Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh

Abstract

1. Introduction

2. Materials and Methods

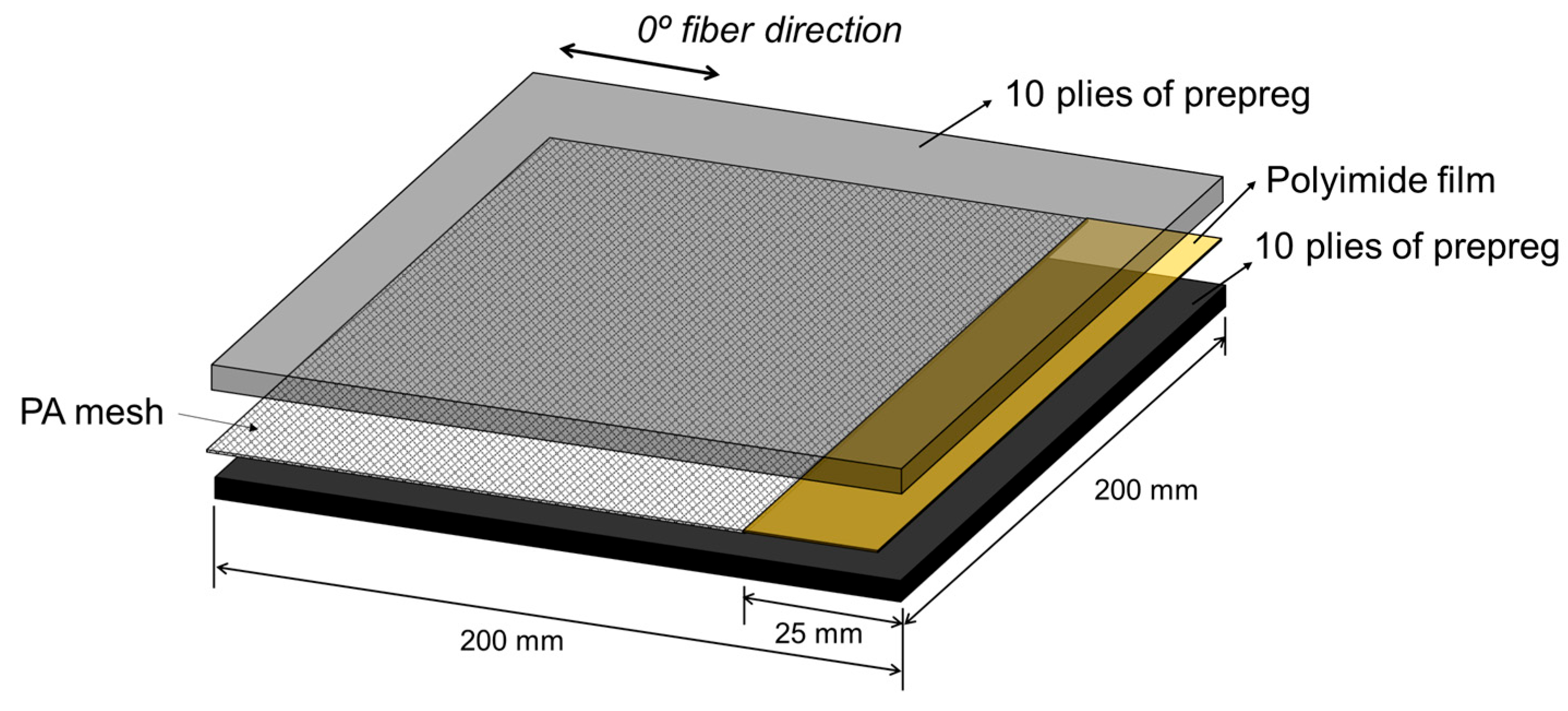

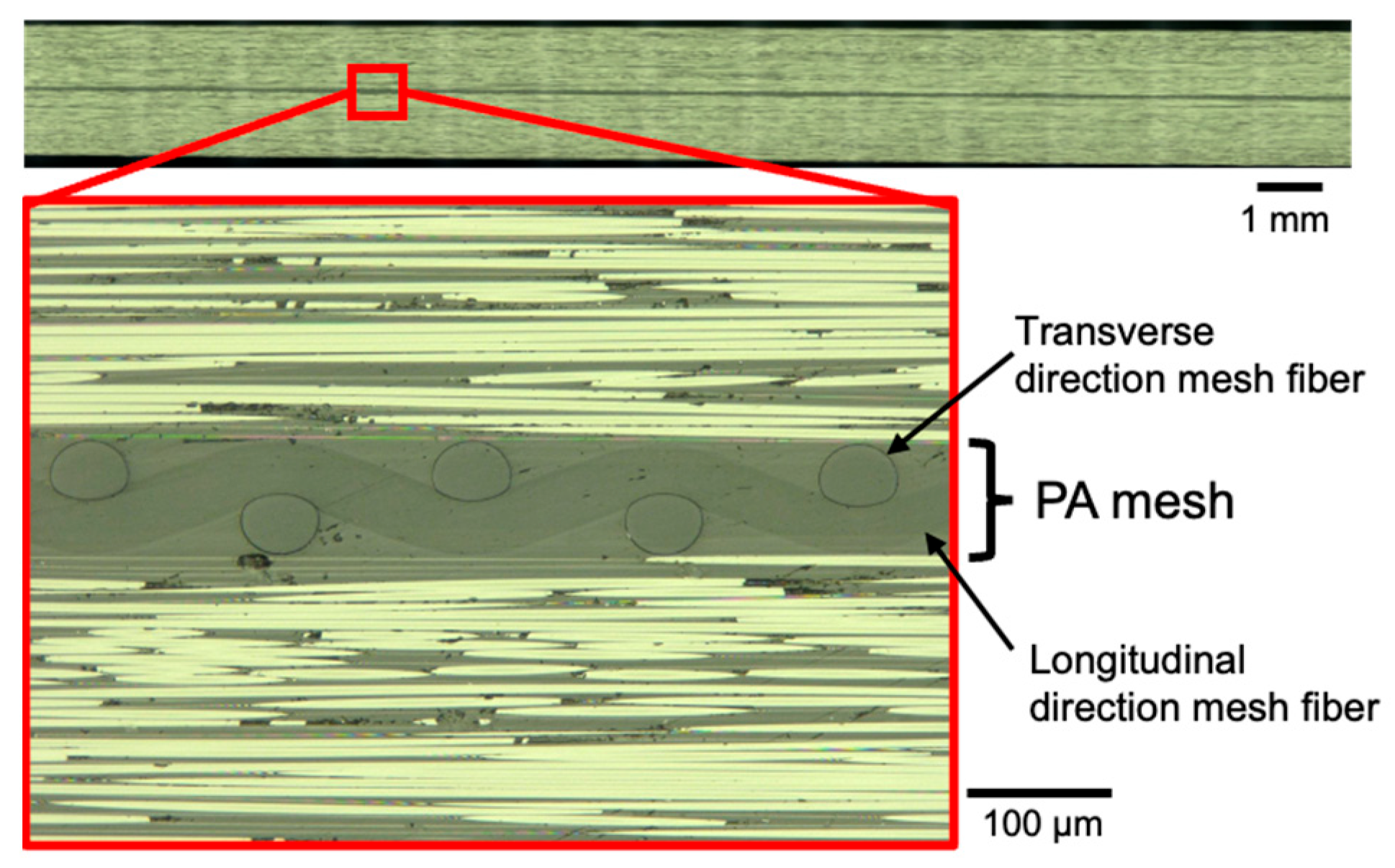

2.1. Evaluation on the Interlaminar Fracture Toughness

