The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process

Abstract

1. Introduction

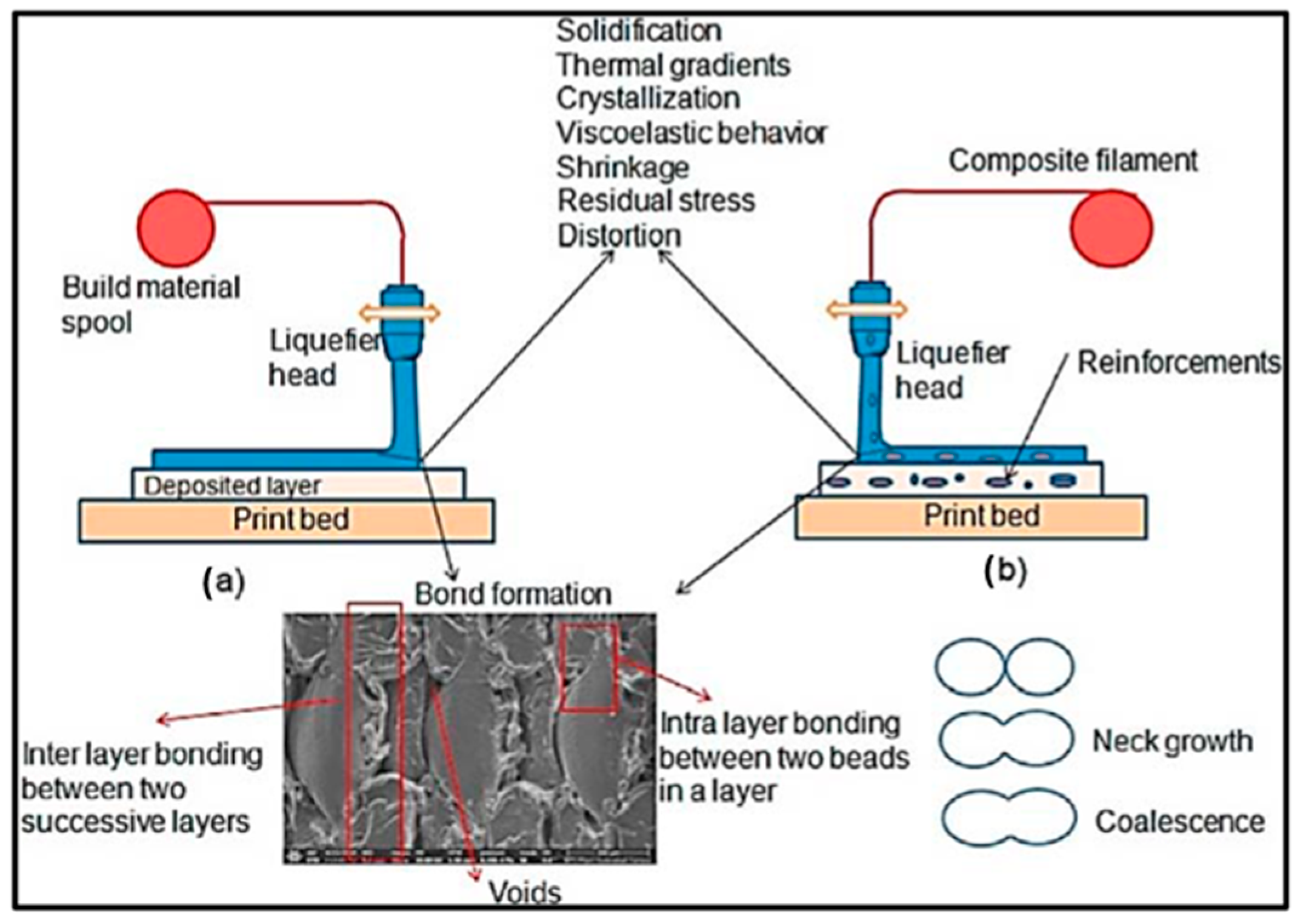

2. Challenges and Key Factors in the 3D Printing of Composites

