Conductive Polymer-Based Thermoelectric Composites: Preparation, Properties, and Applications

Abstract

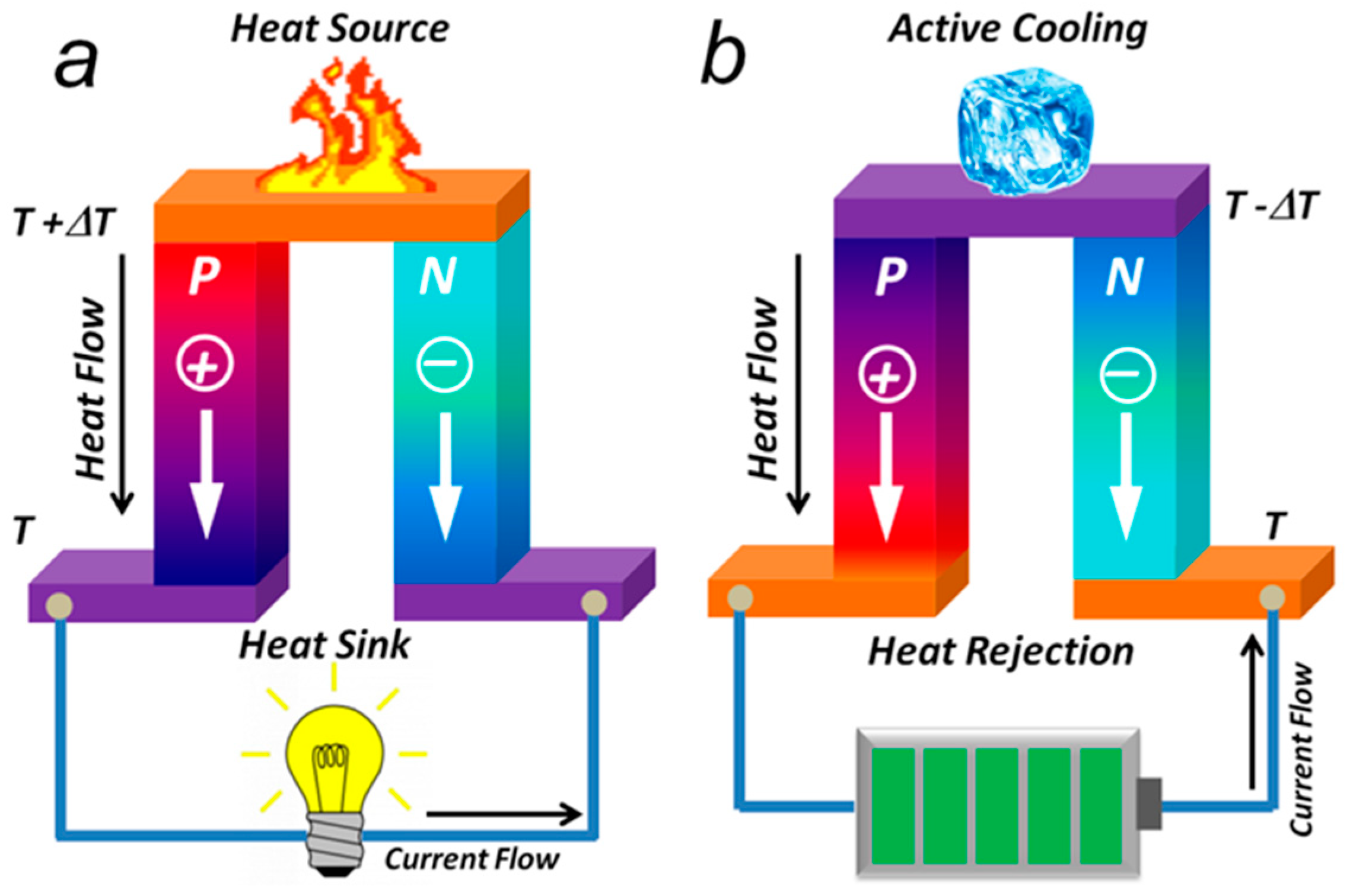

1. Introduction

2. Preparation Method of Conductive Polymer-Based Composite Materials

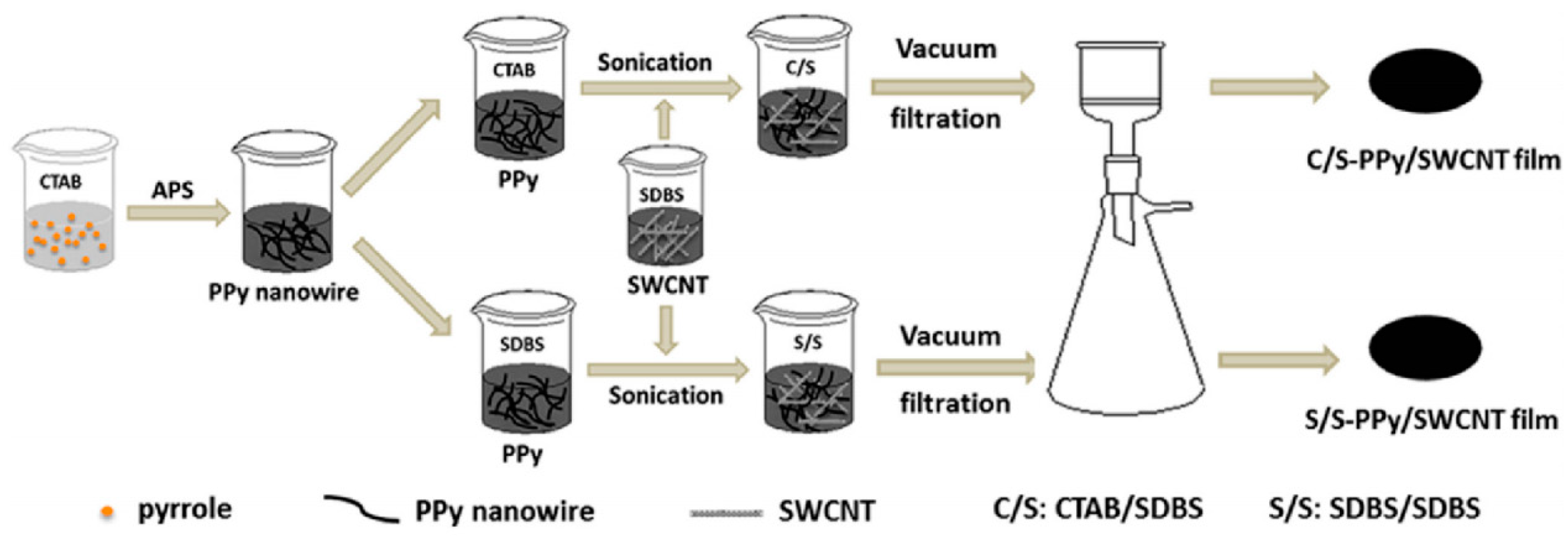

2.1. Physical Mixing

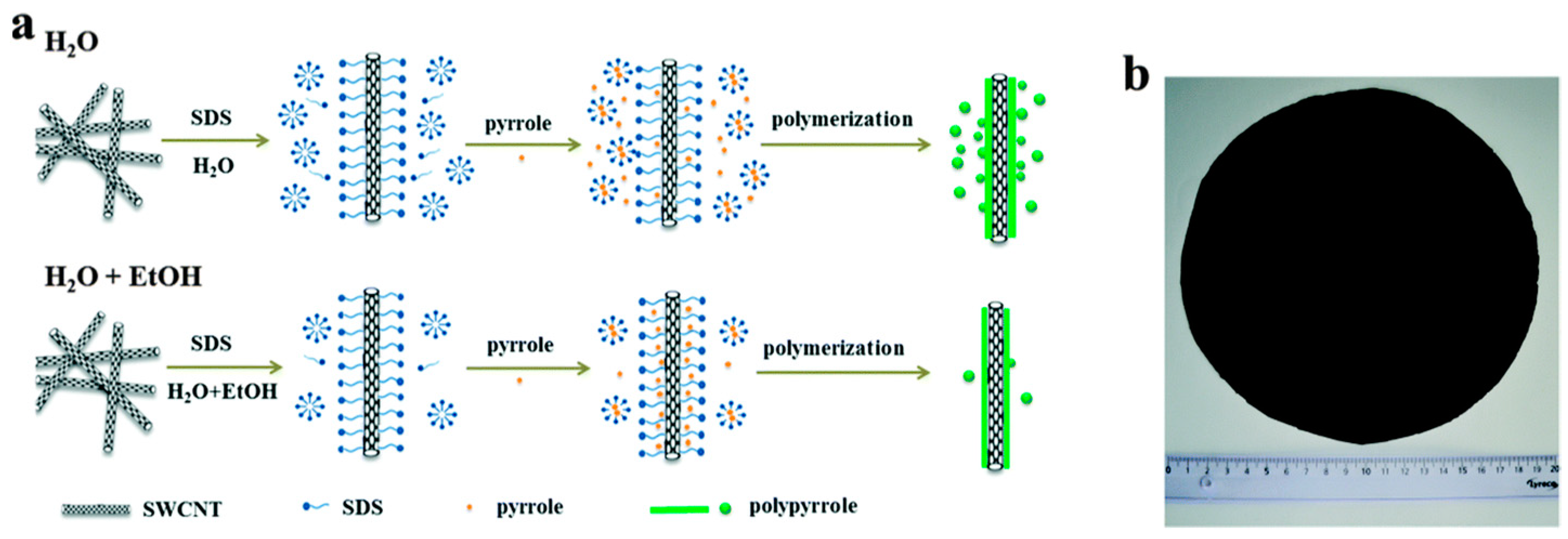

2.2. In Situ Polymerization/Reaction

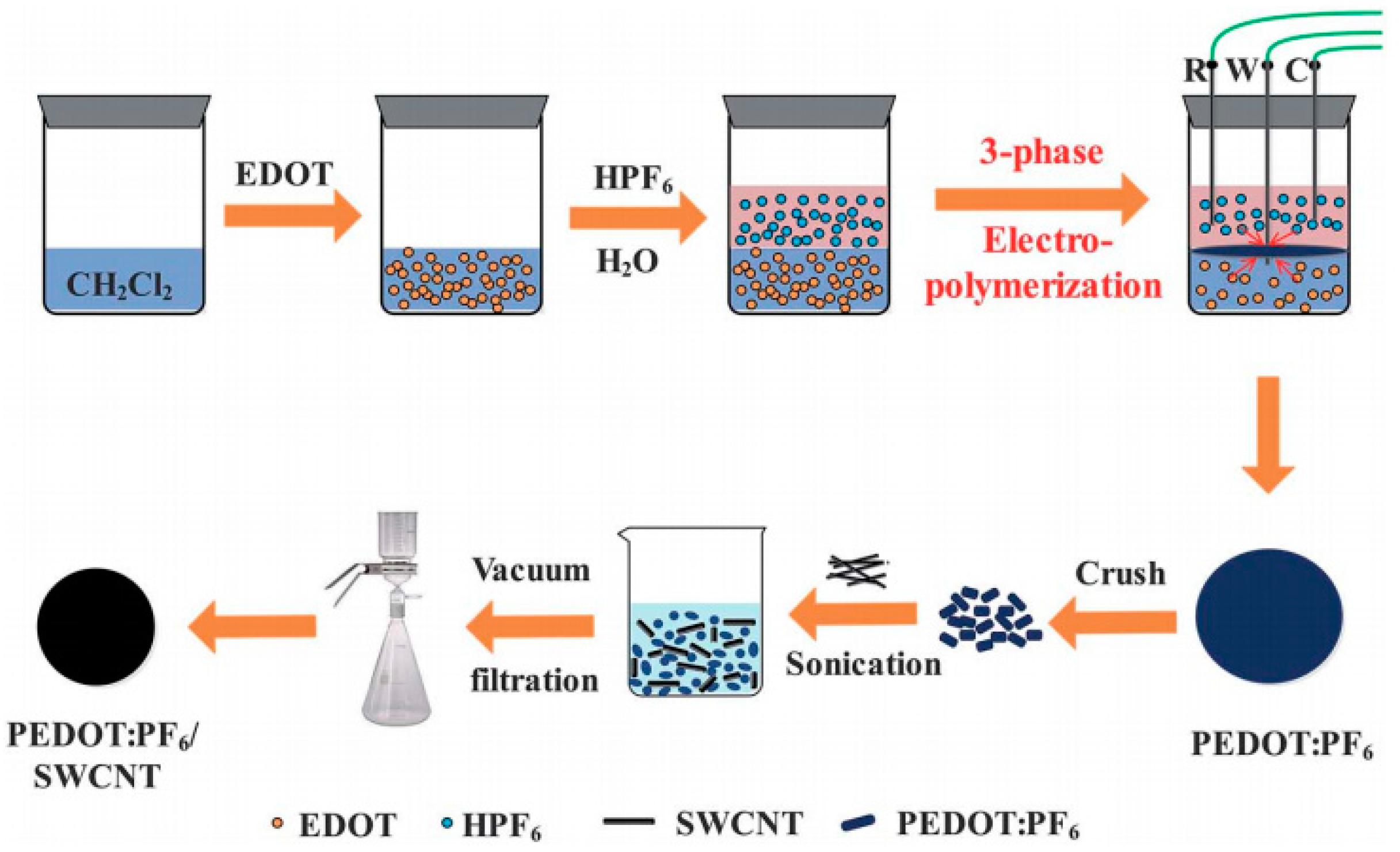

2.3. Electrochemical Polymerization/Deposition

2.4. Other Preparation Methods

2.4.1. Microwave Plasma

