Compression after Impact Response of Kevlar Composites Plates

Abstract

1. Introduction

2. Materials and Methods

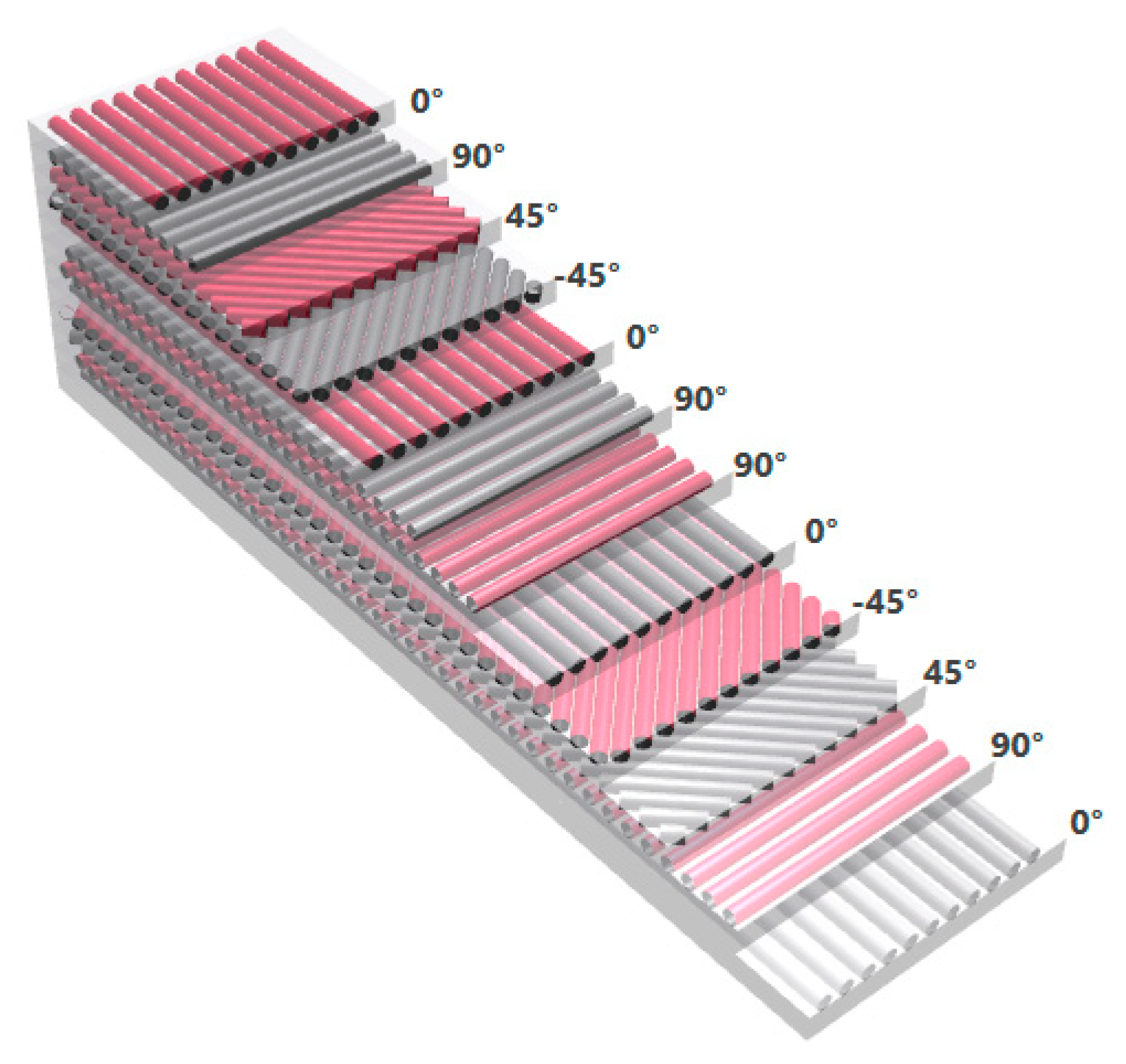

2.1. Material

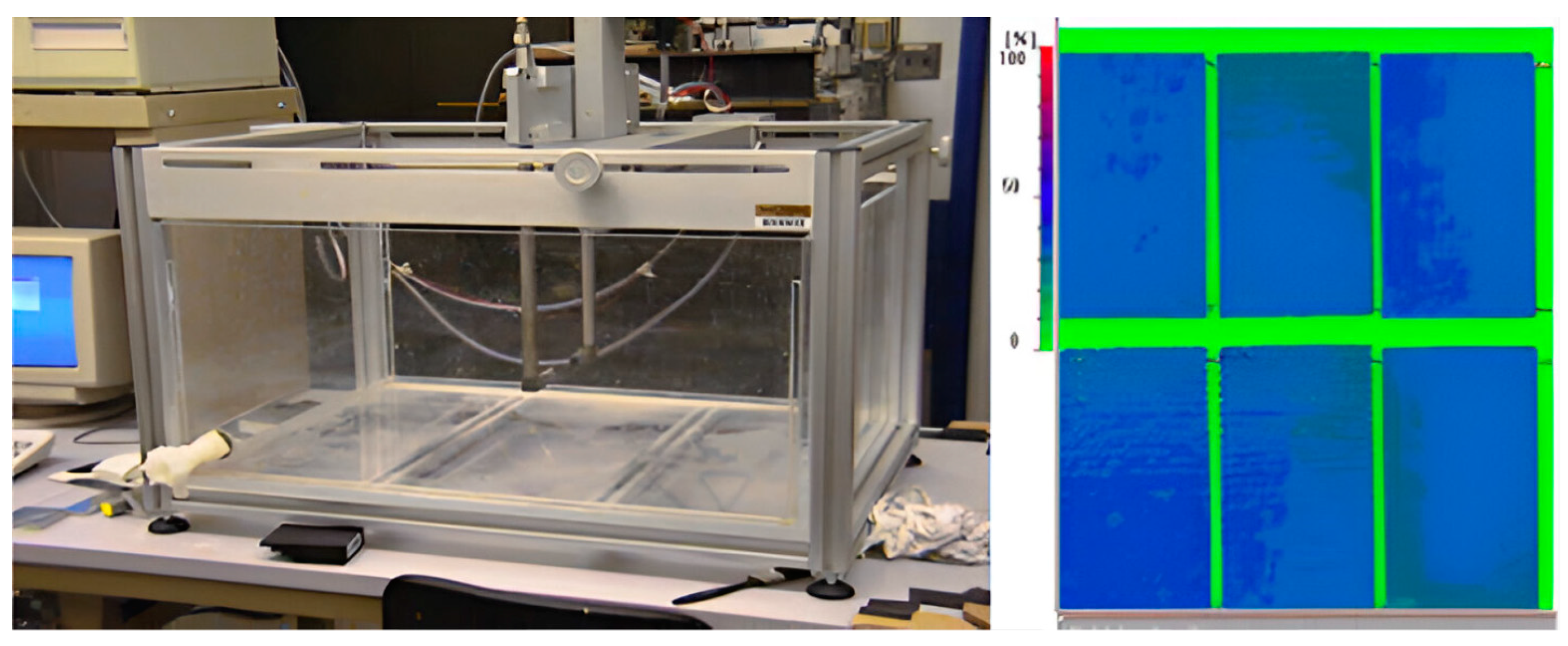

2.2. Experimental Procedure

3. Finite Element Analysis

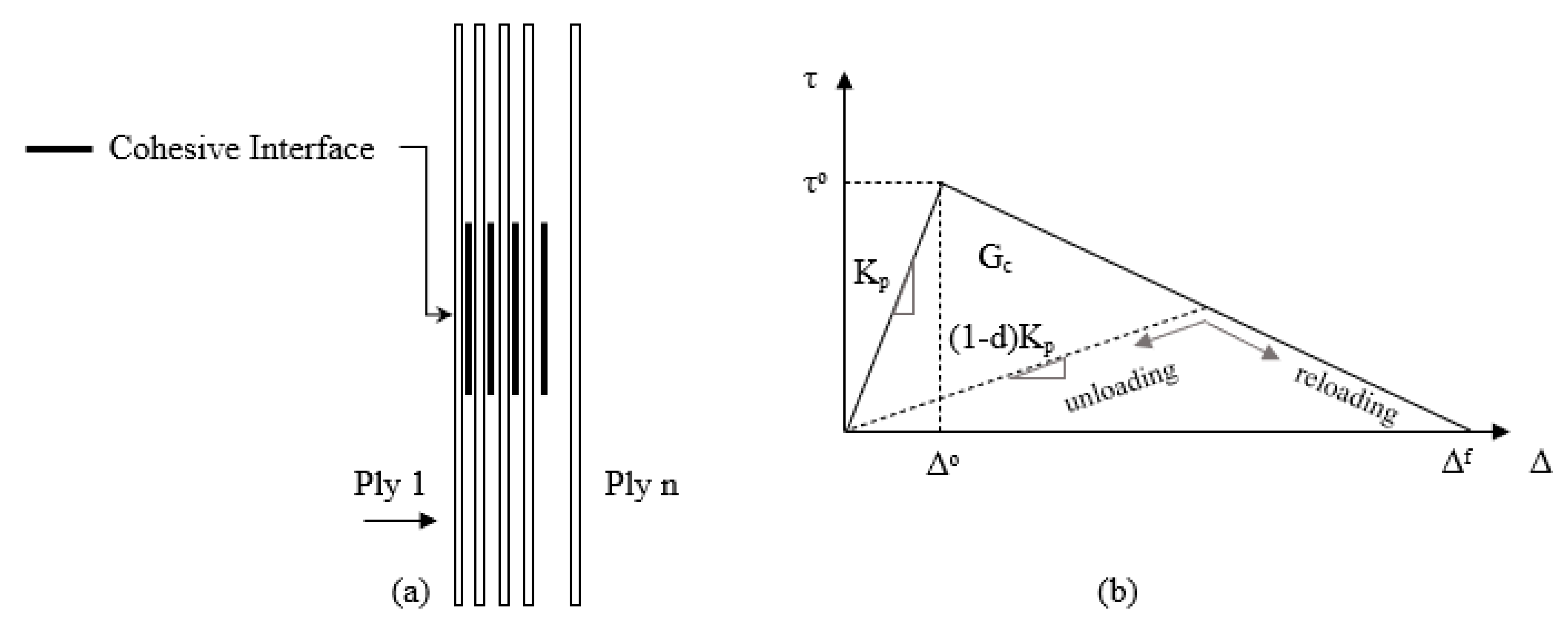

