Advancements in Free-Standing Ferroelectric Films: Paving the Way for Transparent Flexible Electronics

Abstract

1. Introduction

2. Fabrication Techniques

2.1. Chemical and Physical Methods

2.2. Advanced Techniques

2.2.1. Laser Lift-Off (LLO)

2.2.2. Wet Etching

2.2.3. Van der Waals Epitaxy

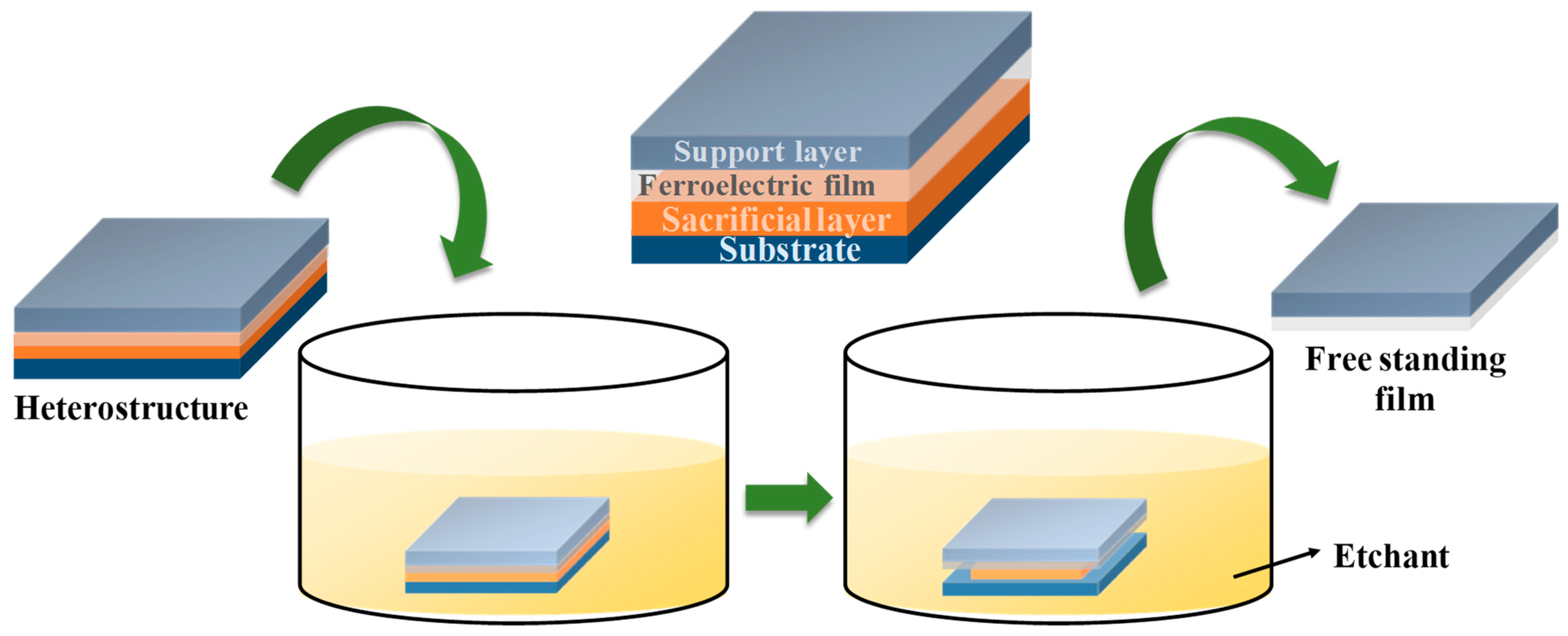

2.2.4. Sacrificial Layers

2.2.5. Phase-Field Simulations

2.3. Challenges in Fabrication

2.3.1. Intrinsic Residual Stresses

2.3.2. Thermal Stresses

2.3.3. Defect Management

3. Properties of Free-Standing Ferroelectric Films

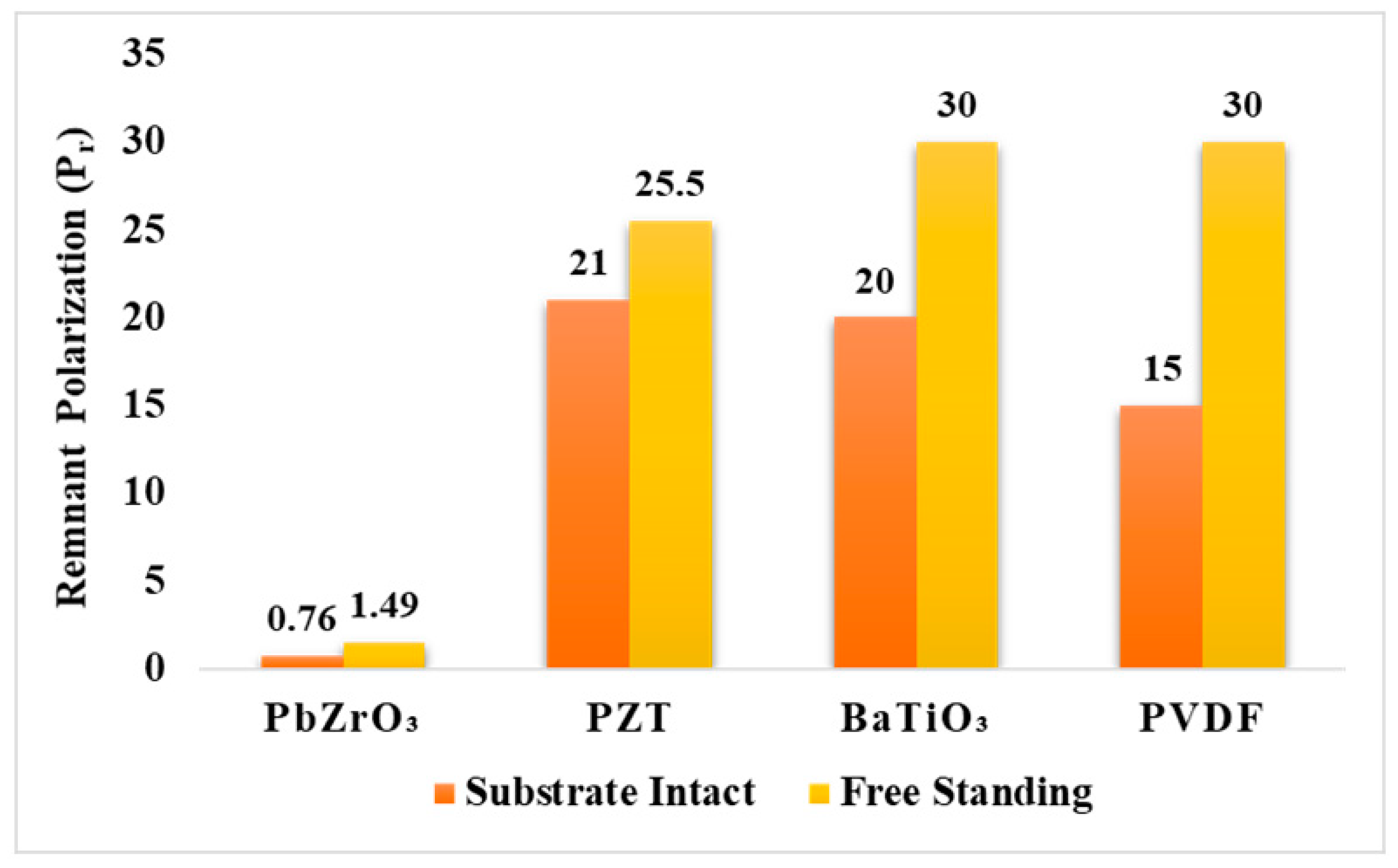

3.1. Ferroelectric Properties

3.1.1. Polarization Stability

| Material | Curie Temperature (°C) | Remnant Polarization (µC/cm2) | Dielectric Constant (εr) | Piezoelectric Coefficient (pC/N) | Flexibility/Compatibility | Applications |

|---|---|---|---|---|---|---|

| Barium Titanate (BTO) | ~120 | ~20–25 | ~1000 | ~190 | High permittivity; brittle, but flexible as thin films | Capacitors and nanogenerators [65,66,67] |

| Lead Zirconate Titanate (PZT) | ~300 | ~30–50 | ~500–1000 | ~250–600 | Brittle; improved flexibility when integrated on polymer substrates | Memory devices, nanogenerators, and sensors [51,68] |

| HfO2-based oxides | ~450–500 | ~10–30 | ~20–30 | ~10–15 | CMOS-compatible; suitable for ultrathin layers | Non-volatile memory and energy storage [69,70] |

| Poly(vinylidene fluoride- trifluoroethylene) | ~100 | ~6–12 | ~10–12 | ~20–30 | Excellent flexibility | Flexible sensors and generators [71,72,73] |

| ZnO-based materials | - | Low (<1) | ~9 | ~10 | Highly flexible | Sensors and actuators [69,74,75] |

