Cost Projection of Global Green Hydrogen Production Scenarios

Abstract

:1. Introduction

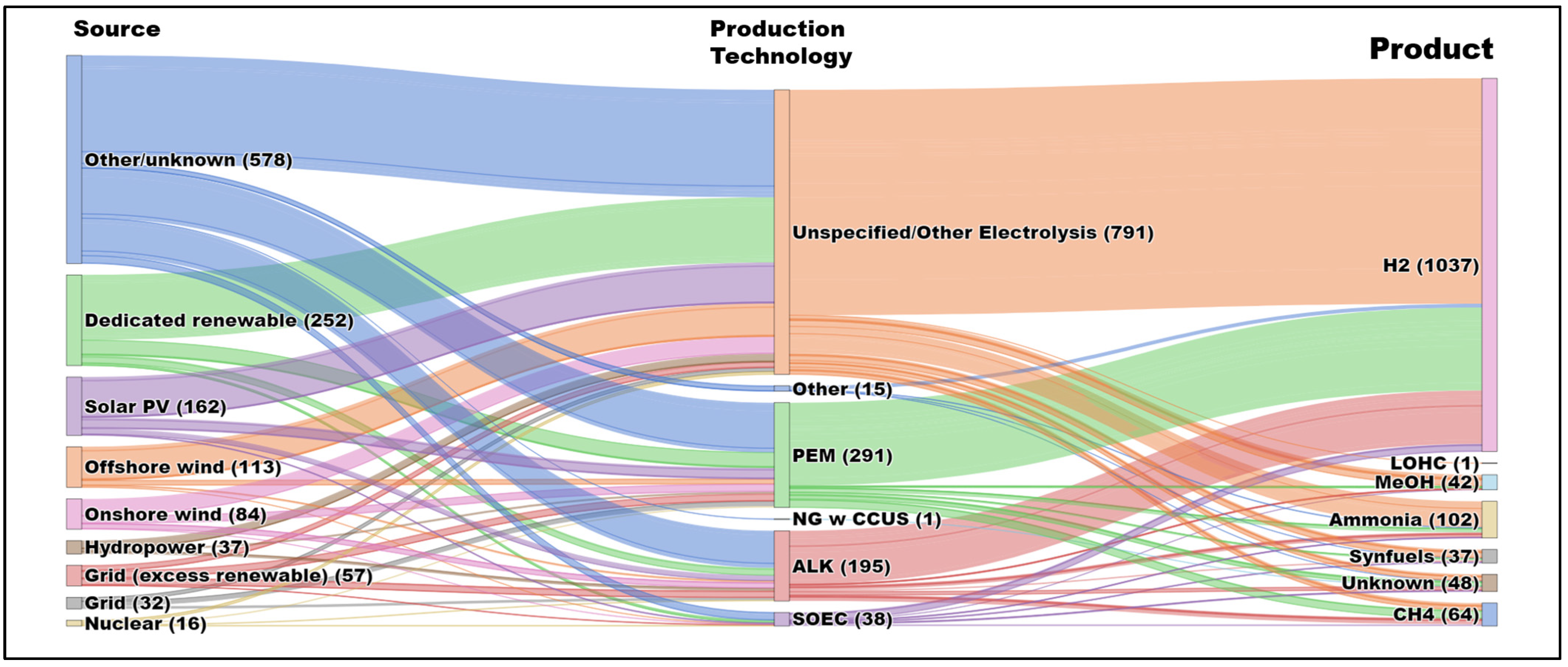

Current Status of Hydrogen from Electrolysis and Its Costs

2. Literature Review

Modeling Cost Reduction Potential in Electrolyzer Systems

3. Materials and Methods

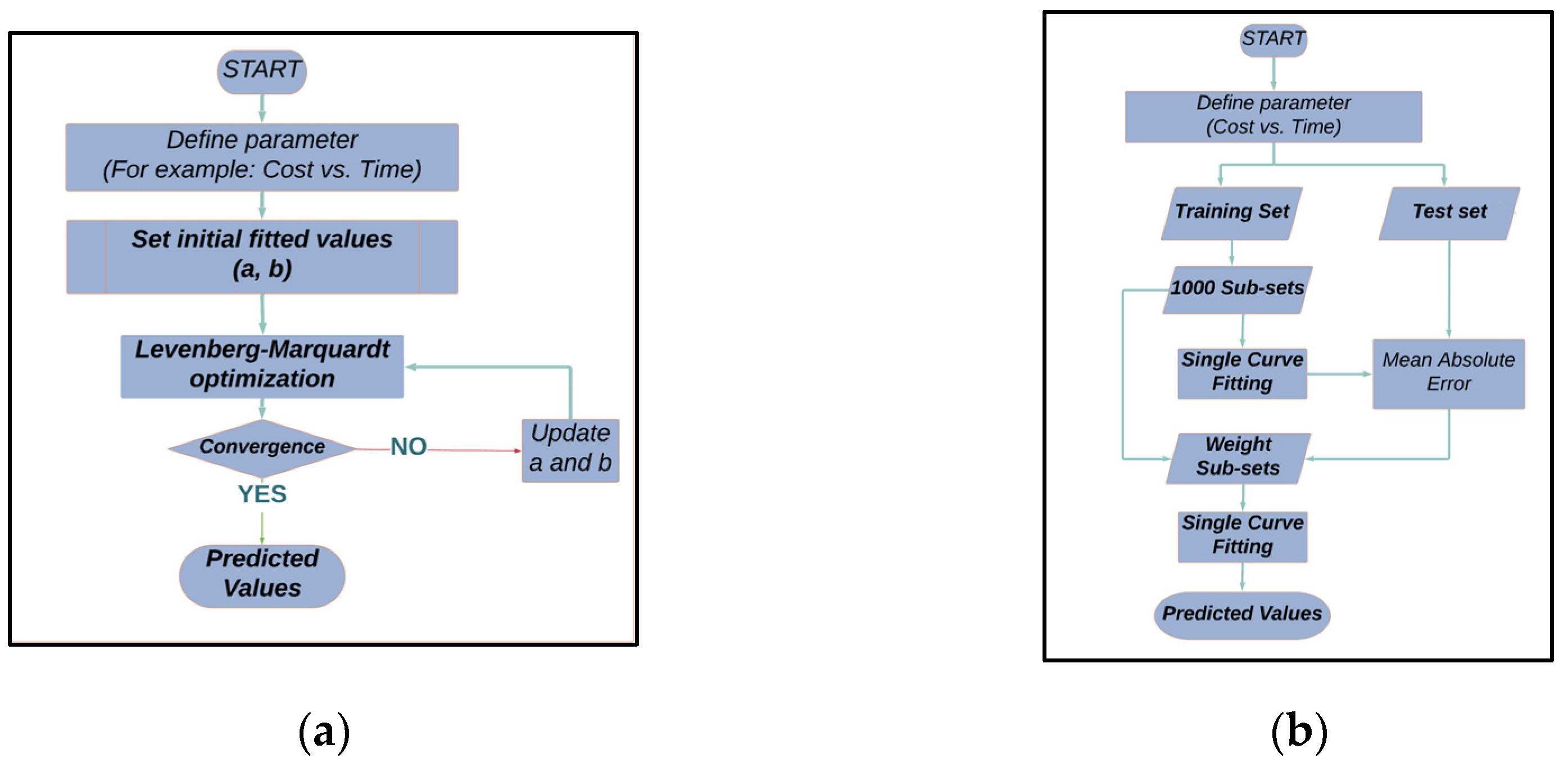

3.1. Projection Models

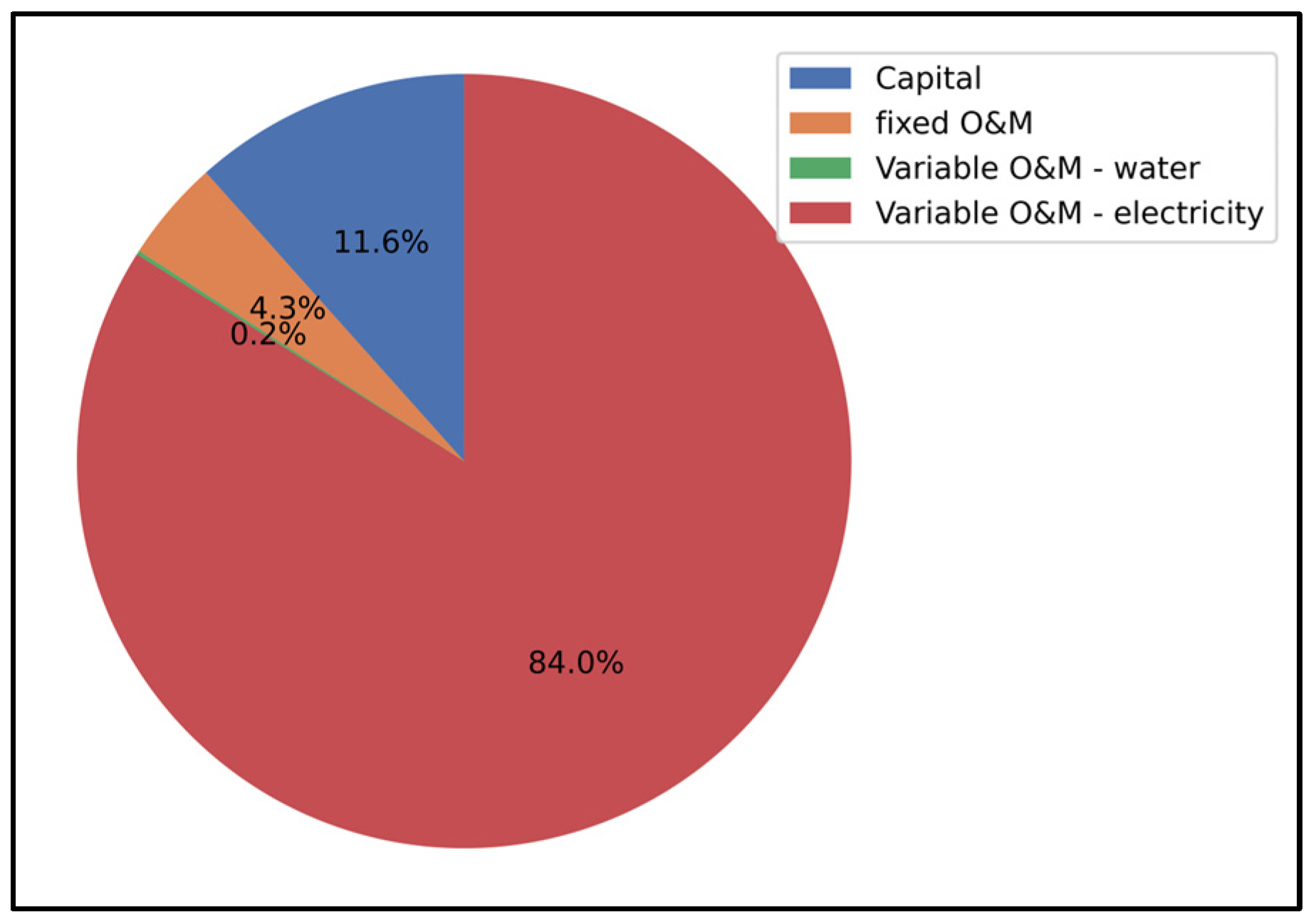

3.2. Levelized Cost of Hydrogen Calculation

