Fatigue Behaviors of High-Speed Track Slabs Reinforced by GFRP Composite Rebar: Full-Scale Experimental Verification

Abstract

1. Introduction

2. Fatigue Design of GFRP Reinforcement

2.1. Governing Limit States

2.2. Stress Calculation Procedure and Design Methodology

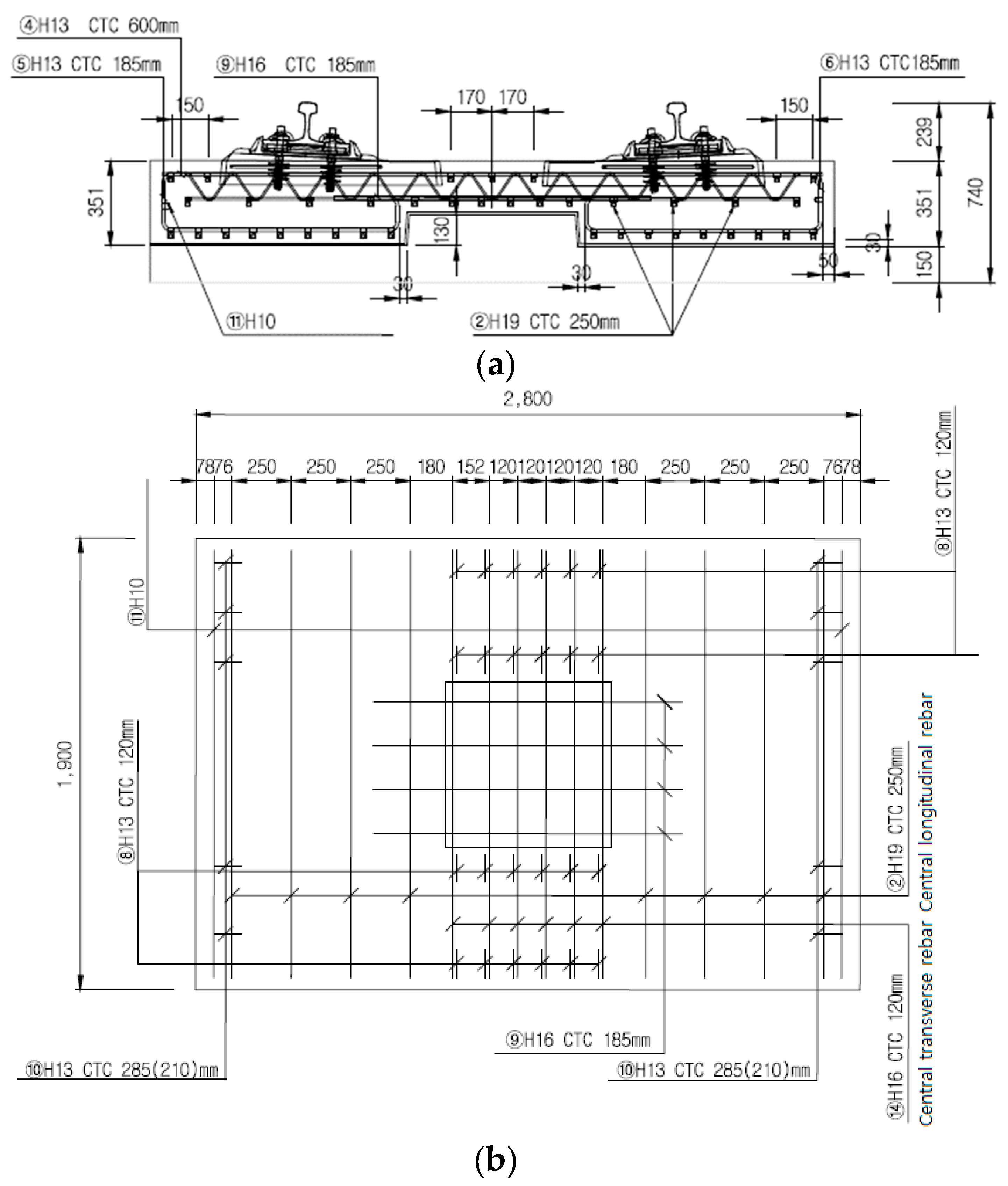

3. Structural Design of a Full-Size Specimen

4. Full-Scale Experiment

Experimental Setup

5. Summary and Conclusions

- (1)

