Comparative Analysis of Wood Waste Species on the Mechanical Performance of Sustainable Cement-Based Mortars

Abstract

1. Introduction

- Wood Waste Characteristics and Sources

- Influence of Wood Species on Composite Behavior

- Research Aim and Scope

2. Materials and Methods

2.1. The Materials Used

2.2. Experimental Procedures

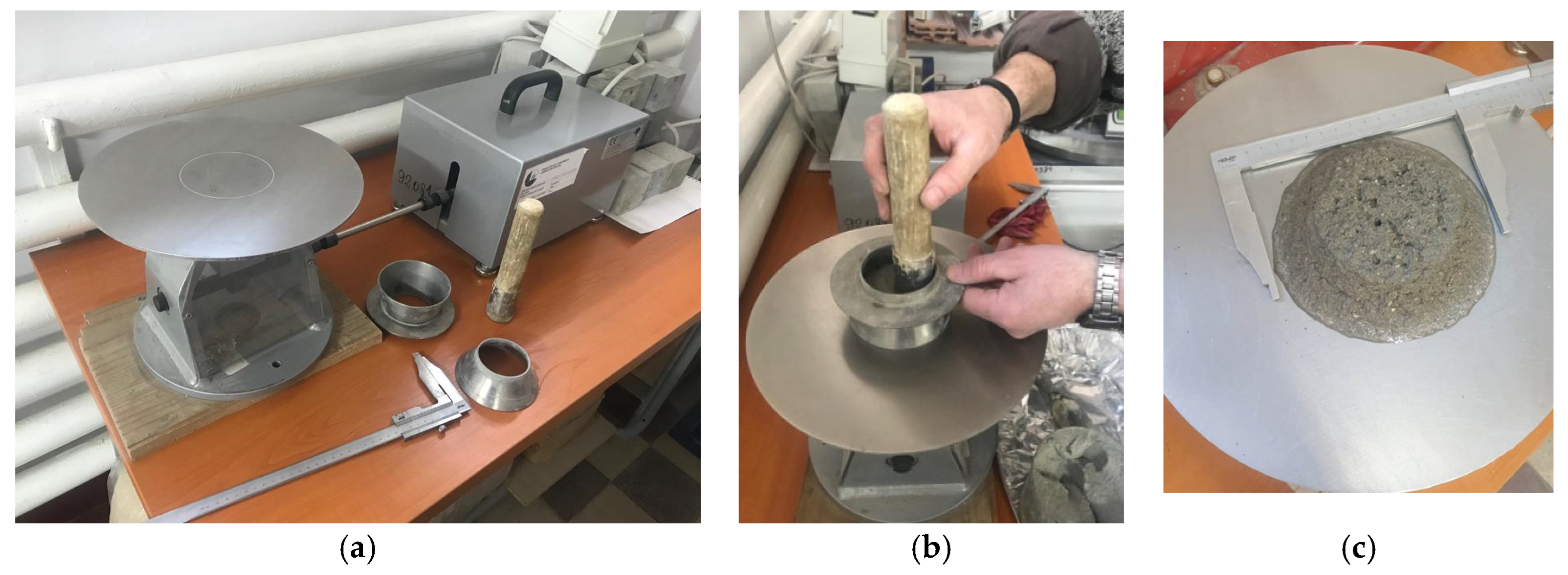

- Determination of fresh mortar properties

- Sample Preparation and Curing

- Flexural Strength Test

- Determination of compressive strength

3. Results and Discussion

