EB Radiation Processing of HDPE/Rice Husk Ash Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Measurements

2.3.1. Differential Scanning Calorimetry (DSC)

2.3.2. Crystallinity Degree

2.3.3. Gel Fraction

2.3.4. Mechanical Tests

2.4. Statistical Analysis

3. Results

3.1. Simultaneous TGA/DSC Analysis and Crystallinity Degree

3.2. Gel Fraction

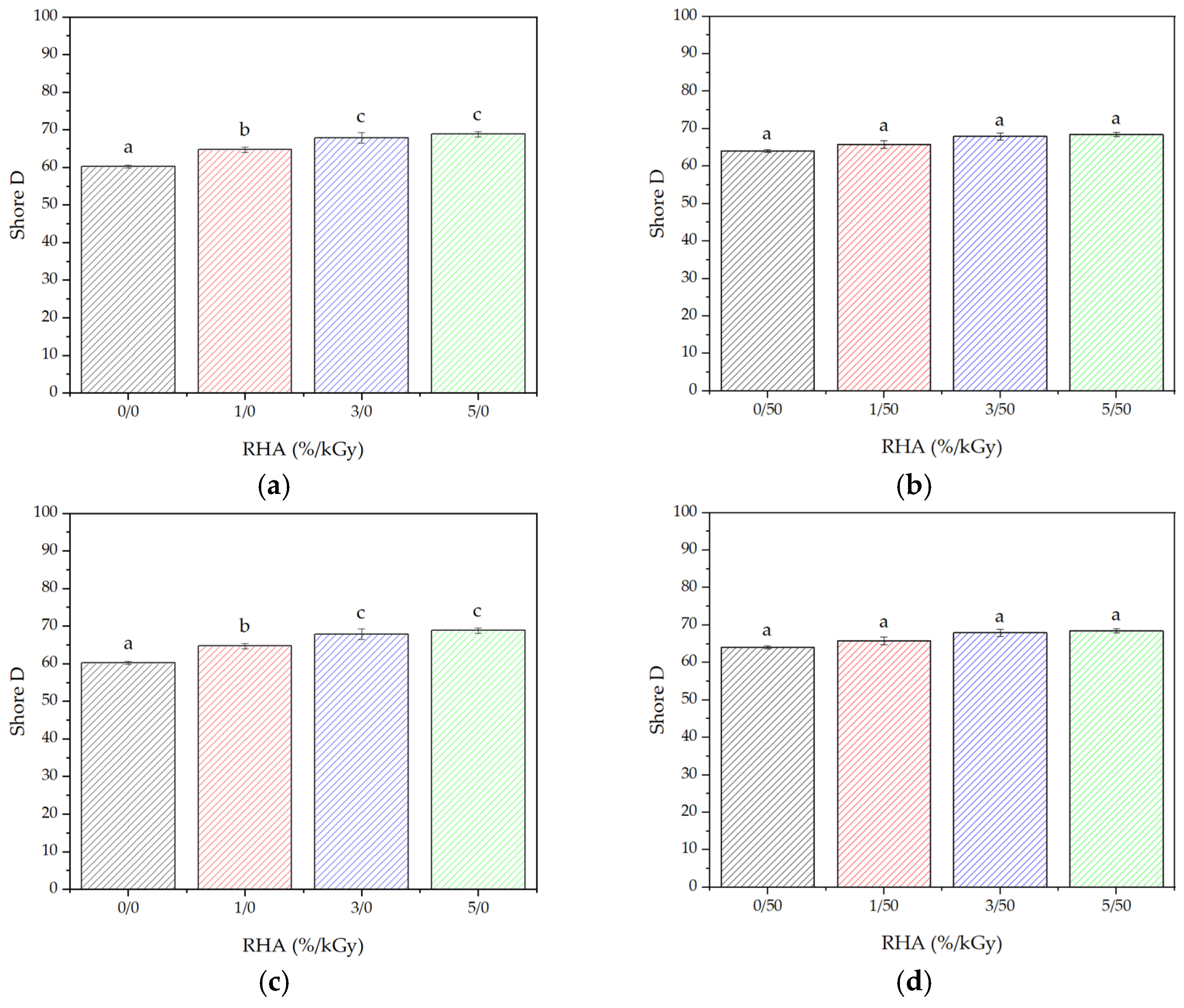

3.3. Mechanical Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American standards for testing and materials |

| BDDA | 1,4-butanediol diacrylate |

| Dynamitron | Electrostatic particle accelerator |

| EB | Electron beam |

| FTIR | Fourier transform infrared spectroscopy |

| HDPE | High-density polyethylene |

| Hm | Fusion heat |

| ΔH | Phase transition enthalpy |

| ICPE CA | Institute for Electrical Engineering, Advanced Research |

| IPEN/CNEN | Research Institute for Nuclear Energy/National Commission of Nuclear Energy |

| kGy | Kilogray |

| MFI | Melt flow index |

| SEM | Scanning electron microscopy |

| SiO2 | Silicon dioxide (silica) |

| RH | Rice husk |

| RHA | Rice husk ash |

| TGA/DSC | Thermogravimetric analysis/differential scanning calorimetry |

| Ti | Fusion temperature |

| Tm | Melting temperature |

| Xc | Crystallinity percentage |

| Xg | Gel content |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

References

- Kumar, S.; Panda, A.; Singh, R. A review on tertiary recycling of high-density polyethylene to fuel. Resour. Conserv. Recycl. 2011, 55, 893–910. [Google Scholar] [CrossRef]

- Ayswarya, E.; Francis, K.; Renju, V.; Thachil, E. Rice husk ash—A valuable reinforcement for high density polyethylene. Mater. Design. 2012, 41, 1–7. [Google Scholar] [CrossRef]

