Fiber Orientation Effects in CFRP Milling: Multiscale Characterization of Cutting Dynamics, Surface Integrity, and Damage Mechanisms

Abstract

1. Introduction

2. Macroscopic Theoretical Model

2.1. Damage Initiation Criteria and Evolution Laws

2.1.1. Damage Failure Criterion

2.1.2. Damage Evolution Model

2.1.3. Macroscopic Finite Element Model

| Density | ρ = 1600 kg/m3 | |

|---|---|---|

| Young’s modulus | E11 = 130 Gpa E22 = E33 = 7.7 Gpa G12 = G13 = 4.8 Gpa G23 = 3.8 GPa | |

| Composite lamina properties | Poisson’s ratio | ν12 = ν13 = 0.33 ν23 = 0.35 |

| Strength | XT = 2080 MPa XC = 1250 MPa YT = 60 MPa YC = 140 MPa ZT = ZC = 290 Mpa S12 = S13 = S23 = 110 MPa | |

| Fracture energy | G1tc = 133 N∕mm G1cc = 40 N∕mm G2tc = 0.6 N∕mm G2cc = 2.1 N∕mm |

| Parameters | Value |

|---|---|

| Density | 3.5 × 10−9 (ton/mm3) |

| Young’s modulus | 960 GPa |

| Poisson’s ratio | 0.2 |

| Rake angle (α) | 25° |

| Relief angle (β) | 10° |

| Tool edge radius | 0.2 µm |

| Depth of cut | 0.1 mm |

| Cutting speed | 480 mm/s |

| Spindle speed | 2000 rpm |