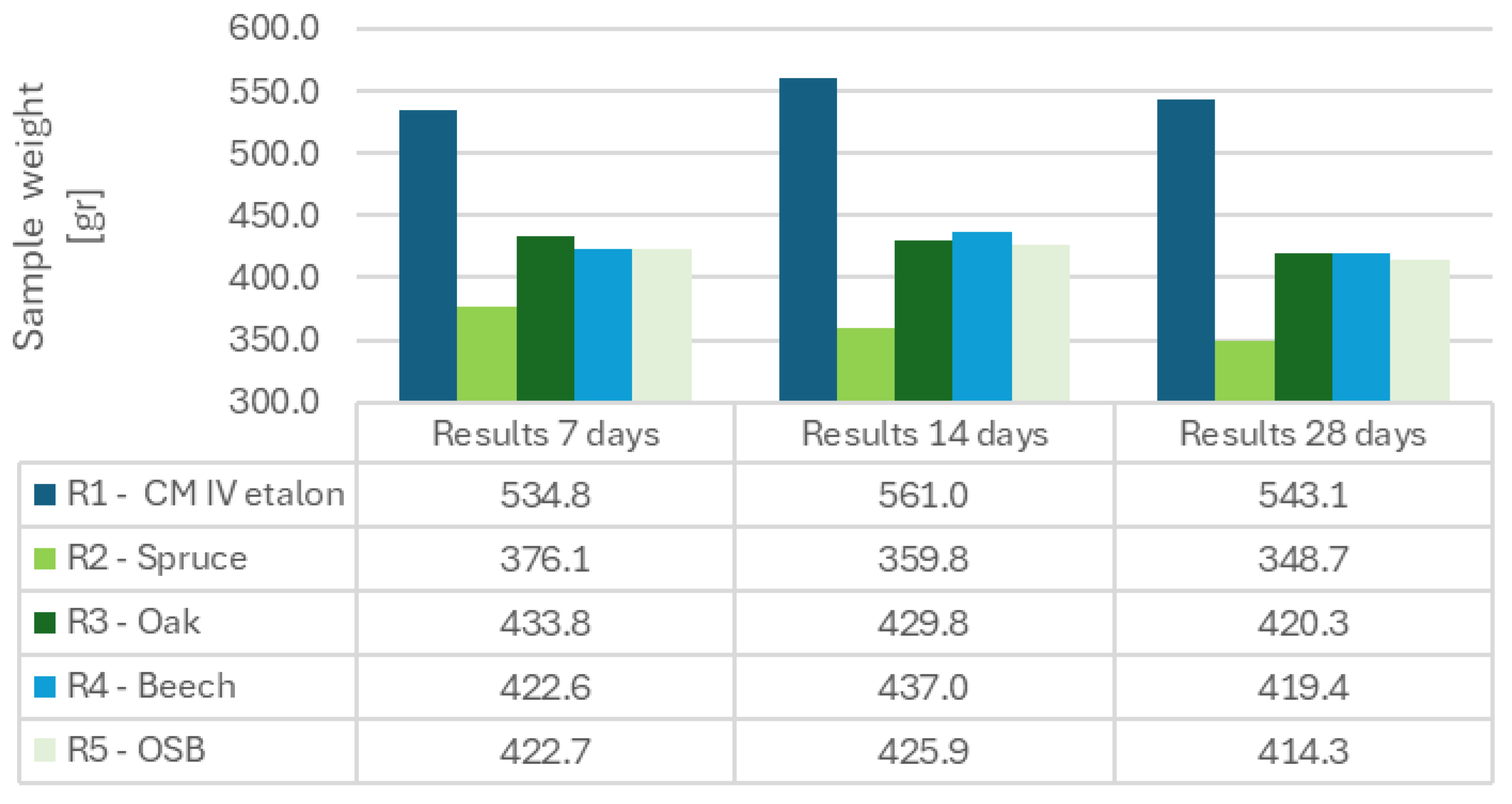

3.1. Weight and Density Evolution

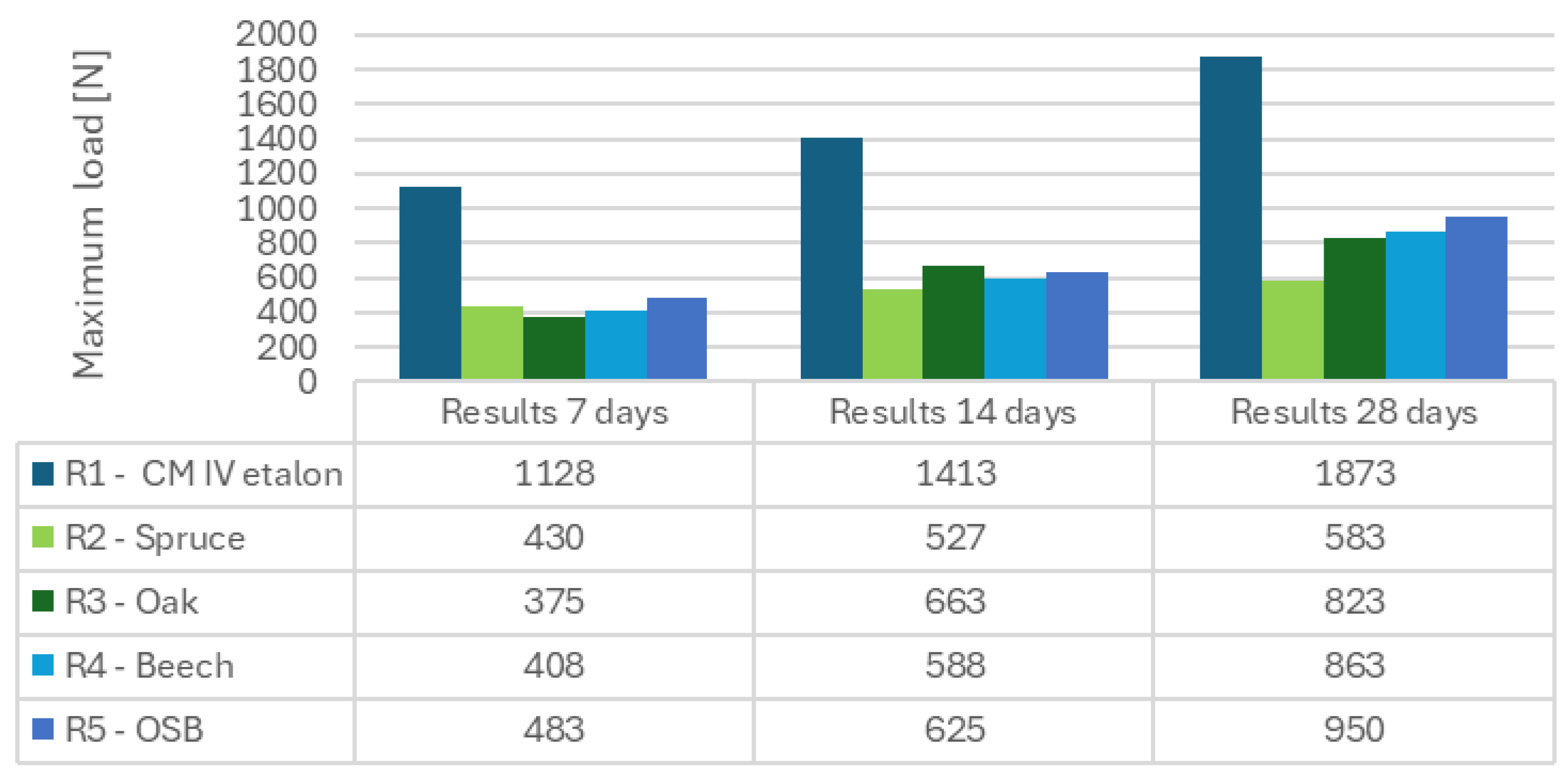

3.2. Flexural Strength

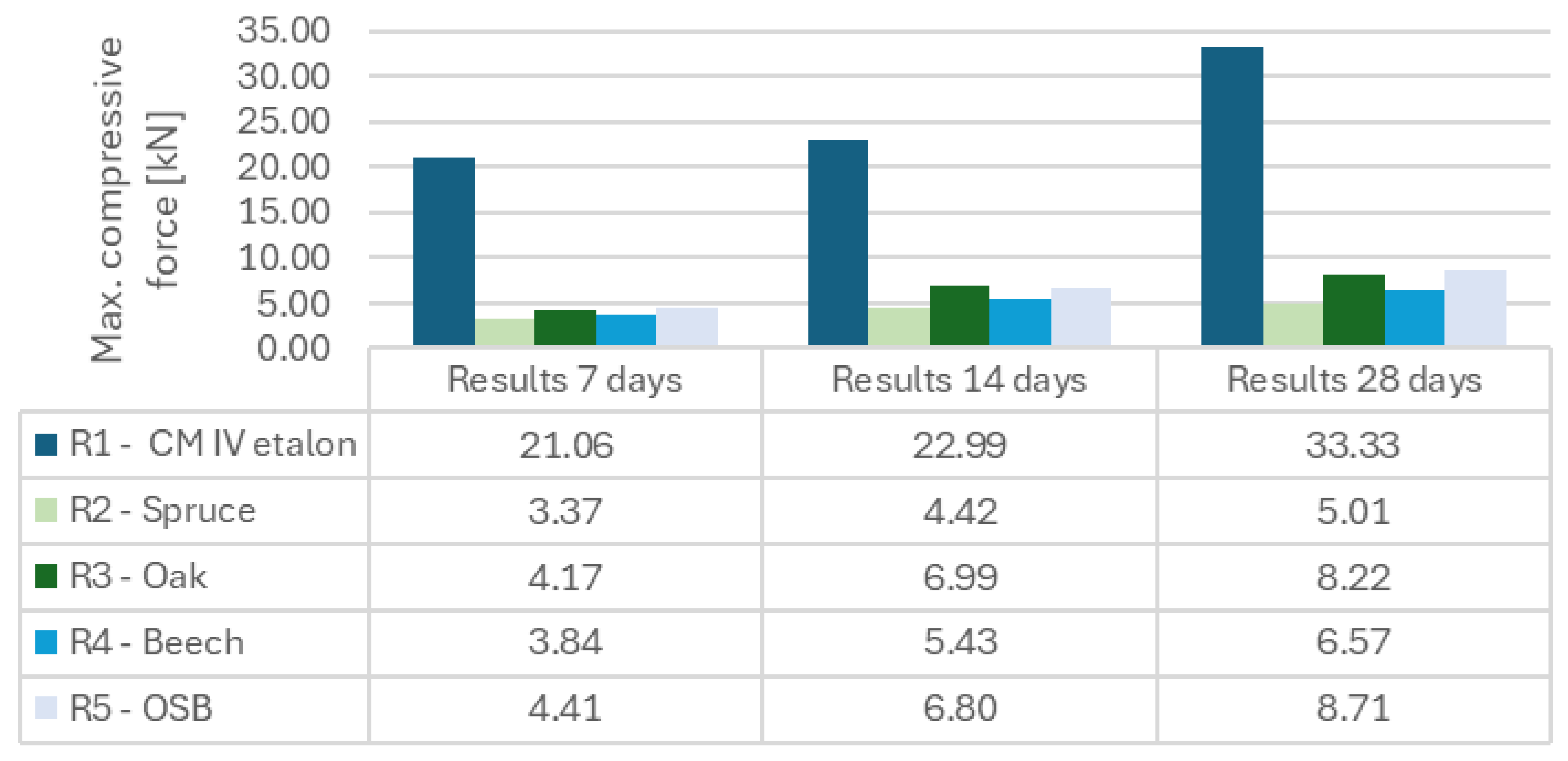

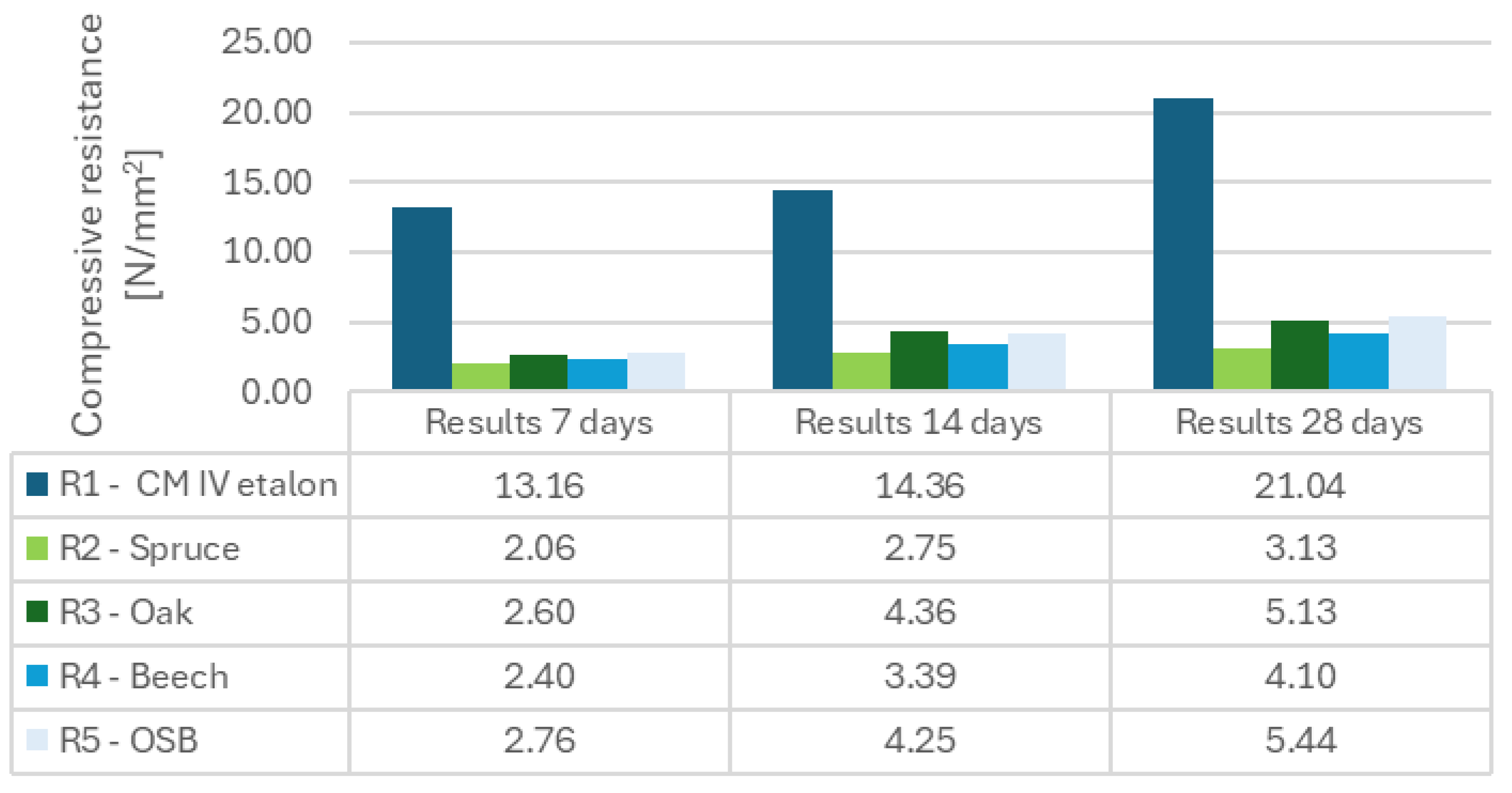

3.3. Compressive Strength

3.4. Comparative Analysis and Mechanistic Interpretation

4. Conclusions

- Density and weight reduction: The incorporation of wood residues decreased density by 20–36% and compressive strength by 70–85%, confirming that mechanical performance is species-dependent.

