1. Introduction

Lightweight Aggregate Reinforced Concrete (LWARC) is a specialized concrete variant that incorporates lightweight aggregates (LWAs) such as expanded clay, shale, or slate to reduce density while maintaining structural integrity. LWARC offers advantages such as reduced dead load, improved thermal insulation, and enhanced seismic performance due to its lower mass [

1,

2]. The mechanical properties of LWARC, including compressive strength and modulus of elasticity, are typically lower than those of normal-weight concrete (NWC), which necessitates careful design considerations for load-bearing applications [

3]. Studies by Marzouk and Hussein [

4] demonstrated that LWARC slabs exhibit comparable flexural behavior to NWC slabs but are more susceptible to shear-related failures due to the brittleness of lightweight aggregates. This brittleness is attributed to the porous structure of LWAs, which reduces aggregate interlock and shear transfer capacity [

5]. Recent advancements in LWARC mix design, such as incorporating supplementary cementitious materials (SCMs) like silica fume, have improved its mechanical properties, enabling its use in flat slab systems where punching shear resistance is critical [

6,

7].

The use of LWARC in flat slabs has gained traction in high-rise construction due to its weight-saving benefits, which reduce foundation costs and enable longer spans [

8]. However, challenges persist in ensuring adequate punching shear capacity, particularly in regions with high shear stress concentrations around columns. Youm et al. [

7] highlighted that LWARC slabs with low reinforcement ratios are prone to sudden punching failures, emphasizing the need for targeted strengthening strategies. Similarly, Zaher et al. [

3] investigated the punching behavior of foamed LWARC slabs and found that their shear capacity was 15–20% lower than NWC counterparts, underscoring the necessity for retrofitting solutions.

A subset of LWARC involves the integration of polystyrene foam as a partial replacement for traditional aggregates, further reducing density while enhancing thermal and acoustic insulation. Polystyrene-based LWARC achieves densities as low as 1200 kg/m

3, making it ideal for prefabricated modular construction [

9]. However, the inclusion of polystyrene compromises mechanical properties, particularly tensile and shear strength, due to the weak interfacial bond between the foam and cement matrix [

10,

11]. Experimental studies by Guandalini et al. [

5] on low-reinforcement-ratio slabs revealed that polystyrene LWARC exhibits higher deflection and earlier crack propagation under concentrated loads compared to conventional LWARC. To mitigate these drawbacks, researchers have explored hybrid systems combining polystyrene with fibrous additives or rigid inclusions to enhance ductility [

12]. For instance, Said et al. [

13] demonstrated that embedding glass fiber-reinforced polymer (GFRP) bars in polystyrene LWARC slabs improved load redistribution and delayed punching failure.

Despite these innovations, the inherent brittleness of polystyrene LWARC remains a concern. Moussa et al. [

9] observed that slabs with polystyrene aggregates failed at 60–70% of the load capacity of traditional LWARC slabs, highlighting the critical need for post-construction strengthening. This has spurred interest in advanced retrofitting techniques, such as fiber-reinforced polymers (FRPs), to enhance punching shear resistance without adding significant mass [

14].

Punching shear failure is a predominant failure mode in flat slab systems, characterized by a conical fracture surface around columns due to high shear stresses. This failure is sudden and catastrophic, often occurring without warning, making it a critical design consideration [

15]. The seminal work by Hawkins et al. [

8] established foundational models for predicting punching shear capacity in NWC slabs, emphasizing the role of flexural reinforcement ratio and concrete tensile strength. Subsequent studies by Marzouk and Hussein [

4] extended these principles to high-strength concrete, noting that increased compressive strength does not proportionally enhance shear resistance due to brittleness.

For LWARC slabs, punching shear behavior is more complex due to reduced aggregate interlock and lower fracture energy. Youm et al. [

7] conducted punching tests on LWARC slabs and found that failure loads were 25% lower than predicted by existing codes, which do not fully account for lightweight aggregate effects. Similarly, Guandalini et al. [

5] reported that slabs with low reinforcement ratios failed at 40% lower loads than code predictions, underscoring the inadequacy of traditional design equations for LWARC. These findings align with Zaher et al. [

3], who observed that foamed LWARC slabs exhibited wider crack patterns and reduced post-cracking stiffness, accelerating shear failure.

To enhance punching shear resistance, traditional methods include increasing slab thickness via drop panels or column heads, installing shear reinforcement (e.g., steel stirrups or studs), and post-construction interventions like steel plate bonding [

9]. While effective, these methods add significant weight, require intrusive installation, and are susceptible to corrosion in aggressive environments [

13]. For instance, Moussa et al. [

9] reported a 30% increase in punching capacity using steel studs but noted challenges in retrofitting existing slabs due to access limitations. Similarly, Ismail et al. [

10] demonstrated that steel plate bonding improved stiffness but introduced anchorage complexities.

In contrast, FRP systems offer a lightweight, non-corrosive alternative [

16,

17]. Carbon fiber-reinforced polymer (CFRP) and GFRP sheets or bars can be externally bonded or embedded to enhance shear capacity without compromising durability [

16,

17,

18]. Mohamed et al. [

18] categorized FRP retrofitting techniques into two primary approaches: (1) bonding CFRP sheets to the tension face of the slab to enhance flexural and shear resistance, and (2) installing vertical FRP strips to mimic shear reinforcement. The latter method, termed the “embedded through section” (ETS) technique, involves inserting FRP bars into pre-drilled holes and anchoring them with epoxy, effectively transferring shear forces across cracks [

19].

FRPs are composite materials comprising high-strength fibers (e.g., carbon, glass, or aramid) embedded in a polymer matrix. Their advantages include high tensile strength (exceeding 1000 MPa for CFRP), corrosion resistance, and minimal weight (70–80% lighter than steel) [

16,

17]. GFRP, in particular, is widely used due to its cost-effectiveness and adequate mechanical properties. Gao et al. [

12] demonstrated that GFRP-reinforced slabs exhibit 1.5 times higher tensile strength than steel-reinforced counterparts, with no yield plateau, enabling better crack control. However, FRPs are anisotropic, with strength primarily in the fiber direction, necessitating careful orientation during installation [

20].

CFRP outperforms GFRP in terms of stiffness and strength but is cost-prohibitive for large-scale applications. Zhou et al. [

21] noted that CFRP’s elasticity modulus (200–300 GPa) surpasses steel (200 GPa), making it ideal for high-stress zones, while Karzad et al. [

15] emphasized its superiority in repair applications requiring minimal thickness. Despite these benefits, economic constraints often favor GFRP, especially in non-critical regions.

CFRP sheets are commonly applied to the tension face of slabs around columns to enhance flexural and shear resistance. Dat and Hieu [

20] reported a 35% increase in punching capacity after bonding CFRP sheets, attributing the improvement to enhanced load redistribution and delayed crack propagation. Alternatively, vertical FRP strips installed via the ETS method provide direct shear reinforcement. Mahmoud et al. [

22] tested GFRP grating systems, where molded FRP grids were embedded into slab-column joints, resulting in a 45% increase in failure load due to improved stress transfer. Bouguerra et al. [

19] replaced steel reinforcement with GFRP bars in flat plates, achieving comparable punching resistance while eliminating corrosion risks.

