Semi-Industrial Preparation of Versatile Panel Rolls from Micronized Hemp Stalks

Abstract

1. Introduction

2. Materials and Methods

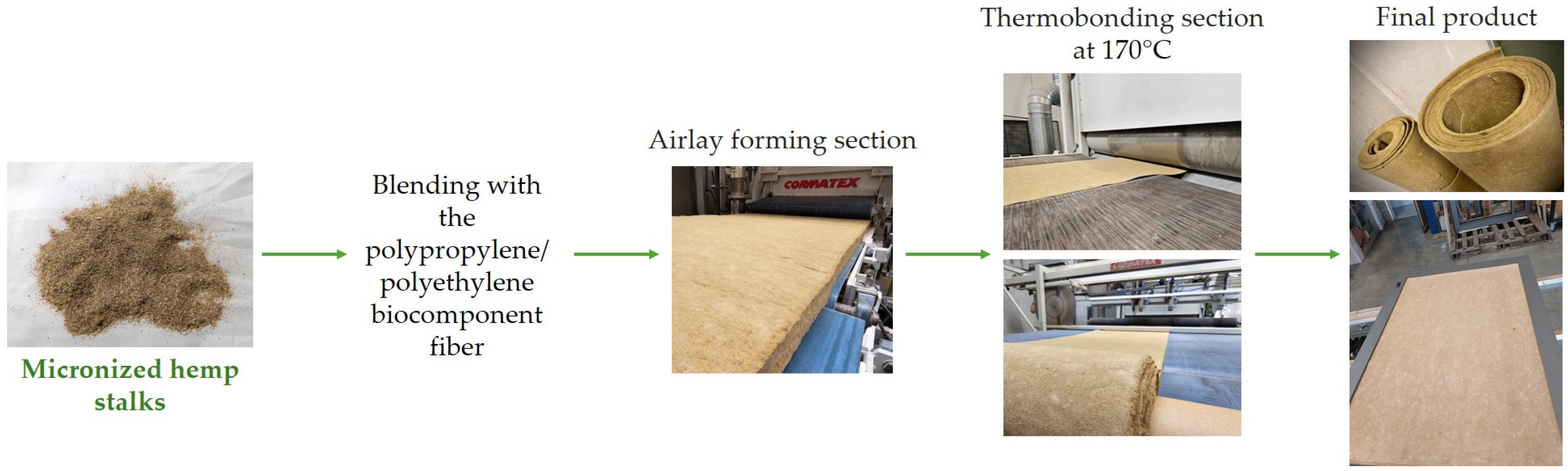

2.1. Panel Preparation

2.2. Thermal Insulation Analysis

2.3. Sound Insulation Analysis

2.4. Structural and Morphological Analysis

3. Results and Discussion

3.1. Thermal Insulation Properties

3.2. Acoustic Insulation Capacity

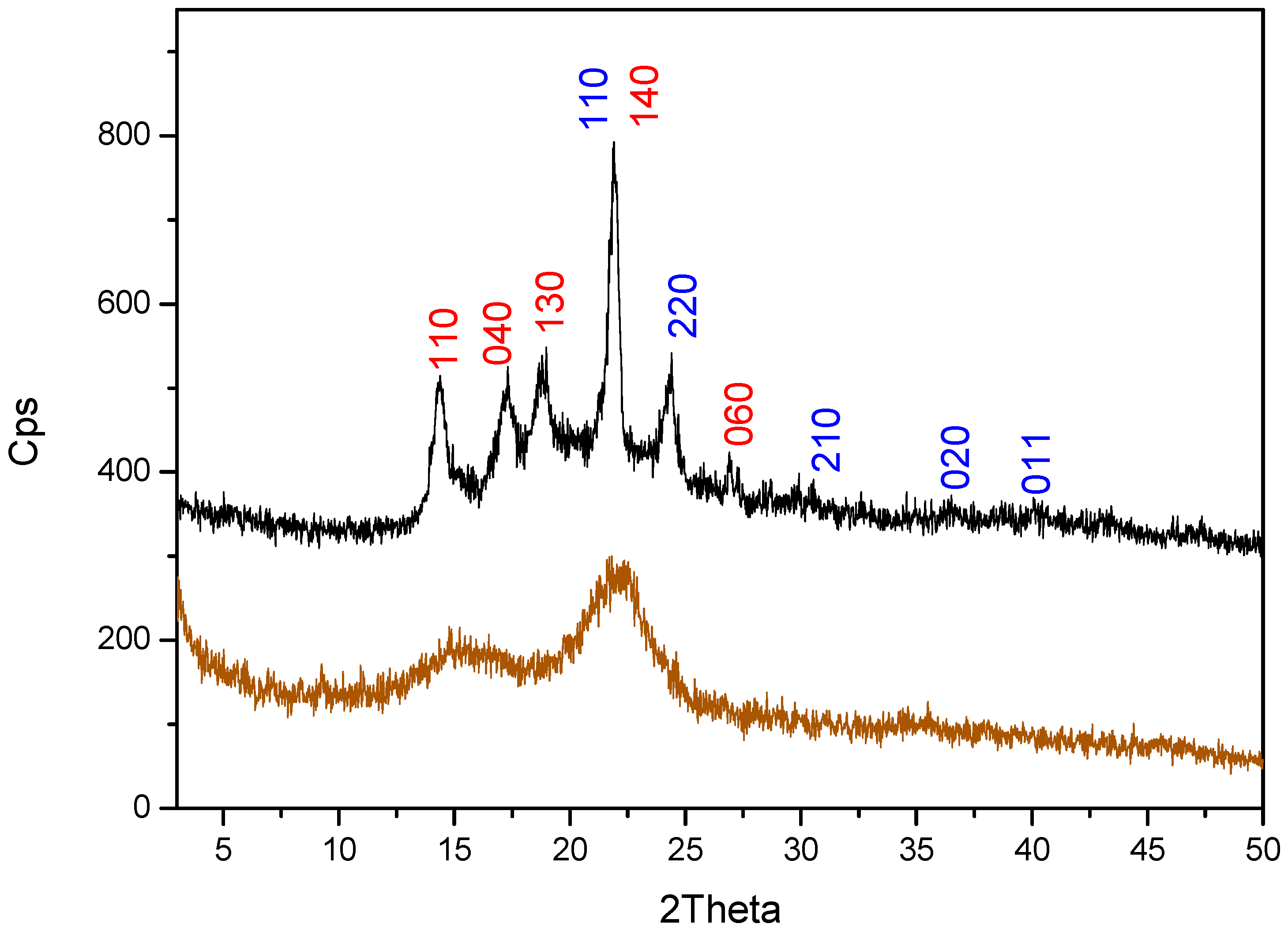

3.3. Morphological and Structural Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Parliament and Council Directive European Parliament and Council Directive 94/62/EC on Packaging and Packaging Waste. 1994. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31994L0062 (accessed on 12 August 2025).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Pathway to a Healthy Planet for All EU Action Plan: “Towards Zero Pollution for Air, Water and Soil”. 2021. Volume COM/2021/400 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52021DC0400 (accessed on 12 August 2025).

- Directive (EU) 2019/of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0904 (accessed on 12 August 2025).

- Mujtaba, M.; Fraceto, L.F.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; Pereira, A.D.E.S.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part. A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance Evaluation and Research of Alternative Thermal Insulations Based on Sheep Wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Ballupete Nagaraju, S.; Puttegowda, M.; Verma, A.; Rangappa, S.M.; Siengchin, S. Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass. J. Compos. Sci. 2023, 7, 242. [Google Scholar] [CrossRef]

- Schilling, S.; Melzer, R.; Dowling, C.A.; Shi, J.; Muldoon, S.; McCabe, P.F. A Protocol for Rapid Generation Cycling (Speed Breeding) of Hemp (Cannabis Sativa) for Research and Agriculture. Plant J. 2023, 113, 437–445. [Google Scholar] [CrossRef]

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef]

