A Comprehensive Review of Aluminium Composite Panels: Current Research, Challenges, and Future Research Direction

Abstract

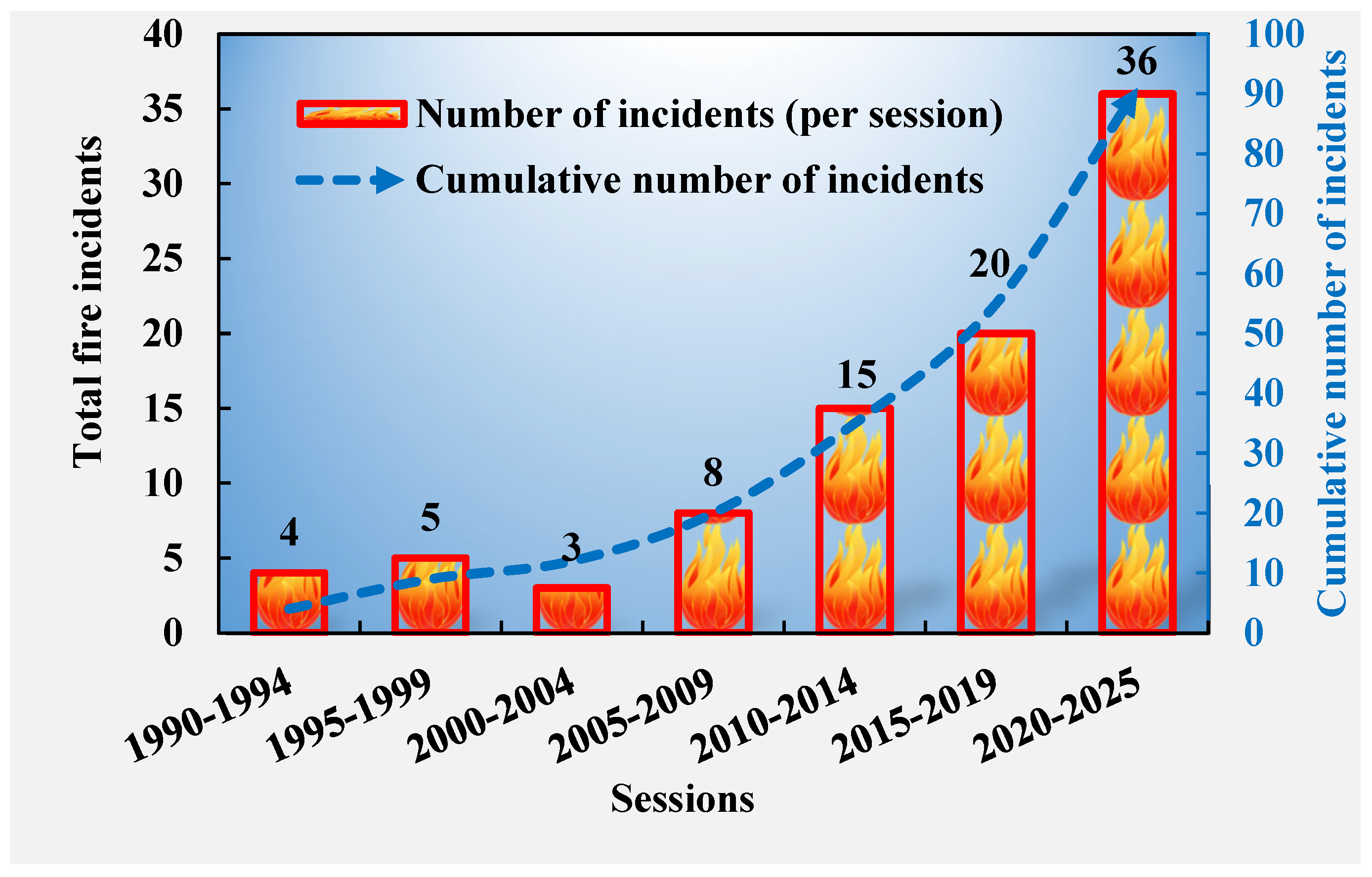

1. Introduction

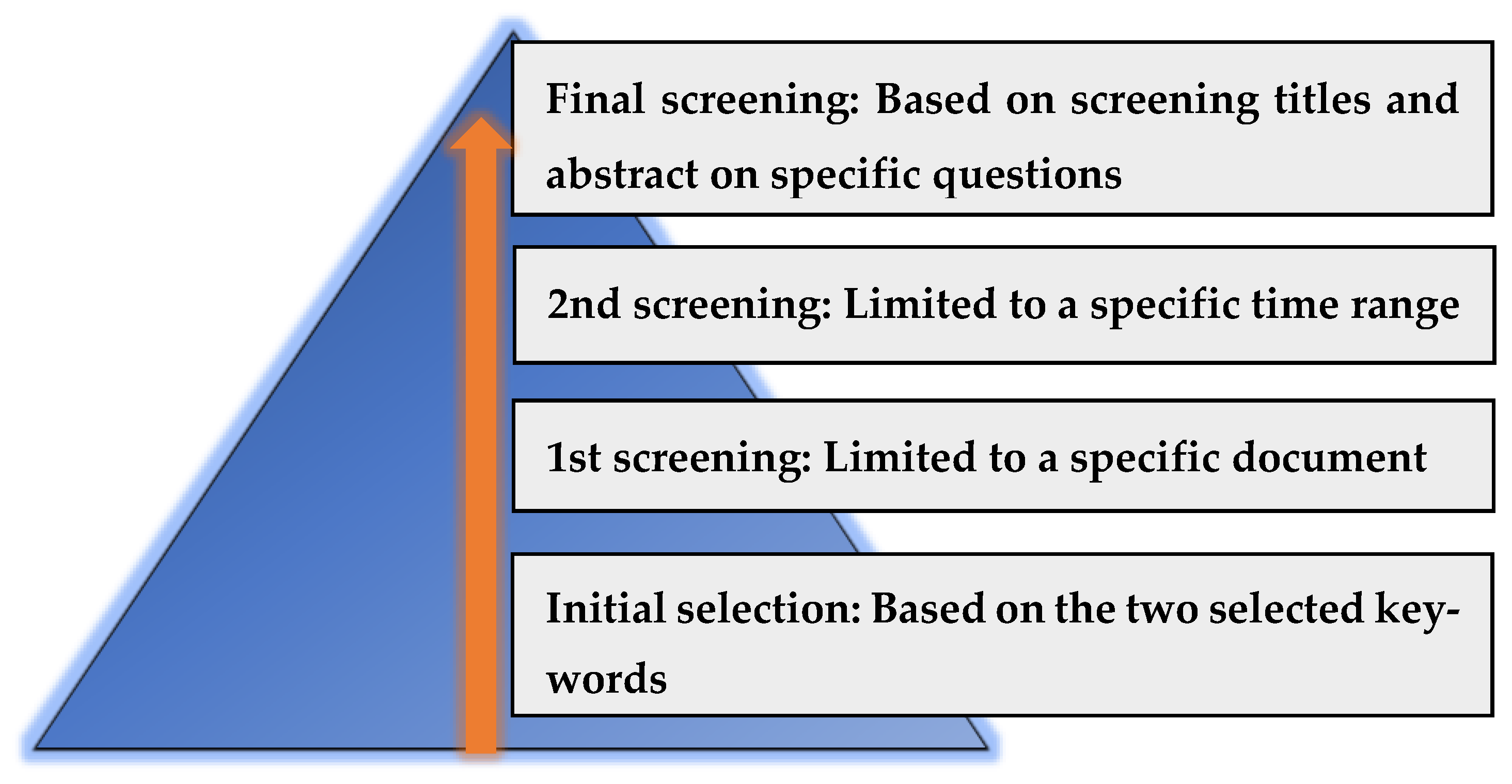

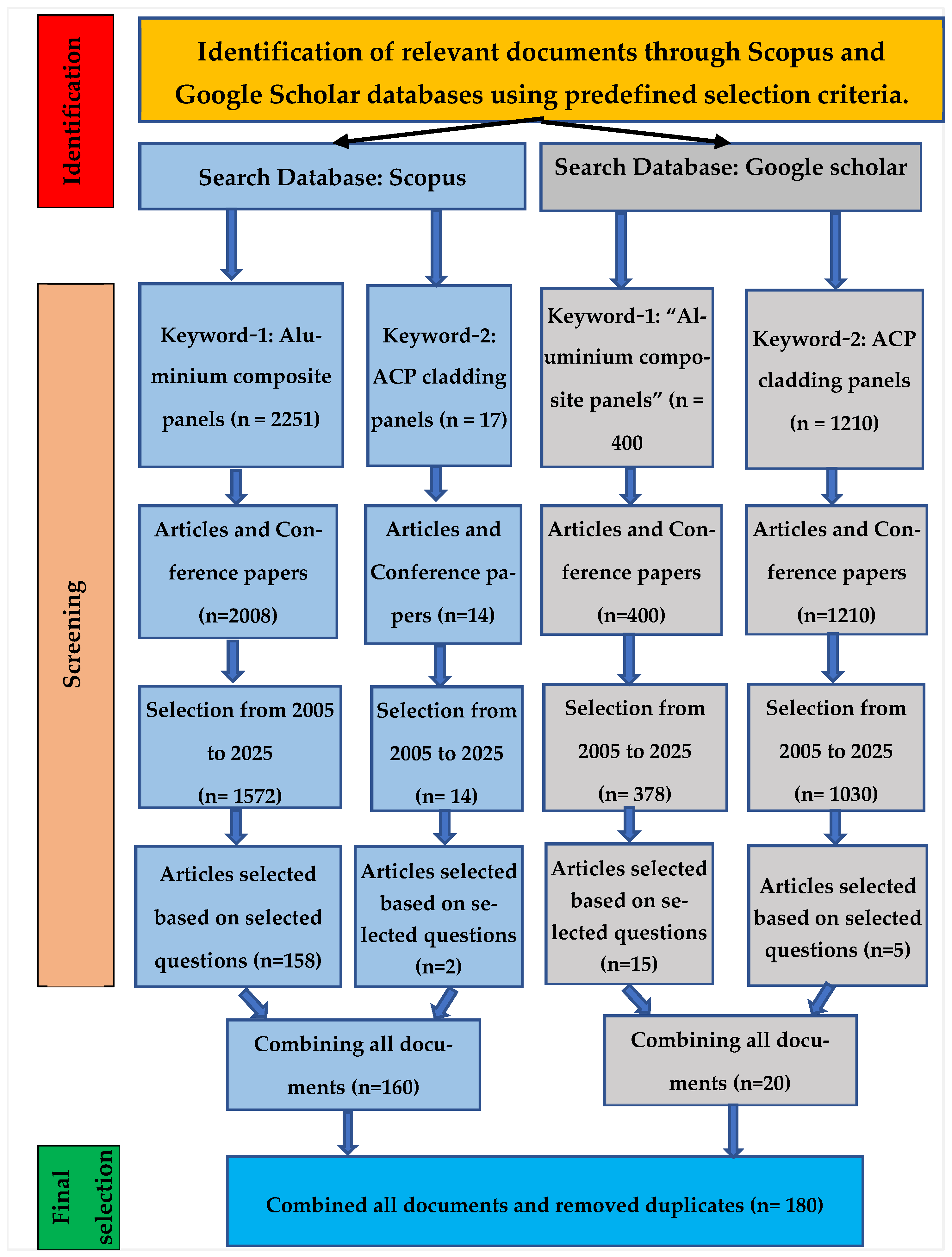

2. Research Method

- Is the document relevant to the topic of this research study?

- Is the document relevant to the objectives of this research paper?

- Has the document already been screened through other keywords or other databases during the screening process for this study?