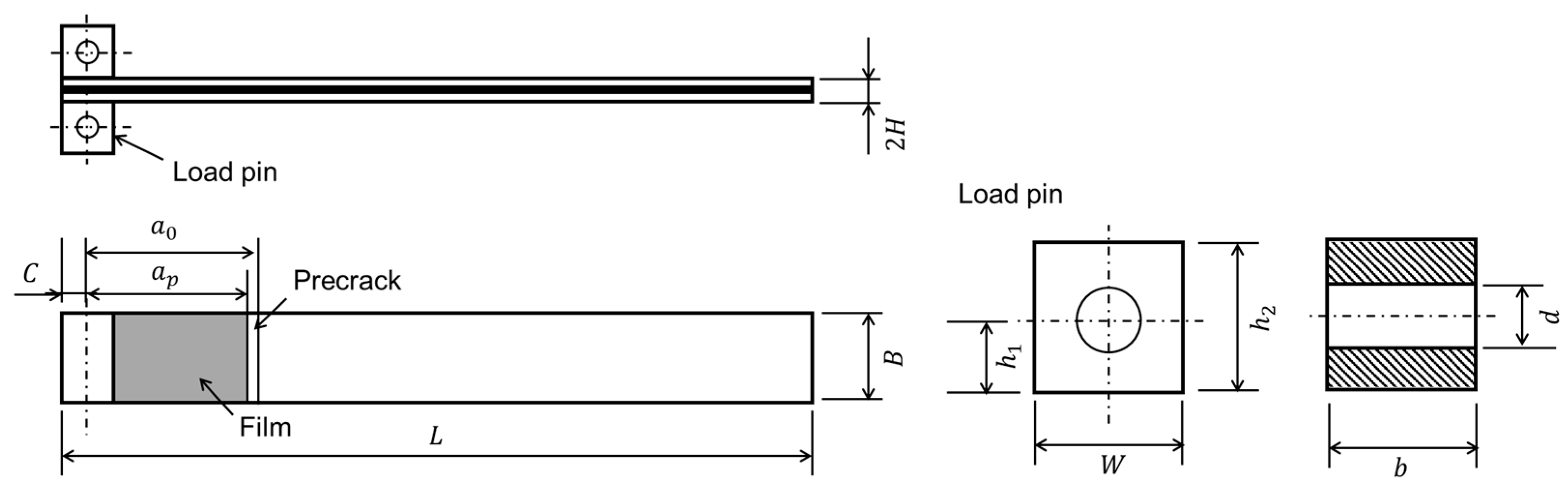

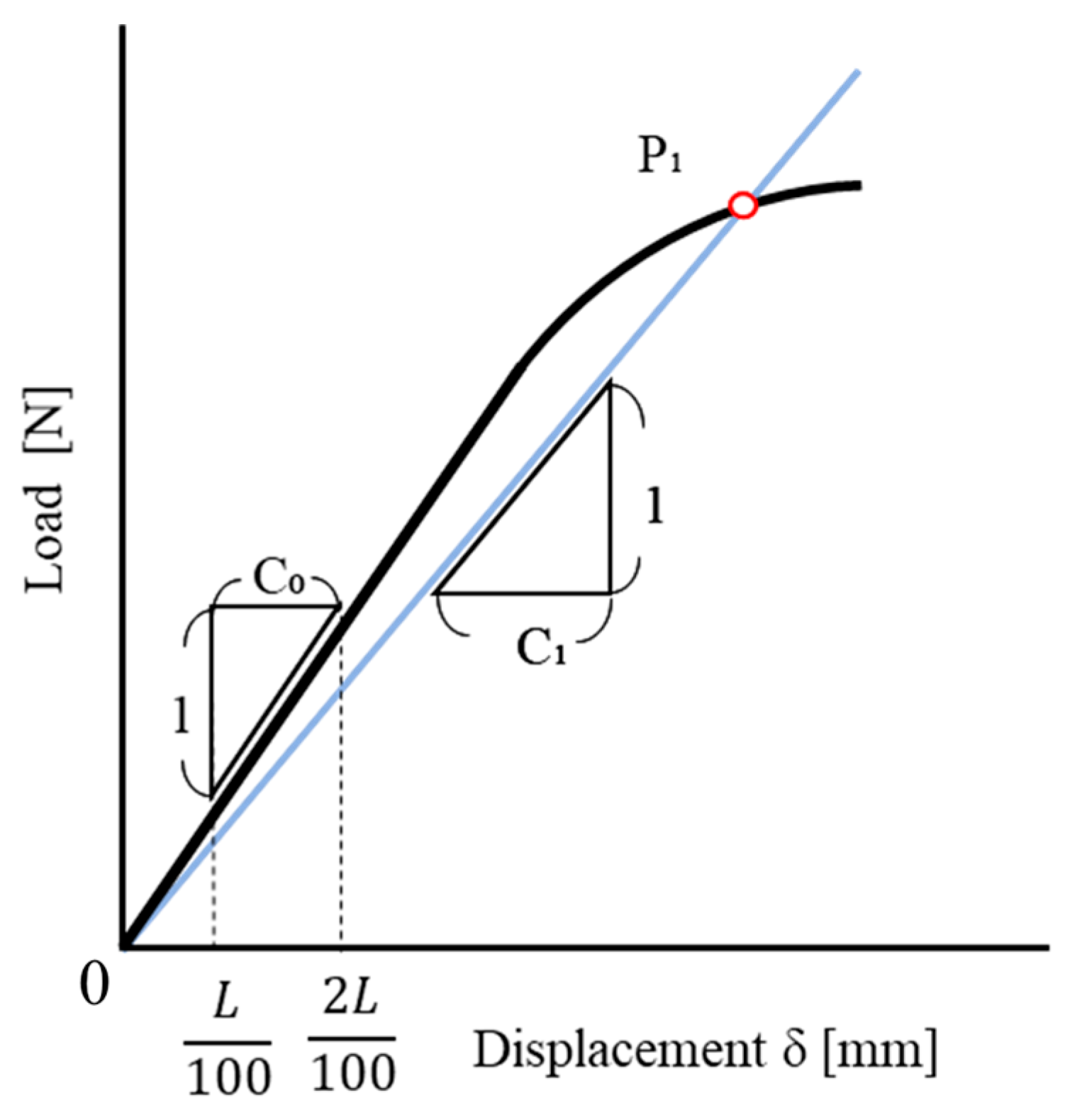

2.1.1. Mode I Interlaminar Fracture Toughness (DCB Test)

2.1.2. Mode II Fracture Toughness Evaluation (ENF Tests)

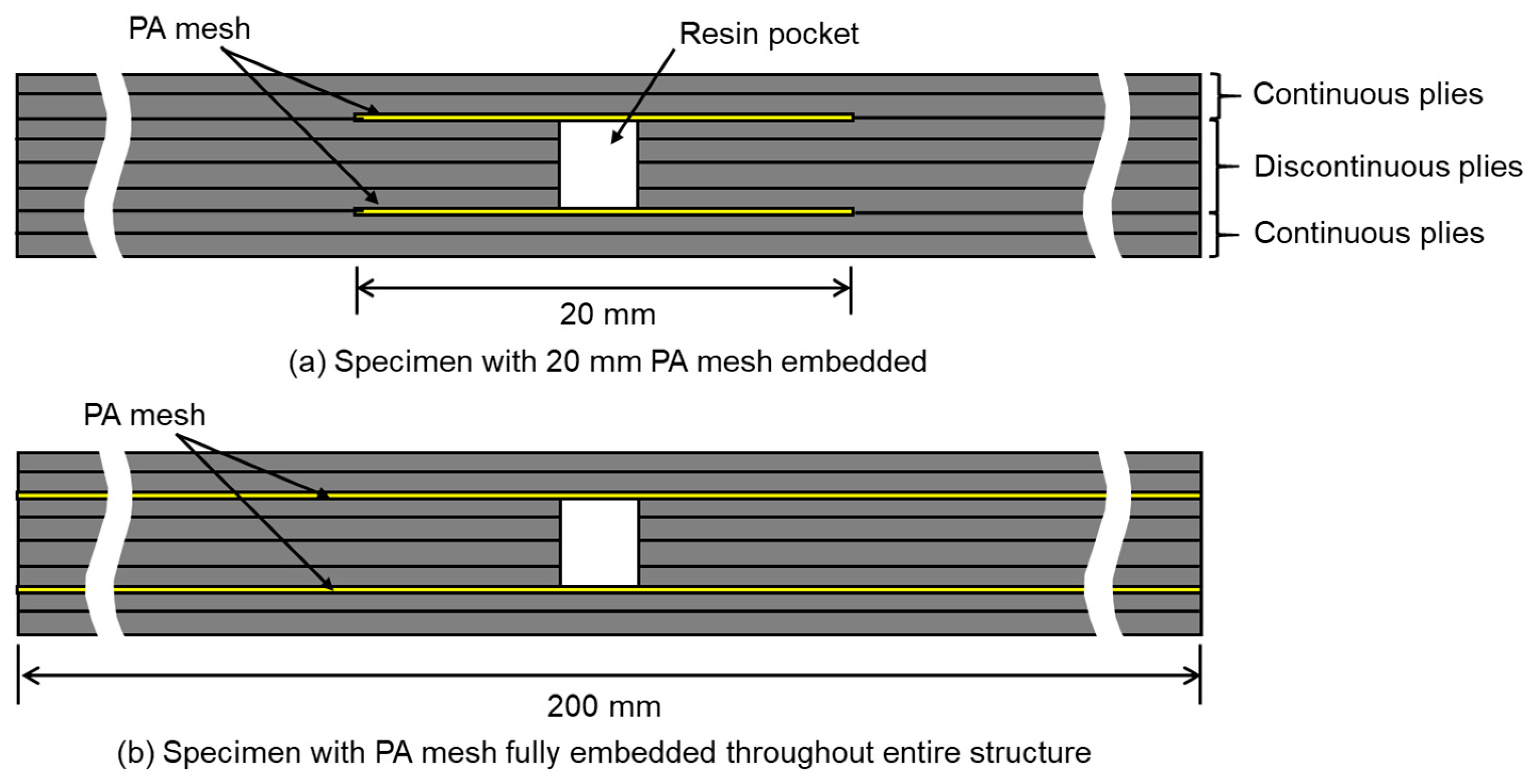

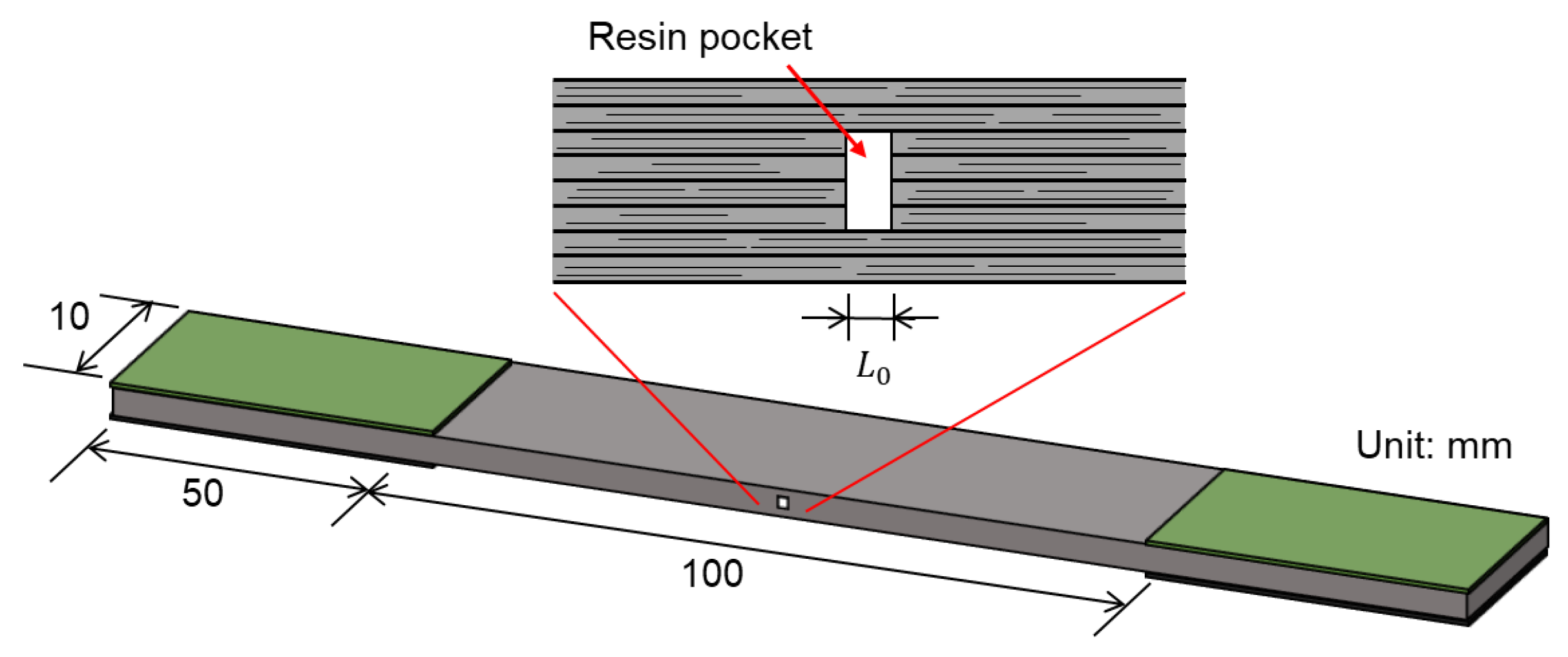