Hybrid systems combining CFRP and GFRP have also shown promise. Said et al. [

13] retrofitted LWARC slabs with externally bonded CFRP and embedded GFRP bars, achieving a 50% strength increase. The study highlighted that inclined ETS bars at 45° were 20% more effective than vertical ones due to optimized shear path alignment.

This paper presents an experimental investigation into the punching shear strengthening of LWARC flat slabs using FRP techniques. Ten slabs were tested under concentric loading, including a control specimen and nine retrofitted with CFRP sheets, ETS-GFRP, and ETS-steel bars. Key parameters such as FRP spacing, bar diameter, and inclination were analyzed. Experimental results were compared with predictions from ECP 203-2023 [

23], ACI 318-19 [

24], and BS 8110 [

25] to assess code applicability. The study aims to bridge gaps in existing design guidelines for FRP-strengthened LWARC slabs and provide insights into optimizing retrofitting configurations.

2. Experimental Work

This section outlines the experimental program used to assess the punching shear behavior of LWARC slabs strengthened with FRP and steel reinforcement. It includes the material properties, the test matrix, and the loading setup used for concentric testing.

2.1. Material Properties

All slabs were cast using lightweight aggregate concrete (LWAC), designed to achieve a target compressive strength of 14.8 MPa. Expanded polystyrene foam (Addibor-55, CMB, Giza, Egypt) was used as a partial replacement for conventional coarse aggregate to reduce the concrete’s unit weight. This substitution resulted in a 17.4% reduction in dry unit weight, from 23.0 kN/m3 to 19.0 kN/m3. The polystyrene foam, characterized by a density of 1900 kg/m3 and a very low specific gravity of 0.06, contributed to the lightweight characteristics of the mix without compromising workability or mechanical properties.

The detailed mix proportions are summarized in Table 2. Ordinary Portland Cement (OPC) Type II, conforming to ASTM C150 [

26], with a 28-day compressive strength grade of 42.5 MPa and a specific gravity of 3.15 was used. The mix was designed with a water-to-cement ratio of 0.38. Well-graded clean river sand with a fineness modulus of 2.6 was used as the fine aggregate (550 kg/m

3), while crushed dolomite with a nominal maximum size of 20 mm was used as the coarse aggregate (650 kg/m

3). To compensate for the reduced workability associated with lightweight mixes, a high-range water-reducing admixture (HRWRA), Addicrete BVF (CMB, Giza, Egypt), was used. Additionally, alkali-resistant polypropylene microfibers were added to enhance crack resistance, control early-age shrinkage, and improve ductility, particularly under localized punching shear loads.

Figure 1 shows the raw material used in this study.

The average compressive strength of the concrete was 14.8 MPa, determined from six standard cubes with dimensions of 150 mm × 150 mm × 150 mm, and tested using a compression testing machine, as shown in

Figure 2. The cubes were cast from the same concrete batch used for preparing the slab specimens to ensure consistency in material properties as listed in

Table 1.

The internal reinforcement used in all reinforced concrete slab specimens consisted of deformed steel bars with a yield strength of 500 MPa and an elastic modulus of 200 GPa. For external strengthening, the Embedded Through-Section (ETS) technique was implemented using both steel and glass fiber-reinforced polymer (GFRP) bars. The GFRP bars were applied in two diameters, 6 mm and 10 mm, with corresponding ultimate tensile strengths of 1171.85 MPa and 1035.41 MPa, respectively, as determined through standard tensile testing in accordance with ASTM D7205/D7205M [

27]. Experimental stress–strain data showed linear elastic behavior up to failure, with the 6 mm and 10 mm GFRP bars reaching rupture at approximately 2.6% and 2.9% strain, respectively. The calculated elastic modulus for both GFRP bar sizes was approximately 40 GPa, based on the slope of the stress–strain curves shown in

Figure 3.

Externally bonded carbon fiber-reinforced polymer (CFRP) sheets were also used for slab strengthening. The CFRP material had an ultimate tensile strength of 3400 MPa, an elastic modulus of 230 GPa, and an ultimate strain of 1.5%, as per the manufacturer’s datasheet. The CFRP sheets were applied using a two-part epoxy adhesive system, with surface preparation carried out in accordance with standard bonding protocols.

