Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates

Abstract

1. Introduction

2. Context and Paper Objectives

3. Experimental Program

3.1. Materials

3.2. Mixture Proportioning and Batching

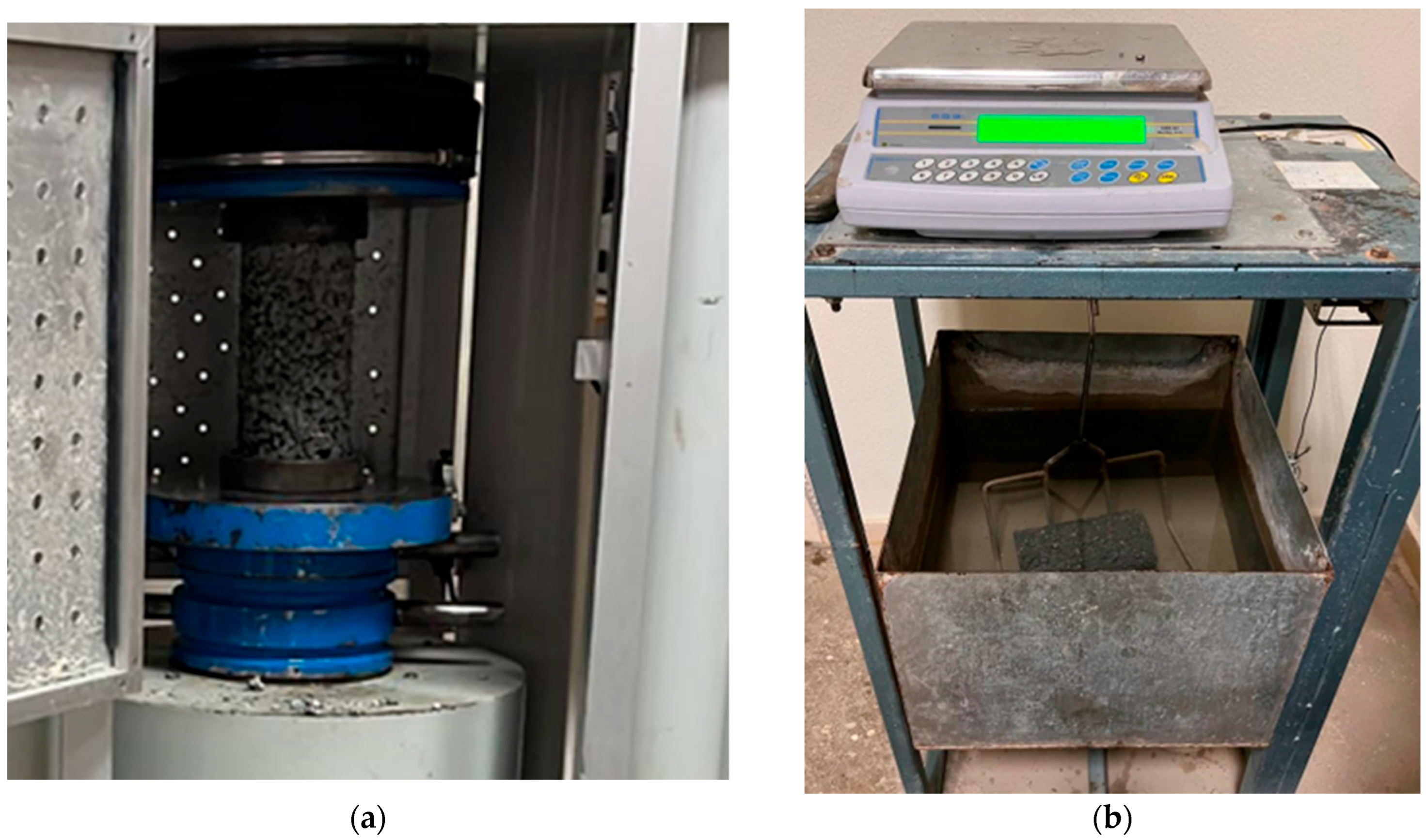

3.3. Performance Evaluation

4. Results and Analysis

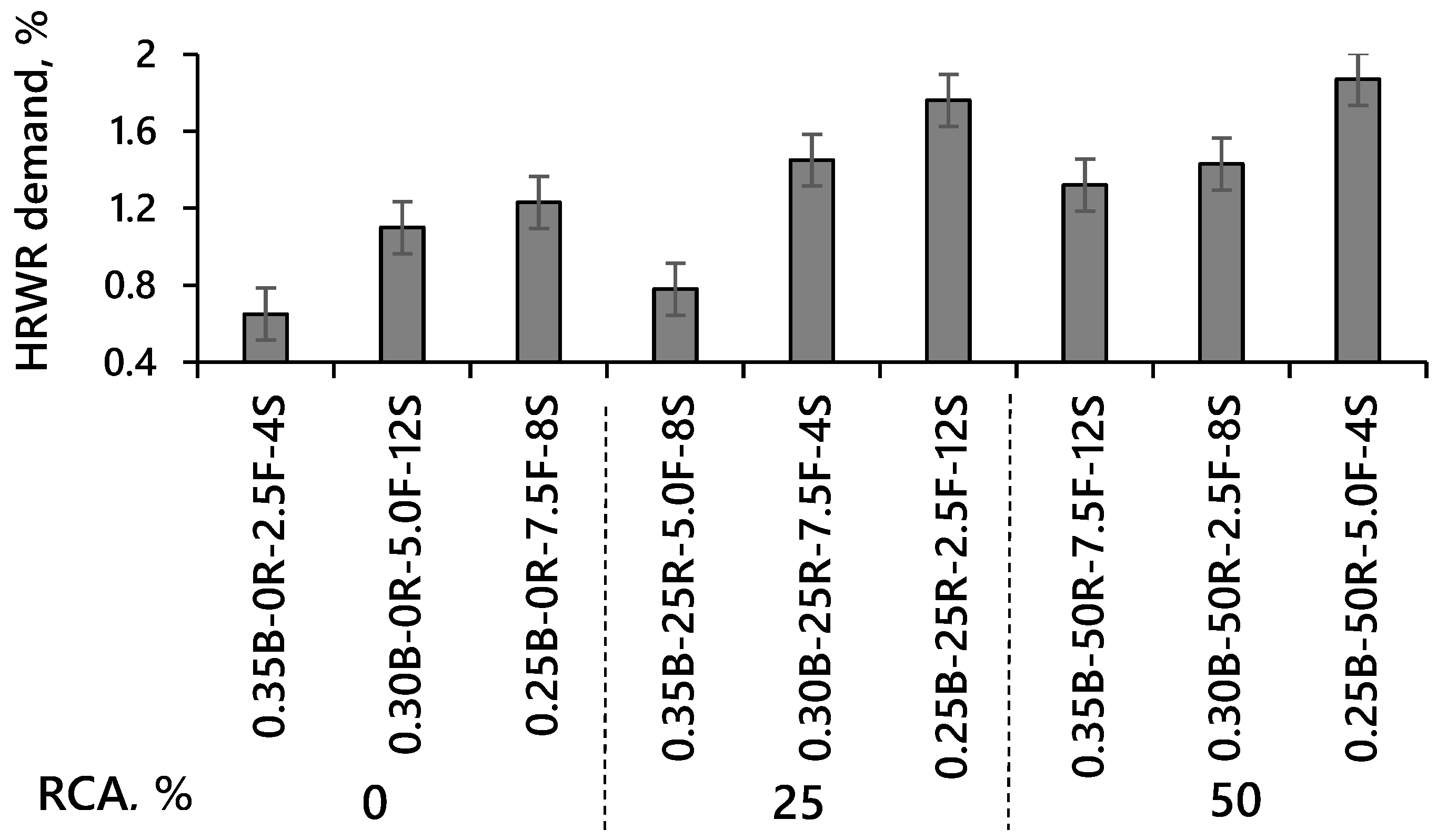

4.1. HRWR Demand

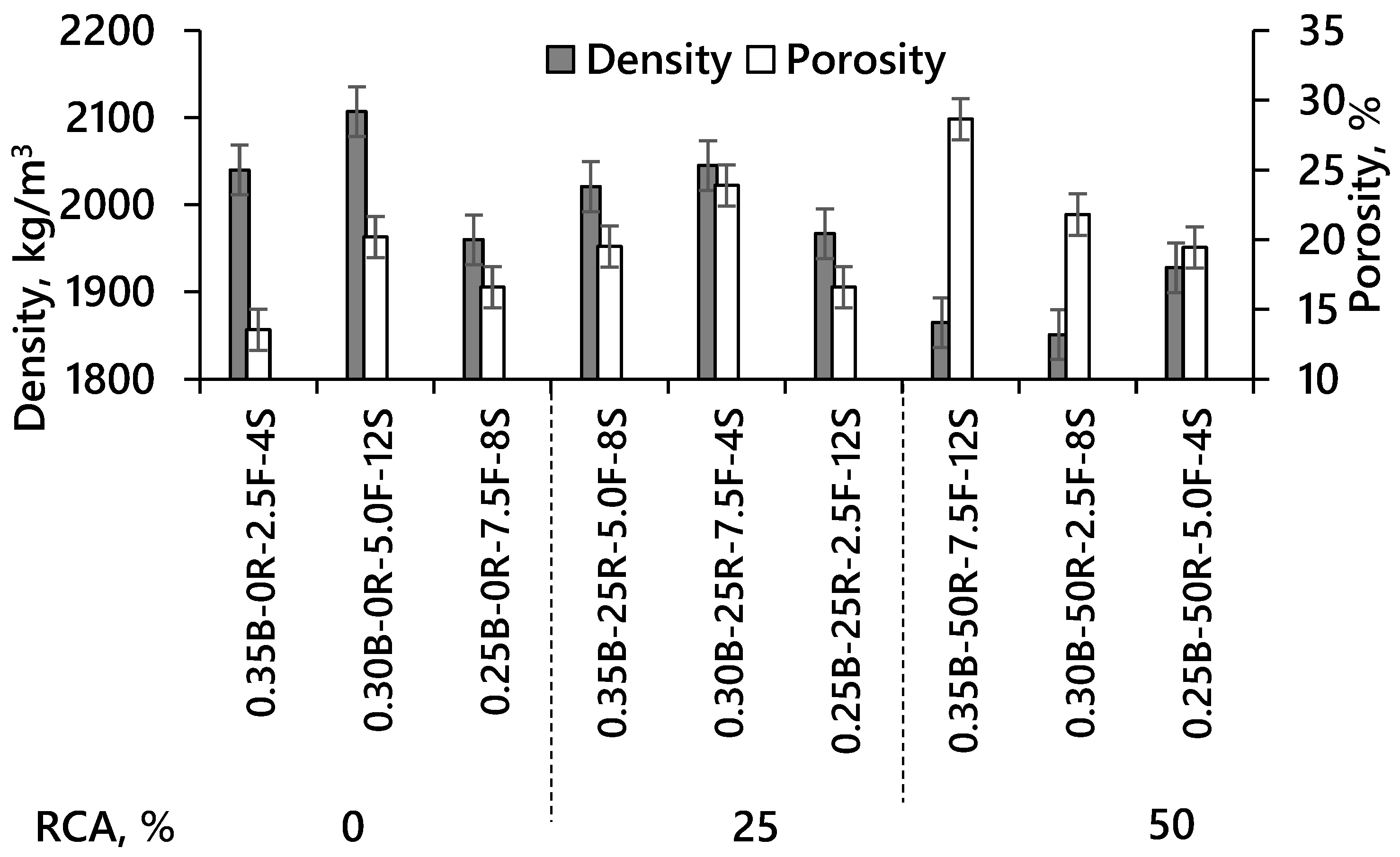

4.2. Density and Porosity

4.3. Compressive Strength

4.4. Splitting Tensile Strength

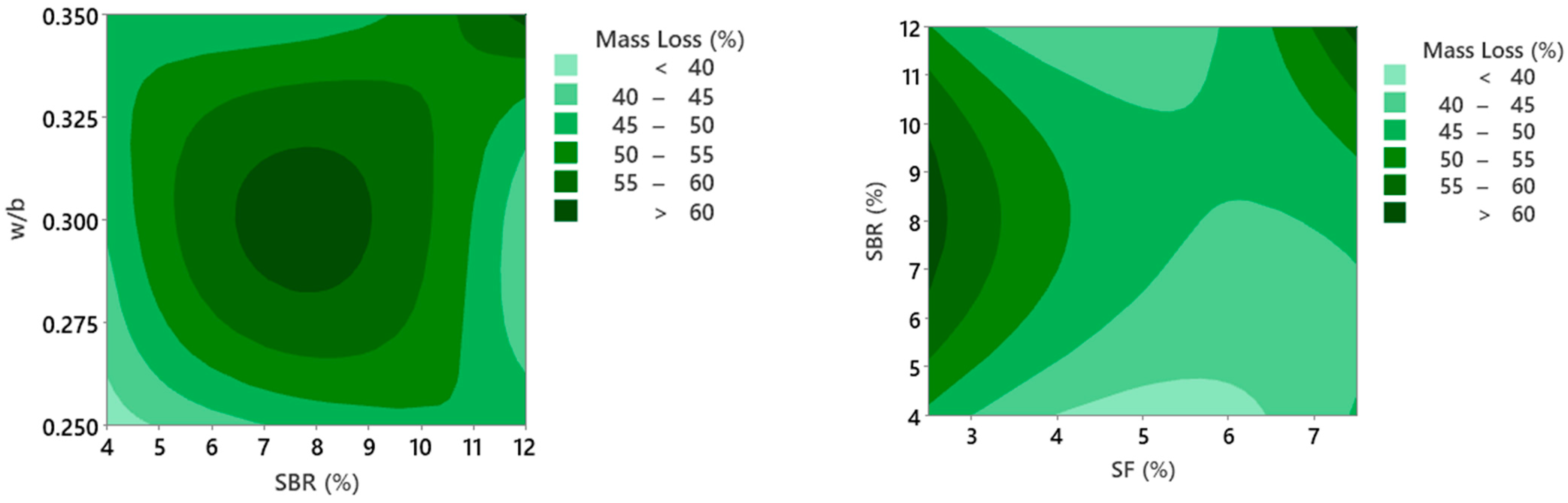

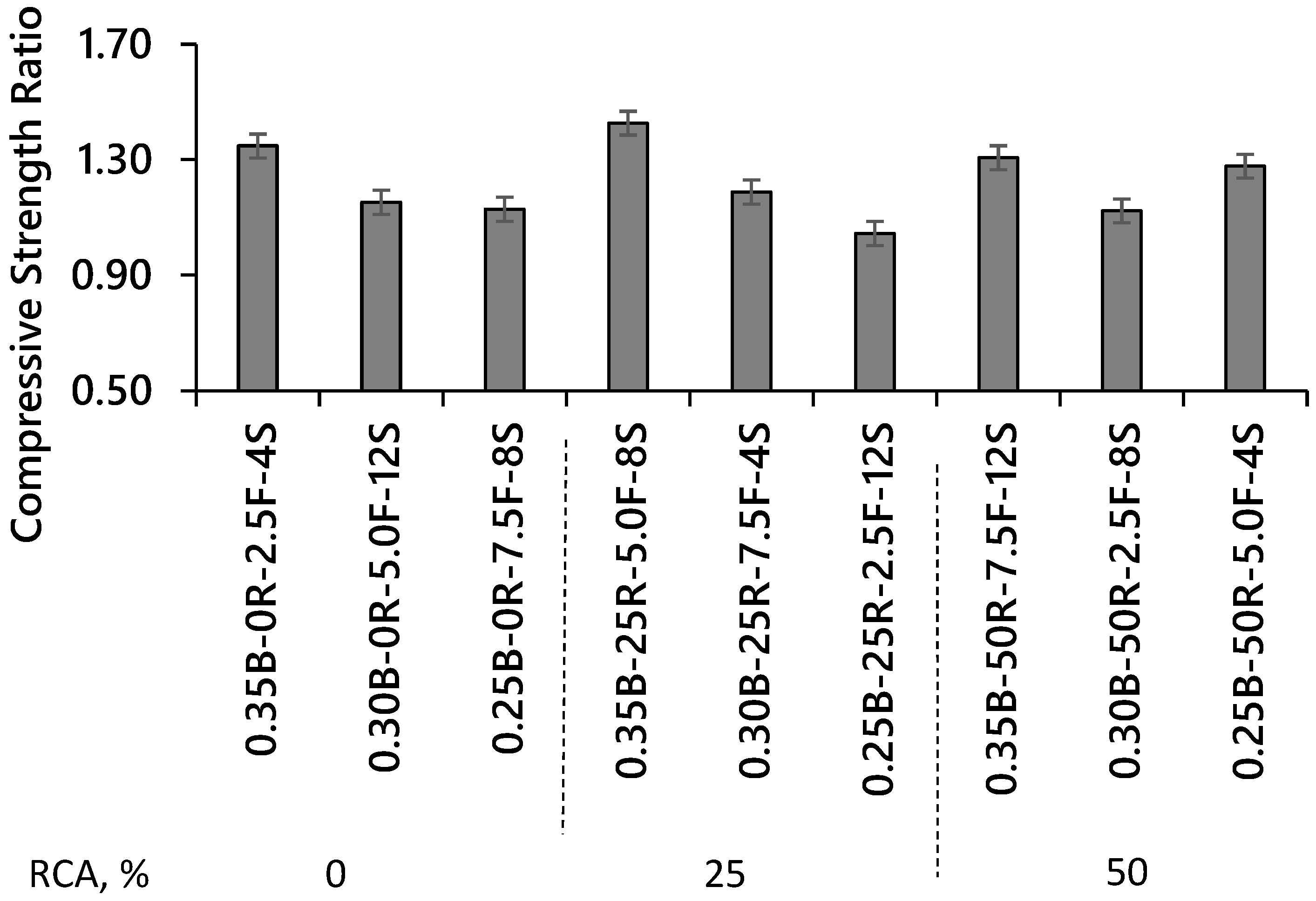

4.5. Abrasion Resistance

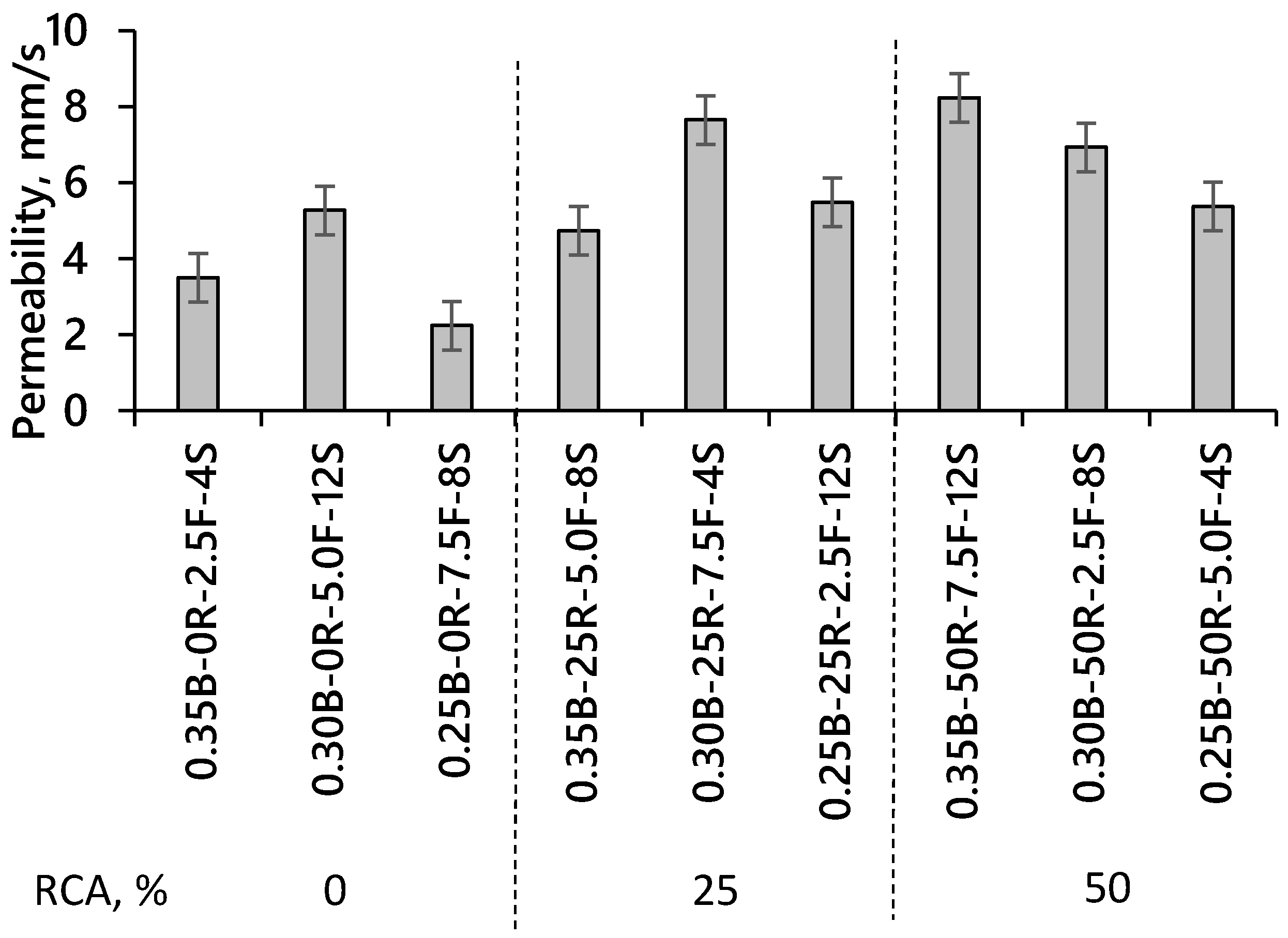

4.6. Permeability

4.7. Freeze and Thaw Resistance

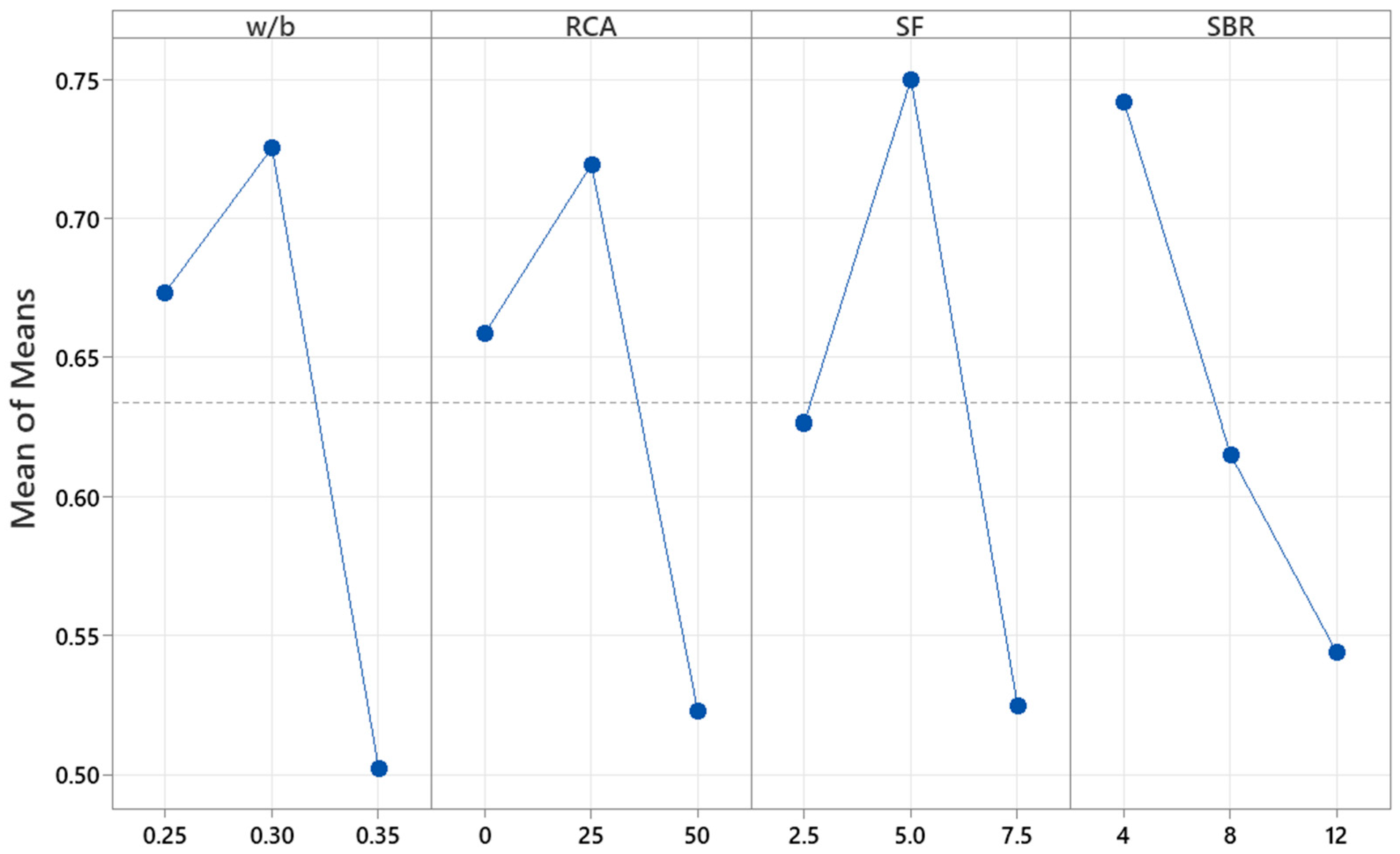

4.8. Multi-Response Optimization

4.8.1. TOPSIS Optimization

4.8.2. Analysis of Variance

5. Conclusions

- Mixtures with higher amounts of RCAs and SF led to an increased demand for HRWR in PC. This increase is due to the higher absorption capacity of RCAs, which increased internal friction within the concrete matrix, reducing workability and consequently requiring more HRWR.