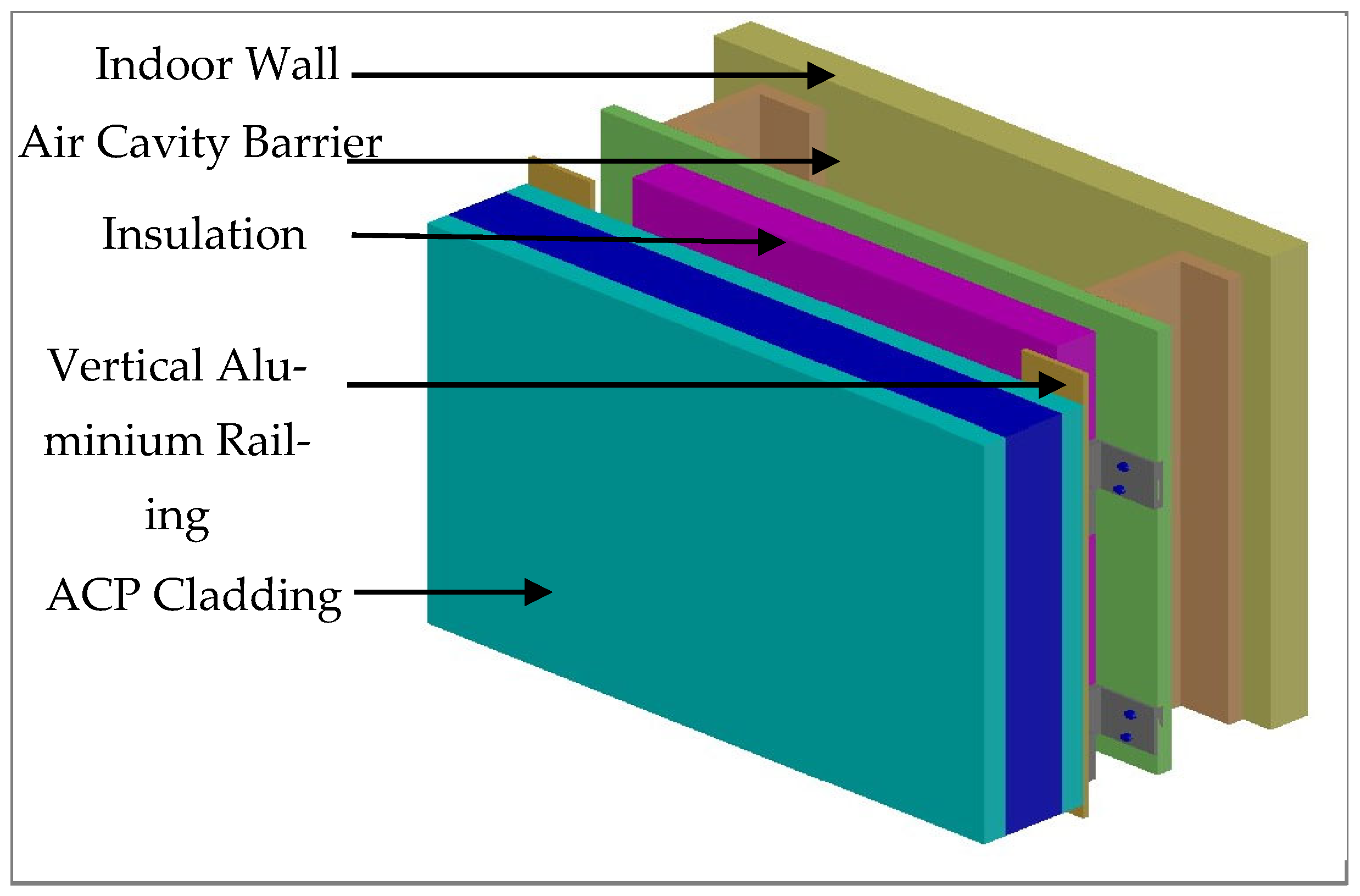

3. Cladding Systems

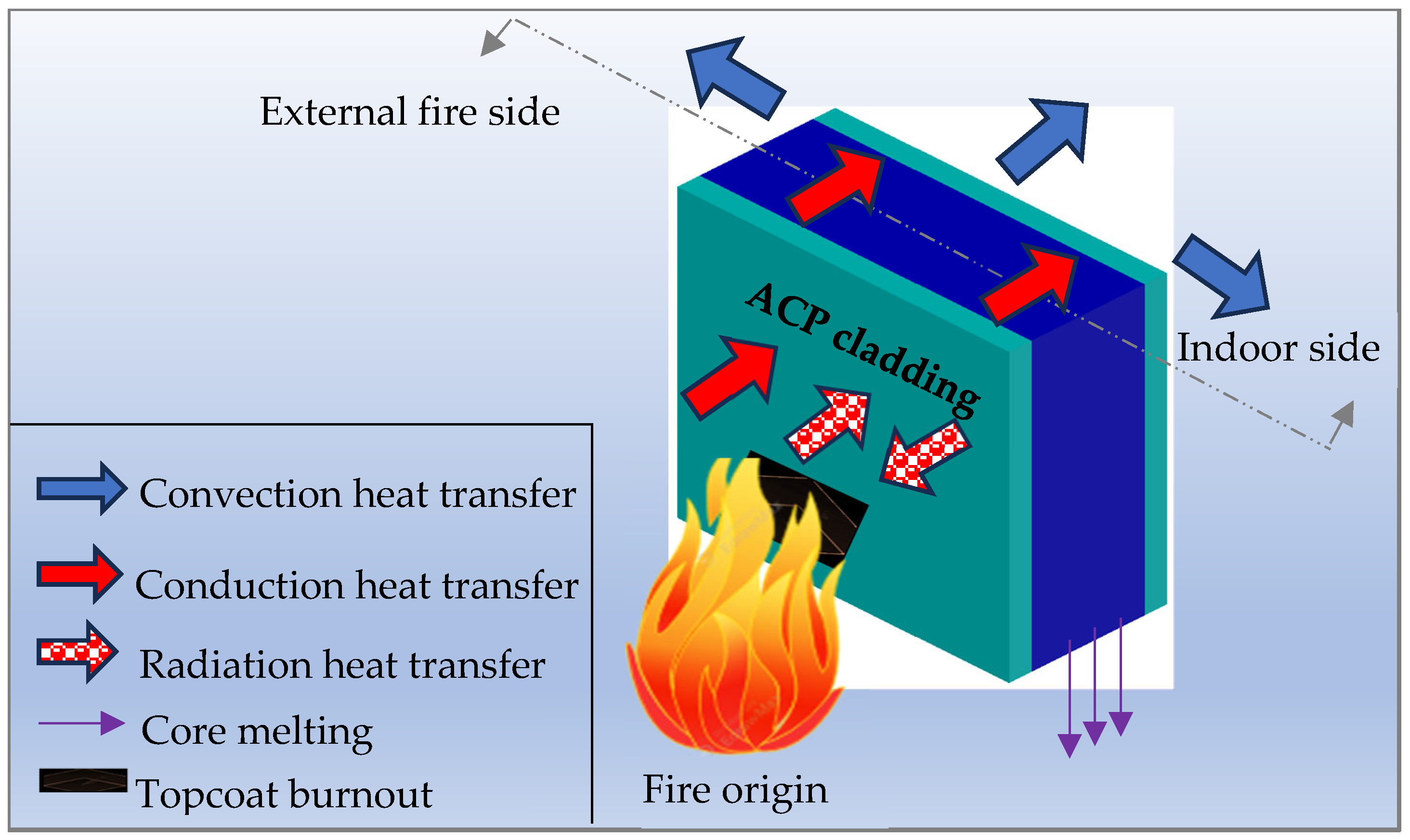

3.1. Cladding Panels

3.2. Types of Cores Used in Cladding Panels

3.3. Insulation

3.4. Cavity and Cavity Barriers

4. Fire-Rated Combustible Cladding Panel’s Filler Types, Mechanism, and Fabrication Process

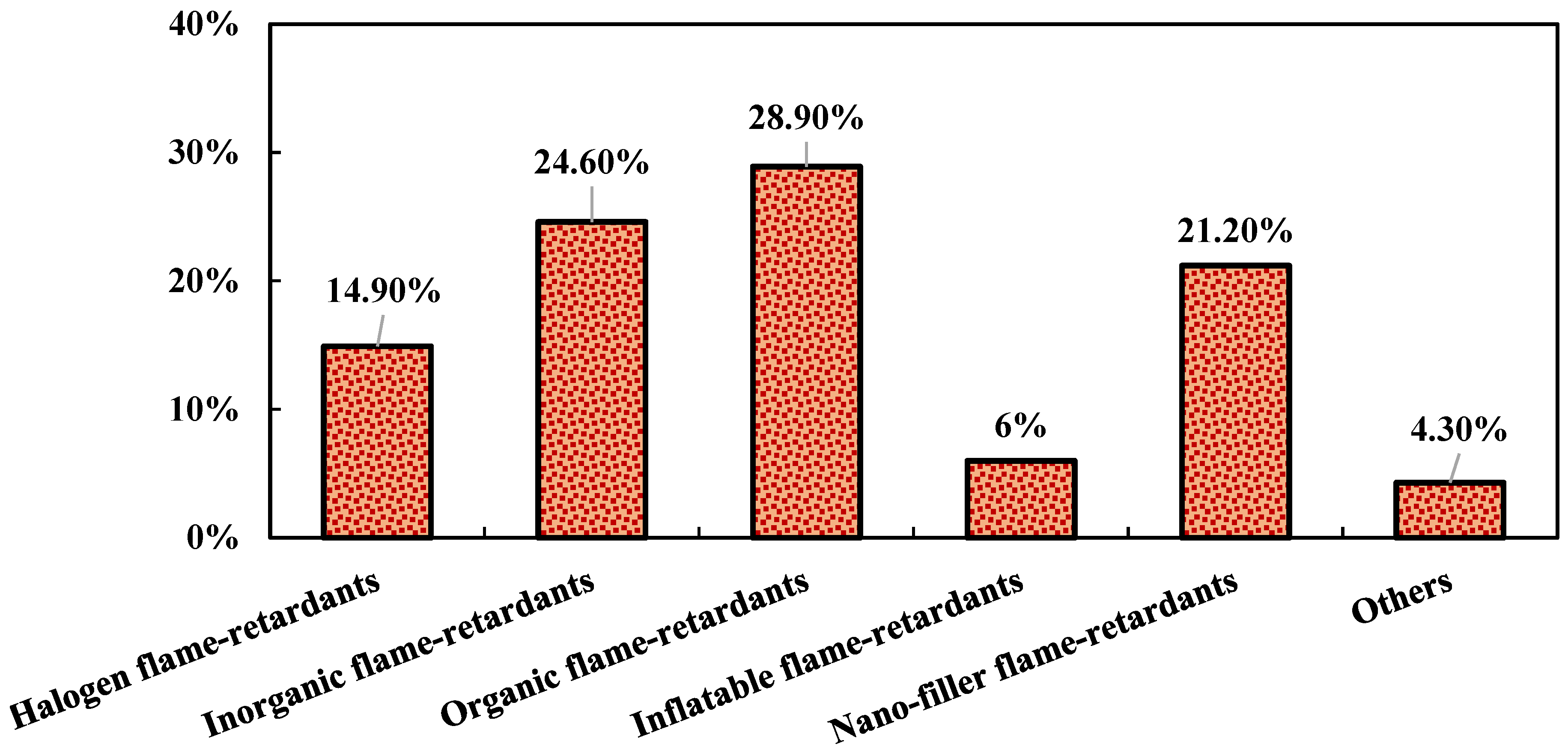

4.1. Types of Flame-Retardant Fillers

4.1.1. Halogen-Containing Flame-Retardants

4.1.2. Inorganic Flame-Retardants

- Metal Hydroxides: Aluminium tri-hydroxide (ATH) and magnesium hydroxide (MH) are the most common inorganic metal hydroxides used for flame-retardancy applications. The decomposition of ATH starts at 200 °C, which is generally suitable for many polymers. It transforms into Al2O3 (see Equation (1)), which is a thermally stable material that works as a heat barrier and reduces heat transfer through the material. On the other hand, MH decomposition begins at around 300 °C and ranges from 340 °C to 490 °C (Equation (2)), which makes it more applicable than ATH as a flame-retardant [74]. This metallic hydroxide, during combustion, decomposes and releases water, which absorbs heat from the surroundings [75,76,77,78,79]. This heat-absorbing tendency greatly helps when these filler materials have been used in the ACP core materials. Both MH and ATH have numerous advantages as flame-retardant materials, such as non-toxicity, no toxic gas being generated during decomposition, good stability, cheapness, and wide availability. One of the drawbacks of these metal hydroxides is that they require a high load content (40% to 60%) in the polymer matrix for optimum flame-retardant effects [80].

- Inorganic phosphorous flame-retardants: These types of flame-retardants contain red phosphorous, coated red phosphorous, and ammonium polyphosphate (APP) [81]. APP and red phosphorous are good flame-retardants because of their remarkable properties [81,82]. There are some drawbacks, such as red phosphorous absorbing water in the air producing phosphoric acid, phosphite, and other substances [83]. Another disadvantage is its poor compatibility with resin and its dispersion complexity, leading to segregation settlement [57,84]. Red phosphorous also releases PH3 gas, which is highly toxic. Coated red phosphorous and polyphosphoric acid are good inorganic flame-retardants because of their low toxicity, good thermal stability, and better dispersion in the polymer matrix. APP has some disadvantages, such as absorbing humid air [85]. The important fact about APP is that the mentioned drawbacks can be overcome by microencapsulating with a coating of melamine-formaldehyde resin, poly-plus, epoxy resin, amino resin, etc. [63].

4.1.3. Organic Flame-Retardants

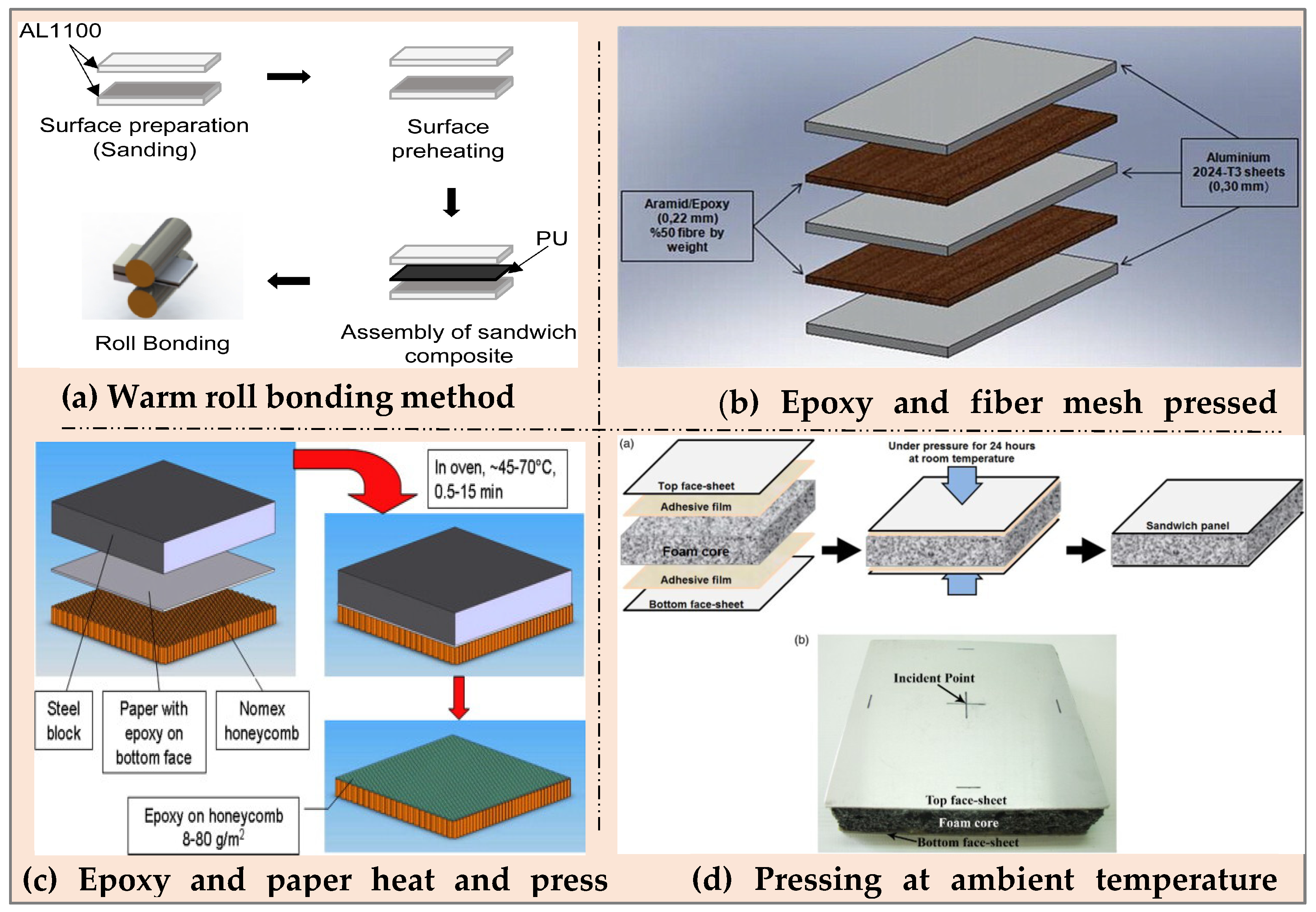

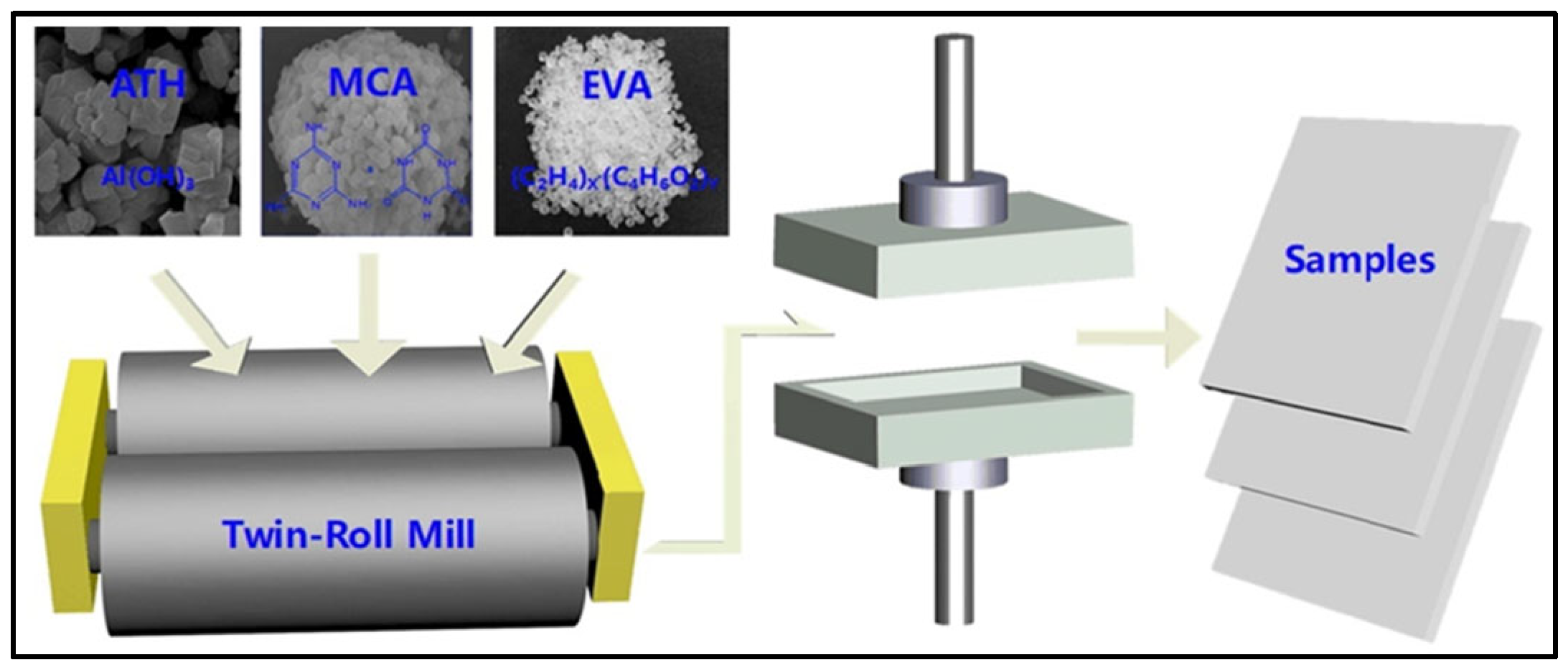

4.2. Fabrication Methods of Flame-Retardant Composite

5. Non-Combustible Cladding Panel’s Binders, Fillers, and Fibres

5.1. Filler Types Used in Non-Combustible Cladding

5.2. Binders Used to Develop Non-Combustible Cladding Materials

5.3. Bonding Mechanisms

| Bonding Techniques | Joining Mechanism | Advantages | Disadvantages |

|---|---|---|---|

| Adhesive bonding | Inter-atomic and inter-molecular forces at interface, mechanical keying led the adhesives to fill cavities, pores, and asperities of adjacent surface | (i) Widely available materials (ii) Flexible with material arrangements (iii) The only effective method to join two element surfaces which have a substantial thickness difference | (i) Requires significant pre-treatment of adherent surfaces (ii) Requires good wettability with surfaces (iii) Cracking failure is very common |

