Exploitation of Plastic and Olive Solid Wastes for Accelerating the Biodegradation Process of Plastic

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Sampling

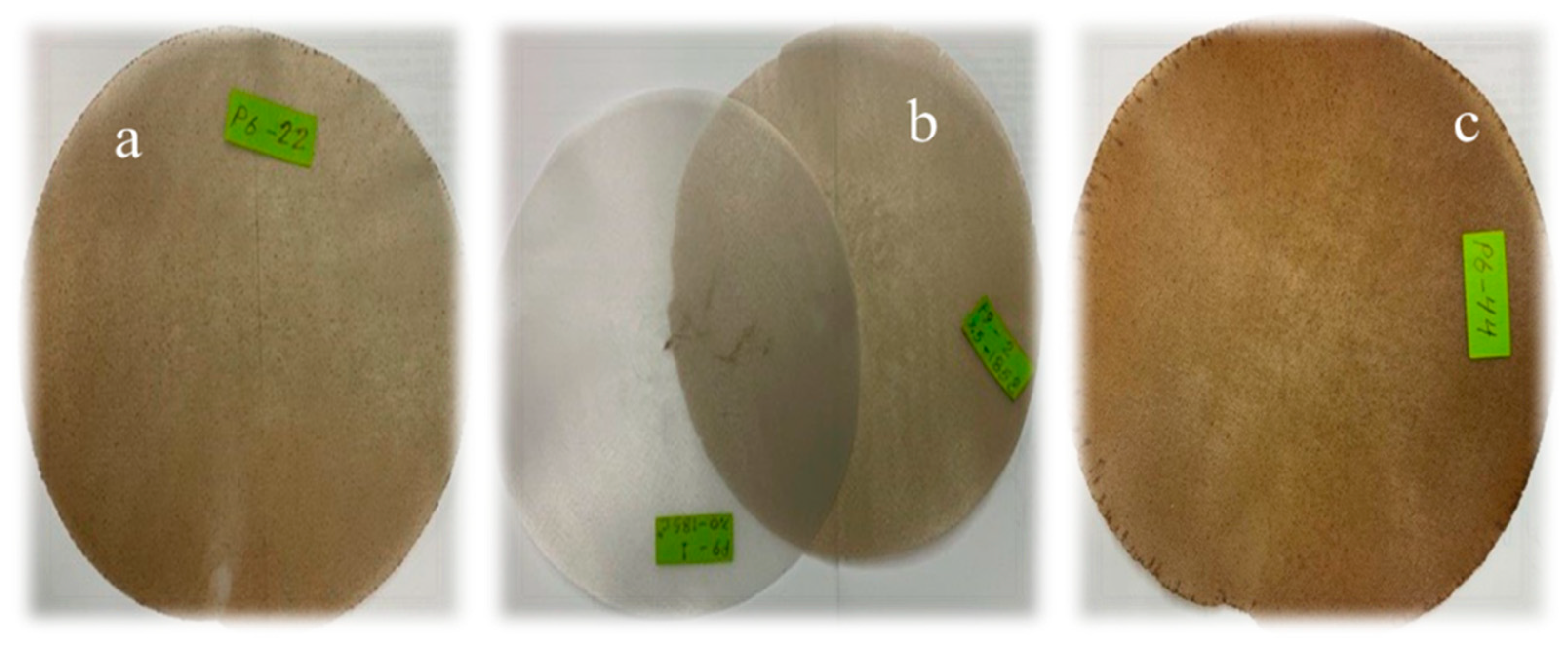

2.2. Preparation of Composite Films

2.3. Analytical Testing

2.3.1. Density

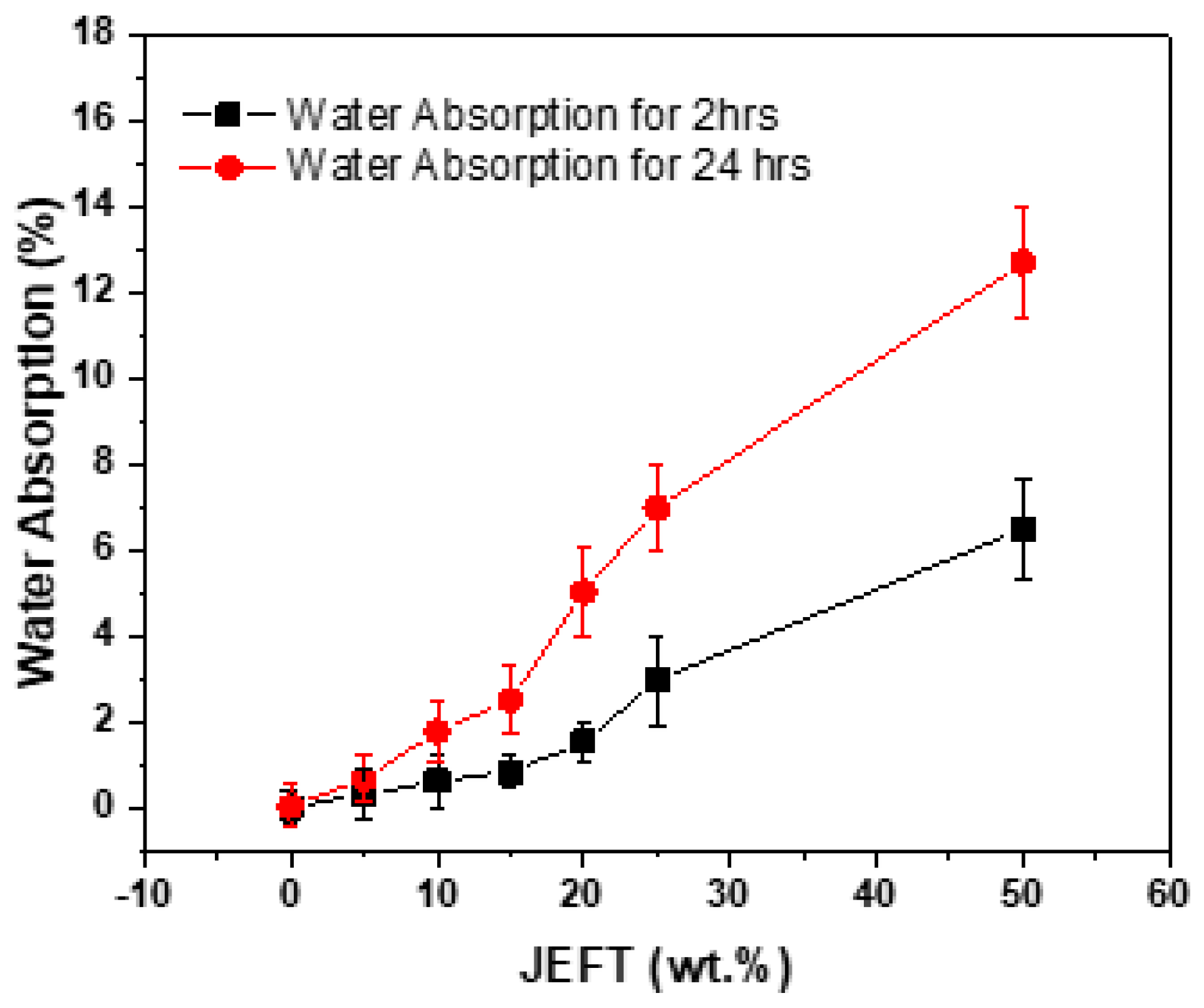

2.3.2. Water Absorption

2.3.3. Tensile Test

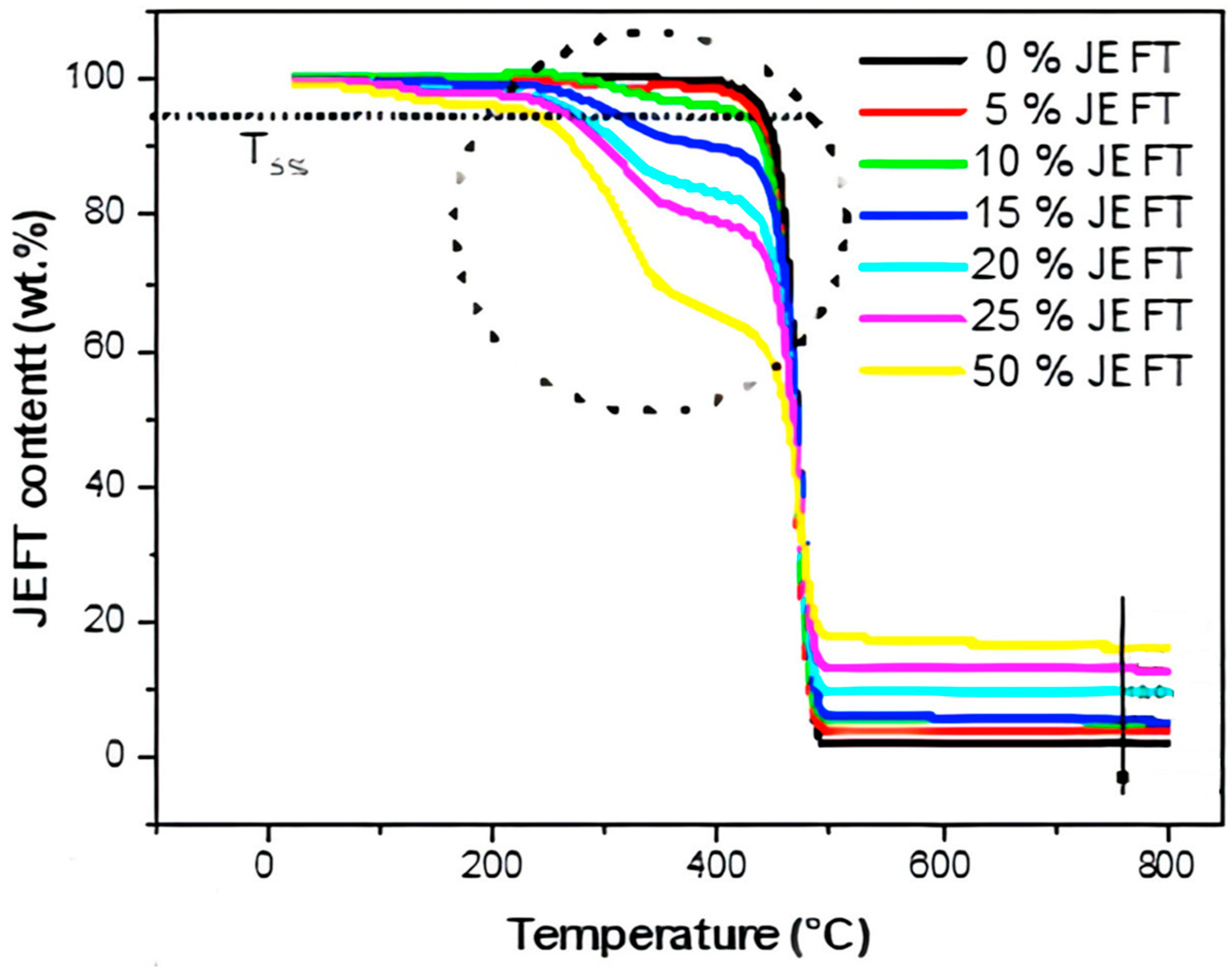

2.3.4. Thermal Characterization

2.3.5. Permeability Test

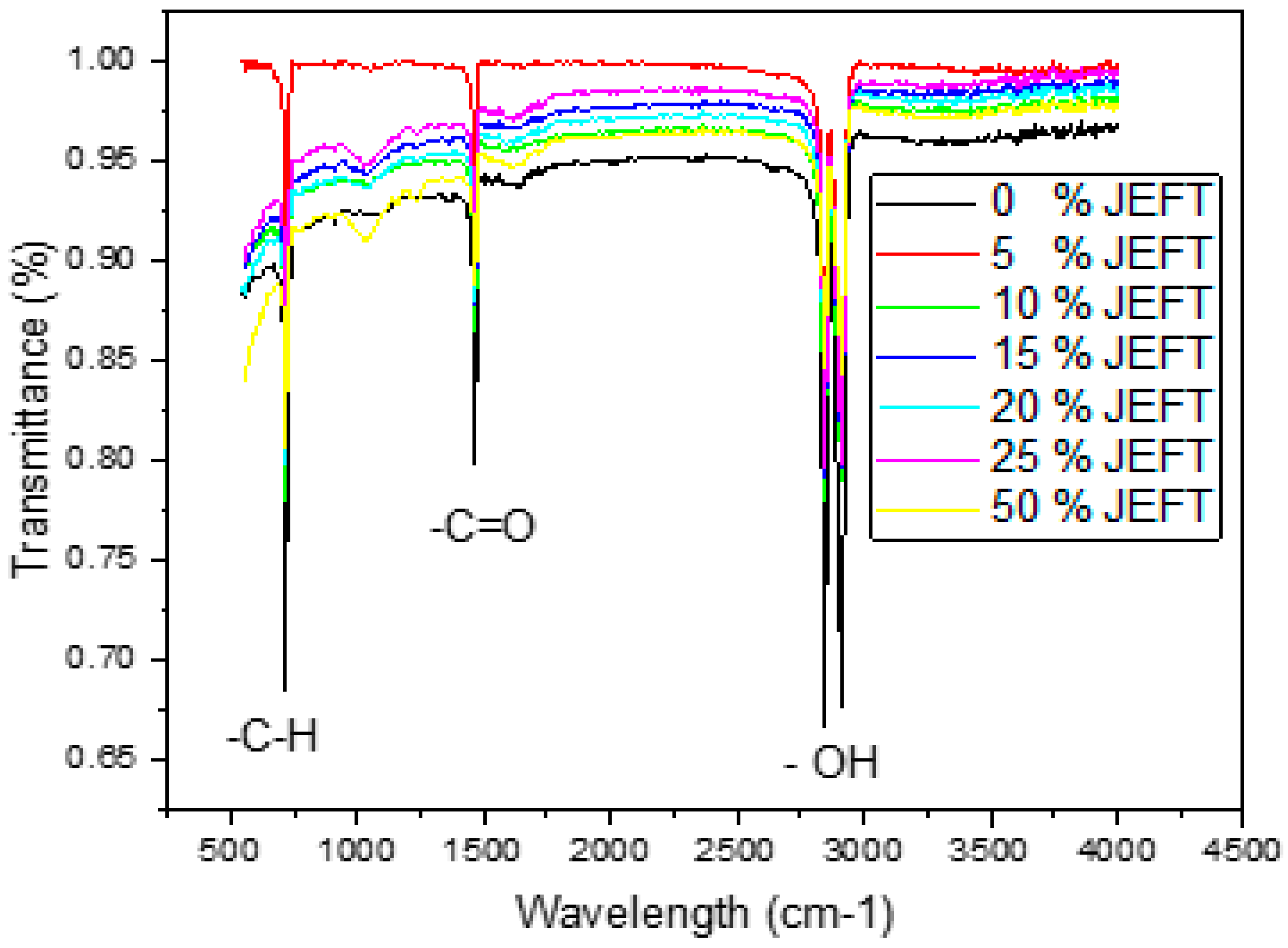

2.3.6. Functional Group Characterization

2.3.7. Biodegradation Investigation

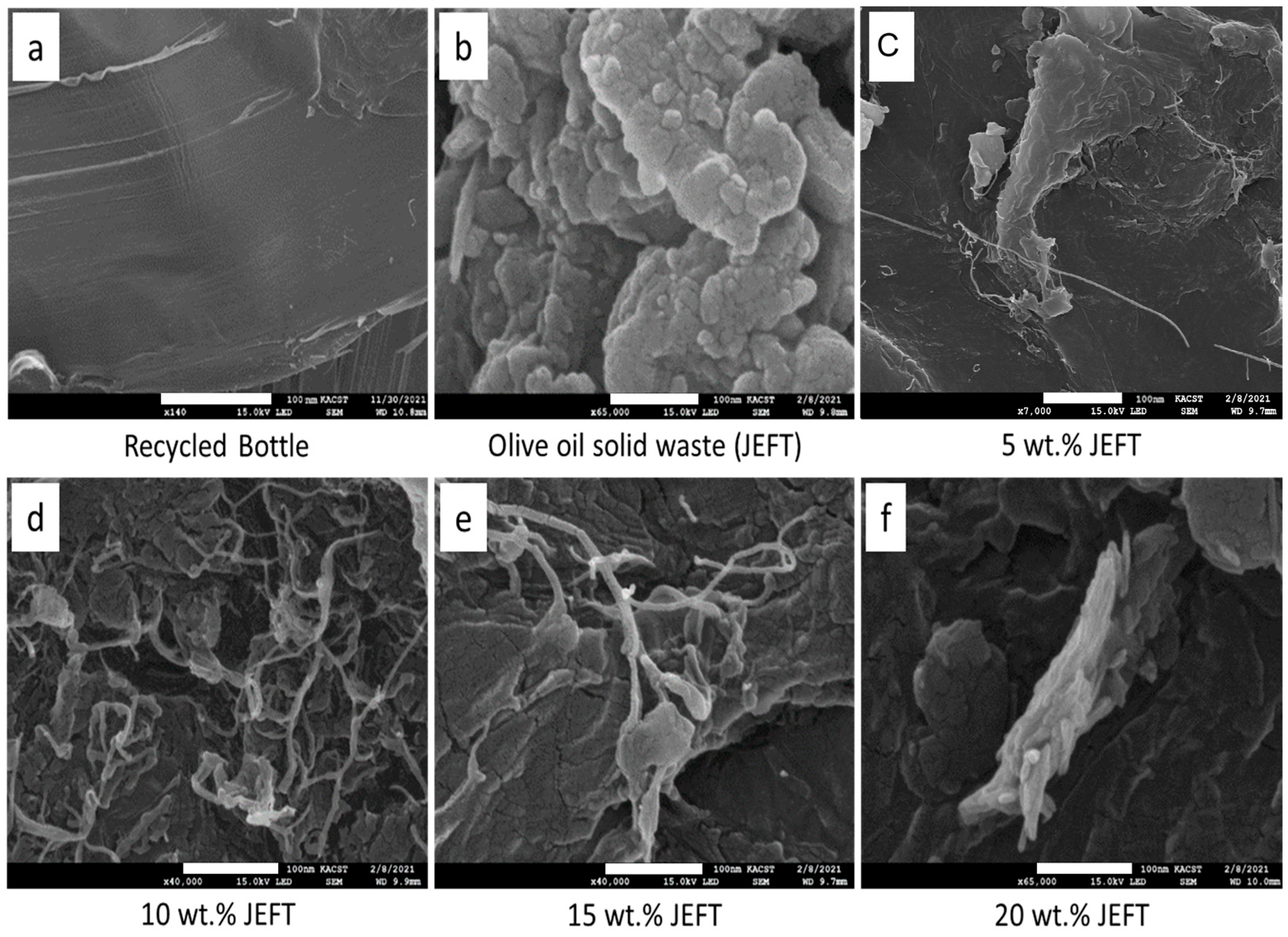

2.3.8. Scanning Electron Microscopy (SEM)