- The porosity of PC increased by up to 28.7% with the addition of RCAs. The lowest density, 1851 kg/m3, was observed in the mixture containing 50% RCAs and a w/b ratio of 0.3. This reduction can be attributed to the porous nature of RCAs and the increased mixing water, both of which contribute to a lower concrete density.

- The compressive strength decreased with the addition of RCAs and SBR but was regained by incorporating SF and/or lowering the w/b ratio. Conversely, the inclusion of SBR improved the splitting tensile strength, which can be attributed to the strengthened bonding within the concrete matrix.

- The results for abrasion resistance mirrored those of compressive strength, suggesting that preserving sufficient abrasion resistance when using RCAs requires lowering the w/b ratio and/or including SF and SBR.

- Permeability values exceeding 7 mm/s were recorded in PC mixes containing a w/b ratio of 0.25–0.35, RCA replacement rates between 25% and 50%, SF replacement rates between 2.5% and 7.5%, and SBR addition rates ranging from 4% to 12%.

- Regardless of the RCA levels, repeated freeze–thaw cycles damaged and weakened the Portland Cement samples, leading to reduced compressive strength. However, lowering the w/b ratio and/or adding SBR helped mitigate this damage, despite the resulting decrease in density.

- The multi-objective optimization analysis revealed that the best performance for PC is achieved with a w/b ratio of 0.30, RCAs of 25%, SF replacement of 5%, and SBR replacement of 4%. Meanwhile, ANOVA results revealed that the mechanical and durability properties were primarily influenced by the w/b ratio and RCA content. While the inclusion of SBR in the mix improved the mechanical performance, it had a limited impact on durability, thereby promoting its use in PC incorporating RCAs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abina, A.; Puc, U.; Zidanšek, A. Challenges and Opportunities of Terahertz Technology in Construction and Demolition Waste Management. J. Environ. Manag. 2022, 315, 115118. [Google Scholar] [CrossRef] [PubMed]

- Uratani, J.M.; Griffiths, S. A Forward Looking Perspective on the Cement and Concrete Industry: Implications of Growth and Development in the Global South. Energy Res. Soc. Sci. 2023, 97, 102972. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Taha, M.R.; Kanaan, D.; Aly, S.T. Ceramic Waste Powder: From Landfill to Sustainable Concretes. Proc. Inst. Civ. Eng.-Constr. Mater. 2017, 171, 109–116. [Google Scholar] [CrossRef]

- Jahami, A.; Younes, H.; Khatib, J. Enhancing Reinforced Concrete Beams: Investigating Steel Dust as a Cement Substitute. Infrastructures 2023, 8, 157. [Google Scholar] [CrossRef]

