Magnetic Thixotropic Fluid for Direct-Ink-Writing 3D Printing: Rheological Study and Printing Performance

Abstract

1. Introduction

2. Experimental Section

2.1. Preparation of Magnetic Thixotropic Fluid

2.2. Characterization

2.3. Direct Ink Writing 3D-Printing Experiments

3. Results

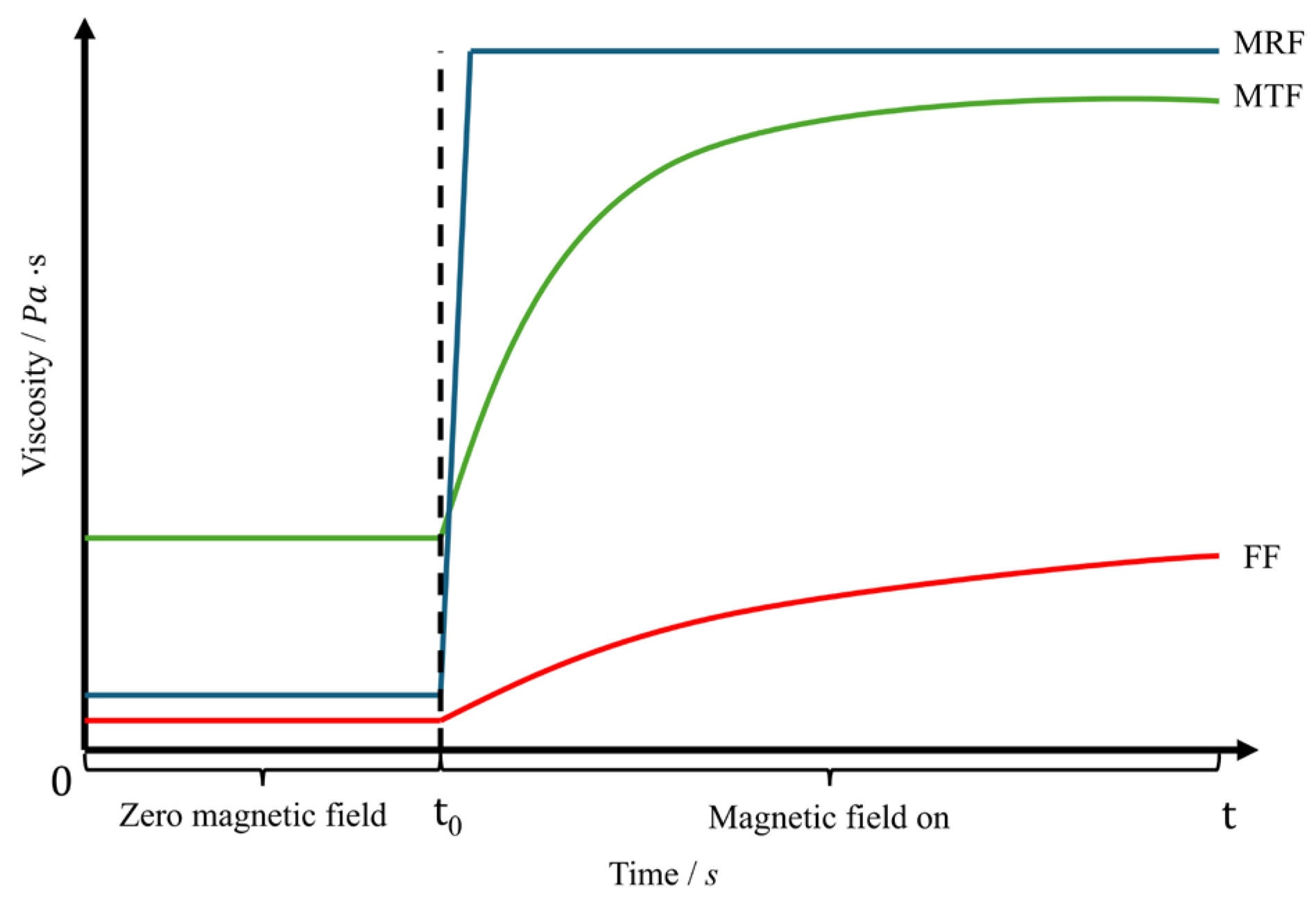

3.1. Rheological Properties of MTF

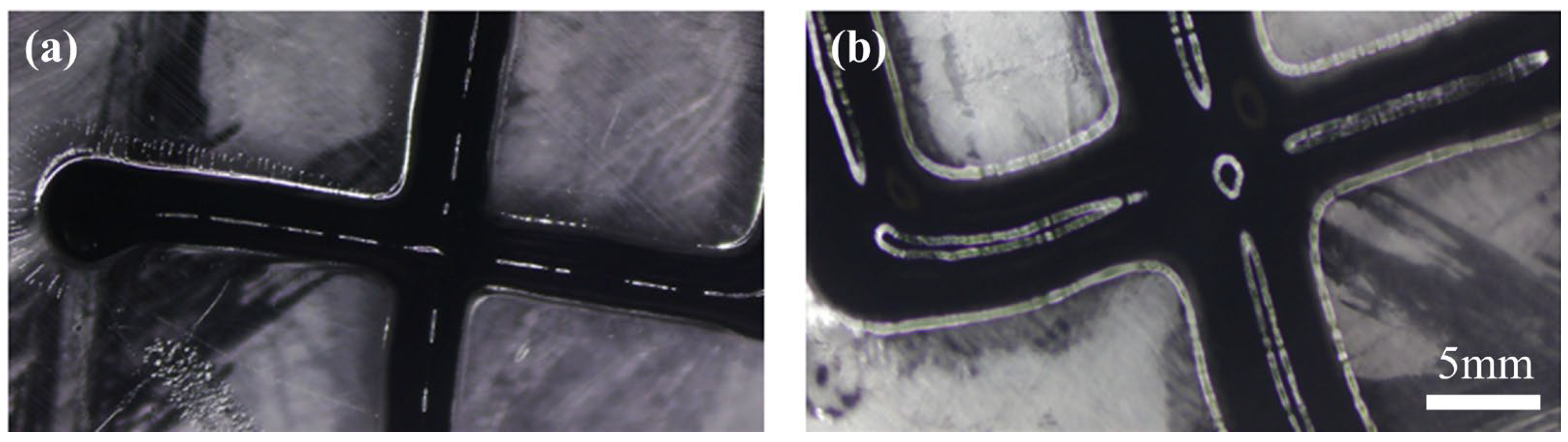

3.2. Direct Ink Writing 3D-Printing Results

4. Conclusions

- Through rheological characterization, microstructural analysis, VSM magnetometry, and modulus tests, the proportions of the MTF components were designed and optimized.

- A stirring structure in the reservoir and a screw section in the extruder head were introduced, enhancing the extrusion uniformity and forming precision.

- The 8% bentonite-8% Fe3O4 sample was ultimately identified as having good printability (Pr = 1, corner angle = 90) under the optimal printing parameters, i.e., the combination of the magnetic field strength H = 20 mT, the extrusion head movement speed v = 5 mm/s, and the extrusion head diameter d = 0.4 mm. The final printing quality was also validated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Murr, L.E. Frontiers of 3D Printing/Additive Manufacturing: From Human Organs to Aircraft Fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-Curing 3D Printing Technique and Its Challenges. Bioact Mater 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Oropallo, W.; Piegl, L.A. Ten Challenges in 3D Printing. Eng. Comput. 2016, 32, 135–148. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A Comprehensive Review of Emerging Additive Manufacturing (3D Printing Technology): Methods, Materials, Applications, Challenges, Trends and Future Potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar] [CrossRef]