2.2. Test Matrix

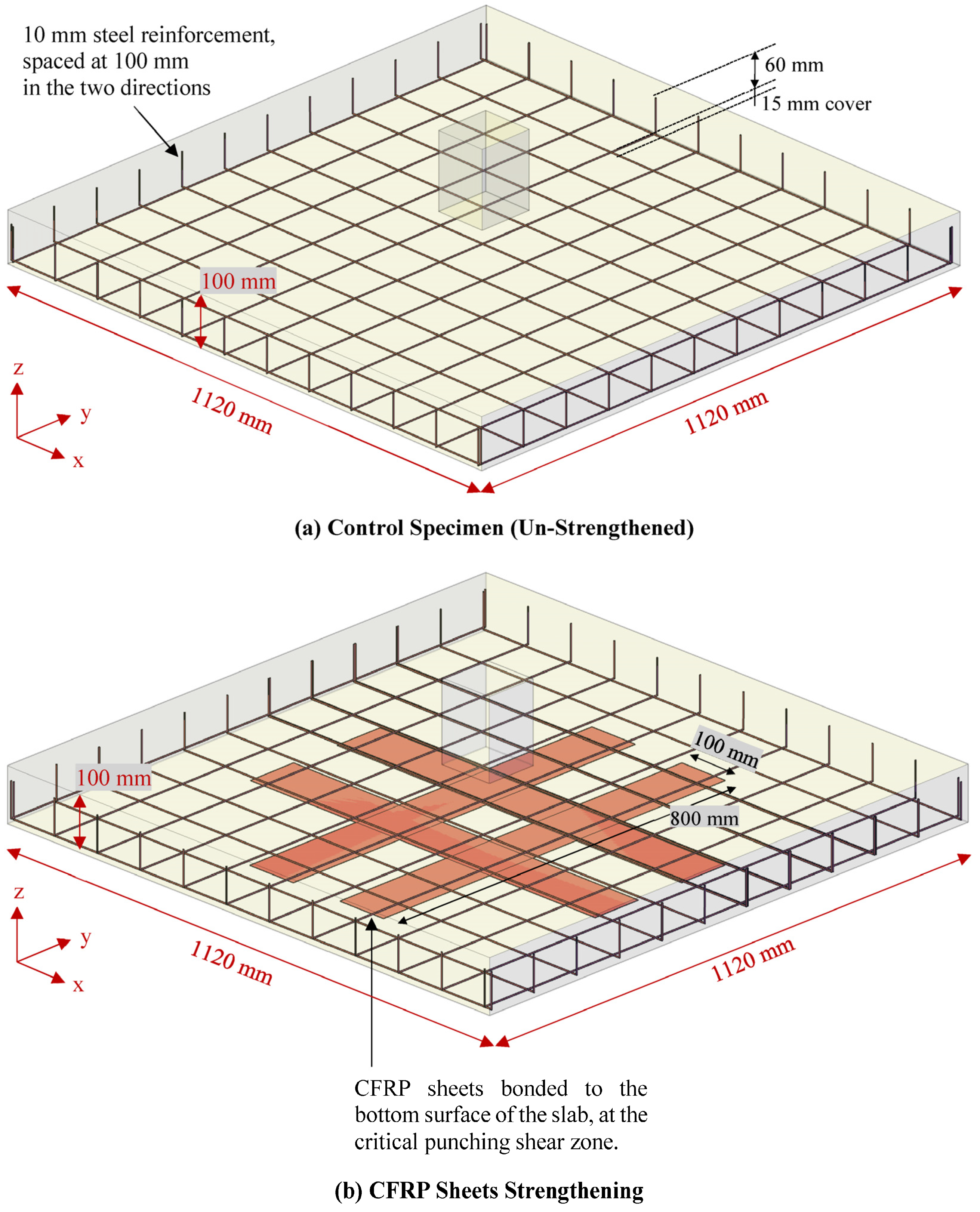

The experimental program consisted of ten lightweight aggregate reinforced concrete (LWARC) flat slabs, each measuring 1120 mm × 1120 mm with a thickness of 100 mm. A thickness of 100 mm was selected to ensure manageable specimen weight for laboratory testing while maintaining realistic structural behavior, as this value lies at the lower bound of slab thicknesses typically adopted in residential and light commercial construction (100–200 mm). The specimens were categorized based on the strengthening technique used: one control slab without any strengthening, one slab strengthened with surface-bonded CFRP sheet, and eight slabs strengthened using the ETS method. ETS reinforcement configurations varied by material type (steel or GFRP), bar diameter (6 mm or 10 mm), orientation (vertical or inclined at 45°), and bar spacing (0.6 d or 1.2 d, where d is the slab effective depth).

Table 2 and

Figure 4 summarizes the key parameters and test results of all specimens, including reinforcement configuration and spacing.

The ETS approach used in this study involves drilling vertical (90°) or inclined (45°) holes through the slab thickness at the designated reinforcement locations, as summarized in

Table 2. The holes were created using a rotary drilling machine with diameters slightly larger (by 2 mm) than the bar diameter to facilitate epoxy injection and bar insertion. After cleaning the holes of debris and dust with compressed air, a two-component structural epoxy resin was injected to ensure full bonding along the drilled length. GFRP or steel bars were then inserted into the holes to the full slab depth and anchored at both the top and bottom surfaces with additional epoxy capping to prevent slippage. The orientation of the ETS reinforcement (vertical or inclined at 45°) was carefully controlled using pre-marked templates to maintain accurate alignment.

For inclined ETS reinforcement, the bars were positioned diagonally to intersect the anticipated punching shear cracks at approximately 45°, providing more effective crack arrest and enhanced shear transfer compared to vertical bars. Close spacing (0.6 d) resulted in a denser reinforcement grid that intercepted more shear cracks, while wider spacing (1.2 d) reduced the effectiveness due to fewer crack intersections.

The strengthening mechanism of ETS-GFRP reinforcement relies on the ability of the embedded bars to bridge developing shear cracks and transfer tensile forces across the slab thickness. Unlike externally bonded CFRP sheets, which mainly restrict surface cracking, ETS bars engage directly with the internal shear planes, thereby increasing shear transfer, delaying crack propagation, and improving ductility. Although GFRP bars exhibit lower stiffness than steel, they are corrosion-resistant and lightweight, making them a suitable option in aggressive environments or where ease of handling is desired.

It is important to distinguish between ETS reinforcement used in strengthening (retrofitting) existing structures and ETS reinforcement incorporated during new construction. In strengthening applications, as performed in this study, holes are drilled post-construction and bars are installed with epoxy anchorage to enhance an already cast slab. In contrast, for new construction, ETS reinforcement may be cast integrally within the slab, eliminating the drilling process and allowing direct embedding of reinforcement during pouring. While the mechanical action of crack bridging remains similar, the strengthening process in existing slabs requires careful consideration of drilling layout, anchorage quality, and possible disruption to serviceability, whereas, in new construction, ETS can be incorporated more seamlessly as part of the reinforcement detailing.

2.3. Test Setup

All slab specimens were tested under controlled laboratory conditions to evaluate their punching shear behavior. A simply supported boundary condition was adopted, where each slab was supported along two opposite edges, allowing free rotation along the remaining two edges. This setup is commonly used in structural testing to simulate realistic support conditions encountered in building floor systems.

A concentrated load was applied at the center of each slab through a square steel plate measuring 150 mm × 150 mm, replicating column loading in flat slab systems. The load was applied gradually in small increments using a hydraulic actuator until failure occurred. Throughout the loading process, the specimens were carefully observed for the development of initial flexural cracks, subsequent propagation of radial and punching cracks, and the onset of failure. The complete loading arrangement and test configuration are shown in

Figure 5.

The vertical load was measured using the actuator’s in-line load cell (capacity ≥ the peak recorded test loads), connected to a digital controller and DAQ. The load cell and testing machine were calibrated/verified on a traceable basis prior to the series in accordance with accepted metrological practice (calibration of the force-measuring instrument per ASTM E74; force verification of the testing machine per ASTM E4). Central deflection was recorded using a linear variable differential transformer (LVDT) positioned beneath the loaded area. Signals were sampled at ≥10 Hz through the DAQ to generate continuous load–deflection histories. Final failure modes (punching cone, radial/shear cracking, and spalling) were photographed immediately after unloading.

3. Results and Discussions

This section presents and analyzes the experimental findings of the tested LWARC flat slabs, focusing on their punching shear behavior under concentric loading. The results are discussed in terms of crack patterns, failure modes, ultimate load capacities, and load–deflection responses. Particular attention is given to the influence of shear reinforcement spacing and configuration on slab performance. Finally, the experimentally measured punching shear strengths are compared with predictions from ECP 203-2023, ACI 318-19, and BS 8110-1997 to assess the accuracy and conservativeness of each code in evaluating both unstrengthened and FRP-strengthened LWARC slabs.