3. Results and Discussions

3.1. Density Measurements

3.2. Moisture Content Behaviors

3.3. Tensile Properties

3.4. Thermal Properties

3.5. Permeability Results

3.6. Functional Group Analysis

3.7. Biodegradation Analysis

3.8. Morphology Observation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mili, S.; Bouhaddane, M. Forecasting Global Developments and Challenges in Olive Oil Supply and Demand: A Delphi Survey from Spain. Agriculture 2021, 11, 191. [Google Scholar] [CrossRef]

- Hung, Y.-T.; Kolla, S.N.; Paul, H.H.; Huhnke, C.R. Olive oil waste treatment: A review. World J. Adv. Res. Rev. 2024, 23, 1791–1795. [Google Scholar] [CrossRef]

- Akay, F.; Kazan, A.; Celiktas, M.S.; Yesil-Celiktas, O. A holistic engineering approach for utilization of olive pomace. J. Supercrit. Fluids 2015, 99, 1–7. [Google Scholar] [CrossRef]

- Ouazzane, H.; Laajine, F.; El Yamani, M.; El Hilaly, J.; Rharrabti, Y.; Amarouch, M.; Mazouzi, D. Olive mill solid waste characterization and recycling opportunities: A review. J. Mater. Environ. Sci. 2017, 8, 2632–2650. [Google Scholar]

- Azbar, N.; Bayram, A.; Filibeli, A.; Muezzinoglu, A.; Sengul, F.; Ozer, A. A review of waste management options in olive oil production. Crit. Rev. Environ. Sci. Technol. 2004, 34, 209–247. [Google Scholar] [CrossRef]