- Del Valle-Zermeño, R.; Aubert, J.E.; Laborel-Préneron, A.; Formosa, J.; Chimenos, J.M. Preliminary Study of the Mechanical and Hygrothermal Properties of Hemp-Magnesium Phosphate Cements. Constr. Build. Mater. 2016, 105, 62–68. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A Review of the Properties of Hemp Concrete for Green Building Applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef]

- Glé, P.; Gourdon, E.; Arnaud, L. Modelling of the Acoustical Properties of Hemp Particles. Constr. Build. Mater. 2012, 37, 801–811. [Google Scholar] [CrossRef]

- Balciunas, G.; Vejelis, S.; Lekunaite, L.; Kremensas, A. Assessment of Structure Influence on Thermal Conductivity of Hemp Shives Composite. Environ. Eng. Manag. J. 2016, 15, 699–705. [Google Scholar] [CrossRef]

- Su, S.; Gao, Y.; Zhou, X.; Xiong, X.; Wang, Y.; Lyu, L. Structure of Waste Hemp Stalks and Their Sound Absorbing Properties. Polymers 2022, 14, 4844. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, H.; Lian, Z.; Tan, B.; Zheng, Y.; Erdun, E. Numerical Simulation for Porous Hemp Plastic Composites Sound Absorption Properties. J. Mater. Res. Technol. 2022, 19, 2458–2469. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Prétot, S.; Lanos, C. Hemp-Straw Composites: Gluing Study and Multi-Physical Characterizations. Materials 2019, 12, 1199. [Google Scholar] [CrossRef]

- Chapman, R.A. Applications of Nonwovens in Technical Textiles. In Woodhead Publishing Series in Textiles; Woodhead: Derbyshire, UK, 2010; ISBN 978-1-84569-437-1. [Google Scholar]

- Zhang, T.; Tan, Y.; Yang, H.; Zhang, X. The Application of Air Layers in Building Envelopes: A Review. Appl. Energy 2016, 165, 707–734. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of Biomass-Based Insulation Materials in Buildings: Current Status in France, End-of-Life Projections and Energy Recovery Potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- EN ISO 11092; The European Standard (September 2014 Edition). International Organization for Standardization: Geneva, Switzerland, 2014.

- Delhomme, F.; Hajimohammadi, A.; Almeida, A.; Jiang, C.; Moreau, D.; Gan, Y.; Wang, X.; Castel, A. Physical Properties of Australian Hurd Used as Aggregate for Hemp Concrete. Mater. Today Commun. 2020, 24, 100986. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Chemical and Multi-Physical Characterization of Agro-Resources’ by-Product as a Possible Raw Building Material. Ind. Crops Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels An Introduction for Specialists; Brunel University: London, UK, 2010; ISBN 978-1-902316-82-6. [Google Scholar]

- Khojasteh-Khosro, S.; Shalbafan, A.; Thoemen, H. Consumer Behavior Assessment Regarding Lightweight Furniture as an Environmentally-Friendly Product. Wood Mater. Sci. Eng. 2022, 17, 192–201. [Google Scholar] [CrossRef]

- Burnett, M.P.; Kharazipour, A. Mechanical Behaviour of a Lightweight, Three-Layered Sandwich Panel Based on the Raw Material Maize. Holzforschung 2017, 72, 65–70. [Google Scholar] [CrossRef]

- Kirilovs, E.; Zotova, I.; Kukle, S.; Pugovičs, K. Low Density Hemp Shive Particleboards for Latent Thermal Energy Storage Performance. J. Energy Syst. 2021, 5, 1–9. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Zvirgzds, K.; Kirilovs, E.; Kukle, S.; Gross, U. Production of Particleboard Using Various Particle Size Hemp Shives as Filler. Materials 2022, 15, 886. [Google Scholar] [CrossRef]

- Gendelis, S.; Jakovičs, A.; Engelhardt, M.; Černý, R.; Kočí, J.; Kočí, V. Thermal and Moisture Adsorption/Desorption Properties for a Selection of Vegetal Insulation Materials. MATEC Web Conf. 2019, 282, 02062. [Google Scholar] [CrossRef][Green Version]