2.4.2. Sequential Infiltration Synthesis

2.4.3. Layer-by-Layer Assembly

| Composites | Preparation Method | σ S cm−1 | S μV K−1 | PF μW m−1 K−2 | ZT | Ref. |

|---|---|---|---|---|---|---|

| PPy/SWCNT (SWCNT: PPy mass ratio is 60 wt%) | Physical mixing | - | - | 21.7 ± 0.8 | - | [33] |

| PANI/Te (70%) | Physical mixing | - | - | 105 | - | [35] |

| PEDOT/PSS/SWCNT (35 wt% SWCNT) | Physical mixing | - | - | - | 0.02 | [31] |

| BST NS/PEDOT: PSS (4.1 wt% BST NS) | Physical mixing | 1295.21 | - | ∼32.26 | - | [38] |

| PE/PEDOT/SWCNT (20 wt% PE) | Physical mixing | - | - | 158.81 ± 8.83 | - | [39] |

| PPy/MWCNT (20 wt% MWCNT) | In situ polymerization | - | - | 2.079 | - | [41] |

| PPy/MWCNT (68 wt% MWCNT) | In situ polymerization | 39.4 | 24.4 | 2.2 | - | [42] |

| PPy/MWCNT (14.6 wt% MWCNT) | In situ polymerization | - | - | 0.77 | 1 × 10−3 | [43] |

| PANI/SWCNT | In situ polymerization | - | - | 407 | - | [44] |

| Poly(ANi-co-Py)/SWCNT (60 wt% SWCNT) | Electrochemical polymerization | 1035.3 ± 9.0 | 33.0 ± 3.2 | 83.2 ± 3.3 | - | [49] |