- Rigail-Cedeño, A.; Lazo, M.; Gaona, J.; Delgado, J.; Tapia-Bastidas, C.V.; Rivas, A.I.; Adrián, E.; Perugachi, R. Processability and physical properties of compatibilized recycled HDPE/rice husk biocomposites. J. Manufact. Mater. Proc. 2022, 6, 67. [Google Scholar] [CrossRef]

- Shah, A.; Jalil, A.; Sadiq, A.; Alzaid, M.; Naseem, M.S.; Alanazi, R.; Alanazi, S.; Alanzy, A.; Alsohaimi, I.; Malik, R. Effect of rice husk and wood flour on the structural, mechanical, and fire-retardant characteristics of recycled high-density polyethylene. Polymers 2023, 15, 4031. [Google Scholar] [CrossRef]

- Kholodkova, E.M.; Vcherashnyaya, A.S.; Bludenko, A.B.; Chulkov, V.N.; Ponomarev, A.V. Radiation-thermal approaches to the processing of complex polymer waste. Radiat. Phys. Chem. 2020, 170, 108664. [Google Scholar] [CrossRef]

- Sirin, M.; Zeybek, M.S.; Sirin, K.; Abali, Y. Effect of gamma irradiation on the thermal and mechanical behaviour of polypropylene and polyethylene blends. Radiat. Phys. Chem. 2022, 194, 110034. [Google Scholar] [CrossRef]

- Fel, E.; Khrouz, L.; Massardier, V.; Cassagnau, P.; Bonneviot, L. Comparative study of gamma-irradiated PP and PE polyolefins part 2: Properties of PP/PE blends obtained by reactive processing with radicals obtained by high shear or gamma-irradiation. Polymer 2016, 82, 217–227. [Google Scholar] [CrossRef]

- Chen, R.; Ab Ghani, M.; Ahmad, S.; Tarawneh, M.; Gan, S. Tensile, thermal degradation and water diffusion behaviour of gamma-radiation induced recycled polymer blend/rice husk composites: Experimental and statistical analysis. Compos. Sci. Technol. 2021, 207, 108748. [Google Scholar] [CrossRef]

- Alfaro, E.; Dias, D.; Silva, L. The study of ionizing radiation effects on polypropylene and rice husk ash composite. Radiat. Phys. Chem. 2013, 84, 163–165. [Google Scholar] [CrossRef]