| Bolted joining | Screwing bolts into nuts on either side | (i) Joining components can be tightened at the required tension (ii) Bolts do not plastically deform | (i) Bearing-mode failure is common (ii) Requires drilling operation on the elements which develop stress and sometimes crack near the hole |

| Clinching | Aluminium sheets are compressed with a punch and die, which helps to interlock within the core segment | (i) Can be joined two dissimilar materials which cannot be welded. (ii) Requires less surface preparation for joining (iii) Improves fatigue performance [142,143,144,145] | (i) Failure can occur due to a lack of sufficient undercut (ii) Initial investment required to set up the die and punch system (iii) Lower bonding strength than self-piercing rivet joining |

| Self-piercing rivet | Semi-tubular rivet joins the elements by plastic deformation of joint components. The compression force creates a mechanical interlock | (i) Requires no surface preparation for joining (ii) No need for proper alignment (iii) Improves fatigue performance [142,143,144,145] | (i) Debonding of composites occur due to discontinuity in joints by adding rivets (ii) Tendency of rivets to bend increases failure chances |

| Laser-assisted welding | Melting and joining parts using a laser beam heat source | (i) Requires less surface preparation (ii) Laser beam conduction welding is suitable for high reflective materials like Al with polymers [151] | (i) High porosity and welding defects reported (ii) Laser beam with high energy is not suitable for highly reflective metals such as Al and concrete |

5.4. Fibres Used to Develop Bendable Cementitious Materials

6. Thermal, Flammability, and Mechanical Properties of Cladding Materials

6.1. Thermal Properties of Cladding Materials

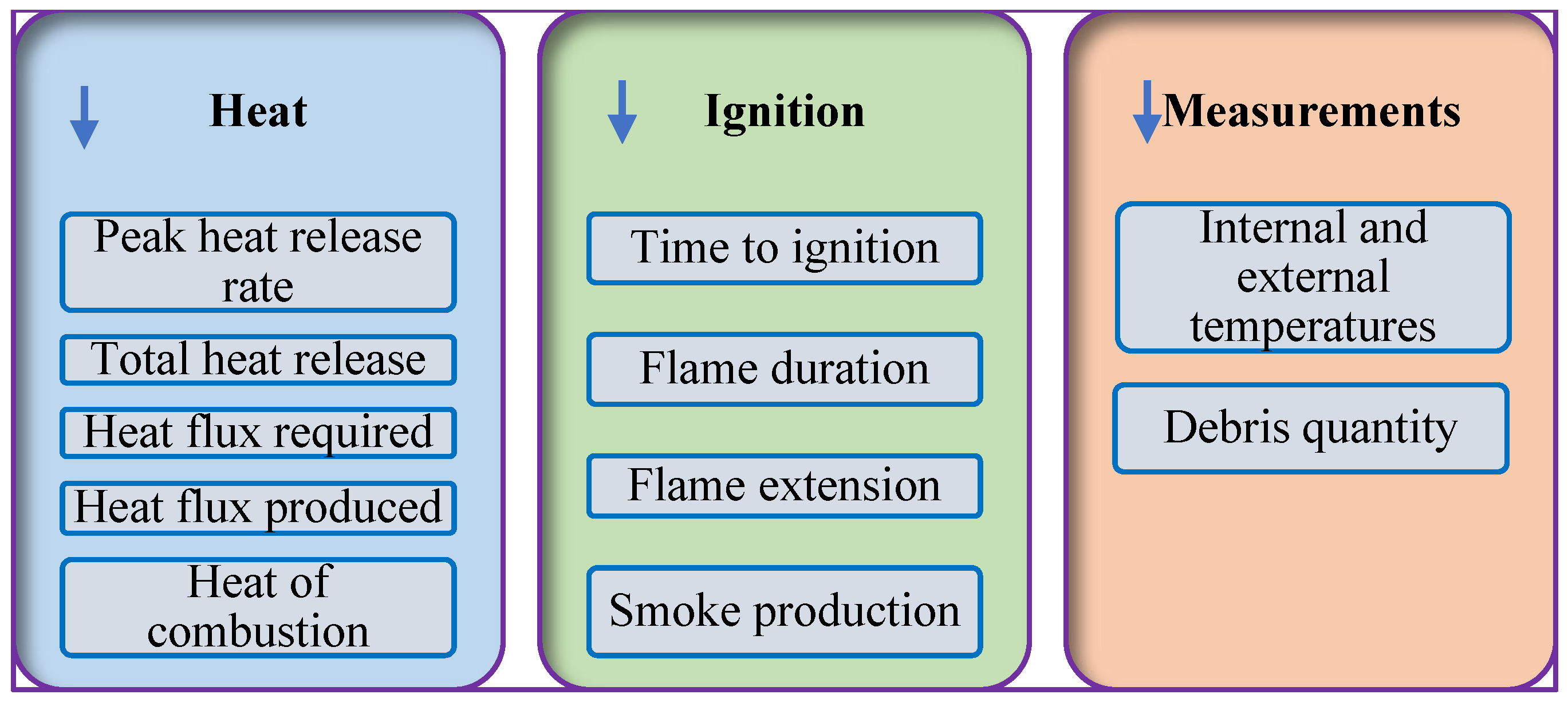

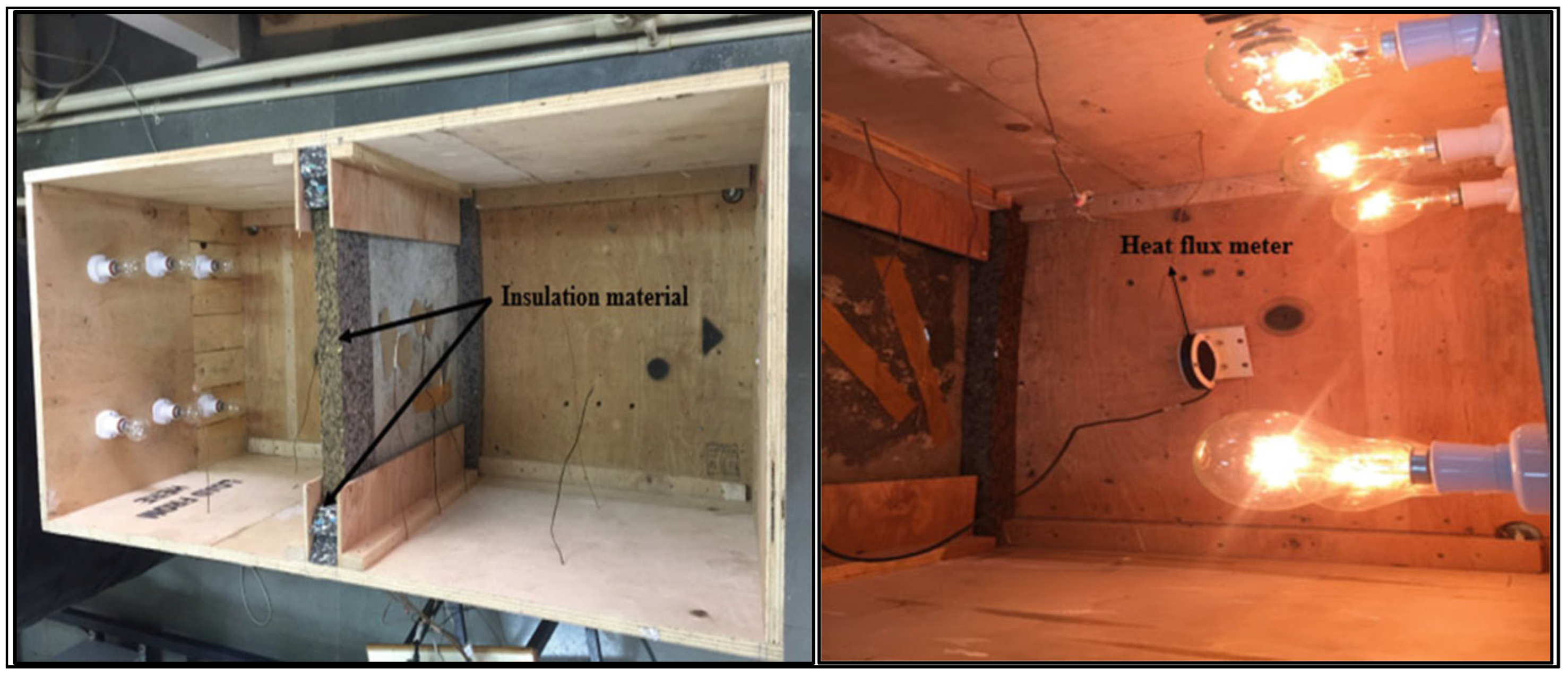

6.2. Flammability Properties of Cladding Materials

6.3. Mechanical Properties of Cladding Materials

7. Survey on the Patents of ACP Cladding Panels

8. Economic Viability of Non-Combustible Panels

- Comparing different cladding systems using full life-cycle cost analysis (LCCA).

- Scalability and supply chain viability of new non-flammable materials.

- Incorporating the concepts of the circular economy to enhance reuse and decrease waste.

9. Recycling Challenges of ACP Panels in Circular Economy

10. Recent Research on Cladding Panels

| Sl No | Title | Source Title | Year | Test Category | Ref. |

|---|---|---|---|---|---|

| 1 | Alternative fire performance screening method of cladding system using cone calorimeter | Construction and Building Materials | 2024 | Cone calorimeter | [39] |

| 2 | Establishing pyrolysis kinetics for fire modelling and thermal analysis of polymeric cladding materials used in high-rise buildings | Case Studies in Construction Materials | 2023 | Small-scale test | [223] |

| 3 | Manufacturing of aluminum composite panels based on aluminum with jute/sisal/kenaf flax natural fibre reinforced epoxy | Journal of Environmental Protection and Ecology | 2023 | Mechanical properties testing | [221] |

| 4 | Full-Scale Fire Performance of Combustible and Non-combustible Curtain Wall Systems with Firestops | Fire Technology | 2023 | Full-scale test | [215] |

| 5 | Assessing the combustibility of claddings: A comparative study of the modified cone calorimeter method and cylindrical furnace test | Fire and Materials | 2022 | Cone calorimeter test | [224] |

| 6 | Experimental and simulation study on the combustion fire spreading characteristics of aluminium composite panels with different thicknesses | Fire and Materials | 2022 | - | [225] |

| 7 | Numerical Investigations on the Influencing Factors of Rapid Fire Spread of Flammable Cladding in a High-Rise Building | Fire | 2022 | Full-scale test | [226] |

| 8 | Effect of different building facade systems on thermal comfort and urban heat island phenomenon: An experimental analysis | Building and Environment | 2022 | - | [219] |

| 9 | Facade Fire Hazards of Bench-Scale Aluminum Composite Panel with Flame-Retardant Core | Fire Technology | 2021 | Cone calorimeter test | [135] |

| 10 | Testing of aluminium composite panels in a cone calorimeter: A new specimen preparation method | Polymer Testing | 2021 | Cone calorimeter | [2] |

| 11 | Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards | Fire and Materials | 2021 | Cone calorimeter | [10] |

| 12 | Quantification of Enhanced Fire Severity in Modern Buildings | Advances in Energy and Combustion | 2021 | Quantitative analysis (full scale) | [227] |

| 13 | An experimental study on effect of aluminum composite panel waste on performance of cement concrete | Ain Shams Engineering Journal | 2021 | Mechanical properties of concrete | [228] |

| 14 | Fire behaviour of modern facade materials—Understanding the Grenfell Tower fire | Journal of Hazardous Materials | 2019 | Full-scale test | [6] |

| 15 | Study of fire behaviour of facade mock-ups equipped with aluminium composite material-based claddings, using intermediate-scale test method | Fire and Materials | 2018 | Intermediate-scale test | [37] |

| 16 | Flammability and multi-objective performance of building Facades: towards optimum design | International Journal of High-Rise Buildings | 2018 | - | [229] |

| 17 | Fire Spread Caused by Combustible Facades in Japan | Fire Technology | 2016 | Intermediate-scale test, full-scale test | [230] |

| Sl No | Title | Cladding Types | Key Findings | Ref. |

|---|---|---|---|---|

| 1 | Experimental Study on PCM-Based External Wall Cladding for Energy Efficient Buildings | (i) Concrete with perlite cladding (ii) Aluminium box cladding with PCM and coarse aggregate (iii) Composite wall cladding | (i) 20.96% reduction in air temperature with composite wall cladding at 100 W heat flux. (ii) Heat flux dropped 98.61% for aluminium box cladding at 60 W and 100 W. | [222] |

| 2 | Experimental Study on the Thermal Performance of Ventilation Wall with Cladding Panels in Hot and Humid Area | (i) Higher-density fibre-reinforced calcium silicate board | (i) 4.9 °C lower air temperature with proposed cladding. (ii) Increase in building thermal resistance. (iii) Need mechanical ventilation to dissipate heat. | [231] |

| 3 | Innovative PCM-incorporated foamed concrete panels for walls’ exterior cladding: An experimental assessment in real-weather conditions | (i) PCM-FC cladding | (i) The average daily fluctuations of the temperatures decreased by 3.59 °C, 7.39 °C, and 6.02 °C, respectively, for the external wall surface, internal wall surface, and room inside temperature, respectively. (ii) The intensity of overheating also decreased by 32.1%, 29.4%, 24.4%, and 21.1% for the south, east, west, and north orientations. | [232] |