3.3. Scenario Development

4. Results

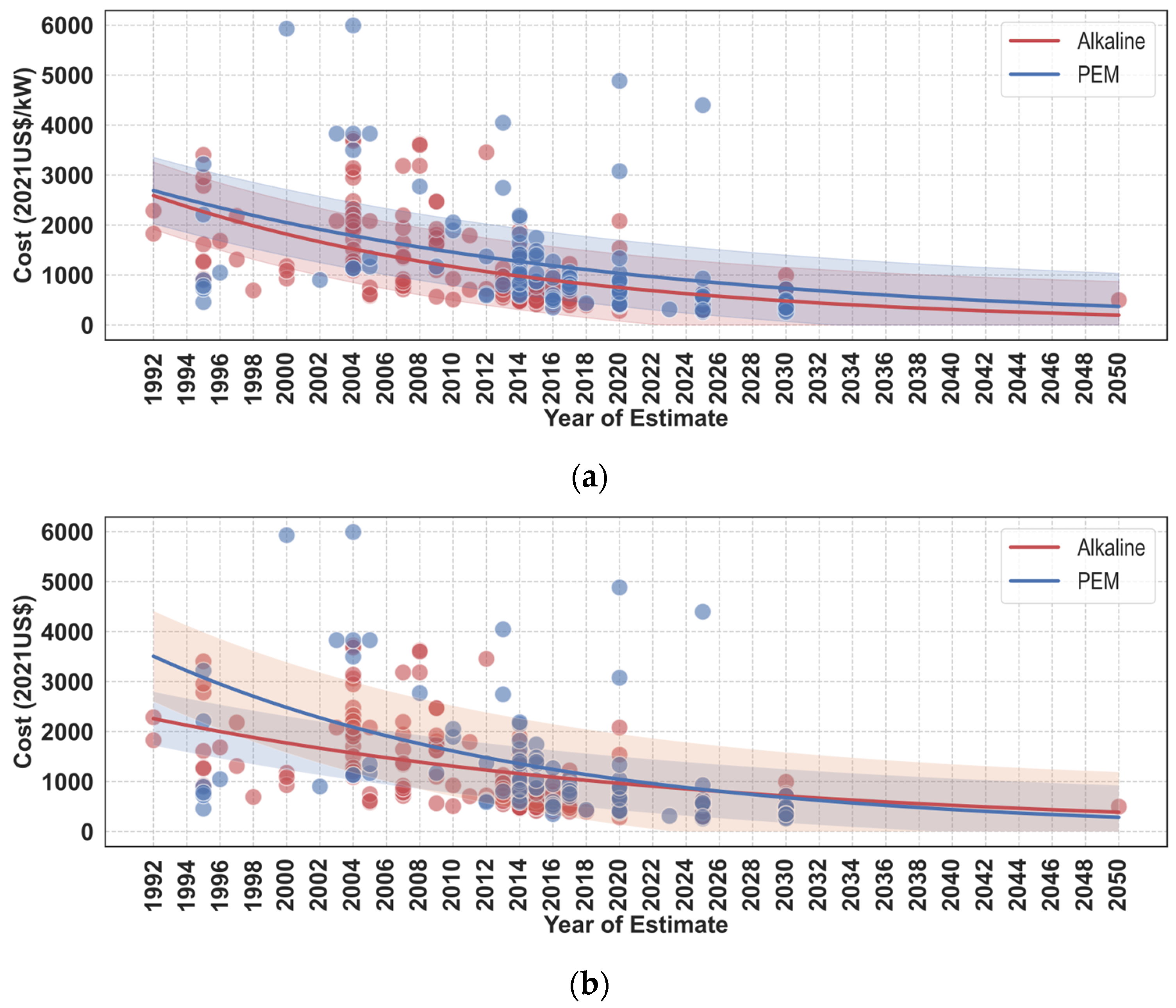

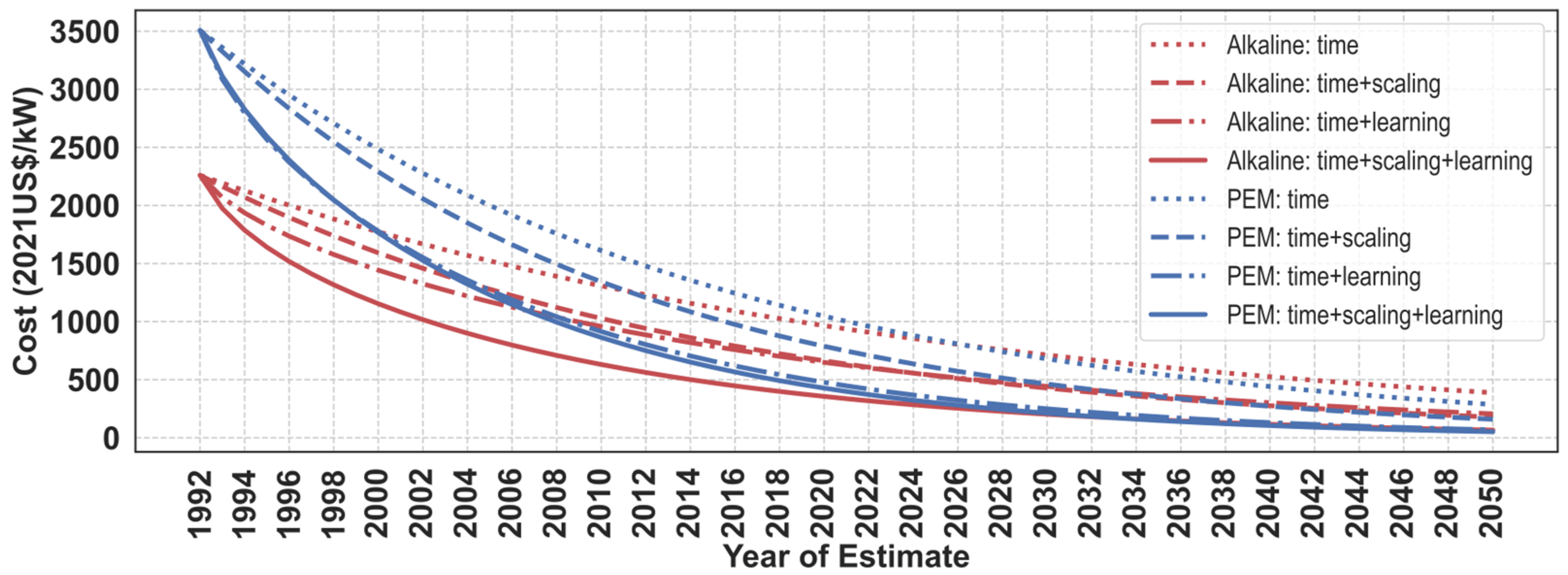

4.1. Cost Projection of Alkaline and PEM Electrolyzer

4.1.1. Yearly Decline Rate: Impact of R&D over Time

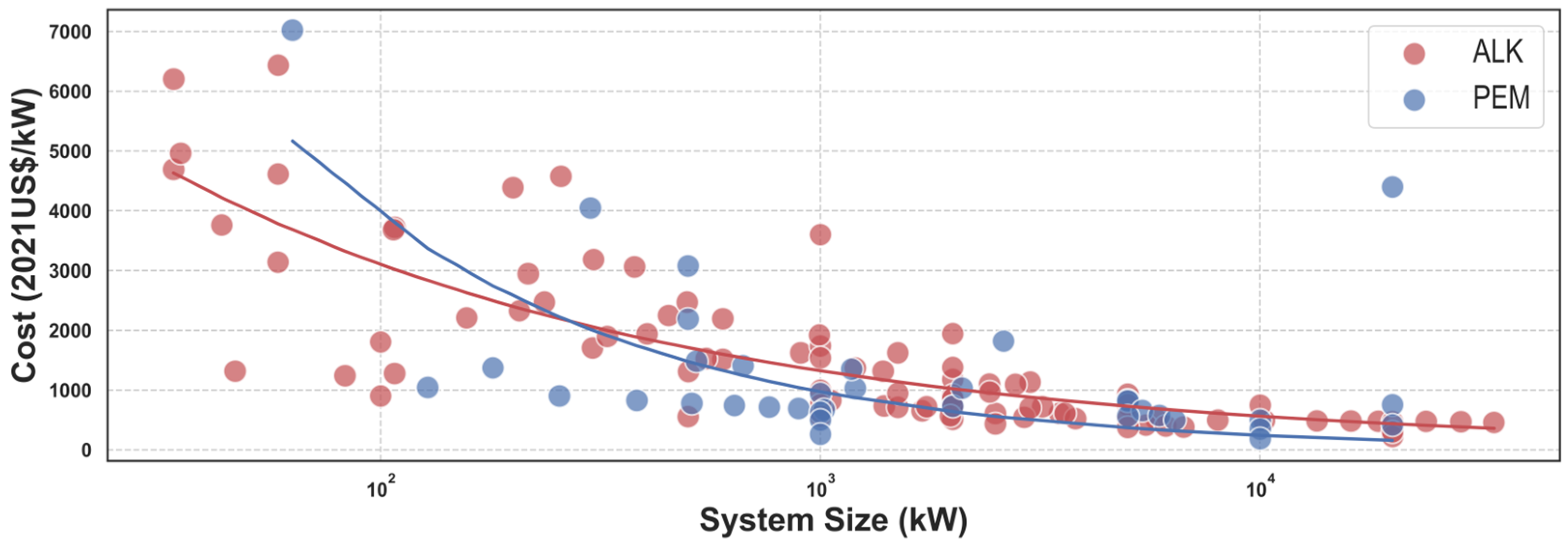

4.1.2. Scaling Effect

4.1.3. Learning Rate: Impact of Learning by Doing

4.1.4. Maximizing Electrolyzer Cost Competitiveness: The Synergistic Effects of R&D-Time, Economies of Scale, and Learning by Doing