- Flexural strength behavior: The results indicate that the use of denser wood residues (oak, OSB) is associated with higher strength retention in the composite and improved bonding and strength retention, while low-density spruce particles increased porosity and mass loss. Beech specimens, despite an intermediate density, showed the highest flexural strength among wood-modified mortars, indicating their potential suitability for applications where bending resistance is prioritized.

- Compressive strength performance: Beech presented intermediate density but the highest flexural strength, suggesting advantages for bending-dominated applications.

- Comparative influence of wood species: The experimental results clearly show that the mechanical performance of wood–cement composites is strongly species-dependent. Engineered (OSB) and hardwood (oak, beech) waste exhibit superior mechanical behavior compared with softwood residues (spruce). Beech exhibited the highest flexural strength, making it more suitable for applications where bending or tensile performance dominate, such as thin panels, overlays, or pavement base layers. This finding emphasizes that not all wood waste is equally suitable for cement-based applications; species selection should be guided by density, particle morphology, and chemical compatibility with cement.

- Practical implications: Although the inclusion of wood waste leads to a reduction in mechanical strength, the resulting materials remain suitable for non-structural or lightweight applications, such as plaster mortars, prefabricated blocks, or insulating panels. The use of 5% wood waste also contributes to waste valorization and the principles of the circular economy by reducing the consumption of natural aggregates.

