Principles of Product Design in Developing Countries

Abstract

:1. Introduction

1.1. Engineering in Developing Country Contexts

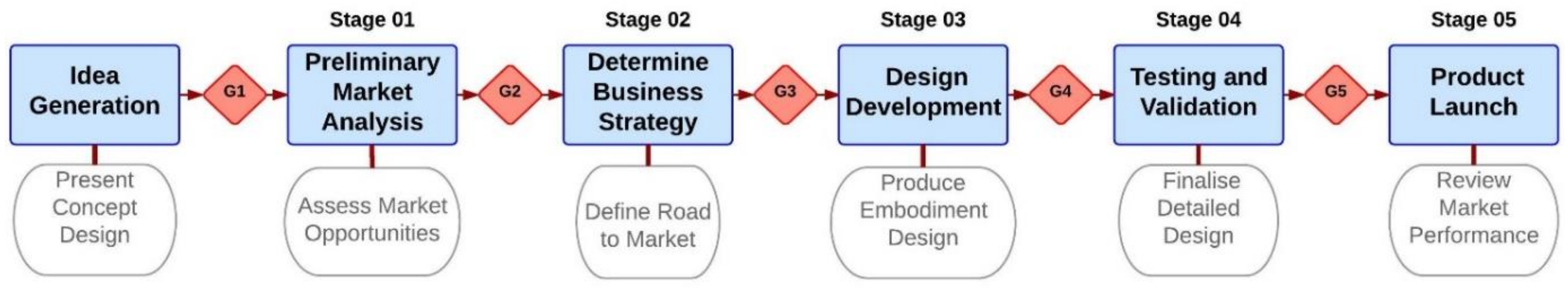

1.2. Process of New Product Development in the Rural DC Context

2. Materials and Methods

2.1. Research Question

2.2. Approach

3. Results

3.1. Project Context and Background

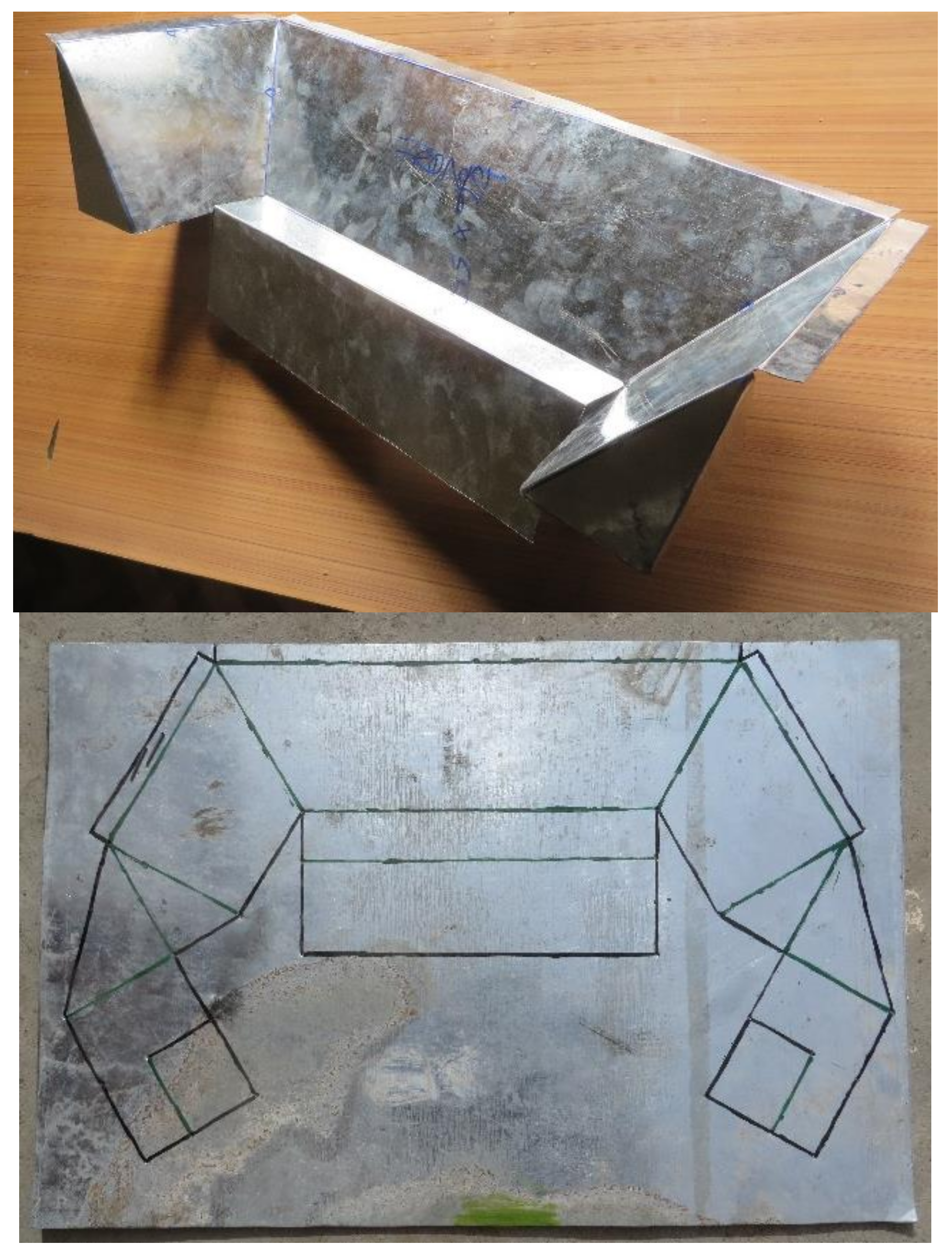

3.2. Development of a Cooker

3.3. Key Factors

3.4. Technical Factors

3.4.1. Global Connectivity

3.4.2. Local Connectivity

3.4.3. Material Constraints

3.4.4. Solution Visualization

3.4.5. Quality of Manufacture

- (1)

- A lack of electricity meant that the purchase of an electric drill was not justifiable, and

- (2)

- A lack of knowledge or concern of how screw adhesion and nail adhesion worked at a mechanical level.

3.5. Sociocultural Influences

3.6. Communicating Ideas

3.6.1 Community Perceptions of Proposed Design

3.6.2. Repair and Maintenance

- Wood that snapped was reinforced at the break so it could be reused

- Metal that was damaged or scrapped by someone else was bashed into shape for continued use. No edge was deemed too rough to be unusable

- Shirts and blankets that were worn out beyond repair were used with rocks as valves for the canals to provide water control for field irrigation

3.6.3. Workplace Safety

- Tradesmen were ignorant of the dangers of inhaling either LPG from leaky canisters or enamel paint fumes while painting.

- The carpenters and metal workers wore sandals or very occasionally leather shoes. None of the workshops or job sites provided gloves, ear protection, eye protection or hard hats to workers.

- The welding metalworkers had tinted sunglasses, although bare faces and arms were exposed to the radiation. No shields or screens were used to protect others in close proximity.

- Many workers were intoxicated at the metal workshop on the day of a festival. Machines were still operating amidst the inebriety.

- Electrical safety was minimal and a supervisor gave himself a mild electric shock while replacing a photovoltaic cell battery when touching both terminals while holding conductive tools.