- Schimpf, V.; Asmacher, A.; Fuchs, A.; Bruchmann, B.; Mülhaupt, R. Polyfunctional Acrylic Non-Isocyanate Hydroxyurethanes as Photocurable Thermosets for 3D Printing. Macromolecules 2019, 52, 3288–3297. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct Selective Laser Sintering and Melting of Ceramics: A Review. RPJ 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Wang, Y.; Blache, R.; Xu, X. Selection of Additive Manufacturing Processes. Rapid Prototyp. J. 2017, 23, 434–447. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J. Direct-Write Fabrication of 4D Active Shape-Changing Structures Based on a Shape Memory Polymer and Its Nanocomposite. ACS Appl. Mater. Interfaces 2017, 9, 876–883. [Google Scholar] [CrossRef]

- Elahee, G.M.F.; Cheng, X.; Rong, L.; Xu, M.; Souza, L.; Advincula, R.C.; Maia, J. On the Cogent Formulation of an Elastomeric Silicone Ink Material for Direct Ink Write ( DIW ) 3D Printing. Polym. Eng. Sci. 2024, 64, 2476–2490. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef] [PubMed]

- Yamagishi, K.; Karyappa, R.; Ching, T.; Hashimoto, M. Direct Ink Writing of Silicone Elastomers to Fabricate Microfluidic Devices and Soft Robots. MRS Communications 2024, 14, 846–861. [Google Scholar] [CrossRef]

- Alebrahim, M.; Ghazali, M.J.; Jamadon, N.H.; Otsuka, Y. A Comprehensive Review of Ceramic Additive Manufacturing: Advancements in Direct Ink Writing (DIW) and Tribological Properties of 3D-Printed Ceramics. Tribol. Int. 2025, 207, 110606. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, P.; Tao, Y.; Zhang, X.; Li, M.; Xu, W.; Zhao, J. Long-Term Stability and Durability of Direct-Ink-Writing 3D-Printed Sensors: Challenges, Strategies and Prospects. Virtual Phys. Prototyp. 2025, 20, e2460211. [Google Scholar] [CrossRef]