| Poly(ANi-co-Py)/SWCNTs | Electrochemical polymerization | - | - | 111.4 ± 3.2 | - | [50] |

| PANI/SWCNT (50 wt% SWCNT) | Electrochemical polymerization | - | - | 236.4 ± 5.9 | - | [51] |

| PANI/MWCNT (1.5 wt% MWCNT) | Microwave plasma | 7.8 | - | - | - | [53] |

| PEDOT/SWCNT | Layer-by-layer assembly | 2100 | - | 155 | - | [55] |

2.4.4. Solvent Evaporation

3. Applications

3.1. Sensors

3.1.1. Wearable Sensor

3.1.2. Fire Warning Sensor

3.1.3. Other Types of Sensors

3.1.4. Some Special Applications of CPs-Based Composite Sensors

3.2. Supercapacitors

3.3. Other Applications of CPs-Based Composites

3.3.1. Corrosion Inhibition

3.3.2. EMI Shielding

3.3.3. Catalytic Applications

4. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Qu, L.; Liu, K.X. Mechanism and current Status of new thermoelectric materials. Elec. Eng. Mater. 2024, 2, 16–19. [Google Scholar]

- Sootsman, J.R.; Chung, D.Y.; Kanatzidis, M.G. New and old concepts in thermoelectric materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.G.; Dargusch, M.S.; Zou, J. High performance thermoelectric materials: Progress and their applications. Adv. Energy Mater. 2018, 8, 1701797. [Google Scholar] [CrossRef]

- Gao, L. Research status and latest applications of thermoelectric material. Adv. Funct. Mater. 2023, 30, 97–102. [Google Scholar]

- Du, Y.; Shen, S.Z.; Cai, K.; Casey, P.S. Research progress on polymer–inorganic thermoelectric nanocomposite materials. Prog. Polym. Sci. 2012, 37, 820–841. [Google Scholar] [CrossRef]

- Xu, Q.; Qu, S.; Ming, C.; Qiu, P.; Yao, Q.; Zhu, C.; Wei, T.-R.; He, J.; Shi, X.; Chen, L. Conformal organic–inorganic semiconductor composites for flexible thermoelectrics. Energ. Environ. Sci. 2020, 13, 511–518. [Google Scholar] [CrossRef]

- Ren, P.; Liu, Y.; He, J.; Lv, T.; Gao, J.; Xu, G. Recent advances in inorganic material thermoelectrics. Inorg. Chem. Front. 2018, 5, 2380–2398. [Google Scholar] [CrossRef]

- Hong, M.; Chen, Z.G.; Yang, L.; Zou, J. Enhancing thermoelectric performance of Bi2Te3-based nanostructures through rational structure design. Nanoscale 2016, 8, 8681–8686. [Google Scholar] [CrossRef] [PubMed]

- Park, D.; Ju, H.; Oh, T.; Kim, J. Fabrication of one-dimensional Cu2Te/Te nanorod composites and their enhanced thermoelectric properties. CrystEngComm 2019, 21, 1555–1563. [Google Scholar] [CrossRef]

- Gao, L.; Mao, X.; Zhu, H.; Xiao, W.; Gan, F.; Wang, D. Electropolymerization of PEDOT on CNTs conductive network assembled at water/oil interface. Electrochim. Acta 2014, 136, 97–104. [Google Scholar] [CrossRef]

- Du, Y.; Shi, Y.; Meng, Q.; Shen, S.Z. Preparation and thermoelectric properties of flexible SWCNT/PEDOT: PSS composite film. Synth. Met. 2020, 261, 116318. [Google Scholar] [CrossRef]

- Fan, W.; Guo, C.-Y.; Chen, G. Flexible films of poly(3,4-ethylenedioxythiophene)/carbon nanotube thermoelectric composites prepared by dynamic 3-phase interfacial electropolymerization and subsequent physical mixing. J. Mater. Chem. A 2018, 6, 12275–12280. [Google Scholar] [CrossRef]

- Chen, L.; Zhai, Y.; Ding, H.; Zhou, G.; Zhu, Y.; Hui, D. Preparation, characterization and thermoelectricity of ATT/TiO2/PANI nano-composites doped with different acids. Compos. Part B-Eng. 2013, 45, 111–116. [Google Scholar] [CrossRef]

- Cochet, M.; Maser, W.K.; Benito, A.M.; Callejas, M.A.; Martínez, M.T.; Benoit, J.-M.; Schreiber, J.; Chauvet, O. Synthesis of a new polyaniline/nanotube composite: In-situ polymerisation and charge transfer through site-selective interaction. Chem. Commun. 2001, 16, 1450–1451. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, Y.; Guo, C.-Y.; Chen, G. Toward high thermoelectric performance for polypyrrole composites by dynamic 3-phase interfacial electropolymerization and chemical doping of carbon nanotubes. Compos. Sci. Technol. 2019, 183, 107794. [Google Scholar] [CrossRef]

- Liang, L.R.; Chen, G.M.; Guo, C.Y. Polypyrrole nanostructures and their thermoelectric performance. Mater. Chem. Front. 2017, 1, 380–386. [Google Scholar] [CrossRef]