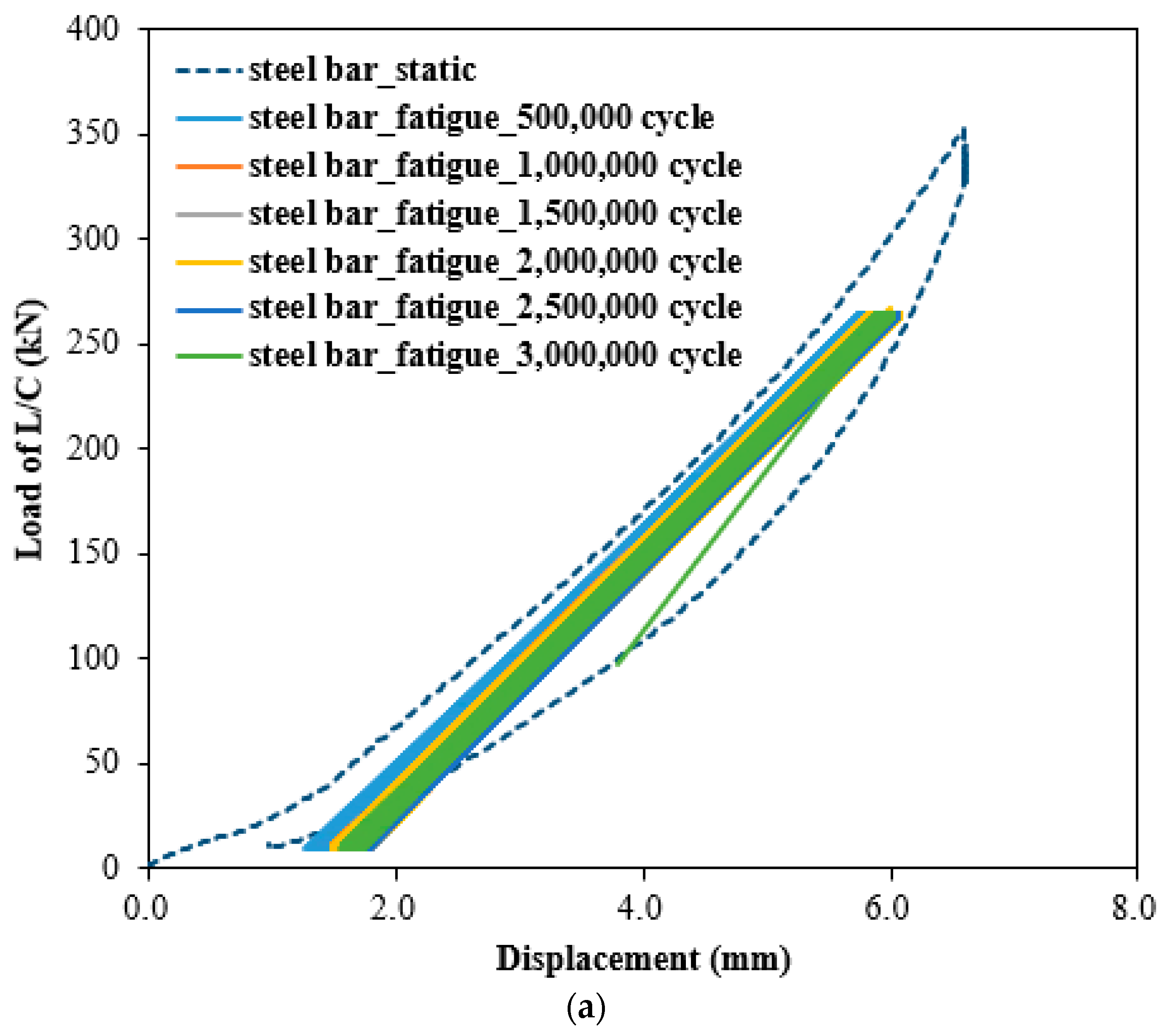

- Both steel- and GFRP-reinforced specimens exhibited a typical nonlinear response characterized by a gradual load increase, plateau, and unloading phase. The steel-reinforced specimen showed slightly higher load capacity and a longer plateau, indicating ductile yielding, whereas the GFRP-reinforced specimen displayed a steeper load–displacement path and faster unloading, consistent with its linear–elastic and brittle characteristics. Under identical displacement levels, the GFRP specimen exhibited higher stiffness and load-carrying capacity, while the steel specimen showed slightly larger residual deformation due to its ductile nature.

- (2)