- Hassen, W.; Hassen, B.; Werhani, R.; Hidri, Y.; Jedidi, N.; Hassen, A. Processes of valorization and management of olive by-products: The pomace and olive mill wastewater. In Wastewater from Olive Oil Production: Environmental Impacts, Treatment and Valorisation; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–25. [Google Scholar]

- Ameziane, H.; Mabrouki, J.; Benchrifa, M.; Hmouni, D. Review of Olive Pomace Valorization Techniques: A Sustainable Perspective for the Olive Oil Industry. In Advanced Technology for Smart Environment and Energy; Springer: Berlin/Heidelberg, Germany, 2024; pp. 165–183. [Google Scholar]

- Najafi, E.; Castro, E.; Karimi, K. Biorefining for olive wastes management and efficient bioenergy production. Energy Convers. Manag. 2021, 244, 114467. [Google Scholar] [CrossRef]

- Ameixa, O.M.; Pinho, M.; Domingues, M.R.; Lillebø, A.I. Bioconversion of olive oil pomace by black soldier fly increases eco-efficiency in solid waste stream reduction producing tailored value-added insect meals. PLoS ONE 2023, 18, e0287986. [Google Scholar] [CrossRef]

- Alaoui, I.; El Ghadraoui, O.; Tanji, K.; Harrach, A.; Farah, A. The Olive Mill Pomace: A Sustainable Biofertilizer to Improve Soil Proprieties and Plant Nutrient Uptake. Waste Biomass Valorization 2024, 15, 2575–2590. [Google Scholar] [CrossRef]