- Yavuz, D.; Yazıcı, Ş. Experimental Study of Aggregate Size and Gradation on Pervious Concretes’ Mechanic, Hydraulic, and Surface Properties. Struct. Concr. 2023, 24, 5451–5464. [Google Scholar] [CrossRef]

- Ouyang, K.; Shi, C.; Chu, H.; Guo, H.; Song, B.; Ding, Y.; Guan, X.; Zhu, J.; Zhang, H.; Wang, Y.; et al. An Overview on the Efficiency of Different Pretreatment Techniques for Recycled Concrete Aggregate. J. Clean. Prod. 2020, 263, 121264. [Google Scholar] [CrossRef]

- Zhan, P.; Xu, J.; Wang, J.; Zuo, J.; He, Z. A Review of Recycled Aggregate Concrete Modified by Nanosilica and Graphene Oxide: Materials, Performances and Mechanism. J. Clean. Prod. 2022, 375, 134116. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of Sustainable Concrete Using Recycled Coarse Aggregate and Ground Granulated Blast Furnace Slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.J. Concurrent Effects of Recycled Aggregates and Polypropylene Fibers on Workability and Key Strength Properties of Self-Consolidating Concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of Pervious Concrete Incorporating Recycled Concrete Aggregates and Slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Maduabuchukwu Nwakaire, C.; Poh Yap, S.; Chuen Onn, C.; Wah Yuen, C.; Adebayo Ibrahim, H. Utilisation of Recycled Concrete Aggregates for Sustainable Highway Pavement Applications; a Review. Constr. Build. Mater. 2020, 235, 117444. [Google Scholar] [CrossRef]

- Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T. Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates. Sustainability 2021, 13, 10348. [Google Scholar] [CrossRef]

- Lu, J.X.; Yan, X.; He, P.; Poon, C.S. Sustainable Design of Pervious Concrete Using Waste Glass and Recycled Concrete Aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Zou, D.; Zhou, A.; Du, J. Strength Enhancement of Recycled Aggregate Pervious Concrete Using a Cement Paste Redistribution Method. Cem. Concr. Res. 2019, 122, 72–82. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious Concrete Mixture Optimization, Physical, and Mechanical Properties and Pavement Design: A Review. J. Clean. Prod. 2021, 288, 125095. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Kareem, Q.; İpek, S. Effect of Different Substitution of Natural Aggregate by Recycled Aggregate on Performance Characteristics of Pervious Concrete. Mater. Struct. Constr. 2016, 49, 521–536. [Google Scholar] [CrossRef]