4.2. Future LCOH Outlook

4.2.1. Projection of Global Levelized Cost of Hydrogen

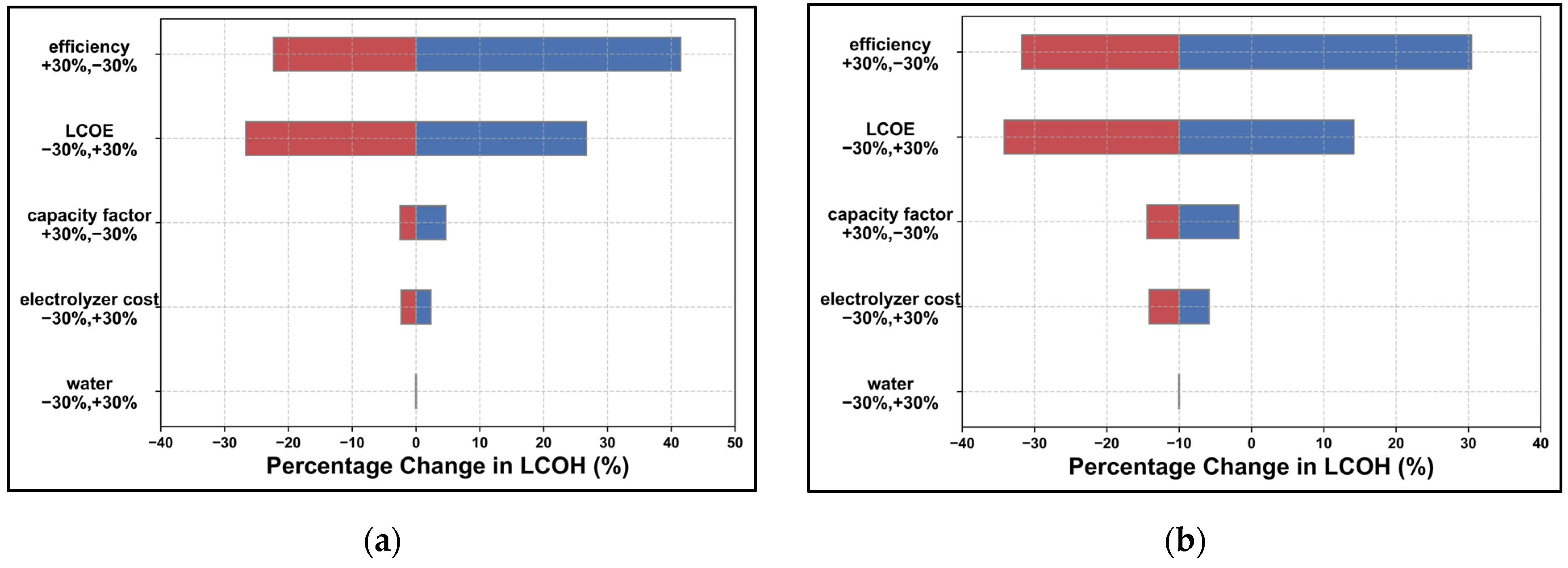

4.2.2. Sensitivity Analysis of LCOH

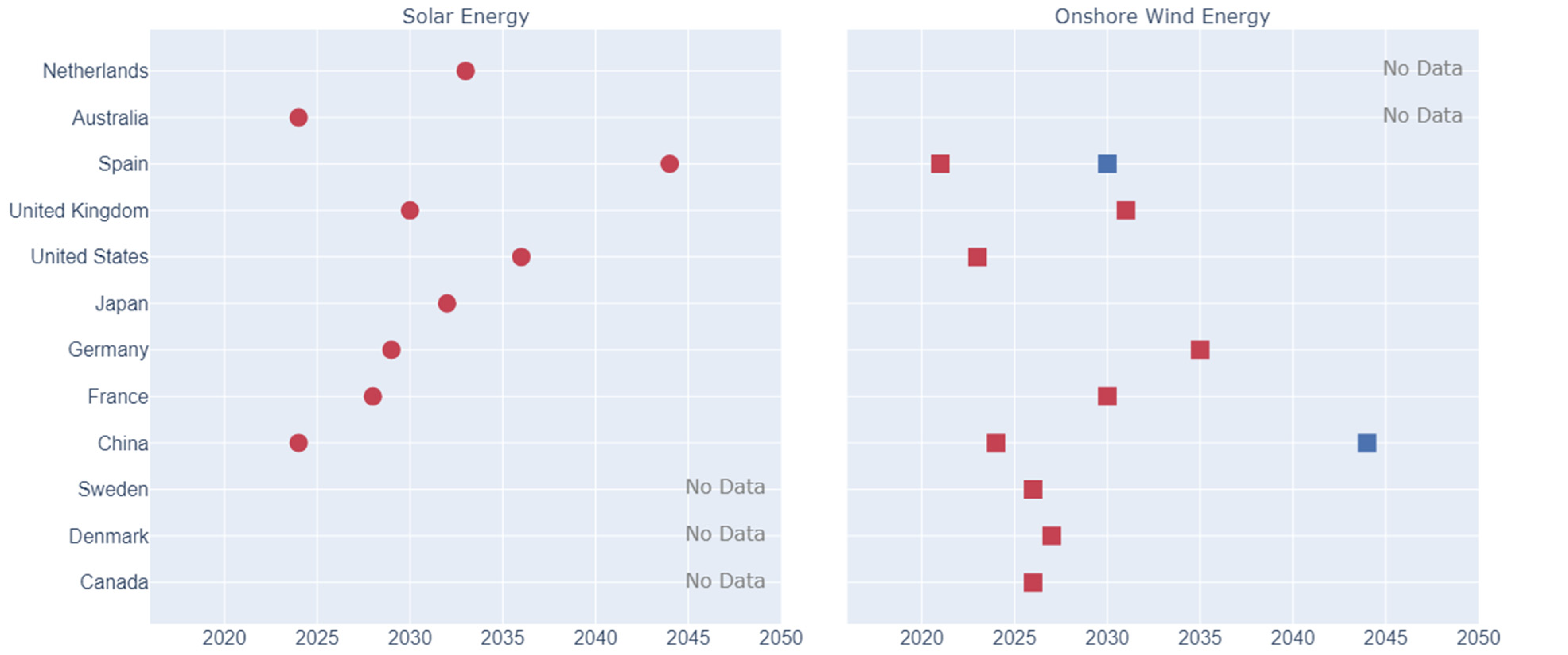

4.2.3. Mapping the Country-Specific Timeline to Cost Convergence with Grey Hydrogen (2 USD/kg)

5. Discussion

5.1. Strategies for Establishing Green Hydrogen as a Competitive Alternative to Grey Hydrogen

5.1.1. Revenue beyond Hydrogen

5.1.2. Bridging the Cost Gap: Carbon Tax and Contract for Difference as Catalysts for Green–Grey Hydrogen Parity

5.2. Limitation of the Present Study and Future Work

6. Conclusions

- The economic viability and competitive advantage of alkaline and PEM electrolyzers rest largely on their potential cost reductions, which stem from the synergy of research and development (R&D) initiatives, economies of scale, and technological learning over time. The analysis reveals that the cost reduction potential for alkaline electrolyzers is 77%, and for PEM electrolyzers, it is 79% when both economies of scale and technological learning are considered over R&D activities. Despite these promising figures, the precise trajectory of cost reduction is contingent on several factors, including the rates of increase in system size and installed capacity. However, the cost reduction of both alkaline and PEM electrolyzers is predicted to be substantial, and PEM will take over alkaline electrolyzers if the conditions are met.

- The sensitivity analysis indicates that LCOH is most sensitive to variations in electrolyzer efficiency and LCOE. However, increasing efficiency and optimizing capacity factors emerge as key areas to focus on for reducing LCOH, with asymmetries in these relationships underscoring the need to prioritize efforts that prevent decreases.

- The comparative analysis of the global LCOH trajectory from 1992 to 2050 using alkaline and PEM electrolyzers, in combination with offshore wind, solar, and onshore wind energy sources, reveals a consistent decline in LCOH across all scenarios, suggesting improved cost-effectiveness in hydrogen production. However, despite the optimistic reduction in electrolyzer costs, achieving targeted LCOH still requires a significant decline in the LCOE, particularly for solar and onshore wind energy to fully exploit the potential of green hydrogen in the envisioned hydrogen economy, and electrolyzer cost reduction alone may not be sufficient to meet the targeted LCOH.

- Under optimistic scenarios, Spain is projected to reach the LCOH target of 2 USD/kg by 2021, largely due to cheap electricity from onshore wind energy. In a pessimistic scenario, where LCOE and electrolyzer costs remain constant, only China and Spain are expected to reach the LCOH target before 2050, underscoring the necessity of reducing renewable energy costs. These developments have significant implications for the global energy and hydrogen markets, positioning early achievers as potential exporters of green hydrogen, while those achieving targets later are likely to become importers.

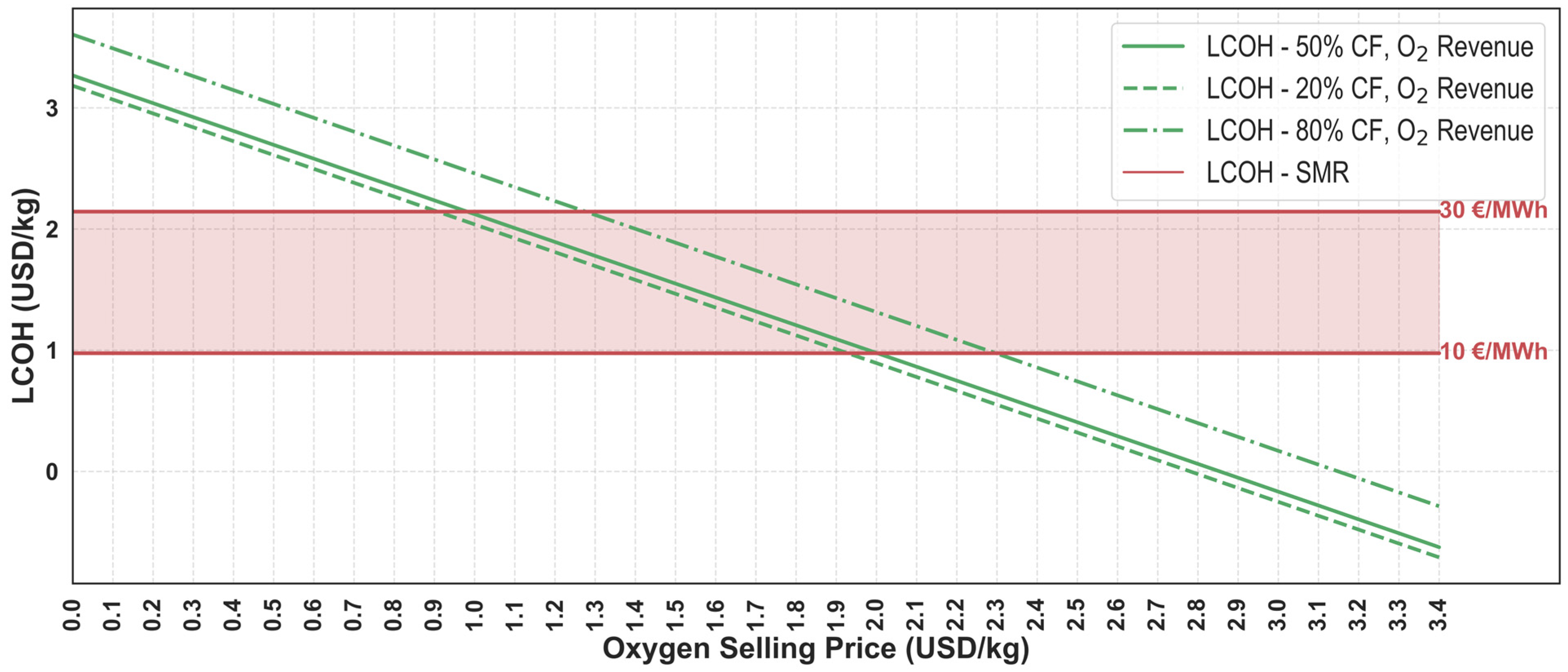

- A hydrogen credit, similar to a carbon credit market, can serve as a significant financial incentive for companies transitioning to green hydrogen production. The byproduct of oxygen, a valuable resource for various industries, can also be sold to supplement revenue and reduce production costs. The most cost-effective scenario under the provided conditions is the byproduct production, depending on factors such as market demand. Nevertheless, the minimum oxygen selling price of only 2 USD/kgO2 is necessary to be competitive with grey hydrogen production cost at a low gas price of (10 USD/MWh).