- Góra, M.; Tranchida, D.; Albrecht, A.; Alejandro, J.; Müller, A.J.; Cavallo, D. A novel approach for accurate determination of polyethylene and polypropylene content in polyolefin blends and recyclates by cross-fractionation chromatography. Polym. Test. 2024, 131, 108351. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Mao, Z.; Zhao, W. Effects of gamma radiation on the impact strength of polypropylene (PP)/high density polyethylene (HDPE) blends. Results Phys. 2019, 12, 2169–2174. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Kalloudis, M.; Koutsos, V. High-density polyethylene–polypropylene blends: Examining the relationship between nano/microscale phase separation and thermomechanical properties. Polymers 2025, 17, 166. [Google Scholar] [CrossRef]

- Bansal, N.; Arora, S. Exploring the impact of gamma rays and electron beam irradiation on physico-mechanical properties of polymers & polymer composites: A comprehensive review. Nucl. Instrum. Phys. Res. 2024, 549, 165297. [Google Scholar] [CrossRef]

- Ferry, M.; Ngono-Ravache, Y.; Aymes-Chodur, C.; Clochard, M.C.; Coqueret, X.; Cortella, L.; Pellizzi, E.; Rouif, S.; Esnouf, S. Ionizing Radiation Effects in Polymers. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Zaharescu, T.; Lugao, A.B. Stability improvement of irradiated polymer composites by inorganic compounds—A pertinent solution with respect to phenolic antioxidants. J. Comp. Sci. 2025, 9, 47. [Google Scholar] [CrossRef]

- Nezafat, P.; Jafari, S.; Khonakdar, H.; Gohs, U.; Jehnichen, D. Experimental analysis and mechanical modeling of effect of stress-relaxation on shape memory and recovery behavior of e-beam irradiated HDPE. Radiat. Phys. Chem. 2020, 168, 108568. [Google Scholar] [CrossRef]

- Ortiz, A.; Teixeira, J.; Gomes, M.; Oliveira, R.; Díaz, F.; Moura, E. Preparation and characterization of electron-beam treated HDPE composites reinforced with rice husk ash and Brazilian clay. Appl. Surf. Sci. 2014, 310, 331–335. [Google Scholar] [CrossRef]

- Mansy, M.S.; Ghobashy, M.M.; Aly, M.I. Enhancing gamma and neutron radiation shielding efficiency of LDPE/PVC polymers using cobalt, aluminum, and magnesium oxide fillers. Radiat. Phys. Chem. 2024, 222, 111862. [Google Scholar] [CrossRef]

- Thiher, N.; Schissel, S.; Jessop, J. Analysis of methods to determine G-values of monomers polymerized via ionizing radiation. Radiat Phys. Chem. 2019, 165, 108394. [Google Scholar] [CrossRef]

- Ferry, M.; Ngono, Y. Energy transfer in polymers submitted to ionizing radiation: A review. Radiat. Phys. Chem. 2021, 180, 109320. [Google Scholar] [CrossRef]

- Peralta, Y.; Molina, R.; Moreno, S. Rice husk silica: A review from conventional uses to new catalysts for advanced oxidation processes. J. Environ. Manag. 2024, 370, 122735. [Google Scholar] [CrossRef]

- Shi, Y.; Qian, M.; Wang, X.; Zhang, W.; Zhang, X.; Wang, X.; Zhu, Y. Effect of rice husk-based silica on the friction properties of high density polyethylene composites. Materials 2022, 15, 3191. [Google Scholar] [CrossRef]

- Shukla, S.; Chava, R.; Appari, S.; Bahurudeen, A.; Kuncharam, B. Sustainable use of rice husk for the cleaner production of value-added products. J. Environ. Chem. Eng. 2022, 10, 106899. [Google Scholar] [CrossRef]

- Ebtasam; Bin Hasan, M.; Nayak, R.; Milon, M.; Ali, M. Nano silica and meso silica extracted from rice husk waste utilized for enhancing leather properties. Polym. Test. 2025, 142, 108680. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Moraes, C.A.M.; Rocha, T.L.A.C.; Brehm, F.A.; Modolo, R.C.E. Characterization of rice husk ash produced using different biomass combustion techniques for energy. Fuel 2016, 165, 351–359. [Google Scholar] [CrossRef]

- ASTM D4976; Standard Specification for Polyethylene Plastics Molding and Extrusion Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2025.