| Feed per tooth | 0.04 mm/tooth |

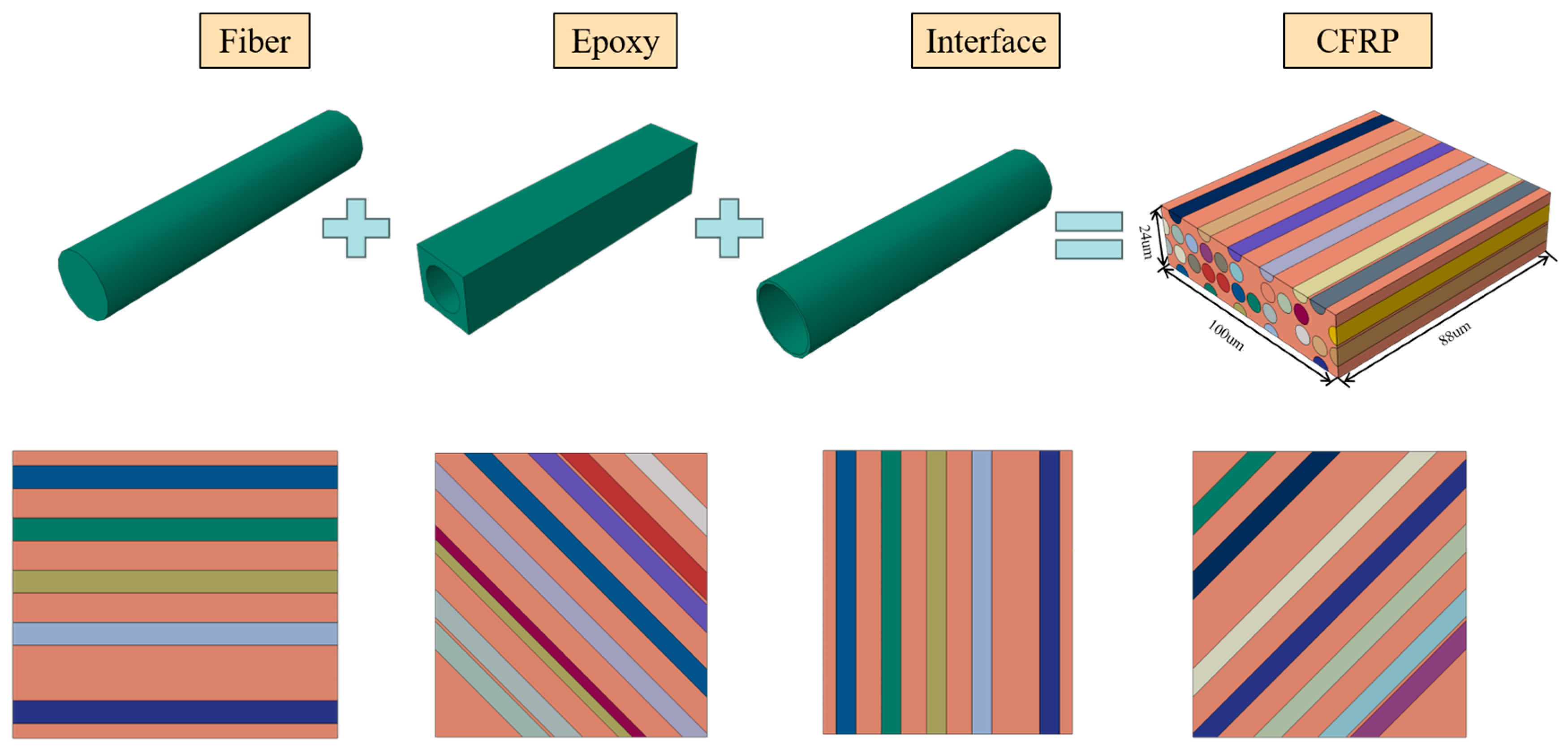

2.2. Microscopic Theoretical Model

2.2.1. Fiber and Matrix Failure Criteria

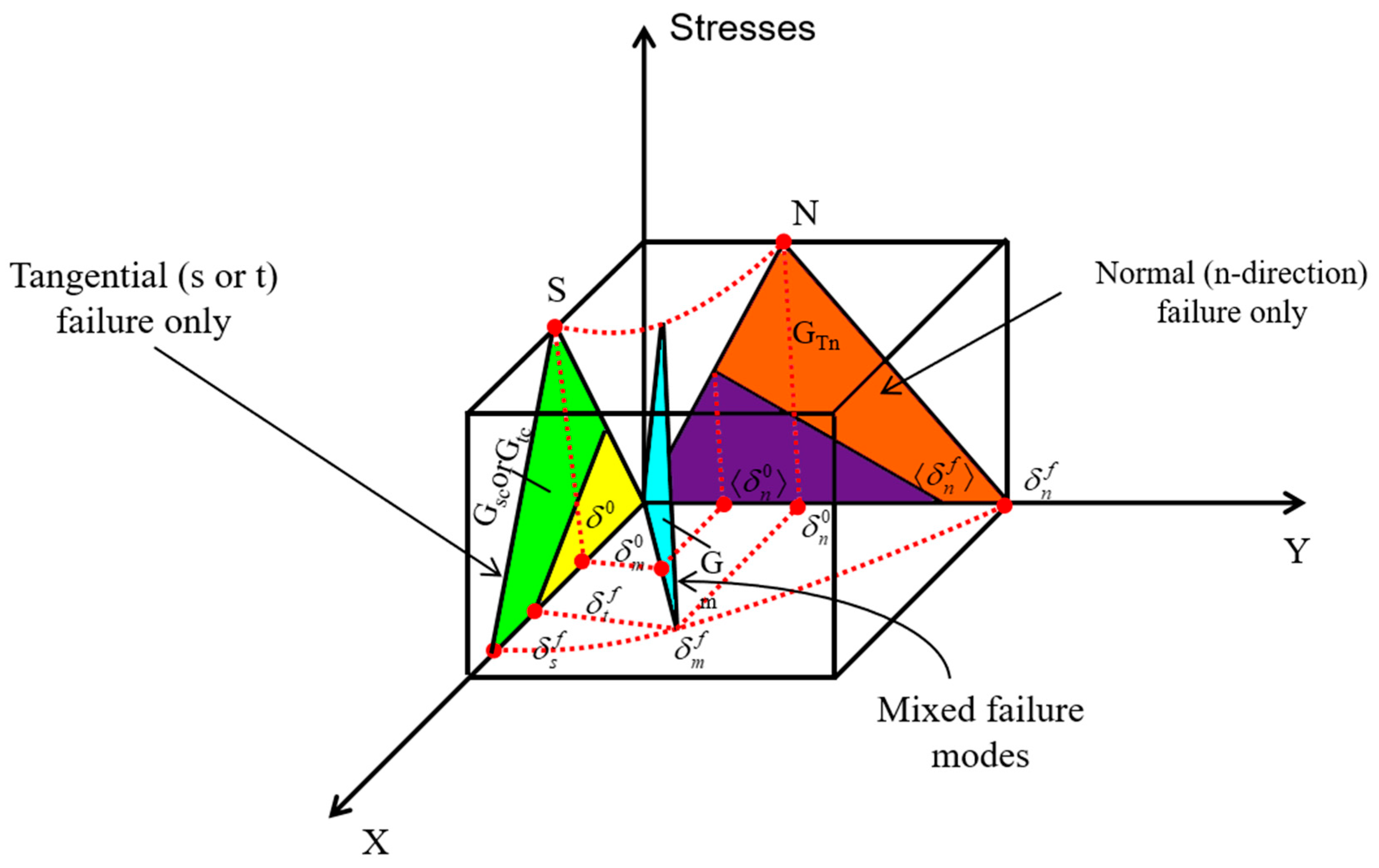

2.2.2. Zero-Thickness Cohesive Element Failure Model

2.2.3. Microscopic Finite Element Model

3. Experimental Setup

4. Results and Discussion

4.1. Experimental Data and Statistical Analysis

4.1.1. Cutting Force Statistics

4.1.2. Assessment of Workpiece Integrity

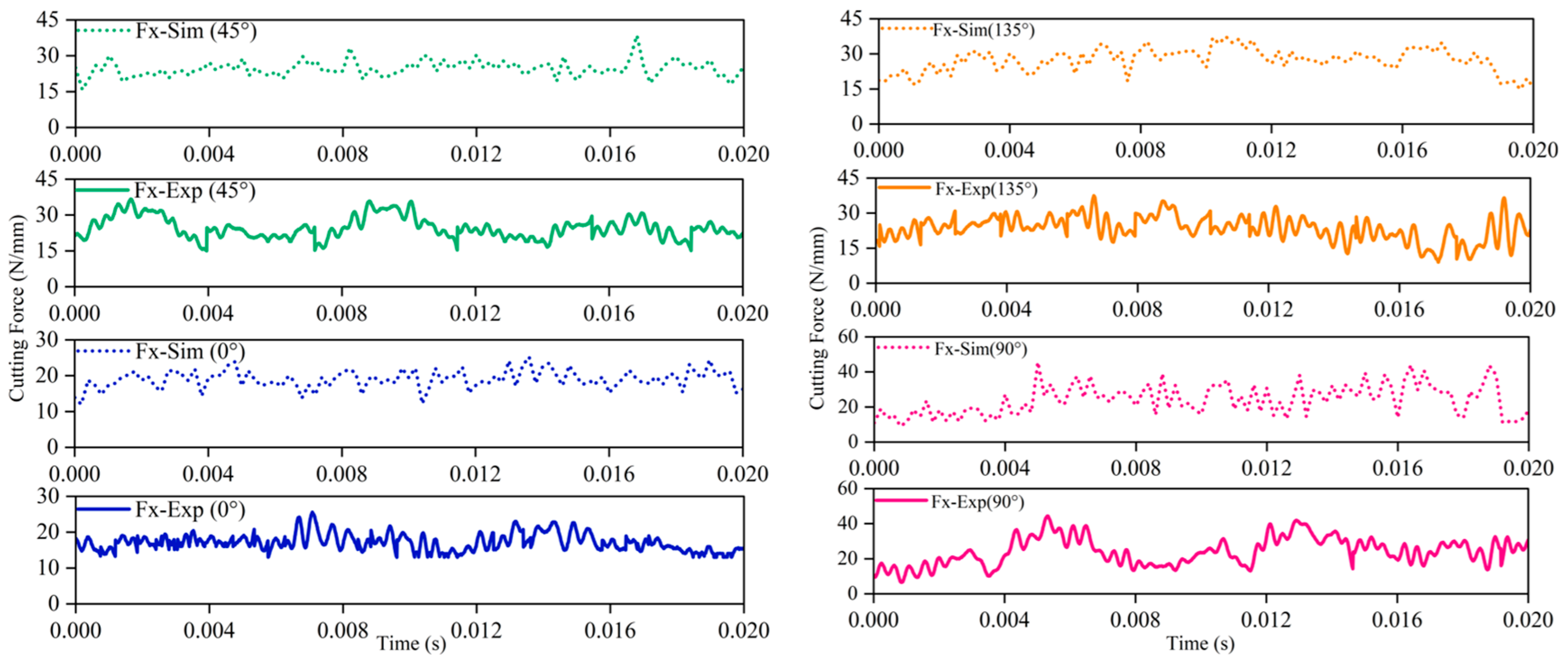

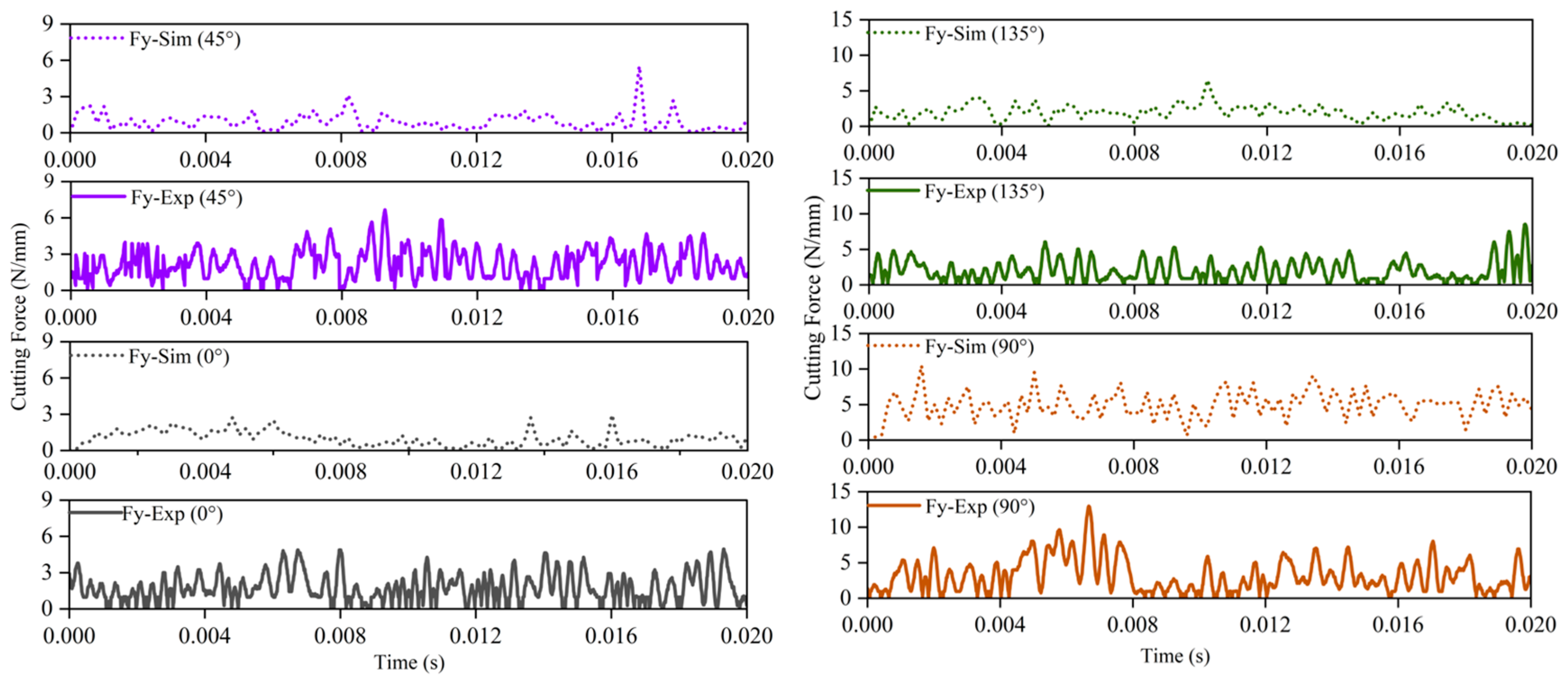

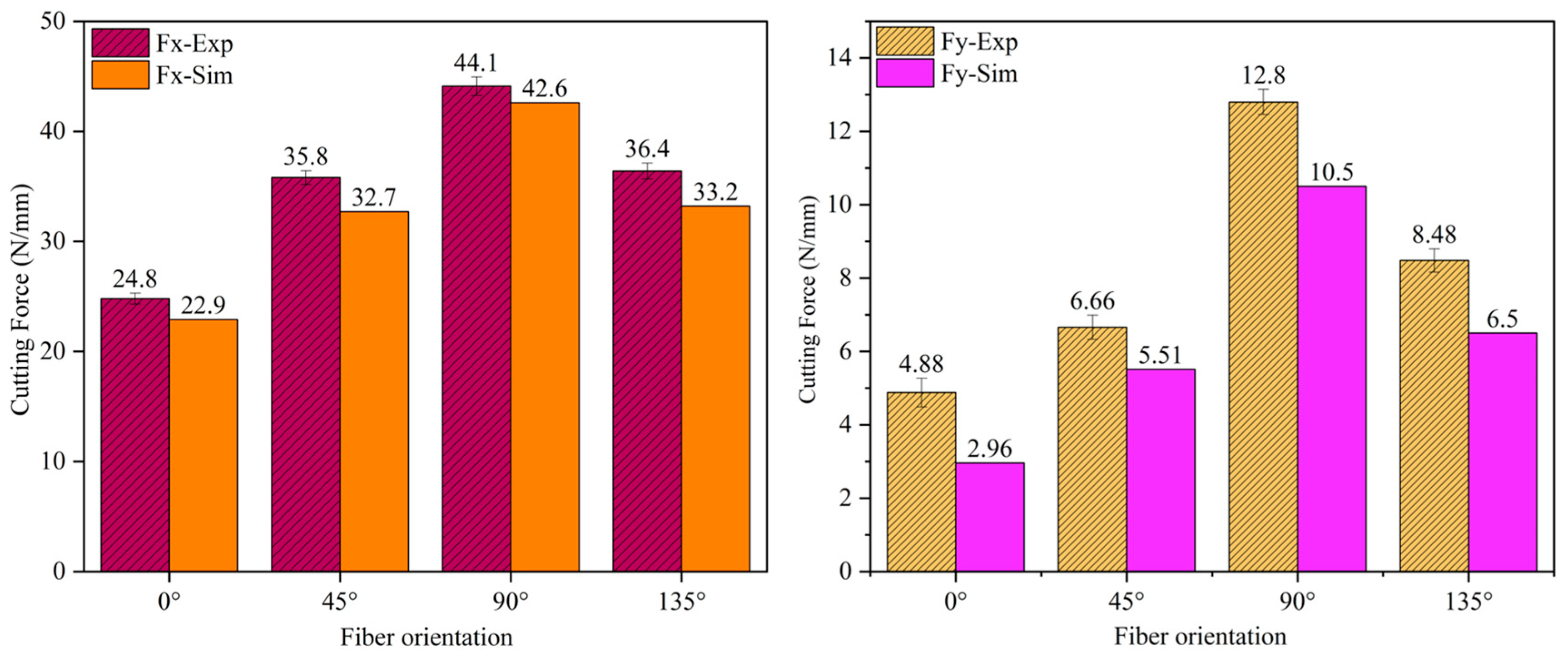

4.2. Cutting Forces

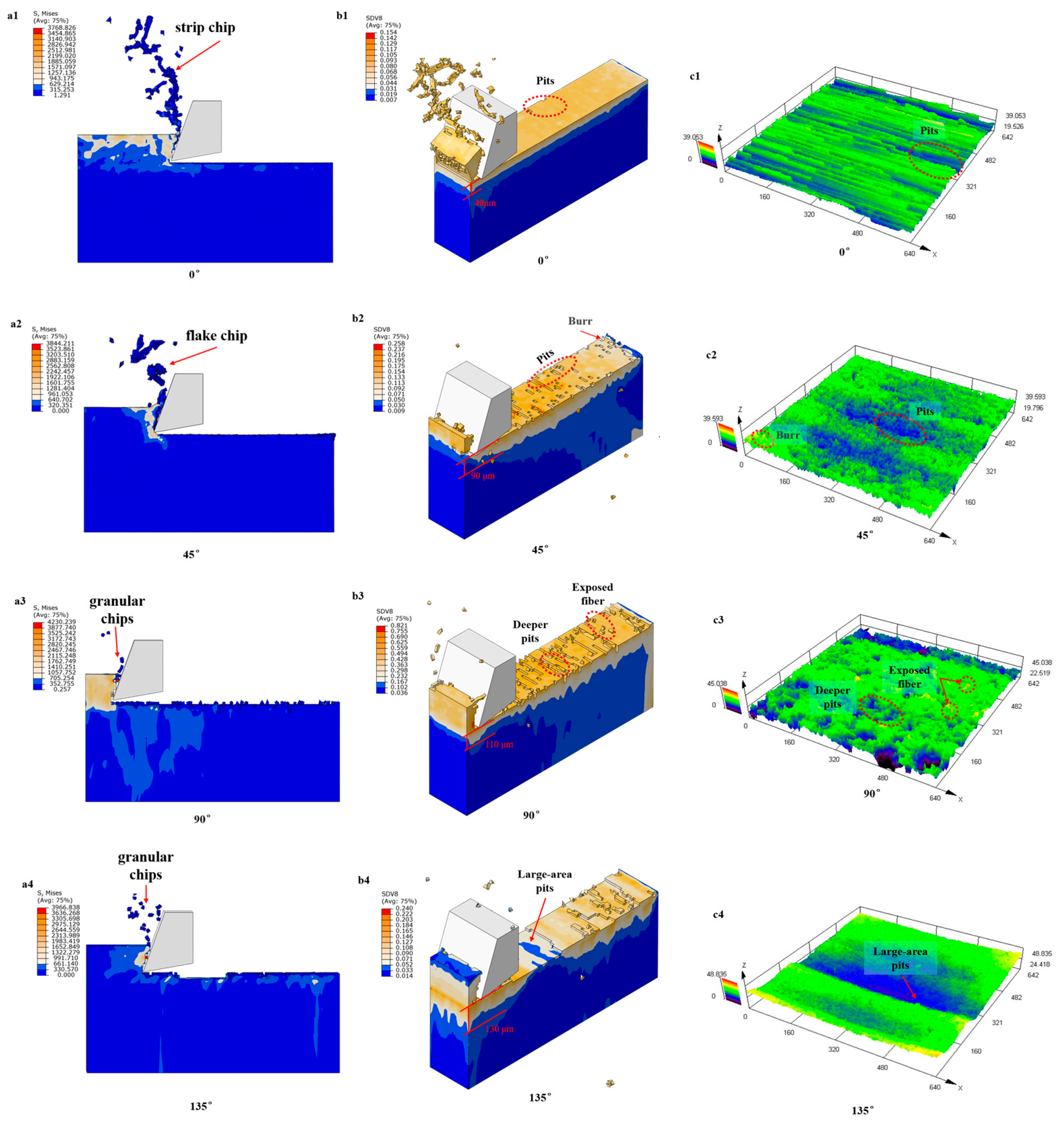

4.3. Macroscopic Chip Formation Process and Macroscopic Surface Morphology of CFRP

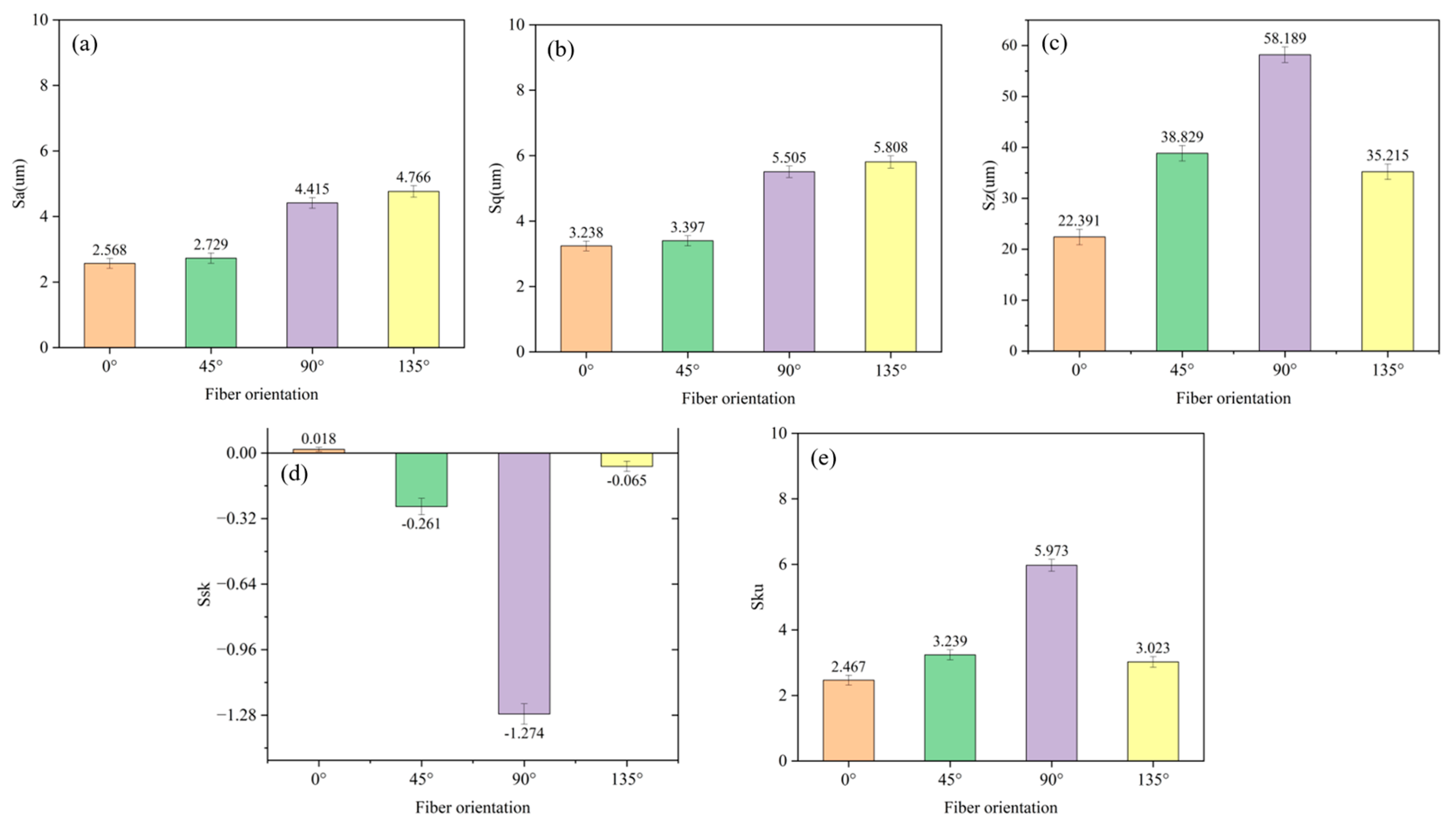

4.4. Analysis of Three-Dimensional Roughness Parameters of CFRP Machined Surfaces

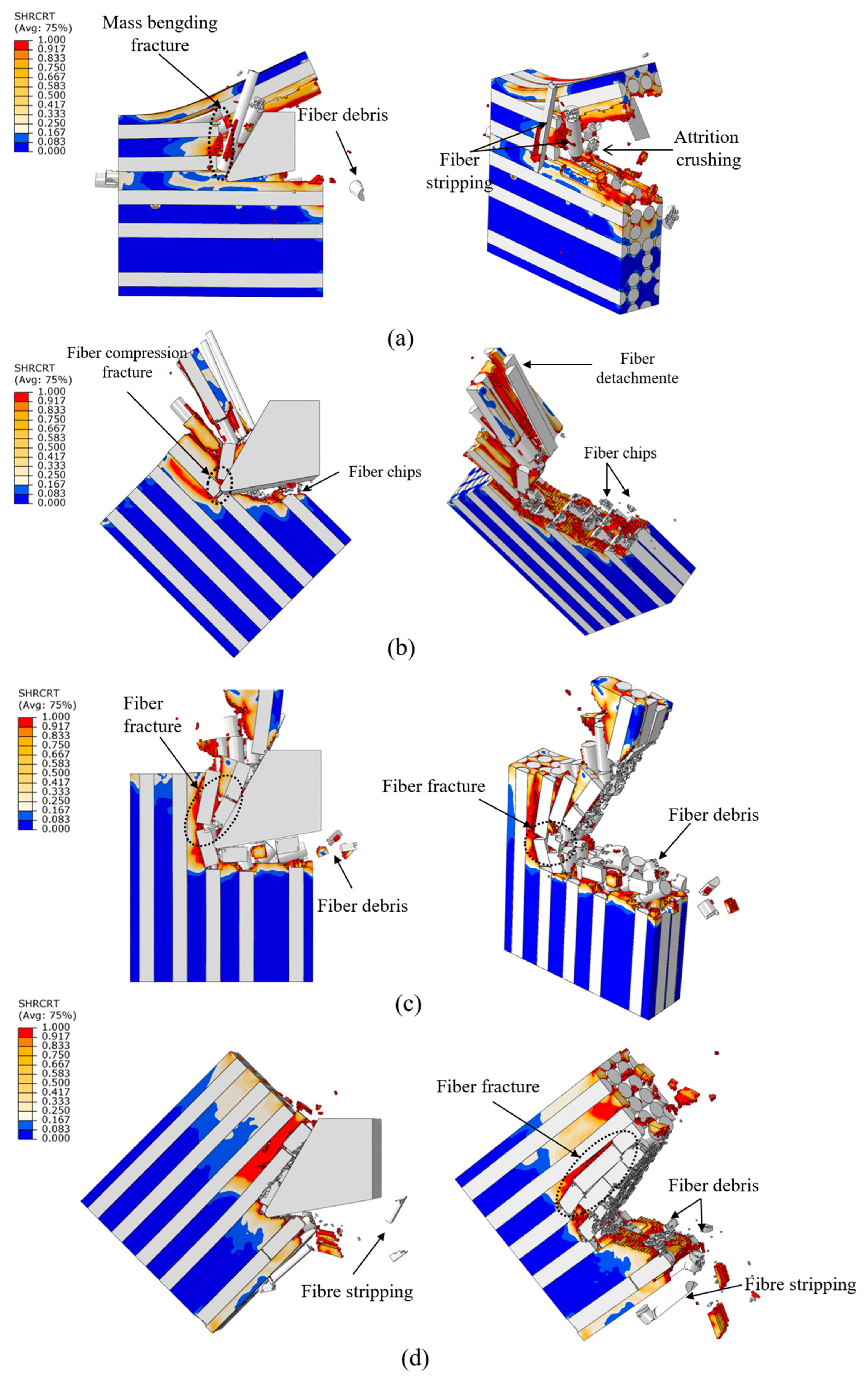

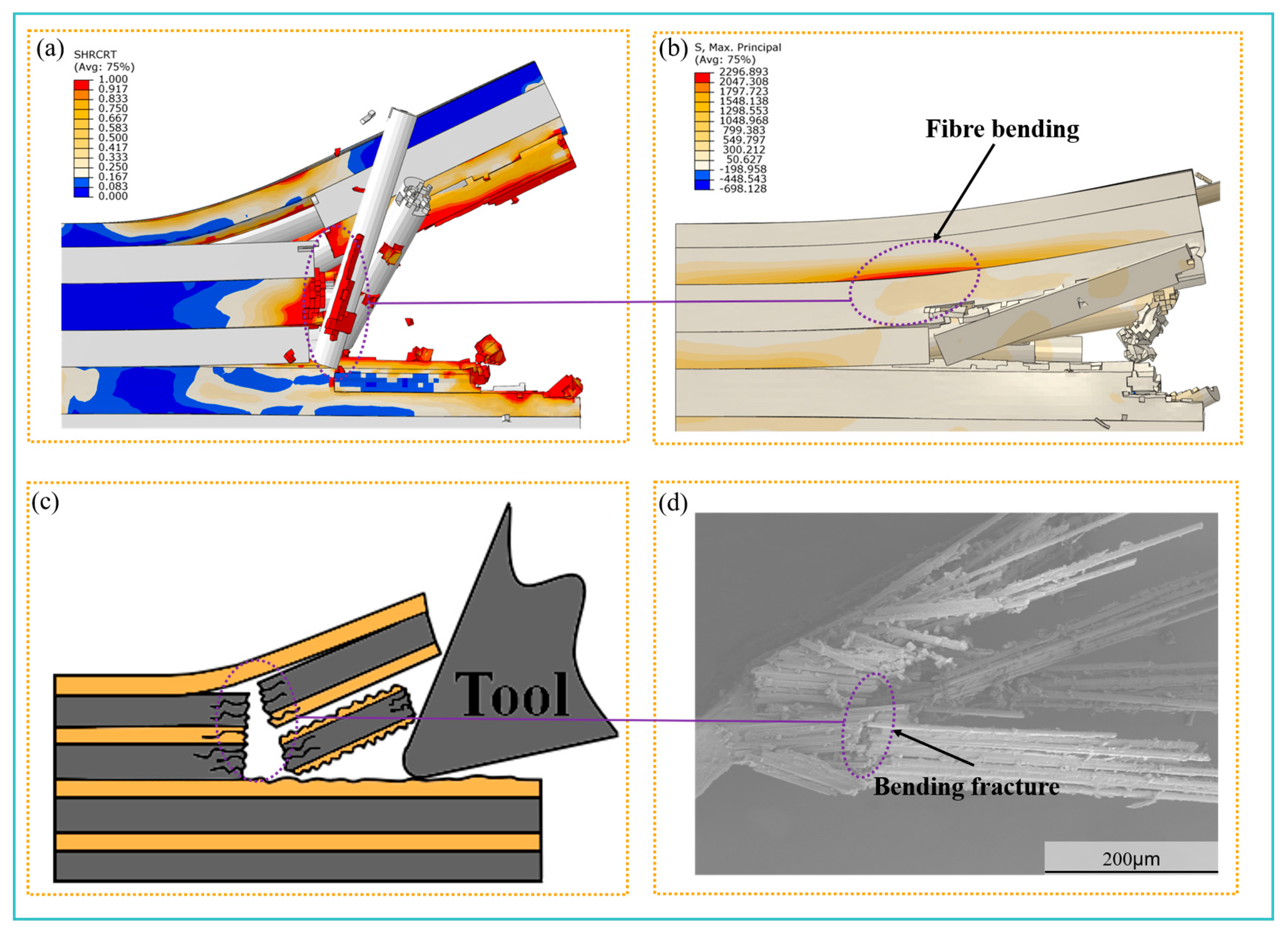

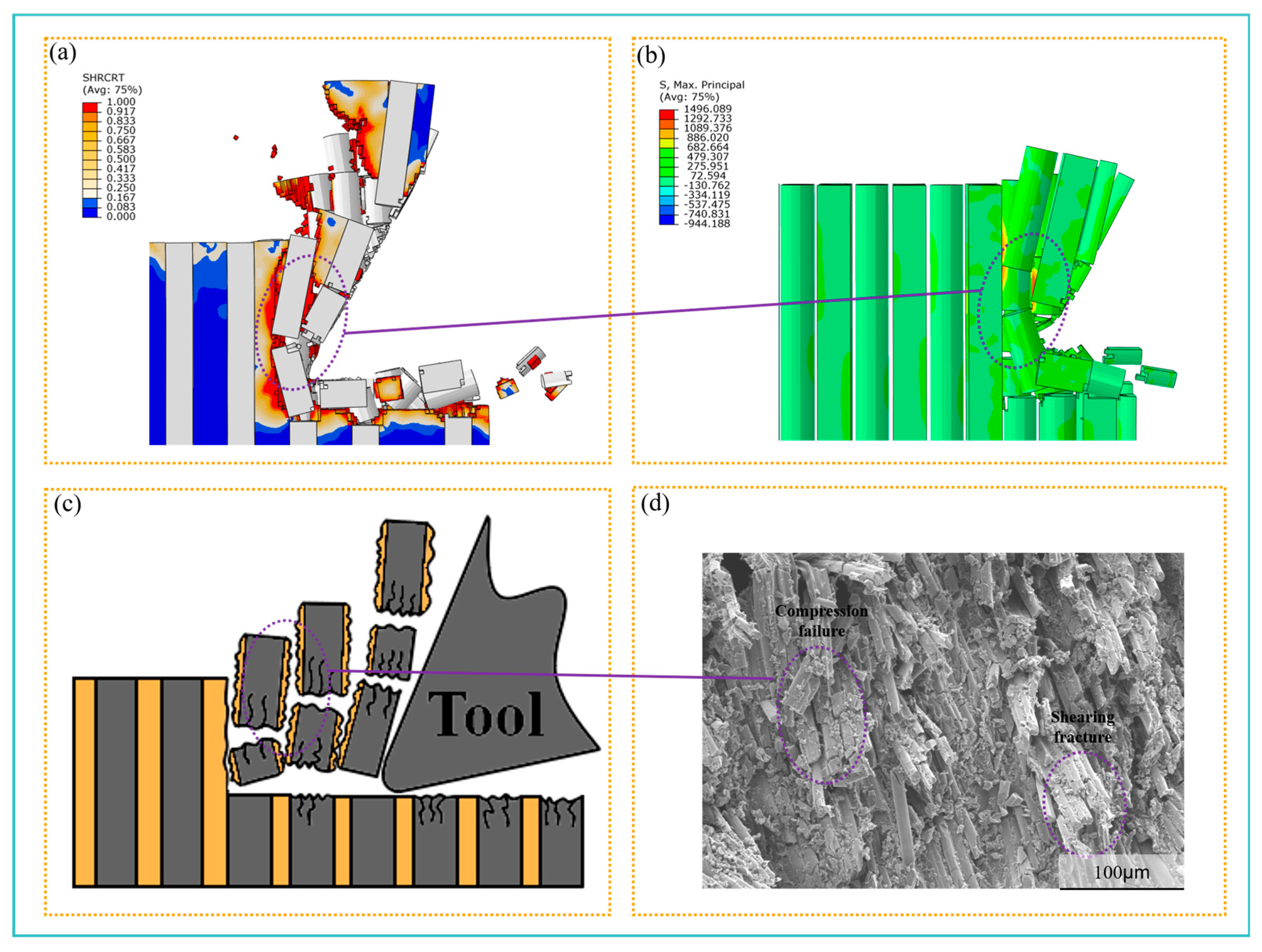

4.5. Microscopic Failure Behavior of CFRP