3.1. Crack Pattern and Mode of Failure

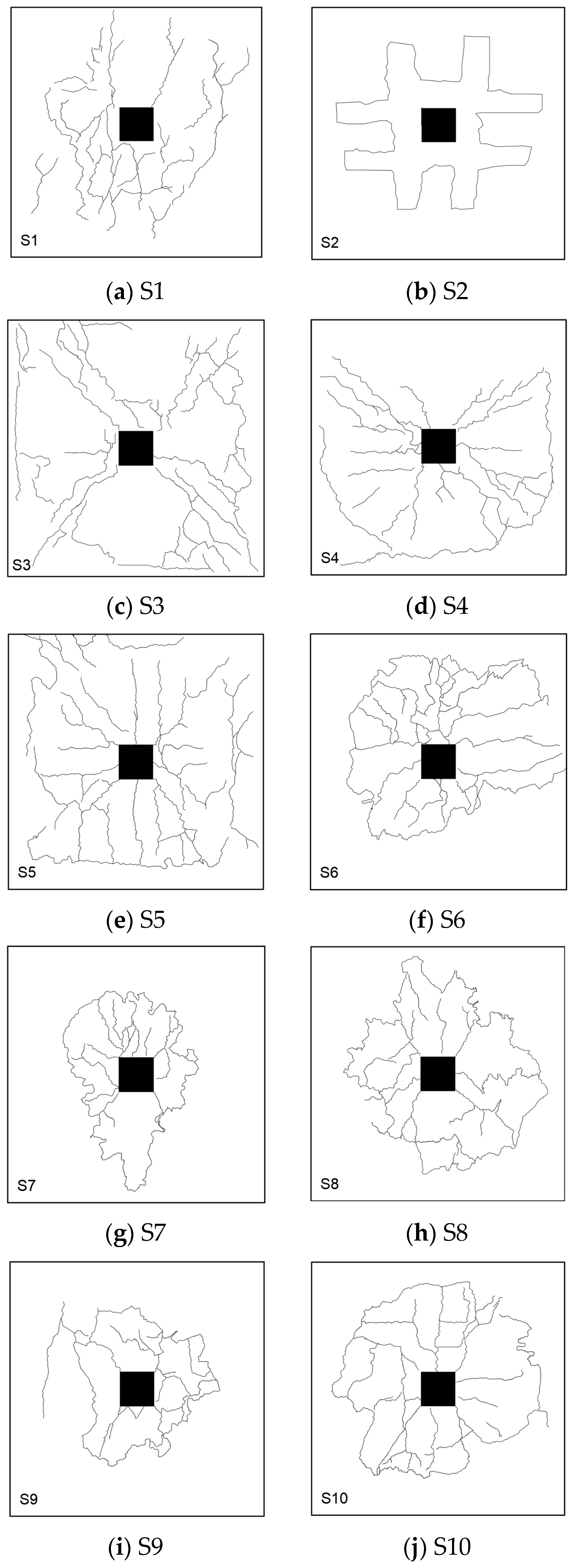

All slabs failed in punching shear, but crack patterns and severity varied with the strengthening technique, bar type, orientation, and spacing. Crack distribution at failure was documented to assess structural behavior (

Figure 6 and

Figure 7).

The control slab (S1) showed classic brittle punching failure with radial cracks and a pronounced conical surface, failing suddenly once concrete shear strength was exceeded. The CFRP-strengthened slab (S2) exhibited slightly narrower cracks due to the bonded sheet, but still failed in a brittle punching mode, indicating limited benefit.

Vertical GFRP bars (S3) arrested some crack propagation, producing more distributed damage and less abrupt failure than S1 and S2. Inclined GFRP bars (S4) further improved crack control, with diagonal cracks aligning with the reinforcement and a more ductile response. Vertical steel bars (S5) bridged cracks effectively and delayed failure, though the failure remained primarily punching in nature.

With wider spacing, vertical GFRP bars (S6) produced fewer, wider cracks and more localized failure, while inclined GFRP bars (S7) offered better crack interception but reduced ductility compared to S4. Inclined steel bars at wider spacing (S8) gave the most favorable pattern of fine, numerous, and well-distributed cracks with clear signs of energy dissipation.

Inclined GFRP bars of smaller diameter (S9, Ø6 mm close spacing) provided moderate control but allowed wider cracks than S4 due to reduced bar area. At wider spacing (S10), cracks were wide and concentrated near the load, showing insufficient reinforcement engagement and limited punching resistance.

The effectiveness of CFRP sheets and ETS-GFRP reinforcement stems from different strengthening mechanisms. CFRP sheets bonded to the slab’s tension face primarily act to restrict crack widths, enhance tensile stress redistribution, and delay the initiation of punching cracks. Their performance, however, is governed by the quality of surface preparation and the long-term durability of the epoxy adhesive layer. In contrast, ETS-GFRP reinforcement operates through a direct mechanical action. Once cracks form, the embedded bars bridge the shear planes across the slab thickness, transferring tensile forces and improving confinement around the punching cone. This mechanism is less dependent on surface bonding conditions and more directly engages with the internal shear transfer path.

The observed trends highlight the role of reinforcement orientation and spacing in controlling punching shear. Inclined bars, oriented at ~45°, intersect potential shear cones more directly than vertical bars, creating a truss-like action that bridges diagonal cracks and enhances shear transfer across the slab thickness. This explains the improved ductility and more distributed cracking in specimens S4, S7, S8, and S9 compared to their vertically reinforced counterparts.

Reinforcement spacing also proved critical. Close spacing provided a denser grid of crack intercepts, limiting crack widths and delaying the formation of a dominant punching cone. Conversely, wider spacing (S6, S7, S10) reduced the number of intercepts, allowing larger localized crack openings and promoting more brittle failure. Together, these mechanisms demonstrate that both inclination and density of ETS reinforcement strongly influence crack propagation, energy dissipation, and the overall punching shear resistance.

3.2. Ultimate Load Capacity of Slabs

The experimental results of the ten tested LWARC slabs under concentric punching loads revealed a wide variation in ultimate load capacity depending on the strengthening technique, reinforcement type, diameter, orientation, and spacing. The unstrengthened control slab (S1) failed at a load of 182.5 kN, establishing a baseline for comparison. The slab strengthened with CFRP sheet (S2) reached a capacity of 183.7 kN, which corresponds to a marginal increase in only 0.7%. This minimal improvement reflects the limited effectiveness of surface CFRP in enhancing punching shear resistance, as it does not engage directly with internal shear planes.

Significant enhancements were observed in the ETS-strengthened specimens. S3, which used vertical GFRP bars with a diameter of 10 mm and a spacing of 0.6 d, achieved a failure load of 205.4 kN, translating to a 12.5% improvement over S1. When the same configuration was implemented using steel bars in S5, the failure load increased further to 259.0 kN, representing a 41.9% improvement. This notable difference confirms that steel, due to its higher stiffness and tensile strength, is more effective in resisting punching shear forces than GFRP when placed vertically.

The use of inclined reinforcement proved particularly beneficial. S4, which incorporated inclined GFRP bars (Ø10 mm at 0.6 d spacing), failed at 251.4 kN, marking a 37.8% increase over the control and nearly matching the performance of S5. Similarly, S8, which used inclined steel bars (Ø10 mm at 1.2 d spacing), reached 250.4 kN. This result indicates that, even with increased spacing, the mechanical advantages of steel contributed to substantial capacity enhancement, reaching 37.2% over S1.

Increasing the ETS bar spacing to 1.2 d had a clear detrimental effect on capacity. S6, which used vertical GFRP bars with the wider spacing, achieved only 191.3 kN, a modest 4.8% increase compared to S3’s 12.5% gain. S7, which utilized inclined GFRP bars at the same wider spacing, reached 235.0 kN, demonstrating a noticeable reduction compared to the 251.4 kN observed in S4 with closer spacing. A similar trend was observed for smaller diameter bars. S9, which used inclined GFRP bars (Ø6 mm) at 0.6 d spacing, reached 206.0 kN, yielding a 12.8% increase over the control. However, S10, which had the same reinforcement spaced at 1.2 d, failed at 189.8 kN, offering only a 4.0% improvement over S1. These findings confirm that bar spacing and diameter both significantly influence punching capacity, and that inclined orientation consistently performs better than vertical.

Table 3 summarizes the ultimate failure loads and corresponding percentage increases relative to the control slab (S1) for all tested specimens.