| 4 | Several facade types for mitigating urban heat island intensity | (i) ACP panels | (i) Best UHI mitigation: green walls and reflective coatings. (ii) Reflective coatings: avg. temp reduction of 0.53 °C, max reduction of 1.89 °C, effective during low sun angles. (iii) Green walls: avg. temp reduction of 0.65 °C, max reduction of 0.99 °C, cooling via evapotranspiration. | [233] |

| 5 | Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings | (i) Lightweight concrete panels with PCM (ii) Normal concrete panel | (i) The influence of thermal mass is higher than that of thermal resistance on discomfort hours. (ii) The position of insulation layer has a significant impact on the energy savings rate. (iii) Heating energy consumption depends on thermal resistance much more than on thermal mass, while cooling energy consumption is influenced more by thermal mass. | [234] |

| 6 | Energy consumption to cool and heat experimental modules for the energy refurbishment of facades. Three case studies in Madrid | (i) Precast concrete panel (M1 model) (ii) Extruded, high-pressure laminate (HPL) ceramic tile ventilated facade (VF) with thermal insulation layer and cavity (M2) (iii) ETIS panel (M3) | (i) Maximum 15.4% energy savings were achieved for south-facing ETISs, while for the standard non-insulated cavity wall it was 13.3%. (ii) For different seasons of the year, energy consumption varied significantly. | [235] |

| 7 | A New Method for Energy Efficiency Design of Building Facade and Its Thermodynamic Evaluation | (i) Cement–rockwool facade | (i) Presented calculation methods for the coefficient of building shape, the resistance of heat transfer, and thermal inertia. (ii) Proposed a thermodynamic evaluation method for assessing the energy-saving efficiency of the facade. | [236] |

| 8 | Ventilated facades energy performance in summer cooling of buildings | (i) Copper plates (ii) Brick slabs (iii) Asbestos cement panels (iv) Slabs of ceramics (v) Brick hollow flat blocks (vi) Polyester panels | (i) With an air duct width increase, the energy savings also increased. (ii) It was suggested to position the insulating layers close to the inner masonry walls. (iii) With increasing solar radiation, the ventilated facades performed more efficiently. (iv) The wall’s outer surface thermal resistance significantly influenced the energy savings of the model. | [237] |

| 9 | Effect of different building facade systems on thermal comfort and urban heat island phenomenon: An experimental analysis | (i) ACP panels (ii) Clear glass (iii) Brick (iv) Concrete | (i) ACP: When combined with brick, it reduces the indoor air temperature significantly; however, it may raise the outdoor air temperature, potentially worsening UHI. (ii) Brick facades absorb and store heat during solar exposure, and re-emit heat to indoor and outdoor environments, contributing to UHI. | [219] |

11. Conclusions and Future Research Directions

- Although solid aluminium panels are lightweight and non-flammable, they have a high thermal conductivity, which causes thermal bridging. Fibre–cement cladding lessens heat transfer, but it is bulky, energy-intensive, and has limited fire performance data.

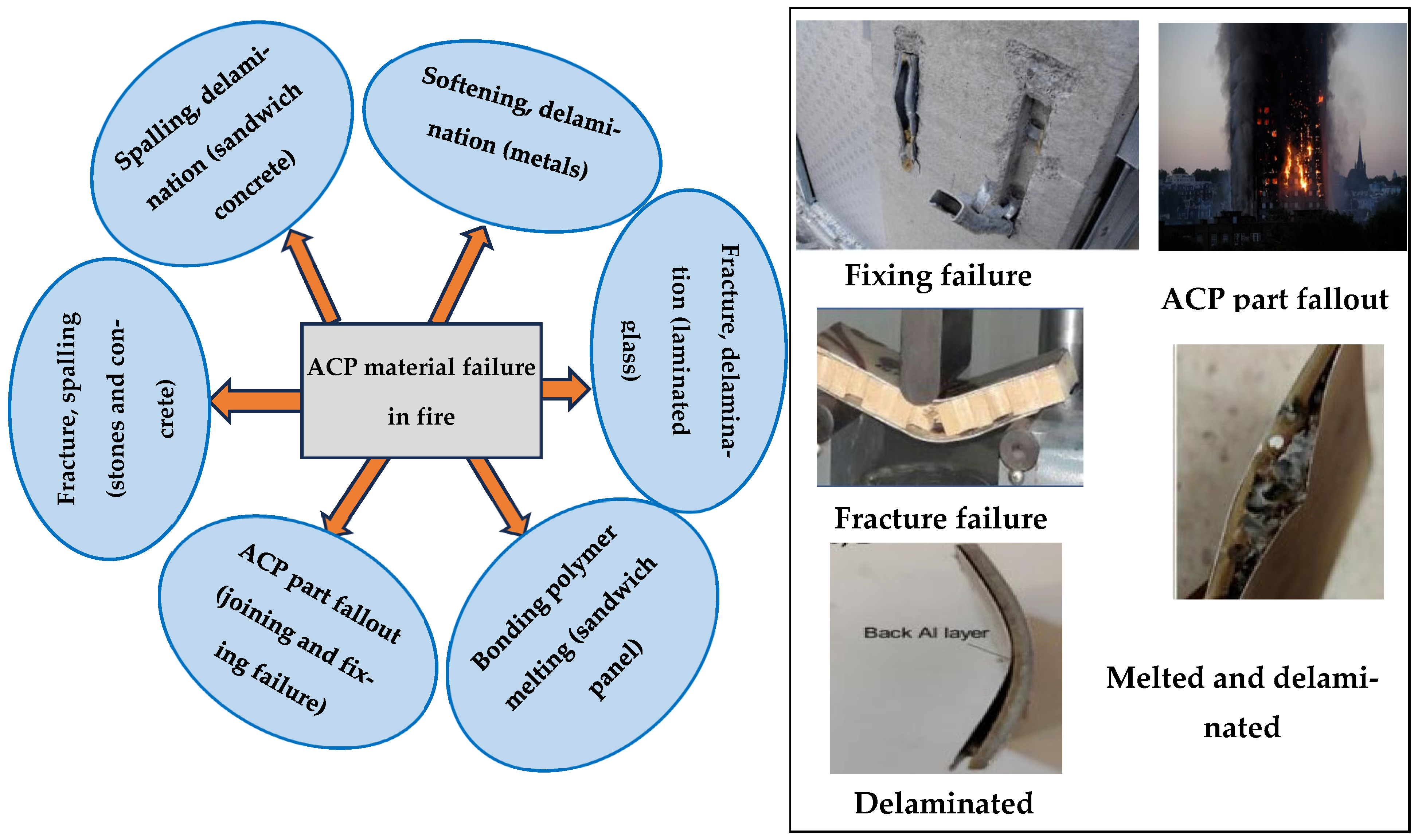

- There are few studies available in the literature on mitigating the delamination issue observed in ACP panels, which is a critical failure mode under thermal stress. Future panel designs should include mechanical bonding or engineered interlocking systems between the aluminium skin and core material to improve overall facade integrity, prevent layer separation during fire exposure, and improve structural cohesion.

- Research on reaction-to-fire properties has largely focused on combustible and fire-rated composites. Detailed studies on the performance parameters of non-combustible claddings are limited and need expansion.

- The energy consumption of a building is directly connected to the heat conduction of the external wall and cladding. Cladding systems significantly affect building energy consumption through heat transfer. However, most energy-efficient panels are combustible, while non-combustible alternatives often lack thermal efficiency.

- There are several cladding panels available on the market, ranging from combustible to non-combustible. Still, detailed analysis of the thermal comfort and energy consumption of non-combustible cladding panels is very limited in the literature. Even the energy efficiency of the newly developed fire-safe cladding system is unknown. Therefore, further research on the energy consumption of buildings using the non-combustible cladding system is required to understand the energy efficiency of non-combustible cladding panels used in high-rise buildings.

- There is still a lack of lightweight, energy-efficient, non-combustible core materials for sustainable high-rise buildings, as the existing panels are either heavyweight or have a low energy efficiency. To develop such a novel cladding material, several research directions can be followed, such as the following:

- Development of mineral-based core material with inorganic, non-combustible fillers (i.e., ATH, MH, Calcium Silicate, Vermiculite, expanded perlite).

- Incorporating the nano-modified fire barriers, such as nano SiO2, nano-clay, into the epoxy or resin-free system for better fire retardancy and avoiding toxic gas generation.

- Core material development with recycled inorganic materials (i.e., geopolymer foam, fly ash), which will be lower in cost, eco-friendly, and non-combustible. This will also promote the circular economy and reduce waste.

Funding

Acknowledgments

Conflicts of Interest

References

- Hossain, M.D.; Hassan, M.K.; Yuen, A.C.Y.; He, Y.; Saha, S.; Hittini, W. Flame behaviour, fire hazard and fire testing approach for lightweight composite claddings—A review. J. Struct. Fire Eng. 2021, 12, 257–292. [Google Scholar] [CrossRef]

- Hossain, M.D.; Saha, S.; Hassan, M.K.; Yuen, A.C.Y.; Wang, C.; Hittini, W.; George, L.; Wuhrer, R. Testing of aluminium composite panels in a cone calorimeter: A new specimen preparation method. Polym. Test. 2022, 106, 107454. [Google Scholar] [CrossRef]

- Kamal, M.A. Recent advances in material science for facade systems in contemporary architecture: An overview. Am. J. Civ. Eng. Arch. 2020, 8, 97–104. [Google Scholar]

- Dabous, S.A.; Ibrahim, T.; Shareef, S.; Mushtaha, E.; Alsyouf, I. Sustainable façade cladding selection for buildings in hot climates based on thermal performance and energy consumption. Results Eng. 2022, 16, 100643. [Google Scholar] [CrossRef]

- Lira, V.N.S.A. A Problemática das Fachadas na Segurança Contra Incêndio em Edifícios: Uma Análise após o Incêndio da Torre Grenfell. Master’s Thesis, Universidade do Porto, Porto, Portugal, 2023. [Google Scholar]

- McKenna, S.T.; Jones, N.; Peck, G.; Dickens, K.; Pawelec, W.; Oradei, S.; Harris, S.; Stec, A.A.; Hull, T.R. Fire behaviour of modern façade materials–Understanding the Grenfell Tower fire. J. Hazard. Mater. 2019, 368, 115–123. [Google Scholar] [CrossRef]

- Wi, S.; Yang, S.; Berardi, U.; Kim, S. Assessment of recycled ceramic-based inorganic insulation for improving energy efficiency and flame retardancy of buildings. Environ. Int. 2019, 130, 104900. [Google Scholar] [CrossRef]

- Mazzucchelli, E.; Rigone, P.; De la Fuente Ceja, B. Fire Safety Facade Design: The Case Study of an Office Tower in Milan, in Face Time 2020: Better Buildings through Better Skins; Tectonic Press: Waltham, MA, USA, 2020; pp. 209–223. [Google Scholar]

- Hasnat, M.R.; Hassan, M.K.; Hossain, M.D.; Saha, S. Experimental study on different types of non-combustible cladding panels using butane torch. In Proceedings of the International Conference on Fire Safety Engineering Research and Practice, Sydney, Australia, 24–27 November 2024; GCSTMR: Sydney, Australia, 2024; pp. 390–396. [Google Scholar]

- Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; De Cachinho Cordeiro, I.M.; Liu, L.; Liu, H.; Lo, A.L.P.; Chan, Q.N.; Yeoh, G.H. Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards. Fire Mater. 2021, 45, 663–689. [Google Scholar] [CrossRef]

- Tran, P.; Nguyen, Q.T.; Lau, K. Fire performance of polymer-based composites for maritime infrastructure. Compos. Part B Eng. 2018, 155, 31–48. [Google Scholar] [CrossRef]

- Mendez, J.E.; McLaggan, M.S.; Lange, D. Upward flame spread behaviour of cladding materials on a medium-scale ventilated façade experimental setup with a single combustible wall. Fire Saf. J. 2024, 142, 104020. [Google Scholar] [CrossRef]

- Peng, L.; Ni, Z.; Huang, X. Review on the Fire Safety of Exterior Wall Claddings in High-rise Buildings in China. Procedia Eng. 2013, 62, 663–670. [Google Scholar] [CrossRef]

- Cook, N.; Taylor, E.J. Assembling Imperceptibility: The Material, Financial and Policy Dimensions of Combustible Cladding in Residential High-Rise. Hous. Theory Soc. 2023, 40, 113–129. [Google Scholar] [CrossRef]

- Chen, T.B.Y.; Yuen, A.C.Y.; Yeoh, G.H.; Yang, W.; Chan, Q.N. Fire risk assessment of combustible exterior cladding using a collective numerical database. Fire 2019, 2, 11. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Weerasinghe, P.; Mendis, P.; Ngo, T. Performance of modern building façades in fire: A comprehensive review. Electron. J. Struct. Eng. 2016, 16, 69–87. [Google Scholar] [CrossRef]

- National Construction Code (NCC) 2022. Volume One—Building Code of Australia Class 2 to 9 Buildings; NCC: Sydney, Australia, 2023. [Google Scholar]

- Building Product Use Ban 2018; NSW Fair Trading; Department of Finance, Services and Innovation, Australia. 2018. Available online: https://www.fairtrading.nsw.gov.au/trades-and-businesses/construction-and-trade-essentials/building-products/aluminium-composite-panel-ban (accessed on 10 January 2025).