2.2. Application of PA Mesh in CFRP Laminates with Ply Discontinuities

2.2.1. Laminate Configurations and Manufacturing

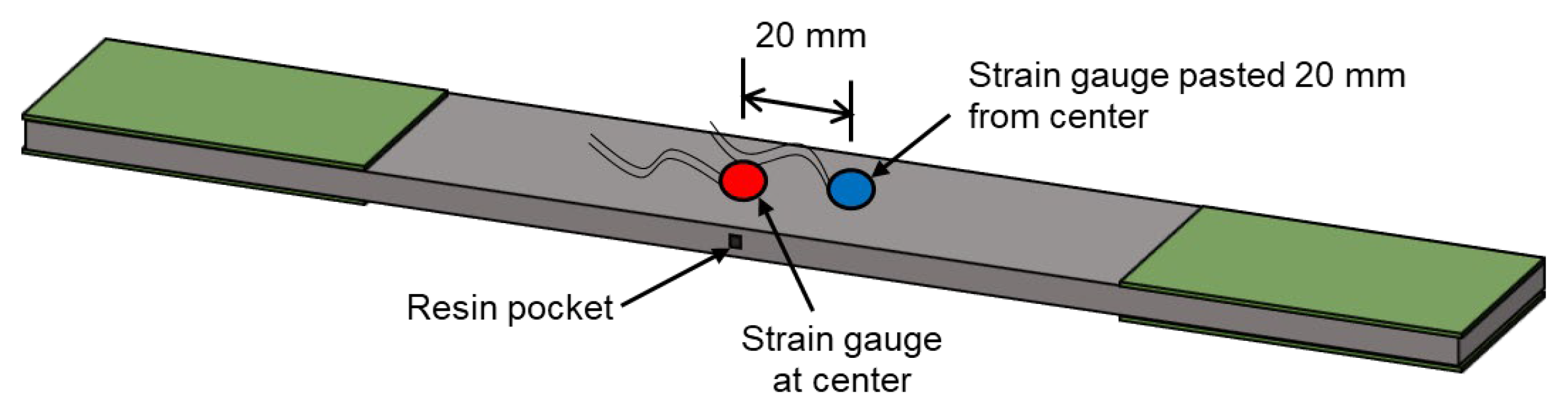

2.2.2. Tensile Tests and Damage Observation

3. Results and Discussion

3.1. Evaluation on the Interlaminar Fracture Toughness