3.1.2. Thickness Dependence

3.1.3. Domain Structure and Switching Behavior

3.1.4. Electromechanical Coupling

3.2. Mechanical Properties

3.2.1. Super-Elasticity

3.2.2. Tensile Strength and Ductility

3.2.3. Strain Engineering

3.3. Thermal and Electrical Stability

3.3.1. Thermal Stability

3.3.2. Electrical Stability

4. Applications in Flexible Electronics

4.1. Energy Harvesting Devices

4.1.1. Mechanisms of Energy Harvesting

4.1.2. Performance Characteristics

4.1.3. Recent Advancements

4.1.4. Flexible Electronics in Energy Harvesting Devices

4.2. Sensors and Actuators

4.2.1. Mechanisms of Sensing and Actuation

4.2.2. Integration with Flexible Substrates

4.2.3. Recent Advances in Design and Fabrication

4.2.4. Flexible Electronics in Sensors and Actuators

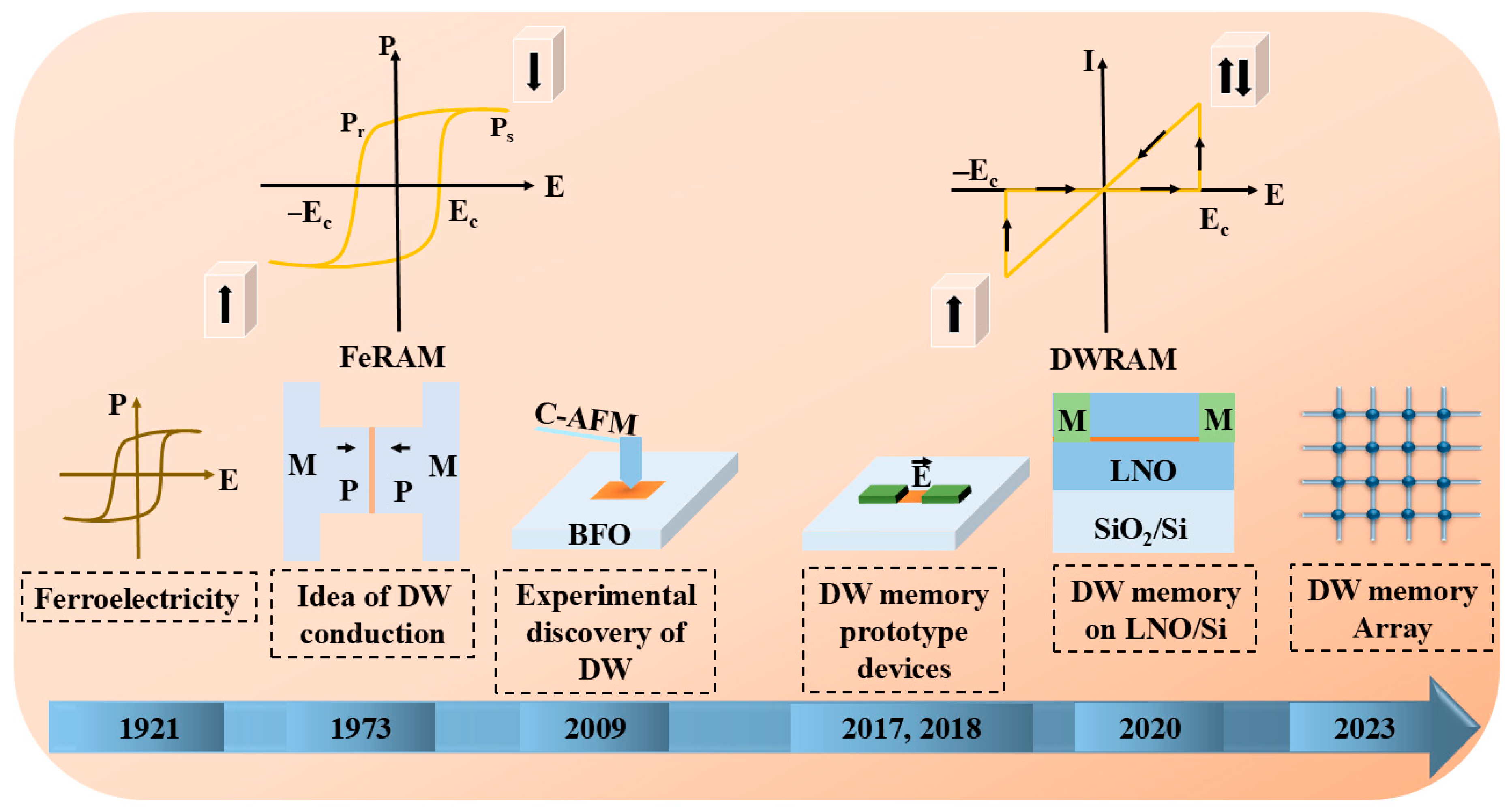

4.3. Next-Generation Devices

4.3.1. Flexible Memory Devices

4.3.2. Energy Harvesting Systems

4.3.3. Advanced Sensors and Actuators

4.3.4. Integration with Other Functional Materials

4.3.5. Environmental Sensors and Biosensors

4.4. Transparent Electronics

- Transparent Displays: Free-standing ferroelectric films on optically clear substrates, such as mica or PET, can be used in displays for augmented reality (AR) or heads-up displays (HUDs). These devices benefit from the films’ high polarization stability and mechanical resilience.

- Smart Windows: the piezoelectric and ferroelectric properties of these films enable the development of smart windows that adjust transparency based on external stimuli, such as light or temperature.

- Wearable Devices: transparent and flexible sensors embedded in clothing or accessories can monitor physiological parameters while remaining visually discreet.

- Energy Harvesting: Transparent piezoelectric films can be integrated into solar panels or window surfaces, allowing for energy harvesting without obstructing visibility.

5. Recent Advances and Innovations

5.1. Performance Optimization Techniques

5.2. Role of Polymer Additives in Enhancing Electronic Properties

5.3. Emerging Material Systems

5.4. Innovative Fabrication Techniques

5.5. Applications in Multifunctional Devices

6. Future Perspectives

6.1. Enhancing Performance

6.2. Expanding Applications

6.3. Addressing Commercialization Challenges

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ji, J.; Park, S.; Do, H.; Kum, H.S. A Review on Recent Advances in Fabricating Freestanding Single-Crystalline Complex-Oxide Membranes and Its Applications. Phys. Scr. 2023, 98, 052002. [Google Scholar] [CrossRef]

- Lee, D. Flexoelectricity in Thin Films and Membranes of Complex Oxides. APL Mater. 2020, 8, 090901. [Google Scholar] [CrossRef]

- Dai, L.; Yao, D.; An, F.; Cheng, M.; Zhong, X.; Tang, Z.H.; Zhong, G. Freestanding Ferroelectric Thin Film with Robust Ferroelectricity Via Inserted Dielectric Layers. Mater. Today Commun. 2024, 42, 111412. [Google Scholar] [CrossRef]

- Jia, X.; Guo, R.; Tay, B.K.; Yan, X. Flexible Ferroelectric Devices: Status and Applications. Adv. Funct. Mater. 2022, 32, 2205933. [Google Scholar] [CrossRef]

- Guo, C.; Huang, H. Design of Super-Elastic Freestanding Ferroelectric Thin Films Guided by Phase-Field Simulations. Microstructures 2022, 2, 21. [Google Scholar] [CrossRef]

- Shen, Y.; Ooe, K.; Yuan, X.; Yamada, T.; Kobayashi, S.; Haruta, M.; Kan, D.; Shimakawa, Y. Ferroelectric Freestanding Hafnia Membranes with Metastable Rhombohedral Structure down to 1-Nm-Thick. Nat. Commun. 2024, 15, 4789. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D Materials and van Der Waals Heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Wang, X.; Jiang, H.; Xu, M.; Huang, W.; Liu, Z. Recent Progress of Flexible Electronics by 2D Transition Metal Dichalcogenides. Nano Res. 2022, 15, 2413–2432. [Google Scholar] [CrossRef]

- Gao, W.; Zhu, Y.; Wang, Y.; Yuan, G.; Liu, J.-M. A Review of Flexible Perovskite Oxide Ferroelectric Films and Their Application. J. Mater. 2020, 6, 1–16. [Google Scholar] [CrossRef]

- Zhang, T.; Yao, G.; Pan, T.; Lu, Q.; Lin, Y. Flexible Inorganic Oxide Thin-Film Electronics Enabled by Advanced Strategies. J. Semicond. 2020, 41, 041602. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Lipkin, M.S.; Shchegolkov, A.V.; Korbova, E.V.; Lipkina, T.V.; Lipkin, V.M. On the Mechanism of Formation of Electrochromic WO3 Films on the Surface of Sn, Ti, ITO Electrodes in the Process of Cathodic Electrodeposition. Inorg. Mater. Appl. Res. 2022, 13, 1605–1614. [Google Scholar] [CrossRef]