- Ameziane, H.; Nounah, A.; Kabbour, M.; Khamar, M. Agronomic valuation of olive pomace obtained by different extraction systems. Ecol. Environ. Conserv. 2020, 26, 371–379. [Google Scholar]

- Pagnanelli, F.; Viggi, C.C.; Toro, L. Development of new composite biosorbents from olive pomace wastes. Appl. Surf. Sci. 2010, 256, 5492–5497. [Google Scholar] [CrossRef]

- Notarnicola, B.; Salomone, R.; Petti, L.; Renzulli, P.A.; Roma, R.; Cerutti, A.K. Life Cycle Assessment in the Agri-Food Sector: Case Studies, Methodological Issues and Best Practices; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef]

- Medouni-Haroune, L.; Zaidi, F.; Medouni-Adrar, S.; Kecha, M. Olive pomace: From an olive mill waste to a resource, an overview of the new treatments. J. Crit. Rev. 2018, 5, 1–6. [Google Scholar] [CrossRef]

- Conde-Innamorato, P.; Arias-Sibillotte, M.; Villamil, J.J.; Bruzzone, J.; Bernaschina, Y.; Ferrari, V.; Zoppolo, R.; Villamil, J.; Leoni, C. It is feasible to produce olive oil in temperate humid climate regions. Front. Plant Sci. 2019, 10, 1544. [Google Scholar] [CrossRef] [PubMed]

- Aly, A.A.; Hasan, Y.N.; Al-Farraj, A.S. Olive mill wastewater treatment using a simple zeolite-based low-cost method. J. Environ. Manag. 2014, 145, 341–348. [Google Scholar] [CrossRef]

- Khdair, A.; Abu-Rumman, G. Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 2020, 8, 671. [Google Scholar] [CrossRef]

- Islam, M.S.; Uddin, M.J.; Alshehri, K. Plastic waste and carbon footprint generation due to the consumption of bottled waters in Saudi Arabia. Res. Dev. Mater. Sci. 2018, 5, 000604. [Google Scholar] [CrossRef]

- Thapliyal, D.; Karale, M.; Diwan, V.; Kumra, S.; Arya, R.K.; Verros, G.D. Current status of sustainable food packaging regulations: Global perspective. Sustainability 2024, 16, 5554. [Google Scholar] [CrossRef]

- Saudi Standards. Technical Regulation for Degradable Plastic Products; Saudi Standards: Riyadh, Saudi Arabia, 2016; p. 24. [Google Scholar]

- Kaur, G.; Uisan, K.; Ong, K.L.; Lin, C.S.K. Recent trends in green and sustainable chemistry & waste valorisation: Rethinking plastics in a circular economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- Eygen, V.; Laner, D.; Fellner, J. Circular economy of plastic packaging: Current practice and perspectives in Austria. Waste Manag. 2018, 72, 55–64. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Astrup, T.F. Characterisation of source-separated, rigid plastic waste and evaluation of recycling initiatives: Effects of product design and source-separation system. Waste Manag. 2019, 87, 161–172. [Google Scholar] [CrossRef]

- Tiago, G.A.; Mariquito, A.; Martins-Dias, S.; Marques, A.C. The problem of polyethylene waste–recent attempts for its mitigation. Sci. Total Environ. 2023, 892, 164629. [Google Scholar] [CrossRef]

- Gounden, K.; Mwangi, F.M.; Mohan, T.P.; Kanny, K. The use of recycled high-density polyethylene waste to manufacture eco-friendly plastic sand bricks. SPE Polym. 2024, 5, 20–34. [Google Scholar] [CrossRef]

- Lourmpas, N.; Papanikos, P.; Efthimiadou, E.K.; Fillipidis, A.; Lekkas, D.F.; Alexopoulos, N.D. Degradation assessment of high-density polyethylene (HDPE) debris after long exposure to marine conditions. Sci. Total Environ. 2024, 954, 176847. [Google Scholar] [CrossRef]

- Boussehel Hamida, M.A.; Nebbache, N.; Maou, S. Mechanical properties of polystyrene/olive stone flour composites. Res. J. Pharm. Biol. Chem. Sci. 2015, 6, 6. [Google Scholar]

- Naghmouchi, I.; Espinach, F.X.; Mutjé, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. Mater. Des. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Olive stones flour as reinforcement in polypropylene composites: A step forward in the valorization of the solid waste from the olive oil industry. Ind. Crops Prod. 2015, 72, 183–191. [Google Scholar] [CrossRef]