- Schulz, J.; Kent, D.; Crimi, T.; Glockling, J.L.D.; Hull, T.R. A Critical Appraisal of the UK’s Regulatory Regime for Combustible Façades. Fire Technol. 2021, 57, 261–290. [Google Scholar] [CrossRef]

- Hirschler, M.M. Façade requirements in the 2021 edition of the US International Building Code. Fire Mater. 2021, 45, 586–597. [Google Scholar] [CrossRef]

- EN 13501-1; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Nazrun, T.; Hassan, M.K.; Hasnat, M.R.; Hossain, M.D.; Saha, S. Improving fire performance of solid aluminium of composite cladding panels incorporating intumescent coatings. Prog. Org. Coat. 2025, 201, 109142. [Google Scholar] [CrossRef]

- Kee Paik, J.; Thayamballi, A.K.; Kim, G.S. The strength characteristics of aluminum honeycomb sandwich panels. Thin-Walled Struct. 1999, 35, 205–231. [Google Scholar] [CrossRef]

- Sun, G.; Huo, X.; Chen, D.; Li, Q. Experimental and numerical study on honeycomb sandwich panels under bending and in-panel compression. Mater. Des. 2017, 133, 154–168. [Google Scholar] [CrossRef]

- Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Gorzelańczyk, T.; Schabowicz, K. Investigation of structural degradation of fiber cement boards due to thermal impact. Materials 2019, 12, 944. [Google Scholar] [CrossRef]

- Naghizadeh, Z.; Faezipour, M.; Ebrahimi, G.; Hamzeh, Y. Manufacture of lignocellulosic fiber–cement boards containing foaming agent. Constr. Build. Mater. 2012, 35, 408–413. [Google Scholar] [CrossRef]

- Hendawitharana, S.; Ariyanayagam, A.; Mahendran, M.; Steau, E. Bushfire resistance of external light steel wall systems lined with fibre cement boards. Fire Saf. J. 2023, 139, 103806. [Google Scholar] [CrossRef]

- Zhang, A.; Li, Y. Thermal Conductivity of Aluminum Alloys—A Review. Materials 2023, 16, 2972. [Google Scholar] [CrossRef] [PubMed]

- Amran, Y.M.; El-Zeadani, M.; Lee, Y.H.; Lee, Y.Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Ming, Y.; Chen, P.; Li, L.; Gan, G.; Pan, G. A Comprehensive Review on the Utilization of Recycled Waste Fibers in Cement-Based Composites. Materials 2021, 14, 3643. [Google Scholar] [CrossRef]

- Shawia, N.B.; Jabber, M.A.; Mamouri, A.F. Mechanical and physical properties of natural fiber cement board for building partitions. Phys. Sci. Res. Int. 2014, 2, 49–53. [Google Scholar]

- Lugaresi, F.; Kotsovinos, P.; Lenk, P.; Rein, G. Review of the mechanical failure of non-combustible facade systems in fire. Constr. Build. Mater. 2022, 361, 129506. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.; Dong, Y.; Sarker, P.; Uddin, M.; Littlefair, G.; Dixit, A.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys–A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Thevega, T.; Jayasinghe, J.; Robert, D.; Bandara, C.; Kandare, E.; Setunge, S. Fire compliance of construction materials for building claddings: A critical review. Constr. Build. Mater. 2022, 361, 129582. [Google Scholar] [CrossRef]

- Aslani, F.; Deghani, A.; Asif, Z. Development of lightweight rubberized geopolymer concrete by using polystyrene and recycled crumb-rubber aggregates. J. Mater. Civ. Eng. 2020, 32, 04019345. [Google Scholar] [CrossRef]

- Liew, J.; Chua, Y.; Dai, Z. Steel concrete composite systems for modular construction of high-rise buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef]

- Guillaume, E.; Fateh, T.; Schillinger, R.; Chiva, R.; Ukleja, S. Study of fire behaviour of facade mock-ups equipped with aluminium composite material-based claddings, using intermediate-scale test method. Fire Mater. 2018, 42, 561–577. [Google Scholar] [CrossRef]

- McLaggan, M.S.; Hidalgo, J.P.; Carrascal, J.; Heitzmann, M.T.; Osorio, A.F.; Torero, J.L. Flammability trends for a comprehensive array of cladding materials. Fire Saf. J. 2021, 120, 103133. [Google Scholar] [CrossRef]

- Hossain, M.D.; Hassan, M.K.; Saha, S.; Yuen, A.C.Y.; Wang, C. Alternative fire performance screening method of cladding system using cone calorimeter. Constr. Build. Mater. 2024, 418, 135442. [Google Scholar] [CrossRef]

- AS 1530.1-1994; Methods for Fire Tests on Building Materials, Components and Structures, Part 1: Combustibility Test for Materials. Standard Australia: Sydney, Australia, 1994.

- Zhang, J.; Delichatsios, M.; Colobert, M. Assessment of fire dynamics simulator for heat flux and flame heights predictions from fires in SBI tests. Fire Technol. 2010, 46, 291–306. [Google Scholar] [CrossRef]

- ISO 1716; Reaction to Fire Tests for Products: Determination of the Gross Heat of Combustion (Calorific Value). International Organization for Standardization: Geneva, Switzerland, 2018.

- ASTM E136-22; Standard Test Method for Assessing Combustibility of Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Approved Document B (Fire Safety) Volume 2: Buildings Other Than Dwellings, 2019 Edition Incorporating 2020 and 2022 Amendments. 2022. Available online: https://www.gov.uk/government/publications/fire-safety-approved-document-b (accessed on 10 July 2023).

- Scimonello, S.; Armstrong, A.; Shee, H. A Performance-Based Building Code On Statutory Maintenance: Exploring The Policy For Consumer Safety In Australia. In Proceedings of the 43rd AUBEA, Noosa, Australia, 6–8 November 2019; p. 489. [Google Scholar]

- White, N. Fire Performance and Test Methods for ACP External Wall Cladding; Department of Environment, Land, Water and Planning: Melbourne, Australia, 2020. [Google Scholar]

- National Construction Code 2022. Available online: https://ncc.abcb.gov.au/editions/ncc-2022 (accessed on 20 July 2023).

- Understanding A1, A2, and B Fire Classification of Cladding Materials in Buildings. 2023. Available online: https://mccoymart.com/post/what-is-a1-a2-and-b-fire-classification-of-cladding-materials-in-buildings/ (accessed on 7 August 2023).

- Moussavi Nadoushani, Z.S.; Akbarnezhad, A.; Jornet, J.F.; Xiao, J. Multi-criteria selection of façade systems based on sustainability criteria. Build. Environ. 2017, 121, 67–78. [Google Scholar] [CrossRef]

- Awad, A.H.; El Gamasy, R.; El Wahab, A.A.; Abdellatif, M.H. Mechanical and Physical Properties of PP and HDPE. Eng. Sci 2019, 4, 34. [Google Scholar] [CrossRef]

- White, N.; Delichatsios, M.; Ahrens, M.; Kimball, A. Fire Hazards of Exterior Wall Assemblies Containing Combustible Components; In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2013. [Google Scholar]

- Aluminium Composite Panels (ACP). 2022. Available online: https://www.vba.vic.gov.au/?a=97579 (accessed on 5 July 2023).

- Carneiro, J.O.; Vasconcelos, G.; Azevedo, S.; Jesus, C.; Palha, C.; Gomes, N.; Teixeira, V. The evaluation of the thermal behaviour of a mortar based brick masonry wall coated with TiO2 nanoparticles: An experimental assessment towards energy efficient buildings. Energy Build. 2014, 81, 1–8. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- DIN 4102; Fire Behaviour of Building Materials and Building Components. Part 3: Fire Walls and Non-Load-Bearing External Walls; Definitions, Requirements and Tests; Beuth Verlag/German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 1977.

- Miao, Z.; Xingna, L.; Zhen, C.; Ji, W. Wenhua, Experimental study of the heat flux effect on combustion characteristics of commonly exterior thermal insulation materials. Procedia Eng. 2014, 84, 578–585. [Google Scholar] [CrossRef][Green Version]

- Puri, R.G.; Khanna, A.S. Intumescent coatings: A review on recent progress. J. Coat. Technol. Res. 2017, 14, 1–20. [Google Scholar] [CrossRef]

- Iavorschi, E.; Milici, L.D.; Ungureanu, C.; Bejenar, C. A Comparative Evaluation of the Thermal Performance of Passive Facades with Variable Cavity Widths for Near-Zero Energy Buildings (nZEB): A Modeling Study. Appl. Sci. 2025, 15, 7019. [Google Scholar]

- Tang, G.; Shang, C.; Qin, Y.; Lai, J. Current Advances in Flame-Retardant Performance of Tunnel Intumescent Fireproof Coatings: A Review. Coatings 2025, 15, 99. [Google Scholar] [CrossRef]

- Britain, G. The Building Regulations 2000: Approved Document B Fire Safety: Volume 2-Buildings Other Than Dwellinghouses/Department for Communities and Local Government; RIBA: London, UK, 2007. [Google Scholar]

- Board, A.B.C. Advisory Note (2020.2.3): Fire Performance of External Walls and Cladding 2020. Available online: https://www.abcb.gov.au/sites/default/files/resources/2022/Advisory-Note-fire-performance-external-walls-cladding.pdf (accessed on 5 July 2023).

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R: Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Wang, S. The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering. Polymers 2022, 14, 82. [Google Scholar] [CrossRef]

- Hasnat, M.R.; Hassan, M.K.; Saha, S. Flame Retardant Polymer Composite and Recent Inclusion of Magnesium Hydroxide Filler Material: A Bibliometric Analysis towards Further Study Scope. Fire 2023, 6, 180. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhothu, T.H.; Mokhena, T.C. Synthesis, mechanical, and flammability properties of metal hydroxide reinforced polymer composites: A review. Polym. Eng. Sci. 2022, 62, 44–65. [Google Scholar] [CrossRef]

- Tai, C.; Li, R.K. Mechanical properties of flame retardant filled polypropylene composites. J. Appl. Polym. Sci. 2001, 80, 2718–2728. [Google Scholar] [CrossRef]

- Zhao, C.-S.; Huang, F.-L.; Xiong, W.-C.; Wang, Y.-Z. A novel halogen-free flame retardant for glass-fiber-reinforced poly (ethylene terephthalate). Polym. Degrad. Stab. 2008, 93, 1188–1193. [Google Scholar] [CrossRef]

- Suppakarn, N.; Jarukumjorn, K. Mechanical properties and flammability of sisal/PP composites: Effect of flame retardant type and content. Compos. Part B Eng. 2009, 40, 613–618. [Google Scholar] [CrossRef]

- Matkó, S.; Toldy, A.; Keszei, S.; Anna, P.; Bertalan, G.; Marosi, G. Flame retardancy of biodegradable polymers and biocomposites. Polym. Degrad. Stab. 2005, 88, 138–145. [Google Scholar] [CrossRef]

- Montalbano, A.M.; Albano, G.D.; Anzalone, G.; Moscato, M.; Gagliardo, R.; Di Sano, C.; Bonanno, A.; Ruggieri, S.; Cibella, F.; Profita, M. Cytotoxic and genotoxic effects of the flame retardants (PBDE-47, PBDE-99 and PBDE-209) in human bronchial epithelial cells. Chemosphere 2020, 245, 125600. [Google Scholar] [CrossRef]

- Cho, J.-H.; Lee, S.; Jeon, H.; Kim, A.H.; Lee, W.; Lee, Y.; Yang, S.; Yun, J.; Jung, Y.-S.; Lee, J. Tetrabromobisphenol A-induced apoptosis in neural stem cells through oxidative stress and mitochondrial dysfunction. Neurotox. Res. 2020, 38, 74–85. [Google Scholar] [CrossRef]

- Simond, A.E.; Houde, M.; Lesage, V.; Michaud, R.; Verreault, J. Metabolomic profiles of the endangered St. Lawrence Estuary beluga population and associations with organohalogen contaminants. Sci. Total Environ. 2020, 717, 137204. [Google Scholar] [CrossRef]

- Sharkey, M.; Harrad, S.; Abdallah, M.A.-E.; Drage, D.S.; Berresheim, H. Phasing-out of legacy brominated flame retardants: The UNEP Stockholm Convention and other legislative action worldwide. Environ. Int. 2020, 144, 106041. [Google Scholar] [CrossRef]

- Witkowski, A.; Hollingbery, L.; Hull, T.R. Fire retardancy of mineral fillers in EVA copolymers. In Fire and Polymers VI: New Advances in Flame Retardant Chemistry and Science; ACS Publications: Washington, DC, USA, 2012; pp. 97–111. [Google Scholar]

- Qin, Z.L.; Li, D.H.; Yang, R.J. Preparation of ammonium polyphosphate coated with aluminium hydroxide and its application in polypropylene as flame retardant. J. Inorg. Mater. 2015, 30, 1267–1272. [Google Scholar]

- Lewin, M.; Endo, M. Catalysis of intumescent flame retardancy of polypropylene by metallic compounds. Polym. Adv. Technol. 2003, 14, 3–11. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Wang, Q. Preparation of high loading magnesium hydroxide flame retardant polypropylene by solid state shear milling. J. Compos. Mater. 2007, 41, 1995–2003. [Google Scholar] [CrossRef]

- Marosfoi, B.; Garas, S.; Bodzay, B.; Zubonyai, F.; Marosi, G. Flame retardancy study on magnesium hydroxide associated with clays of different morphology in polypropylene matrix. Polym. Adv. Technol. 2008, 19, 693–700. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Lu, S.; Wu, H.; Guo, S.; Luo, Z. Combustion characteristics of polypropylene/magnesium hydroxide/expandable graphite composites. J. Macromol. Sci. Part B 2009, 48, 1081–1092. [Google Scholar] [CrossRef]

- Papazoglou, E. Chapter 4: Flame retardants for plastics. In Handbook of Building Materials for Fire Protection; McGraw-Hill: New York, NY, USA, 2004; pp. 4.1–4.88. [Google Scholar]

- Liu, Y.; Gao, Y.; Zhang, Z.; Wang, Q. Preparation of ammonium polyphosphate and dye co-intercalated LDH/polypropylene composites with enhanced flame retardant and UV resistance properties. Chemosphere 2021, 277, 130370. [Google Scholar] [CrossRef]

- Yan, J.; Xu, P.; Zhang, P.; Fan, H. Surface-modified ammonium polyphosphate for flame-retardant and reinforced polyurethane composites. Colloids Surf. A Physicochem. Eng. Asp. 2021, 626, 127092. [Google Scholar] [CrossRef]

- Cui, M.; Li, J.; Qin, D.; Sun, J.; Chen, Y.; Xiang, J.; Yan, J.; Fan, H. Intumescent flame retardant behavior of triazine group and ammonium polyphosphate in waterborne polyurethane. Polym. Degrad. Stab. 2021, 183, 109439. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, L.; Li, D.-F.; Fu, T.; He, L.; Wang, X.-L.; Wang, Y.-Z. Biomimetic construction peanut-leaf structure on ammonium polyphosphate surface: Improving its compatibility with poly (lactic acid) and flame-retardant efficiency simultaneously. Chem. Eng. J. 2021, 412, 128737. [Google Scholar] [CrossRef]

- Rabe, S.; Chuenban, Y.; Schartel, B. Exploring the modes of action of phosphorus-based flame retardants in polymeric systems. Materials 2017, 10, 455. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Liu, Y.; Wang, Q. Properties and mechanisms of different guanidine flame retardant wood pulp paper. J. Anal. Appl. Pyrolysis 2017, 128, 224–231. [Google Scholar] [CrossRef]

- Wan, C.; Liu, S.; Chen, Y.; Zhang, F. Facile, one–pot, formaldehyde-free synthesis of reactive NP flame retardant for a biomolecule of cotton. Int. J. Biol. Macromol. 2020, 163, 1659–1668. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Rahman, M.Z.; Song, L.; Hu, Y. An environmentally friendly approach to fabricating flame retardant, antibacterial and antifungal cotton fabrics via self-assembly of guanazole-metal complex. J. Clean. Prod. 2020, 273, 122832. [Google Scholar] [CrossRef]

- Wu, K.; Wang, X.; Xu, Y.; Guo, W. Flame retardant efficiency of modified para-aramid fiber synergizing with ammonium polyphosphate on PP/EPDM. Polym. Degrad. Stab. 2020, 172, 109065. [Google Scholar] [CrossRef]

- Reuter, J.; Greiner, L.; Kukla, P.; Döring, M. Efficient flame retardant interplay of unsaturated polyester resin formulations based on ammonium polyphosphate. Polym. Degrad. Stab. 2020, 178, 109134. [Google Scholar] [CrossRef]

- Gao, X.; Lin, Y.; Li, J.; Xu, Y.; Qian, Z.; Lin, W. Spatial pattern analysis reveals multiple sources of organophosphorus flame retardants in coastal waters. J. Hazard. Mater. 2021, 417, 125882. [Google Scholar] [CrossRef]

- Mata, M.d.C.; Castro, V.; Quintana, J.; Rodil, R.; Beiras, R.; Vidal-Liñán, L. Bioaccumulation of organophosphorus flame retardants in the marine mussel Mytilus galloprovincialis. Sci. Total Environ. 2022, 805, 150384. [Google Scholar] [CrossRef] [PubMed]

- Zhong, W.; Cui, Y.; Li, R.; Yang, R.; Li, Y.; Zhu, L. Distribution and sources of ordinary monomeric and emerging oligomeric organophosphorus flame retardants in Haihe Basin, China. Sci. Total Environ. 2021, 785, 147274. [Google Scholar] [CrossRef]