- Tarani, E.; Arvanitidis, I.; Christofilos, D.; Bikiaris, D.; Chrissafis, K.; Vourlias, G. Calculation of the degree of crystallinity of HDPE/GNPs nanocomposites by using various experimental techniques: A comparative study. J. Mater. Sci. 2023, 58, 1621–1639. [Google Scholar] [CrossRef]

- Praveen, T.; Rajan, J.; Sailaja, R. Evaluation of thermal and flame properties of HDPE-MWCNT-SiO2 nanocomposites. Compos. Interfaces 2016, 24, 215–232. [Google Scholar] [CrossRef]

- Aggarwal, S.; Sajwan, M.; Singh, R. Crystallinity of HDPE Pipes by DSC, XRD and FTIR Spectroscopy—A Forensic Comparison. Indian J. Criminol. Criminal. 2008, XXIX, 141–148. [Google Scholar]

- Park, J.; Cho, I.; Gwon, S.; Lim, Y.; Nho, Y. Preparation of a high-density polyethylene (HDPE) film with a nucleating agent during a stretching process. Radiat. Phys. Chem. 2009, 78, 501–503. [Google Scholar] [CrossRef]

- ASTM D2765-16; Standard Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- Navratil, J.; Manas, M.; Mizera, A.; Bednarik, M.; Stanek, M.; Danek, M. Recycling of irradiated high-density polyethylene. Radiat. Phys. Chem. 2015, 106, 68–72. [Google Scholar] [CrossRef]

- ASTM D882-12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

- Sajwan, M.; Aggarwal, S.; Singh, R. Forensic characterization of HDPE pipes by DSC. Forensic Sci. Int. 2008, 175, 130–133. [Google Scholar] [CrossRef]

- Jin, H.; Chen, Z.; Yu, Q.; Wu, S. Compatibilization of irradiated HDPE. J. Thermoplast. Compos. Mater. 2016, 29, 904–912. [Google Scholar] [CrossRef]

- Khonakdar, H.; Jafari, S.; Wagenknecht, U.; Jehnichen, D. Effect of electron-irradiation on cross-link density and crystalline structure of low- and high-density polyethylene. Radiat. Phys. Chem. 2006, 75, 78–86. [Google Scholar] [CrossRef]

- Mao, X.; Liao, S.; Wu, M.; Wang, Z. The relationship between the crystallization of UHMWPE/HDPE injection-molded products and their frictional and mechanical properties. Polymers 2025, 320, 128092. [Google Scholar] [CrossRef]

- Zaki, M.; Elshaer, Y.; Taha, D. The alterations in high density polyethylene properties with gamma irradiation. Radiat. Phys. Chem. 2017, 139, 90–96. [Google Scholar] [CrossRef]

- Ferreira, M.; Sartori, M.; Oliveira, R.; Guven, O.; Moura, E. Short vegetal-fiber reinforced HDPE-A study of electron-beam radiation treatment effects on mechanical and morphological properties. Appl. Surf. Sci. 2014, 310, 325–330. [Google Scholar] [CrossRef]

- Cao, Z.; Daly, M.; Geever, L.; Major, I.; Higginbotham, C.; Devine, D. Synthesis and characterization of high density polyethylene/peat ash composites. Compos. Part B-Eng. 2016, 94, 312–321. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.-R.; Kang, S.-Y.; Jung, S.-T.; Nho, Y.-C.; Park, J.-S.; Lee, B.-M.; Choi, J.-H. Effect of electron beam irradiation on properties of EVA/HDPE blends with intumescent flame retardants. Radiat. Phys. Chim. 2025, 232, 112664. [Google Scholar] [CrossRef]