- Tripathy, A.; Saravanakumar, B.; Mohanty, S.; Nayak, S.K.; Ramadoss, A. Comprehensive Review on Flexoelectric Energy Harvesting Technology: Mechanisms, Device Configurations, and Potential Applications. ACS Appl. Electron. Mater. 2021, 3, 2898–2924. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, B.; Dong, G.; Wang, Y.; Yang, G.; Zhang, J.; Peng, B.; Zhao, Y.; Liu, M. Enhanced Piezoelectric Energy Harvester by Employing Freestanding Single-Crystal BaTiO3 Films in PVDF-TrFE Based Composites. Adv. Funct. Mater. 2024, 34, 2316519. [Google Scholar] [CrossRef]

- Khatua, D.K.; Kim, S.-J. Perspective on the Development of High Performance Flexible Piezoelectric Energy Harvesters. J. Mater. Chem. C 2022, 10, 2905–2924. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Yang, M.; Miao, J.; Lin, K.; Li, Q.; Chen, X.; Deng, J.; Xing, X. Ferroelectric Thin Films: Performance Modulation and Application. Mater. Adv. 2022, 3, 5735–5752. [Google Scholar] [CrossRef]

- Dai, L.; An, F.; Zou, J.; Zhong, X.; Zhong, G. Freestanding Inorganic Oxide Films for Flexible Electronics. J. Appl. Phys. 2022, 132, 070904. [Google Scholar] [CrossRef]

- Badillo, M.; Taleb, S.; Mokabber, T.; Rieck, J.; Castanedo, R.; Torres, G.; Noheda, B.; Acuautla, M. Low-Toxicity Chemical Solution Deposition of Ferroelectric Ca:HfO2. J. Mater. Chem. C 2023, 11, 1119–1133. [Google Scholar] [CrossRef]

- Sun, Y.; Ning, J.; Xi, J.; Duan, J.; Zhou, D. Enhancement of Ferroelectricity in Chemical-Solution-Deposited ZrO2 Thin Films through Fine Phase Transition Control. Ceram. Int. 2024, 50, 27371–27379. [Google Scholar] [CrossRef]

- Wang, L.; Sun, G.; Yuan, S. Chemical Vapor Deposition Growth of 2D Ferroelectric Materials for Device Applications. Adv. Mater. Technol. 2024, 9, 2301973. [Google Scholar] [CrossRef]

- Dalba, D.A.; Zhang, X.; Xu, W.; Bhattarai, B.; Gamachchi, D.M.; Karunarathne, I.M.; Meng, W.J.; Meng, A.C. Effect of ZnO Interfacial Seed Layer in Sol–Gel Grown ZnMgO Ferroelectric. ACS Appl. Electron. Mater. 2024, 6, 8703–8709. [Google Scholar] [CrossRef]

- Yi, J.; Liu, L.; Shu, L.; Huang, Y.; Li, J.-F. Outstanding Ferroelectricity in Sol–Gel-Derived Polycrystalline BiFeO 3 Films within a Wide Thickness Range. ACS Appl. Mater. Interfaces 2022, 14, 21696–21704. [Google Scholar] [CrossRef]

- Luo, Y.; Tang, Z.; Yin, X.; Chen, C.; Fan, Z.; Qin, M.; Zeng, M.; Zhou, G.; Gao, X.; Lu, X.; et al. Ferroelectricity in Dopant-Free HfO2 Thin Films Prepared by Pulsed Laser Deposition. J. Mater. 2022, 8, 311–318. [Google Scholar] [CrossRef]

- Song, T.; Solanas, R.; Qian, M.; Fina, I.; Sánchez, F. Large Enhancement of Ferroelectric Polarization in Hf0.5Zr0.5O2 Films by Low Plasma Energy Pulsed Laser Deposition. J. Mater. Chem. C 2022, 10, 1084–1089. [Google Scholar] [CrossRef]

- Savant, C.; Gund, V.; Nomoto, K.; Maeda, T.; Jadhav, S.; Lee, J.; Ramesh, M.; Kim, E.; Nguyen, T.-S.; Chen, Y.-H.; et al. Ferroelectric AlBN Films by Molecular Beam Epitaxy. Appl. Phys. Lett. 2024, 125, 072902. [Google Scholar] [CrossRef]

- Wang, D.; Wang, P.; Wang, B.; Mi, Z. Fully Epitaxial Ferroelectric ScGaN Grown on GaN by Molecular Beam Epitaxy. Appl. Phys. Lett. 2021, 119, 111902. [Google Scholar] [CrossRef]

- Mimura, T.; Shimizu, T.; Uchida, H.; Funakubo, H. Room-Temperature Deposition of Ferroelectric HfO2-Based Films by the Sputtering Method. Appl. Phys. Lett. 2020, 116, 062901. [Google Scholar] [CrossRef]

- Dhole, S.; Chen, A.; Nie, W.; Park, B.; Jia, Q. Strain Engineering: A Pathway for Tunable Functionalities of Perovskite Metal Oxide Films. Nanomaterials 2022, 12, 835. [Google Scholar] [CrossRef]

- Pesquera, D.; Parsonnet, E.; Qualls, A.; Xu, R.; Gubser, A.J.; Kim, J.; Jiang, Y.; Velarde, G.; Huang, Y.; Hwang, H.Y.; et al. Beyond Substrates: Strain Engineering of Ferroelectric Membranes. Adv. Mater. 2020, 32, 2003780. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Shi, X.; Pan, H.; Gao, R.; Wang, J.; Lin, Y.; Huang, H. Strain Engineering of Energy Storage Performance in Relaxor Ferroelectric Thin Film Capacitors. Adv. Theory Simul. 2022, 5, 2100324. [Google Scholar] [CrossRef]

- Han, L.; Fang, Y.; Zhao, Y.; Zang, Y.; Gu, Z.; Nie, Y.; Pan, X. Giant Uniaxial Strain Ferroelectric Domain Tuning in Freestanding PbTiO3 Films. Adv. Mater. Interfaces 2020, 7, 1901604. [Google Scholar] [CrossRef]

- Zang, Y.; Di, C.; Geng, Z.; Yan, X.; Ji, D.; Zheng, N.; Jiang, X.; Fu, H.; Wang, J.; Guo, W.; et al. Giant Thermal Transport Tuning at a Metal/Ferroelectric Interface. Adv. Mater. 2022, 34, 2105778. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, A.; Acharya, M.; Lee, H.; Schimpf, J.; Jiang, Y.; Lou, D.; Tian, Z.; Martin, L.W. Thin-Film Ferroelectrics. Adv. Mater. 2022, 34, 2108841. [Google Scholar] [CrossRef] [PubMed]

- Lyu, J.; Fina, I.; Solanas, R.; Fontcuberta, J.; Sánchez, F. Tailoring Lattice Strain and Ferroelectric Polarization of Epitaxial BaTiO3 Thin Films on Si(001). Sci. Rep. 2018, 8, 495. [Google Scholar] [CrossRef]

- Xu, R.; Huang, J.; Barnard, E.S.; Hong, S.S.; Singh, P.; Wong, E.K.; Jansen, T.; Harbola, V.; Xiao, J.; Wang, B.Y.; et al. Strain-Induced Room-Temperature Ferroelectricity in SrTiO3 Membranes. Nat. Commun. 2020, 11, 3141. [Google Scholar] [CrossRef] [PubMed]

- Bae, I.-T.; Lingley, Z.R.; Foran, B.J.; Adams, P.M.; Paik, H. Large Bi-Axial Tensile Strain Effect in Epitaxial BiFeO3 Film Grown on Single Crystal PrScO3. Sci. Rep. 2023, 13, 19018. [Google Scholar] [CrossRef]

- Adamo, C.; Ke, X.; Wang, H.Q.; Xin, H.L.; Heeg, T.; Hawley, M.E.; Zander, W.; Schubert, J.; Schiffer, P.; Muller, D.A.; et al. Effect of Biaxial Strain on the Electrical and Magnetic Properties of (001) La0.7Sr0.3MnO3 Thin Films. Appl. Phys. Lett. 2009, 95, 112504. [Google Scholar] [CrossRef]

- Jeong, C.K.; Park, K.-I.; Son, J.H.; Hwang, G.-T.; Lee, S.H.; Park, D.Y.; Lee, H.E.; Lee, H.K.; Byun, M.; Lee, K.J. Self-Powered Fully-Flexible Light-Emitting System Enabled by Flexible Energy Harvester. Energy Environ. Sci. 2014, 7, 4035–4043. [Google Scholar] [CrossRef]

