Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

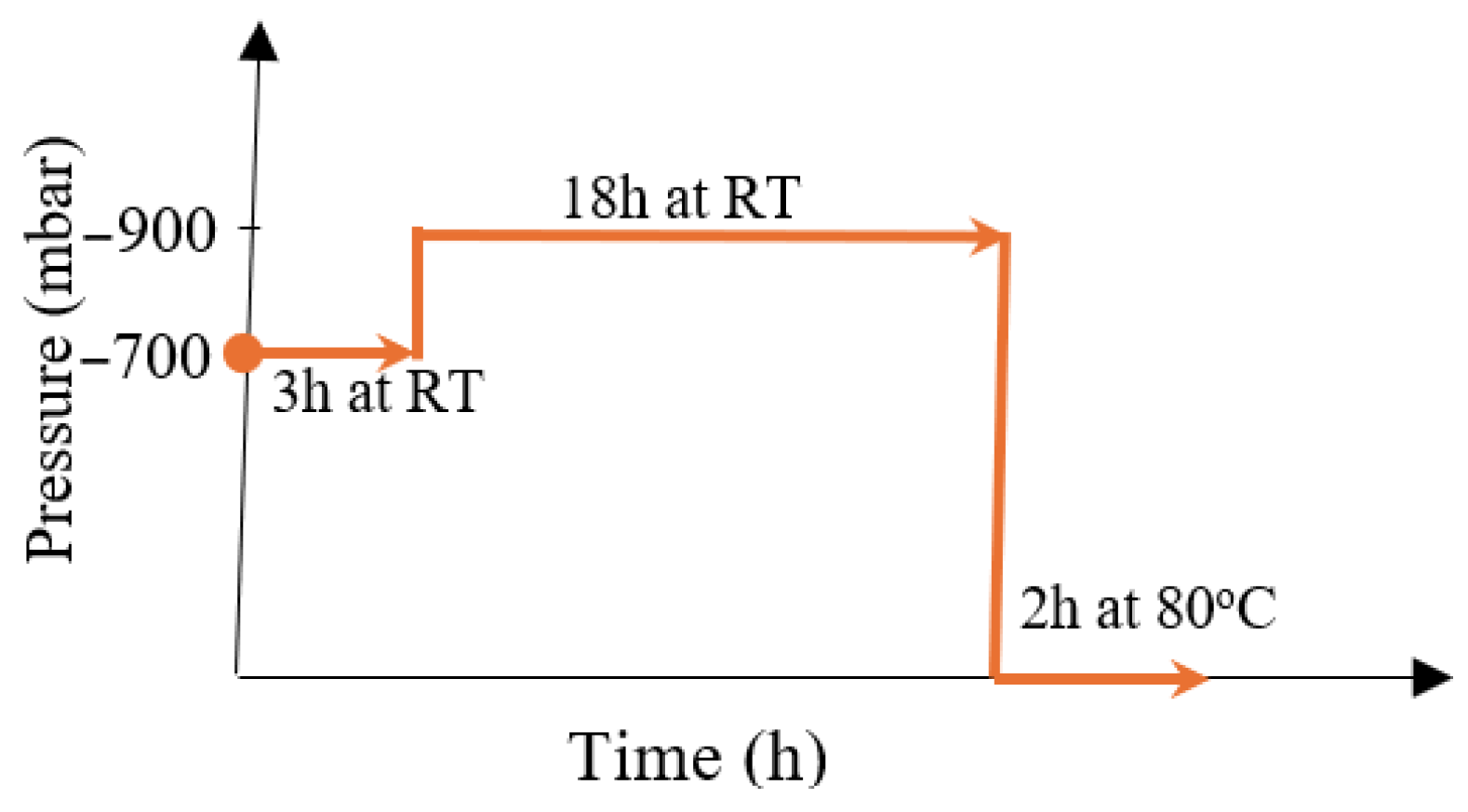

2.2. Manufacturing

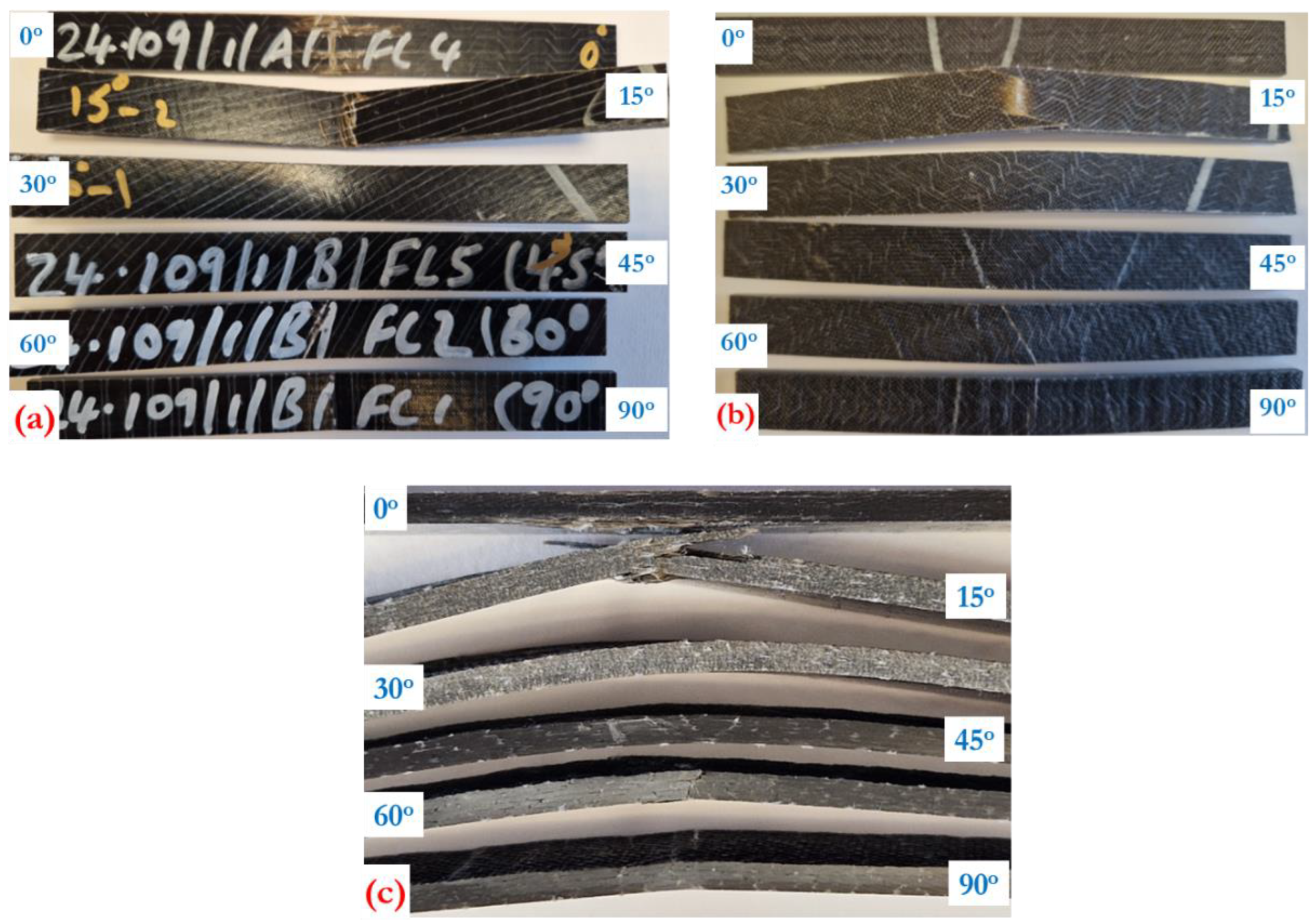

2.3. Flexural Testing Procedures

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A Review on Durability of Basalt Fiber Reinforced Concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Valente, T.; Cioffi, S.; Iannace, S.; Sorrentino, L. Effect of Basalt Fiber Hybridization on the Impact Behavior under Low Impact Velocity of Glass/Basalt Woven Fabric/Epoxy Resin Composites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 109–123. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L.; Gaudenzi, P.; Cioffi, S.; Iannace, S.; Sorrentino, L. Drop-Weight Impact Behaviour of Woven Hybrid Basalt–Carbon/Epoxy Composites. Compos. Part B Eng. 2014, 59, 204–220. [Google Scholar] [CrossRef]

- Shi, J.-W.; Zhu, H.; Wu, G.; Wu, Z.-S. Tensile Behavior of FRP and Hybrid FRP Sheets in Freeze–Thaw Cycling Environments. Compos. Part B Eng. 2014, 60, 239–247. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical Characterisation of Basalt Fibre Reinforced Plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Fatigue Resistance of Basalt Fibers-Reinforced Laminates. J. Compos. Mater. 2012, 46, 1773–1785. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of Basalt Fibre and Glass Fibre/Epoxy Resin Composites in Seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Sun, W.; Wu, Z.; Huang, C.; Wang, Z.; Huang, R.; Gong, L.; Nishimura, A.; Zhou, Y.; Li, L. Investigation on Cryogenic Mechanical Properties of Basalt Fiber-Reinforced Epoxy Composites. Cryogenics 2023, 132, 103684. [Google Scholar] [CrossRef]