- Aghelinejad, M.; Zhang, Y.C.; Leung, S.N. Processing parameters to enhance the electrical conductivity and thermoelectric power factor of polypyrrole/multi-walled carbon nanotubes nanocomposites. Synth. Met. 2019, 247, 59–66. [Google Scholar] [CrossRef]

- He, M.; Ge, J.; Lin, Z.Q.; Feng, X.H.; Wang, X.W.; Lu, H.B.; Yang, Y.L.; Qiu, F. Thermopower enhancement in conducting polymer nanocomposites via carrier energy scattering at the organic–inorganic semiconductor interface. Energy Environ. Sci. 2012, 5, 8351–8358. [Google Scholar] [CrossRef]

- Liang, L.; Gao, C.Y.; Chen, G.M.; Guo, C.Y. Large-area, stretchable, super flexible and mechanically stable thermoelectric films of polymer/carbon nanotube composites. J. Mater. Chem. C 2016, 4, 526–532. [Google Scholar] [CrossRef]

- Bharti, M.; Singh, A.; Samanta, S.; Aswal, D.K. Conductive polymers for thermoelectric power generation. Prog. Polym. Sci. 2018, 93, 270–310. [Google Scholar] [CrossRef]

- Fan, W. Preparation and Thermoelectric Performance of poly(3,4-ethylenedioxythiophene)/Carbon Nanotube Composites. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2019. [Google Scholar]

- Park, D.; Ju, H.; Oh, T.; Kim, J. Facile fabrication of one-dimensional Te/Cu2Te nanorod composites with improved thermoelectric power factor and low thermal conductivity. Sci. Rep. 2018, 8, 18082. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.; Stevens, B.; Hsu, J.H.; Bureau, R.; Hagen, D.A.; Regev, O.; Yu, C.; Grunlan, J.C. Completely organic multilayer thin film with thermoelectric power factor rivaling inorganic tellurides. Adv. Mater. 2015, 27, 2996–3001. [Google Scholar] [CrossRef] [PubMed]

- Meng, C.; Liu, C.; Fan, S. A promising approach to enhanced thermoelectric properties using carbon nanotube networks. Adv. Mater. 2010, 22, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.M.; Zhang, Z.M.; Liu, Y.C.; Wang, B.R.; Fang, L.; Qiu, J.J.; Zhang, K.; Wang, S.R. Exceptional thermoelectric properties of flexible organic−inorganic hybrids with monodispersed and periodic nanophase. Nat. Commun. 2018, 9, 3817. [Google Scholar] [CrossRef]

- Nunna, R.; Qiu, P.F.; Yin, M.J.; Chen, H.Y.; Hanus, R.; Song, Q.F.; Zhang, T.S.; Chou, M.Y.; Agne, M.T.; He, J.Q.; et al. Ultrahigh thermoelectric performance in Cu2Se-based hybrid materials with highly dispersed molecular CNTs. Energy Environ. Sci. 2017, 10, 1928–1935. [Google Scholar] [CrossRef]

- Xiang, J.L.; Drzal, L.T. Templated growth of polyaniline on exfoliated graphene nanoplatelets (GNP) and its thermoelectric properties. Polymer 2012, 53, 4202–4210. [Google Scholar] [CrossRef]

- Zhao, Y.; Tang, G.S.; Yu, Z.Z.; Qi, J.S. The effect of graphite oxide on the thermoelectric properties of polyaniline. Carbon 2012, 50, 3064–3073. [Google Scholar] [CrossRef]

- Xu, K.L.; Chen, G.M.; Qiu, D. Convenient const construction of poly (3,4-ethylenedioxythiophene)-graphene pie-like structure with enhanced thermoelectric performance. J. Mater. Chem. A 2013, 1, 12395–12399. [Google Scholar] [CrossRef]

- Yu, C.; Choi, K.; Yin, L.; Grunlan, J.C. Light-Weight Flexible Carbon Nanotube Based Organic Composites with Large Thermoelectric Power Factors. ACS Nano 2011, 5, 7885–7892. [Google Scholar] [CrossRef]

- Kim, D.; Kim, Y.; Choi, K.; Grunlan, J.C.; Yu, C. Improved thermoelectric behavior of nanotube-filled polymer composites with poly(3,4-ethylenedioxythiophene) poly(styrenesulfonate). ACS Nano 2010, 4, 513–523. [Google Scholar] [CrossRef]

- Xiong, J.; Jiang, F.; Shi, H.; Xu, J.; Liu, C.; Zhou, W.; Jiang, Q.; Zhu, Z.; Hu, Y. Liquid exfoliated graphene as dopant for improving the thermoelectric power factor of conductive PEDOT:PSS nanofilm with hydrazine treatment. ACS Appl. Mater. Interfaces 2015, 7, 14917–14925. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Chen, G.; Guo, C.-Y. Enhanced thermoelectric performance by self-assembled layered morphology of polypyrrole nanowire/single-walled carbon nanotube composites. Compos. Sci. Technol. 2016, 129, 130–136. [Google Scholar] [CrossRef]