- Lee, H.S.; Chung, J.; Hwang, G.; Jeong, C.K.; Jung, Y.; Kwak, J.; Kang, H.; Byun, M.; Kim, W.D.; Hur, S.; et al. Flexible Inorganic Piezoelectric Acoustic Nanosensors for Biomimetic Artificial Hair Cells. Adv. Funct. Mater. 2014, 24, 6914–6921. [Google Scholar] [CrossRef]

- Han, S.; Meng, Y.; Xu, Z.; Kim, J.S.; Li, Y.; Roh, I.-P.; Ahn, H.; Kim, D.-H.; Bae, S.-H. Freestanding Membranes for Unique Functionality in Electronics. ACS Appl. Electron. Mater. 2023, 5, 690–704. [Google Scholar] [CrossRef]

- Bakaul, S.R.; Serrao, C.R.; Lee, M.; Yeung, C.W.; Sarker, A.; Hsu, S.-L.; Yadav, A.K.; Dedon, L.; You, L.; Khan, A.I.; et al. Single Crystal Functional Oxides on Silicon. Nat. Commun. 2016, 7, 10547. [Google Scholar] [CrossRef] [PubMed]

- Bakaul, S.R.; Serrao, C.R.; Lee, O.; Lu, Z.; Yadav, A.; Carraro, C.; Maboudian, R.; Ramesh, R.; Salahuddin, S. High Speed Epitaxial Perovskite Memory on Flexible Substrates. Adv. Mater. 2017, 29, 1605699. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Baek, D.J.; Hong, S.S.; Kourkoutis, L.F.; Hikita, Y.; Hwang, H.Y. Synthesis of Freestanding Single-Crystal Perovskite Films and Heterostructures by Etching of Sacrificial Water-Soluble Layers. Nat. Mater. 2016, 15, 1255–1260. [Google Scholar] [CrossRef] [PubMed]

- Yao, M.; Cheng, Y.; Zhou, Z.; Liu, M. Recent Progress on the Fabrication and Applications of Flexible Ferroelectric Devices. J. Mater. Chem. C 2020, 8, 14–27. [Google Scholar] [CrossRef]

- Jiang, J.; Bitla, Y.; Huang, C.-W.; Do, T.H.; Liu, H.-J.; Hsieh, Y.-H.; Ma, C.-H.; Jang, C.-Y.; Lai, Y.-H.; Chiu, P.-W.; et al. Flexible Ferroelectric Element Based on van Der Waals Heteroepitaxy. Sci. Adv. 2017, 3, e1700121. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, G.; Yan, Z.; Wang, Y.; Lu, X.; Liu, J. Flexible, Semitransparent, and Inorganic Resistive Memory Based on BaTi0.95Co0.05O3 Film. Adv. Mater. 2017, 29, 1700425. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, L.; Liu, M.; Li, X.; Lu, X.; Lu, L.; Ma, C.; You, C.; Chen, A.; Huang, C.; et al. Flexible Quasi-Two-Dimensional CoFe 2 O 4 Epitaxial Thin Films for Continuous Strain Tuning of Magnetic Properties. ACS Nano 2017, 11, 8002–8009. [Google Scholar] [CrossRef] [PubMed]

- Peng, R.-C.; Cheng, X.; Peng, B.; Zhou, Z.; Chen, L.-Q.; Liu, M. Domain Patterns and Super-Elasticity of Freestanding BiFeO3 Membranes via Phase-Field Simulations. Acta Mater. 2021, 208, 116689. [Google Scholar] [CrossRef]

- Zhang, K.; Ren, Y.; Cao, Y. Mechanically Tunable Elastic Modulus of Freestanding Ba1−xSrxTiO3 Membranes via Phase-Field Simulation. Appl. Phys. Lett. 2022, 121, 152902. [Google Scholar] [CrossRef]

- Dinu, L.A.; Romanitan, C.; Aldrigo, M.; Parvulescu, C.; Nastase, F.; Vulpe, S.; Gavrila, R.; Varasteanu, P.; Serban, A.B.; Noumi, R.; et al. Investigation of Wet Etching Technique for Selective Patterning of Ferroelectric Zirconium-Doped Hafnium Oxide Thin Films for High-Frequency Electronic Applications. Mater. Des. 2023, 233, 112194. [Google Scholar] [CrossRef]

- Su, Y.; Liu, Y.; Fei, Y.; Wang, L.; Cai, J.; Chen, S.; Wu, Z. A Two-Step Wet Etching Process of PZT Thin Film with Ultra-Low Undercut for MEMS Applications. Sens. Actuators Phys. 2023, 349, 114014. [Google Scholar] [CrossRef]

- Yang, C.; Han, Y.; Qian, J.; Cheng, Z. Flexible, Temperature-Stable, and Fatigue-Endurable PbZr0.52Ti0.48O3 Ferroelectric Film for Nonvolatile Memory. Adv. Electron. Mater. 2019, 5, 1900443. [Google Scholar] [CrossRef]

- Jeong, C.K.; Kim, I.; Park, K.-I.; Oh, M.H.; Paik, H.; Hwang, G.-T.; No, K.; Nam, Y.S.; Lee, K.J. Virus-Directed Design of a Flexible BaTiO3 Nanogenerator. ACS Nano 2013, 7, 11016–11025. [Google Scholar] [CrossRef]

- Denis-Rotella, L.M.; Esteves, G.; Walker, J.; Zhou, H.; Jones, J.L.; Trolier-McKinstry, S. Residual Stress and Ferroelastic Domain Reorientation in Declamped {001} Pb(Zr0.3Ti0.7)O3 Films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 259–272. [Google Scholar] [CrossRef]

- Huff, M. Review Paper: Residual Stresses in Deposited Thin-Film Material Layers for Micro- and Nano-Systems Manufacturing. Micromachines 2022, 13, 2084. [Google Scholar] [CrossRef] [PubMed]

- Pesquera, D.; Fernández, A.; Khestanova, E.; Martin, L.W. Freestanding Complex-Oxide Membranes. J. Phys. Condens. Matter 2022, 34, 383001. [Google Scholar] [CrossRef] [PubMed]

- Park, D.-S.; Pryds, N. The Fabrication of Freestanding Complex Oxide Membranes: Can We Avoid Using Water? J. Mater. Res. 2024, 39, 2907–2917. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-C.; Chen, B.-C.; Wei, C.-C.; Ho, S.-Z.; Liou, Y.-D.; Kaur, P.; Rahul; Chen, Y.-C.; Yang, J.-C. Thickness-Dependent Ferroelectricity in Freestanding Hf0.5Zr0.5O2 Membranes. ACS Appl. Electron. Mater. 2024, 6, 8617–8625. [Google Scholar] [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.Y.; Stephenson, G.B.; et al. Ferroelectric Thin Films: Review of Materials, Properties, and Applications. J. Appl. Phys. 2006, 100, 051606. [Google Scholar] [CrossRef]

- Martin, L.W.; Rappe, A.M. Thin-Film Ferroelectric Materials and Their Applications. Nat. Rev. Mater. 2016, 2, 16087. [Google Scholar] [CrossRef]

- Shao, M.-H.; Zhao, R.-T.; Liu, H.; Xu, W.-J.; Guo, Y.-D.; Huang, D.-P.; Yang, Y.-Z.; Li, X.-R.; Shao, W.; Shen, P.-H.; et al. Challenges and Recent Advances in HfO2-Based Ferroelectric Films for Non-Volatile Memory Applications. Chip 2024, 3, 100101. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Z.J.; He, B.; Cui, J.Z.; Zhang, Z.D. Enhancement of Polarization in Ferroelectric Films via the Incorporation of Gold Nanoparticles. ACS Omega 2017, 2, 9067–9073. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Peng, B.; Lu, G.; Dong, G.; Yang, G.; Chen, B.; Qiu, R.; Liu, H.; Zhang, B.; Yao, Y.; et al. Remarkable Flexibility in Freestanding Single-Crystalline Antiferroelectric PbZrO3 Membranes. Nat. Commun. 2024, 15, 4414. [Google Scholar] [CrossRef]

- Tian, Z.; Kim, J.; Fernandez, A.; Huang, X.; Martin, L.W. Effect of Substrate Clamping on Evolution of Properties in Homovalent and Heterovalent Relaxor Thin Films. Phys. Rev. B 2022, 105, 094107. [Google Scholar] [CrossRef]

- Xu, Q.; Jia, M.; Zhou, P.; Zhang, Y.; Guo, W.; Zhao, S.; Zeng, H.; Zhang, J.; Yan, M.; Jiang, S.; et al. High-Performance Ultrasensitive Flexible Piezoelectric Thin Film Sensors via a Cost-Effective Transfer Strategy. Adv. Funct. Mater. 2024, 35, 2414211. [Google Scholar] [CrossRef]

- Park, K.-I.; Lee, S.Y.; Kim, S.; Chang, J.; Kang, S.-J.L.; Lee, K.J. Bendable and Transparent Barium Titanate Capacitors on Plastic Substrates for High Performance Flexible Ferroelectric Devices. Electrochem. Solid-State Lett. 2010, 13, G57. [Google Scholar] [CrossRef]