- Hejna, A.; Sulyman, M.; Przybysz, M.; Saeb, M.; Klein, M.; Formela, K. On the correlation of lignocellulosic filler composition with the performance properties of poly (ε-caprolactone) based biocomposites. Waste Biomass Valorization 2020, 11, 1467–1479. [Google Scholar] [CrossRef]

- Kaya, N.; Atagur, M.; Akyuz, O.; Seki, Y.; Sarikanat, M.; Sutcu, M.; Seydibeyoglu, M.; Sever, K. Fabrication and characterization of olive pomace filled PP composites. Compos. Part B Eng. 2018, 150, 277–283. [Google Scholar] [CrossRef]

- Espadas-Aldana, G.; Guaygua-Amaguaña, P.; Vialle, C.; Belaud, J.-P.; Evon, P.; Sablayrolles, C. Life cycle assessment of olive pomace as a reinforcement in polypropylene and polyethylene biocomposite materials: A new perspective for the valorization of this agricultural by-product. Coatings 2021, 11, 525. [Google Scholar] [CrossRef]

- Valvez, S.; Maceiras, A.; Santos, P.; Reis, P.N. Olive stones as filler for polymer-based composites: A review. Materials 2021, 14, 845. [Google Scholar] [CrossRef]

- Gårdebjer, S.; Larsson, A.; Löfgren, C.; Ström, A. Controlling water permeability of composite films of polylactide acid, cellulose, and xyloglucan. J. Appl. Polym. Sci. 2015, 132, 41219. [Google Scholar] [CrossRef]

- Li, Y.; Xie, L.; Ma, H. Permeability and mechanical properties of plant fiber reinforced hybrid composites. Mater. Des. 2015, 86, 313–320. [Google Scholar] [CrossRef]

- Alshabanat, M. Morphological, thermal, and biodegradation properties of LLDPE/treated date palm waste composite buried in a soil environment. J. Saudi Chem. Soc. 2019, 23, 355–364. [Google Scholar] [CrossRef]

- Banat, R. Olive pomace flour as potential organic filler in composite materials: A brief review. Am. J. Polym. Sci. 2019, 9, 10–15. [Google Scholar]

- Abd Mohammed, A.; Depart, A. Study the thermal properties and water absorption of composite materials rrinforced with data and olive seeds. Iraqi J. Mech. Mater. Eng. 2015, 15, 138–152. [Google Scholar]

- Banat, R.; Fares, M.M. Olive oil waste filled high density polyethylene bio-composite: Mechanical, morphological and water absorption properties. Int. J. Compos. Mater. 2015, 5, 133–141. [Google Scholar]

- Sawalha, S.; El-Hamouz, A. Improvements of the tensile properties of recycled high density polyethylene (HDPE) by the use of carbonized olive solid waste. Polym. Plast. Technol. Eng. 2010, 49, 387–393. [Google Scholar] [CrossRef]

- Nassar, M.M.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and challenges in sustainability, compatibility, and production of eco-composites: A state-of-art review. J. Appl. Polym. Sci. 2021, 138, 51284. [Google Scholar] [CrossRef]

- Abdulkarem, M.A.; Rasool, D.A.; Nabhan, B.J. Utilization of olive and pumice stones to improve the thermal properties of cement mortar. Int. J. Nanoelectron. Mater. 2020, 13, 181–188. [Google Scholar]

- Banat, R.; Fares, M.M. Thermo-gravimetric stability of high density polyethylene composite filled with olive shell flour. Am. J. Polym. Sci. 2015, 5, 65–74. [Google Scholar]

- Hu, X.; Chen, L.; Tao, D.; Ma, Z.; Liu, S. A facile pathway to modify cellulose composite film by reducing wettability and improving barrier towards moisture. Materials 2017, 10, 39. [Google Scholar] [CrossRef]

- Jin, J.; Rafiq, R.; Gill, Y.Q.; Song, M. Preparation and characterization of high performance of graphene/nylon nanocomposites. Eur. Polym. J. 2013, 49, 2617–2626. [Google Scholar] [CrossRef]

- Onuoha, C.; Onyemaobi, O.O.; Anyakwo, C.N.; Onuegbu, G.C. Effect Of Filler Loading And Particle Size On The Mechanical Properties Of Periwinkle Shell-Filled Recycled Polypropylene Composites. Am. J. Eng. Res. 2017, 6, 72–79. [Google Scholar]