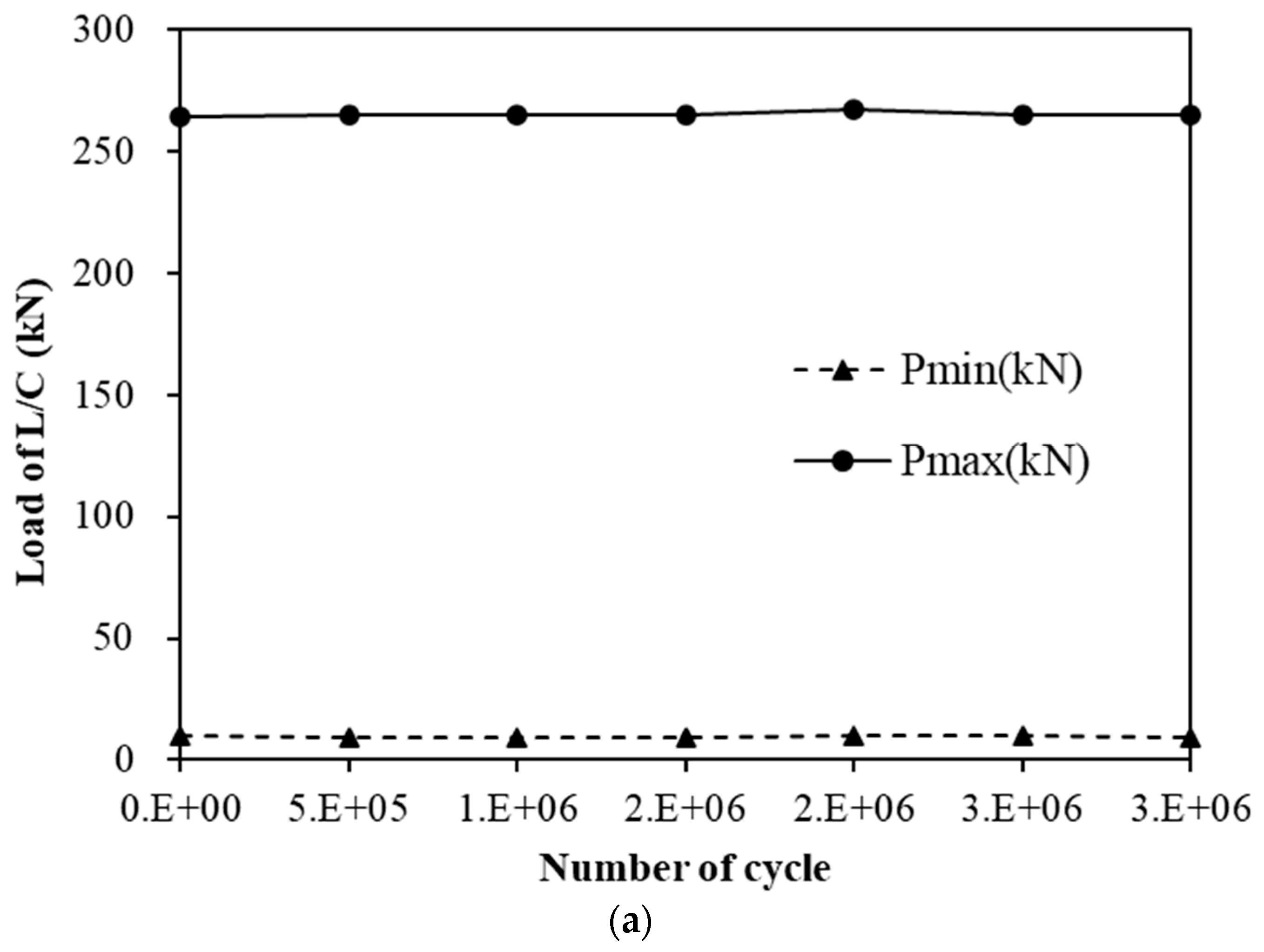

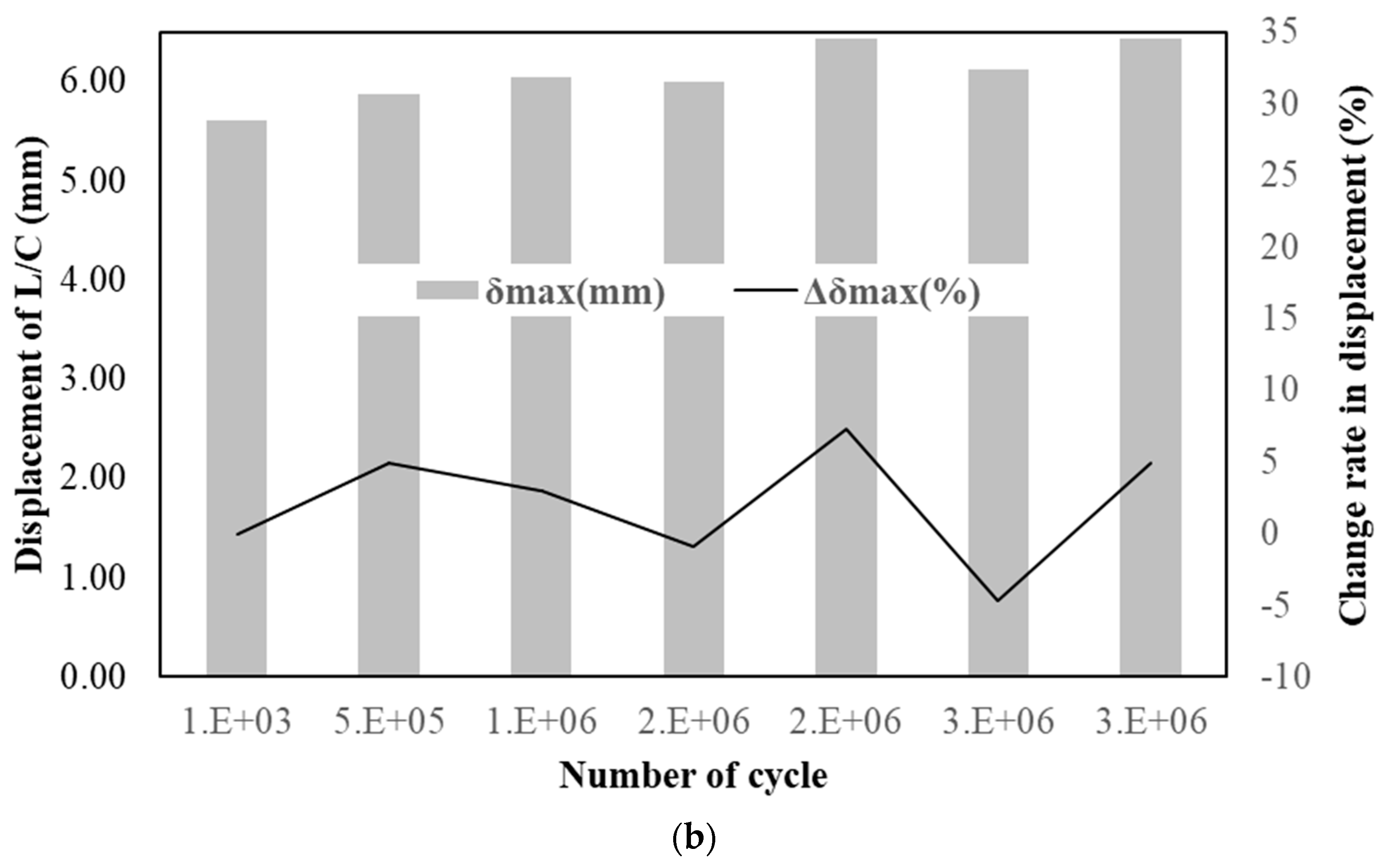

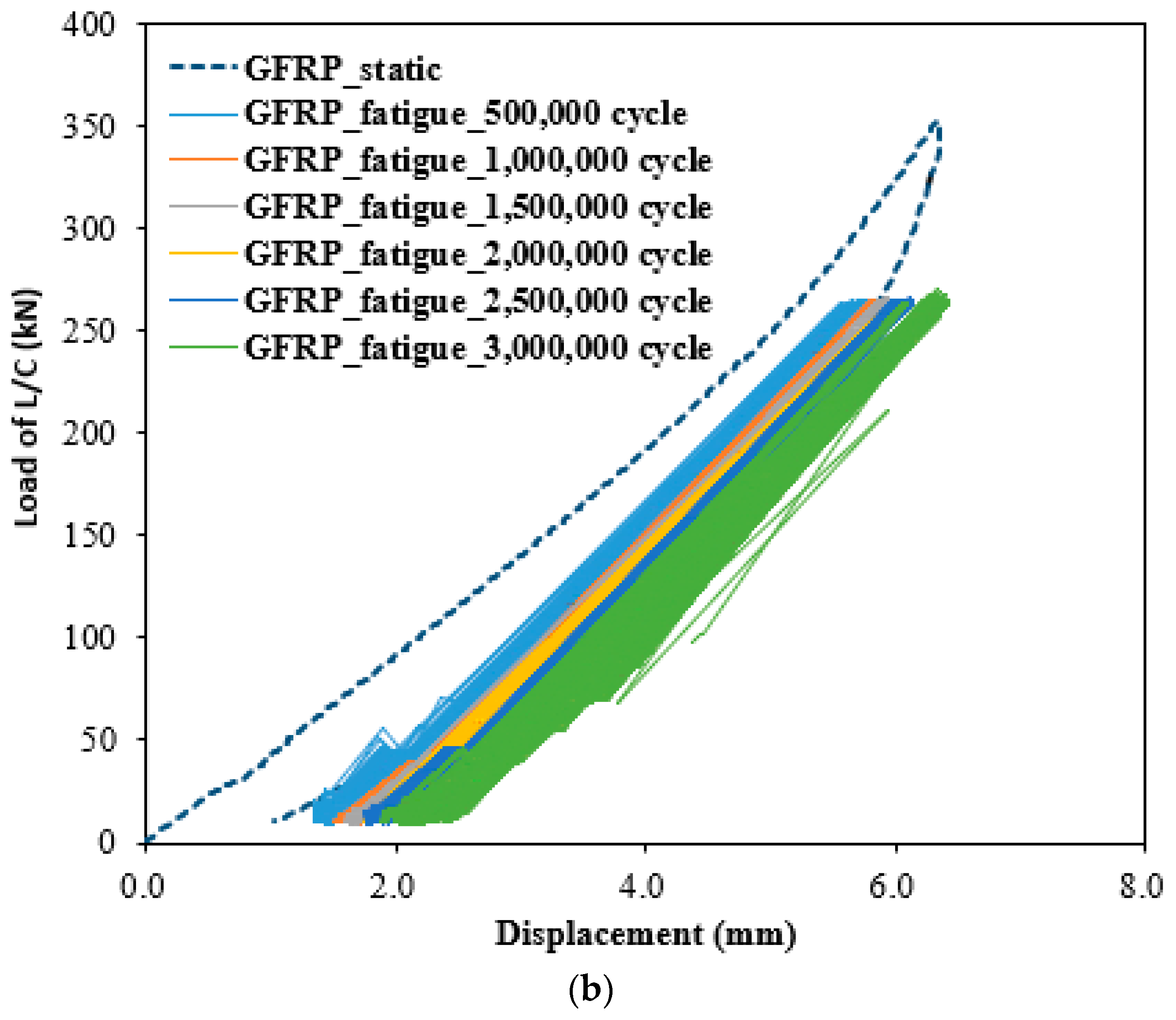

- For both materials, displacement variations during cyclic loading remained within 1 mm, and load variations were within 10 kN, indicating excellent stability under accumulated fatigue cycles. The fluctuation in displacement change rates decreased as the number of cycles increased, implying stabilization of internal stresses. The steel-reinforced specimen maintained stable deformation behavior without progressive displacement growth up to three million cycles. Similarly, the GFRP-reinforced specimen exhibited only minor elastic adjustments with no signs of stiffness degradation, confirming superior fatigue resistance.

- (3)

- Both steel- and GFRP-reinforced slabs maintained nearly identical load–displacement relationships across 1 to 3 million loading cycles, closely following the static curve. Displacement