- He, J.; Shi, J.; Cao, X.; Hu, Y. Tensile Mechanical Properties and Failure Modes of a Basalt Fiber/Epoxy Resin Composite Material. Adv. Civ. Eng. 2018, 2018, 7914727. [Google Scholar] [CrossRef]

- Raajeshkrishna, C.R.; Chandramohan, P. Effect of Reinforcements and Processing Method on Mechanical Properties of Glass and Basalt Epoxy Composites. SN Appl. Sci. 2020, 2, 959. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Marra, F.; Pulci, G.; Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, M. Post-Impact Mechanical Characterisation of Glass and Basalt Woven Fabric Laminates. Appl. Compos. Mater. 2012, 19, 475–490. [Google Scholar] [CrossRef]

- Manikandan, V.; Winowlin Jappes, J.T.; Suresh Kumar, S.M.; Amuthakkannan, P. Investigation of the Effect of Surface Modifications on the Mechanical Properties of Basalt Fibre Reinforced Polymer Composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Gideon, R.K.; Hu, H.; Wambua, P.; Gu, B. Characterizations of Basalt Unsaturated Polyester Laminates under Static Three-point Bending and Low-velocity Impact Loadings. Polym. Compos. 2014, 35, 2203–2213. [Google Scholar] [CrossRef]

- Patel, N.; Patel, K.; Chaudhary, V.; Gohil, P. Investigations on Drilling of Hybrid Basalt/Glass Polyester Composites. Aust. J. Mech. Eng. 2022, 20, 1154–1163. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Patel, S.; Sachan, Y.; Ahmad, S.; Alagirusamy, R.; Bhatnagar, N. Mechanical Behavior of Kevlar/Basalt Reinforced Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 642–652. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Patel, S.; Sachan, Y.; Ahmad, S.; Alagirusamy, R.; Bhatnagar, N. Mechanical Characterization of 3D Angle-Interlock Kevlar/Basalt Reinforced Polypropylene Composites. Polym. Test. 2016, 55, 238–246. [Google Scholar] [CrossRef]

- Tehrani Dehkordi, M.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. The Influence of Hybridization on Impact Damage Behavior and Residual Compression Strength of Intraply Basalt/Nylon Hybrid Composites. Mater. Des. 2013, 43, 283–290. [Google Scholar] [CrossRef]

- Raajeshkrishna, C.; Pradeep, A.; Rishi Kumar, R. Influence of Fiber Content on Mechanical, Tribological Properties of Short Basalt Fiber-Reinforced Nylon 6 and Polypropylene Composites. J. Thermoplast. Compos. Mater. 2021, 34, 765–779. [Google Scholar] [CrossRef]

- Yan, X.; Wang, F.; Luo, Y.; Liu, X.; Yang, Z.; Mao, H. Mechanical Performance Study of Basalt-Polyethylene Fiber Reinforced Concrete under Dynamic Compressive Loading. Constr. Build. Mater. 2023, 409, 133935. [Google Scholar] [CrossRef]

- Kumar, P.; Maiti, T.K.; Maurya, A.K.; Adwani, P. Effect of Alkali Treated Groundnut Shell Powder in the Basalt Fiber Reinforced Polyethylene Hybrid Composites: A Sustainable Approach towards Green Composites. Polym. Compos. 2023, 44, 3952–3963. [Google Scholar] [CrossRef]

- Arkema. Liquid Thermoplastic Resin for Tougher Composites. Available online: https://www.Arkema.Com/Global/En/Resources/Post/Elium-Resin-Breakthrough-Innovation/ (accessed on 21 April 2025).