3. Finite Element Simulations of Additive Manufacturing Processes for Composites

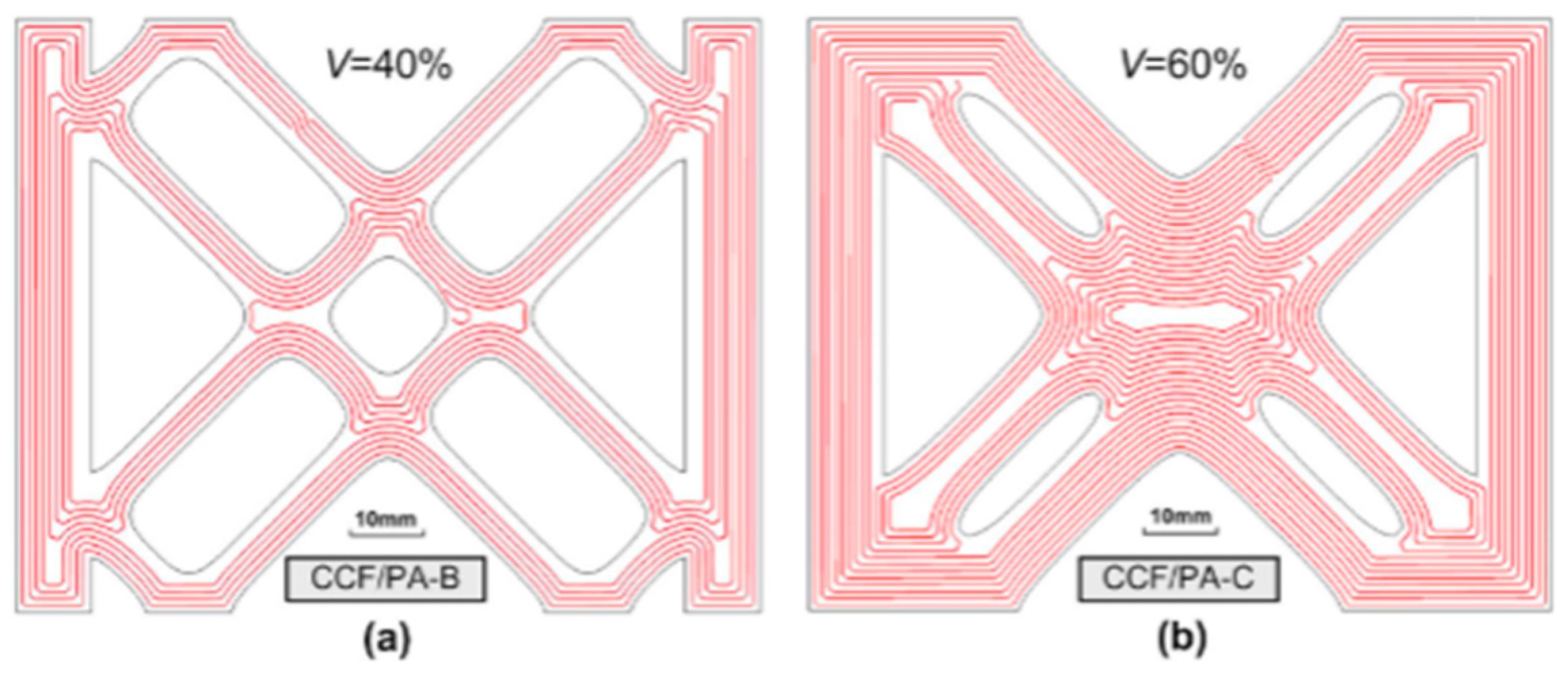

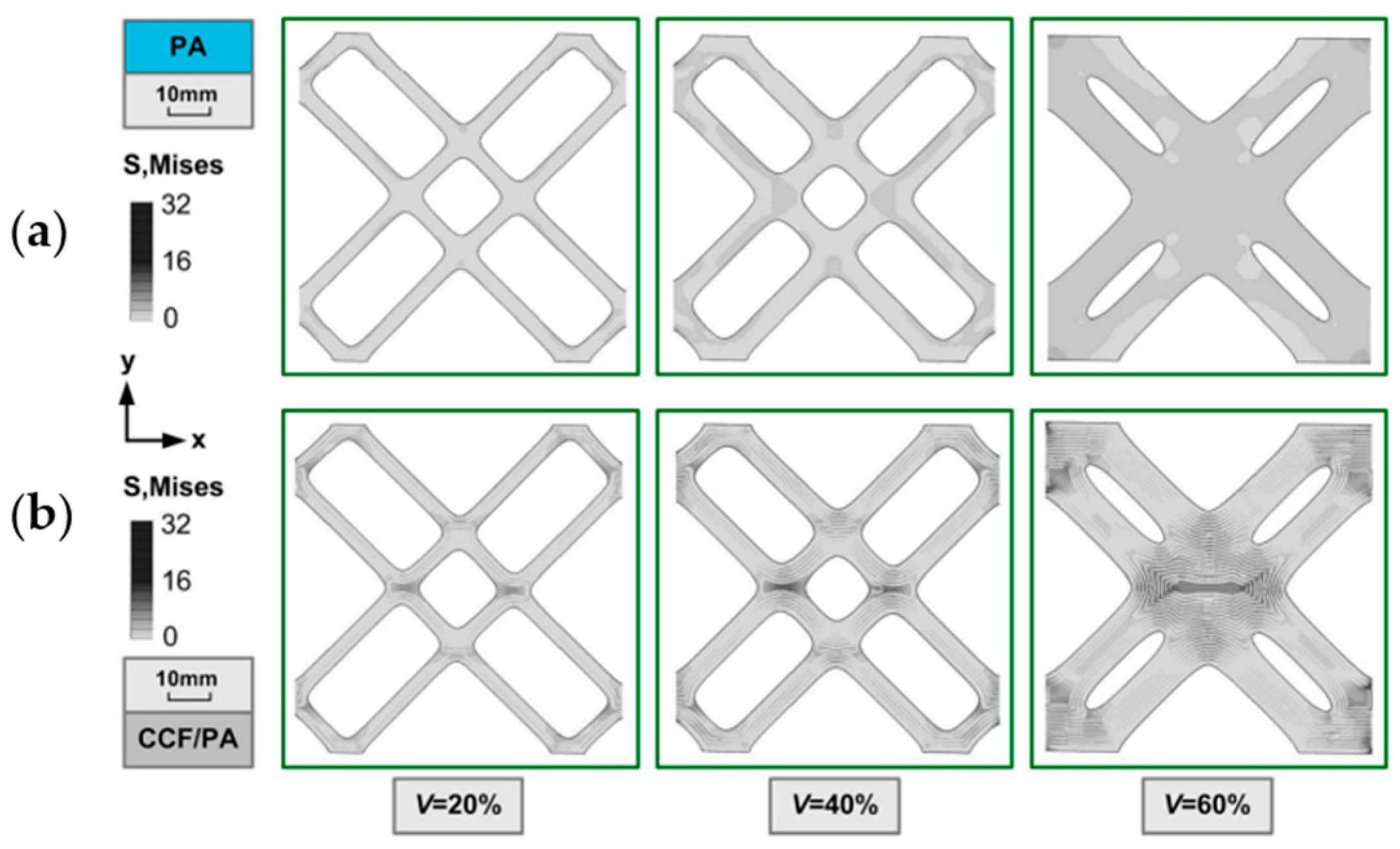

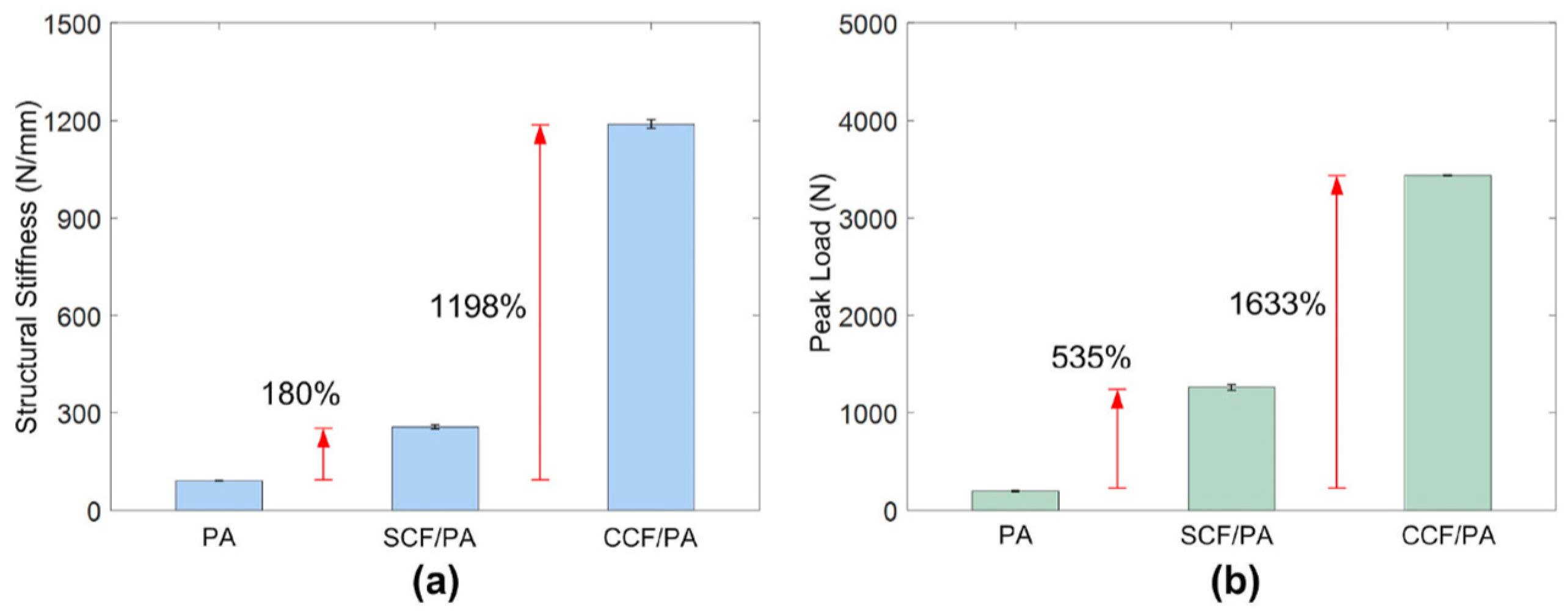