- Future work: The correlations established in this study suggest that mechanisms such as variations in interfacial bonding, matrix porosity due to water absorption, and potential chemical interactions are likely responsible for the performance differences. However, direct microstructural validation is required to confirm these hypotheses. Future work will therefore employ techniques such as Scanning Electron Microscopy (SEM) and Mercury Intrusion Porosimetry (MIP) to quantitatively analyze the wood–cement interface and pore structure. Such analyses are currently being planned as part of an extended study using SEM imaging and XRD phase identification on the same materials, to verify whether the hypothesized mechanisms—related to hydration inhibition, pore morphology, and particle–matrix bonding—can be experimentally confirmed. This will provide the microstructural evidence required to support the macroscopic trends described in this paper.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- WEF. Cement Is a Big Problem for the Environment. Here’s How to Make It More Sustainable. World Economic Forum. Available online: https://www.weforum.org/stories/2024/09/cement-production-sustainable-concrete-co2-emissions/ (accessed on 11 April 2025).

- EU Council. Building Materials: Council Adopts Law for Clean and Smart Construction Products. European Council. Available online: https://www.consilium.europa.eu/en/press/press-releases/2024/11/05/building-materials-council-adopts-law-for-clean-and-smart-construction-products/ (accessed on 13 April 2025).

- CDRA. Wood Waste. Construction & Demolition Recycling Association. Available online: https://www.cdrecycling.org/wood (accessed on 8 April 2025).

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Leone, R.; Campisi, T.; Saeli, M. Wood Industry Wastes Valorisation and Reuse for a Greener Architecture. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2025; Volume 611 LNCE, pp. 439–455. [Google Scholar] [CrossRef]

- Liang, H.; Liu, H.; Bian, X.; Wang, Y.; Dong, L. Supporting zero-waste building: A novel spatial explicit material flow analysis model for construction waste. J. Clean. Prod. 2024, 456, 142369. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, B.; Lu, W.; Peng, Z. Carbon footprint accounting across the construction waste lifecycle: A critical review of research. Environ. Impact Assess. Rev. 2024, 107, 107551. [Google Scholar] [CrossRef]

- Maier, D. A Review of the Environmental Benefits of Using Wood Waste and Magnesium Oxychloride Cement as a Composite Building Material. Materials 2023, 16, 1944. [Google Scholar] [CrossRef] [PubMed]

- Leone, R.; La Scalia, G.; Saeli, M. A critical review on reuse potentials of wood waste for innovative products and applications: Trends and future challenges. Sustain. Futures 2025, 10, 100869. [Google Scholar] [CrossRef]

- Farjana, S.H.; Tokede, O.; Tao, Z.; Ashraf, M. Life cycle assessment of end-of-life engineered wood. Sci. Total Environ. 2023, 887, 164018. [Google Scholar] [CrossRef] [PubMed]

- Maier, A.; Dan, H. Influence of the marketing innovation on the organizational performance. Int. J. Adv. Eng. Manag. Res. 2018, 3, 182–192. [Google Scholar]

- Ouellet-Plamondon, C.M.; Ramseier, L.; Balouktsi, M.; Delem, L.; Foliente, G.; Francart, N.; Garcia-Martinez, A.; Hoxha, E.; Lützkendorf, T.; Rasmussen, F.N.; et al. Carbon footprint assessment of a wood multi-residential building considering biogenic carbon. J. Clean. Prod. 2023, 404, 136834. [Google Scholar] [CrossRef]

- Farjana, S.H.; Tokede, O.; Ashraf, M. Environmental Impact Assessment of Waste Wood-to-Energy Recovery in Australia. Energies 2023, 16, 4182. [Google Scholar] [CrossRef]

- de la Caba, K.; Guerrero, P.; del Rio, M.; Mondragon, I. Weathering behaviour of wood-faced construction materials. Constr. Build. Mater. 2007, 21, 1288–1294. [Google Scholar] [CrossRef]

- Bartolucci, B.; De Rosa, A.; Bertolin, C.; Berto, F.; Penta, F.; Siani, A.M. Mechanical properties of the most common European woods: A literature review. Frat. Integrita Strutt. 2020, 14, 249–274. [Google Scholar] [CrossRef]