- Nash, N.H.; Bachour Sirerol, C.; Manolakis, I.; Comer, A. Thermoplastic Infusible Resin Systems: Candidates for the Marine Sector? In Proceedings of the 18th European Conference on Composite Materials (ECCM 2018), Athens, Greece, 25–28 June 2018; European Society for Composite Materials: Nantes, France, 2018. [Google Scholar]

- Han, N.; Baran, I.; Zanjani, J.S.M.; Yuksel, O.; An, L.; Akkerman, R. Experimental and Computational Analysis of the Polymerization Overheating in Thick Glass/Elium® Acrylic Thermoplastic Resin Composites. Compos. Part B Eng. 2020, 202, 108430. [Google Scholar] [CrossRef]

- Khalili, P.; Blinzler, B.; Kádár, R.; Bisschop, R.; Försth, M.; Blomqvist, P. Flammability, Smoke, Mechanical Behaviours and Morphology of Flame Retarded Natural Fibre/Elium® Composite. Materials 2019, 12, 2648. [Google Scholar] [CrossRef]

- Carallo, G.A.; Casa, M.; Kelly, C.; Alsaadi, M. Comparative Life Cycle Assessment (LCA) of Traditional and New Sustainable Wind Blade Construction. Sustainability 2025, 17, 2026. [Google Scholar] [CrossRef]

- Arkema. Elium® Resin for Composite Hydrogen Tanks. Available online: https://www.Arkema.Com/Global/En/Products/Product-Finder/Product/Incubator/Elium/Elium-Resin-Forcomposite-Hydrogen-Tanks/ (accessed on 29 March 2025).

- Raponi, O.d.A.; Barbosa, L.C.M.; de Souza, B.R.; Ancelotti Junior, A.C. Study of the Influence of Initiator Content in the Polymerization Reaction of a Thermoplastic Liquid Resin for Advanced Composite Manufacturing. Adv. Polym. Technol. 2018, 37, 3579–3587. [Google Scholar] [CrossRef]

- Obande, W.; Brádaigh, C.M.Ó.; Ray, D. Continuous Fibre-Reinforced Thermoplastic Acrylic-Matrix Composites Prepared by Liquid Resin Infusion—A Review. Compos. Part B Eng. 2021, 215, 108771. [Google Scholar] [CrossRef]

- Stanley, W.F.; Bandaru, A.K.; Rana, S.; Parveen, S.; Pichandi, S. Mechanical, Dynamic-Mechanical and Wear Performance of Novel Non-Crimp Glass Fabric-Reinforced Liquid Thermoplastic Composites Filled with Cellulose Microcrystals. Mater. Des. 2021, 212, 110276. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Taheri, F. Mechanical Performance of a Novel Environmentally Friendly Basalt-Elium® Thermoplastic Composite and Its Stainless Steel-Based Fiber Metal Laminate. Polym. Compos. 2021, 42, 4660–4672. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Analysis of the Mechanical Behaviour of Flax and Glass Fabrics-Reinforced Thermoplastic and Thermoset Resins. J. Reinf. Plast. Compos. 2016, 35, 1217–1232. [Google Scholar] [CrossRef]

- Taheri, F.; Llanos, J.R.J.G. Comparative Performance of Kevlar, Glass and Basalt Epoxy- and Elium-Based Composites under Static-, Low- and High-Velocity Loading Scenarios—Introduction to an Effective Recyclable and Eco-Friendly Composite. Polymers 2024, 16, 1494. [Google Scholar] [CrossRef] [PubMed]

- Bandaru, A.K.; Pothnis, J.R.; Portela, A.; Gujjala, R.; Ma, H.; O’Higgins, R.M. Flexural and Interlaminar Shear Response of Novel Methylmethacrylate Composites Reinforced with High-Performance Fibres. Polym. Test. 2024, 140, 108578. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Karuppanan, S.; Choudhry, R.S.; Sajid, Z. Off-Axis and On-Axis Performance of Novel Acrylic Thermoplastic (Elium®) 3D Fibre-Reinforced Composites under Flexure Load. Polymers 2022, 14, 2225. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Sun, M.; Liu, X.; Xiao, X.; Qian, K. Off-Axis Bending Behaviors and Failure Characterization of 3D Woven Composites. Compos. Struct. 2019, 208, 45–55. [Google Scholar] [CrossRef]

- Alsaadi, M.; Erkliğ, A.; Alrawi, H. Effect of S-Glass Fabric on the Mechanical Characteristics of a Hybrid Carbon/Aramid Fabric Reinforced Epoxy Composites. Mater. Res. Express 2017, 4, 055304. [Google Scholar] [CrossRef]

- Bulut, M.; Erkliğ, A.; Alsaadi, M.; Kchany, S. Effects of Stacking Sequence on Mechanical Properties of Hybrid Composites Reinforced with Carbon, Kevlar and S-Glass Fibers. Mater. Test. 2017, 59, 472–479. [Google Scholar] [CrossRef]