- Han, Y.; Xu, S.; Wang, A.; Cheng, P.; Li, J.; Shen, L.; Liu, H. Remarkable effects of silicone rubber on flame retardant property of high-density polyethylene/magnesium hydroxide composites. Polym. Degrad. Stab. 2022, 203, 110061. [Google Scholar] [CrossRef]

- Sahu, A.; Vijayvargiya, R.; Sarviya, R. Study of the Effect of UV-exposure on HDPE/Carbon Black Composite Floating Structure. J. Polym. Mater. 2022, 39, 183–193. [Google Scholar] [CrossRef]

- Hylová, L.; Manas, D.; Manas, M.; Gajzlerova, L.; Mizera, A. Local Mechanical Properties of Irradiated Cross-Linked HDPE. Mater. Technol. 2018, 52, 27–29. [Google Scholar] [CrossRef]

- Koffi, A.; Koffi, D.; Toubal, L. Mechanical properties and drop-weight impact performance of injection-molded HDPE/birch fiber composites. Polym. Test. 2021, 93, 106956. [Google Scholar] [CrossRef]

- Ejeta, L.O. Investigation of the mechanical and thermal behaviour of CS/HDPE biocomposites based on processing techniques. Clean. Circ. Bioeconomy 2024, 8, 100078. [Google Scholar] [CrossRef]

- Awan, M.; Shakoor, A.; Rehan, M.; Gill, Y. Development of HDPE composites with improved mechanical properties using calcium carbonate and NanoClay. Phys. B—Cond. Mat. 2021, 606, 412568. [Google Scholar] [CrossRef]

- Shiota, J.; Takahashi, D.; Chen, L.; Yokota, S.; Yutani, T.; Alhasan, H.; Endo, T.; Sugimoto, T.; Uetsuki, K.; Terkawi, M.A.; et al. Impact of different dosages of e-beam irradiation on mechanical strength of vitamin E-blended ultra-high-molecular-weight polyethylene and the osteolytic activities of its wear debris. Materialia 2025, 39, 102345. [Google Scholar] [CrossRef]

- Karagöz, I.; Tamer, L.; Cavusoglu, A.; Sepetcioglu, H. Investigation of mechanical, thermal, and morphological properties of walnut shell and nano clay reinforced HDPE composites. Mater. Today Commun. 2024, 41, 110905. [Google Scholar] [CrossRef]

- Vallavi, M.; Mugilan, T.; Sridhar, N. Exploring the material and mechanical characteristics of 3D printed composites utilizing nSiO2-particulate-reinforced PLA/HDPA filaments with potential applications in the medical field. Int. J. Polym. Anal. Charact. 2025, 30, 155–176. [Google Scholar] [CrossRef]

- Ayyanar, C.; Marimuthu, K.; Mohan, S.; Gayathri, B.; Bharathiraj, C.; Phiri, R.; Gapsari, F.; Setyarini, P.H.; Rangappa, S.M.; Siengchin, S. Thermoplastic bio-composites from natural Samanea Saman fillers loaded HDPE: Mechanical, thermal, and structural analysis. Results Eng. 2024, 23, 102841. [Google Scholar] [CrossRef]

- Chmielewski, A.G.; Al-Sheikhly, M.; Berejka, A.J.; Cleland, M.R.; Antoniak, M. Recent developments in the application of electron accelerators for polymer processing. Radiat. Phys. Chem. 2014, 94, 147–150. [Google Scholar] [CrossRef]

- Nabiyev, A.A.; Mustafayev, I.I.; Mehdiyeva, R.N.; Nuriyev, M.A.; Andreev, E.V.; Ponomareva, O.Y.; Azhibekov, A.K.; Doroshkevich, A.S.; Elmekawy, A.H.A.; Mirzayev, M.N.; et al. Post-γ-irradiation effects in nano-SiO2 particle reinforced high-density polyethylene composite films: Structure–property relationships, thermal stability and degradation. Polym. Compos. 2025, 46, S44–S62. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alenad, A.M.; Al-Mubaddel, F.S.; Alharbi, A.G.; Al-shehri, A.S.; Albalwi, H.A.; Alsuabie, F.M.; Hassan, F.; Mourad, A.-H.I. Impact of hybrid fillers on the properties of high density polyethylene based composites. Polymers 2022, 14, 3427. [Google Scholar] [CrossRef] [PubMed]