3.1. Pre-Processing (Slicing and Trajectory) Optimization

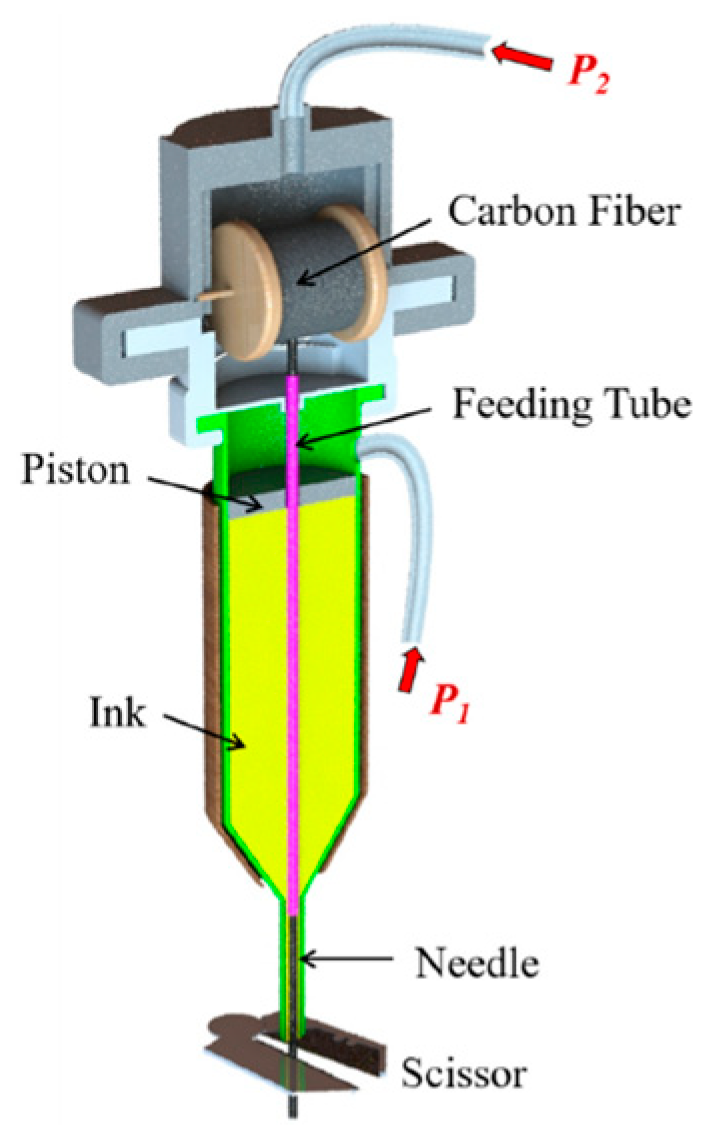

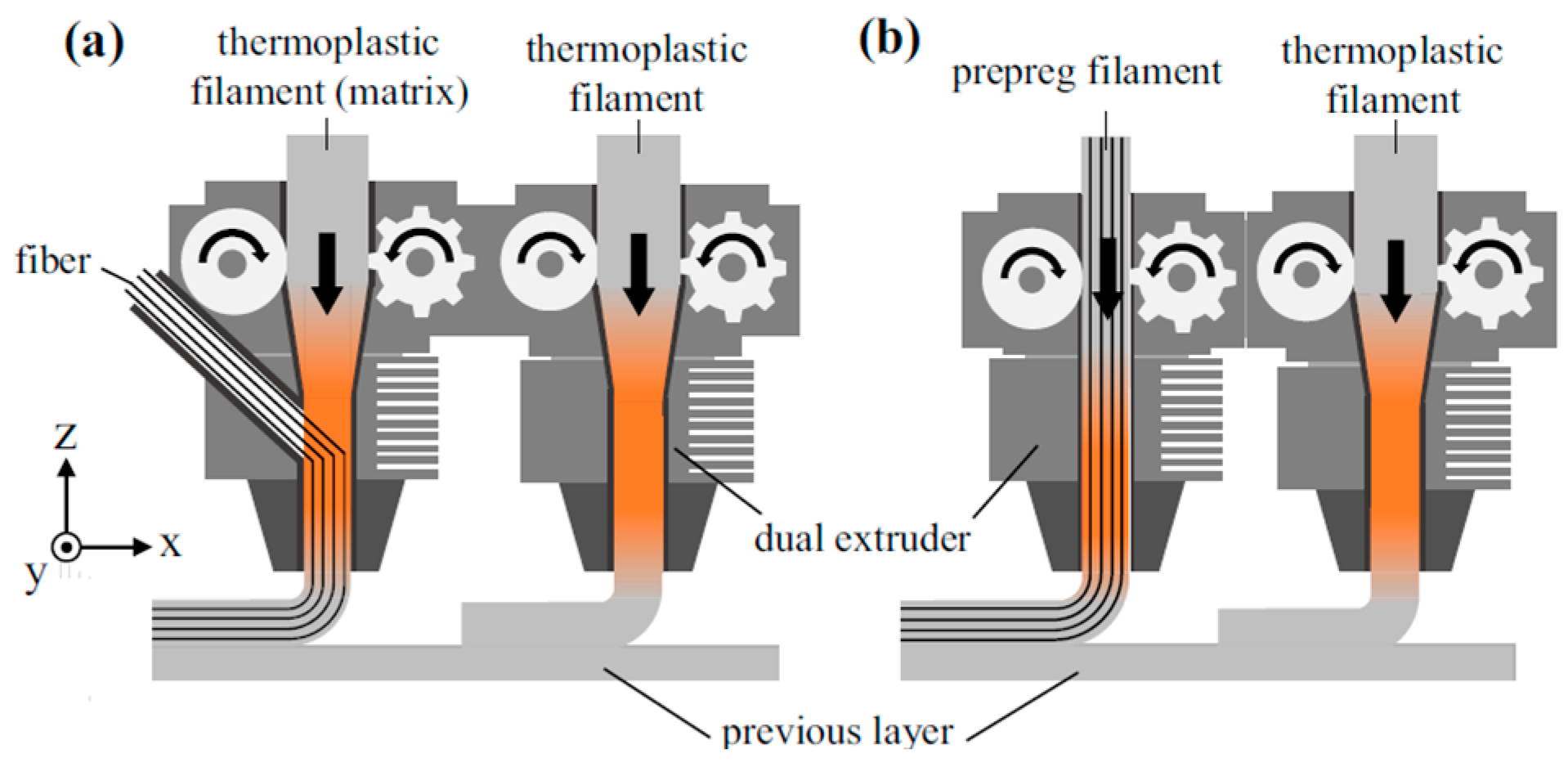

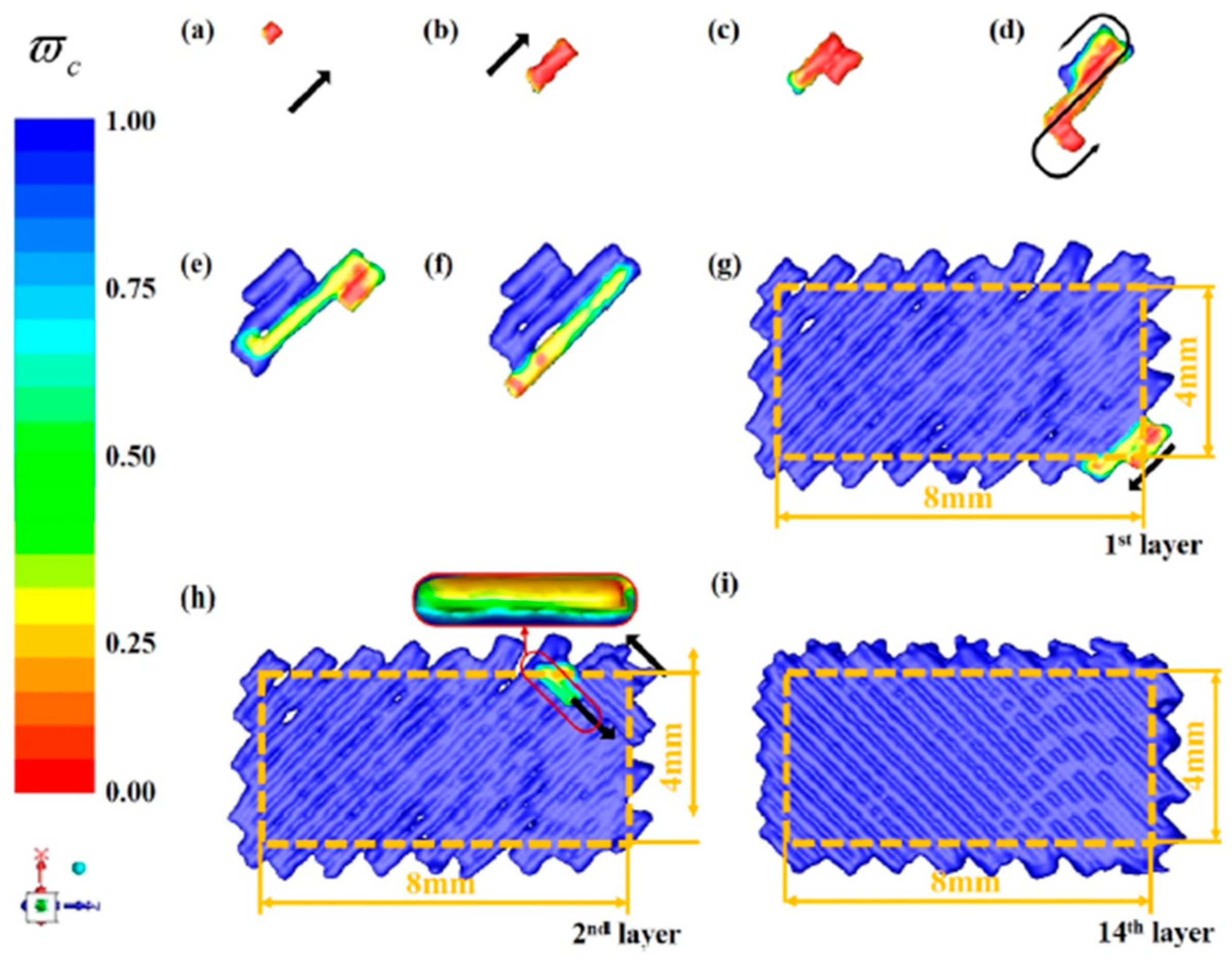