- Toshima, N.; Imai, M.; Ichikawa, S. Organic–inorganic nanohybrids as novel thermoelectric materials: Hybrids of polyaniline and bismuth (III) telluride nanoparticles. J. Electron. Mater. 2011, 40, 898–902. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.M.; Deng, Y. Flexible low-grade energy utilization devices based on high-performance thermoelectric polyaniline/tellurium nanorod hybrid films. J. Mater. Chem. A 2016, 4, 3554–3559. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, G.; Sheng, M.; Yu, C.; Deng, Y. Flexible thermopower generation over broad temperature range by PANI/nanorod hybrid-based p–n couples. J. Mater. Chem. A 2019, 7, 1718–1724. [Google Scholar] [CrossRef]

- Liu, F.W.; Luo, S.; Liu, D.; Chen, W.; Huang, Y.; Dong, L.; Wang, L. Facile processing of free-standing polyaniline/SWCNT film as an integrated electrode for flexible supercapacitor application. ACS Appl. Mater. Interfaces 2017, 9, 33791–33801. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Cai, K.F.; Chen, S.; Cizek, P.; Lin, T. Facile preparation and thermoelectric properties of Bi2Te3 based alloy nanosheet/PEDOT:PSS composite films. ACS Appl. Mater. Interfaces 2014, 6, 5735–5743. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yin, S.; Guo, C.-Y. Self-Healable and Robust PE/PEDOT/SWCNT Thermoelectric Composites. ACS Appl. Mater. Interfaces 2022, 14, 32056–32065. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yao, Q.; Bi, H.; Huang, F.; Wang, Q.; Chen, L. PANI/graphene nanocomposite films with high thermoelectric properties by enhanced molecular ordering. J. Mater. Chem. A 2015, 3, 7086–7092. [Google Scholar] [CrossRef]

- Wang, J.; Cai, K.; Shen, S.; Yin, J. Preparation and thermoelectric properties of multi-walled carbon nanotubes/polypyrrole composites. Synth. Met. 2014, 195, 132–136. [Google Scholar] [CrossRef]

- Song, H.J.; Cai, K.; Wang, J.; Shen, S. Influence of polymerization method on the thermoelectric properties of multi-walled carbon nanotubes/polypyrrole composites. Synth. Met. 2016, 211, 58–65. [Google Scholar] [CrossRef]

- Baghdadi, N.; Zoromba, M.S.; Abdelaziz, M.H.; Alhossainy, A.F.; Bassyouni, M.; Salah, N. One-dimensional nanocomposites based on polypyrrole-carbon nanotubes and their thermoelectric performance. Polymers 2021, 13, 278. [Google Scholar] [CrossRef]

- 6Yao, Q.; Chen, L.; Zhang, W.; Liufu, S.; Chen, X. Enhanced thermoelectric performance of single-walled carbon nanotubes/polyaniline hybrid nanocomposites. ACS Nano 2010, 4, 2445–2451. [Google Scholar]

- Saini, V.; Abdulrazzaq, O.; Bourdo, S.; Dervishi, E.; Petre, A.; Bairi, V.G.; Schnackenberg, L.; Viswanathan, T.; Biris, A.S. Structural and optoelectronic properties of P3HT-graphene composites prepared by in situ oxidative polymerization. J. Appl. Phys. 2012, 112, 054327. [Google Scholar] [CrossRef]

- Das, M.; Roy, S. Preparation, characterization and properties of newly synthesized SnO2-polycarbazole nanocomposite via room temperature solution phase synthesis process. Mater. Today 2019, 18, 5438–5446. [Google Scholar] [CrossRef]

- Canobre, S.C.; Xavier, F.; Fagundes, W.S.; Freitas, A.C.; Amaral, F.A. Performance of the chemical and electrochemical composites of PPy/CNT as electrodes in type I supercapacitors. J. Nanomater. 2015, 16, 160. [Google Scholar] [CrossRef]

- Wei, P.; Tanabe, H. Synergy effects between single-walled carbon nanotubes and polypyrrole on the electrocatalysis of their composites for the oxygen reduction reaction. Carbon 2011, 49, 4877–4889. [Google Scholar] [CrossRef]

- Lu, W.; Luo, Q.; Yin, S.; Wu, X.; Guo, C.Y. Aniline-pyrrole copolymer/SWCNT thermoelectric composites from electrochemical polymerization. Compos. Commun. 2021, 27, 100860. [Google Scholar] [CrossRef]

- Lu, W.; Yin, S.; Wu, X.; Luo, Q.; Wang, E.; Cui, L.; Guo, C.Y. Aniline-pyrrole copolymer formed on single-walled carbon nanotubes with enhanced thermoelectric performance. J. Mater. Chem. C 2021, 9, 2898–2903. [Google Scholar] [CrossRef]

- Yin, S.; Lu, W.; Wu, X.; Luo, Q.; Wang, E.; Guo, C.Y. Enhancing thermoelectric performance of polyaniline/single-walled carbon nanotubes composites via dimethyl sulfoxide-mediated electropolymerization. ACS Appl. Mater. Interfaces 2021, 13, 3930–3936. [Google Scholar] [CrossRef]