3.3. Load–Deflection Behavior

The load–deflection behavior of the tested slabs provided additional insight into the structural response under increasing shear demand.

Table 4 presents the peak deflection and toughness values for all tested specimens, highlighting the variation in deformation capacity and energy absorption across different reinforcement configurations.

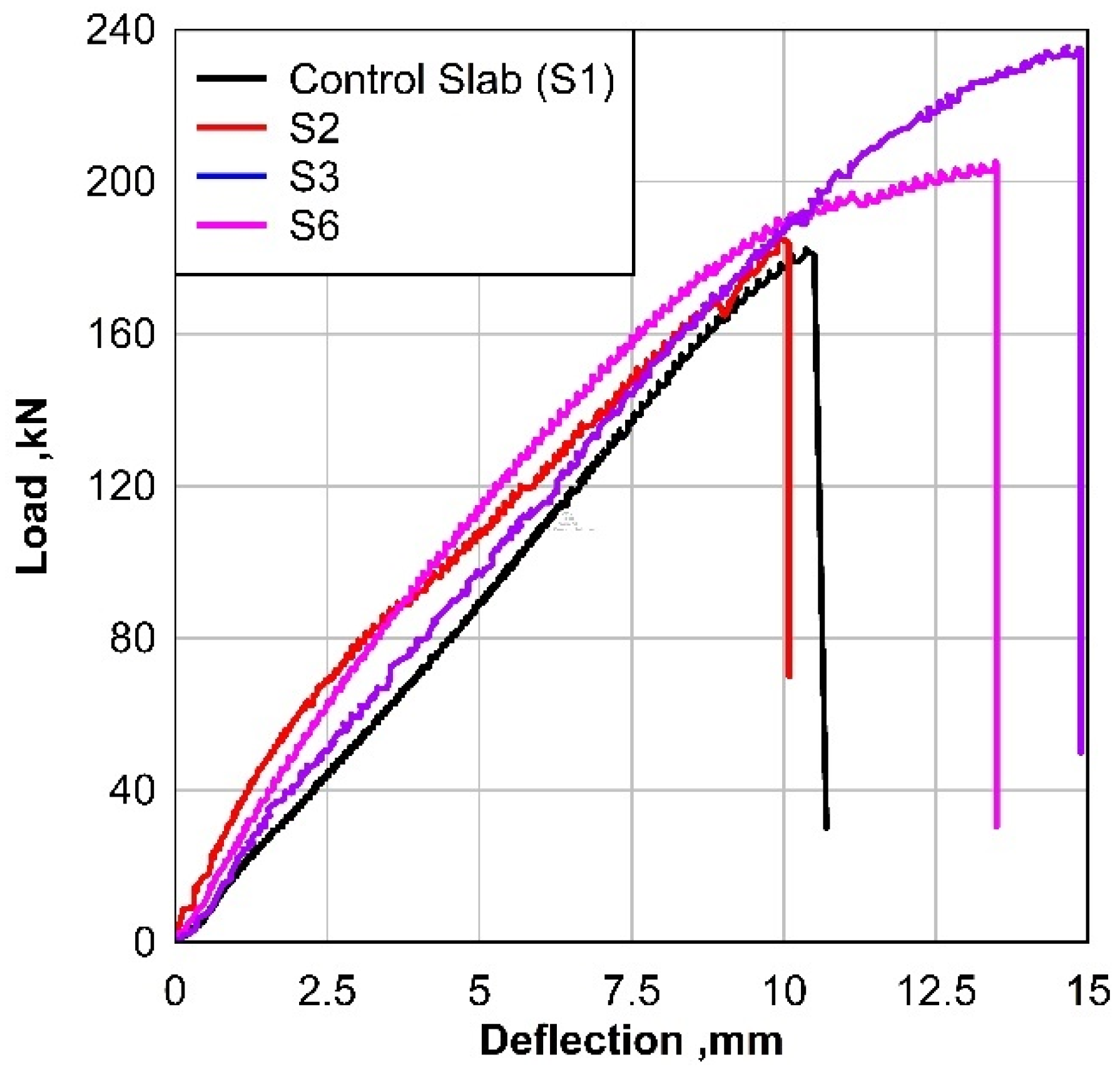

The control specimen (S1) demonstrated a brittle response with a sharp load drop following peak capacity. S2, which was strengthened with CFRP sheet, exhibited a response nearly identical to S1, confirming the minimal influence of surface-bonded CFRP on stiffness or ductility.

In

Figure 8, the responses of slabs S3 and S6 were compared with the control slab S1. S3, containing vertical GFRP bars at 0.6 d spacing, showed an improved peak load and slightly more ductile behavior than S1, with a maximum deflection of 13.5 mm compared to 10.7 mm for the control—an increase in approximately 26.2%. It also exhibited a toughness of 1592 kN·mm, which is 46.5% higher than the control slab’s toughness of 1087 kN·mm, indicating significantly improved energy absorption. In contrast, S6, which had the same reinforcement but at a wider spacing of 1.2 d, exhibited a reduced peak load and a maximum deflection of 14.88 mm. Although its deflection was about 39.1% higher than S1, its toughness was only 2000 kN·mm, representing an 83.9% increase over the control, but it remained lower than S3. This result highlights that increasing bar spacing can reduce structural efficiency and crack control despite slightly higher deformation capacity and confirms that tighter reinforcement spacing improves both strength and energy dissipation.

Figure 9 compares S3 and S5, both with vertical reinforcement but different materials. S5, containing steel bars, exhibited higher load capacity and greater stiffness due to the superior tensile strength and modulus of elasticity of steel. It reached a maximum deflection of 17.4 mm compared to 13.5 mm for S3—an increase in approximately 28.9%, reflecting enhanced deformation capacity. In terms of toughness, S5 achieved 2586 kN·mm, which is 62.5% higher than the 1592 kN·mm recorded for S3. This substantial increase in energy absorption highlights the effectiveness of steel reinforcement in enhancing both strength and toughness compared to GFRP under vertical shear reinforcement conditions.

Figure 10 illustrates the effect of bar spacing in inclined configurations by comparing S4 and S7. S4, with closely spaced inclined GFRP bars at 0.6 d spacing, achieved a higher load and a maximum deflection of 18.13 mm. In contrast, S7, which used the same bars at wider spacing (1.2 d), exhibited a reduced load capacity and a lower deflection of 13.8 mm, a decrease in approximately 23.9% compared to S4. In terms of toughness, S4 reached 2621 kN·mm, while S7 recorded 1518 kN·mm—indicating a 42.1% reduction. This comparison confirms that closer spacing not only enhances crack arrest and stress redistribution but also significantly improves the slab’s energy absorption and overall performance under punching shear.

Figure 11 focuses on the effect of bar diameter by comparing S4 (Ø10 mm) and S9 (Ø6 mm), both reinforced with inclined GFRP bars at 0.6 d spacing. S4 exhibited a higher load capacity and reached a maximum deflection of 18.13 mm, while S9 showed a lower peak load and a deflection of 11.97 mm—a 33.9% reduction. In terms of toughness, S4 recorded 2621 kN·mm, compared to 1418 kN·mm for S9, reflecting a 45.9% decrease. These results highlight that reducing bar diameter significantly limits shear engagement, energy absorption, and deformation capacity in inclined reinforcement configurations.

