M. Structural-parametric model and diagram of a multilayer electromagnetoelastic actuator for nanomechanics. Actuators 2019, 8, 52. [Google Scholar] [CrossRef] [Green Version]

- Afonin, S.M. A block diagram of electromagnetoelastic actuator nanodisplacement for communications systems. Trans. Netw. Commun. 2018, 6, 1–9. [Google Scholar] [CrossRef]

- Afonin, S.M. Decision matrix equation and block diagram of multilayer electromagnetoelastic actuator micro and nanodisplacement for communications systems. Trans. Netw. Commun. 2019, 7, 11–21. [Google Scholar] [CrossRef]

- Afonin, S.M. Condition absolute stability control system of electromagnetoelastic actuator for communication equipment. Trans. Netw. Commun. 2020, 8, 8–15. [Google Scholar] [CrossRef]

- Afonin, S.M. A Block diagram of electromagnetoelastic actuator for control systems in nanoscience and nanotechnology. Trans. Mach. Learn. Artif. Intell. 2020, 8, 23–33. [Google Scholar] [CrossRef]

- Afonin, S.M. Optimal control of a multilayer electroelastic engine with a longitudinal piezoeffect for nanomechatronics systems. Appl. Syst. Innov. 2020, 3, 53. [Google Scholar] [CrossRef]

- Bhushan, B. Springer Handbook of Nanotechnology; Springer: Berlin, Germany; New York, NY, USA, 2004; p. 1222. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afonin, S.M. Coded Control of a Sectional Electroelastic Engine for Nanomechatronics Systems. Appl. Syst. Innov. 2021, 4, 47. https://doi.org/10.3390/asi4030047

Afonin SM. Coded Control of a Sectional Electroelastic Engine for Nanomechatronics Systems. Applied System Innovation. 2021; 4(3):47. https://doi.org/10.3390/asi4030047

Chicago/Turabian StyleAfonin, Sergey M. 2021. "Coded Control of a Sectional Electroelastic Engine for Nanomechatronics Systems" Applied System Innovation 4, no. 3: 47. https://doi.org/10.3390/asi4030047

APA StyleAfonin, S. M. (2021). Coded Control of a Sectional Electroelastic Engine for Nanomechatronics Systems. Applied System Innovation, 4(3), 47. https://doi.org/10.3390/asi4030047