4.6. Microscopic Morphology of Chips and Its Material Removal Mechanism

4.7. Mechanism and Validation of Surface Damage Formation for Different Fiber Orientations

5. Conclusions

- The macroscopic model proposed in this study demonstrates good predictability for cutting force, which can guide practical machining and production. The model explains that the cutting force exhibits a non-monotonic trend, following the order 0° < 45° < 135° < 90°. The maximum value is reached at 90° (experimental value: 44.1 N/mm, simulated value: 42.6 N/mm), while the minimum value occurs at 0° (experimental value: 24.8 N/mm, simulated value: 22.9 N/mm), with deviations from experimental values not exceeding 9%.

- The microscopic model helps other researchers better and more easily understand the process. This model accurately predicts the chip and surface damage modes for each fiber orientation. At 0°, axial brittle fracture occurs with minimal surface damage, resulting in a smooth surface, and columnar pits are formed through resin extrusion and localized fiber bending fracture. At 45°, a mixed shear-tensile mode occurs, leading to surface quality degradation and the appearance of groove-like pits, primarily due to fiber–matrix interface delamination and increased resin plastic deformation. At 90°, shear-dominated pull-out generates an irregular surface, accompanied by granular debris and microcracks. At 135°, compression-bending results in highly fragmented granular chips, and the machined surface exhibits continuous large-area pits, showing the poorest quality.

- The model assumes an ideal fiber–matrix interface, a rigid tool, and neglects thermal effects, which may influence predictions under high-speed conditions. Future research will incorporate thermo-mechanical coupling, tool wear, and random fiber distribution to enhance the realism of the model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, Y.; Cao, H.; Zheng, W.; Qu, D.; Liu, L.; Yan, C. Cutting force modeling of machining carbon fiber reinforced polymer (CFRP) composites: A review. Compos. Struct. 2022, 299, 116096. [Google Scholar] [CrossRef]