- Kim, J.H.; Quang, H.L.; Sim, H.H.; Yang, J.C.; Pyo, J.; Kim, M.W.; Seol, S.K. Direct-Ink-Writing of Highly Deformable, Multi-Layered Electrical Devices Using Elastomer-Based Dual Inks. Virtual Phys. Prototyp. 2025, 20, e2509611. [Google Scholar] [CrossRef]

- Demirkal, E.; Banerjee, D.; Barto, R.; Sabolsky, K.; Sierros, K.A.; Sabolsky, E.M. 3D Printing by Direct Ink Writing (DIW) of UV-Curable Elastomers with Embedded Sensors for Soft Robotic and Flexible Electronic Applications. Flex. Print. Electron. 2025, 10, 035001. [Google Scholar] [CrossRef]

- Wajahat, M.; Kim, J.H.; Kim, J.H.; Jung, I.D.; Pyo, J.; Seol, S.K. 4D Printing of Ultrastretchable Magnetoactive Soft Material Architectures for Soft Actuators. ACS Appl. Mater. Interfaces 2023, 15, 59582–59591. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Chu, P.K.; Gelinsky, M. 3D Printing of Hydrogels: Rational Design Strategies and Emerging Biomedical Applications. Mater. Sci. Eng. R: Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Jiang, P.; Lin, P.; Yang, C.; Qin, H.; Wang, X.; Zhou, F. 3D Printing of Dual-Physical Cross-Linking Hydrogel with Ultrahigh Strength and Toughness. Chem. Mater. 2020, 32, 9983–9995. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, S.; Ke, Y.; Ding, L.; Zeng, X.; Magdassi, S.; Long, Y. 4D Printed Hydrogels: Fabrication, Materials, and Applications. Adv. Mater. Technol. 2020, 5, 2000034. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Hou, Z.; Lu, H.; Li, Y.; Yang, L.; Gao, Y. Direct Ink Writing of Materials for Electronics-Related Applications: A Mini Review. Front. Mater. 2021, 8, 647229. [Google Scholar] [CrossRef]

- Neumann, T.V.; Dickey, M.D. Liquid Metal Direct Write and 3D Printing: A Review. Adv. Mater. Technol. 2020, 5, 2000070. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.-H.; Lee, J.-W.; Choi, K.H. 3D Printing for Soft Robotics—A Review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef]

- Mantelli, A.; Romani, A.; Suriano, R.; Levi, M.; Turri, S. Direct Ink Writing of Recycled Composites with Complex Shapes: Process Parameters and Ink Optimization. Adv. Eng. Mater. 2021, 23, 2100116. [Google Scholar] [CrossRef]

- Cui, H.; Zhou, H.; Xu, H.; Deng, C.; Sun, X.; Lu, J.; Cheng, Y.; Xu, J.; Zhenkun, L. Designing and Fabrication of a Biomimetic Soft Gripper Utilizing Phase Transition 3D Printing Technology. Adv. Eng. Mater. 2025, 27, 2402501. [Google Scholar] [CrossRef]

- Meng, X.; Li, S.; Shen, X.; Tian, C.; Mao, L.; Xie, H. Programmable Spatial Magnetization Stereolithographic Printing of Biomimetic Soft Machines with Thin-Walled Structures. Nat. Commun. 2024, 15, 10442. [Google Scholar] [CrossRef]

- Zhang, F.; Wen, N.; Wang, L.; Bai, Y.; Leng, J. Design of 4D Printed Shape-Changing Tracheal Stent and Remote Controlling Actuation. Int. J. Smart Nano Mater. 2021, 12, 375–389. [Google Scholar] [CrossRef]

- Lin, C.; Liu, L.; Liu, Y.; Leng, J. 4D Printing of Bioinspired Absorbable Left Atrial Appendage Occluders: A Proof-of-Concept Study. ACS Appl. Mater. Interfaces 2021, 13, 12668–12678. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yao, Y.; Yang, B.; Liu, Y. 3D Printing of Shape Memory Magnetorheological Elastomers Composites. Eur. Polym. J. 2024, 220, 113403. [Google Scholar] [CrossRef]

- Park, B.J.; Fang, F.F.; Choi, H.J. Magnetorheology: Materials and Application. Soft Matter 2010, 6, 5246–5253. [Google Scholar] [CrossRef]

- Yu, L.; Chen, F.; Li, H. Study on Sedimentation Stability of Silicone Oil-Based Magnetorheological Fluids with Fumed Silica as Additive. Front. Mater. 2024, 11, 1395507. [Google Scholar] [CrossRef]