- Sahu, M.; Hajra, S.; Lee, K.; Deepti, P.; Mistewicz, K.; Kim, H.J. Piezoelectric Nanogenerator Based on Lead-Free Flexible PVDF-Barium Titanate Composite Films for Driving Low Power Electronics. Crystals 2021, 11, 85. [Google Scholar] [CrossRef]

- Dudem, B.; Kim, D.H.; Bharat, L.K.; Yu, J.S. Highly-Flexible Piezoelectric Nanogenerators with Silver Nanowires and Barium Titanate Embedded Composite Films for Mechanical Energy Harvesting. Appl. Energy 2018, 230, 865–874. [Google Scholar] [CrossRef]

- Ma, S.W.; Fan, Y.J.; Li, H.Y.; Su, L.; Wang, Z.L.; Zhu, G. Flexible Porous Polydimethylsiloxane/Lead Zirconate Titanate-Based Nanogenerator Enabled by the Dual Effect of Ferroelectricity and Piezoelectricity. ACS Appl. Mater. Interfaces 2018, 10, 33105–33111. [Google Scholar] [CrossRef]

- Liu, X.; Wei, C.; Zhang, F.; Peng, Y.; Sun, T.; Peng, Y.; Tang, H.; Yang, J.; Ding, M.; Jiang, C.; et al. A Flexible Hf0.5Zr0.5O2 Nonvolatile Memory with High Polarization Based on Mica Substrate. ACS Appl. Electron. Mater. 2024, 6, 6266–6274. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Y.; Yuan, P.; Jiang, P.; Xu, Y.; Lv, S.; Ding, Y.; Dang, Z.; Gong, T.; Wang, Y.; et al. Flexible HfxZr1-xO2 Thin Films on Polyimide for Energy Storage With High Flexibility. IEEE Electron. Device Lett. 2022, 43, 930–933. [Google Scholar] [CrossRef]

- Pereira, N.; Gonçalves, S.; Barbosa, J.C.; Gonçalves, R.; Tubio, C.R.; Vilas-Vilela, J.L.; Costa, C.M.; Lanceros-Mendez, S. High Dielectric Constant Poly (Vinylidene Fluoride-Trifluoroethylene-Chlorofluoroethylene) for Capacitive Pressure and Bending Sensors. Polymer 2021, 214, 123349. [Google Scholar] [CrossRef]

- Shepelin, N.A.; Lussini, V.C.; Fox, P.J.; Dicinoski, G.W.; Glushenkov, A.M.; Shapter, J.G.; Ellis, A.V. 3D Printing of Poly(Vinylidene Fluoride-Trifluoroethylene): A Poling-Free Technique to Manufacture Flexible and Transparent Piezoelectric Generators. MRS Commun. 2019, 9, 159–164. [Google Scholar] [CrossRef]

- Stadlober, B.; Zirkl, M.; Irimia-Vladu, M. Route towards Sustainable Smart Sensors: Ferroelectric Polyvinylidene Fluoride-Based Materials and Their Integration in Flexible Electronics. Chem. Soc. Rev. 2019, 48, 1787–1825. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.-H.; Park, D.H.; Jung, J.-Y.; Lee, M.H.; Nah, J. Ferroelectric Zinc Oxide Nanowire Embedded Flexible Sensor for Motion and Temperature Sensing. ACS Appl. Mater. Interfaces 2017, 9, 9233–9238. [Google Scholar] [CrossRef]

- Dutta, S.; Chakraborty, T.; Sharma, S.; Mondal, D.; Saha, A.; Pradhan, A.K.; Chakraborty, C.; Das, S.; Sutradhar, S. Fabrication of Rare Earth-Doped ZnO-PVDF Flexible Nanocomposite Films for Ferroelectric Response and Their Application in Piezo-Responsive Bending Sensors. Dalton Trans. 2024, 53, 14347–14363. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Liu, L.; Tang, L.; Yuan, X.; Chen, H.; Zhou, K.; Zhang, D. Thickness-Dependent Ferroelectric Properties of HfO2/ZrO2 Nanolaminates Using Atomic Layer Deposition. J. Mater. Sci. 2021, 56, 6064–6072. [Google Scholar] [CrossRef]

- Sawabe, Y.; Saraya, T.; Hiramoto, T.; Su, C.-J.; Hu, V.P.-H.; Kobayashi, M. On the Thickness Dependence of the Polarization Switching Kinetics in HfO2-Based Ferroelectric. Appl. Phys. Lett. 2022, 121, 082903. [Google Scholar] [CrossRef]

- Hagiwara, K.; Byun, K.N.; Morita, S.; Yamamoto, E.; Kobayashi, M.; Liu, X.; Osada, M. Molecularly Thin BaTiO3 Nanosheets with Stable Ferroelectric Response. Adv. Electron. Mater. 2023, 9, 2201239. [Google Scholar] [CrossRef]

- Han, M.-G.; Marshall, M.S.J.; Wu, L.; Schofield, M.A.; Aoki, T.; Twesten, R.; Hoffman, J.; Walker, F.J.; Ahn, C.H.; Zhu, Y. Interface-Induced Nonswitchable Domains in Ferroelectric Thin Films. Nat. Commun. 2014, 5, 4693. [Google Scholar] [CrossRef]

- Balakrishna, A.R.; Huber, J.E. Nanoscale Domain Patterns and a Concept for an Energy Harvester. Smart Mater. Struct. 2016, 25, 104001. [Google Scholar] [CrossRef]

- Lu, H.; Schönweger, G.; Petraru, A.; Kohlstedt, H.; Fichtner, S.; Gruverman, A. Domain Dynamics and Resistive Switching in Ferroelectric Al1–xScxN Thin Film Capacitors. Adv. Funct. Mater. 2024, 34, 2315169. [Google Scholar] [CrossRef]

- Buragohain, P.; Erickson, A.; Mimura, T.; Shimizu, T.; Funakubo, H.; Gruverman, A. Effect of Film Microstructure on Domain Nucleation and Intrinsic Switching in Ferroelectric Y:HfO2 Thin Film Capacitors. Adv. Funct. Mater. 2022, 32, 2108876. [Google Scholar] [CrossRef]

- Lv, H.-P.; Liao, W.-Q.; You, Y.-M.; Xiong, R.-G. Inch-Size Molecular Ferroelectric Crystal with a Large Electromechanical Coupling Factor on Par with Barium Titanate. J. Am. Chem. Soc. 2022, 144, 22325–22331. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, R.; Zhou, J.; Zhang, Y.; Wang, J.; Weng, S. Unveiling Frequency-Dependent Electromechanical Dynamics in Ferroelectric BaTiO3 Nanofilm with a Core-Shell Structure. Coatings 2024, 14, 1437. [Google Scholar] [CrossRef]

- Yang, S.; Li, J.; Liu, Y.; Wang, M.; Qiao, L.; Gao, X.; Chang, Y.; Du, H.; Xu, Z.; Zhang, S.; et al. Textured Ferroelectric Ceramics with High Electromechanical Coupling Factors over a Broad Temperature Range. Nat. Commun. 2021, 12, 1414. [Google Scholar] [CrossRef]

- Dong, G.; Li, S.; Yao, M.; Zhou, Z.; Zhang, Y.-Q.; Han, X.; Luo, Z.; Yao, J.; Peng, B.; Hu, Z.; et al. Super-Elastic Ferroelectric Single-Crystal Membrane with Continuous Electric Dipole Rotation. Science 2019, 366, 475–479. [Google Scholar] [CrossRef]

- Ji, D.; Cai, S.; Paudel, T.R.; Sun, H.; Zhang, C.; Han, L.; Wei, Y.; Zang, Y.; Gu, M.; Zhang, Y.; et al. Freestanding Crystalline Oxide Perovskites down to the Monolayer Limit. Nature 2019, 570, 87–90. [Google Scholar] [CrossRef] [PubMed]

- Elangovan, H.; Barzilay, M.; Seremi, S.; Cohen, N.; Jiang, Y.; Martin, L.W.; Ivry, Y. Giant Superelastic Piezoelectricity in Flexible Ferroelectric BaTiO3 Membranes. ACS Nano 2020, 14, 5053–5060. [Google Scholar] [CrossRef]

- Guo, C.; Yang, H.; Dong, S.; Tang, S.; Wang, J.; Wang, X.; Huang, H. Advancing Energy-Storage Performance in Freestanding Ferroelectric Thin Films: Insights from Phase-Field Simulations. Adv. Electron. Mater. 2024, 10, 2400001. [Google Scholar] [CrossRef]

- Meng, N.; Ren, X.; Wu, J.; Bilotti, E.; Reece, M.J.; Yan, H. Low-Cost Free-Standing Ferroelectric Polymer Films with High Polarization Produced via Pressing-and-Folding. J. Mater. 2022, 8, 640–648. [Google Scholar] [CrossRef]