- Xu, J.; Yin, Y.; Paulo Davim, J.; Li, L.; Ji, M.; Geier, N.; Chen, M. A critical review addressing drilling-induced damage of CFRP composites. Compos. Struct. 2022, 294, 115594. [Google Scholar] [CrossRef]

- Ge, J.; Catalanotti, G.; Falzon, B.G.; Higgins, C.; McClory, C.; Thiebot, J.-A.; Zhang, L.; He, M.; Jin, Y.; Sun, D. Process characteristics, damage mechanisms and challenges in machining of fibre reinforced thermoplastic polymer (FRTP) composites: A review. Compos. Part B Eng. 2024, 273, 111247. [Google Scholar] [CrossRef]

- Duboust, N.; Pinna, C.; Ghadbeigi, H.; Collis, A.; Ayvar-Soberanis, S.; Kerrigan, K.; Scaife, R. FE modelling of CFRP machining- prediction of the effects of cutting edge rounding. Procedia CIRP 2019, 82, 59–64. [Google Scholar] [CrossRef]

- Qin, X.; Bao, Z.; Wu, W.; Li, H.; Li, S.; Zhao, Q. Surface quality evaluation for CFRP milling and its impact on the mechanical properties. Int. J. Adv. Manuf. Technol. 2022, 122, 1083–1097. [Google Scholar] [CrossRef]