3.1. Cohesive Elements for Delamination Modeling

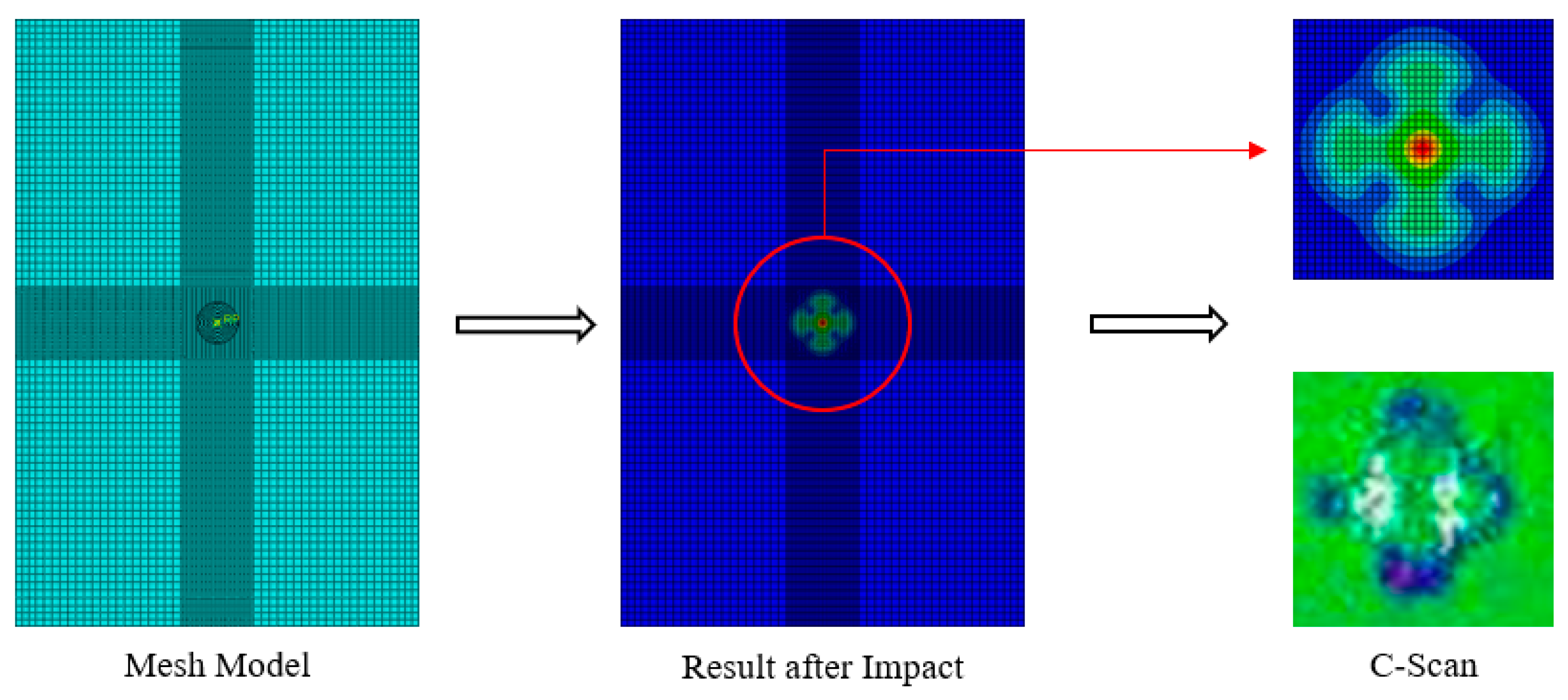

3.2. Abaqus FEA for Composite Damage Analysis

4. Results and Discussion

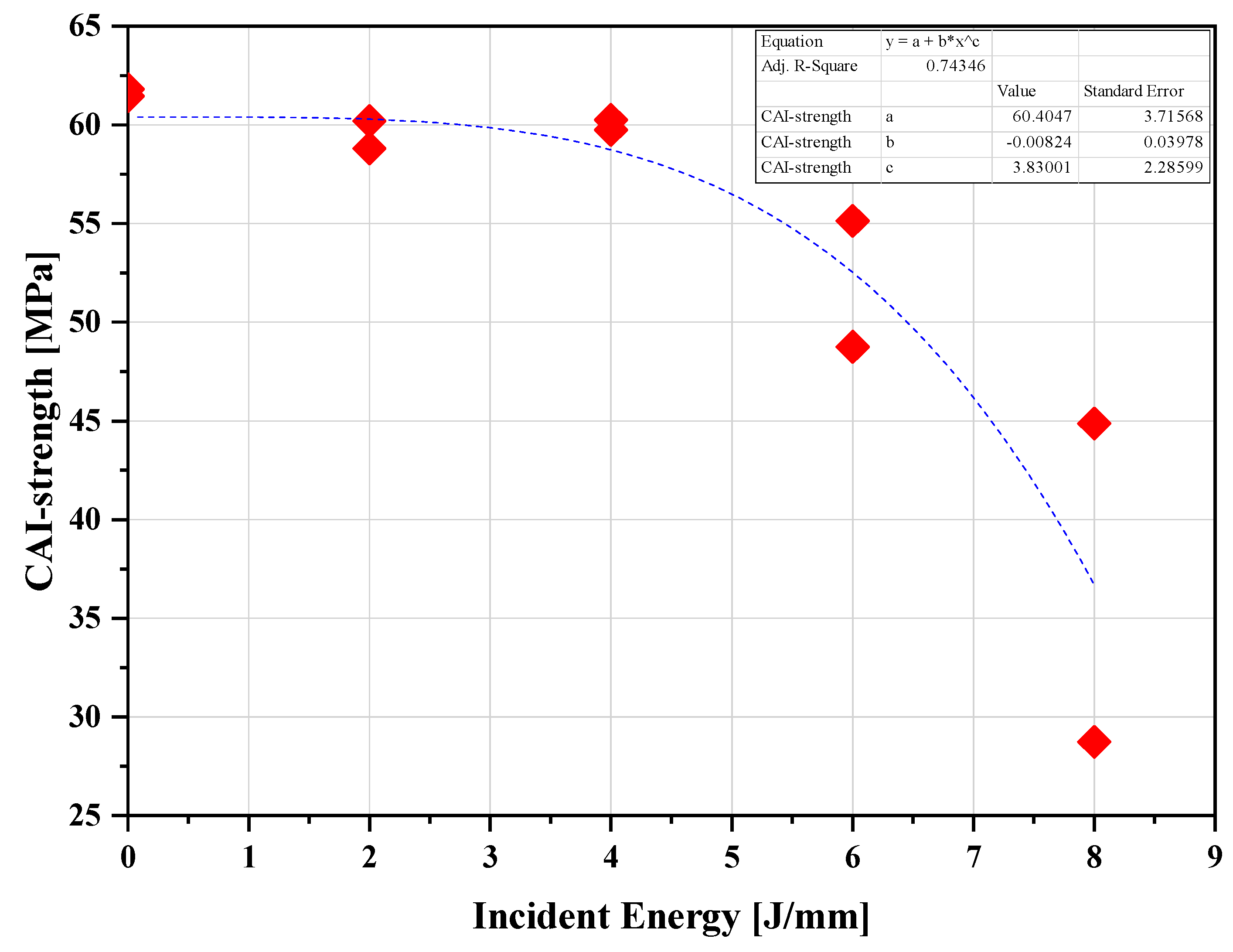

Experimental Results

5. Finite Element Results

6. Conclusions

- Impact significantly reduces CAI strength due to permanent delaminations within the laminate. This highlights the importance of considering pre-existing damage when evaluating the post-impact strength of composite materials.

- For superior CAI strength under compression, laminates should have top and bottom plies oriented in the 0° direction (aligned with the loading direction).

- While useful for analysis, the finite element model employs a simplified approach by representing impact damage as an equivalent hole. This may not fully capture the complexities of real-world damage, such as crack formation and propagation.