- Jiang, T.; Wan, P.B.; Ren, Z.; Yan, S.K. Anisotropic polyaniline/SWCNT composite films prepared by in situ electropolymerization on highly oriented polyethylene for high-efficiency ammonia sensor. ACS Appl. Mater. Interfaces 2019, 11, 38169–38176. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.I.; Wasfi, A.S. A comparative study of polyaniline/MWCNT with polyaniline/SWCNT nanocomposite films synthesized by microwave plasma polymerization. Synth. Met. 2019, 250, 49–54. [Google Scholar] [CrossRef]

- Jiwoong, H.; Sangbaek, P.; Nari, J. Conductive polyaniline–indium oxide composite films prepared by sequential infiltration synthesis for electrochemical energy storage. ACS Omega 2023, 8, 946–953. [Google Scholar]

- Culebras, M.; Cho, C.; Krecker, M.; Smith, R.; Song, Y.; Gómez, C.M.; Cantarero, A.; Grunlan, J.C. High thermoelectric power factor organic thin films through combination of nanotube multilayer assembly and electrochemical polymerization. ACS Appl. Mater. Interfaces 2017, 9, 6306–6313. [Google Scholar] [CrossRef] [PubMed]

- Arciniegas, M.P.; Stasio, F.D.; Li, H.; Altamura, D.; De Trizio, L.; Prato, M.; Scarpellini, A.; Moreels, R.; Krahne, R.; Manna, L. Self-assembled dense colloidal Cu2Te nanodisk networks in P3HT thin films with enhanced photocurrent. Adv. Funct. Mater. 2016, 26, 4535–4542. [Google Scholar] [CrossRef]

- Das, T.K.; Prusty, S. Review on conducting polymers and their applications. Polym. Plast. Technol. Eng. 2012, 51, 1487–1500. [Google Scholar] [CrossRef]

- Sadi, M.S.; Kumpikaitė, E. Highly conductive composites using polypyrrole and carbon nanotubes on polydopamine functionalized cotton fabric for wearable sensing and heating applications. Cellulose 2023, 30, 7981–7999. [Google Scholar] [CrossRef]

- Gao, X.-Z.; Gao, F.-L.; Liu, J.; Li, Y.; Wan, P.; Yu, Z.-Z.; Li, X. Self-powered resilient porous sensors with thermoelectric poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) and carbon nanotubes for sensitive temperature and pressure dual-mode sensing. ACS Appl. Mater. Interfaces 2022, 14, 43783–43791. [Google Scholar] [CrossRef]

- Du, C.; Cao, M.; Li, G.; Hu, Y.; Zhang, Y.; Liang, L.; Liu, Z.; Chen, G. Toward precision recognition of complex hand motions: Wearable thermoelectrics by synergistic 2D nanostructure confinement and controlled reduction. Adv. Funct. Mater. 2022, 32, 2206083. [Google Scholar] [CrossRef]

- He, X.; Hao, Y.; He, M.; Qin, X.; Wang, L.; Yu, J. Stretchable thermoelectric-based self-powered dual-parameter sensors with decoupled temperature and strain sensing. ACS Appl. Mater. Interfaces 2021, 13, 60498–60507. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, S.; Li, P.C.; Zhang, C.L.; He, C.B. Wet-spun flexible carbon nanotubes/polyaniline fibers for wearable thermoelectric energy harvesting. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107386. [Google Scholar] [CrossRef]

- Li, G.; Hu, Y. Thermoelectric and photoelectric dual modulated sensors for human internet of things application in accurate fire recognition and warning. Adv. Funct. Mater. 2023, 33, 2303861. [Google Scholar] [CrossRef]

- Zou, T.; Zhang, D. Smart fire-safety cotton fabric with fire-warning capability via dual working mechanisms. Cellulose 2023, 30, 6015–6030. [Google Scholar] [CrossRef]

- Maity, D.; Kumar, R.T.R. Highly sensitive amperometric detection of glutamate by glutamic oxidase immobilized Pt nanoparticle decorated multiwalled carbon nanotubes (MWCNTs)/polypyrrole composite. Biosens. Bioelectron. 2019, 130, 307–314. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Zhang, X.; Wu, Y.; Li, Y.; Pang, J.; Zhang, H.; Jiang, L. Ordered-assembly conductive nanowires array with tunable polymeric structure for specific organic vapor detection. Small 2019, 15, 1900590. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Liu, S.; Zhu, L.; Liu, Y.; Li, N.; Shi, X.; Jiao, T.; Qin, Z. Hydroxypropyl methyl cellulose reinforced conducting polymer hydrogels with ultra-stretchability and low hysteresis as highly sensitive strain sensors for wearable health monitoring. Int. J. Biol. Macromol. 2023, 236, 123956. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.; Tsai, T.-C.; Liang, C.-T.; Wu, R.-J.; Chavalia, M. Application of impedance measurement technology in distinguishing different tea samples with PPy/SWCNT composite sensing material. J. Chin. Chem. Soc. 2011, 58, 714–722. [Google Scholar] [CrossRef]

- Wu, R.J.; Tsai, T.C.; Luk, H.N.; Chavali, M. Fast detection of local anesthetic levobupivacaine by impedance method on PPy/SWCNT. J. Nanosci. Nanotechnol. 2011, 11, 4667–4674. [Google Scholar] [CrossRef] [PubMed]