- Guido, R.; Lomenzo, P.D.; Islam, M.R.; Wolff, N.; Gremmel, M.; Schönweger, G.; Kohlstedt, H.; Kienle, L.; Mikolajick, T.; Fichtner, S.; et al. Thermal Stability of the Ferroelectric Properties in 100 Nm-Thick Al0.72Sc0.28N. ACS Appl. Mater. Interfaces 2023, 15, 7030–7043. [Google Scholar] [CrossRef]

- Islam, M.R.; Wolff, N.; Yassine, M.; Schönweger, G.; Christian, B.; Kohlstedt, H.; Ambacher, O.; Lofink, F.; Kienle, L.; Fichtner, S. On the Exceptional Temperature Stability of Ferroelectric Al1-xScxN Thin Films. Appl. Phys. Lett. 2021, 118, 232905. [Google Scholar] [CrossRef]

- Kim, H.-B.; Jung, M.; Oh, Y.; Lee, S.W.; Suh, D.; Ahn, J.-H. Superior and Stable Ferroelectric Properties of Hafnium-Zirconium-Oxide Thin Films Deposited via Atomic Layer Deposition Using Cyclopentadienyl-Based Precursors without Annealing. Nanoscale 2021, 13, 8524–8530. [Google Scholar] [CrossRef]

- Zhu, B.; Kong, Z.; Cheng, H.; Han, K.; Chen, P.; Wang, K.; Zhang, H.; Wang, J.; Huang, Z.; Wu, W.; et al. Interfacial Strain-Insensitive Thermal and Electrical Stability of (K,Na)NbO3-Based Lead-Free Ferroelectric Films. J. Phys. Chem. C 2024, 128, 17886–17893. [Google Scholar] [CrossRef]

- Kang, S.; Jang, W.-S.; Morozovska, A.N.; Kwon, O.; Jin, Y.; Kim, Y.-H.; Bae, H.; Wang, C.; Yang, S.-H.; Belianinov, A.; et al. Highly Enhanced Ferroelectricity in HfO2-Based Ferroelectric Thin Film by Light Ion Bombardment. Science 2022, 376, 731–738. [Google Scholar] [CrossRef]

- Kale, S.; Petraru, A.; Kohlstedt, H.; Soni, R. Electrically Controlled Reversible Polarization Fatigue–Recovery in Ferroelectric Thin Film Capacitors. ACS Appl. Electron. Mater. 2022, 4, 1692–1702. [Google Scholar] [CrossRef]

- Chen, C.; Sharafi, A.; Sun, J.-Q. A High Density Piezoelectric Energy Harvesting Device from Highway Traffic—Design Analysis and Laboratory Validation. Appl. Energy 2020, 269, 115073. [Google Scholar] [CrossRef]

- Nechibvute, A.; Chawanda, A.; Luhanga, P. Piezoelectric Energy Harvesting Devices: An Alternative Energy Source for Wireless Sensors. Smart Mater. Res. 2012, 2012, 853481. [Google Scholar] [CrossRef]

- Li, T.; Lee, P.S. Piezoelectric Energy Harvesting Technology: From Materials, Structures, to Applications. Small Struct. 2022, 3, 2100128. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Gupta, R.; Sahoo, S.; Deswal, S.; Kothavade, P.; Dixit, P.; Zaręba, J.K.; Shanmuganathan, K.; Boomishankar, R. A Flexible Energy Harvester from an Organic Ferroelectric Ammonium Salt. Chem.–Asian J. 2021, 16, 4122–4129. [Google Scholar] [CrossRef]

- Jangra, M.; Thakur, A.; Dam, S.; Chatterjee, S.; Hussain, S. Enhanced Dielectric Properties of MoS2/PVDF Free-Standing, Flexible Films for Energy Harvesting Applications. Mater. Today Commun. 2023, 34, 105109. [Google Scholar] [CrossRef]

- Veeralingam, S.; Badhulika, S. Lead-Free Transparent Flexible Piezoelectric Nanogenerator for Self-Powered Wearable Electronic Sensors and Energy Harvesting through Rainwater. ACS Appl. Energy Mater. 2022, 5, 12884–12896. [Google Scholar] [CrossRef]

- Panda, S.; Shin, H.; Hajra, S.; Oh, Y.; Oh, W.; Lee, J.; Rajaitha, P.M.; Panigrahi, B.K.; Shukla, J.; Sahu, A.K.; et al. Ferroelectric Composite-Based Piezoelectric Energy Harvester for Self-Powered Detection of Obstructive Sleep. J. Mater. 2023, 9, 609–617. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef]

- Aabid, A.; Raheman, M.A.; Ibrahim, Y.E.; Anjum, A.; Hrairi, M.; Parveez, B.; Parveen, N.; Mohammed Zayan, J. A Systematic Review of Piezoelectric Materials and Energy Harvesters for Industrial Applications. Sensors 2021, 21, 4145. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Song, K.; Huang, H.; Han, W.; Yang, Y. Ferroelectric Materials for Solar Energy Scavenging and Photodetectors. Adv. Opt. Mater. 2022, 10, 2101741. [Google Scholar] [CrossRef]

- Yan, M.; Xiao, Z.; Ye, J.; Yuan, X.; Li, Z.; Bowen, C.; Zhang, Y.; Zhang, D. Porous Ferroelectric Materials for Energy Technologies: Current Status and Future Perspectives. Energy Environ. Sci. 2021, 14, 6158–6190. [Google Scholar] [CrossRef]

- Li, H.; Bowen, C.R.; Yang, Y. Scavenging Energy Sources Using Ferroelectric Materials. Adv. Funct. Mater. 2021, 31, 2100905. [Google Scholar] [CrossRef]

- Wei, X.; Domingo, N.; Sun, Y.; Balke, N.; Dunin-Borkowski, R.E.; Mayer, J. Progress on Emerging Ferroelectric Materials for Energy Harvesting, Storage and Conversion (Adv. Energy Mater. 24/2022). Adv. Energy Mater. 2022, 12, 2270102. [Google Scholar] [CrossRef]

- Jia, X.; Guo, R.; Chen, J.; Yan, X. Flexoelectric Effect in Thin Films: Theory and Applications. Adv. Funct. Mater. 2024, 35, 2412887. [Google Scholar] [CrossRef]

- Deng, C.; Zhang, Y.; Yang, D.; Zhang, H.; Zhu, M. Recent Progress on Barium Titanate-Based Ferroelectrics for Sensor Applications. Adv. Sens. Res. 2024, 3, 2300168. [Google Scholar] [CrossRef]

- Li, W.; Li, C.; Zhang, G.; Li, L.; Huang, K.; Gong, X.; Zhang, C.; Zheng, A.; Tang, Y.; Wang, Z.; et al. Molecular Ferroelectric-Based Flexible Sensors Exhibiting Supersensitivity and Multimodal Capability for Detection. Adv. Mater. 2021, 33, 2104107. [Google Scholar] [CrossRef]

- Ji, Y.; Yin, S.; Liu, Y.; Bowen, C.R.; Yang, Y. Dual-Mode Temperature Sensor Based on Ferroelectric Bi0.5Na0.5TiO3 Materials for Robotic Tactile Perception. Nano Energy 2024, 128, 109982. [Google Scholar] [CrossRef]

- Liu, W.; Lin, D.; Zeng, W.; Wang, Q.; Yang, J.; Peng, Z.; Zhang, Q.; Zhu, G. A Multifunctional Flexible Ferroelectric Transistor Sensor for Electronic Skin. Adv. Mater. Interfaces 2021, 8, 2101166. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, K.; Xu, H.; Li, T.; Jin, Q.; Cui, D. Recent Developments in Sensors for Wearable Device Applications. Anal. Bioanal. Chem. 2021, 413, 6037–6057. [Google Scholar] [CrossRef] [PubMed]

- Fraga, M.A.; Massi, M.; Pessoa, R.S. Sputtered Piezoelectric Films as Materials for Flexible Devices and Sensors: A Review. IEEE Sens. J. 2024, 24, 28–39. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Z.; Yu, Y.; Pan, C.; Jin, T.; Zhang, Y.; Li, Z.; Sheng, P.; Zhang, J. Flexible Piezoelectric-Coupling Organic Transistor-Based Press Sensors with Ferroelectric Charge-Transfer Complex Integrated Dielectrics. ACS Appl. Electron. Mater. 2024, 6, 7170–7178. [Google Scholar] [CrossRef]

- Behera, C.; Pradhan, N.; Das, P.R.; Choudhary, R.N.P. Development of Self-Standing, Lightweight and Flexible Polymer-Cobalt Ferrite Nanocomposites for Field Sensor. J. Polym. Res. 2022, 29, 65. [Google Scholar] [CrossRef]