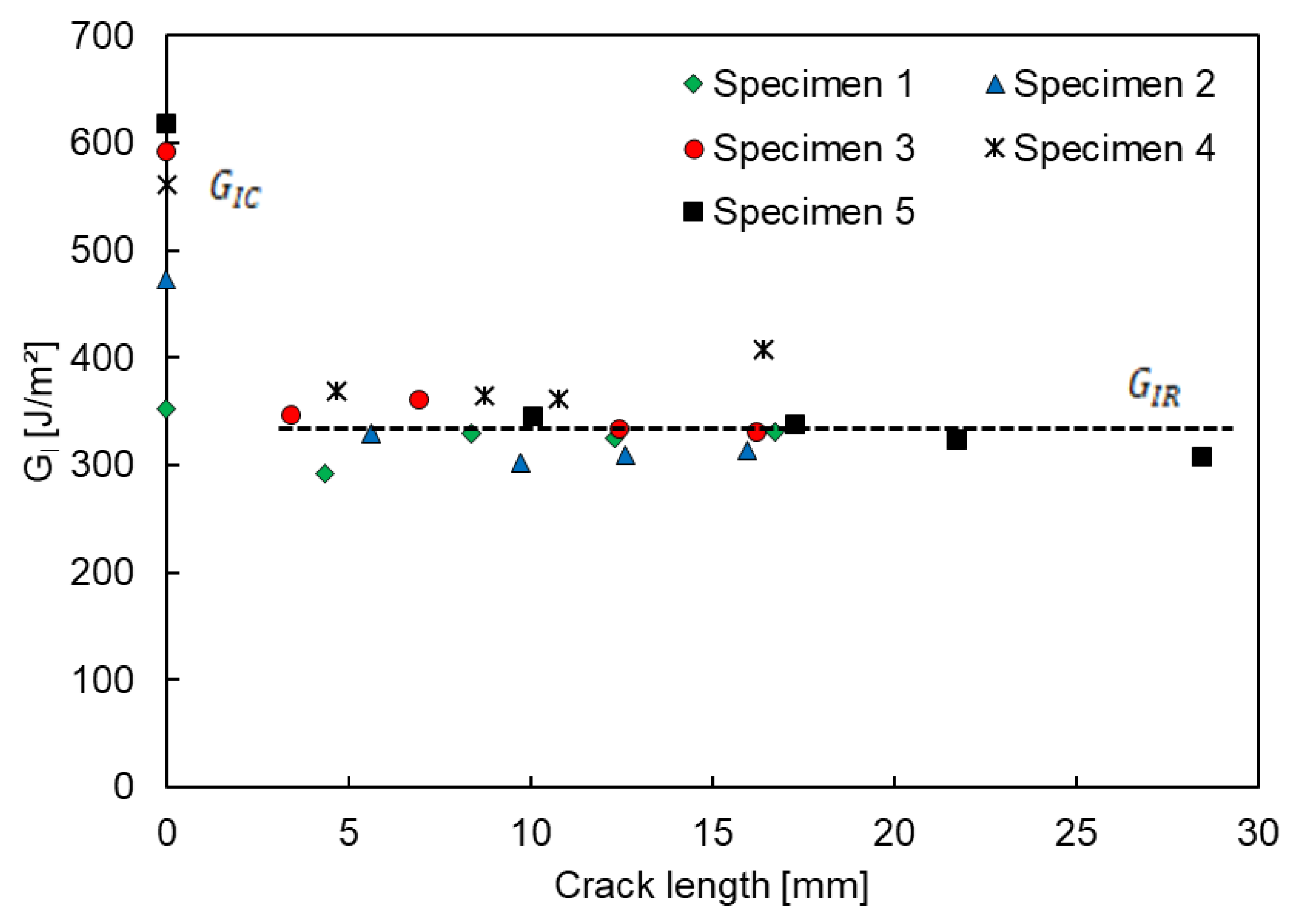

3.1.1. Mode I Interlaminar Fracture Toughness (DCB Tests)

3.1.2. Mode II Interlaminar Fracture Toughness (ENF Tests)

3.2. Application of PA Mesh in CFRP Laminates with Ply Discontinuities