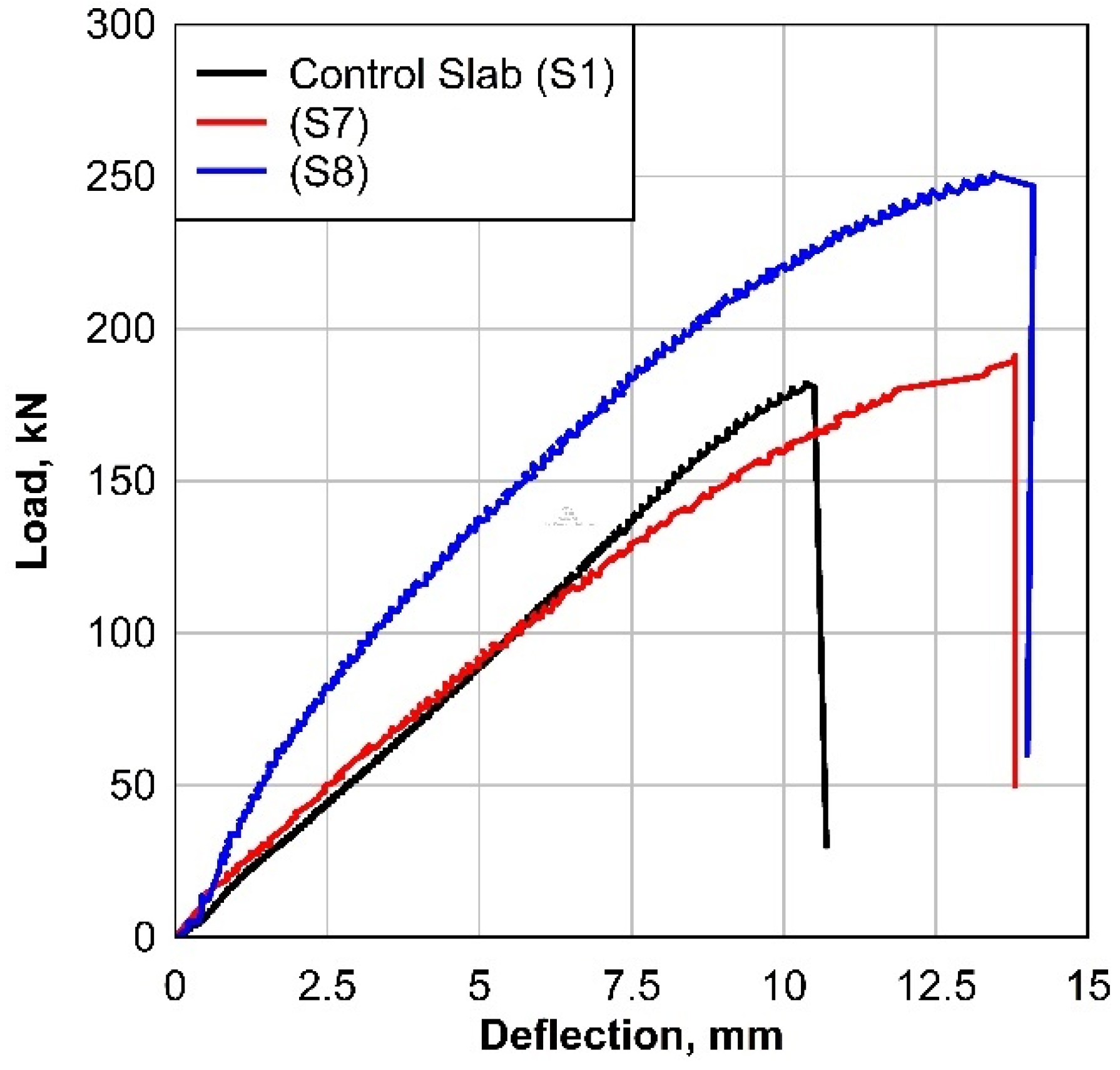

In

Figure 12, inclined steel bars in S8 were compared to inclined GFRP bars in S7, both at 1.2 d spacing. S8 reached a higher load and recorded a maximum deflection of 14.0 mm compared to 13.8 mm for S7, an increase in approximately 1.4%. Although the difference in deflection was small, the toughness of S8 was 1941 kN·mm compared to 1518 kN·mm for S7, reflecting a 27.8% increase. This significant gain in energy absorption, coupled with the higher load capacity, underscores the material advantage of steel over GFRP in resisting punching shear under similar reinforcement layouts.

Lastly,

Figure 13 compares S9 and S10 to examine the effect of bar spacing for the same small-diameter inclined GFRP bars (Ø6 mm). S9, with 0.6 d spacing, reached a maximum deflection of 11.97 mm, while S10, with wider 1.2 d spacing, reached 13.94 mm, a 16.4% increase. Despite the higher deflection, S10 failed at a lower load and exhibited reduced energy absorption, with a toughness of 1526 kN·mm compared to 1418 kN·mm for S9, a difference in just 7.6%. This minimal toughness gain, paired with reduced strength, indicates that wider spacing compromises shear resistance and structural reliability. These results confirm that closely spaced reinforcement enhances both load capacity and energy absorption, even when using smaller-diameter bars.

Across all configurations, the inclusion of ETS bars significantly enhanced the structural performance compared to the unstrengthened control slab. The experimental results clearly demonstrate that the most effective outcomes were achieved using inclined steel reinforcement or closely spaced GFRP bars. Bar spacing and diameter had a substantial impact on both load capacity and ductility, while the choice of reinforcement material played a critical role in determining the overall punching shear resistance. These findings highlight the importance of optimizing reinforcement configuration to achieve both strength and deformation control in lightweight concrete slabs subjected to punching loads.

Compared to CFRP sheets bonded on the tension face, ETS reinforcement directly engages the slab thickness and acts along the shear transfer path. Once cracks initiate, ETS bars bridge them and provide additional tensile capacity across the shear planes, enhancing aggregate interlock and restraining crack widening. This mechanism improves post-cracking stiffness, delays sudden strength loss, and increases the energy absorption capacity of the slabs. The combined action of epoxy anchorage and bar embedment also enables better stress redistribution around the column–slab interface, reducing stress concentrations and promoting a more ductile response. As a result, ETS strengthening transforms the load–deflection behavior from brittle, abrupt failure (as seen in the control and CFRP slabs) to a more gradual, resilient performance.

It is important to note that the mechanical response of LWARC-incorporating polystyrene foam can be influenced by the variability in foam properties such as density and bond strength. The very low density of polystyrene reduces the unit weight of the mix, but even small deviations in foam density may significantly alter the concrete’s overall strength and stiffness. In addition, the weak interfacial bond between polystyrene particles and the cementitious matrix introduces uncertainty in crack initiation and shear transfer, which can affect the reproducibility of experimental results. This variability was evident in the differences in ultimate load and ductility across specimens, where slabs with similar reinforcement layouts exhibited slightly different failure modes and deflection responses. To minimize these effects, the mix design in this study included polypropylene microfibers and superplasticizers to enhance the bond quality and improve consistency. Nevertheless, the inherent heterogeneity of polystyrene-based LWARC remains a factor influencing mechanical variability, and future research should focus on systematic characterization of foam properties to better standardize performance outcomes.