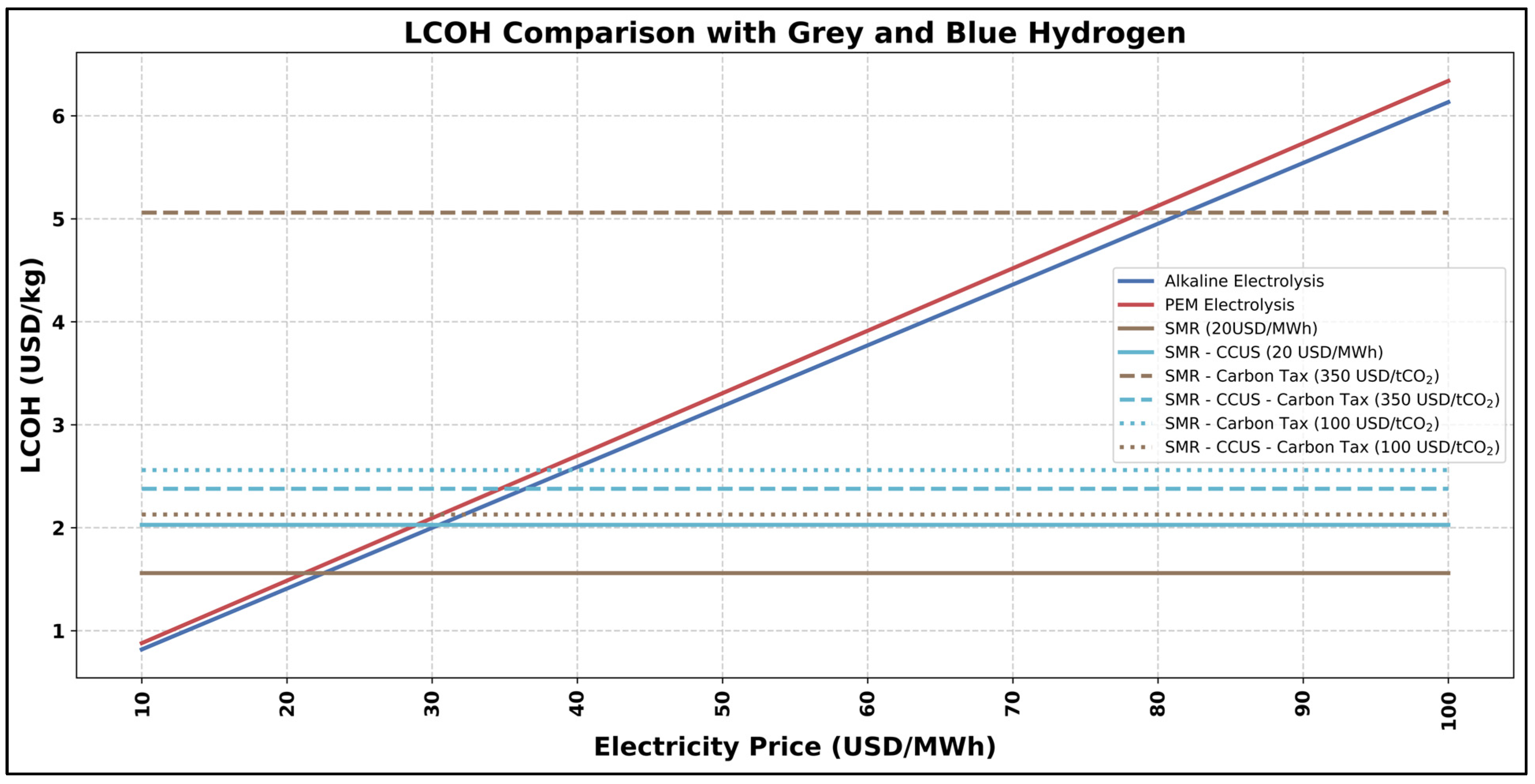

- The economic viability of hydrogen production is highly dependent on electricity pricing and carbon taxes. With the current electrolyzer costs, electricity prices need to drop below 22 USD/MWh for green hydrogen production to compete with grey hydrogen produced from natural gas priced at around 20 USD/MWh. Nevertheless, SMR with CCS/CCUS appears to be the most cost-effective production route with or without carbon tax, which is the most suitable option in the short-medium term. Moreover, strategies such as the Contract for Difference (CfD) scheme could promote the transition to green hydrogen by ensuring price stability for consumers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ALK | Alkaline electrolyzer |

| PEM | Proton exchange membrane electrolyzer |

| SOEC | Solid oxide electrolytic cell electrolyzer |

| LCOH | Levelized cost of hydrogen |

| LCOE | Levelized cost of electricity |

| LOHC | Liquid organic hydrogen carrier |

| CCS | Carbon capture and storage |

| CCUS | Carbon capture, utilization, and storage |

| CfD | Contract for difference |

| CH4 | Methane |

| MeOH | Methanol |

| H.C. | Hydrogen credits |

Appendix A. Data Acquisition

| Timeline | Data Points | Research Gap |

|---|---|---|

| 2001–2020 | 123 | [38] |

| 2000–2030 | 160 | [31] |

| 1992–2013 | 68 | [37] |

Appendix B. Levelized Cost of Hydrogen Calculation

| Direct Capital Cost | |

|---|---|

| Stack capital cost 1 [75] | = |

| Mechanical capital cost [75] | = |

| Electrical capital cost [75] | = |

| Installation factor [43] | = |

| Indirect Capital Cost | |

| Stack capital cost | =2% of direct capital cost |

| Mechanical capital cost | =1% of direct capital cost |

| Electrical capital cost | =15% of direct capital cost |

| Installation factor | =15% of direct capital cost |

| Total Capital Cost | |

| Depreciable cost | =direct cost + indirect cost |

| Land cost | = |

| Planned replacement cost 2 | = |

| Unplanned replacement cost | =0.5% of depreciable cost |

| Fixed Operational Cost 1 | |

|---|---|

| Labor cost | =total plant staff × labor cost per hour × work hour |

| Overhead GA cost | =2% of labor cost |

| Property tax insurance cost | =2% of total capital cost |

| Material cost | =3% of the direct cap |

| Variable Operational Cost | |

| Water cost | =water required × water cost |

| Electricity cost | =LCOE [56] |

| Others | |

| Decommissioning cost | =1% of depreciable cost |

| Salvage value | =1% of depreciable cost |

| Depreciation cost | MACRS–15 years |

| Electrolyzer Type | Current Density (A/cm2) | Stack | Power Conditioning | Gas Conditioning | Others |