- Poór, D.I.; Geier, N.; Pereszlai, C.; Xu, J. A critical review of the drilling of CFRP composites: Burr formation, characterisation and challenges. Compos. Part B Eng. 2021, 223, 109155. [Google Scholar] [CrossRef]

- Wang, C.; Liu, G.; An, Q.; Chen, M. Occurrence and formation mechanism of surface cavity defects during orthogonal milling of CFRP laminates. Compos. Part B Eng. 2017, 109, 10–22. [Google Scholar] [CrossRef]

- Liu, C.; Ren, J.; Shi, K.; Zhang, Y. Investigation of fracture mechanism evolution model for UD-CFRP and MD-CFRP during the milling process. Compos. Struct. 2023, 306, 116585. [Google Scholar] [CrossRef]

- Ge, J.; Tan, W.; Ahmad, S.; Falzon, B.G.; Catalanotti, G.; Higgins, C.; Jin, Y.; Sun, D. Temperature-dependent cutting physics in orthogonal cutting of carbon fibre reinforced thermoplastic (CFRTP) composite. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107820. [Google Scholar] [CrossRef]

- An, Q.; Ming, W.; Cai, X.; Chen, M. Study on the cutting mechanics characteristics of high-strength UD-CFRP laminates based on orthogonal cutting method. Compos. Struct. 2015, 131, 374–383. [Google Scholar] [CrossRef]