3.2. Computational Fluid Dynamics of Additive Maufacturing Composites

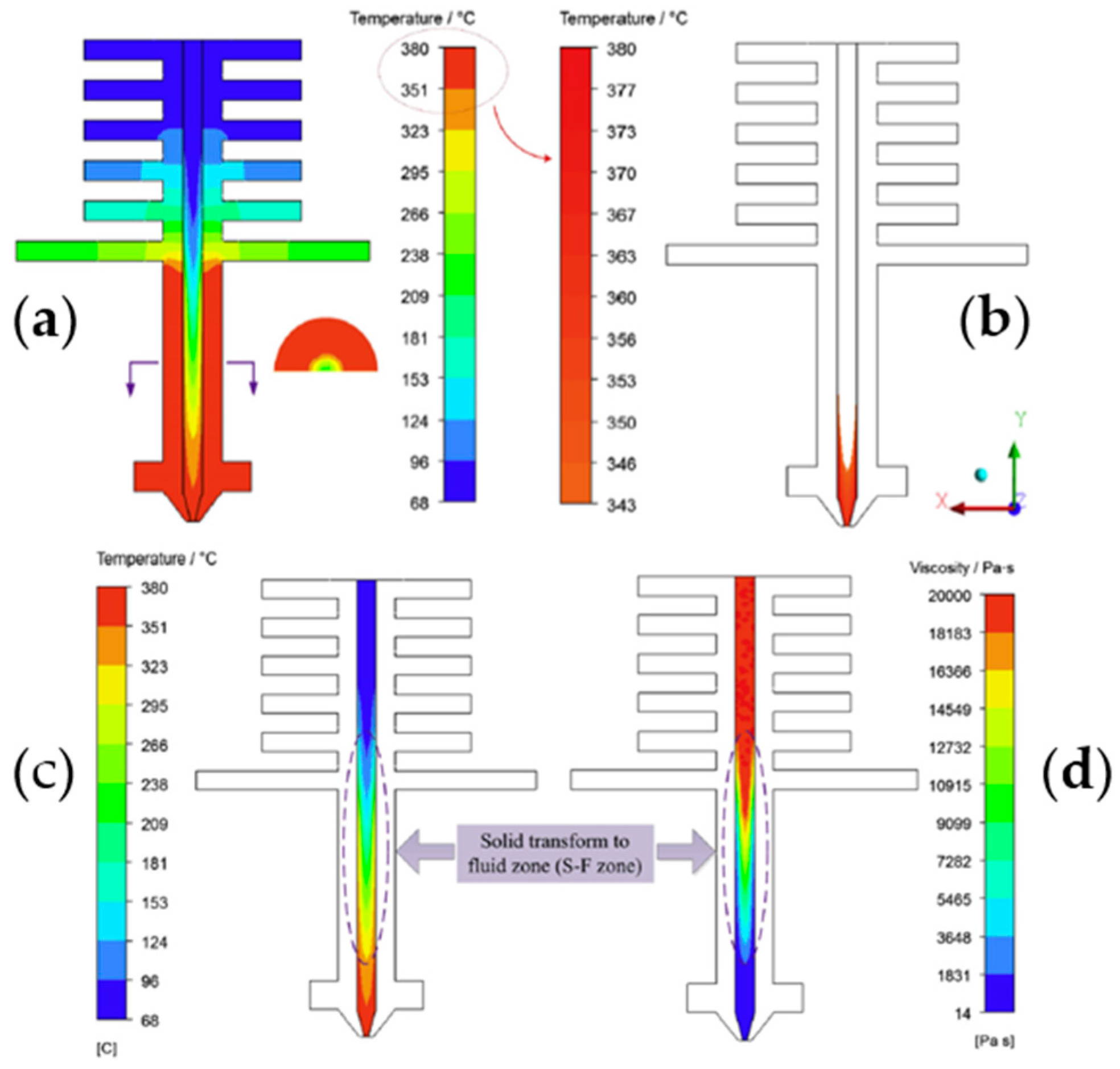

3.3. Melting Simulation of Additive Maufacturing Composites