- Dorigato, A.; Govaert, L.E.; Pegoretti, A. Lifetime assessment of high-density polyethylene–silica nanocomposites. Nanomater. Nanotechnol. 2019, 9, 1847980419849984. [Google Scholar] [CrossRef]

- Nurhayati, C.; Susanto, T. The Effects of rice husk ashes filled recycled polyethylene composites towards physical, mechanical properties and Its degradation characteristics. In Proceedings of the International Conference on Materials and Technologies, London, UK, 5–6 October 2020. [Google Scholar]

- He, H.; Shen, X.; Nie, Z. Engineering interactions between nanoparticles using polymers. Prog. Polym. Sci. 2023, 143, 101710. [Google Scholar] [CrossRef]

- Okamoto, K.; Ganbe, T.; Nobuyuki Sekine, N.; Aoki, M.; Inutsuka, M.; Shundo, A.; Daisuke, K.; Tanaka, K. Nanoscale characterization of epoxy interface on silica. In Proceedings of the IEEE International Conference on Dielectrics, Southampton, UK, 3–7 July 2016. [Google Scholar]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, A.P.I.; Popoola, O.M. Silica nanofillers-reinforced polyimide composites for mechanical, thermal, and electrical insulation applications and recommendations: A review. In Proceedings of the 11th Global Conference on Materials Science and Engineering (CMSE 2022), Shenzhen, China, 8–11 August 2022. [Google Scholar]

- Alghamdi, R.D.; Yudhanto, A.; Lubineau, G.; Abou-Hamad, E.; Hadjichristidis, N. Polyethylene grafted silica nanoparticles via surface-initiated polyhomologation: A novel filler for polyolefin nanocomposite. Polymer 2022, 254, 125129. [Google Scholar] [CrossRef]

- Kim, M.; Hyun, K. Characterization of polyethylene/silica nanocomposites using different rheological analyses. Korea-Aust. Rheol. J. 2021, 33, 25–36. [Google Scholar] [CrossRef]

- Moradkhani, E.; Entezam, M.; Ahmadi, M.; Ali Khonakdar, H.; Ruckdäschel, H.; Altstaedt, V. Irradiation processing to modify HDPE molecular architecture: Correlation with irradiation conditions and polymer grade. Mater. Today Commun. 2022, 11, 103462. [Google Scholar] [CrossRef]

- Al-Ghamdi, H.; Farah, K.; Almuqrin, A.; Hosni, F. FTIR study of gamma and electron irradiated high-density polyethylene for high dose measurements. Nucl. Eng. Technol. 2022, 54, 255–261. [Google Scholar] [CrossRef]

- Nabiyev, A.A.; Olejniczak, A.; Islamov, A.K.; Pawlukojc, A.; Ivankov, O.I.; Balasoiu, M.; Alexander Zhigunov, A.; Nuriyev, M.A.; Guliyev, F.V.; Soloviov, D.V.; et al. Composite films of HDPE with SiO2 and ZrO2 nanoparticles: The structure and interfacial effects. Nanomaterials 2021, 11, 2673. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.L.; Gandla, K.; Kakaravada, I.; Rao, P.B.B.; Vinukonda, A.; Hasan, H.G.; Hussain, Z.; Sheikh, A.A. Silica-polymer composites for biomedical applications. In Fiber and Ceramic Filler-Based Polymer Composites for Biomedical Engineering; Parameswaranpillai, J., Ganguly, S., Das, P., Gopi, J.A., Eds.; Springer: Singapore, 2024; pp. 109–142. [Google Scholar]