increased slightly with loading cycles; however, the total variation remained below 1 mm, signifying negligible deformation accumulation. The minimal change in load cell displacement and load with cycle accumulation indicates that dynamic structural stability and long-term serviceability can be effectively maintained under repeated loading. These findings verify that both reinforcement types provide sufficient stiffness retention and fatigue durability over extended service life.

- (4)

- No cracking was observed in the GFRP-reinforced specimen after the 3-million-cycle fatigue test, confirming that the bond between the GFRP bars and surrounding concrete was well maintained under dynamic loading. Similar behavior was observed in the steel-reinforced specimen. Based on these findings, a fatigue design methodology for GFRP-reinforced track slabs is proposed, harmonized with international standards. The methodology incorporates cracked-section elastic analysis for stress evaluation under sustained and cyclic loading, ensuring compliance with creep-rupture and fatigue limit states. Furthermore, serviceability criteria such as crack width and deflection limits are included to guarantee durability and safety. Overall, this study demonstrates that GFRP reinforcement offers a reliable, durable, and sustainable alternative to steel reinforcement for high-speed railway track slabs, contributing significantly to modern, long-life, low-maintenance infrastructure design.

Funding

Data Availability Statement

Conflicts of Interest

References

- AASHTO. Guide Specifications for the Design of Concrete Bridge Decks Reinforced with GFRP Bars, 2nd ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018. [Google Scholar]

- S6-19; Canadian Highway Bridge Design Code. Canadian Standards Association: Toronto, ON, Canada, 2019.

- S807-19; Specification for Fibre-Reinforced Polymers. Canadian Standards Association: Toronto, ON, Canada, 2019.

- ACI 440.11-22; Building Code Requirements for Structural Concrete Reinforced with Glass Fiber-Reinforced Polymer Bars. American Concrete Institute: Farmington Hills, MI, USA, 2022.

- Nagy, I.E.; Asadian, A.; Galal, K. Fatigue life and behaviour of ribbed GFRP reinforced concrete beams. Eng. Struct. 2024, 309, 117989. [Google Scholar] [CrossRef]

- Gao, K.; Wu, Z.; Li, Z.; Cai, C.; Zhang, L.; Xiao, S.; Hu, J. Fatigue bond behavior of glass fiber reinforced polymer bars with varying confinement levels. J. Build. Eng. 2025, 111, 113115. [Google Scholar] [CrossRef]

- Ebrahimzadeh, S.; Manalo, A.; Alajarmeh, O.; Sorbello, C.D.; Weerakoon, S.; Mohammed, A.; Hassanli, R.; Benmokrane, B. GFRP-reinforced concrete segmental decks for maritime infrastructures: Structural behaviour review. Sustain. Resilient Infrastruct. 2025, 1–32. [Google Scholar] [CrossRef]