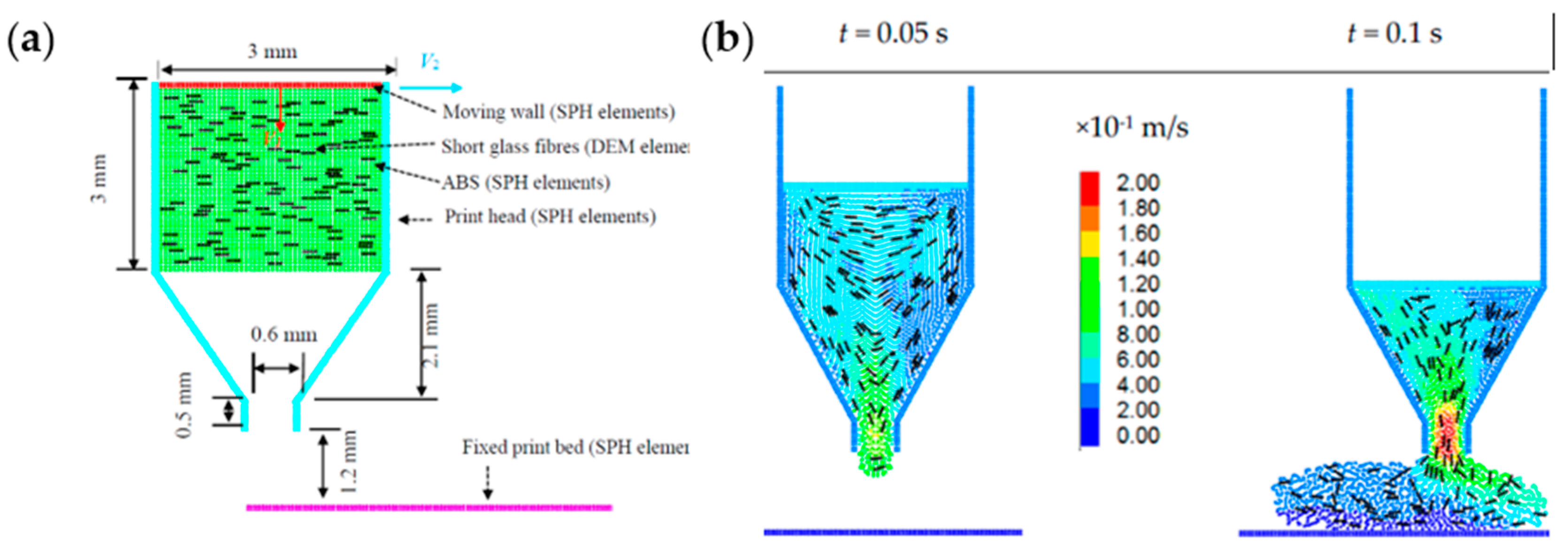

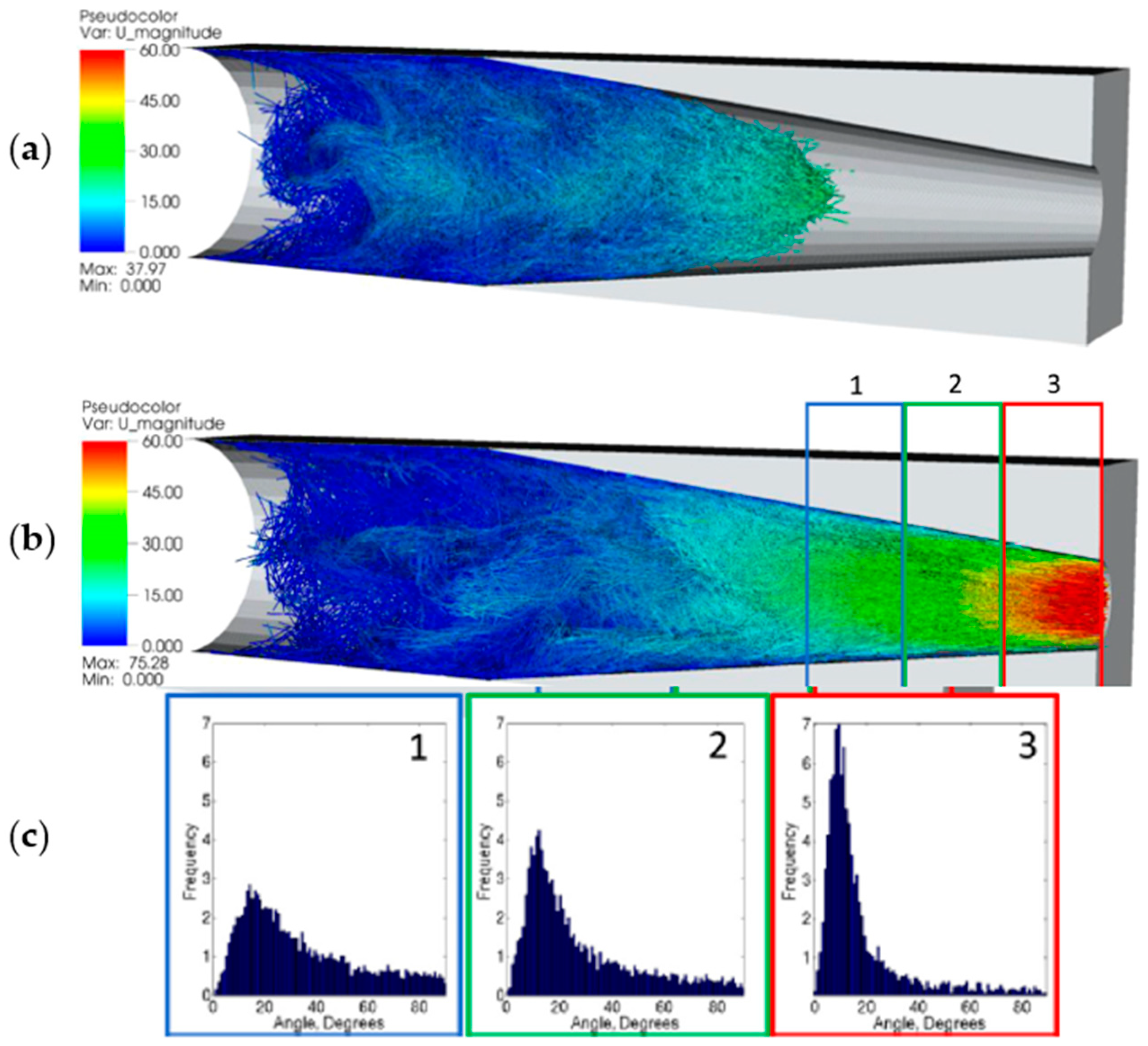

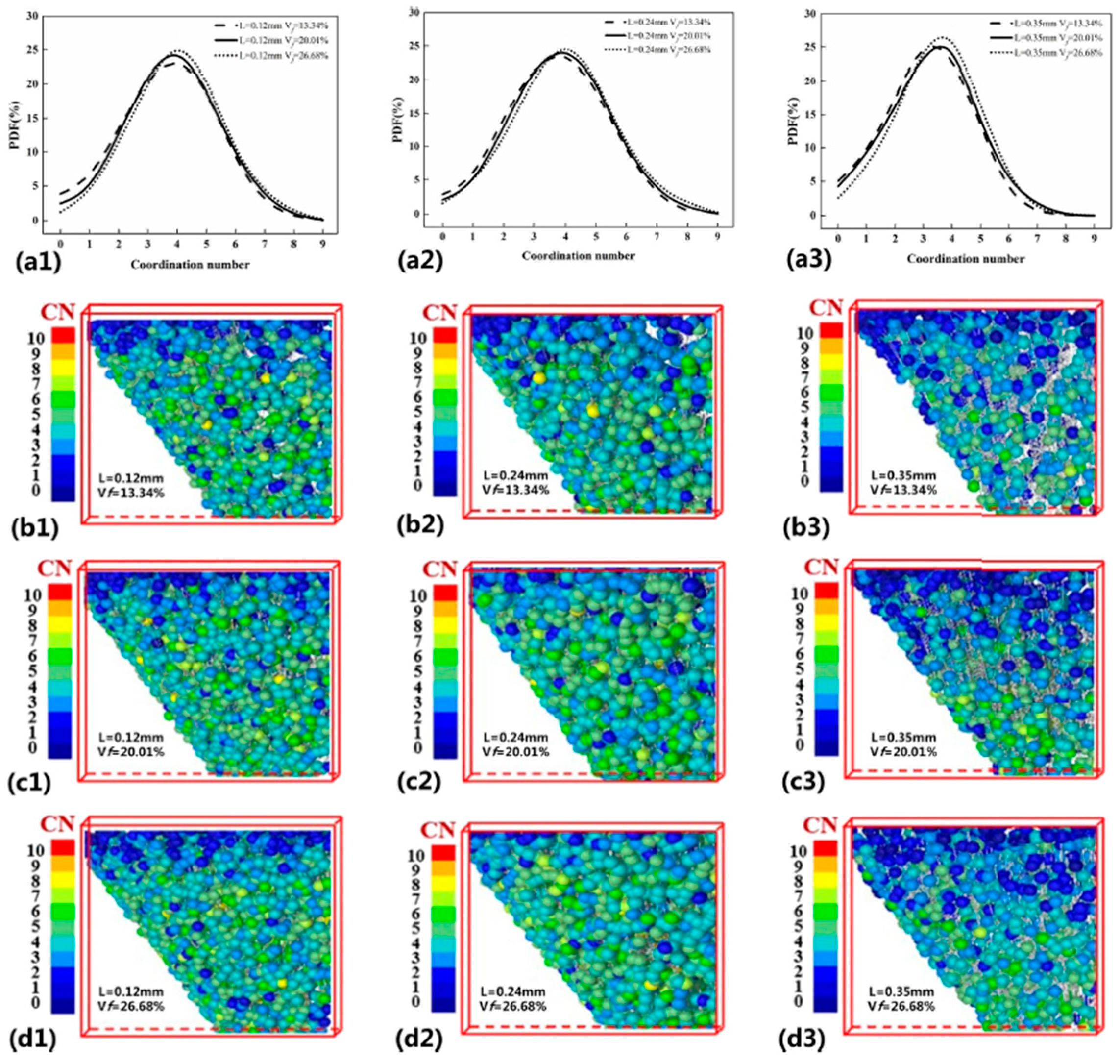

3.4. In-Nozzle Flow for Additive Manufacturing Composites (Fiber Orientation)