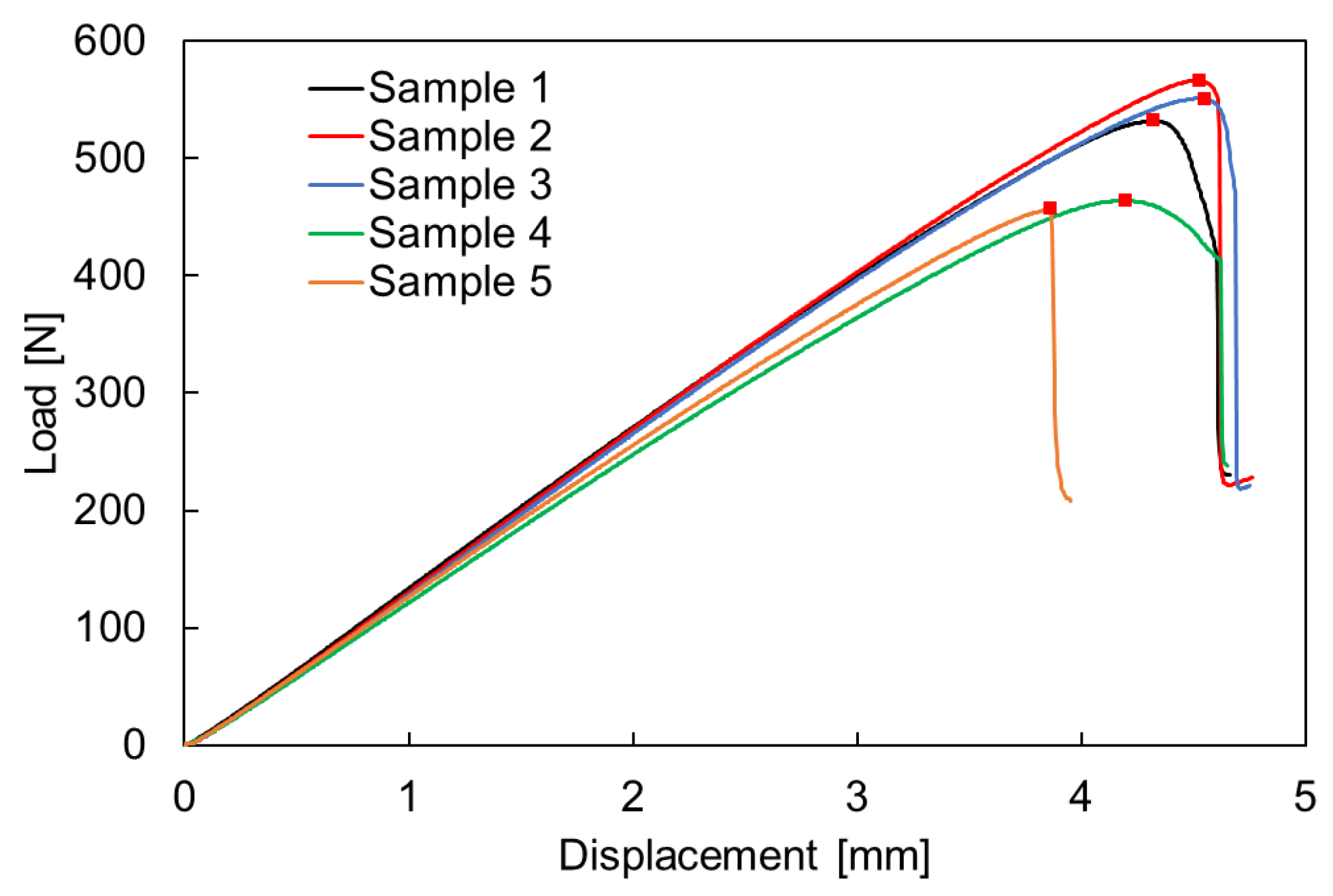

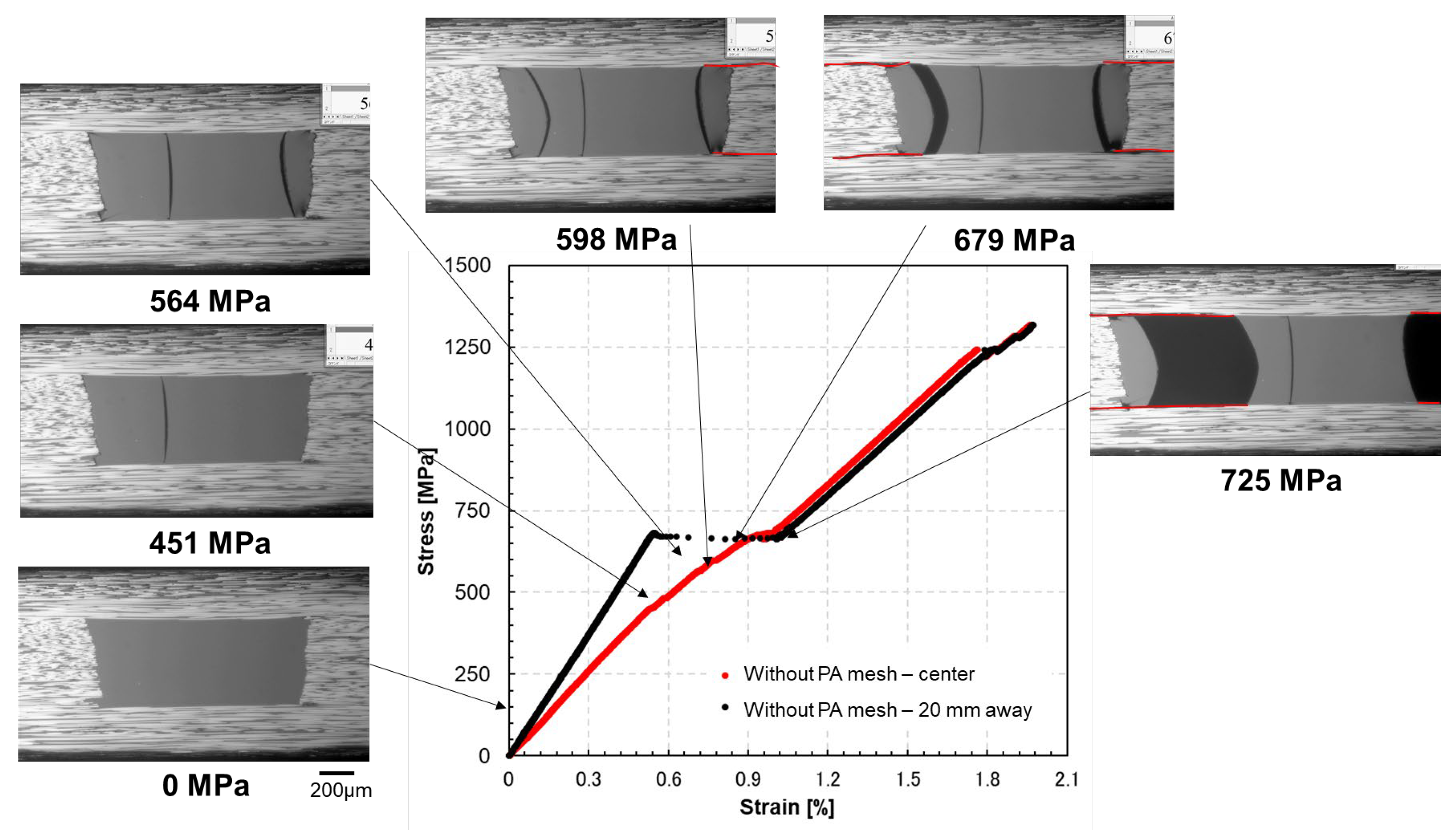

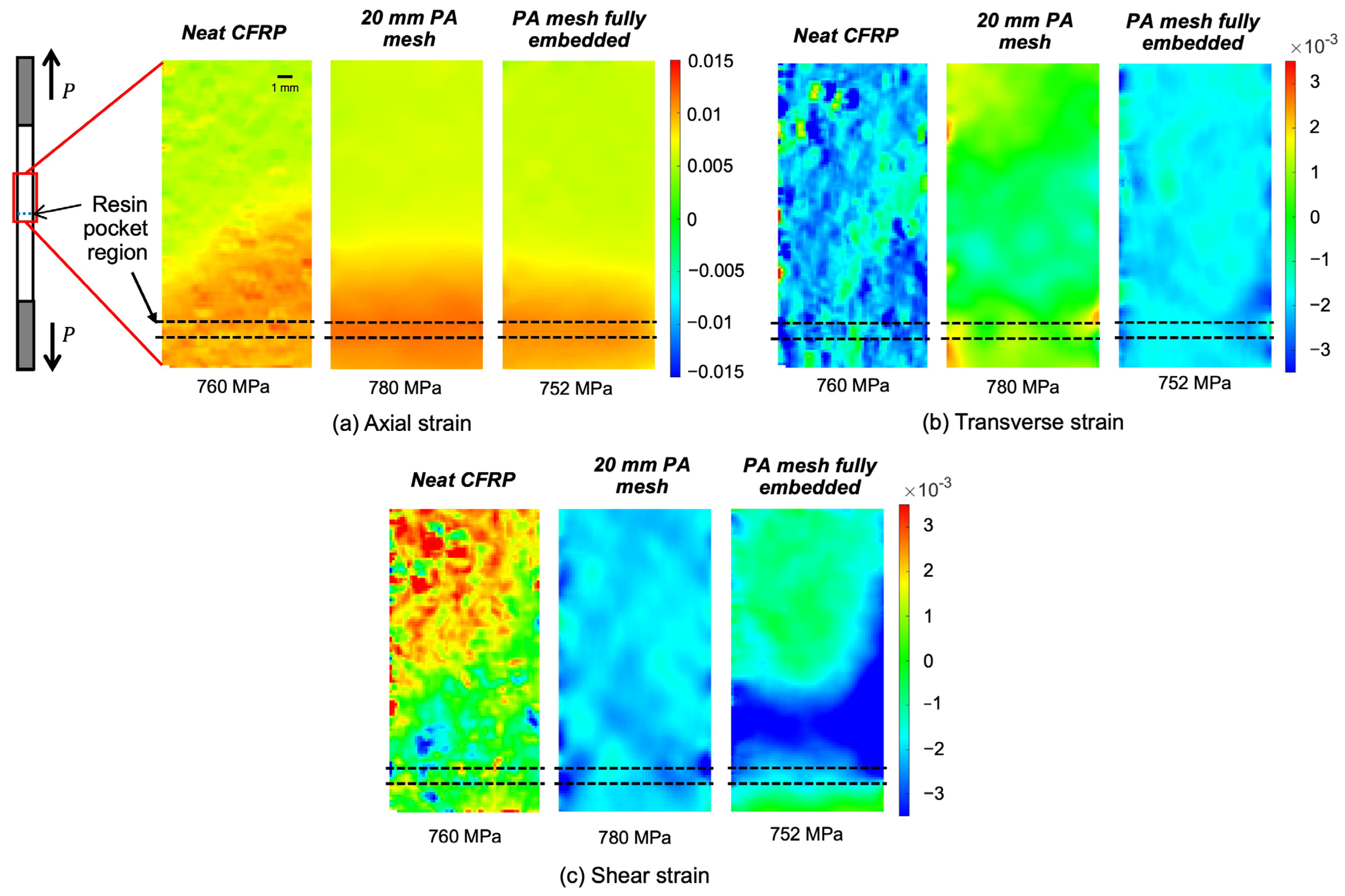

3.2.1. CFRP Laminate with No PA Mesh Embedded (Neat CFRP)

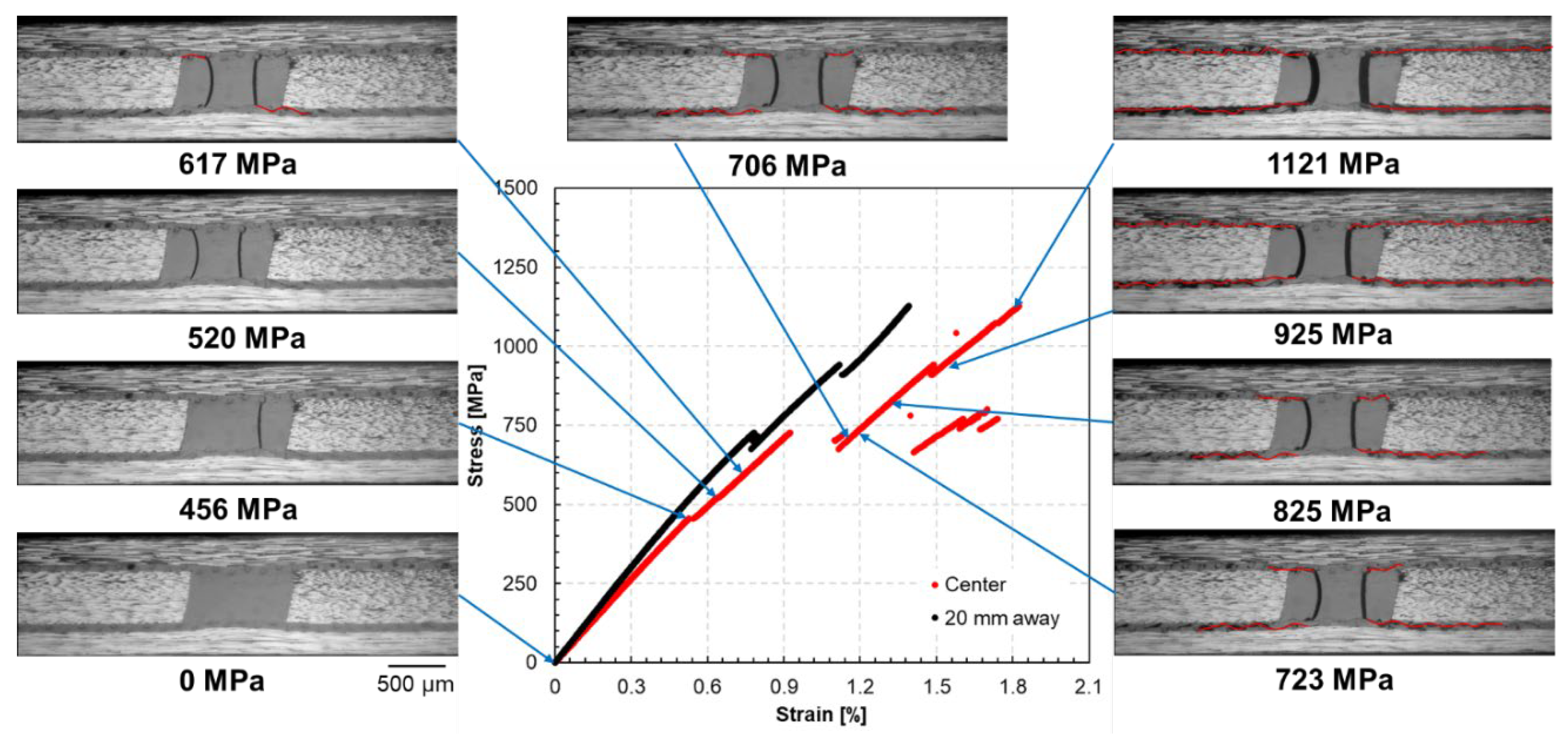

3.2.2. CFRP Laminate with 20 mm PA Mesh Embedded