- Shi, Q.; Guo, W.; Shen, Q.; Han, J.; Lei, L.; Chen, L.; Yang, L.; Feng, C.; Zhou, B. In vitro biolayer interferometry analysis of acetylcholinesterase as a potential target of aryl-organophosphorus flame-retardants. J. Hazard. Mater. 2021, 409, 124999. [Google Scholar] [CrossRef] [PubMed]

- Albaqami, M.D.; Shaikh, S.F.; Nafady, A. Utilization of hybrid silicone rubber/Exolit AP 422 composite for the fabrication of mechanically flexible, flame-retardant and superhydrophobic polyurethane foams. Mater. Chem. Phys. 2021, 273, 125133. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Song, S. Preparation of a novel type of flame retardant diatomite and its application in silicone rubber composites. Adv. Powder Technol. 2019, 30, 1567–1575. [Google Scholar] [CrossRef]

- Beaugendre, A.; Lemesle, C.; Bellayer, S.; Degoutin, S.; Duquesne, S.; Casetta, M.; Pierlot, C.; Jaime, F.; Kim, T.; Jimenez, M. Flame retardant and weathering resistant self-layering epoxy-silicone coatings for plastics. Prog. Org. Coat. 2019, 136, 105269. [Google Scholar] [CrossRef]

- Kim, Y.; Hwang, S.; Choi, J.; Lee, J.; Yu, K.; Baeck, S.-H.; Shim, S.E.; Qian, Y. Valorization of fly ash as a harmless flame retardant via carbonation treatment for enhanced fire-proofing performance and mechanical properties of silicone composites. J. Hazard. Mater. 2021, 404, 124202. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. Mechanical and thermal properties of kenaf fiber reinforced polypropylene/magnesium hydroxide composites. J. Eng. Fibers Fabr. 2017, 12, 50–58. [Google Scholar] [CrossRef]

- Huang, H.; Tian, M.; Yang, J.; Li, H.; Liang, W.; Zhang, L.; Li, X. Stearic acid surface modifying Mg (OH) 2: Mechanism and its effect on properties of ethylene vinyl acetate/Mg (OH) 2 composites. J. Appl. Polym. Sci. 2008, 107, 3325–3331. [Google Scholar] [CrossRef]

- Zhu, X.; Pang, H.; Zheng, N.; Tian, P.; Ning, G. High effects of smoke suppression and char formation of Ni–Mo/Mg (OH) 2 for polypropylene. Polym. Adv. Technol. 2020, 31, 1688–1698. [Google Scholar] [CrossRef]

- Casetta, M.; Michaux, G.; Ohl, B.; Duquesne, S.; Bourbigot, S. Key role of magnesium hydroxide surface treatment in the flame retardancy of glass fiber reinforced polyamide 6. Polym. Degrad. Stab. 2018, 148, 95–103. [Google Scholar] [CrossRef]

- Meng, W.; Wu, H.; Wu, R.; Wang, T.; Wang, A.; Ma, J.; Xu, J.; Qu, H. Fabrication of surface-modified magnesium hydroxide using Ni2+ chelation method and layer-by-layer assembly strategy: Improving the flame retardancy and smoke suppression properties of ethylene-vinyl acetate. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125712. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Shan, Z.; Wang, S.; Xiao, Y. Surface modification of magnesium hydroxide by wet process and effect on the thermal stability of silicone rubber. Appl. Surf. Sci. 2019, 465, 740–746. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Q.; Liu, Y. Flame-retardant polypropylene composites with magnesium hydroxide encapsulated by polypropylene grafted with maleic anhydride. Polym. Plast. Technol. Eng. 2010, 49, 367–372. [Google Scholar] [CrossRef]

- Kalali, E.N.; Zhang, L.; Shabestari, M.E.; Croyal, J.; Wang, D.-Y. Flame-retardant wood polymer composites (WPCs) as potential fire safe bio-based materials for building products: Preparation, flammability and mechanical properties. Fire Saf. J. 2019, 107, 210–216. [Google Scholar] [CrossRef]

- Xu, S.; Li, J.; Ye, Q.; Shen, L.; Lin, H. Flame-retardant ethylene vinyl acetate composite materials by combining additions of aluminum hydroxide and melamine cyanurate: Preparation and characteristic evaluations. J. Colloid Interface Sci. 2021, 589, 525–531. [Google Scholar] [CrossRef] [PubMed]

- Cinausero, N.; Azema, N.; Lopez-Cuesta, J.M.; Cochez, M.; Ferriol, M. Synergistic effect between hydrophobic oxide nanoparticles and ammonium polyphosphate on fire properties of poly(methyl methacrylate) and polystyrene. Polym. Degrad. Stab. 2011, 96, 1445–1454. [Google Scholar] [CrossRef]

- Nazaré, S.; Kandola, B.K.; Horrocks, A.R. Flame-retardant unsaturated polyester resin incorporating nanoclays. Polym. Adv. Technol. 2006, 17, 294–303. [Google Scholar] [CrossRef]

- Richardson, L.R.; Brooks, M.E. Combustibility of building materials. Fire Mater. 1991, 15, 131–136. [Google Scholar] [CrossRef]

- Non-Combustible Brands. 2023. Available online: https://hvgfacades.com.au/non-combustible-brands/ (accessed on 8 August 2024).

- Sauerwein, R. Mineral Filler Flame Retardants. In Non-Halogenated Flame Retardant Handbook; Wiley: Hoboken, NJ, USA, 2021; pp. 101–168. [Google Scholar]

- Pritchard, G. Plastics Additives: An A-Z Reference; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Akindele, O.E.; dos Anjos, E.G.R.; Mapossa, A.B.; Sundararaj, U. Sustainable Fire-Resistant Materials: Recycled Polyethylene Composites with Non-Halogenated Intumescent Flame Retardants for Construction Applications. Recycling 2025, 10, 45. [Google Scholar] [CrossRef]

- CSIRO. Identification of Aluminium Composite Panels. 2022. Available online: https://research.csiro.au/infratech/fire-safety/building-facade-fire-safety/identification-of-aluminium-composite-panels/ (accessed on 10 August 2024).

- PROMINIUM®. 2023. Available online: https://www.probond.com.au/products/prominium/ (accessed on 10 August 2024).

- PROCORE A1®. 2023. Available online: https://www.probond.com.au/products/procore-a1/ (accessed on 10 August 2024).

- PROBOND FacadeFR. 2022. Available online: https://www.probond.com.au/products/probond-facadefr/ (accessed on 10 August 2024).

- PROCORE LiteA1®. 2023. Available online: https://www.probond.com.au/products/procore-litea1/ (accessed on 10 August 2024).

- PROBOND UltraFR. Available online: https://www.probond.com.au/products/probond-ultra-fr-rv/ (accessed on 10 August 2024).

- Alucobond Technical Data. 2023. Available online: https://alucobond.com.sg/products/alucobond-a2/technical-data-a2/ (accessed on 8 August 2024).

- larcore ® Aluminium Honeycomb Panels. 2018. Available online: https://alucoil.com/larcore/?lang=en (accessed on 22 June 2025).

- larcoreA2 Aluminium Honeycomb Panels for Architectural Envelopes Technical Information Notebook. 2021. Available online: https://alucoil.com/wp-content/uploads/2024/04/TECH_INFO_NOTEBOOK_LARCORE_HONEYCOMB_PANEL_ARCHITECTURE_ENGLISH.pdf (accessed on 22 June 2025).

- EVA Aluminium Panel. 2023. Available online: https://www.evabond.com/technical-specification-aluminium-composite-panel (accessed on 22 June 2023).

- ALPOLIC NC. 2023. Available online: https://www.alpolic.com/alpolic-intl/alpolic-nc/ (accessed on 22 June 2023).

- First Choice for Maximum Fire Safety: ALPOLIC™ A2. Available online: https://www.alpolic.eu/en/products/alpolic-a2 (accessed on 22 June 2025).

- Mitsubishi ALPOLIC™/FR. Available online: https://www.networkarchitectural.com.au/products/alpolic-fr/ (accessed on 22 June 2025).

- ALPOLIC™/fr LT. 2023. Available online: https://www.alpolic.com/alpolic-intl/product_frlt/ (accessed on 22 June 2025).

- Mitsubishi Chemical Infratec Co., Ltd. Summary of Technical Data—ALPOLIC™/fr TCM Titanium Composite Material; Mitsubishi Chemical Group: Tokyo, Japan, 2022. [Google Scholar]

- Barestone Lunar 2023. Available online: https://www.cemintel.com.au/products/barestone-lunar/ (accessed on 22 June 2023).

- SWISSPEARL. Architecture with Swisspearl-Fascinating fibre cement. 2024. Available online: https://www.swisspearl.com/company/fibre-cement (accessed on 22 June 2023).

- EQUITONE [natura]. 2024. Available online: https://www.equitone.com/en-au/materials/natura/ (accessed on 22 June 2025).

- Bluechip Facade Panels. Ultrabound FR Technical Manual; Bluechip Facade Panels: Forrestfield, Australia, 2019. [Google Scholar]

- Srivastava, G.; Nakrani, D.; Ghoroi, C. Performance of Combustible Facade Systems with Glass, ACP and Firestops in Full-Scale, Real Fire Experiments. Fire Technol. 2020, 56, 1575–1598. [Google Scholar] [CrossRef]

- Khan, A.A.; Lin, S.; Huang, X.; Usmani, A. Facade Fire Hazards of Bench-Scale Aluminum Composite Panel with Flame-Retardant Core. Fire Technol. 2023, 59, 5–28. [Google Scholar] [CrossRef]

- Byrnes, T.; Angel, L.; Hunt, K.; Flynn, T. Review of techniques for identifying the chemical composition of Aluminium Composite Cladding cores. Electron. J. Struct. Eng. 2019, 19, 14–22. [Google Scholar] [CrossRef]

- Shao, Y.; Parks, A.; Ostertag, C.P. Lightweight concrete façade with multiple air gaps for sustainable and energy-efficient buildings in Singapore. Build. Environ. 2022, 223, 109463. [Google Scholar] [CrossRef]

- Aghdasi, P.; Ostertag, C.P. Green ultra-high performance fiber-reinforced concrete (G-UHP-FRC). Constr. Build. Mater. 2018, 190, 246–254. [Google Scholar] [CrossRef]

- Schabowicz, K.; Sulik, P.; Zawiślak, Ł. Reduction of load capacity of fiber cement board facade cladding under the influence of fire. Materials 2021, 14, 1769. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A.; Ali, A.A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Benayoune, A.; Samad, A.A.A.; Trikha, D.N.; Ali, A.A.A.; Ashrabov, A.A. Structural behaviour of eccentrically loaded precast sandwich panels. Constr. Build. Mater. 2006, 20, 713–724. [Google Scholar] [CrossRef]

- Varis, J.P. The suitability of clinching as a joining method for high-strength structural steel. J. Mater. Process. Technol. 2003, 132, 242–249. [Google Scholar] [CrossRef]

- Abe, Y.; Kato, T.; Mori, K. Joining of Aluminium Alloy and Mild Steel Sheets Using Mechanical Clinching. Materials Science Forum 2007, 561, 1043–1046. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Kato, T. Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J. Mater. Process. Technol. 2012, 212, 884–889. [Google Scholar] [CrossRef]

- Gao, S.; Budde, L. Mechanism of mechanical press joining. Int. J. Mach. Tools Manuf. 1994, 34, 641–657. [Google Scholar] [CrossRef]

- Khan, I.; Poh, B. Natural rubber-based pressure-sensitive adhesives: A review. J. Polym. Environ. 2011, 19, 793–811. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Mousa, S.; Kim, G.-Y. A direct adhesion of metal-polymer-metal sandwich composites by warm roll bonding. J. Mater. Process. Technol. 2017, 239, 133–139. [Google Scholar] [CrossRef]

- Rion, J.; Leterrier, Y.; Månson, J.-A.E. Prediction of the adhesive fillet size for skin to honeycomb core bonding in ultra-light sandwich structures. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1547–1555. [Google Scholar] [CrossRef]

- Babakhani, A.; Golestanipour, M.; Zebarjad, S.M. Modelling of aluminium foam core sandwich panels under impact perforation. Mater. Sci. Technol. 2016, 32, 1330–1337. [Google Scholar] [CrossRef]

- Assuncao, D.; Ganguly, S.; Yapp, D.; Williams, S. Conduction mode: Broadening the range of applications for laser welding. In Proceedings of the 63rd Annual Assembly & International Conference of the International Institute of Welding, Istanbul, Turkey, 11–17 July 2010. [Google Scholar]

- Prabha, S.L.; Lalremruati, R. A Study On Fibre Reinforced Bendable Concrete. Eur. Chem. Bull. 2023, 12, 19. [Google Scholar]

- Solanki, V.; Priyan, K.; Pitroda, D.J. A Review on Bendable Concrete. Eur. Chem. Bull. 2023, 8, 72–90. [Google Scholar]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Guo, X.; Pan, X. Mechanical properties and mechanisms of fiber reinforced fly ash–steel slag based geopolymer mortar. Constr. Build. Mater. 2018, 179, 633–641. [Google Scholar] [CrossRef]

- Al-mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Saranya, P.; Nagarajan, P.; Shashikala, A.P. Performance evaluation of geopolymer concrete beams under monotonic loading. Structures 2019, 20, 560–569. [Google Scholar] [CrossRef]

- Riahi, S.; Nemati, A.; Khodabandeh, A.R.; Baghshahi, S. Investigation of interfacial and mechanical properties of alumina-coated steel fiber reinforced geopolymer composites. Constr. Build. Mater. 2021, 288, 123118. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Isomoisio, H.; Karhu, M.; Illikainen, M. Mechanical and acoustic properties of fiber-reinforced alkali-activated slag foam concretes containing lightweight structural aggregates. Constr. Build. Mater. 2018, 187, 371–381. [Google Scholar] [CrossRef]

- Khan, M.Z.; Hao, Y.; Hao, H. Mechanical properties and behaviour of high-strength plain and hybrid-fiber reinforced geopolymer composites under dynamic splitting tension. Cem. Concr. Compos. 2019, 104, 103343. [Google Scholar] [CrossRef]

- Deng, L.; Ma, Y.; Hu, J.; Yin, S.; Ouyang, X.; Fu, J.; Liu, A.; Zhang, Z. Preparation and piezoresistive properties of carbon fiber-reinforced alkali-activated fly ash/slag mortar. Constr. Build. Mater. 2019, 222, 738–749. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Borges, P.H.R.; de Andrade Silva, F. Mechanical behavior of strain-hardening geopolymer composites reinforced with natural and PVA fibers. Mater. Today: Proc. 2019, 8, 753–759. [Google Scholar] [CrossRef]

- Silva Mondragón, G.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Optimization of a reinforced geopolymer composite using natural fibers and construction wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Korniejenko, K.; Frączek, E.; Pytlak, E.; Adamski, M. Mechanical Properties of Geopolymer Composites Reinforced with Natural Fibers. Procedia Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Poletanovic, B.; Dragas, J.; Ignjatovic, I.; Komljenovic, M.; Merta, I. Physical and mechanical properties of hemp fibre reinforced alkali-activated fly ash and fly ash/slag mortars. Constr. Build. Mater. 2020, 259, 119677. [Google Scholar] [CrossRef]

- Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Characterizations of flax fabric reinforced nanoclay-geopolymer composites. Compos. Part B Eng. 2016, 95, 412–422. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Synthesis and mechanical properties of cotton fabric reinforced geopolymer composites. Compos. Part B Eng. 2014, 60, 36–42. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 2021, 282, 124543. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of geopolymer concrete with basalt fiber using digital image correlation. Theor. Appl. Fract. Mech. 2021, 112, 102909. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Q.; Wang, Z. Properties of Polyvinyl Alcohol-Steel Hybrid Fiber-Reinforced Composite with High-Strength Cement Matrix. J. Mater. Civ. Eng. 2017, 29, 04017026. [Google Scholar] [CrossRef]

- Teng, T.-L.; Chu, Y.-A.; Chang, F.-A.; Shen, B.-C.; Cheng, D.-S. Development and validation of numerical model of steel fiber reinforced concrete for high-velocity impact. Comput. Mater. Sci. 2008, 42, 90–99. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile Strain-Hardening Behavior of Polyvinyl Alcohol Engineered Cementitious Composite (PVA-ECC). Mater. J. 2001, 98, 483–492. [Google Scholar]

- Wang, S.; Li, V.C. Polyvinyl alcohol fiber reinforced engineered cementitious composites: Material design and performances. In Proceedings of the International Workshop on High Performance Fiber Reinforced Cementitious Composites (HPFRCC) in Structural Applications, Honolulu, HI, USA, 23–26 May 2005. [Google Scholar]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Bindiganavile, V.; Goncalves, J.R.A.; Boluk, Y. Crack Growth Resistance in Fibre Reinforced Geopolymer Concrete Exposed to Sustained Extreme Temperatures. Key Eng. Mater. 2016, 711, 511–518. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. The effect of organic and inorganic fibres on the mechanical and thermal properties of aluminate activated geopolymers. Compos. Part B Eng. 2015, 76, 218–228. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef]

- Haddaji, Y.; Majdoubi, H.; Mansouri, S.; Tamraoui, Y.; El Bouchti, M.; Manoun, B.; Oumam, M.M.; Hannache, H. Effect of synthetic fibers on the properties of geopolymers based on non-heat treated phosphate mine tailing. Mater. Chem. Phys. 2020, 260, 124147. [Google Scholar] [CrossRef]

- Pokharel, A.; Falua, K.J.; Babaei-Ghazvini, A.; Acharya, B. Biobased Polymer Composites: A Review. J. Compos. Sci. 2022, 6, 255. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Ahmetli, G.; Kocaman, S.; Ozaytekin, I.; Bozkurt, P. Epoxy composites based on inexpensive char filler obtained from plastic waste and natural resources. Polym. Compos. 2013, 34, 500–509. [Google Scholar] [CrossRef]

- Mishra, A.; Bhattacharyya, D. Sustainable Enhancement of the Mechanical and Flammability Performances of Keratinous Feather-PP Composites: The Effects of Processing Temperature and Solvent Choice. J. Compos. Sci. 2023, 7, 305. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Hassan, Z.F.B.A.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Cheng, J.; Niu, S.; Zhao, Y.; Liu, Y.; Kang, M.; Guan, Y.; Zhang, F. The flame retardant and thermal conductivity properties of high thermal conductivity expandable graphite microcapsule filled natural rubber composites. Constr. Build. Mater. 2022, 318, 125998. [Google Scholar] [CrossRef]

- Alsabbagh, N.; Steit, M.; Nessim, A. Evaluating the use of aluminum composite panel on thermal performance in office buildings in hot climate. Eng. Res. J. 2025, 54, 35–47. [Google Scholar]

- Gbran, H.; Alzamil, W. Ai-Enhanced Thermal Performance and Energy Efficiency in Tropical Buildings: A Case Study of Advanced Glass and Aluminum Composite Panels; Open Ukrainian Scientific Content Initiative: Online, 2025. [Google Scholar]

- Soja, E.; Wade, C.; Frank, K. 4—Flammability tests for building facades. In Flammability Testing of Materials Used in Construction, Transport and Mining, 2nd ed.; Apte, V., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 89–126. [Google Scholar]

- Chow, W.K.; Han, S.S. Superposition of heat release rate curves for combustibles with bench-scale tests. Polym. Test. 2006, 25, 75–82. [Google Scholar] [CrossRef]

- Agarwal, G.; Wang, Y.; Dorofeev, S. Fire performance evaluation of cladding wall assemblies using the 16-ft high parallel panel test method of ANSI/FM 4880. Fire Mater. 2021, 45, 609–623. [Google Scholar] [CrossRef]

- Ahcene, A.; Bey, K.; Mzad, H. Mechanical Fatigue Test of Aluminum Composite Panel (ACP) with Aramid Nida-Core Under Cyclic Bending. Stroj. Časopis-J. Mech. Eng. 2020, 70, 1–10. [Google Scholar] [CrossRef]

- Lopes, R.T.; da Silva, R.J.; Santos Freire, R.T.; dos Santos, J.C.; Christoforo, A.L.; Panzera, T.H.; Scarpa, F. Statistical evaluation of three-point bending properties of sustainable aluminium sandwich panels with arched-core geometry. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 14644207231219647. [Google Scholar] [CrossRef]

- Tamilarasan, U.; Karunamoorthy, L.; Palanikumar, K. Mechanical properties evaluation of the carbon fibre reinforced aluminium sandwich composites. Mater. Res. 2015, 18, 1029–1037. [Google Scholar] [CrossRef]

- Mahdi, A.Z.; Abdullah, O.S. Experimental and numerical study of fatigue life for Aluminum Composite Panel (ACP) under the ranges of wind speed effect. Aust. J. Mech. Eng. 2025, 23, 357–365. [Google Scholar] [CrossRef]

- Kurşun, A.; Şenel, M.; Enginsoy, H.M.; Bayraktar, E. Effect of impactor shapes on the low velocity impact damage of sandwich composite plate: Experimental study and modelling. Compos. Part B Eng. 2016, 86, 143–151. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Adhesion properties of bonded composite-to-aluminium joints using peel tests. J. Adhes. 2014, 90, 511–525. [Google Scholar] [CrossRef]

- Şimşir, E. Study of Impact Behavior of Glass-Fiber-Reinforced Aluminum Composite Sandwich Panels at Constant Energy Levels. Coatings 2025, 15, 299. [Google Scholar] [CrossRef]

- Starešinič, G.; Zoubek, B.; Gams, M.; Isaković, T.; Fischinger, M. Modelling in-plane dynamic response of a fastening system for horizontal concrete facade panels in RC precast buildings. Eng. Struct. 2020, 224, 111210. [Google Scholar] [CrossRef]

- Hussain, M.; Abbas, N.; Zahra, N.; Sajjad, U.; Awan, M.B. Investigating the performance of GFRP/wood-based honeycomb sandwich panels for sustainable prefab building construction. SN Appl. Sci. 2019, 1, 875. [Google Scholar] [CrossRef]

- HeWenjun CaoJianwei, Aluminum-Plastic Composite Panel with Fireproof Structure. In Google Patents; Shandong Jixiangge Building Material Technology Co., Ltd.: Shandong, China, 2025.

- LeVan, K.E. Building Facade System. U.S. Patent US 9,752,319, 5 September 2017. [Google Scholar]

- Wucongke, A2-Grade Halogen-Free Flame-Retardant Fireproof Aluminum-Plastic Composite Board and Preparation Method; Liaoning Weiketrui Flame Retardant Material Technology Co Ltd.: Dandong, China, 2024.

- Correa, E.; Koenig, B. Non-Combustible Composite Panel and Manufacturing Method. U.S. Patent US9346243B2, 24 May 2016. [Google Scholar]

- Olson, P.; Yannetti, W.; Moses, J.; Bowie, M. Composite Panel Having Noncombustible Polymer Matrix Core. U.S. Patent US 11,312,109, 26 April 2022. [Google Scholar]

- Mechsner, J.A.H.S.K. Aluminum Composite Panel. German Patent DE69915506T2, 3 March 2005. [Google Scholar]

- Au, B. Fire-Resistant Panel and Method of Manufacture. U.S. Patent Application US20060070321A1, 6 April 2006. [Google Scholar]

- Severus-Laubenfeld, H. Composite Panels which are not Easily Combustible. U.S. Patent US4221835A, 9 September 1980. [Google Scholar]

- Bauer, R.; Lynam, P.H. Composite Plate for the Facing of Building Surfaces. U.S. Patent US4973506A, 27 November 1990. [Google Scholar]

- Gleason, J.R.; Minnick, J.E.; Dempsey, S.E.; Chadderdon, P.J. Fire-Resistant Core for a Combustible Fire-Rated Panel. U.S. Patent US 6,271,156, 7 August 2001. [Google Scholar]

- Chen, J.; Liu, J.; Bai, X.; Yang, Y. Inorganic Non-Combustible Safe Aluminum Composite Panel. Chinese Patent CN103481566B, 1 July 2015. [Google Scholar]

- Li, H. Aluminum Composite Panel. Chinese Patent CN203126044U, 14 August 2013. [Google Scholar]

- Bregenzer, R.E. Composite panel with two outer layers and core. Japanese Patent JPH071678A, 8 April 2002. [Google Scholar]

- Oswald, D.; Moore, T.; Lockrey, S. Combustible costs! Financial implications of flammable cladding for homeowners. Int. J. Hous. Policy 2022, 22, 225–250. [Google Scholar] [CrossRef]

- McNamee, M.; Marlair, G.; Truchot, B.; Meacham, B.J. Research Roadmap: Environmental Impact of Fires in the Built Environment; Fire Protection Research Foundation: Norfolk County, MA, USA, 2020. [Google Scholar]

- Hossain, M.D.; Hassan, M.K.; Akl, M.; Pathirana, S.; Rahnamayiezekavat, P.; Douglas, G.; Bhat, T.; Saha, S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire 2022, 5, 81. [Google Scholar] [CrossRef]

- Nakrani, D.; Srivastava, G. Full-Scale Fire Performance of Combustible and Non-combustible Curtain Wall Systems with Firestops. Fire Technol. 2023, 59, 153–190. [Google Scholar] [CrossRef]

- Zaimi, M.Z.M.; Jusoh, W.N.W.; Tharima, A.F.; Asbar, A.R.; Aldahar, Z.A.; Abdullah, S.A.S. Simulation of Thermal Analysis of Aluminium Composite Panel’s Core Material Using Fire Dynamic Simulator (FDS). Mater. Sci. Forum. 2023, 1101, 17–22. [Google Scholar] [CrossRef]

- Hasnat, M.R.; Hassan, M.K.; Hossain, M.D.; Saha, S. Thermal characterization of composite cladding core materials by thermogravimetric analysis. In Proceedings of the International Conference on Fire Safety Engineering Research and Practice, Sydney, Australia, 24–27 November 2024; pp. 411–416. [Google Scholar]

- Jusoh, W.N.W.; Zaimi, M.Z.M.; Taib, M.N.M.; Asbar, A.R.; Tharima, A.F. Characterization of the Thermal Properties of Polyethylene and Fire Retardant Aluminum Composite External Cladding Panel. In Advanced Engineering and Sustainable Solutions; Singh, D.K., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 261–270. [Google Scholar]

- Wonorahardjo, S.; Sutjahja, I.M.; Mardiyati, Y.; Andoni, H.; Achsani, R.A.; Steven, S.; Thomas, D.; Tunçbilek, E.; Arıcı, M.; Rahmah, N. Effect of different building façade systems on thermal comfort and urban heat island phenomenon: An experimental analysis. Build. Environ. 2022, 217, 109063. [Google Scholar] [CrossRef]

- Gagliano, A.; Aneli, S. Analysis of the energy performance of an Opaque Ventilated Façade under winter and summer weather conditions. Sol. Energy 2020, 205, 531–544. [Google Scholar] [CrossRef]

- Selvakumar, M.; James, D.J.D.; Thangadurai, K.R. Manufacturing of Aluminum Composite Panels Based on Aluminum with Jute/Sisal/Kenaf Flax Natural Fibre Reinforced Epoxy. J. Environ. Prot. Ecol. 2023, 24, 1615–1626. [Google Scholar]

- Sravani, K.; Parameshwaran, R.; Ram, V.V. Experimental Study on PCM-Based External Wall Cladding for Energy Efficient Buildings. In Recent Advances in Mechanical Engineering; Springer: Singapore, 2020. [Google Scholar]

- Hossain, M.D.; Saha, S.; Hassan, M.K.; Yuen, A.C.Y.; Wang, C. Establishing pyrolysis kinetics for fire modelling and thermal analysis of polymeric cladding materials used in high-rise buildings. Case Stud. Constr. Mater. 2023, 19, e02535. [Google Scholar] [CrossRef]

- Nguyen, K.; Kim, N.K.; Bhattacharyya, D.; Mouritz, A. Assessing the combustibility of claddings: A comparative study of the modified cone calorimeter method and cylindrical furnace test. Fire Mater. 2022, 46, 450–462. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, R.; Wu, T.; Huang, C.; Chen, Z.; Jiang, J. Experimental and simulation study on the combustion fire spreading characteristics of aluminum composite panels with different thicknesses. Fire Mater. 2023, 47, 651–664. [Google Scholar] [CrossRef]

- Hassan, M.K.; Hossain, M.D.; Gilvonio, M.; Rahnamayiezekavat, P.; Douglas, G.; Pathirana, S.; Saha, S. Numerical Investigations on the Influencing Factors of Rapid Fire Spread of Flammable Cladding in a High-Rise Building. Fire 2022, 5, 149. [Google Scholar] [CrossRef]

- Nakrani, D.; Srivastava, G. Quantification of Enhanced Fire Severity in Modern Buildings. In Advances in Energy and Combustion: Safety and Sustainability; Gupta, A.K., De, A., Aggarwal, S.K., Kushari, A., Runchal, A.K., Eds.; Springer: Singapore, 2022; pp. 413–427. [Google Scholar]

- Paktiawal, A.; Alam, M. An experimental study on effect of aluminum composite panel waste on performance of cement concrete. Ain Shams Eng. J. 2021, 12, 83–98. [Google Scholar] [CrossRef]

- Bonner, M.; Rein, G. Flammability and multi-objective performance of building façades: Towards optimum design. Int. J. High-Rise Build. 2018, 7, 363–374. [Google Scholar]

- Nishio, Y.; Yoshioka, H.; Noguchi, T.; Kanematsu, M.; Ando, T.; Hase, Y.; Hayakawa, T. Fire spread caused by combustible facades in Japan. Fire Technol. 2016, 52, 1081–1106. [Google Scholar] [CrossRef]

- Zhu, Z.; Jin, X.; Li, Q.; Meng, Q. Experimental Study on the Thermal Performance of Ventilation Wall with Cladding Panels in Hot and Humid Area. Procedia Eng. 2015, 121, 410–414. [Google Scholar] [CrossRef]

- Al-Absi, Z.A.; Hafizal, M.I.M.; Ismail, M. Innovative PCM-incorporated foamed concrete panels for walls’ exterior cladding: An experimental assessment in real-weather conditions. Energy Build. 2023, 288, 113003. [Google Scholar] [CrossRef]

- Ornam, K.; Wonorahardjo, S.; Triyadi, S. Several façade types for mitigating urban heat island intensity. Build. Environ. 2024, 248, 111031. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Doshi, A.J. Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings. Buildings 2023, 13, 720. [Google Scholar] [CrossRef]

- Alonso, C.; Oteiza, I.; García-Navarro, J.; Martín-Consuegra, F. Energy consumption to cool and heat experimental modules for the energy refurbishment of façades. Three case studies in Madrid. Energy Build. 2016, 126, 252–262. [Google Scholar] [CrossRef]