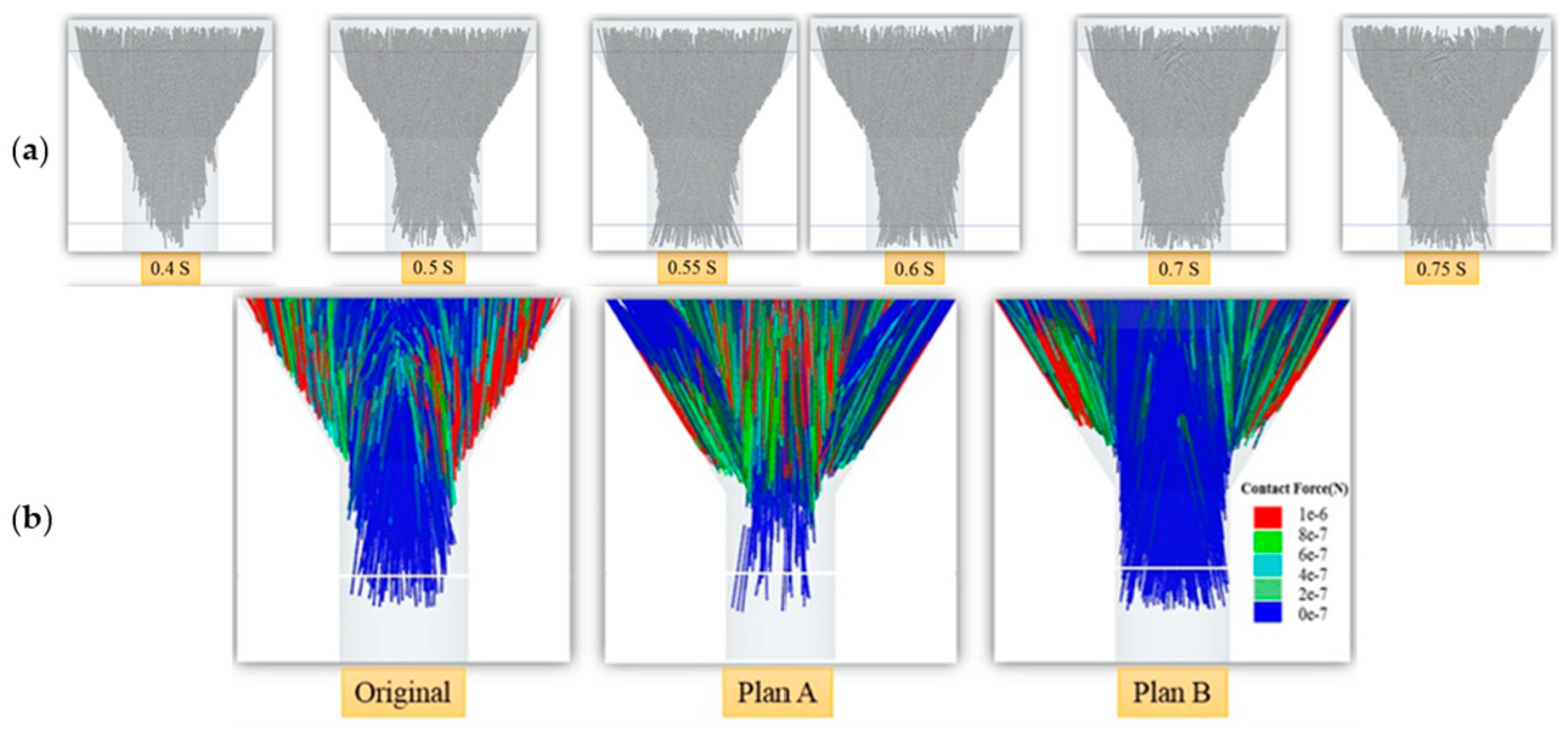

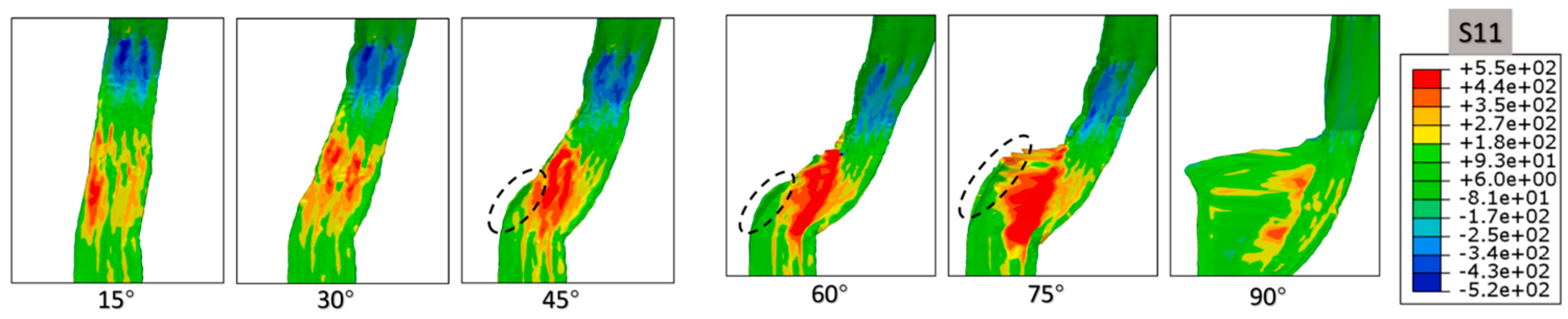

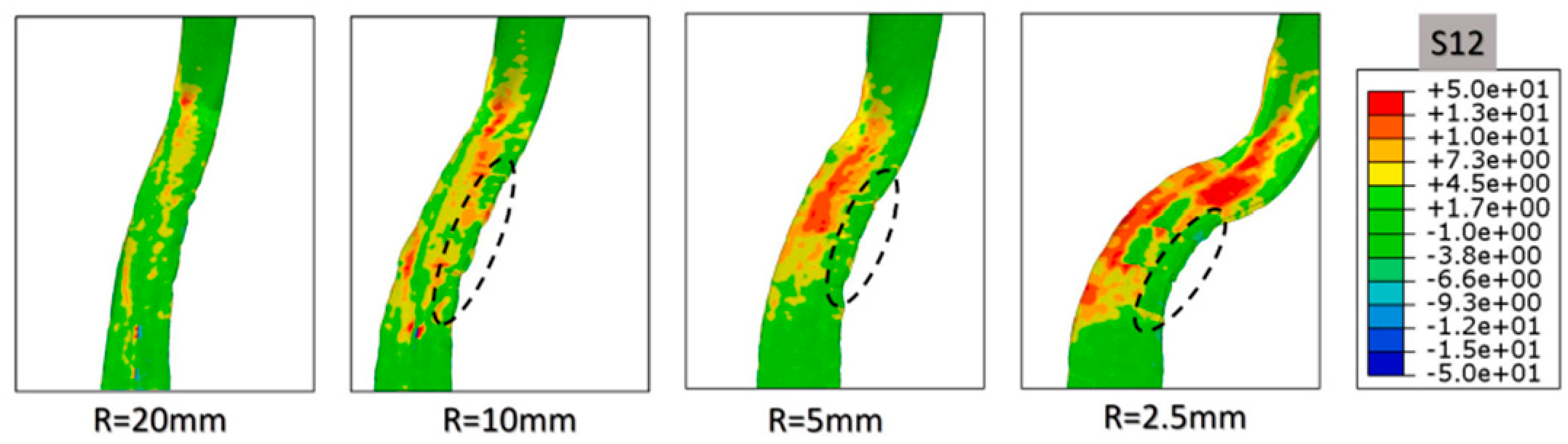

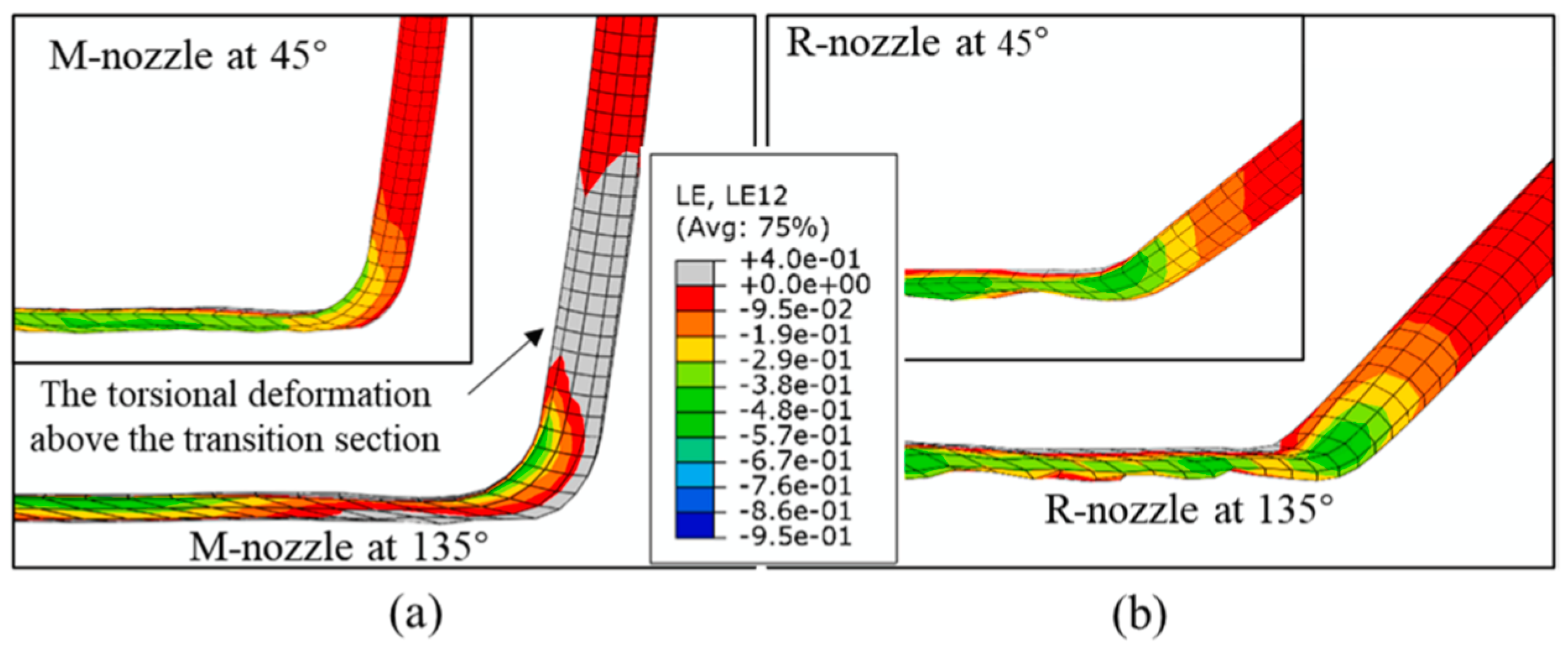

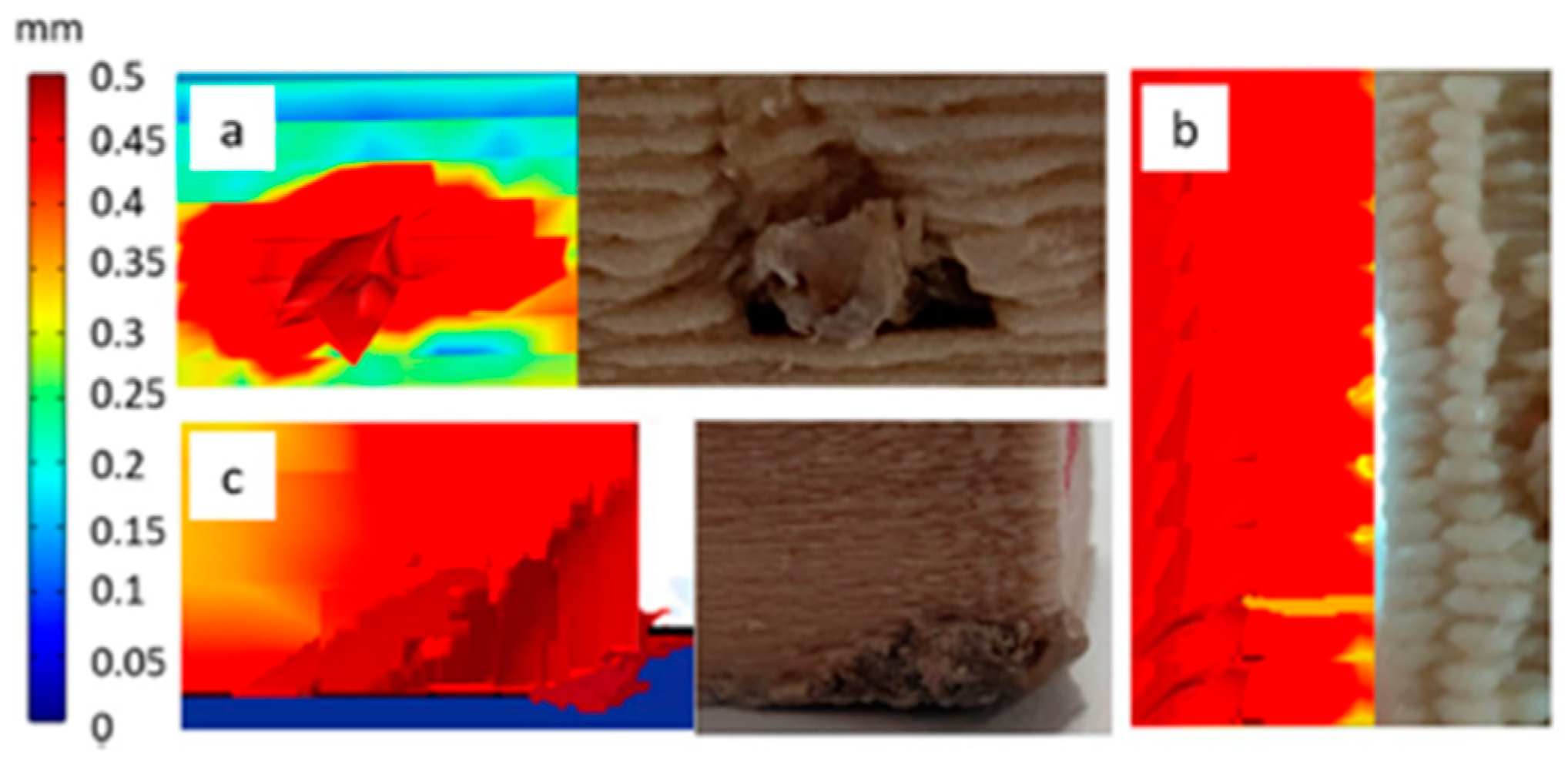