3.4. Effect of Shear Reinforcement Spacing

The spacing of shear reinforcement was one of the key variables studied in this experimental program, and its influence on punching shear capacity was clearly demonstrated. Three specimen pairs were evaluated to isolate the effect of bar spacing: S3 vs. S6 (vertical GFRP bars), S4 vs. S7 (inclined GFRP bars, Ø10 mm), and S9 vs. S10 (inclined GFRP bars, Ø6 mm). In each pair, the only parameter changed was the spacing between bars—0.6 d for the first specimen and 1.2 d for the second—allowing direct assessment of how reinforcement density affects performance.

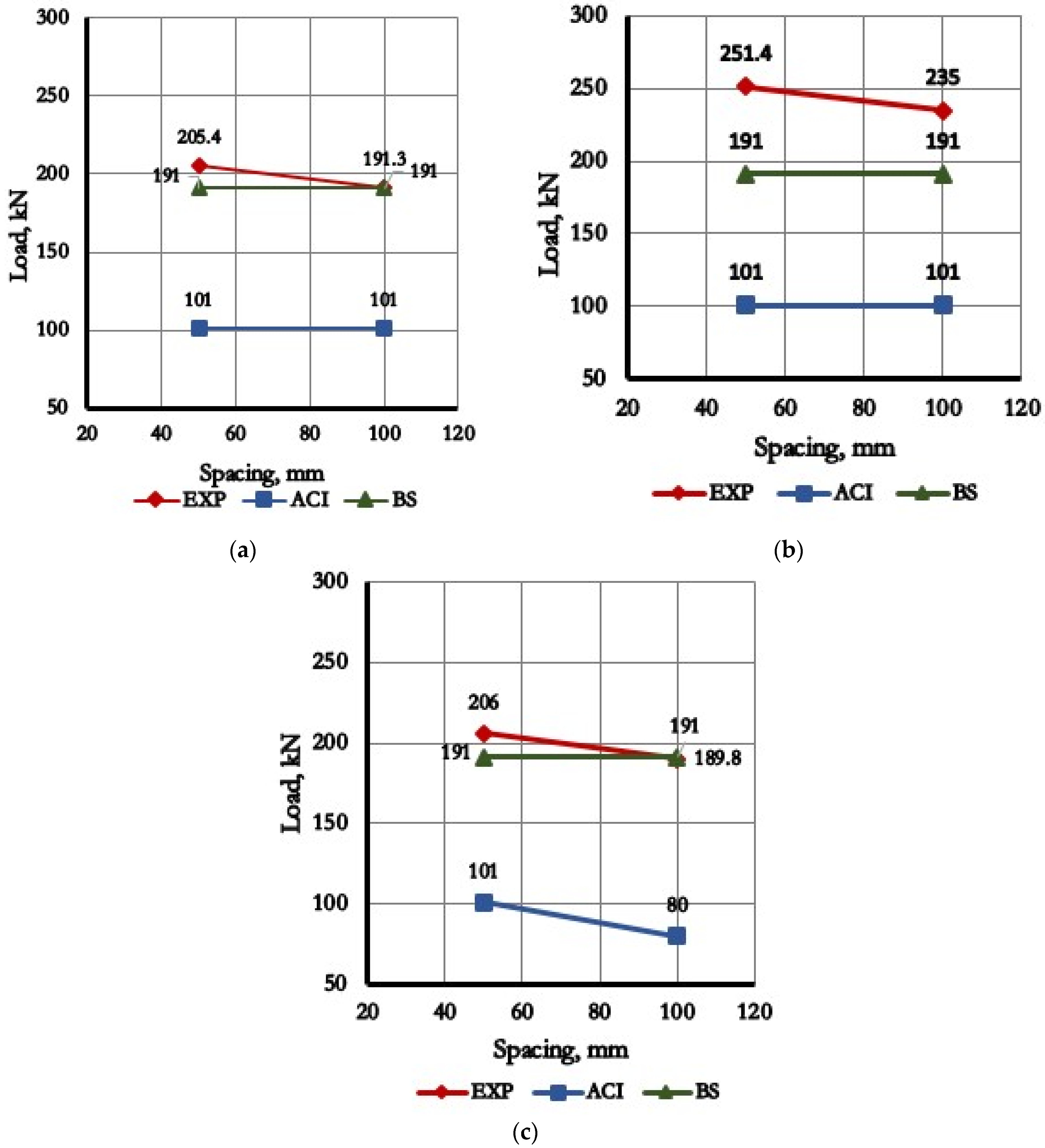

In the vertical GFRP group (S3 and S6), reducing the spacing from 1.2 d to 0.6 d increased the punching shear capacity from 191.3 kN (S6) to 205.4 kN (S3), representing a 7.4% improvement. This increase confirms that tighter spacing improves shear force transfer and enhances slab confinement. As shown in

Figure 14a, experimental values were consistently higher than both ACI 318 and BS 8110 predictions, with experimental-to-code ratios improving as spacing decreased.

In the inclined GFRP group with Ø10 mm bars (S4 and S7), the difference was more pronounced. S4, with bars at 0.6 d, achieved a load of 251.4 kN, while S7, spaced at 1.2 d, reached only 235.0 kN. This reflects a 6.5% reduction in capacity due solely to increased spacing. Notably, both values remained well above ACI predictions (101 kN) and marginally above BS predictions (191 kN), as illustrated in

Figure 14b. The inclined orientation likely provided better alignment with the principal shear cracks, enhancing the spacing effect.

For the Ø6 mm inclined GFRP bars (S9 and S10), spacing had an even greater impact. S9, spaced at 0.6 d, resisted up to 206.0 kN, while S10, with wider spacing at 1.2 d, failed at 189.8 kN—a 7.9% reduction in capacity. Interestingly, ACI predictions dropped from 101 kN to 80 kN for wider spacing, underestimating both results. BS predictions remained flat at 191 kN across both configurations, as shown in

Figure 14c, indicating its insensitivity to bar spacing changes.

Across all spacing comparisons, the experimental results confirmed a consistent trend: decreasing the spacing of ETS reinforcement significantly improves punching shear resistance, regardless of bar diameter or orientation. The magnitude of improvement ranged from 6.5% to 7.9%, depending on the configuration, and all experimental values exceeded code-based predictions. These results suggest that current design codes may be overly conservative or insufficiently sensitive to reinforcement spacing in LWARC slabs. Therefore, careful consideration of spacing should be integrated into the design of ETS-strengthened slabs to achieve optimal performance.

3.5. Durability and Long-Term Effects

Although the present study concentrated on the punching shear response of LWARC slabs, long-term durability issues warrant careful consideration. Lightweight aggregate concretes typically exhibit higher creep and shrinkage strains than normal-weight concretes due to their more porous aggregate structure. Excessive creep and shrinkage may alter stress redistribution around slab–column connections and influence crack development over time.