3.6.4. Sanitation and Hygiene

4. Discussion

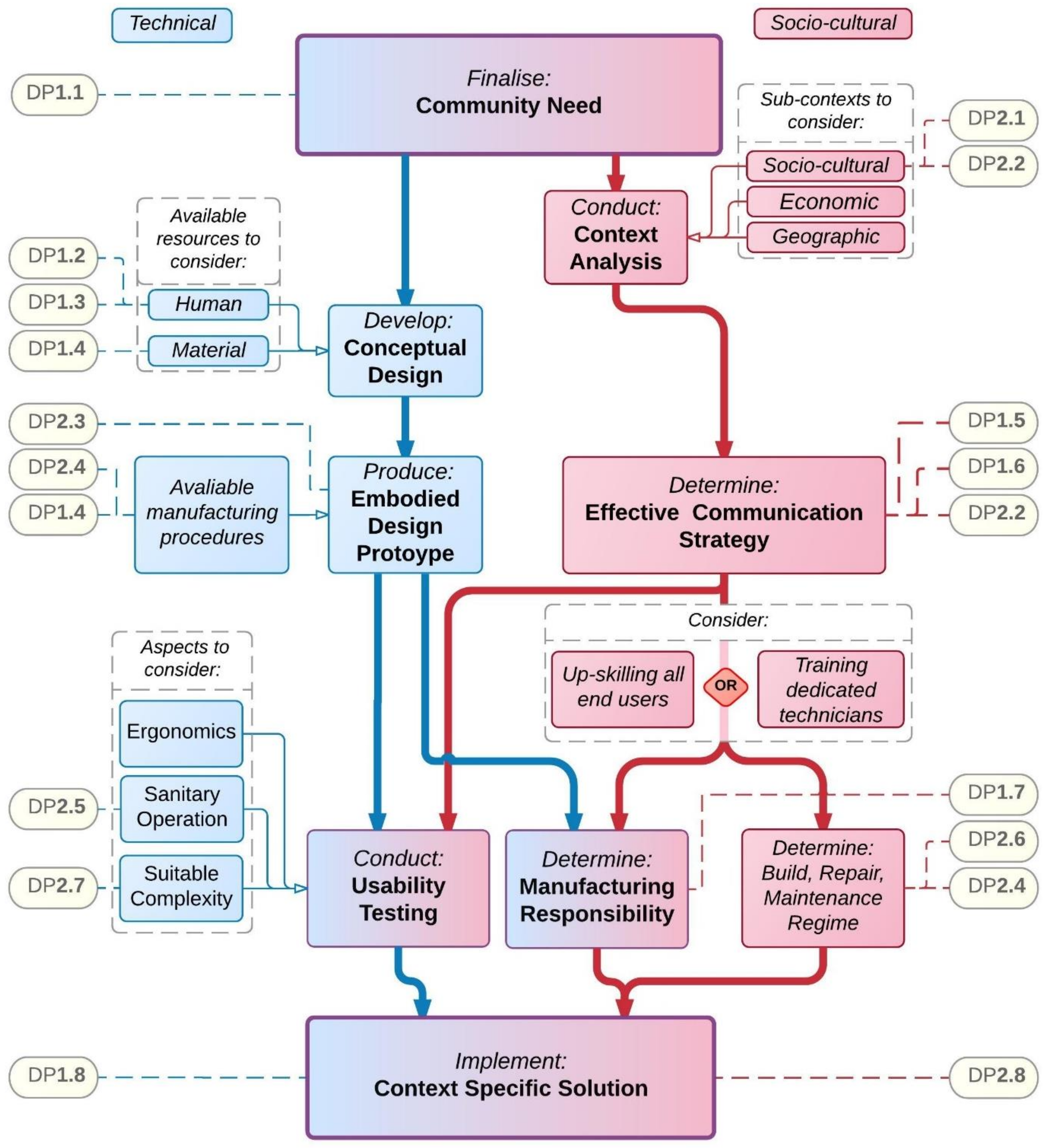

4.1. Proposed NPD Framework

4.2. Originality

4.3. Implications for Practitioners

- Involve community members early and often to and direct the solution toward a user-identified need rather than an externally identified need for optimal appeal and acceptance by the user

4.4. Limitations

4.5. Implications for Further Research

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Choudhary, M.A.; Faheem, A.; Hanif, M.N.; Naeem, S.; Pasha, F. Price setting and price stickiness: A developing economy perspective. J. Macroecon. 2016, 48, 44–61. [Google Scholar] [CrossRef]

- Danis, W.M.; De Clercq, D.; Petricevic, O. Are social networks more important for new business activity in emerging than developed economies? An empirical extension. Int. Bus. Rev. 2011, 20, 394–408. [Google Scholar] [CrossRef]

- World Economic Situation and Prospects; United Nations Publication: Herndon, VA, USA, 2016; pp. 1–25.