- Ali, Y.M.S.; Wang, X.; Huawei, G.; Liu, S.; Da, L.; Wu, Z.; Moussa, A.M.A. Static and fatigue behavior of concrete bridge deck slabs reinforced with BFRP and steel bars. Structures 2024, 65, 106707. [Google Scholar] [CrossRef]

- Alajarmeh, O.; Manalo, A.; Ferdous, W.; Almasabha, G.; Tarawneh, A.; Awwad, K.E.; Safonov, A.; Zeng, X.; Schubel, P. Fatigue behavior of unidirectional fiber-reinforced pultruded composites with high volume fiber fraction. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 2034–2048. [Google Scholar] [CrossRef]

- Toprak, M.A.; Güllü, A.; Özden, B.; Ölçer, B.; Durgun, Y.; Şahin, F.; Saruhan, H.; Yüksel, E. Fatigue behavior evaluation of two full-scale composite ballastless slab tracks incorporating steel and glass fiber rods. Constr. Build. Mater. 2025, 468, 140456. [Google Scholar] [CrossRef]

- DIN 1045-1:2008-08; Concrete, Reinforced and Prestressed Concrete Structures—Part 1: Design and Construction. Beuth Verlag: Berlin, Germany, 2008.

- Aly, M.H.F.; El-Naga, I.M.A.; Soliman, A.A.H.; Diab, M.A. Modelling of slab track systems for design purposes. J. Eng. Appl. Sci. 2023, 70, 115. [Google Scholar] [CrossRef]

- ACI 440.1R-06; Guide for the Design and Construction of Concrete Reinforced with FRP Bars. American Concrete Institute: Farmington Hills, MI, USA, 2006.

- BS EN 13230-4; Railway Applications—Track—Concrete Sleepers and Bearers. BSI Standards: London, UK, 2016.

- EN 1991-2; Eurocode 1—Actions on Structures, Part 2: Traffic Loads on Bridges. CEN: Brussels, Belgium, 2003.

| Item | Notation | Unit | Values |

|---|---|---|---|

| Design axial load (Express railway) | F | kN | 220 |

| Single wheel load | 1/2 × F | kN | 110 |

| Impact factor | i | 1.2 | |

| Fatigue test load per single wheel load | F0 (=i × F/2) | kN | 132 |

| Increased load factor | Φ | 4/3 | |

| Design load per single wheel load | Fd (=Φ × F0) | kN | 176 |

| Maximum fatigue test load | P0 (=2 × F0) | kN | 264 |

| Static cyclic load | Pd (=2 × Fd) | kN | 352 |

| Fatigue minimum load per single wheel load | Fmin | kN | 5 |

| Minimum fatigue test load | Pmin (=2 × Fmin) | kN | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-Y. Fatigue Behaviors of High-Speed Track Slabs Reinforced by GFRP Composite Rebar: Full-Scale Experimental Verification. J. Compos. Sci. 2025, 9, 597. https://doi.org/10.3390/jcs9110597

Lee S-Y. Fatigue Behaviors of High-Speed Track Slabs Reinforced by GFRP Composite Rebar: Full-Scale Experimental Verification. Journal of Composites Science. 2025; 9(11):597. https://doi.org/10.3390/jcs9110597

Chicago/Turabian StyleLee, Sang-Youl. 2025. "Fatigue Behaviors of High-Speed Track Slabs Reinforced by GFRP Composite Rebar: Full-Scale Experimental Verification" Journal of Composites Science 9, no. 11: 597. https://doi.org/10.3390/jcs9110597

APA StyleLee, S.-Y. (2025). Fatigue Behaviors of High-Speed Track Slabs Reinforced by GFRP Composite Rebar: Full-Scale Experimental Verification. Journal of Composites Science, 9(11), 597. https://doi.org/10.3390/jcs9110597