- Ziaee, S.; Kerr-Anderson, E.; Johnson, A.; Eastep, D.; Abdel-Magid, B. Effect of High Fiber Content on Properties and Performance of CFRTP Composites. J. Compos. Sci. 2024, 8, 364. [Google Scholar] [CrossRef]

- Mazloomi, M.S.; He, W.; Evans, P.D. Finite Element Modelling of the Effect of Adhesive Z-Connections on the Swelling of a Laminated Wood Composite. J. Compos. Sci. 2023, 7, 442. [Google Scholar] [CrossRef]

| Wood Type/Product | Density (kg/m3) | Compressive Strength (MPa) | Modulus of Elasticity (MPa) | Waste Characteristics | Potential in Cement Composites |

|---|---|---|---|---|---|

| Spruce (softwood) | ~450 | 40–45 | 9000–12,000 | Light, porous sawdust/shavings | Low-density composites, risk of higher water absorption |

| Oak (hardwood) | 650–750 | 60–65 | 12,000–14,000 | Dense, heavy sawdust, offcuts | Higher strength potential, slower hydration |

| Beech (hardwood) | ~700 | 55–60 | 12,000–14,000 | Dense chips, fine sawdust | Durable composites, risk of incompatibility with cement |

| OSB (engineered) | 600–650 | 35–45 (board-level) | 5000–7000 | Strands with resin content | Consistent structure, possible chemical interference |

| MDF (engineered) | 700–800 | 40–50 (board-level) | 4000–6000 | Fine fibers with adhesives | Homogeneous mixes, environmental concerns |

| Receipt | Water Cement Ratio | Wood Waste (%) | Consistency |

|---|---|---|---|

| R1_CS IV—reference | 0.74 | 0 | 11 |

| R2_Spruce | 1.57 | 5 | 8.5 |

| R3_Oak | 1.30 | 5 | 9 |

| R4_Beech | 1.29 | 5 | 9 |

| R5_OSB | 1.3 | 5 | 9 |

| R6_Spruce shavings | 1.73 | 5 | 6 |

| Recipes | Weight at 28 Days (g) | Flexural Strength (N) | Compressive Strength (N/mm2) | Reduction vs. Reference (%) | Comments |

|---|---|---|---|---|---|

| R1—Control | 543.1 | 1873 | 21.03 | — | Reference sample |

| R2—Spruce | 348.7 | 583 | 3.13 | −70 to −85 | Lowest strength and density |

| R3—Oak | 420.3 | 823 | 5.13 | −55 to −76 | Good performance among hardwoods |

| R4—Beech | 419.4 | 863 | 4.10 | −54 to −80 | Moderate strength, good balance |

| R5—OSB | 414.3 | 950 | 5.44 | −49 to −74 | Best performance among wood waste |

| R6—Spruce shavings | 349.8 | 367 | 1.51 | −80 to −93 | Poor consistency and strength |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maier, D.; Manea, D.L.; Tămaș-Gavrea, D.-R.; Țiriac, A.; Costin, P. Comparative Analysis of Wood Waste Species on the Mechanical Performance of Sustainable Cement-Based Mortars. J. Compos. Sci. 2025, 9, 634. https://doi.org/10.3390/jcs9110634

Maier D, Manea DL, Tămaș-Gavrea D-R, Țiriac A, Costin P. Comparative Analysis of Wood Waste Species on the Mechanical Performance of Sustainable Cement-Based Mortars. Journal of Composites Science. 2025; 9(11):634. https://doi.org/10.3390/jcs9110634

Chicago/Turabian StyleMaier, Dorin, Daniela Lucia Manea, Daniela-Roxana Tămaș-Gavrea, Alexandra Țiriac, and Paul Costin. 2025. "Comparative Analysis of Wood Waste Species on the Mechanical Performance of Sustainable Cement-Based Mortars" Journal of Composites Science 9, no. 11: 634. https://doi.org/10.3390/jcs9110634

APA StyleMaier, D., Manea, D. L., Tămaș-Gavrea, D.-R., Țiriac, A., & Costin, P. (2025). Comparative Analysis of Wood Waste Species on the Mechanical Performance of Sustainable Cement-Based Mortars. Journal of Composites Science, 9(11), 634. https://doi.org/10.3390/jcs9110634