- Sorrentino, L.; Turchetta, S. Cutting Forces in Milling of Carbon Fibre Reinforced Plastics. Int. J. Manuf. Eng. 2014, 2014, 439634. [Google Scholar] [CrossRef]

- He, Y.; Sheikh-Ahmad, J.; Zhu, S.; Zhao, C. Cutting force analysis considering edge effects in the milling of carbon fiber reinforced polymer composite. J. Mater. Process. Technol. 2020, 279, 116541. [Google Scholar] [CrossRef]

- Geier, N. Influence of fibre orientation on cutting force in up and down milling of UD-CFRP composites. Int. J. Adv. Manuf. Technol. 2020, 111, 881–893. [Google Scholar] [CrossRef]

- He, Y.; Qing, H.; Zhang, S.; Wang, D.; Zhu, S. The cutting force and defect analysis in milling of. carbon fiber-reinforced polymer (CFRP) composite. Int. J. Adv. Manuf. Technol. 2017, 93, 1829–1842. [Google Scholar] [CrossRef]

- Böhland, F.; Hilligardt, A.; Schulze, V. Analysis of subsurface damage during milling of CFRP due to spatial fibre cutting angle, tool geometry and cutting parameters. Compos. Part B Eng. 2024, 281, 111533. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, X.; Zhang, K.; Guo, D.; Zhou, C.; Gai, L. Study on the surface quality of CFRP machined by micro-textured milling tools. J. Manuf. Process. 2019, 37, 114–123. [Google Scholar] [CrossRef]

- Wang, C.; Wen, L.; Ming, W.; An, Q.; Chen, M. Experimental study on effects of fiber cutting angle in milling of high-strength unidirectional carbon fiber–reinforced polymer laminates. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 232, 1813–1824. [Google Scholar] [CrossRef]

- Li, C.; Liu, N.; Chen, L.; Chen, W.; Liu, Y.; Zhang, M. Analysis of the effects of different milling strategies on helical milling of unidirectional CFRP under minimum quantity lubrication. J. Manuf. Process. 2024, 132, 27–37. [Google Scholar] [CrossRef]

- Cai, C.; Dang, J.; An, Q.; Ming, W.; Chen, M. Surface morphology characterization of unidirectional carbon fibre reinforced plastic machined by peripheral milling. Chin. J. Aeronaut. 2022, 35, 361–375. [Google Scholar] [CrossRef]

- Wu, W.; Li, S.; Qin, X.; Fu, G.; Bao, Z.; Li, H.; Zhao, Q. Tool wear influence on surface roughness, burrs and cracks in milling unidirectional carbon fiber reinforced plastics (UD-CFRP). J. Mater. Res. Technol. 2024, 30, 3052–3065. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X. Effect of cooling and lubrication conditions on the variable angle milling of unidirectional CFRP with PCD tools. J. Mater. Process. Technol. 2023, 319, 118073. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, L.; Wu, Y. Effect of tool vibration on chip formation and cutting forces in the machining of fiber-reinforced polymer composites. Mach. Sci. Technol. 2016, 20, 312–329. [Google Scholar] [CrossRef]

- Ge, J.; Luo, M.; Zhang, D.; Catalanotti, G.; Falzon, B.G.; McClelland, J.; Higgins, C.; Jin, Y.; Sun, D. Temperature field evolution and thermal-mechanical interaction induced damage in drilling of thermoplastic CF/PEKK-A comparative study with thermoset CF/epoxy. J. Manuf. Process. 2023, 88, 167–183. [Google Scholar] [CrossRef]

- Ge, J.; Catalanotti, G.; Falzon, B.G.; McClelland, J.; Higgins, C.; Jin, Y.; Sun, D. Towards understanding the hole making performance and chip formation mechanism of thermoplastic carbon fibre/polyetherketoneketone composite. Compos. Part B Eng. 2022, 234, 109752. [Google Scholar] [CrossRef]

- Cepero-Mejías, F.; Phadnis, V.A.; Kerrigan, K.; Curiel-Sosa, J.L. A finite element assessment of chip formation mechanisms in the machining of CFRP laminates with different fibre orientations. Compos. Struct. 2021, 268, 113966. [Google Scholar] [CrossRef]

- Cepero-Mejías, F.; Curiel-Sosa, J.L.; Zhang, C.; Phadnis, V.A. Effect of cutter geometry on machining induced damage in orthogonal cutting of UD polymer composites: FE study. Compos. Struct. 2019, 214, 439–450. [Google Scholar] [CrossRef]

- Wang, X.; Wang, F.; Jin, X.; Fu, R.; Shi, Y. Numerical prediction of the chip formation and damage response in CFRP cutting with a novel strain rate based material model. Compos. Struct. 2022, 294, 115746. [Google Scholar] [CrossRef]

- Chen, R.; Li, S.; Li, P.; Li, X.; Qiu, X.; Ko, T.J.; Jiang, Y. Effect of fiber orientation angles on the material removal behavior of CFRP during cutting process by multi-scale characterization. Int. J. Adv. Manuf. Technol. 2020, 106, 5017–5031. [Google Scholar] [CrossRef]

- Cheng, H.; Gao, J.; Kafka, O.L.; Zhang, K.; Luo, B.; Liu, W.K. A micro-scale cutting model for UD CFRP composites with thermo-mechanical coupling. Compos. Sci. Technol. 2017, 153, 18–31. [Google Scholar] [CrossRef]

- He, Y.; Li, L.; Wan, M.; Xue, H. Three-dimensional finite element simulations of milling carbon/epoxy composites. Compos. Struct. 2022, 282, 115037. [Google Scholar] [CrossRef]

- Yan, X.; Reiner, J.; Bacca, M.; Altintas, Y.; Vaziri, R. A study of energy dissipating mechanisms in orthogonal cutting of UD-CFRP composites. Compos. Struct. 2019, 220, 460–472. [Google Scholar] [CrossRef]

- Huang, L.; Tao, Y.; Sun, J.; Zhang, D.; Zhao, J. Assessment of numerical modeling approaches for thin composite laminates under low-velocity impact. Thin-Walled Struct. 2023, 191, 111053. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Z.; Li, Q.; Qi, Z.; Chen, W.; Liu, P. Comparative analysis of dynamic progressive failure of CFRPs using the scale-span and macroscopic modeling method in drilling. Eng. Fract. Mech. 2022, 268, 108434. [Google Scholar] [CrossRef]

- Liu, P.F.; Liao, B.B.; Jia, L.Y.; Peng, X.Q. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact. Compos. Struct. 2016, 149, 408–422. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, G.; Xu, X.; Xuan, S.; Fan, X.; Kan, Y.; Yao, X. Thermal–mechanical coupling numerical simulation and low damage analysis for drilling composite. Compos. Struct. 2023, 324, 117542. [Google Scholar] [CrossRef]

- Klinkova, O.; Rech, J.; Drapier, S.; Bergheau, J.-M. Characterization of friction properties at the workmaterial/cutting tool interface during the machining of randomly structured carbon fibers reinforced polymer with carbide tools under dry conditions. Tribol. Int. 2011, 44, 2050–2058. [Google Scholar] [CrossRef]