- Delaminated regions lead to localized buckling of sub-laminates under compressive loads. The size of the delaminated zone increases with impact energy, consequently reducing the CAI strength of the material.

- Anti-buckling jigs successfully prevented peripheral buckling during CAI tests, adhering to the DIN65561 standard. However, these results emphasize the limitations of solely relying on buckling analysis for post-impact behavior predictions. Plate failure can involve factors beyond buckling, such as delamination and matrix cracking.

- The absence of mid-plane fractures in all tested plates suggests insufficient internal damage to induce micro-buckling and subsequent ply failure. The C-Scan technique proved effective for quantifying the extent of the damaged zone. Specimens generally exhibited a linear stress–strain response until they reached their ultimate strength, followed by a significant drop in stress signifying failure.

- Increasing impact energy leads to a proportional increase in the delamination area within the composite, highlighting the detrimental effect on its internal integrity.

- Discrepancies between experimental results and model predictions can be partially attributed to model limitations, such as the assumption of linear elastic buckling behavior. Real-world damage introduces complexities not fully captured by the model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pelletier, J.L.; Vel, S.S. Multi-objective optimization of fiber reinforced composite laminates for strength, stiffness and minimal mass. Comput. Struct. 2006, 84, 2065–2080. [Google Scholar] [CrossRef]

- Marble, E.; Boles, T. A Review of the Structural Characteristics of Aerospace Composites. Sci. Insights 2022, 41, 749–753. [Google Scholar] [CrossRef]

- Aktas, M.; Karakuzu, R.; Icten, B.M. Impact behavior of glass/epoxy laminated composite plates at high temperatures. J. Compos. Mater. 2010, 44, 2289–2299. [Google Scholar] [CrossRef]

- Aktaş, M.; Karakuzu, R.; İçten, B. Thermal impact behavior of glass–epoxy laminated composite plates. J. Thermoplast. Compos. Mater. 2011, 24, 535–553. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, X.; Li, S. A review of aerospace composite materials for high-performance structures. Compos. Struct. 2020, 249, 112738. [Google Scholar]

- Carvelli, V.; Fiore, V.; Micheletti, G. Progressive damage modeling for the prediction of the compressive after impact response of woven Kevlar® 49/epoxy composites. Compos. Struct. 2021, 267, 114037. [Google Scholar]

- Gökçe, A.; Çoban, M.Z.; Uysal, M. The influence of moisture absorption on the low-velocity impact and compression after impact (CAI) response of Kevlar 49® epoxy composites. Mater. Sci. Appl. 2019, 10, 301–313. [Google Scholar]

- Hitte, J.; Périé, J.P.; Hemptinne, C. Experimental characterization of variable low velocity impact damage for flax fiber reinforced composites. Compos. Part A Appl. Sci. Manuf. 2014, 61, 188–196. [Google Scholar]

- Zhou, G.; Wang, Z.; Huang, J. Numerical simulation of compression after impact (CAI) for CFRP laminates considering progressive damage. Compos. Struct. 2018, 185, 42–53. [Google Scholar]

- Yang, H.H. Kevlar Aramid Fiber; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Gökçe, A.; Çoban, M.Z.; Uysal, M. Effect of surface modification on the low-velocity impact and compression after impact (CAI) response of Kevlar 49® epoxy composites. J. Compos. Mater. 2020, 54, 4251–4267. [Google Scholar]

- Seyednejad, S.A.; Rahmani, M.; Sultan, M.T. Kevlar® composites for ballistic applications: A review of ballistic impact mechanisms, influencing factors and material enhancements. Compos. Part B Eng. 2018, 154, 238–258. [Google Scholar]

- Li, Y.; Mamouri, H.; Li, S.; Wang, Y. Effects of multi-scale reinforcements on the low-velocity impact and compression after impact (CAI) behaviors of Kevlar 49/epoxy composites. Compos. Part B Eng. 2023, 134, 110253. [Google Scholar]

- Dong, Z.; Sun, C.T. Testing and modeling of yarn pull-out in plain woven Kevlarfabrics. Compos. A Appl. Sci. Manuf. 2009, 40, 1863–1869. [Google Scholar] [CrossRef]

- Pinho, S.; Iannucci, L.; Robinson, P. Physically based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking. Part II: FE implementation. Compos. A Appl. Sci. Manuf. 2006, 37, 766–777. [Google Scholar] [CrossRef]

- Pinho, S.; Iannucci, L.; Robinson, P. Physically-based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking: Part I: Development. Compos. Part A Appl. Sci. Manuf. 2006, 37, 63–73. [Google Scholar] [CrossRef]