- Bergman, B.; Klefsjö, B. Quality: From Customer Needs to Customer Satisfaction; Studentlitteratur: Åkergränden, Sweden, 1994. [Google Scholar]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W. Engineering Design: A Systematic Approach; Springer: Berlin, Germany; The Design Council: London, UK, 1988. [Google Scholar]

- Hubka, V.; Eder, W.E. Theory of Technical System; Springer: Berlin, Germany, 1988. [Google Scholar]

- Pugh, S. Total Design, Integrated Methods for Successful Product Engineering; Addison Wesley: Boston, MA, USA, 1991. [Google Scholar]

- Ullman, D.G. Robust decision-making for engineering design. J. Eng. Des. 2001, 12, 3–13. [Google Scholar] [CrossRef]

- Hales, C. Managing Engineering Design; Longman Scientific & Technical: London, UK, 1994. [Google Scholar]

- International Organization for Standardization. Guidance on Project Management; ISO 21500:2012; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Project Management Institute (PMI). A Guide to the Project Management Body of Knowledge (Pmbok Guide), 5th ed.; Project Management Institute: Newtown Square, PA, USA, 2013. [Google Scholar]

- International Council on Systems Engineering (INCOSE). What is systems engineering? In International Council on Systems Engineering; INCOSE: San Diego, CA, USA, 2017. [Google Scholar]

- Finger, S.; Dixon, J. A review of research in mechanical engineering design. Part 1: Descriptive, prescriptive, and computer-based models of design process. Res. Eng. Des. 1989, 1, 51–67. [Google Scholar] [CrossRef]

- Finger, S.; Dixon, J. A review of research in mechanical engineering design. Part 2: Representations, analysis, and design for the life cycle. Res. Eng. Des. 1989, 1, 121–137. [Google Scholar] [CrossRef]

- Grunert, K.G.; van Trijp, H.C.M. Consumer-oriented new product development A2—Alfen, neal k. Van. In Encyclopedia of Agriculture and Food Systems; Academic Press: Oxford, UK, 2014; pp. 375–386. [Google Scholar]

- Suharyanti, Y.; Subagyo; Masruroh, N.A.; Bastian, I. The scheme of product development process as a trigger to product success: A theoretical framework. Ind. Eng. Serv. Sci. 2015, 4, 46–53. [Google Scholar]

- Olson, E.M.; Walker, O.C., Jr.; Ruekert, R.W. Organizing for effective new product development: The moderating role of product innovativeness. J. Market. 1995, 59, 48–62. [Google Scholar] [CrossRef]

- Mavondo, F.T.; Chimhanzi, J.; Stewart, J. Learning orientation and market orientation: Relationship with innovation, human resource practices and performance. Eur. J. Market. 2005, 39, 1235–1263. [Google Scholar] [CrossRef]

- Olson, E.M.; Walker, O.C., Jr.; Ruekert, R.W.; Bonner, J.M. Patterns of cooperation during new product development among marketing, operations and R&D: Implications for project performance. J. Prod. Innov. Manag. 2001, 18, 258–271. [Google Scholar]

- Rakthin, S.; Calantone, R.J.; Wang, J.F. Managing market intelligence: The comparative role of absorptive capacity and market orientation. J. Bus. Res. 2016, 69, 5569–5577. [Google Scholar] [CrossRef]