- Sadeghifar, H.; Ragauskas, A. Lignin as a UV light blocker—A review. Polymers 2020, 12, 1134. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Liu, W.; Wang, S.; Zhang, L.; Sang, R.; Hou, Q.; Li, J. Facile fabrication of cellulose composite films with excellent UV resistance and antibacterial activity. Carbohydr. Polym. 2019, 225, 115213. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.A.; Momohjimoh, I.; Gimba, A.S. Effect of groundnut shell powder on the mechanical properties of recycled polyethylene and its biodegradability. J. Miner. Mater. Charact. Eng. 2016, 4, 228. [Google Scholar] [CrossRef][Green Version]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological degradation of plastics: A comprehensive review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Degradation behavior of biocomposites based on cassava starch buried under indoor soil conditions. Carbohydr. Polym. 2014, 101, 20–28. [Google Scholar] [CrossRef]

- Arutchelvi, J.; Sudhakar, M.; Arkatkar, A.; Doble, M.; Bhaduri, S.; Uppara, P.V. Biodegradation of polyethylene and polypropylene. Indian J. Biotechnol. 2008, 7, 9–22. [Google Scholar]

- Zakaria, M.R.S.B.; Abid, M.B.; Shamim, A.; Suradi, S.S.; Marsi, N.B.; Kormin, F.B. A review on biodegradable composite films containing organic material as a natural filler. J. Inorg. Organomet. Polym. Mater. 2024, 35, 2126–2161. [Google Scholar] [CrossRef]

- Brebu, M. Environmental degradation of plastic composites with natural fillers—A review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef]

- Pardalis, N.; Xanthopoulou, E.; Zamboulis, A.; Bikiaris, D.N. Olive stone as a filler for recycled high-density polyethylene: A promising valorization of solid wastes from olive oil industry. Sustain. Chem. Environ. 2024, 6, 100090. [Google Scholar] [CrossRef]

| Composite Samples # | Loading Ratios of JEFT/r-HDPE in wt.% |

|---|---|

| Sample 1 | 0/100 |

| Sample 2 | 5/95 |

| Sample 3 | 10/90 |

| Sample 4 | 15/85 |

| Sample 5 | 20/80 |

| Sample 6 | 25/75 |

| Sample 7 | 50/50 |

| JEFT wt.% | T5% (°C) | Residue (wt.%) |

|---|---|---|

| 0 | 480.3 ± 1.5 | 0.25 |

| 5 | 475.8 ± 0.9 | 8.0 |

| 10 | 466.5 ± 0.5 | 8.20 |

| 15 | 330.7 ± 2.0 | 9.5 |

| 20 | 305.1 ± 1.4 | 12.0 |

| 25 | 300.5 ± 2.2 | 18.5 |

| 50 | 275.0 ± 3.5 | 20 |

| JEFT wt.% | Initial Weight (g) | Final Weight (g) | Weight Loss (%) in 60 Days |

|---|---|---|---|

| 0 | 1.096 | 1.094 | 0.1 |

| 5 | 1.172 | 1.161 | 0.9 |

| 10 | 1.154 | 1.140 | 1.2 |

| 15 | 1.093 | 1.078 | 1.4 |

| 20 | 1.066 | 1.043 | 2.1 |

| 25 | 1.089 | 1.011 | 7.0 |

| 50 | 1.190 | 1.031 | 13.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfaifi, H.Y.; Aldress, S.D.; Alshammari, B.A. Exploitation of Plastic and Olive Solid Wastes for Accelerating the Biodegradation Process of Plastic. J. Compos. Sci. 2025, 9, 445. https://doi.org/10.3390/jcs9080445

Alfaifi HY, Aldress SD, Alshammari BA. Exploitation of Plastic and Olive Solid Wastes for Accelerating the Biodegradation Process of Plastic. Journal of Composites Science. 2025; 9(8):445. https://doi.org/10.3390/jcs9080445

Chicago/Turabian StyleAlfaifi, Hassan Y., Sami D. Aldress, and Basheer A. Alshammari. 2025. "Exploitation of Plastic and Olive Solid Wastes for Accelerating the Biodegradation Process of Plastic" Journal of Composites Science 9, no. 8: 445. https://doi.org/10.3390/jcs9080445

APA StyleAlfaifi, H. Y., Aldress, S. D., & Alshammari, B. A. (2025). Exploitation of Plastic and Olive Solid Wastes for Accelerating the Biodegradation Process of Plastic. Journal of Composites Science, 9(8), 445. https://doi.org/10.3390/jcs9080445