- Meddour, O.; Mamouri, H.; Guerrouache, M.; Benzeggagh, M.L. Prediction of the compressive response after impact of composite laminates using a damage mechanics approach. Compos. Struct. 2014, 116, 556–567. [Google Scholar]

- de Freitas, M.; Reis, L. Failure mechanisms on composite specimens subjected to compression after impact. Compos. Struct. 1998, 42, 365–373. [Google Scholar] [CrossRef]

- Johnson, W.; Masters, J.; Wilson, D.; Hosur, M.; Murthy, C.; Ramurthy, T. Compression after impact testing of carbon fiber reinforced plastic laminates. ASTM J. Compos. Technol. Res. 1999, 21, 51–64. [Google Scholar] [CrossRef]

- Naik, N.K.; Joglekar, M.N.; Arya, H.; Borade, S.V.; Ramakrishna, K.N. Impact and compression after impact characteristics of plain weave fabric composites: Effect of plate thickness. Adv. Compos. Mater. 2004, 12, 261–280. [Google Scholar] [CrossRef]

- Sanchez-Saez, S.; Barbero, E.; Zaera, R.; Navarro, C. Compression after impact of thin composite laminates. Compos. Sci. Technol. 2005, 65, 1911–1919. [Google Scholar] [CrossRef]

- Khondker, O.; Leong, K.; Herszberg, I.; Hamada, H. Impact and compression-after-impact performance of weft-knitted glass textile composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 638–648. [Google Scholar] [CrossRef]

- Cartié, D.; Irving, P. Effect of resin and fibre properties on impact and compression after impact performance of CFRP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 483–493. [Google Scholar] [CrossRef]

- Liu, Y.; Mamouri, H.; Li, S.; Wang, C. Experimental and numerical investigation of the effect of fiber hybridization on the compressive after impact (CAI) behavior of Kevlar® 49/epoxy composites. Compos. Struct. 2022, 272, 114320. [Google Scholar]

- Abrate, S. Impact on Composite Structures; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Rouchon, J. Fatigue and damage tolerance aspects for composite aircraft structures. In Proceedings of the ICAF Symposium, Delft, The Netherlands; March 1995. [Google Scholar]

- Rhead, A.T.; Marchant, D.; Butler, R. Compressive strength of composite laminates following free edge impact. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1056–1065. [Google Scholar] [CrossRef]

- Choi, H.Y.; Chang, K. A model for predicting damage in graphite-epoxy laminated composites resulting from low-velocity point impact. J. Compos. Mater. 1992, 26, 2134–2169. [Google Scholar] [CrossRef]

- Carvelli, V.; Wegner, L.; Micheletti, G. Effect of stacking sequence and hygrothermal conditioning on the compressive after impact (CAI) response of woven Kevlar® 49/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 305–317. [Google Scholar]

- Liu, X.; Li, S.; Mamouri, H. Experimental investigation on the effect of stacking sequence on the compression after impact (CAI) behavior of flax/epoxy composites. Compos. Struct. 2019, 222, 110942. [Google Scholar]

- Liu, D.; Raju, B.B.; Dang, X. Size effects on impact response of composite laminates. Int. J. Impact Eng. 1998, 21, 837–854. [Google Scholar] [CrossRef]

- Dale, M.; Acha, B.A.; Carlsson, L.A. Low velocity impact and compression after impact characterization of woven carbon/vinylester at dry and water saturated conditions. Compos. Struct. 2012, 94, 1582–1589. [Google Scholar] [CrossRef]

- Soutis, C.; Curtis, P. Prediction of the post-impact compressive strength of CFRP laminated composites. Compos. Sci. Technol. 1996, 56, 677–684. [Google Scholar] [CrossRef]

- Chai, H.; Babcock, C.D.; Knauss, W.G. One dimensional modelling of failure in laminated plates by delamination buckling. Int. J. Solids Struct. 1981, 17, 1069–1083. [Google Scholar] [CrossRef]

- Donadon, M.; Iannucci, L.; Falzon, B.; Hodgkinson, J.; de Almeida, S. A progressive failure model for composite laminates subjected to low velocity impact damage. Comput. Struct. 2008, 86, 1232–1252. [Google Scholar] [CrossRef]

- Maire, J.-F.; Lesne, P.-M. An explicit damage model for the design of composite structures. Compos. Sci. Technol. 1998, 58, 773–778. [Google Scholar] [CrossRef]

- Iannucci, L.; Dechaene, R.; Willows, M.; Degrieck, J. A failure model for analysis of thin woven glass composite structures under impact loadings. Comput. Struct. 2001, 79, 785–799. [Google Scholar] [CrossRef]

- Williams, K.V.; Vaziri, R.; Poursartip, A. A physically based continuum damage mechanics model for thin laminated composite structures. Int. J. Solids Struct. 2003, 40, 2267–2300. [Google Scholar] [CrossRef]