- Mandelli, S.; Barbieri, J.; Mereu, R.; Colombo, E. Off-grid systems for rural electrification in developing countries: Definitions, classification and a comprehensive literature review. Renew. Sustain. Energy Rev. 2016, 58, 1621–1646. [Google Scholar] [CrossRef]

- Rahman, M.M.; Paatero, J.V.; Lahdelma, R. Evaluation of choices for sustainable rural electrification in developing countries: A multicriteria approach. Energy Policy 2013, 59, 589–599. [Google Scholar] [CrossRef]

- Rahman, M.M.; Paatero, J.V.; Poudyal, A.; Lahdelma, R. Driving and hindering factors for rural electrification in developing countries: Lessons from bangladesh. Energy Policy 2013, 61, 840–851. [Google Scholar] [CrossRef]

- Mahesh, C.; James, P.N. Product development and innovation for developing countries: Potential and challenges. J. Manag. Dev. 2008, 27, 1017–1025. [Google Scholar]

- Austin-Breneman, J.; Yang, M. Design for micro-enterprise: An approach to product design for emerging markets. In Proceedings of the ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, IDETC/CIE 2013, Portland, OR, USA, 4–7 August 2013; American Society of Mechanical Engineers: Portland, OR, USA, 2013; Volume 5. [Google Scholar]

- Xiao, Q.; Saikawa, E.; Yokelson, R.J.; Chen, P.; Li, C.; Kang, S. Indoor air pollution from burning yak dung as a household fuel in tibet. Atmos. Environ. 2015, 102, 406–412. [Google Scholar] [CrossRef]

| 1. Technical Deployment Principles | 2. Socio-Cultural Deployment Principles |

|---|---|

| DP 1.1: Finalize projects through prior communication or assume resource and technical knowledge availability is limited to what the embedded participant comes in with | DP 2.1: Observe the ways that locals learn best and tailor the knowledge transfer process toward these |

| DP 1.2: Plan for project delays by integrating parallel work streams | DP 2.2: Involve the end user(s) as much as possible so they feel a sense of ownership for the solution |

| DP 1.3: Consider the reliability of transporting materials in from external suppliers | DP 2.3: Design for lifespan reliability rather than optimal efficiency |

| DP 1.4: Acknowledge that material or component quality will be variable and limited, make design decisions accordingly | DP 2.4: Maximize the unskilled, hand fabrication/repair processes required by the end user(s) to limit risk exposure |

| DP 1.5: Appreciate that visual communication may be a learnt skill | DP 2.5: Assume sanitation practices common in developed countries or standard operating practices will not necessarily be adhered to |

| DP 1.6: Trial the broadest possible range of learning styles and capitalize on the style(s) that are most readily understood | DP 2.6: Acknowledge the local perception towards repurposing materials to fix system failure points |

| DP 1.7: Design for manufacturability by capitalizing on available resources and skills | DP 2.7: Assume standard operating practices will not necessarily be adhered to the entirety of the time |

| DP 1.8: Provide parametric templates for reproducing complex parts | DP 2.8: Appreciate that community acceptance of the solution is a crucial factor in successful design |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorrie, A.W.T.; Pons, D.J.; Maples, D.; Docherty, P.D. Principles of Product Design in Developing Countries. Appl. Syst. Innov. 2018, 1, 11. https://doi.org/10.3390/asi1020011

Gorrie AWT, Pons DJ, Maples D, Docherty PD. Principles of Product Design in Developing Countries. Applied System Innovation. 2018; 1(2):11. https://doi.org/10.3390/asi1020011

Chicago/Turabian StyleGorrie, Alexander W. T., Dirk J. Pons, David Maples, and Paul D. Docherty. 2018. "Principles of Product Design in Developing Countries" Applied System Innovation 1, no. 2: 11. https://doi.org/10.3390/asi1020011

APA StyleGorrie, A. W. T., Pons, D. J., Maples, D., & Docherty, P. D. (2018). Principles of Product Design in Developing Countries. Applied System Innovation, 1(2), 11. https://doi.org/10.3390/asi1020011