- Guo, A.; Liu, Z. A New Method for Energy Efficiency Design of Building Facade and Its Thermodynamic Evaluation. Int. J. Heat Technol. 2020, 38. [Google Scholar] [CrossRef]

- Ciampi, M.; Leccese, F.; Tuoni, G. Ventilated facades energy performance in summer cooling of buildings. Sol. Energy 2003, 75, 491–502. [Google Scholar] [CrossRef]

- Gandhi, P.; Jagdish, V.; Karthikeyan, G.; Chakravarthy, A.; Nakrani, D.; Ghoroi, C.; Srivastava, G. Performance of glass-ACP façade system in a full-scale real fire test in a G+2 structure. Procedia Eng. 2017, 210, 512–519. [Google Scholar] [CrossRef]

| Class | UK & BRE [42] | ICA (Australia) [39] | EN 13501-1 [21] | ASTM E 136 (USA) [42] | AS 1530.1/ISO 1182/BS 476.4 [42] |

|---|---|---|---|---|---|

| Category 1 | HOC ≤ 3 MJ kg−1 | ||||

| Category 2 | HOC > 3 MJ kg−1 and ≤35 MJ kg−1 | ||||

| Category 3 | HOC > 35 MJ kg−1 | ||||

| A | PE 30–100% | ||||

| B | PE 8–29% | FIGRA0.2MJ ≤ 250 W/s and THR600s ≤ 7.5 MJ | |||

| C | PE 1–7% | FIGRA0.4MJ ≤ 120 W/s and THR600s ≤ 15 MJ | |||

| D | PE 0% | FIGRA0.2MJ ≤ 750 W/s | |||

| A1 | FIGRA0.2MJ ≤ 20 W/s and THR600s ≤ 4 MJ | ||||

| A2 | FIGRA0.2MJ ≤ 120 W/s and THR600s ≤ 7.5 MJ | ||||

| E | Fs ≤ 150 mm with 60 s | ||||

| F | No performance (fail) | ||||

| Combustible | Ti ≥ 30 °C and/or flame for any duration | If flaming for 5 s or longer and/or Tf > 50 °C and/or Ts > 50 °C | |||

| Non-combustible | (1) No flaming for first 30 s and increase of Ti ≤ 30 °C for material having a total mass loss less than 50% (2) For a material total mass loss greater than 50%, no flaming at any time and no increase in Ti | If flaming < 5 s and/or Tf ≤ 50 °C and/or Ts ≤ 50 °C |

| Class | Definition |

|---|---|

| A1 | Non-combustible |

| A2 | Limited combustibility |

| B | FIGRA ≤ 120 W/s; LFS < Edge of specimen and THR600s ≤ 7.5 MJ |

| C | FIGRA ≤ 250 W/s; LFS < Edge of specimen and THR600s ≤ 15 MJ |

| Panel Type | Fire Rating | Use | Drawbacks |

|---|---|---|---|

| Combustible Panels | Flammable | Restricted use to signage, low-rise factories, warehouses | (1) High risk of fire accidents like Grenfell (2017) and Lacrosse (2014) [6,45] (2) Banned in different countries for high-rise buildings [46] |

| FR Panels | Difficult to ignite | Restricted use in high-rise buildings with additional requirements | (1) Contains polymer which does not meet non-combustibility criteria [47] |

| A2 Panels | Limited combustibility | Not recommended for high-rise buildings | (1) Thermal insulation needs to be improved [48] (2) Melting and dripping issues [48] |

| A1 or NC panel | Non-combustible | Can be used in high-rise buildings | (1) Energy consumption still higher (2) High cost due to processing (3) AdheUnnecessary and can be removed.sion quality between honeycomb and plain sheet often deteriorates [23] (4) Precast concrete panels much heavier [49] |

| Insulation Materials | Thermal Conductivity (W/mK) | Density (kg/m3) | Thermal Degradation Temperature (°C) | Peak Heat Release Rate (kW/m2) | Reaction-to-Fire Class (Range) | Ref. |

|---|---|---|---|---|---|---|

| EPS | 0.029–0.041 | 18–50 | 220 | 226 (35 kW/m2) 325 (50 kW/m2) | B1–B2 | [54] |

| XPS | 0.024 | 30–33 | - | 475 (50 kW/m2) | B1–B2 | [54] |

| Polyisocyanurate (PIR) | 0.023 | 31 | 100 | 64.59 (35 kW/m2) 82.12 (50 kW/m2) | B1–B2 | [56] |

| Stone wool | 0.035 | 100–110 | 550 | <50 (50 kW/m2) | A1–A2 | [54] |

| Mineral wool | 0.035 | 120–140 | - | 200, 300 (100 kW/m2 for ACP A2 and FR, respectively) | A1–A2 | [37] |

| Phenolic foam | 0.018–0.025 | 35 | 50 | 244, 280 (100 kW/m2 for ACP A2 and FR, respectively) | B1 | [37,56] |

| Glass wool | 0.030–0.045 | 13–100 | 260 | <10 (50 kW/m2) | A1–A2 | [54] |

| Polyurethane foam | 0.020–0.027 | 30–80 | 150 | 165 (50 kW/m2) | B1–B2 | [37,54] |

| Flame-Retardant Chemical Nature | Example of Flame-Retardants | Working Mechanism | Ref. |

|---|---|---|---|

| Metal oxides and hydroxide | Aluminium hydroxide, alumina trihydrate, magnesium hydroxide, calcium carbonate | Heat sink | [65] |

| Halogen based | 1 TCPA, 2 TBPA, polybrominated diphenyl ethers, polybrominated diphenyl | Gas phase | [66] |

| Phosphorus based | 3 THPC | Condensed phase | [67] |

| Boron based | Boric acid, zinc borate, borax, boron phosphate | By forming insulating layer | [68] |

| Synergistic | Halogen/antimony trioxide, P/halogen | Flame-retardancy of the primary compound enhanced by the presence of another | [69] |

| Brand | Thickness (mm) | Weight (kg/m2) | Thermal Conductivity (W/mK) | Filler Materials | Ref. |

|---|---|---|---|---|---|

| PROMINIUM | 3 | 8.2 | 237 (Al) | - | [116] |

| PROCORE-A1 | 4 | 4.5 | 237 (Al) | - | [117] |

| PROBOND-FACADE-FR | 4 | 7.55 | 0.35 | 75% MH + carbon additives | [118] |

| PROCORE lite A1 | 3 | 3.87 | 237 (Al) | - | [119] |

| PROBOND ultra FR | 3 | 5 | 0.375 | 75% MH | [120] |

| ALUCOBOND® PLUS | 4 | 7.6 | 0.44 | Mineral-filled polymer | [121] |

| LARCORE | 6 | 4.19 | 0.89 | - | [122] |

| LARCORE A2 | 6 | 4.19 | 0.3 | - | [123] |

| EVA BOND | 4 | 5.5 | 0.22 | LDPE | [124] |

| ALPOLIC NC | 4 | 8.2 | 0.4 | NC mineral filled | [125] |

| ALPOLIC A2 | 4 | 8.2 | 0.45 | Mineral filled + PE (10%) | [126] |

| ALPOLIC FR | 4 | 7.6 | 0.45 | NC mineral filled | [127] |

| ALPOLIC FR LTE | 3 | 5.5 | 0.3 | NC mineral filled | [128] |

| ALPOLIC FR TCM | 4 | 9.3 | 0.4 | NC mineral | [129] |

| CEMINTEL BARESTONE | 9 | 17.8 | 0.411 | NC fibre cement | [130] |

| SWISSPEARL | 8 | 15.7 | 0.56 | NC fibre cement | [131] |

| EQUITONE | 8 | 15.4 | - | Cement 70% + fibre 10% | [132] |

| ULTRABOND FR | 4 | - | - | 70% mineral-filled core | [133] |

| Material Category | Fibre Types | Density (g/cm3) | Length (mm) | Diameter (mm) | Aspect Ratio | Tensile Strength (MPa) | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Metallic | Steel | Micro steel (MSF) | 7.85 | 6–22 | 0.16–0.20 | 30–110 | 2200–2500 | [155] |

| Straight steel (SSF) | 7.85 | 6–50 | 0.17–1 | 35–50 | 1170–2100 | [156] | ||

| Chopped steel wool (CSW) | 7.85 | 2–6 | 0.02–0.06 | 100 | 200–400 | |||

| Crimped steel (CSF) | 7.85 | 30 | 0.5 | 60 | 1200 | [157] | ||

| Polymeric | Synthetic | Polypropylene (PPF) | 0.9–0.91 | 6–51 | 0.02 | 300 | 310–910 | [155,156,158] |

| Polyvinyl alcohol (PVA) | 1.30 | 8–12 | 0.015–0.04 | 200–800 | 1560–1600 | [159] | ||

| Polyethylene (PEF) | 0.97 | 12–18 | 0.012–0.016 | 750–1500 | 2700–35,600 | [160] | ||

| Carbon fibre (CF) | 1.3-1.8 | 3–15 | 0.003–0.072 | 416–1666 | 2930–4900 | [161] | ||

| Natural | Sisal fibre (SF) | 1.45 | 35–40 | 0.137–0.179 | 73–223 | 371.61 | [162] | |

| Jute fibre (JF) | 1.3–1.45 | 10 | 0.057–0.093 | 75.3–189 | [162,163] | |||

| Coir fibre | 1.2–1.35 | 25–50 | 0.177–0.31 | 197–254 | 120–200 | [164] | ||

| Hemp | 1.4–1.5 | 0.5–8 | 270–900 | [165] | ||||

| Flax | 1.50 | 0.002 | 660 | [166] | ||||

| Cotton | 1.45 | 10 | 0.2 | 50 | 400 | [167] | ||

| Inorganic | Glass fibre (GF) | 2.4–2.7 | 6–20 | 0.18 | 100–600 | 1620–2500 | [168] | |

| Basalt fibre (BF) | 2.65–3.0 | 5–12 | 0.03–0.07 | 600–1200 | 4000–4700 | [155,169] | ||

| Brand | Weight (kg/m2) | Thermal Conductivity (W/mK) | Thermal Resistance (m2·K/W) | Ref. |

|---|---|---|---|---|

| PROMINIUM | 8.2 | 237 (Al) | 0.0000127 | [116] |

| PROCORE-A1 | 4.5 | 237 (Al) | 0.0000127 | [117] |

| PROBOND-FACADE-FR | 7.55 | 0.35 | 0.0103 | [118] |

| PROCORE lite A1 | 3.87 | 237 (Al) | 0.0000127 | [119] |

| PROBOND ultra FR | 5 | 0.375 | 0.008 | [120] |

| ALUCOBOND® PLUS | 7.6 | 0.44 | 0.007–0.009 | [121] |

| LARCORE | 4.19 | 0.89 | 0.012–0.020 | [122] |

| LARCORE A2 | 4.19 | 0.3 | 0.012–0.020 | [123] |

| EVA BOND | 5.5 | 0.22 | - | [124] |

| ALPOLIC NC | 8.2 | 0.4 | 0.010 | [125] |

| ALPOLIC A2 | 8.2 | 0.45 | 0.009 | [126] |

| ALPOLIC FR | 7.6 | 0.45 | 0.009 | [127] |

| ALPOLIC FR LTE | 5.5 | 0.3 | 0.013 | [128] |

| ALPOLIC FR TCM | 9.3 | 0.4 | 0.010 | [129] |

| CEMINTEL BARESTONE | 17.8 | 0.411 | 0.024 | [130] |

| SWISSPEARL | 15.7 | 0.56 | 0.021 | [131] |

| Core Type | Core Thickness | Polymer (%) | Main Filler | Time to Ignition | Avg. pHRRPUA | Total Energy Released | Ref. |

|---|---|---|---|---|---|---|---|

| ACP-1 | 3 | PE (100) | - | 202 | 950 | 113 | [39] |

| ACP-2 | 3 | PE (30) | Al(OH)3/Calcite | - | 46 | 8 | [39] |

| ACP-3 | 3 | PE (7) | Al(OH)3/Calcite | - | 5 | - | [39] |

| ACP-1 | 2.81 | EVA (7) | CaCO3 | 135 | 98.96 | 10.85 | [46] |

| ACP-2 | 2.9 | EVA (28) | Al(OH)3 | 75 | 145.3 | 56.9 | [46] |

| ACP-3 | 2.86 | PE (99) | CaCO3 | 31 | 724.65 | 93.3 | [46] |

| ACP-4 | 3.12 | PE-EVA (33) | MgOH | 64 | 189.66 | 87.58 | [46] |

| ACP-5 | 3.18 | PE (78) | CaCO3 | 26 | 543.06 | 104.65 | [46] |

| ACP-6 | 3.11 | PE-EVA (24) | MgOH | 102 | 185.13 | 74.94 | [46] |

| ACP-7 | 3.38 | PE (27) | Al(OH)3 | 66 | 254.57 | 73.41 | [46] |

| ACP-8 | 5.3 | PE-EVA (30) | MgOH | 120 | 159.2 | 129.61 | [46] |

| Brand | Flexural Strength (MPa) | Impact Resistance (Kg/cm2) | Tensile Strength (MPa) | Ref. |

|---|---|---|---|---|

| PROMINIUM | - | 50 | 155–160 | [116] |

| PROCORE-A1 | - | 50 | 52.5 | [117] |

| PROBOND-FACADE-FR | 60 | - | 52.5 | [118] |

| PROCORE lite A1 | - | 50 | 160 (Al) | [119] |

| PROBOND ultra FR | - | 50 | 50 | [120] |

| ALUCOBOND® PLUS | - | - | 130 | [121] |

| LARCORE | - | - | 125 | [122] |

| LARCORE A2 | - | - | 125 | [123] |

| ALPOLIC NC | 45.6 | - | 48 | [125] |

| ALPOLIC A2 | 38.5 | - | 43 | [126] |

| ALPOLIC FR | 39.8 | - | 49 | [127] |

| CEMINTEL BARESTONE | 18 | - | - | [130] |

| SWISSPEARL | 26 | - | 5 | [131] |

| Patents | Country of Origin | Manufacturer | Panel Type | Ref. |

|---|---|---|---|---|

| CN119308484B | China | Shandong Jixiangge Building Material Technology Co., Ltd. | Composite board with fireproof structure | [199] |

| US10233638B2 | USA | Talon Wall Holdings LLC. | ACP panel with structural framing | [200] |

| CN119036960B | China | Liaoning Weiketrui Flame Retardant Material Technology Co., Ltd. | Plastic composite board A2 grade | [201] |

| US9346243B2 | USA | Alcoa Architectural Products SAS | Non-combustible composite panels | [202] |

| US11312109B2 | USA | Mitsubishi Chemical America Inc. | Non-combustible polymer matrix | [203] |

| DE69915506T2 | Germany | Novelis Koblenz GmbH | Corrugated composite panel | [204] |

| US20060070321A1 | USA | R E P Tech Ltd. | FR Panel | [205] |

| US4221835A | USA | Alcan Holdings Switzerland AG | Flame-resistant composite panel | [206] |

| US4973506A | USA | HA Whitten & Co. | Honeycomb | [207] |

| US6271156B1 | USA | Lydall Inc. | FR panel | [208] |

| CN103481566B | China | Shandong Propitious Decoration Building Materials Co., Ltd. | Non-combustible ACP panel | [209] |

| CN203126044U | China | Zhangjiagang Muzi Machinery Technology Co., Ltd. | FR panel | [210] |

| JPH071678A | Japan | 3A Composites International AG | Non-combustible panel | [211] |