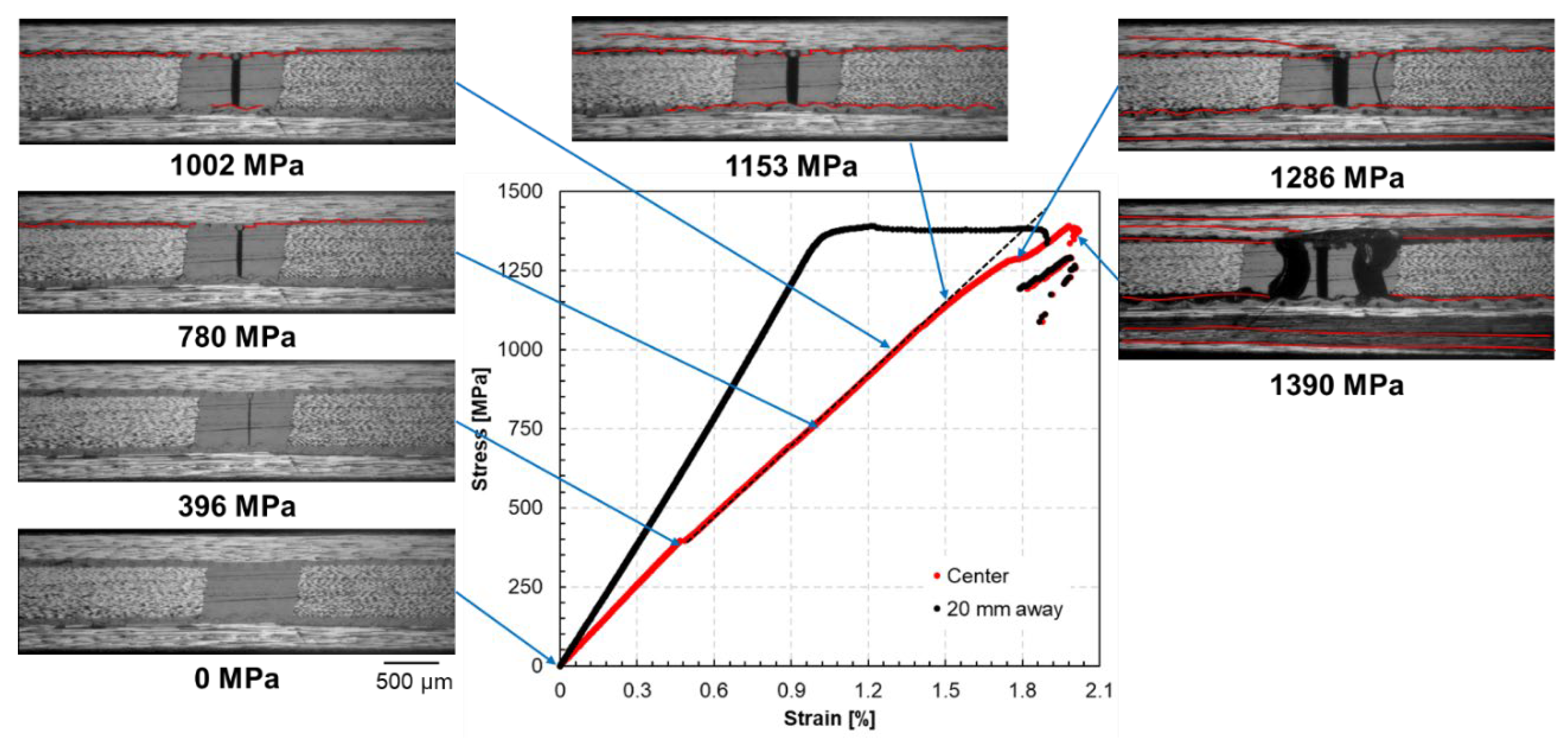

3.2.3. CFRP Laminate with PA Mesh Fully Embedded Throughout Entire Structure

4. Effect of Embedded PA Mesh on Delamination and Mechanical Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | Carbon fiber reinforced plastic |