- Calzada, K.A.; Kapoor, S.G.; DeVor, R.E.; Samuel, J.; Srivastava, A.K. Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J. Manuf. Process. 2012, 14, 141–149. [Google Scholar] [CrossRef]

- Hongkarnjanakul, N.; Bouvet, C.; Rivallant, S. Validation of low velocity impact modelling on different stacking sequences of CFRP laminates and influence of fibre failure. Compos. Struct. 2013, 106, 549–559. [Google Scholar] [CrossRef]

- Tan, W.; Falzon, B.G.; Chiu, L.N.S.; Price, M. Predicting low velocity impact damage and Compression-After-Impact (CAI) behaviour of composite laminates. Compos. Part A Appl. Sci. Manuf. 2015, 71, 212–226. [Google Scholar] [CrossRef]

- Li, C.; Zhao, Y.; Qiu, X.; Li, S.; Niu, Q.; Li, P.; Ko, T.J. Interface mechanical damage mechanism in machining carbon fiber-reinforced plastic/Ti stacks based on a three-dimensional microscopic oblique cutting model. Compos. Struct. 2022, 279, 114737. [Google Scholar] [CrossRef]

- Isbilir, O.; Ghassemieh, E. Finite Element Analysis of Drilling of Carbon Fibre Reinforced Composites. Appl. Compos. Mater. 2011, 19, 637–656. [Google Scholar] [CrossRef]

- Jia, Z.-y.; Chen, C.; Wang, F.-j.; Ma, J.-w.; Yang, F. Three-dimensional oblique cutting model for sub-surface damage analysis in CFRP/Ti stack composite machining. Int. J. Adv. Manuf. Technol. 2018, 96, 643–655. [Google Scholar] [CrossRef]

- Han, L.; Zhang, J.; Liu, Y.; Sun, T. Effect of fiber orientation on depth sensing intra-laminar failure of unidirectional CFRP under nano-scratching. Compos. Part B Eng. 2021, 224, 109211. [Google Scholar] [CrossRef]

- Liu, C.; Ren, J.; Zhang, Y.; Shi, K. A cutting force prediction model for UD-CFRP and MD-CFRP milling based on fracture mechanisms and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2025, 194, 108892. [Google Scholar] [CrossRef]

- Świrad, S.; Wydrzynski, D.; Nieslony, P.; Krolczyk, G.M. Influence of hydrostatic burnishing strategy on the surface topography of martensitic steel. Measurement 2019, 138, 590–601. [Google Scholar] [CrossRef]

- Li, H.; Qin, X.; He, G.; Jin, Y.; Sun, D.; Price, M. Investigation of chip formation and fracture toughness in orthogonal cutting of UD-CFRP. Int. J. Adv. Manuf. Technol. 2015, 82, 1079–1088. [Google Scholar] [CrossRef]

- Qin, X.; Wu, X.; Li, H.; Li, S.; Zhang, S.; Jin, Y. Numerical and experimental investigation of orthogonal cutting of carbon fiber-reinforced polyetheretherketone (CF/PEEK). Int. J. Adv. Manuf. Technol. 2021, 119, 1003–1017. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, J.; Xuan, S.; Yu, J.; Kang, R.; Tian, W. Investigation on cutting mechanism and micro-damage evolution in orthogonal cutting of T300/USN20000-7901 unidirectional laminates. Int. J. Adv. Manuf. Technol. 2023, 126, 4475–4494. [Google Scholar] [CrossRef]

| Normal strength | tn = 50 Mpa | |

| Interface | Shear strength | ts = 75 Mpa |

| Elastic stiffness | K = 100,000 N/mm3 | |

| Fracture energy | G = 0.002 N/mm3 |

| Material | Property | Values |

|---|---|---|

| Carbon fiber | Elastic constants | E1 = 231 GPa, E2 = E3 = 15 GPa |

| Poisson’s ratio | V12 = V13 = 0.2, V23 = 0.25 | |

| Shear modulus | G12 = G13 = 15 GPa, G23 = 7 GPa | |

| Tensile strength | Xt = 4.62 GPa, Yt = 1.5 GPa | |

| Compressive strength | Xc = 3.96 GPa, Yc = 3.34 GPa | |

| Matrix | Poisson’s ratio | V = 0.35 |

| Young’s modulus | E = 3.35 Gpa | |

| Yield strength | σm = 120 MPa | |

| Fracture energy | Gm = 0.1 N/mm | |

| Interface | Normal strength | tn = 50 MPa |

| Shear strength | ts = 75 MPa | |

| Elastic stiffness | K = 100,000 N/mm3 | |

| Fracture energy | GI = 0.002 N/mm, GII = GIII = 0.006 N/mm |

| Materials | T700s |

| Density | 1.8 g/cm3 |

| Young Modulus | 230 GPa |

| Strength | 4900 Mpa |

| Poisson’s ratio | 0.2 |

| Elongation ratio | 2.1% |

| Fiber Orientation (°) | Cutting Force Measurements (N/mm) | Mean | Standard Deviation (SD) | Sum | Number of Observations |

|---|---|---|---|---|---|

| 0° | 25.5,24.1,23.9 | 24.8 | 0.49 | 74.5 | 3 |

| 45° | 36.7,35.2,34.9 | 35.8 | 0.63 | 107.4 | 3 |

| 90° | 43.9,43.1,45.5 | 44.1 | 1.49 | 132.5 | 3 |

| 135° | 37.4,35.8,36.8 | 36.4 | 0.72 | 109.3 | 3 |

| Source of Variation | SS | df | MS | F | p-Value |

|---|---|---|---|---|---|

| Between Groups | 569.1 | 3 | 189.7 | 227.2 | <0.0001 |

| Within Groups | 6.68 | 8 | 0.83 | ||

| Total | 575.8 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, Q.; Zhang, J.; Xiao, G.; Xu, C.; Yi, M.; Chen, Z.; Chen, H.; Zheng, C.; Li, G. Fiber Orientation Effects in CFRP Milling: Multiscale Characterization of Cutting Dynamics, Surface Integrity, and Damage Mechanisms. J. Compos. Sci. 2025, 9, 342. https://doi.org/10.3390/jcs9070342

An Q, Zhang J, Xiao G, Xu C, Yi M, Chen Z, Chen H, Zheng C, Li G. Fiber Orientation Effects in CFRP Milling: Multiscale Characterization of Cutting Dynamics, Surface Integrity, and Damage Mechanisms. Journal of Composites Science. 2025; 9(7):342. https://doi.org/10.3390/jcs9070342

Chicago/Turabian StyleAn, Qi, Jingjie Zhang, Guangchun Xiao, Chonghai Xu, Mingdong Yi, Zhaoqiang Chen, Hui Chen, Chengze Zheng, and Guangchen Li. 2025. "Fiber Orientation Effects in CFRP Milling: Multiscale Characterization of Cutting Dynamics, Surface Integrity, and Damage Mechanisms" Journal of Composites Science 9, no. 7: 342. https://doi.org/10.3390/jcs9070342

APA StyleAn, Q., Zhang, J., Xiao, G., Xu, C., Yi, M., Chen, Z., Chen, H., Zheng, C., & Li, G. (2025). Fiber Orientation Effects in CFRP Milling: Multiscale Characterization of Cutting Dynamics, Surface Integrity, and Damage Mechanisms. Journal of Composites Science, 9(7), 342. https://doi.org/10.3390/jcs9070342