|---|---|---|---|---|---|

| Alkaline | 0.2–0.6 | 50% | 15% | 15% | 20% |

| PEM | 1–2 | 60% | 15% | 10% | 15% |

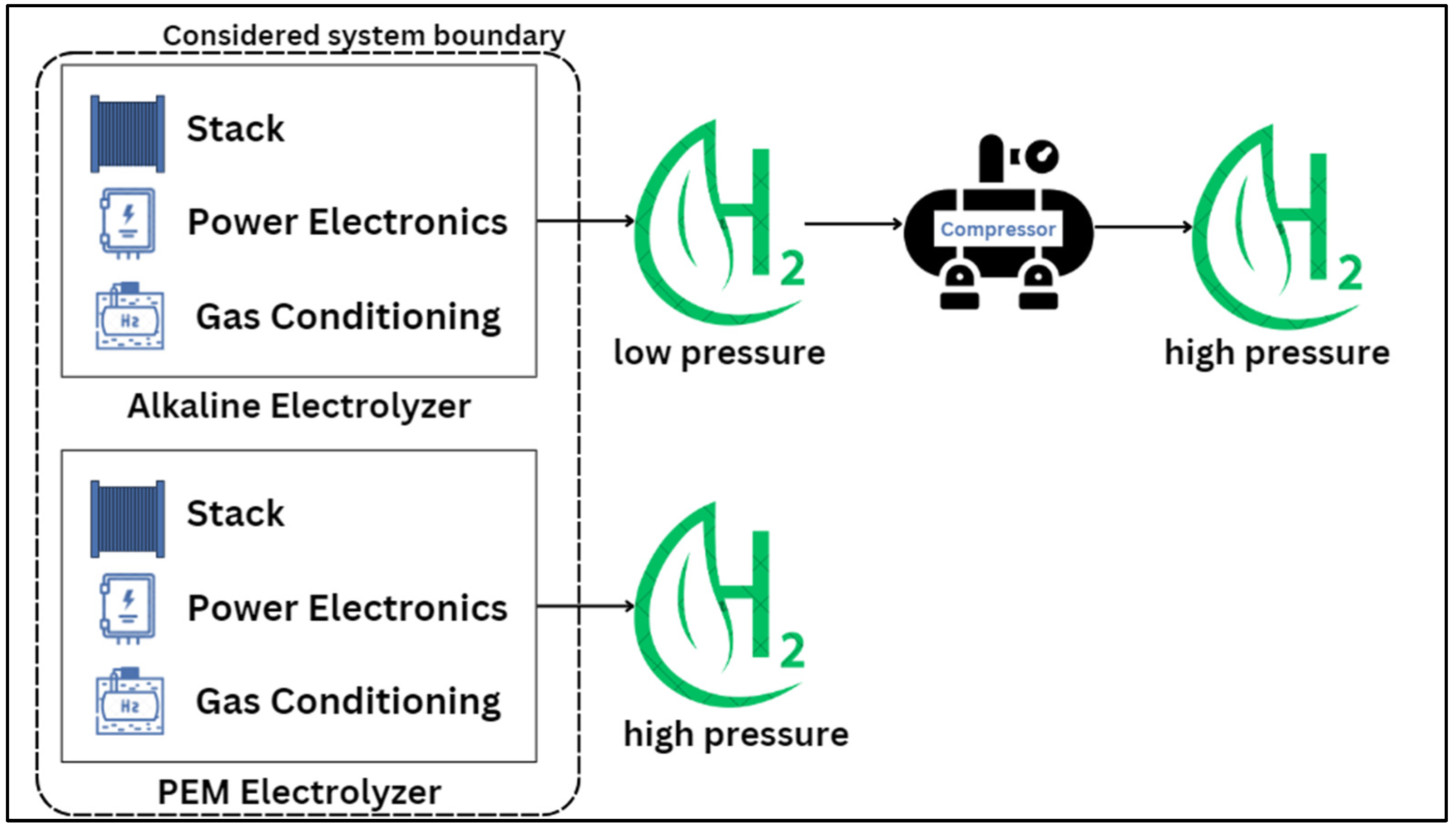

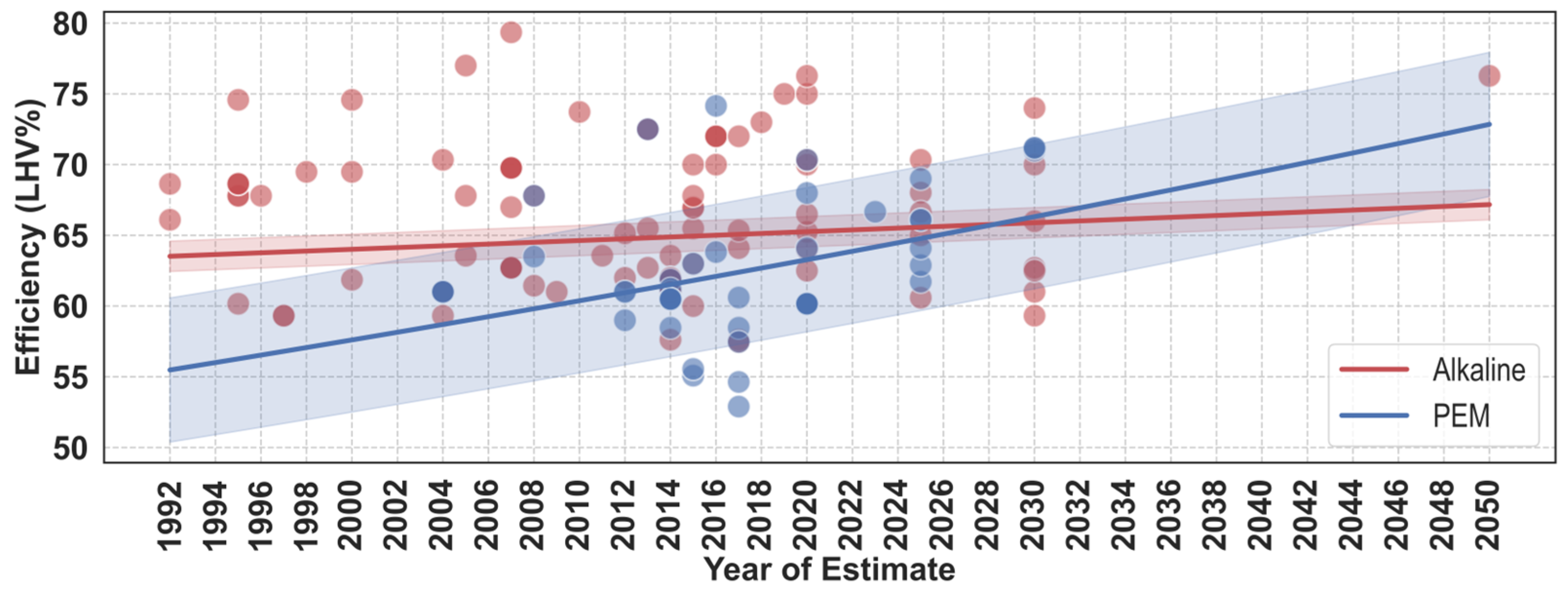

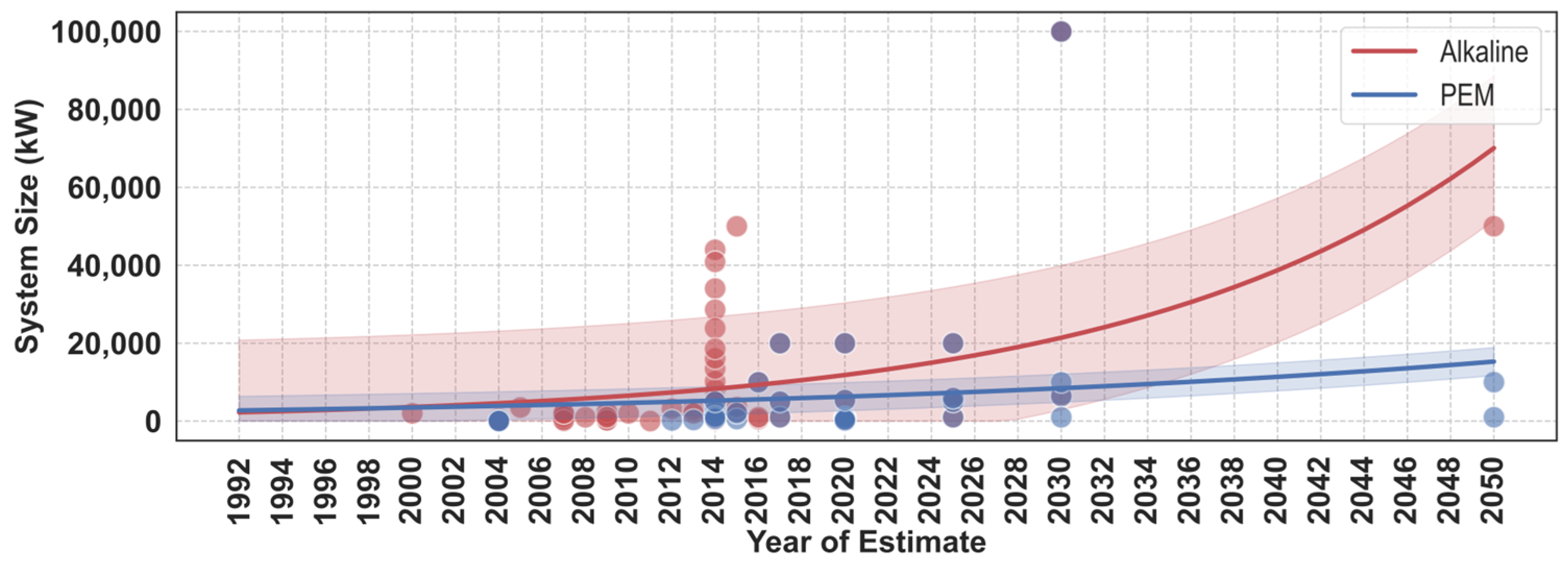

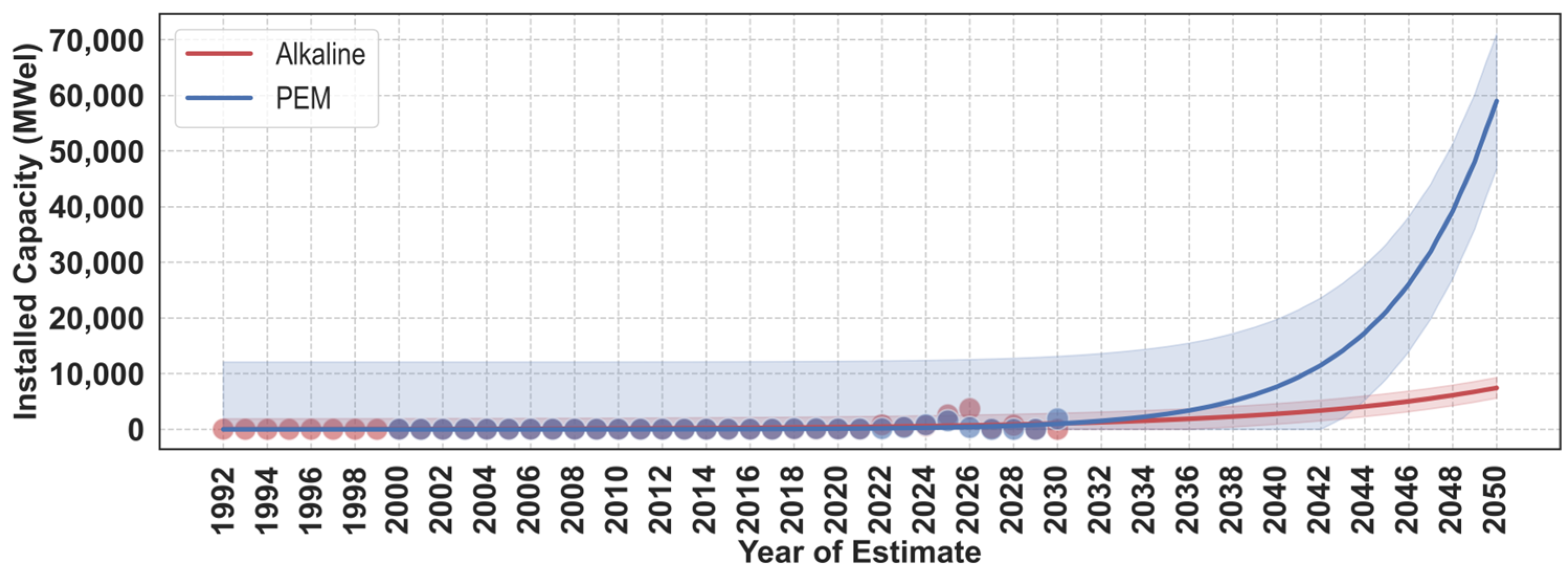

Appendix C. Temporal Projection of Electrolyzer System Sizes and Installed Capacity

| Electrolyzer Type | Incline Rate | R2 Score |

|---|---|---|

| Alkaline | 0.1% | 0.01 |

| PEM | 0.47% | 0.14 |

| Electrolyzer Type | Incline Rate | R2 Score |

|---|---|---|

| Alkaline | 6% | 0.24 |

| PEM | 3% | 0.04 |

| Electrolyzer Type | Incline Rate | R2 Score |

|---|---|---|

| Alkaline | 10% | 0.19 |

| PEM | 20% | 0.34 |

Appendix D. Sensitivity Analysis of Alkaline Electrolyzer

References

- Touili, S.; Alami Merrouni, A.; El Hassouani, Y.; Amrani, A.; Rachidi, S. Analysis of the yield and production cost of large-scale electrolytic hydrogen from different solar technologies and under several Moroccan climate zones. Int. J. Hydrog. Energy 2020, 45, 26785–26799. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; International Energy Agency: Paris, France, 2019. [Google Scholar]