- Jayakrishnan, A.R.; Kumar, A.; Druvakumar, S.; John, R.; Sudeesh, M.; Puli, V.S.; Silva, J.P.B.; Gomes, M.J.M.; Sekhar, K.C. Inorganic Ferroelectric Thin Films and Their Composites for Flexible Electronic and Energy Device Applications: Current Progress and Perspectives. J. Mater. Chem. C 2023, 11, 827–858. [Google Scholar] [CrossRef]

- Liu, X.; Wei, C.; Sun, T.; Zhang, F.; Li, H.; Liu, L.; Peng, Y.; Li, H.; Hong, M. A BaTiO3-Based Flexible Ferroelectric Capacitor for Non-Volatile Memories. J. Mater. 2025, 11, 100870. [Google Scholar] [CrossRef]

- Zhong, H.; Li, M.; Zhang, Q.; Yang, L.; He, R.; Liu, F.; Liu, Z.; Li, G.; Sun, Q.; Xie, D.; et al. Large-Scale Hf0.5Zr0.5O2 Membranes with Robust Ferroelectricity. Adv. Mater. 2022, 34, 2109889. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Sun, H.; Li, J.; Du, X.; Wang, H.; Luo, Z.; Wang, Z.; Lin, Y.; Shen, S.; Yin, Y.; et al. A Flexible Hf0.5Zr0.5O2 Thin Film with Highly Robust Ferroelectricity. J. Mater. 2024, 10, 210–217. [Google Scholar] [CrossRef]

- Margolin, I.; Chouprik, A.; Mikheev, V.; Zarubin, S.; Negrov, D. Flexible HfO2-Based Ferroelectric Memristor. Appl. Phys. Lett. 2022, 121, 102901. [Google Scholar] [CrossRef]

- Ali, F.; Zhou, D.; Ali, M.; Ali, H.W.; Daaim, M.; Khan, S.; Hussain, M.M.; Sun, N. Recent Progress on Energy-Related Applications of HfO2-Based Ferroelectric and Antiferroelectric Materials. ACS Appl. Electron. Mater. 2020, 2, 2301–2317. [Google Scholar] [CrossRef]

- Yang, K.; Lee, E.B.; Lee, D.H.; Park, J.Y.; Kim, S.H.; Park, G.H.; Yu, G.T.; Lee, J.I.; Kim, G.H.; Park, M.H. Energy Conversion and Storage Using Artificially Induced Antiferroelectricity in HfO2/ZrO2Nanolaminates. Compos. Part B Eng. 2022, 236, 109824. [Google Scholar] [CrossRef]

- Mart, C.; Abdulazhanov, S.; Czernohorsky, M.; Kampfe, T.; Lehninger, D.; Falidas, K.; Eslinger, S.; Kuhnel, K.; Oehler, S.; Rudolph, M.; et al. Energy Harvesting in the Back-End of Line with CMOS Compatible Ferroelectric Hafnium Oxide. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 26.3.1–26.3.4. [Google Scholar]

- Weinreich, W.; Lederer, M.; Czernohorsky, M. Enablement of CMOS Integrated Sensor, Harvesting and Storage Applications by Ferroelectric HfO2. In Proceedings of the 2022 International Conference on IC Design and Technology (ICICDT), Hanoi, Vietnam, 21–23 September 2022; pp. 84–87. [Google Scholar]

- Feng, G.-H.; Yeh, C.-T. Ferroelectric Film-Based Stretch Sensor with Successive Stretch and Release Motions Characterized by a Combined Piezoelectric and Electrostrictive Effect. Smart Mater. Struct. 2023, 32, 125017. [Google Scholar] [CrossRef]

- Wang, W.; Li, J.; Liu, H.; Ge, S. Advancing Versatile Ferroelectric Materials Toward Biomedical Applications. Adv. Sci. 2021, 8, 2003074. [Google Scholar] [CrossRef]

- Sengupta, P.; Sahoo, D.; Ikbal, A.; Ray, R. C3H7NH3PbI3@PVDF Porous Piezo-Active Film: A Wearable Potential Bio-Sensor. Emergent Mater. 2024, 1–13. [Google Scholar] [CrossRef]

- Hwang, G.; Byun, M.; Jeong, C.K.; Lee, K.J. Flexible Piezoelectric Thin-Film Energy Harvesters and Nanosensors for Biomedical Applications. Adv. Healthc. Mater. 2015, 4, 646–658. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Yang, B.D.; Su, Y.; Tran, P.L.; Joe, P.; Anderson, E.; Xia, J.; Doraiswamy, V.; Dehdashti, B.; Feng, X.; et al. Conformal Piezoelectric Energy Harvesting and Storage from Motions of the Heart, Lung, and Diaphragm. Proc. Natl. Acad. Sci. USA 2014, 111, 1927–1932. [Google Scholar] [CrossRef]

- Park, H.S.; Choi, S.; Kim, K.D.; Yeom, M.K.; Lee, S.H.; Ryoo, S.K.; Hwang, C.S. Optimization of the 4 Nm-Thick Hf1–xZrxO2 Film with Low Operating Voltage and High Endurance for Ferroelectric Random Access Memory. ACS Appl. Electron. Mater. 2024, 6, 6826–6836. [Google Scholar] [CrossRef]

- Mittmann, T.; Fengler, F.P.G.; Richter, C.; Park, M.H.; Mikolajick, T.; Schroeder, U. Optimizing Process Conditions for Improved Hf1– xZrxO2 Ferroelectric Capacitor Performance. Microelectron. Eng. 2017, 178, 48–51. [Google Scholar] [CrossRef]

- Huan, Y.; Wang, X.; Yang, W.; Hou, L.; Zheng, M.; Wei, T.; Wang, X. Optimizing Energy Harvesting Performance by Tailoring Ferroelectric/Relaxor Behavior in KNN-Based Piezoceramics. J. Adv. Ceram. 2022, 11, 935–944. [Google Scholar] [CrossRef]

- Schroeder, U.; Richter, C.; Park, M.H.; Schenk, T.; Pešić, M.; Hoffmann, M.; Fengler, F.P.G.; Pohl, D.; Rellinghaus, B.; Zhou, C.; et al. Lanthanum-Doped Hafnium Oxide: A Robust Ferroelectric Material. Inorg. Chem. 2018, 57, 2752–2765. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Asare-Yeboah, K.; Bi, S.; He, Z. Poly(α-methyl styrene) polymer additive for organic thin film transistors. J. Mater. Sci. Mater. Electron. 2022, 33, 1101–1122. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S. Tailoring the molecular weight of polymer additives for organic semiconductors. Mater. Adv. 2022, 3, 1953–1973. [Google Scholar] [CrossRef]

- Haase, K.; da Rocha, C.T.; Hauenstein, C.; Zheng, Y.C.; Hambsch, M.; Mannsfeld, S.C.B. High-mobility, solution-processed organic field-effect transistors from C8-BTBT:polystyrene blends. Adv. Electron. Mater. 2018, 4, 180076. [Google Scholar] [CrossRef]

- Nikolka, M.; Nasrallah, I.; Rose, B.; Ravva, M.K.; Broch, K.; Sadhanala, A.; Harkin, D.; Charmet, J.; Hurhangee, M.; Brown, A.; et al. High operational and environmental stability of high-mobility conjugated polymer field-effect transistors through the use of molecular additives. Nat. Mater. 2017, 16, 356–362. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, Q.; Liu, X.; Hu, Y.; Lou, Z.; Hou, Y.; Teng, F. Property modulation of two-dimensional lead-free perovskite thin films by aromatic polymer additives for performance enhancement of field-effect transistors. ACS Adv. Mater. Interfaces 2021, 13, 24272–24284. [Google Scholar] [CrossRef]

- Liu, S.; Liao, J.; Huang, X.; Zhang, Z.; Wang, W.; Wang, X.; Shan, Y.; Li, P.; Hong, Y.; Peng, Z.; et al. Green Fabrication of Freestanding Piezoceramic Films for Energy Harvesting and Virus Detection. Nano-Micro Lett. 2023, 15, 131. [Google Scholar] [CrossRef] [PubMed]

- Mittmann, T.; Materano, M.; Chang, S.-C.; Karpov, I.; Mikolajick, T.; Schroeder, U. Impact of Oxygen Vacancy Content in Ferroelectric HZO Films on the Device Performance. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 18.4.1–18.4.4. [Google Scholar]

- Lyu, S.; Jiang, P.; Gao, Z.; Yang, Y.; Chen, Y.; Wang, B.; Chen, M.; Wang, Y.; Chen, Y.; Wang, Y. Performance Optimization for Ferroelectric HfZrOx on a Ge Substrate by Modifying the Deposition Temperature. IEEE Trans. Nanotechnol. 2024, 23, 139–143. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Q.; Huang, H.; Hong, J.; Wang, X. Strain Manipulation of Ferroelectric Skyrmion Bubbles in a Freestanding PbTiO3 Film: A Phase Field Simulation. Phys. Rev. B 2022, 105, 224101. [Google Scholar] [CrossRef]