- Pavan, R.C.; Creus, G.J.; Maghous, S. A simplified approach to continuous damage of composite materials and micromechanical analysis. Compos. Struct. 2009, 91, 84–94. [Google Scholar] [CrossRef]

- Donadon, M.V.; de Almeida, S.F.M.; Arbelo, M.A.; de Faria, A.R. A three dimensional ply failure model for composite structures. Int. J. Aerospace Eng. 2009, 2009, 486063. [Google Scholar] [CrossRef]

- Ianucci, L.; Willow, M.L. An energy based damage mechanics approach to modeling impact onto composite materials. Part I—Numerical models. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2041–2056. [Google Scholar] [CrossRef]

- Ianucci, L.; Willow, M.L. An energy based damage mechanics approach to modeling impact onto composite materials. Part II—Experimental and numerical results. Compos. Part A Appl. Sci. Manuf. 2007, 38, 540–554. [Google Scholar] [CrossRef]

- Johnson, A.; Pickett, A.; Rozycki, P. Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 2001, 61, 2183–2192. [Google Scholar] [CrossRef]

- Iannucci, L.; Ankersen, J. An energy based damage model for thin laminated composites. Compos. Sci. Technol. 2006, 66, 934–951. [Google Scholar] [CrossRef]

- Mamouri, H.; Bessaieh, A.; Laksimi, A.; Aidoun, Z. Experimental and numerical investigation of the compressive behaviour after impact of woven flax/epoxy composites. Compos. Struct. 2014, 110, 346–355. [Google Scholar]

- Wang, Z.; Zhou, G.; Huang, J. Progressive damage modeling for compression after impact of CFRP laminates. Compos. Struct. 2017, 171, 372–383. [Google Scholar]

- Donadon, M.V. The Structural Behavior of Composite Laminate Manufactured Using Resign Infusion under Flexible Tooling (RIFT) Process. Ph.D. Thesis, Department of Aeronautics, Imperial College London, London, UK, 2005. [Google Scholar]

- Falzon, B.G.; Apruzzese, P. Numerical analysis of intralaminar failure mechanisms in composite structures. Part I: FE implementation. Compos. Struct. 2011, 93, 1039–1046. [Google Scholar] [CrossRef]

- Falzon, B.G.; Apruzzese, P. Numerical analysis of intralaminar failure mechanisms in composite structures. Part II: Applications. Compos. Struct. 2011, 93, 1047–1053. [Google Scholar] [CrossRef]

- Bouvet, C.; Rivallant, S.; Barrau, J. Low velocity impact modeling in composite laminates capturing permanent indentation. Compos. Sci. Technol. 2012, 72, 1977–1988. [Google Scholar] [CrossRef]

- Hongkarnjanakul, N.; Bouvet, C.; Rivallant, S. Validation of low velocity impact modelling on different stacking sequences of CFRP laminates and influence of fibre failure. Compos. Struct. 2013, 106, 549–559. [Google Scholar] [CrossRef]

- Rivallant, S.; Bouvet, C.; Hongkarnjanakul, N. Failure analysis of CFRP laminates subjected to compression after impact: FE simulation using discrete interface elements. Compos. Part A Appl. Sci. Manuf. 2013, 55, 83–93. [Google Scholar] [CrossRef]

- Mendes, P.A.A.E.; Arbelo, M.A.; Donadon, M.V.; de Almeida, S.F.M. Numerical modeling of compression after impact response of woven fiber-reinforced composites. In Proceedings of the 21st Brazilian Congress of Mechanical Engineering, Natal, Brazil, 24–28 October 2011. [Google Scholar]

- Ghorbani, M.; Jafar, S.H.; Shariati, M. A progressive damage modeling approach for predicting the impact response and damage mechanisms of laminated composite plates. Compos. Struct. 2020, 244, 112323. [Google Scholar]

- ABAQUS 2023 User’s Manual; ABAQUS Inc.: Providence, RI, USA, 2023.