For FRP reinforcement, durability is strongly influenced by the bond between the bar or sheet and the surrounding matrix. Epoxy-bonded systems are susceptible to degradation under sustained loading, elevated temperature, moisture, or alkaline environments, which can reduce bond strength and stiffness. ETS-GFRP reinforcement also relies on epoxy anchorage, and long-term creep of the resin could reduce its crack-bridging efficiency. In contrast, steel ETS reinforcement provides higher stiffness but may be vulnerable to corrosion if not adequately protected. Environmental exposure (freeze–thaw cycles, chloride ingress, and thermal variations) can further affect both the LWARC matrix and the FRP systems.

These considerations suggest that while ETS strengthening significantly improves short-term punching shear resistance, its long-term effectiveness depends on the combined interaction of creep, shrinkage, and durability factors. Future work should include sustained-load testing, environmental conditioning, and extended monitoring to establish reliable design recommendations for service-life performance.

4. Shear Strength According to Design Codes

To evaluate the performance of design standards, the punching shear capacities of the tested LWARC slabs were compared with predictions from three international codes: ECP 203-2023, ACI 318-19, and BS 8110-1997. The main formulations used are summarized in

Table 5, while the corresponding shear perimeters are shown in

Figure 15.

Table 6 and

Table 7 present the comparison between experimental results and code predictions. For the control specimen (S1), ECP, ACI, and BS predicted ultimate loads of 95 kN, 66 kN, and 124 kN, respectively, while the actual load was 182.5 kN. The ACI prediction was the most conservative, underestimating the experimental value by 63.8%, followed by ECP (47.9%) and BS (32.0%). Similar trends were observed for the CFRP-strengthened slab (S2), where the experimental load was 183.7 kN, yet ACI still underestimated by 64.1%, ECP by 48.3%, and BS by 29.2%.

For the ETS-strengthened slabs (S3 to S10), experimental values consistently exceeded ACI and BS predictions. For example, S4 (inclined GFRP, ø10 mm) had an experimental capacity of 251.4 kN, compared to 101 kN (ACI) and 191 kN (BS), resulting in underestimations of 59.8% and 24.0%, respectively. S5 (vertical steel bars, ø10 mm) showed a similar pattern: ACI and BS predictions fell short by 60.9% and 26.3%, respectively.

In specimens with wider bar spacing (S6, S7, S10), the difference remained considerable. For instance, S6 failed at 191.3 kN, while ACI and BS predicted 101 kN and 191 kN—showing good agreement with BS (0.2% difference) but a 47.2% underestimation by ACI. The smallest diameter bars (S9 and S10) also showed notable gaps. S9 (ø6 mm inclined GFRP) reached 206.0 kN compared to 101 kN (ACI) and 191 kN (BS), and S10 failed at 189.8 kN compared to just 80 kN from ACI and 191 kN from BS.

Looking at the shear strength ratios (Vexp/Vcode), the ACI code showed an average underestimation of 58% across all applicable specimens (average Vexp/VACI = 2.37), while the BS code had a smaller deviation (average Vexp/VBS = 1.22). ECP values were available only for selected specimens but similarly underestimated punching capacity (average Vexp/VECP = 1.90). Overall, the ACI code proved to be the most conservative, often underpredicting experimental strength by more than 60%, while BS 8110 yielded results closest to the observed values.

Within the limitations of our test matrix (ten specimens covering one geometry, one LWA mixture, and selected ETS/CFRP configurations), the ACI 318-19 and ECP 203-2023 equations tended to be conservative relative to our measurements, while BS 8110 was closer on average for the present LWARC slabs and loading arrangement. These observations should be viewed as indicative rather than definitive, because code provisions are calibrated to broad datasets and boundary conditions that exceed the scope of the current series. Consequently, extending these trends to other slab geometries, reinforcement ratios, or lightweight mixes, require caution and preferably a larger database or meta-analysis. We, therefore, regard our code comparison as informative for the studied configurations, and complementary to prior LWAC/LWARC punching studies, rather than a basis for re-calibration.

5. Conclusions

This study experimentally investigated the punching shear strengthening of Lightweight Aggregate Reinforced Concrete (LWARC) flat slabs using different Fiber-Reinforced Polymer (FRP) and steel reinforcement configurations. Ten full-scale slab specimens were tested under concentric punching loads, including a control specimen and nine strengthened using externally bonded CFRP sheets or Embedded Through-Section (ETS) GFRP and steel bars. The study evaluated the effects of reinforcement material, bar diameter, spacing, and orientation on punching shear capacity, deformation behavior, and energy absorption. Experimental results were compared with predictions from ECP 203-2023, ACI 318-19, and BS 8110-1997 to assess code applicability. Based on the findings, the following conclusions are drawn: The use of ETS reinforcement significantly enhanced punching shear performance. The highest increase in ultimate capacity was achieved by the slab with vertical steel bars (S5), showing a 41.9% improvement over the control:

Inclined GFRP bars with close spacing (S4) also performed well, with a 37.8% increase in load capacity and the highest toughness value of 2621 kN·mm among all specimens.

Increasing bar spacing from 0.6 d to 1.2 d reduced punching capacity by up to 7.9%, depending on reinforcement type and diameter, and reduced toughness by up to 42.1% in inclined configurations.

Reducing the bar diameter from 10 mm to 6 mm (S4 vs. S9) resulted in a 45.9% decrease in toughness and 33.9% lower peak deflection, confirming that bar size has a direct impact on shear engagement and energy dissipation.

CFRP sheet strengthening (S2) offered only a marginal improvement of 0.7% in capacity and showed almost identical behavior to the control in both load and deflection.

In terms of ductility, the most deformable specimen was S4 (18.13 mm peak deflection), while the least deformable was S2 (10.09 mm), reinforcing the benefit of embedded inclined reinforcement.

The ACI 318-19 code consistently underestimated the experimental punching shear strength by an average of 58%, while the BS 8110-1997 code was more accurate, with an average deviation of 22%. The ECP 203-2023 predictions were also conservative, underestimating strength by an average of 47% for applicable cases.

The results support the use of embedded FRP or steel reinforcement, especially in inclined orientations with tight spacing, as a highly effective strategy to improve punching shear resistance in LWARC slabs.

While both CFRP sheets and ETS-GFRP bars rely on epoxy resin either for bonding or anchorage, alternative approaches such as Textile Reinforced Concrete (TRC) have been developed to overcome this limitation. In TRC systems, continuous carbon, glass, or polymer fibers are arranged within a fine cementitious matrix, enabling crack control and stress transfer without the need for resin bonding. Recent studies have demonstrated promising performance of TRC shells in bond with PVC tubes [

28] and the flexural response of Carbon Fiber TRC sheets with short AR-glass fibers [

29], highlighting TRC as a sustainable and durable alternative to epoxy-bonded FRP systems. Future research may integrate TRC concepts into LWARC slab strengthening, potentially eliminating adhesive-related durability concerns.

Limitations and Reproducibility: The present study tested one specimen per configuration, which restricts the statistical generalizability of the results. Nonetheless, the systematic variation in reinforcement type, orientation, spacing, and diameter produced consistent behavioral trends that strengthen confidence in the observed mechanisms. These results provide valuable reference data and highlight promising configurations for ETS reinforcement in LWARC slabs. Future research should include multiple replicates per configuration, combined with numerical simulations or probabilistic analyses, to better quantify variability and ensure reproducibility for design applications.