| PA | Polyamide |

| DCB | Double cantilever beam |

| ENF | End-notched flexure |

| DIC | Digital image correlation |

| SEM | Scanning electron microscopy |

References

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Hasebe, S.; Higuchi, R.; Yokozeki, T.; Takeda, S. Prediction of compression after impact strength from surface profile of low-velocity impact damaged CFRP laminates using machine learning. Compos. Part A Appl. Sci. Manuf. 2025, 189, 108560. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Li, A.; Zhang, H.; Yang, D. Bearing performance and progressive failure analysis of bolted joint in 3D printed pseudo-woven CFRP composite with fibre steering. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108526. [Google Scholar] [CrossRef]

- Yoneyama, S.; Koyanagi, J.; Arikawa, S. Measurement of discontinuous displacement/strain using mesh-based digital image correlation. Adv. Compos. Mater. 2015, 25, 329–343. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Yao, Y.; Mobasher, B.; Huang, L. Mechanical properties and failure characteristics of CFRP under intermediate strain rates and varying temperatures. Compos. Part B Eng. 2016, 95, 123–136. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Jiang, P.; Guo, F.; Cheng, J. Study on Delamination Damage of CFRP Laminates Based on Acoustic Emission and Micro Visualization. Materials 2022, 15, 1483. [Google Scholar] [CrossRef]

- Oshima, S.; Higuchi, R.; Kobayashi, S. Experimental characterization of cracking behavior initiating from microdefects in cross-ply CFRP laminates. Eng. Fract. Mech. 2023, 281, 109116. [Google Scholar] [CrossRef]

- Li, Y.; Wang, B.; Zhou, L. Study on the effect of delamination defects on the mechanical properties of CFRP composites. Eng. Fail. Anal. 2023, 153, 107576. [Google Scholar] [CrossRef]

- Bätzel, T.; Welker, C.; Hornig, A.; Stommel, M.; Spickenheuer, A.; Gude, M. Interlaminar properties of tailored fiber placement based CFRP laminates. Mech. Adv. Mater. Struct. 2025; 1–12, in press. [Google Scholar]

- Fikry, M.J.M.; Terashi, N.; Koizumi, K.; Ogihara, S. Inhibition of interlaminar damage in CFRP laminates by inserting non-woven carbon fiber interlaminar reinforced tissue. Adv. Compos. Mater. 2024, 34, 513–533. [Google Scholar] [CrossRef]

- Woigk, W.; Zhang, B.; Jones, M.I.; Kuhtz, M.; Hornig, A.; Gude, M.; Hallett, S.R. Effect of saw-tooth ply drops on the mechanical performance of tapered composite laminates. Compos. Struct. 2021, 272, 114197. [Google Scholar] [CrossRef]

- Nakatani, H.; Nakaya, K.; Matsuba, A.; Kouno, Y.; Ogihara, S. Effect of prepreg cut on the mechanical properties in CFRP laminates. J. Solid Mech. Mater. Eng. 2011, 5, 742–752. [Google Scholar] [CrossRef]

- Kukwi, T.; Shan, C.; Pengfei, L.; Zhang, B.; Leiyang, G.; Wang, Z. Continuous improvement in composite manufacturing: A review of automated fiber placement process evolution and future research prospects. Appl. Compos. Mater. 2025; in press. [Google Scholar]

- Xu, X.; Cheng, L.; Cai, Z.; Li, J.; Ke, Y. Multi-source lay-up error analysis and lay-up pressure optimization for robotic automated fiber placement (AFP). Compos. Part A Appl. Sci. Manuf. 2025, 193, 108825. [Google Scholar] [CrossRef]

- Simacek, P.; Minakuchi, S.; Advani, S.G. A model to describe transient transverse deformation during prepreg consolidation. Compos. Part A Appl. Sci. Manuf. 2025, 197, 109021. [Google Scholar] [CrossRef]

- He, K.; Hoa, S.V.; Ganesan, R. The study of tapered laminated composite structures: A review. Compos. Sci. Technol. 2000, 60, 2643–2657. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Vinogradov, V.; Ogihara, S. Mechanical properties and damage behavior of tapered unidirectional CFRP laminates. Mech. Eng. J. 2023, 10, 23-00079. [Google Scholar] [CrossRef]

- Lu, X.; Higuchi, R.; Hua, X.; Nagashima, T.; Yokozeki, T. Experimental and numerical study on failure mechanisms of tapered laminates: Effects of ply thickness and taper ratio. Compos. Sci. Technol. 2024, 256, 110784. [Google Scholar] [CrossRef]

- Minakuchi, S.; Takeda, N. Ply curving termination to suppress delamination in composite ply drop-off. In ICAF 2019—Structural Integrity in the Age of Additive Manufacturing; Niepokolczycki, A., Komorowski, J., Eds.; Springer: Cham, Switzerland, 2020; pp. 124–132. [Google Scholar]

- Ohashi, N.; Yoshida, T.; Minakuchi, S. Ply curving termination for enhancing tensile strength of composite ply drop-off: Static evaluation and failure mechanism. Adv. Compos. Mater. 2025, 34, 307–328. [Google Scholar] [CrossRef]

- Zhang, B.; Kawashita, L.F.; Jones, M.I.; Lander, J.K.; Hallett, S.R. An experimental and numerical investigation into damage mechanisms in tapered laminates under tensile loading. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105862. [Google Scholar] [CrossRef]

- Minakuchi, S.; Simacek, P.; Advani, S.G. In-situ consolidation deformation of composite laminate with gaps of various widths. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108054. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Arai, Y.; Inoue, R.; Vinogradov, V.; Tan, K.T.; Ogihara, S. Damage behavior in unidirectional CFRP laminates with ply discontinuity. Appl. Compos. Mater. 2025; 1–19, in press. [Google Scholar]

- Gan, K.W.; Allegri, G.; Hallett, S.R. A simplified layered beam approach for predicting ply drop delamination in thick composite laminates. Mater. Des. 2016, 108, 570–580. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Vinogradov, V.; Ogihara, S. Experimental observation and modeling of resin pocket cracking in unidirectional laminates with ply discontinuity. Compos. Sci. Technol. 2022, 218, 109175. [Google Scholar] [CrossRef]

- Fikry, M.J.M.; Vinogradov, V.; Ogihara, S. Analytical prediction of the local Young’s modulus in CFRP laminate with ply discontinuity: A variational approach. Adv. Compos. Mater. 2023, 32, 843–865. [Google Scholar] [CrossRef]

- Chen, L.; Wu, L.-W.; Jiang, Q.; Tian, D.; Zhong, Z.; Wang, Y.; Fu, H.-J. Improving interlaminar fracture toughness and impact performance of carbon fiber/epoxy laminated composite by using thermoplastic fibers. Molecules 2019, 24, 3367. [Google Scholar] [CrossRef]

- Veeramani, N.; Devine, M.; Quinn, J.A.; Alapati, A.K.; Bolluk, A.; Ray, D. Enhancing fracture toughness of carbon fiber/epoxy composites using polyphenylene ether as a modifier. J. Appl. Polym. Sci. 2024, 141, e55388. [Google Scholar] [CrossRef]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Rubbery-modified CFRPs with improved Mode I fracture toughness: Effect of nanofibrous mat grammage and positioning on tanδ behaviour. Polymers 2021, 13, 1918. [Google Scholar] [CrossRef]