- Syed, T.R.; Sharaby, M.R.; Salmieri, S.; Lacroix, M. Innovations in active food packaging: Harnessing waste valorization and irradiation-assisted functionalization for sustainable food preservation. Trends Food Sci. Technol. 2025, 163, 105183. [Google Scholar] [CrossRef]

- Tanaka, T. Aging of polymeric and composite insulating materials. Aspects of interfacial performance in aging. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 704–716. [Google Scholar] [CrossRef]

- Ali, N.; Bilal, M.; Khaan, A.; Nguyen, T.A.; Gupta, R.K. Smart Polymer Nanocomposites; Elsevier: London, UK, 2023. [Google Scholar]

| Concentration (wt%) | ||||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | K2O | CaO | Cl | P2O5 |

| 90.02 | 0.08 | 0.01 | 0.81 | 0.00 | 0.03 | 0.34 |

| MgO | SO3 | TiO2 | ZnO | MnO | LOI * | TC ** |

| ND *** | 0.07 | ND *** | 0.01 | 0.00 | 9.88 | 8.63 |

| Specific Weight (g cm−3) | Surface Area (m2 g−1) | Mean Particle Diameter (Retained Fraction, µm) |

|---|---|---|

| 2.20 | 39.27 | 19.74 |

| RHA (%) | 0 kGy | 50 kGy | 75 kGy | 100 kGy |

|---|---|---|---|---|

| 0 | 0/0 | 0/50 | 0/75 | 0/100 |

| 1 | 1/0 | 1/50 | 1/75 | 1/100 |

| 3 | 3/0 | 3/50 | 3/75 | 3/100 |

| 5 | 5/0 | 5/50 | 5/75 | 5/100 |

| Samples (%/kGy) * | Tf (°C) | ΔHf (J g−1) | % Xc |

|---|---|---|---|

| 0/0 | 132.41 | 146.5 | 50 |

| 1/0 | 119.84 | 106.5 | 36.35 |

| 3/0 | 116.81 | 112.2 | 38.29 |

| 5/0 | 117.53 | 110.3 | 37.64 |

| 0/50 | 115.81 | 112.8 | 38.50 |

| 1/50 | 116.29 | 103.1 | 35.18 |

| 3/50 | 116.51 | 90.92 | 31.03 |

| 5/50 | 116.37 | 141.1 | 48.15 |

| 0/75 | 117.59 | 115.4 | 39.38 |

| 1/75 | 116.60 | 133.9 | 45.70 |

| 3/75 | 120.16 | 105.8 | 36.11 |

| 5/75 | 115.94 | 106.1 | 36.21 |

| 0/100 | 116.82 | 131.5 | 44.88 |

| 1/100 | 118.01 | 134.6 | 45.94 |

| 3/100 | 118.56 | 132.6 | 45.25 |

| 5/100 | 116.03 | 116.2 | 39.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, M.E.M.; Zaharescu, T.; Harada, J.; de Castro, D.P.; de Andrade e Silva, L.G. EB Radiation Processing of HDPE/Rice Husk Ash Composites. J. Compos. Sci. 2025, 9, 601. https://doi.org/10.3390/jcs9110601

dos Santos MEM, Zaharescu T, Harada J, de Castro DP, de Andrade e Silva LG. EB Radiation Processing of HDPE/Rice Husk Ash Composites. Journal of Composites Science. 2025; 9(11):601. https://doi.org/10.3390/jcs9110601

Chicago/Turabian Styledos Santos, Maria Elizabeth Maués, Traian Zaharescu, Júlio Harada, Dione Pereira de Castro, and Leonardo Gondim de Andrade e Silva. 2025. "EB Radiation Processing of HDPE/Rice Husk Ash Composites" Journal of Composites Science 9, no. 11: 601. https://doi.org/10.3390/jcs9110601

APA Styledos Santos, M. E. M., Zaharescu, T., Harada, J., de Castro, D. P., & de Andrade e Silva, L. G. (2025). EB Radiation Processing of HDPE/Rice Husk Ash Composites. Journal of Composites Science, 9(11), 601. https://doi.org/10.3390/jcs9110601