- Wallenberger, F.T.; Weston, N. Natural Fibers, Plastics and Composites; Springer: Boston, MA, USA, 2004; ISBN 978-1-4020-7643-5. [Google Scholar]

- Pfundstein, M.; Gellert, R.; Spitzner, M.; Rudolphi, A. Insulating Materials: Principles, Materials, Applications; DETAIL-Institut für internationale Architektur-Dokumentation GmbH & Co. KG: Munich, Germany, 2008; ISBN 978-3-7643-8654-2. [Google Scholar]

- Lekavicius, V.; Shipkovs, P.; Ivanovs, S.; Rucins, A. Thermo-Insulation Properties Of Hemp-Based Products. Latv. J. Phys. Tech. Sci. 2015, 52, 38–51. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and Sound Insulation Materials from Waste Wool and Recycled Polyester Fibers and Their Biodegradation Studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Lee, Y.; Joo, C. Sound Absorption Properties of Recycled Polyester Fibrous Assembly Absorbers. AUTEX Res. J. 2003, 3, 78–84. [Google Scholar] [CrossRef]

- Küçük, M.; Korkmaz, Y. The Effect of Physical Parameters on Sound Absorption Properties of Natural Fiber Mixed Nonwoven Composites. Text. Res. J. 2012, 82, 2043–2053. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous Materials for Sound Absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Gao, Y.; Li, Z.; Shang, Y.; Li, H. Porous Thermal Insulation Polyurethane Foam Materials. Polymers 2023, 15, 3818. [Google Scholar] [CrossRef]

- Jorge, P.A.; Crocker, M.J. Recent Trends in Porous Sound-Absorbing Materials. Sound Vib. 2010, 44, 12–17. [Google Scholar]

- Gallina, L.; Chaji, S.; Manzoli, M.; Cravero, F.; Gnoffo, C.; Gesti, S.; Frache, A.; Cravotto, G. Preparation of Hemp-based Biocomposites and Their Potential Industrial Application. Polym. Compos. 2025, 46, 3791–3802. [Google Scholar] [CrossRef]

- Roumeli, E.; Terzopoulou, Z.; Pavlidou, E.; Chrissafis, K.; Papadopoulou, E.; Athanasiadou, E.; Triantafyllidis, K.; Bikiaris, D.N. Effect of Maleic Anhydride on the Mechanical and Thermal Properties of Hemp/High-Density Polyethylene Green Composites. J. Therm. Anal. Calorim. 2015, 121, 93–105. [Google Scholar] [CrossRef]

- Gallina, L.; Chaji, S.; Mantegna, S.; Manzoli, M.; Cravotto, G. Mechanochemical Preparation of New Biocomposites Starting from Polymers and Plant-Derived Fibres. J. Compos. Sci. 2024, 8, 452. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A Study of the Effect of Acetylation and Propionylation Surface Treatments on Natural Fibres. Compos. Part. A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallina, L.; Chaji, S.; Querci, L.; Manzoli, M.; Cravotto, G. Semi-Industrial Preparation of Versatile Panel Rolls from Micronized Hemp Stalks. J. Compos. Sci. 2025, 9, 440. https://doi.org/10.3390/jcs9080440

Gallina L, Chaji S, Querci L, Manzoli M, Cravotto G. Semi-Industrial Preparation of Versatile Panel Rolls from Micronized Hemp Stalks. Journal of Composites Science. 2025; 9(8):440. https://doi.org/10.3390/jcs9080440

Chicago/Turabian StyleGallina, Lorenzo, Salah Chaji, Luca Querci, Maela Manzoli, and Giancarlo Cravotto. 2025. "Semi-Industrial Preparation of Versatile Panel Rolls from Micronized Hemp Stalks" Journal of Composites Science 9, no. 8: 440. https://doi.org/10.3390/jcs9080440

APA StyleGallina, L., Chaji, S., Querci, L., Manzoli, M., & Cravotto, G. (2025). Semi-Industrial Preparation of Versatile Panel Rolls from Micronized Hemp Stalks. Journal of Composites Science, 9(8), 440. https://doi.org/10.3390/jcs9080440