3.5. Extrusion Defects Simulation

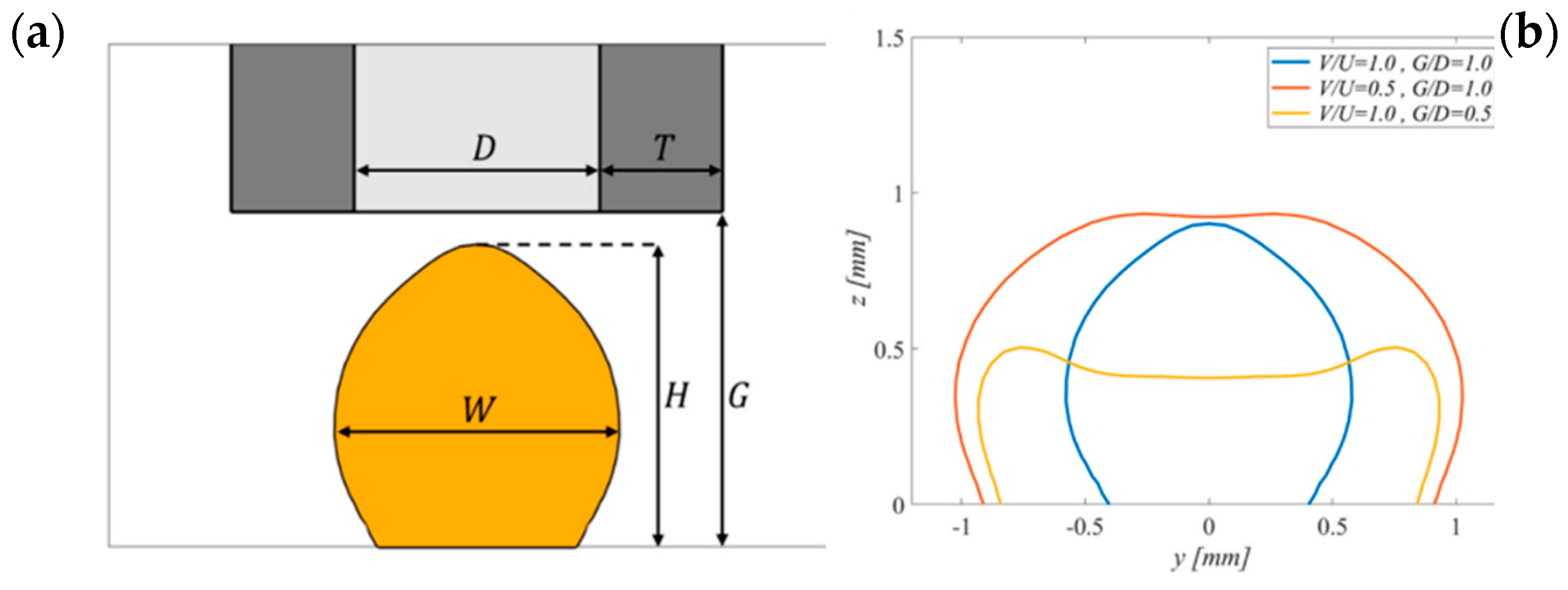

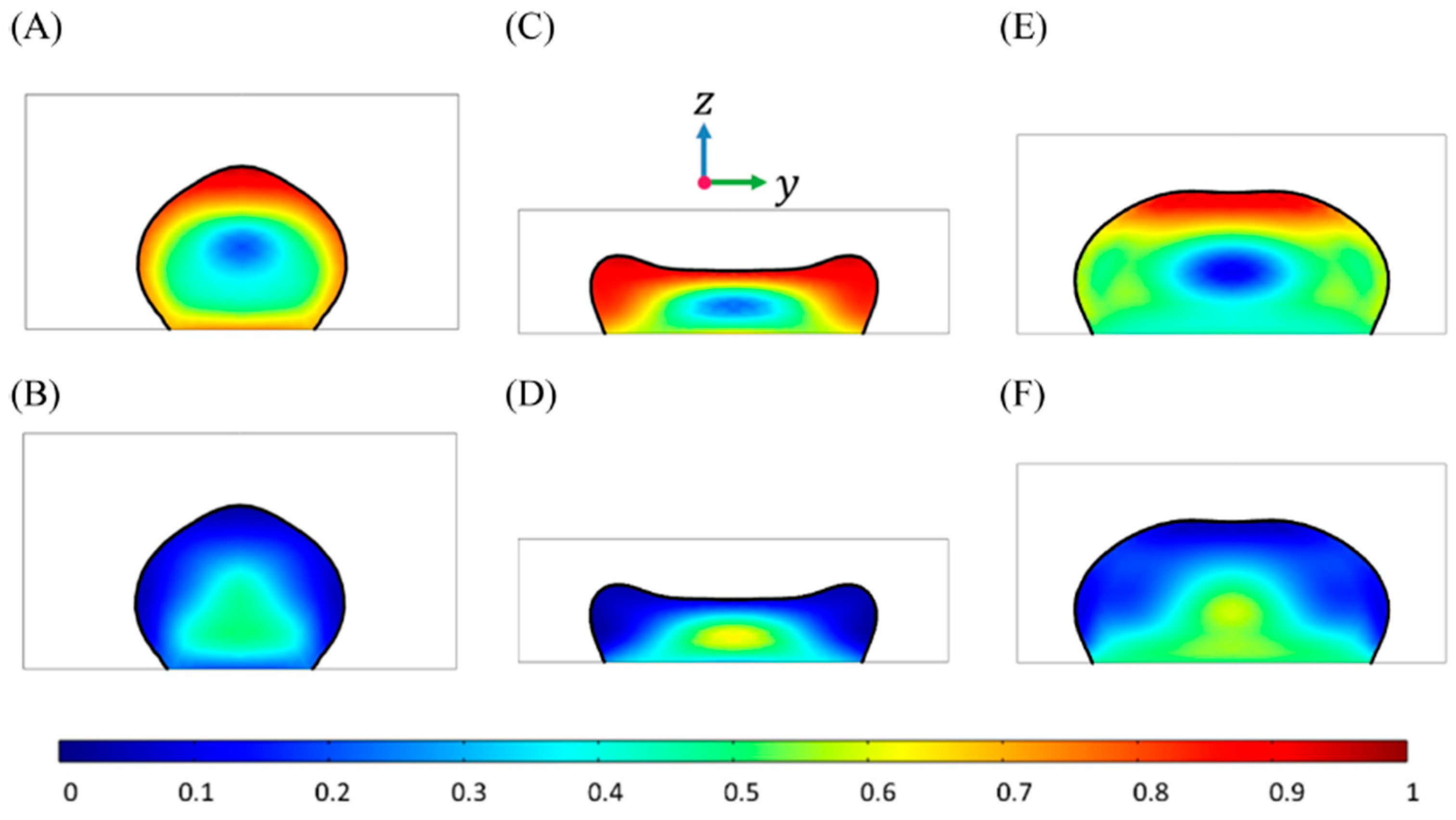

3.6. Deposition Simulation (First Layer Simulation for Thermoplastic Composites)