- Wang, J.; Pozegic, T.R.; Xu, Z.; Nigmatullin, R.; Harniman, R.L.; Eichhorn, S.J. Cellulose nanocrystal-polyetherimide hybrid nanofibrous interleaves for enhanced interlaminar fracture toughness of carbon fibre/epoxy composites. Compos. Sci. Technol. 2019, 182, 107744. [Google Scholar] [CrossRef]

- Song, W.; Chen, Y.; Mu, Z.; Wang, Y.; Zhang, Z.; Wang, Z.; Liu, L.; Zhang, B.; Li, Y.; Li, B.; et al. A feather-inspired interleaf for enhanced interlaminar fracture toughness of carbon fiber reinforced polymer composites. Compos. Part B Eng. 2022, 236, 109827. [Google Scholar] [CrossRef]

- Ou, Y.; Fu, A.; Wu, L.; Yi, X.; Mao, D. Enhanced interlaminar fracture toughness of unidirectional CFRP laminates with tailored microstructural heterogeneity of toughening layer. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107872. [Google Scholar] [CrossRef]

- Sun, X.; Liu, H.-Y.; Yan, W.; Tong, L.; Mai, Y.-W. Modelling composite reinforcement by stitching and z-pinning. In Multi-Scale Modelling of Composite Material Systems; Woodhead Publishing: Cambridge, UK, 2005; pp. 319–355. [Google Scholar]

- Tong, L.; Mouritz, A.P.; Bannister, M.K. 3D Fibre Reinforced Polymer Composites; Elsevier Science Ltd.: Oxford, UK, 2002. [Google Scholar]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar fracture toughness of CFRP laminates incorporating multi-walled carbon nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar] [CrossRef]

- Xu, F.; Yang, B.; Feng, L.; Huang, D.; Xia, M. Improved interlaminar fracture toughness and electrical conductivity of CFRPs with non-woven carbon tissue interleaves composed of fibers with different lengths. Polymers 2020, 12, 803. [Google Scholar] [CrossRef]

- Sager, R.; Klein, P.; Davis, D.; Lagoudas, D.C.; Warren, G.L.; Sue, H. Interlaminar fracture toughness of woven fabric composite laminates with carbon nanotube/epoxy interleaf films. J. Appl. Polym. Sci. 2011, 121, 2394–2405. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, G.; Cheng, X.; Zhang, Z.; Li, M.; Ji, S.; Huang, Z. Mode I and Mode II interlaminar fracture toughness of CFRP/magnesium alloys hybrid laminates. Compos. Interfaces 2016, 23, 453–465. [Google Scholar] [CrossRef]

- Topzeven. Meshes, Plastic Mesh, Nylon (PA) Mesh (Woven). Available online: https://www.topzeven.com/meshes-2/plastic-mesh-nylon-pa-mesh/?lang=en (accessed on 20 April 2024).

- Wang, W.-T.; Yu, H.; Potter, K.; Kim, B.C. Effect of the characteristics of nylon microparticles on Mode-I interlaminar fracture toughness of carbon-fibre/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106073. [Google Scholar] [CrossRef]

- Wang, C.; He, Y.; Lin, Z.; Zhao, X.; Sun, C.; Guo, R.; Wang, X.; Zhou, F. Mechanical and tribological properties of FDM-printed polyamide. Tribol. Int. 2024, 191, 109198. [Google Scholar] [CrossRef]

- Kovács, T.; Simon-Stőger, L.; Heller, B.; Cs, V. Enhancing properties of PC/PA blends via compatibilization of olefin-maleic-anhydride copolymer based additives in masterbatch form. J. Polym. Res. 2021, 28, 294. [Google Scholar] [CrossRef]

- Dai, R.; Huang, M.; Ma, L.; Liu, W.; He, S.; Liu, H.; Zhu, C.; Wang, Y.; Zhang, Z.; Sun, A. Study on crystal structure and phase transitions of polyamide 12 via wide-angle X-ray diffraction with variable temperature. Adv. Compos. Hybrid Mater. 2020, 3, 522–529. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Effect of polyamide-6,6 (PA 66) nonwoven veils on the mechanical performance of carbon fiber/epoxy composites. Compos. Struct. 2018, 194, 21–35. [Google Scholar] [CrossRef]

- Marino, S.G.; Košťáková, E.K.; Czél, G. Development of pseudo-ductile interlayer hybrid composites of standard thickness plies by interleaving polyamide 6 nanofibrous layers. Compos. Sci. Technol. 2023, 234, 109924. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, Z.; Xue, Y.; Feng, Y.; Zhang, W.; Peng, Y.; Liu, Y.; Zhang, H.; Yu, J. Performance of interlayer toughened carbon fiber/epoxy composites of low areal density PA66 fiber veil. Acta Mater. Compos. Sin. 2025, 42, 263–271. [Google Scholar]

- Meireman, T.; Daelemans, L.; Rijckaert, S.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Delamination resistant composites by interleaving bio-based long-chain polyamide nanofibers through optimal control of fiber diameter and fiber morphology. Compos. Sci. Technol. 2020, 193, 108126. [Google Scholar] [CrossRef]

- Daelemans, L.; Kizildag, N.; Van Paepegem, W.; D’hooge, D.R.; De Clerck, K. Interdiffusing core-shell nanofiber interleaved composites for excellent mode I and mode II delamination resistance. Compos. Sci. Technol. 2019, 175, 143–150. [Google Scholar] [CrossRef]

- J.I.S. K7086-1993; Testing Methods for Interlaminar Fracture Toughness of Carbon Fibre Reinforced Plastics. Japanese Standards Association: Tokyo, Japan, 1993.

| Part | Symbol | Dimension | Size [mm] |

|---|---|---|---|

| DCB specimen | Length | 90 | |

| Thickness | 2.3 | ||

| Width | 10 | ||

| Distance from specimen end load line | 6 | ||

| Film crack length | 25 | ||

| Precrack length | 28–32 | ||

| Load pin | Width | 12 | |

| Length | 12 | ||

| Half height | 6 | ||

| Height | 12 | ||

| Hole diameter | 5 |

| Symbol | Parts | Size [mm] |

|---|---|---|

| Length | 110 | |

| Thickness | 2.3 | |

| Width | 10 | |

| C | Distance from specimen end load line | 20 |

| Film crack length | 25 | |

| Precrack length | 31–35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fikry, M.J.M.; Iizuka, K.; Nakatani, H.; Yoneyama, S.; Vinogradov, V.; Koyanagi, J.; Ogihara, S. Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh. J. Compos. Sci. 2025, 9, 414. https://doi.org/10.3390/jcs9080414

Fikry MJM, Iizuka K, Nakatani H, Yoneyama S, Vinogradov V, Koyanagi J, Ogihara S. Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh. Journal of Composites Science. 2025; 9(8):414. https://doi.org/10.3390/jcs9080414

Chicago/Turabian StyleFikry, M. J. Mohammad, Keisuke Iizuka, Hayato Nakatani, Satoru Yoneyama, Vladimir Vinogradov, Jun Koyanagi, and Shinji Ogihara. 2025. "Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh" Journal of Composites Science 9, no. 8: 414. https://doi.org/10.3390/jcs9080414

APA StyleFikry, M. J. M., Iizuka, K., Nakatani, H., Yoneyama, S., Vinogradov, V., Koyanagi, J., & Ogihara, S. (2025). Suppression of Delamination in CFRP Laminates with Ply Discontinuity Using Polyamide Mesh. Journal of Composites Science, 9(8), 414. https://doi.org/10.3390/jcs9080414