- IEA. The Future of Hydrogen: Seizing Today’s Opportunities; International Energy Agency: Paris, France, 2019. [Google Scholar]

- IEA. Global Hydrogen Review 2021; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Guan, D.; Wang, B.; Zhang, J.; Shi, R.; Jiao, K.; Li, L.; Wang, Y.; Xie, B.; Zhang, Q.; Yu, J.; et al. Hydrogen society: From present to future. Energy Environ. Sci. 2023. [Google Scholar] [CrossRef]

- Hubert, M.A.; King, L.A.; Jaramillo, T.F. Evaluating the Case for Reduced Precious Metal Catalysts in Proton Exchange Membrane Electrolyzers. ACS Energy Lett. 2022, 7, 17–23. [Google Scholar] [CrossRef]

- Jovan, D.J.; Dolanc, G. Can Green Hydrogen Production Be Economically Viable under Current Market Conditions. Energies 2020, 13, 6599. [Google Scholar] [CrossRef]

- Janssen, J.L.L.C.C.; Weeda, M.; Detz, R.J.; van der Zwaan, B. Country-specific cost projections for renewable hydrogen production through off-grid electricity systems. Appl. Energy 2022, 309, 118398. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- EIA. Annual Energy Outlook 2022 with Projections to 2050; U.S. Department of Energy: Washington, DC, USA, 2022. [Google Scholar]

- Bhandari, R.; Shah, R.R. Hydrogen as energy carrier: Techno-economic assessment of decentralized hydrogen production in Germany. Renew. Energy 2021, 177, 915–931. [Google Scholar] [CrossRef]

- Ginsberg, M.J.; Venkatraman, M.; Esposito, D.V.; Fthenakis, V.M. Minimizing the cost of hydrogen production through dynamic polymer electrolyte membrane electrolyzer operation. Cell Rep. Phys. Sci. 2022, 3, 100935. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrog. Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Böhm, H.; Zauner, A.; Rosenfeld, D.C.; Tichler, R. Projecting cost development for future large-scale power-to-gas implementations by scaling effects. Appl. Energy 2020, 264, 114780. [Google Scholar] [CrossRef]

- Panah, P.G.; Cui, X.; Bornapour, M.; Hooshmand, R.-A.; Guerrero, J.M. Marketability analysis of green hydrogen production in Denmark: Scale-up effects on grid- connected electrolysis. Int. J. Hydrog. Energy 2022, 47, 12443–12455. [Google Scholar] [CrossRef]

- Perez, R.J.; Brent, A.C.; Hinkley, J. Assessment of the Potential for Green Hydrogen Fuelling of Very Heavy Vehicles in New Zealand. Energies 2021, 14, 2636. [Google Scholar] [CrossRef]

- IRENA. Green Hydrogen Cost Reduction: Scaling up Electrolysers to Meet the 1.5 °C Climate Goal; National Renewable Energy Laboratory: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Graf, F.; Götz, M.; Schaaf, T.; Tichler, R. Technoökonomische Studie von Power-to-Gas-Konzepten Teilprojekte B-D Abschlussbericht; DVGW: Bonn, Germany, 2014. [Google Scholar]

- Müller-Syring, G.; Henel, M.; Köppel, W.; Mlaker, H. Entwicklung von Modularen Konzepten zur Erzeugung, Speicherung und Einspeisung von Wasserstoff und Methan ins Erdgasnetz; DVGW: Bonn, Germany, 2013. [Google Scholar]

- Graf, F.; Götz, M.; Wonneberger, A.-M.; Köppel, W. Techno-Ökonomische Studie zur Biologischen Methanisierung bei PtG-Konzepten; DVGW: Bonn, Germany, 2014. [Google Scholar] [CrossRef]

- Aicher, T.; González, M.; Schaub, G.; Götz, M. Arbeitspaket 5: Betrachtungen des Gesamtsystems im Hinblick auf Dynamik und Prozessintegration. Energ. Wasser-Prax. 2014, 65, 51–55. [Google Scholar]

- Buchholz, O.S.; van der Ham, A.G.J.; Veneman, R.; Brilman, D.W.F.; Kersten, S.R.A. Power-to-Gas: Storing surplus electrical energy. A design study. Energy Procedia 2014, 63, 7993–8009. [Google Scholar] [CrossRef]

- Lehner, M.; Tichler, R.; Steinmüller, H.; Koppe, M. Power-to-Gas: Technology and Business Models; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, N.; Tong, X.; Duan, L.; Lin, T.-E.; Maréchal, F.; Van Herle, J.; Wang, L.; Yang, Y. Reversible solid-oxide cell stack based power-to-x-to-power systems: Economic potential evaluated via plant capital-cost target. Appl. Energy 2021, 290, 116700. [Google Scholar] [CrossRef]

- McDonagh, S.; Ahmed, S.; Desmond, C.; Murphy, J.D. Hydrogen from offshore wind: Investor perspective on the profitability of a hybrid system including for curtailment. Appl. Energy 2020, 265, 114732. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Ochoa-Mendoza, A.; Rodríguez-Antón, L.M. Pre-investigation of water electrolysis for flexible energy storage at large scales: The case of the Spanish power system. Int. J. Hydrog. Energy 2015, 40, 5544–5551. [Google Scholar] [CrossRef]

- Oi, T.; Wada, K. Feasibility study on hydrogen refueling infrastructure for fuel cell vehicles using the off-peak power in Japan. Int. J. Hydrog. Energy 2004, 29, 347–354. [Google Scholar] [CrossRef]

- Matute, G.; Yusta, J.M.; Beyza, J.; Correas, L.C. Multi-state techno-economic model for optimal dispatch of grid connected hydrogen electrolysis systems operating under dynamic conditions. Int. J. Hydrog. Energy 2021, 46, 1449–1460. [Google Scholar] [CrossRef]

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- IEA. Hydrogen Project Database; IEA: Paris, France, 2022. [Google Scholar]

- Schmidt, O.; Hawkes, A.; Gambhir, A.; Staffell, I. The future cost of electrical energy storage based on experience rates. Nature Energy 2017, 2, 17110. [Google Scholar] [CrossRef]

- Böhm, H.; Goers, S.; Zauner, A. Estimating future costs of power-to-gas—A component-based approach for technological learning. Int. J. Hydrog. Energy 2019, 44, 30789–30805. [Google Scholar] [CrossRef]

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrog. Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- Schoots, K.; Ferioli, F.; Kramer, G.; Vanderzwaan, B. Learning curves for hydrogen production technology: An assessment of observed cost reductions. Int. J. Hydrog. Energy 2008, 33, 2630–2645. [Google Scholar] [CrossRef]

- Saba, S.M.; Müller, M.; Robinius, M.; Stolten, D. The investment costs of electrolysis—A comparison of cost studies from the past 30 years. Int. J. Hydrog. Energy 2018, 43, 1209–1223. [Google Scholar] [CrossRef]

- Reksten, A.H.; Thomassen, M.S.; Møller-Holst, S.; Sundseth, K. Projecting the future cost of PEM and alkaline water electrolysers; a CAPEX model including electrolyser plant size and technology development. Int. J. Hydrog. Energy 2022, 47, 38106–38113. [Google Scholar] [CrossRef]

- Mayyas, A.; Mann, M. Emerging Manufacturing Technologies for Fuel Cells and Electrolyzers. Procedia Manuf. 2019, 33, 508–515. [Google Scholar] [CrossRef]

- Elshurafa, A.; Albardi, S.; Bollino, C.A. Estimating the Learning Curve of Solar PV Balance-of-Systems for Over 20 Countries. J. Clean. Prod. 2018, 196, 122–134. [Google Scholar] [CrossRef]

- Jamasb, T. Learning Curves for Energy Technology: A Critical Assessment; Cambridge University: Cambridge, UK, 2007. [Google Scholar]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Ministry of Industry and Trade of the Czech Republic. The Czech Republic’s Hydrogen Strategy; Ministry of Industry and Trade of the Czech Republic: Prague, Czech Republic, 2021. [Google Scholar]

- Statista Global. Solar PV Capacity Factor. 2021. Available online: https://www.statista.com/statistics/799330/global-solar-pv-installation-cost-per-kilowatt/ (accessed on 26 September 2023).

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation Paper); International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Statista Global. Offshore Wind Capacity Factor. 2021. Available online: https://www.statista.com/statistics/1368679/global-offshore-wind-capacity-factor/ (accessed on 26 September 2023).