- ACI Committee 522. Pervious Concrete; Report No. 522R-10; American Concrete Institute: Farmington Hills, MI, USA, 2010; p. 40. [Google Scholar]

- Akand, L.; Yang, M.; Gao, Z. Characterization of Pervious Concrete through Image Based Micromechanical Modeling. Constr. Build. Mater. 2016, 114, 547–555. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Abdelhady, A.; Yang, J. Comparative laboratory measurement of pervious concrete permeability using constant-head and falling-head permeameter methods. Constr. Build. Mater. 2020, 263, 120614. [Google Scholar] [CrossRef]

- Schaefer, V.R.; Wang, K. Mix Design Development for Pervious Concrete in Cold Weather Climates. Available online: https://www.cptechcenter.org/research/completed/mix-design-development-for-pervious-concrete-in-cold-weather-climates/ (accessed on 1 May 2025).

- Zhong, R.; Leng, Z.; Poon, C. Research and Application of Pervious Concrete as a Sustainable Pavement Material: A State-of-the-Art and State-of-the-Practice Review. Constr. Build. Mater. 2018, 183, 544–553. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, M.; Song, B. Public Perceptions of and Willingness to Pay for Sponge City Initiatives in China. Resour. Conserv. Recycl. 2017, 122, 11–20. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Abdelhady, A.; Yang, J. Effect of Different Factors on Sound Absorption Property of Porous Concrete. Transp. Res. Part D Transp. Environ. 2020, 87, 102532. [Google Scholar] [CrossRef]

- Haselbach, L.; Poor, C.; Tilson, J. Dissolved Zinc and Copper Retention from Stormwater Runoff in Ordinary Portland Cement Pervious Concrete. Constr. Build. Mater. 2014, 53, 652–657. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J. Interfacial Transition Zone of Cement Composites with Recycled Concrete Aggregate of Different Moisture States. Adv. Civ. Eng. Mater. 2018, 7, 87–102. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R.; Salas, A. Initial Moisture and Mixing Effects on Higher Quality Recycled Coarse Aggregate Concrete. Constr. Build. Mater. 2015, 79, 83–89. [Google Scholar] [CrossRef]

- Jahami, A.; Zeaiter, N.; Cheaib, M. Reviewing the Potential: A Comprehensive Review of Natural Fibers (NFs) in Structural Concrete and Their Multifaceted Influences. Innov. Infrastruct. Solut. 2024, 9, 102. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of Silica Fume in Concrete: Review of Hardened Properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Hama, S.M.; Hamadi, E.F.; Jahami, A. Structural Behavior of Reinforced Fibrous Concrete Beams Incorporating Nano Silicon Dioxide Powder. Eng. Rep. 2025, 7, e13078. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, G. Experimental Study on Properties of Pervious Concrete Pavement Materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, Fracture and Fatigue of Pervious Concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Bilal, H.; Gao, X.; Cavaleri, L.; Khan, A.; Ren, M. Mechanical, Durability, and Microstructure Characterization of Pervious Concrete Incorporating Polypropylene Fibers and Fly Ash/Silica Fume. J. Compos. Sci. 2024, 8, 456. [Google Scholar] [CrossRef]

- Liu, R.; Liu, H.; Sha, F.; Yang, H.; Zhang, Q.; Shi, S.; Zheng, Z. Investigation of the Porosity Distribution, Permeability, and Mechanical Performance of Pervious Concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef]

- Fu, T.C.; Yeih, W.; Chang, J.J.; Huang, R. The Influence of Aggregate Size and Binder Material on the Properties of Pervious Concrete. Adv. Mater. Sci. Eng. 2014, 2014, 963971. [Google Scholar] [CrossRef]

- Selvakumar, M.; Geetha, S.; Muthu Lakshmi, S. Optimization of Pervious Concrete with Polymer for Efficient Storm Water Run-Off. Mater. Today Proc. 2022, 64, 995–999. [Google Scholar] [CrossRef]

- Assaad, J.J.; El Mir, A. Durability of Polymer-Modified Lightweight Flowable Concrete Made Using Expanded Polystyrene. Constr. Build. Mater. 2020, 249, 118764. [Google Scholar] [CrossRef]

- Grinys, A.; Augonis, A.; Daukšys, M.; Pupeikis, D. Mechanical Properties and Durability of Rubberized and SBR Latex Modified Rubberized Concrete. Constr. Build. Mater. 2020, 248, 118584. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of Silica Fume, Metakaolin & SBR Latex on Strength and Durability Performance of Pervious Concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar] [CrossRef]

- Borhan, T.M.; Al Karawi, R.J. Experimental Investigations on Polymer Modified Pervious Concrete. Case Stud. Constr. Mater. 2020, 12, e00335. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, G.; Qi, Y.; Zeng, Q. In-Situ Assessment of the Water-Penetration Resistance of Polymer Modified Cement Mortars by μ-XCT, SEM and EDS. Cem. Concr. Compos. 2020, 114, 103821. [Google Scholar] [CrossRef]

- Giustozzi, F. Polymer-Modified Pervious Concrete for Durable and Sustainable Transportation Infrastructures. Constr. Build. Mater. 2016, 111, 502–512. [Google Scholar] [CrossRef]

- Pindado, M.Á.; Aguado, A.; Josa, A. Fatigue Behavior of Polymer-Modified Porous Concretes. Cem. Concr. Res. 1999, 29, 1077–1083. [Google Scholar] [CrossRef]

- Kantasiri, T.; Kasemsiri, P.; Pongsa, U.; Posi, P.; Chindaprasirt, P. Optimization of Concrete Containing Waste Crumb Rubber Mix Design for Thermal Insulating Applications Using Taguchi Method. Constr. Build. Mater. 2024, 434, 136636. [Google Scholar] [CrossRef]

- Yildizel, S.A.; Özkılıç, Y.O.; Yavuz, A. Optimization of Waste Tyre Steel Fiber and Rubber Added Foam Concretes Using Taguchi Method and Artificial Neural Networks. Structures 2024, 61, 106098. [Google Scholar] [CrossRef]

- Vinod, B. Characterization and Preparation of Eco-Friendly Foamed Concrete Using a Foaming Agent: Optimizing the Design by Taguchi Analysis. J. Build. Eng. 2024, 88, 109068. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C1240; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM: West Conshohocken, PA, USA, 2017.