- Li, Z.; Dong, J.; Zhang, S.; Li, Y.; Deng, C.; Li, D.; Cui, H.; Li, Z.; Song, Z.; Yao, J.; et al. Phase Transition Reversible 3D Printing of Magnetic Thixotropic Fluid. Appl. Mater. Today 2023, 34, 101920. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing Ferromagnetic Domains for Untethered Fast-Transforming Soft Materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial Magnetically Assisted 3D Printing of Composite Materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef]

- Leon-Rodriguez, H.; Le, V.H.; Ko, S.Y.; Park, J.-O.; Park, S. Ferrofluid Soft-Robot Bio-Inspired by Amoeba Locomotion. In Proceedings of the 2015 15th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2015; pp. 1833–1838. [Google Scholar]

- Neal, C.A.P.; Shetty, A.M.; Linn, J.D.; Quan, M.C.; Casas, J.D.; Calabrese, M.A. Magnetic Field-Dependent Rheological Behavior of Thermoresponsive Poly(N-Isopropylacrylamide) Solutions. Rheol. Acta 2024, 63, 493–512. [Google Scholar] [CrossRef]

- Villegas Arcos, X.; Blanco Mayorga, J.D.; Chaves-Guerrero, A.; Mercado, R. Wettability Assessment of Hydrophobized Granular Solids: A Rheological Approach Using Surfactant Adsorption. Materials 2025, 18, 1305. [Google Scholar] [CrossRef]

- Ren, J.; Deshun, Y.; Zhai, R. Rheological Behavior of Bentonite-Water Suspension at Various Temperatures: Effect of Solution Salinity. Eng. Geol. 2021, 295, 106435. [Google Scholar] [CrossRef]

- Pang, Y.H.; Cao, J.J.; Sun, B. Research on the Preparation of Organic Modified Bentonite and the Control of Biological Invasion in Ballast Water. Appl. Mech. Mater. 2014, 608–609, 1136–1140. [Google Scholar] [CrossRef]

- Deng, C.; Dong, J.; Guo, Y.; Sun, X.; Song, Z.; Li, Z. Amoeboid Soft Robot Based on Multi-Material Composite 3D Printing Technology. J. Magn. Magn. Mater. 2023, 588, 171390. [Google Scholar] [CrossRef]

- Wen, P.; Hong, J.; Wang, Y.; Wang, X.; Guo, L.; Zhou, X.; Liu, J. Confined and Focused Electric Fields Induce Array Jet Crosstalk Suppression for Multi-Nozzle Electrohydrodynamic Printing. Phys. Fluids 2025, 37, 082052. [Google Scholar] [CrossRef]

- Raisee, M.; Vahedi, N.; Rostamzadeh, A. Prediction of Gas Flow Through Short and Long 2-D Micro and Nano-Channels Using a Generalized Slip Model. In Proceedings of the ASME 2008 6th International Conference on Nanochannels, Microchannels, and Minichannels, ASMEDC, Darmstadt, Germany, 23–25 June 2008; pp. 103–109. [Google Scholar]

| Sample Number | Fe3O4 (%) | OMBT (%) | L-AN32 (%) |

|---|---|---|---|

| 1 | 8 | 8 | 84 |

| 2 | 12 | 8 | 80 |

| 3 | 14 | 4 | 82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Liu, T.; Cui, H.; Dong, J.; Geng, Z.; Deng, C.; Zhang, S.; Sun, Y.; Zhou, H. Magnetic Thixotropic Fluid for Direct-Ink-Writing 3D Printing: Rheological Study and Printing Performance. Colloids Interfaces 2025, 9, 66. https://doi.org/10.3390/colloids9050066

Li Z, Liu T, Cui H, Dong J, Geng Z, Deng C, Zhang S, Sun Y, Zhou H. Magnetic Thixotropic Fluid for Direct-Ink-Writing 3D Printing: Rheological Study and Printing Performance. Colloids and Interfaces. 2025; 9(5):66. https://doi.org/10.3390/colloids9050066

Chicago/Turabian StyleLi, Zhenkun, Tian Liu, Hongchao Cui, Jiahao Dong, Zijian Geng, Chengyao Deng, Shengjie Zhang, Yin Sun, and Heng Zhou. 2025. "Magnetic Thixotropic Fluid for Direct-Ink-Writing 3D Printing: Rheological Study and Printing Performance" Colloids and Interfaces 9, no. 5: 66. https://doi.org/10.3390/colloids9050066

APA StyleLi, Z., Liu, T., Cui, H., Dong, J., Geng, Z., Deng, C., Zhang, S., Sun, Y., & Zhou, H. (2025). Magnetic Thixotropic Fluid for Direct-Ink-Writing 3D Printing: Rheological Study and Printing Performance. Colloids and Interfaces, 9(5), 66. https://doi.org/10.3390/colloids9050066