- Zoulias, M.; Gløckner, R.; Lymberopoulos, N.; Vosseler, I.; Tsoutsos, T.; Mydske, H.J.; Brodin, M.; Taylor, P. Market Potential Analysis for the Introduction of Hydrogen Energy Technology in Stand-Alone Power Systems; CRES: Pikermi, Greece, 2004. [Google Scholar]

- Rogner, H.-H. Hydrogen technologies and the technology learning curve. Int. J. Hydrog. Energy 1998, 23, 833–840. [Google Scholar] [CrossRef]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Carberry, J.J.; Fair, J.R.; Schowalter, W.P.; Tipell, M.; Wei, J.; Peters, M.S. Plant Design and Economics for Chemical Engineers, 4th ed.; McGraw Hill: New York, NY, USA, 1991. [Google Scholar]

- IRENA. Global Hydrogen Trade to Meet the 1.5 °C Climate Goal: Part III—Green Hydrogen Cost and Potential; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- BloombergNEF. New Energy Outlook 2022; Bloomberg: New York, NY, USA, 2019. [Google Scholar]

- Kaldellis, J.K.; Kapsali, M. Shifting towards offshore wind energy—Recent activity and future development. Energy Policy 2013, 53, 136–148. [Google Scholar] [CrossRef]

- Rezaei, M.; Akimov, A.; Gray, E.M. Economics of solar-based hydrogen production: Sensitivity to financial and technical factors. Int. J. Hydrog. Energy 2022, 47, 27930–27943. [Google Scholar] [CrossRef]

- Ainscough, P. Hydrogen Production cost from PEM Electrolysis; U.S. Department of Energy: Washington, DC, USA, 2014. [Google Scholar]

- Our World in Data. Levelized Cost of Energy by Technology. Our World in Data. 2021. Available online: https://ourworldindata.org/grapher/levelized-cost-of-energy (accessed on 9 July 2023).

- Brändle, G.; Schönfisch, M.; Schulte, S. Estimating long-term global supply costs for low-carbon hydrogen. Appl. Energy 2021, 302, 117481. [Google Scholar] [CrossRef]

- Khan, M.H.A.; Daiyan, R.; Han, Z.; Hablutzel, M.; Haque, N.; Amal, R.; MacGill, I. Designing optimal integrated electricity supply configurations for renewable hydrogen generation in Australia. iScience 2021, 24, 102539. [Google Scholar] [CrossRef]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrog. Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Blanco, H.; Nijs, W.; Ruf, J.; Faaij, A. Potential for hydrogen and Power-to-Liquid in a low-carbon EU energy system using cost optimization. Appl. Energy 2018, 232, 617–639. [Google Scholar] [CrossRef]

- Dong, Z.Y.; Yang, J.; Yu, L.; Daiyan, R.; Amal, R. A green hydrogen credit framework for international green hydrogen trading towards a carbon neutral future. Int. J. Hydrog. Energy 2022, 47, 728–734. [Google Scholar] [CrossRef]

- Kazi, M.-K.; Eljack, F.; El-Halwagi, M.M.; Haouari, M. Green hydrogen for industrial sector decarbonization: Costs and impacts on hydrogen economy in qatar. Comput. Chem. Eng. 2021, 145, 107144. [Google Scholar] [CrossRef]

- Nicita, A.; Maggio, G.; Andaloro, A.P.F.; Squadrito, G. Green hydrogen as feedstock: Financial analysis of a photovoltaic-powered electrolysis plant. Int. J. Hydrog. Energy 2020, 45, 11395–11408. [Google Scholar] [CrossRef]

- Finke, C.E.; Leandri, H.F.; Karumb, E.T.; Zheng, D.; Hoffmann, M.R.; Fromer, N.A. Economically advantageous pathways for reducing greenhouse gas emissions from industrial hydrogen under common, current economic conditions. Energy Environ. Sci. 2021, 14, 1517–1529. [Google Scholar] [CrossRef]

- Bellotti, D.; Rivarolo, M.; Magistri, L.; Massardo, A.F. Feasibility study of methanol production plant from hydrogen and captured carbon dioxide. J. CO2 Util. 2017, 21, 132–138. [Google Scholar] [CrossRef]

- Kato, T.; Kubota, M.; Kobayashi, N.; Suzuoki, Y. Effective utilization of by-product oxygen from electrolysis hydrogen production. Energy 2005, 30, 2580–2595. [Google Scholar] [CrossRef]

- Dorris, C.; Lu, E.; Park, S.; Toro, F. High-Purity Oxygen Production Using Mixed Ionic-Electronic Conducting Sorbents; University of Pennsylvania: Philadelphia, PA, USA, 2016. [Google Scholar]

- Hurskainen, M. Industrial Oxygen Demand in Finland; Technical Research Centre of Finland VTT Ltd.: Espoo, Finland, 2017. [Google Scholar]

- Ebrahimi, A.; Meratizaman, M.; Akbarpour Reyhani, H.; Pourali, O.; Amidpour, M. Energetic, exergetic and economic assessment of oxygen production from two columns cryogenic air separation unit. Energy 2015, 90, 1298–1316. [Google Scholar] [CrossRef]

- Nami, H.; Rizvandi, O.B.; Chatzichristodoulou, C.; Hendriksen, P.V.; Frandsen, H.L. Techno-economic analysis of current and emerging electrolysis technologies for green hydrogen production. Energy Convers. Manag. 2022, 269, 116162. [Google Scholar] [CrossRef]

- Muellerlanger, F.; Tzimas, E.; Kaltschmitt, M.; Peteves, S. Techno-economic assessment of hydrogen production processes for the hydrogen economy for the short and medium term. Int. J. Hydrog. Energy 2007, 32, 3797–3810. [Google Scholar] [CrossRef]

- Gallandat, N.; Romanowicz, K.; Züttel, A. An Analytical Model for the Electrolyser Performance Derived from Materials Parameters. J. Power Energy Eng. 2017, 5, 34–49. [Google Scholar] [CrossRef]

- The World Bank. Official Exchange Rate. World Bank Open Data 2023. Available online: https://data.worldbank.org (accessed on 8 July 2023).

- The World Bank. Inflation, Consumer Prices. 2023. Available online: https://data.worldbank.org/indicator/FP.CPI.TOTL.ZG (accessed on 8 July 2023).

- Bertuccioli, L.; Chan, A.; Hart, D.; Lehner, F.; Madden, B.; Standen, E. Development of Water Electrolysis in the European Union; Fuel Cells and Hydrogen Joint Undertaking: Brussels, Belgium, 2014. [Google Scholar]

| References | Electrolyzer Type | Learning Rate | Research Gap |

|---|---|---|---|

| [4] | - | 15% |

|

| [15,34] | Alkaline | 18.8% |

|

| PEM | 18% | ||

| SOEC | 28% | ||

| [35] | Alkaline | 18% |

|

| PEM | 18% | ||

| SOEC | 28% | ||

| [36] | - | 18% |

|

| [38] | Alkaline | 25.1% |

|

| PEM | 36.4% | ||

| [18] | - | 16–21% |

|

| Function | Input | Output |

|---|---|---|

| Exponential | year, cost | Rate of change, parameter projection |

| year, system size | ||

| year, installed capacity | ||

| Power | cost, system size | Scaling effect |

| cost, installed capacity | Learning rate |

| Technology | Alkaline | PEM |

|---|---|---|

| Time (R&D activities)–2050 Value | 388 USD/kW | 286 USD/kW |

| Time + Scaling Effect | −54% | −44% |

| Time + Technological Learning | −47% | −76% |

| Time + Scaling Effect + Technological Learning | −77% | −79% |

| Source | Alkaline | PEM |

|---|---|---|

| Current study | 270–712 | 243–679 |

| [51] | <126 | <126 |

| [3] | 252 | 412 |

| [31] | 230–322 | 230–414 |

| [37] | 276–417 | 311 |

| [52] | 72–85 | 268–630 |

| Parameters | Decrease in LCOH | Baseline (2021 Values) | Increase in LCOH |

|---|---|---|---|

| Electrolyzer efficiency (%) | 83.2 | 64 (Appendix C: efficiency projection) | 44.8 |

| Capacity factor (%) | 50.7 | 39 (offshore wind) | 27.3 |

| Electrolyzer cost (USD/kW) | 701.4 | 1002 (cost projection: R&D) | 1302.6 |

| Electricity price (USD/kWh) | 0.056 | 0.08 (offshore wind [56]) | 0.104 |

| Water cost (USD/gal) | 0.00161 | 0.0023 (The United States [39]) | 0.00299 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zun, M.T.; McLellan, B.C. Cost Projection of Global Green Hydrogen Production Scenarios. Hydrogen 2023, 4, 932-960. https://doi.org/10.3390/hydrogen4040055

Zun MT, McLellan BC. Cost Projection of Global Green Hydrogen Production Scenarios. Hydrogen. 2023; 4(4):932-960. https://doi.org/10.3390/hydrogen4040055

Chicago/Turabian StyleZun, Moe Thiri, and Benjamin Craig McLellan. 2023. "Cost Projection of Global Green Hydrogen Production Scenarios" Hydrogen 4, no. 4: 932-960. https://doi.org/10.3390/hydrogen4040055

APA StyleZun, M. T., & McLellan, B. C. (2023). Cost Projection of Global Green Hydrogen Production Scenarios. Hydrogen, 4(4), 932-960. https://doi.org/10.3390/hydrogen4040055