- Papanicolaou, G.; Charitidis, P.; Mouzakis, D.; Jiga, G. Experimental and numerical investigation of unbalanced boron/epoxy-aluminum single lap joints subjected to a corrosive environment. J. Compos. Mater. 2015, 50, 145–157. [Google Scholar] [CrossRef]

- Papanicolaou, G.; Charitidis, P.; Mouzakis, D.; Karachalios, E.; Jiga, G.; Portan, D. Experimental and numerical investigation of balanced Boron/Epoxy single lap joints subjected to salt spray aging. Int. J. Adhes. Adhes. 2016, 68, 9–18. [Google Scholar] [CrossRef]

- Tan, K.; Watanabe, N.; Iwahori, Y.; Ishikawa, T. Effect of stitch density and stitch thread thickness on compression after impact strength and response of stitched composites. Compos. Sci. Technol. 2012, 72, 587–598. [Google Scholar] [CrossRef]

- Suemasu, H.; Sasaki, W.; Aoki, Y.; Ishikawa, T. Compressive behaviour of impact damaged composite laminates. In Proceedings of the 16th International Conference on Composite Materials (ICCM-16), Kyoto, Japan, 7 July 2007. [Google Scholar]

- Hitchen, S.A.; Kemp, R.M.J. The effect of stacking-sequence on impact damage in carbon–fibre epoxy com-posite. Composites 1995, 26, 207–214. [Google Scholar] [CrossRef]

- Hashin, Z. Failure criteria for unidirectional fiber composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A Fatigue Failure Criterion for Fiber Reinforced Materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef]

- Xiong, Y.; Poon, C.; Straznicky, P.; Vietinghoff, H. A prediction method for the compressive strength of impact damaged composite laminates. Compos. Struct. 1995, 30, 357–367. [Google Scholar] [CrossRef]

- Raimondo, L.; Iannucci, L.; Robinson, P.; Curtis, P. A progressive failure model for mesh-size-independent FE analysis of composite laminates subject to low-velocity impact damage. Compos. Sci. Technol. 2012, 72, 624–632. [Google Scholar] [CrossRef]

- Yan, H.; Oskay, C.; Krishnan, A.; Xu, L.R. Compression-after-impact response of woven fiber-reinforced composites. Compos. Sci. Technol. 2010, 70, 2128–2136. [Google Scholar] [CrossRef]

- Zhang, X.; Davies, G.; Hitchings, D. Impact damage with compressive preload and post-impact compression of carbon composite plates. Int. J. Impact Eng. 1999, 22, 485–509. [Google Scholar] [CrossRef]

- Zhou, G. Effect of impact damage on residual compressive strength of glass-fibre reinforced polyester (GFRP) laminates. Compos. Struct. 1996, 35, 171–181. [Google Scholar] [CrossRef]

- Cantwell, W.; Morton, J. The impact resistance of composite materials—A review. Composites 1991, 22, 347–362. [Google Scholar] [CrossRef]

- Abdulhamid, H.; Bouvet, C.; Michel, L.; Aboissiere, J.; Minot, C. Numerical simulation of impact and compression after impact of asymmetrically tapered laminated CFRP. Int. J. Impact Eng. 2016, 95, 154–164. [Google Scholar] [CrossRef]

| E1 (GPa) | E2 (GPa) | E3 (GPa) | G12 (GPa) | G13 (GPa) | G23 (GPa) | v12 | v13 | v23 |

|---|---|---|---|---|---|---|---|---|

| 69.80 | 7.41 | 7.41 | 4.36 | 4.36 | 4.1 | 0.33 | 0.33 | 0.36 |

| XT (MPa). | XC (MPa) | YT (MPa) | YC (MPa) | SL (MPa) |

|---|---|---|---|---|

| 69.80 | 7.41 | 7.41 | 4.36 | 4.36 |

| Impact Energy [J/mm] | 0 | 2 | 4 | 6 | 8 |

| Buckling Stress [MPa] | 61.63 | 59.99 | 59.92 | 51.94 | 46.80 |

| Impact Energy [J/mm] | Experiment | FE-Analysis |

|---|---|---|

| Buckling Stress [MPa] | ||

| 0 | 61.63 | 64.64 |

| 2 | 59.99 | 61.61 |

| 4 | 59.52 | 60.45 |

| 6 | 51.92 | 53.96 |

| 8 | 46.80 | 48.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouzakis, D.E.; Charitidis, P.J.; Zaoutsos, S.P. Compression after Impact Response of Kevlar Composites Plates. J. Compos. Sci. 2024, 8, 299. https://doi.org/10.3390/jcs8080299

Mouzakis DE, Charitidis PJ, Zaoutsos SP. Compression after Impact Response of Kevlar Composites Plates. Journal of Composites Science. 2024; 8(8):299. https://doi.org/10.3390/jcs8080299

Chicago/Turabian StyleMouzakis, Dionysis E., Panagiotis J. Charitidis, and Stefanos P. Zaoutsos. 2024. "Compression after Impact Response of Kevlar Composites Plates" Journal of Composites Science 8, no. 8: 299. https://doi.org/10.3390/jcs8080299

APA StyleMouzakis, D. E., Charitidis, P. J., & Zaoutsos, S. P. (2024). Compression after Impact Response of Kevlar Composites Plates. Journal of Composites Science, 8(8), 299. https://doi.org/10.3390/jcs8080299