- El-Mir, A.; Nehme, S.; Assaad, J. Magazine of Civil Engineering Feasibility of Concrete Mixtures Containing Coarse and/or Fine Recycled Brick Aggregates. Mag. Civ. Eng. 2022, 116, 11603. [Google Scholar] [CrossRef]

- Pereira da Costa, F.B.; Haselbach, L.M.; da Silva Filho, L.C.P. Pervious Concrete for Desired Porosity: Influence of w/c Ratio and a Rheology-Modifying Admixture. Constr. Build. Mater. 2021, 268, 121084. [Google Scholar] [CrossRef]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C1754; Standard Test Method for Determining Potential Resistance to Degradation of Pervious Concrete by Impact and Abrasion. ASTM: West Conshohocken, PA, USA, 2011.

- ASTM C1747; Standard Test Method for Density and Void Content of Hardened Pervious Concrete. ASTM: West Conshohocken, PA, USA, 2021.

- Safiuddin, M.D.; Salam, M.A.; Jumaat, M.Z. Effects of Recycled Concrete Aggregate on the Fresh Properties of Self-Consolidating Concrete. Arch. Civ. Mech. Eng. 2011, 11, 1023–1041. [Google Scholar] [CrossRef]

- Xu, C.; Li, Q.; Wang, P.; Fan, Q.; Kong, Z.; Wang, L.; Yue, G.; Zheng, S.; Shao, C.; Guo, Y. Theoretical Porosity Design, Mechanical Properties, and Durability of Large-Pore Sandy Recycled Concrete. Case Stud. Constr. Mater. 2024, 21, e03655. [Google Scholar] [CrossRef]

- El-Mir, A.; Fayad, T.; Assaad, J.J.; Ezzedine El Dandachy, M.; Khatib, J.; El-Hassan, H. Multi-criteria optimization of SBR-modified mortar incorporating polyethylene terephthalate waste. Case Stud. Constr. Mat. 2024, 20, e03295. [Google Scholar] [CrossRef]

- Kevern, J.T.; Schaefer, V.R.; Wang, K. Mixture Proportion Development and Performance Evaluation of Pervious Concrete for Overlay Applications; American Concrete Institute: Farmington Hills, MI, USA, 2011; Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal.aspx?m=details&id=51683117 (accessed on 1 May 2025).

- Siddique, R.; Bennacer, R. Resources, Conservation and Recycling Use of Iron and Steel Industry by-Product (GGBS) in Cement Paste and Mortar. Resour. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Seifeddine, K.; Amziane, S.; Toussaint, E. State of the Art on the Mechanical Properties of Pervious Concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 7727–7755. [Google Scholar] [CrossRef]

- Ribeiro, M.S.S.; Gonçalves, A.F.; Branco, F.A.B. Styrene-Butadiene Polymer Action on Compressive and Tensile Strengths of Cement Mortars. Mater. Struct. Constr. 2008, 41, 1263–1273. [Google Scholar] [CrossRef]

- Ohama, Y. Handbook of Polymer-modified Concrete and Mortars: Properties and Process Technology; Noyes Publications: Saddle River, NJ, USA, 1995. [Google Scholar]

- Sakka, F.E.; Assaad, J.J.; Hamzeh, F.R.; Nakhoul, C. Thixotropy and Interfacial Bond Strengths of Polymer-Modified Printed Mortars. Mater. Struct. Constr. 2019, 52, 79. [Google Scholar] [CrossRef]

- Xiao, S.; Cheng, H.; Que, Z.; Liu, T.; Zou, D. Enhancing Marine Anti-Washout Concrete: Optimal Silica Fume Usage for Improved Compressive Strength and Abrasion Resistance. Constr. Build. Mater. 2024, 428, 136262. [Google Scholar] [CrossRef]

- Tennis, P.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Portland Cement Association and National Ready Mixed Concrete Association: Skokie, IL, USA; Silver Spring, MD, USA, 2004; Available online: https://trid.trb.org/View/813983 (accessed on 1 May 2025).

- Doğan, M.; Bideci, A. Effect of Styrene Butadiene Copolymer (SBR) admixture on high strength concrete. Constr. Build. Mater. 2016, 112, 378–385. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Daiezadeh, M.J.; Zakertabrizi, M.; Zahmatkesh, F.; Habibnejad Korayem, A. A Review of the Impact of Micro- and Nanoparticles on Freeze-Thaw Durability of Hardened Concrete: Mechanism Perspective. Constr. Build. Mater. 2018, 186, 1105–1113. [Google Scholar] [CrossRef]

- Craeye, B.; Cockaerts, G.; Kara De Maeijer, P. Improving Freeze–Thaw Resistance of Concrete Road Infrastructure by Means of Superabsorbent Polymers. Infrastructures 2018, 3, 4. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, Y.; Zhang, S.; Xu, F.; Zhu, X.; Jiang, X.; Zhou, L.; Shen, Y.; Chen, Q.; Yan, Z.; et al. Research Progress of the Thermophysical and Mechanical Properties of Concrete Subjected to Freeze-Thaw Cycles. Constr. Build. Mater. 2022, 330, 127254. [Google Scholar] [CrossRef]