- Li, C.; Zhou, L.; Guo, X.; Huang, Y.; Zhang, H.; Dong, S.; Wu, Y.; Hong, Z. Phase Diagrams, Dielectric, and Piezoelectric Properties of Metal-Free Perovskite Thin Films: Phase-Field Simulations. J. Mater. Res. 2023, 38, 664–674. [Google Scholar] [CrossRef]

- Liu, D.; Wang, J.; Jafri, H.M.; Wang, X.; Shi, X.; Liang, D.; Yang, C.; Cheng, X.; Huang, H. Phase-Field Simulations of Vortex Chirality Manipulation in Ferroelectric Thin Films. npj Quantum Mater. 2022, 7, 34. [Google Scholar] [CrossRef]

- Ortega, N.; Kumar, A.; Scott, J.F.; Katiyar, R.S. Multifunctional Magnetoelectric Materials for Device Applications. J. Phys. Condens. Matter 2015, 27, 504002. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Zhu, H.; Liu, Y.; Luo, J.; Lyu, Y. Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Sr0.7Bi0.2TiO3 Relaxor Ferroelectric Thin Films by Entropy Design. ACS Appl. Electron. Mater. 2023, 5, 2809–2818. [Google Scholar] [CrossRef]

- Eckstein, U.; Khansur, N.H.; Bergler, M.; Urushihara, D.; Asaka, T.; Kakimoto, K.; Sadl, M.; Dragomir, M.; Uršič, H.; De Ligny, D.; et al. Room Temperature Deposition of Freestanding BaTiO3 Films: Temperature-Induced Irreversible Structural and Chemical Relaxation. J. Mater. Sci. 2022, 57, 13264–13286. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Zhang, B.; Yin, C.; Zhang, Y.; Zhang, Y.; Zhang, T.; Cui, Y.; Chi, Q. High-Energy Storage Performance Achieved in PbZrO3 Thin Films via Li+ Doping and Low-Temperature Annealing. Thin Solid Films 2024, 794, 140289. [Google Scholar] [CrossRef]

- Diao, C.; Li, H.; Yang, Y.; Hao, H.; Yao, Z.; Liu, H. Significantly Improved Energy Storage Properties of Sol-Gel Derived Mn-Modified SrTiO3 Thin Films. Ceram. Int. 2019, 45, 11784–11791. [Google Scholar] [CrossRef]

- Pan, T.-M.; Chen, Z.-Y.; Her, J.-L. Enhanced Ferroelectric Properties of BiFeO3 Thin Films Utilizing Four Buffer Layers: Nd3O2, Eu2O3, Ho2O3, and Er2O3. Appl. Phys. A 2024, 130, 564. [Google Scholar] [CrossRef]

- Kobald, A.M.; Kobald, H.; Deluca, M. Phase Stability and Energy Storage Properties of Polycrystalline Antiferroelectric BaTiO3-Substituted NaNbO3 Thin Films. J. Eur. Ceram. Soc. 2024, 44, 2831–2841. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, J.Y.; Song, J.Y.; Jang, H.W. Overcoming Size Effects in Ferroelectric Thin Films. Adv. Phys. Res. 2023, 2, 2200096. [Google Scholar] [CrossRef]

- Mesić, M.; Dunatov, M.; Puškarić, A.; Štefanić, Z.; Androš Dubraja, L. Humidity and Temperature Driven Transformations in Ferroelectric Quinuclidine-Based Chlorocobaltate(ii) Complex Salt: Bulk and Thin Films with Preferred Orientation. J. Mater. Chem. C 2024, 12, 12397–12404. [Google Scholar] [CrossRef]

- Chiabrera, F.M.; Yun, S.; Li, Y.; Dahm, R.T.; Zhang, H.; Kirchert, C.K.R.; Christensen, D.V.; Trier, F.; Jespersen, T.S.; Pryds, N. Freestanding Perovskite Oxide Films: Synthesis, Challenges, and Properties. Ann. Phys. 2022, 534, 2200084. [Google Scholar] [CrossRef]

- Li, D.; Huang, X.; Wu, Q.; Zhang, L.; Lu, Y.; Hong, X. Ferroelectric Domain Control of Nonlinear Light Polarization in MoS2 via PbZr0.2Ti0.8O3 Thin Films and Free-Standing Membranes. Adv. Mater. 2023, 35, 2208825. [Google Scholar] [CrossRef]

- Hsain, H.A.; Lee, Y.; Lomenzo, P.D.; Alcala, R.; Xu, B.; Mikolajick, T.; Schroeder, U.; Parsons, G.N.; Jones, J.L. Wake-up Free Ferroelectric Hafnia-Zirconia Capacitors Fabricated via Vacuum-Maintaining Atomic Layer Deposition. J. Appl. Phys. 2023, 133, 225304. [Google Scholar] [CrossRef]

- Li, Y.; Liang, R.; Wang, J.; Zhang, Y.; Tian, H.; Liu, H.; Li, S.; Mao, W.; Pang, Y.; Li, Y.; et al. A Ferroelectric Thin Film Transistor Based on Annealing-Free HfZrO Film. IEEE J. Electron. Devices Soc. 2017, 5, 378–383. [Google Scholar] [CrossRef]

- Bouaziz, J.; Romeo, P.R.; Baboux, N.; Vilquin, B. Huge Reduction of the Wake-Up Effect in Ferroelectric HZO Thin Films. ACS Appl. Electron. Mater. 2019, 1, 1740–1745. [Google Scholar] [CrossRef]

| Method | Strengths | Weaknesses |

|---|---|---|

| Chemical Methods | Cost-effective, composition control, scalability | Polycrystalline films with inferior properties |

| Physical Methods | High-quality epitaxial films, atomic-level control | Expensive equipment, limited scalability |

| Fabrication Technique | Advantages Over Traditional Methods | Advantage in Applications |

|---|---|---|

| Laser lift-off | 1. High precision and fewer defects 2. Promotes flexible and innovative device designs | Suitable for flexible electronics and LEDs, increasing efficiency and simplifying fabrication |

| Wet etching | 1. Enhanced control over geometry and etching depth 2. Suitable for creating fine features and complex structures | Utilized in microelectronics to enhance yield and efficiency |

| Sacrificial Layers | 1. Minimize material waste 2. Allows for fabrication of complex structures | Used in the fabrication of sensors |

| Van der Waals epitaxy | 1. Enables integration of diverse materials 2. Reduces defects | Beneficial in fabricating next-generation transistors and optoelectronic devices |

| Fabrication Techniques | Advantages | Disadvantages | Application |

|---|---|---|---|

| Laser lift-off | No corrosion of the thin film layer | High-energy laser is required which might damage the material of the film | Flexible energy harvester [37] |

| Wet etching | Cost-effective and enhances conversion efficiency of energy harvesting devices | Successful and intact separation is challenging. The film may be damaged by the etching solution. | Electronic systems [49,50] |

| Van der Waals epitaxy | Reduced defect density and easy layer transfer | Compared to conventional epitaxy, lower-quality films are produced. | Non-volatile memory devices [51] |

| Formation of nanocomposites | Low-cost and large-area self-powered energy harvesting devices | Poor piezoelectric properties and low energy conversion rate. | Flexible nanocomposite generator [52] |

| Challenges | Description | Potential Solution |

|---|---|---|

| Fabrication technique | The complex fabrication process hinders the large-scale production of defect-free films | Development of cost-effective fabrication techniques |

| Material compatibility | Strain-free membrane etching options are limited | Exploring new materials and combinations |

| Integration challenges | Wafer-scale thin film deposition remains a significant challenge | Creating advanced interface engineering |

| Cost-effectiveness | High cost of production and scalability | Optimization of processes to lower production cost |

| Long term stability | Potential degradation of properties over time | Development of stable storage conditions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, R.; Anoop, G.; Samanta, S. Advancements in Free-Standing Ferroelectric Films: Paving the Way for Transparent Flexible Electronics. J. Compos. Sci. 2025, 9, 71. https://doi.org/10.3390/jcs9020071

Pathak R, Anoop G, Samanta S. Advancements in Free-Standing Ferroelectric Films: Paving the Way for Transparent Flexible Electronics. Journal of Composites Science. 2025; 9(2):71. https://doi.org/10.3390/jcs9020071

Chicago/Turabian StylePathak, Riya, Gopinathan Anoop, and Shibnath Samanta. 2025. "Advancements in Free-Standing Ferroelectric Films: Paving the Way for Transparent Flexible Electronics" Journal of Composites Science 9, no. 2: 71. https://doi.org/10.3390/jcs9020071

APA StylePathak, R., Anoop, G., & Samanta, S. (2025). Advancements in Free-Standing Ferroelectric Films: Paving the Way for Transparent Flexible Electronics. Journal of Composites Science, 9(2), 71. https://doi.org/10.3390/jcs9020071