- Min, K.; Yoo, Y.J. Amperometric detection of dopamine based on tyrosinase-SWNTs-PPy composite electrode. Talanta 2009, 80, 1007–1011. [Google Scholar] [CrossRef]

- Lu, Q.; Chen, J.G.; Xiao, J.Q. Nanostructured electrodes for high-performance pseudocapacitors. Angew. Chem. Int. Ed. 2013, 52, 1882–1889. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, K.; Zhang, Y.; Wei, Z. Hierarchical porous graphene/polyaniline composite film with superior rate performance for flexible supercapacitors. Adv. Mater. 2013, 25, 6985–6990. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Zhang, M.; Liu, K.; Parit, M.; Jiang, Z.; Zhang, X.; Li, B.; Si, C. Conductive PEDOT:PSS/cellulose nanofibril paper electrodes for flexible supercapacitors with superior areal capacitance and cycling stability. Chem. Eng. J. 2022, 428, 131994. [Google Scholar] [CrossRef]

- Grdzka, E.; Duewski, P.; Wigda, I.; Wysockazolopa, M.; Winkler, K. Formation and electrochemical properties of multiwalled carbon nanotubes and polypyrrole composite with (n-Oc4N) Br binder. Synth. Met. 2021, 272, 116661. [Google Scholar] [CrossRef]

- Babu, A.; Somesh, T.E.; Dechamma, C.A.; Hemavathi, A.B.; Kakarla, R.R.; Kulkarni, R.V.; Raghu, A.V. Ternary structured magnesium cobalt oxide/graphene/polycarbazole nanohybrids for high performance electrochemical supercapacitors. Mater. Sci. Energy Technol. 2023, 6, 399–408. [Google Scholar] [CrossRef]

- Ates, M.; Özyılmaz, A.T. The application of polycarbazole, polycarbazole/nanoclay and polycarbazole/Zn-nanoparticles as a corrosion inhibition for SS304 in saltwater. Prog. Org. Coat. 2015, 84, 50–58. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, E.; Liu, X.; Song, W.; Zhao, M.; Zi, L.; Wang, X.C.; Liu, C.T. Synergistic effect of polypyrrole functionalized graphene oxide and zinc phosphate for enhanced anticorrosion performance of epoxy coatings. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105752. [Google Scholar] [CrossRef]

- Rayar, A.; Naveen, C.S.; Onkarappa, H.S.; Betageri, V.S.; Prasanna, G.D. EMI shielding applications of PANI-Ferrite nanocomposite materials: A review. Synth. Met. 2023, 295, 117338. [Google Scholar] [CrossRef]

- Rashid, I.A.; Hamza, A.; Asim, S.; Zubair, K.; Shakir, H.F.; Afzal, A.; Zubair, Z. Achieving enhanced electromagnetic shielding by novel flexible rubber based nanocomposite with the incorporation of nickel spinal ferrites and polyaniline. Synth. Met. 2023, 295, 117339. [Google Scholar] [CrossRef]

- Gallon, B.J.; Kojima, R.W.; Kaner, R.B.; Diaconescu, P.L. Palladium nanoparticles supported on polyaniline nanofibers as a semiheterogeneous catalyst in water. Angew. Chem. Int. Ed. 2007, 46, 7251–7254. [Google Scholar] [CrossRef]

- Kong, L.; Lu, X.; Jin, E.; Jiang, S.; Wang, C.; Zhang, W. Templated synthesis of polyaniline nanotubes with Pd nanoparticles attached onto their inner walls and its catalytic activity on the reduction of p-nitroanilinum. Compos. Sci. Technol. 2009, 69, 561–566. [Google Scholar] [CrossRef]

- Huang, H.; Feng, X.; Zhu, J.J. Synthesis, characterization and application in electrocatalysis of polyaniline/Au composite nanotubes. Nat. Nanotechnol. 2008, 19, 145607. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, E.; Liu, P.; Lv, Y.; Wang, E.; Guo, C.-Y. Conductive Polymer-Based Thermoelectric Composites: Preparation, Properties, and Applications. J. Compos. Sci. 2024, 8, 308. https://doi.org/10.3390/jcs8080308

Song E, Liu P, Lv Y, Wang E, Guo C-Y. Conductive Polymer-Based Thermoelectric Composites: Preparation, Properties, and Applications. Journal of Composites Science. 2024; 8(8):308. https://doi.org/10.3390/jcs8080308

Chicago/Turabian StyleSong, Erwei, Peiyao Liu, Yifan Lv, Erqiang Wang, and Cun-Yue Guo. 2024. "Conductive Polymer-Based Thermoelectric Composites: Preparation, Properties, and Applications" Journal of Composites Science 8, no. 8: 308. https://doi.org/10.3390/jcs8080308

APA StyleSong, E., Liu, P., Lv, Y., Wang, E., & Guo, C.-Y. (2024). Conductive Polymer-Based Thermoelectric Composites: Preparation, Properties, and Applications. Journal of Composites Science, 8(8), 308. https://doi.org/10.3390/jcs8080308