- Ma, Y. Characterisation of Mechanical Behaviour of Fibre Reinforced Thermoplastic Composites Subjected to Off-Axis Compressive Loading. Métodos Numéricos Para Cálculo Diseño Ing. Rev. Int. 2023, 39, 1–11. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Cacik, F.; Eskizeybek, V.; Avci, A. Multi-Scale Mechanical Behavior of Liquid Elium® Based Thermoplastic Matrix Composites Reinforced with Different Fiber Types: Insights from Fiber–Matrix Adhesion Interactions. Fibers Polym. 2024, 25, 4935–4950. [Google Scholar] [CrossRef]

- Mandal, T.K.; Nguyen, V.P.; Wu, J.-Y. Length Scale and Mesh Bias Sensitivity of Phase-Field Models for Brittle and Cohesive Fracture. Eng. Fract. Mech. 2019, 217, 106532. [Google Scholar] [CrossRef]

- Mujika, F.; Valea, A.; Gañán, P.; Mondragon, I. Off-Axis Flexure Test: A New Method for Obtaining In-Plane Shear Properties. J. Compos. Mater. 2005, 39, 953–980. [Google Scholar] [CrossRef]

- Wisnom, M.R. The Role of Delamination in Failure of Fibre-Reinforced Composites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2012, 370, 1850–1870. [Google Scholar] [CrossRef] [PubMed]

- ASTM D 790-10; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2010.

| Property | Elium®191 XO/SA |

|---|---|

| Viscosity (cP) at 25 °C | 100 |

| Density (g/cm3) at RT | 1.01 |

| Gel time (min) at 25 °C | 210–260 |

| Curing process at RT | 24 h infusion and cure |

| Post-curing | 2 h at 80 °C |

| Tensile strength (MPa) | 47.10 |

| Tensile modulus (GPa) | 2.68 |

| Flexural strength (MPa) | 80.51 |

| Flexural modulus (GPa) | 2.77 |

| Composite | Basalt Fibre Structure | Polymer Matrix |

|---|---|---|

| Elium®191 XO/SA, three parts: | ||

| BF/Elium | BAS-UNI 550:

| 191 XO acrylic resin (50 wt%), 191 SA accelerator (50 wt%), and methyl ethyl ketone peroxide (MEKP) initiator (2 wt%) |

| Fibre Orientation (Deg.) | Max. Load (N) | Flexural Strength (MPa) | Variation (%) | Failure Strain (%) | Variation (%) | Flexural Modulus (GPa) | Variation (%) |

|---|---|---|---|---|---|---|---|

| 0° | 806.0 ± 4.5 | 1128.3 ± 5.90 | - | 3.86 ± 0.42 | - | 36.60 ± 1.49 | - |

| 15° | 396.6 ± 2.1 | 594.8 ± 2.49 | −47.4 | 5.79 ± 0.02 | 50.1 | 31.78 ± 0.80 | −13.2 |

| 30° | 172.2 ± 1.8 | 254.2 ± 2.12 | −77.5 | 6.00 ± 0.23 | 55.6 | 18.16 ± 0.36 | −50.4 |

| 45° | 95.4 ± 12.1 | 143.4 ± 14.68 | −87.3 | 6.04 ± 0.32 | 55.7 | 12.59 ± 0.05 | −65.6 |

| 60° | 96.8 ± 5.8 | 145.0 ± 6.13 | −87.1 | 4.77 ± 0.05 | 23.7 | 11.94 ± 0.86 | −67.4 |

| 90° | 107.1 ± 14.4 | 165.2 ± 16.99 | −85.4 | 2.58 ± 0.36 | −33.1 | 13.14 ± 1.19 | −64.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaadi, M.; Bandaru, A.K.; Flanagan, T.; Devine, D.M. Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites. J. Compos. Sci. 2025, 9, 347. https://doi.org/10.3390/jcs9070347

Alsaadi M, Bandaru AK, Flanagan T, Devine DM. Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites. Journal of Composites Science. 2025; 9(7):347. https://doi.org/10.3390/jcs9070347

Chicago/Turabian StyleAlsaadi, Mohamad, Aswani Kumar Bandaru, Tomas Flanagan, and Declan M. Devine. 2025. "Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites" Journal of Composites Science 9, no. 7: 347. https://doi.org/10.3390/jcs9070347

APA StyleAlsaadi, M., Bandaru, A. K., Flanagan, T., & Devine, D. M. (2025). Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites. Journal of Composites Science, 9(7), 347. https://doi.org/10.3390/jcs9070347