- El-Mir, A.; Najm, O.; El-Hassan, H.; El-Dieb, A.; Alzamly, A. Enhancing the electrical conductivity of concrete using metal-organic frameworks. Constr. Build. Mater. 2024, 425, 136061. [Google Scholar] [CrossRef]

| Factor, F | Levels | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| F1: w/b, by mass | 0.35 | 0.30 | 0.25 |

| F2: RCA replacement, % by mass | 0 | 25 | 50 |

| F3: SF replacement rate, % by mass | 2.5 | 5.0 | 7.5 |

| F4: SBR addition rate, % by mass | 4 | 8 | 12 |

| Mix No. | Mix Code * | w/b | RCA Replacement, % Mass | SF Replacement Rate, % Mass | SBR Addition Rate, % Mass |

|---|---|---|---|---|---|

| 1 | 0.35B-0R-2.5F-4S | 0.35 | 0 | 2.5 | 4 |

| 2 | 0.35B-25R-5.0F-8S | 0.35 | 25 | 5 | 8 |

| 3 | 0.35B-50R-7.5F-12S | 0.35 | 50 | 7.5 | 12 |

| 4 | 0.30B-0R-5.0F-12S | 0.30 | 0 | 5 | 12 |

| 5 | 0.30B-25R-7.5F-4S | 0.30 | 25 | 7.5 | 4 |

| 6 | 0.30B-50R-2.5F-8S | 0.30 | 50 | 2.5 | 8 |

| 7 | 0.25B-0R-7.5F-8S | 0.25 | 0 | 7.5 | 8 |

| 8 | 0.25B-25R-2.5F-12S | 0.25 | 25 | 2.5 | 12 |

| 9 | 0.25B-50R-5.0F-4S | 0.25 | 50 | 5 | 4 |

| Mix Codification | Density, kg/m3 | HRWR, % | Porosity, % | Compressive Strength, MPa | Splitting Tensile Strength, MPa | Permeability, mm/s | Abrasion Resistance, % | * Residual Compressive Strength, MPa |

|---|---|---|---|---|---|---|---|---|

| 0.35B-0R-2.5F-4S | 2040 | 0.51 | 13.5 | 10.9 | 1.1 | 3.50 | 48.5 | 8.1 |

| 0.35B-25R-5.0F-8S | 2021 | 0.78 | 19.5 | 9.8 | 1.3 | 4.73 | 46.5 | 6.9 |

| 0.35B-50R-7.5F-12S | 1865 | 0.90 | 28.7 | 7.2 | 0.6 | 8.23 | 62.3 | 5.5 |

| 0.30B-0R-5.0F-12S | 2107 | 1.10 | 20.2 | 11.1 | 1.2 | 5.27 | 40.9 | 9.7 |

| 0.30B-25R-7.5F-4S | 2045 | 1.60 | 23.9 | 11.2 | 1.3 | 7.65 | 45.7 | 9.5 |

| 0.30B-50R-2.5F-8S | 1851 | 0.87 | 21.8 | 8.2 | 0.9 | 6.93 | 61.9 | 7.3 |

| 0.25B-0R-7.5F-8S | 1960 | 0.43 | 16.6 | 10.1 | 1.0 | 2.24 | 46.5 | 9.0 |

| 0.25B-25R-2.5F-12S | 1967 | 0.23 | 16.6 | 8.9 | 1.0 | 5.48 | 50.2 | 8.6 |

| 0.25B-50R-5.0F-4S | 1928 | 1.30 | 19.4 | 11.5 | 1.4 | 5.37 | 37.7 | 9.0 |

| Performance Indicator | S/N Goal Response | Rank (r) | Normalized r |

|---|---|---|---|

| Density | Smaller is better | 9 | 0.167 |

| Compressive Strength | Larger is better | 9 | 0.167 |

| Permeability | Larger is better | 9 | 0.167 |

| Freeze and thaw resistance | Smaller is better | 9 | 0.167 |

| Property | w/b | RCA | SF | SBR |

|---|---|---|---|---|

| Density | 5.5 | 71.2 | 13.9 | 9.5 |

| Compressive strength | 41.8 | 28.3 | 20.9 | 9.0 |

| Splitting tensile strength | 10.0 | 21.2 | 36.2 | 32.6 |

| Permeability | 26.3 | 56.1 | 0.1 | 17.5 |

| Abrasion resistance | 47.1 | 16.2 | 16.5 | 20.2 |

| Freeze–thaw resistance | 52.9 | 28.8 | 4.0 | 14.4 |

| Source | DF | Seq SS | Adj SS | Adj MS |

|---|---|---|---|---|

| w/b | 2 | 0.06 | 0.06 | 0.03 |

| RCA | 2 | 0.81 | 0.81 | 0.41 |

| SF | 2 | 0.16 | 0.16 | 0.08 |

| SBR | 2 | 0.11 | 0.11 | 0.05 |

| Source | DF | Seq SS | Adj SS | Adj MS |

|---|---|---|---|---|

| w/b | 2 | 26.23 | 26.23 | 13.11 |

| RCA | 2 | 55.85 | 55.85 | 27.92 |

| SF | 2 | 0.05 | 0.05 | 0.03 |

| SBR | 2 | 17.47 | 17.47 | 8.74 |

| Source | DF | Seq SS | Adj SS | Adj MS |

|---|---|---|---|---|

| w/b | 2 | 2.78 | 2.78 | 1.39 |

| RCA | 2 | 2.72 | 2.72 | 1.36 |

| SF | 2 | 7.92 | 7.92 | 3.96 |

| SBR | 2 | 3.40 | 3.40 | 1.70 |

| Source | DF | Seq SS | Adj SS | Adj MS |

|---|---|---|---|---|

| w/b | 2 | 10.76 | 10.76 | 5.38 |

| RCA | 2 | 5.87 | 5.87 | 2.93 |

| SF | 2 | 0.81 | 0.81 | 0.40 |

| SBR | 2 | 2.93 | 2.93 | 1.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Mir, A.; Tannouri, P.; Assaad, J.J.; Nasr, D.; Ghannoum, M.; Barraj, F.; El-Hassan, H. Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates. J. Compos. Sci. 2025, 9, 372. https://doi.org/10.3390/jcs9070372

El-Mir A, Tannouri P, Assaad JJ, Nasr D, Ghannoum M, Barraj F, El-Hassan H. Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates. Journal of Composites Science. 2025; 9(7):372. https://doi.org/10.3390/jcs9070372

Chicago/Turabian StyleEl-Mir, Abdulkader, Perla Tannouri, Joseph J. Assaad, Dana Nasr, Maria Ghannoum, Firas Barraj, and Hilal El-Hassan. 2025. "Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates" Journal of Composites Science 9, no. 7: 372. https://doi.org/10.3390/jcs9070372

APA StyleEl-Mir, A., Tannouri, P., Assaad, J. J., Nasr, D., Ghannoum, M., Barraj, F., & El-Hassan, H. (2025). Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates. Journal of Composites Science, 9(7), 372. https://doi.org/10.3390/jcs9070372