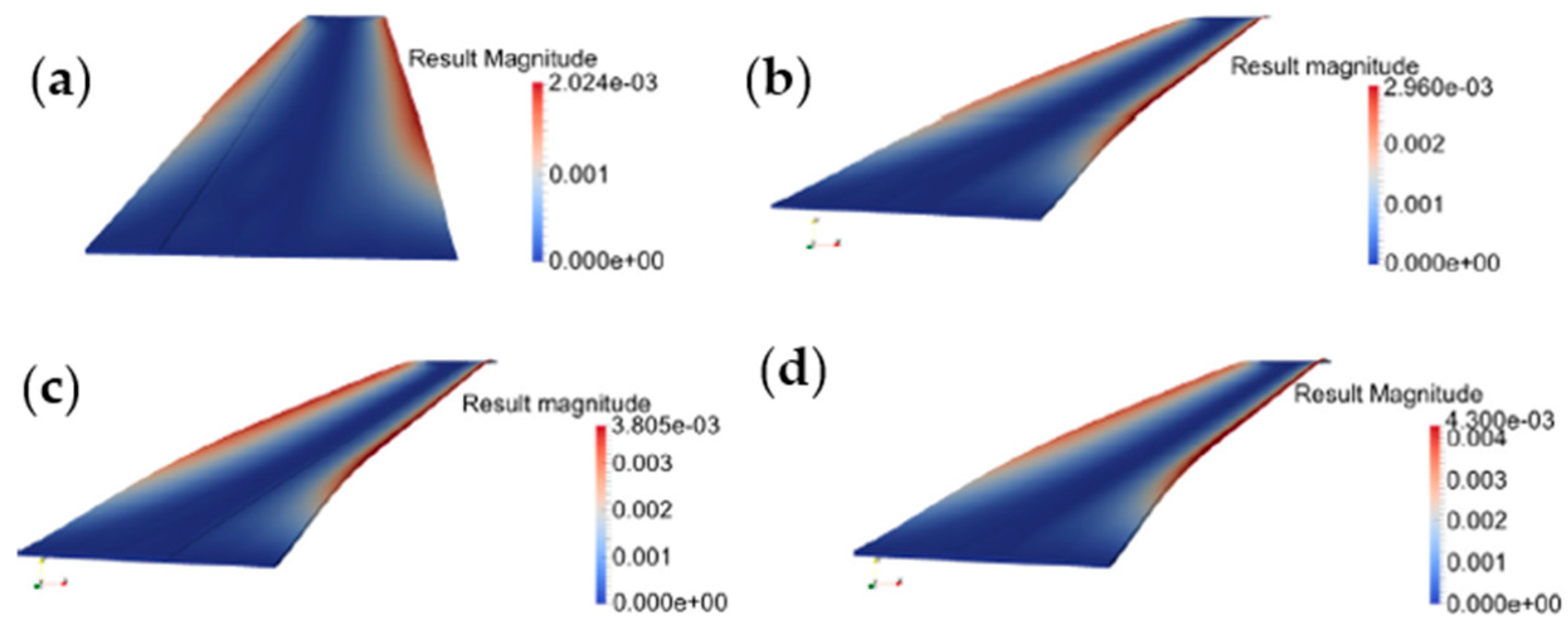

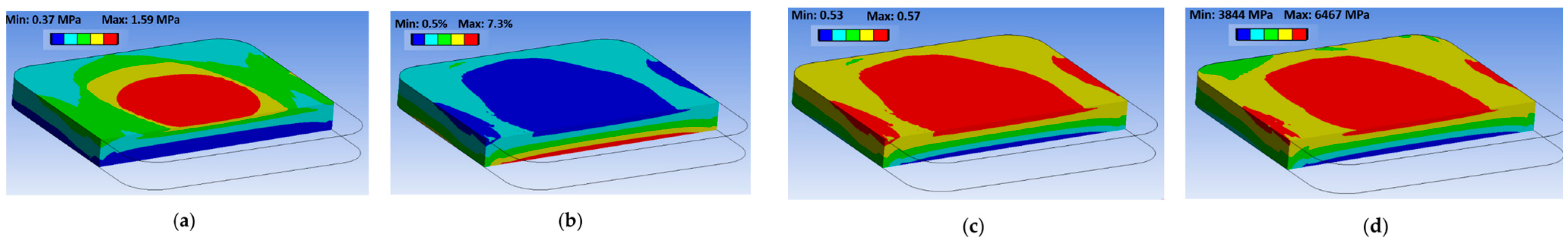

3.7. Solidification of 3D-Printed Composites (Residual Stress and Dimensional Precision)

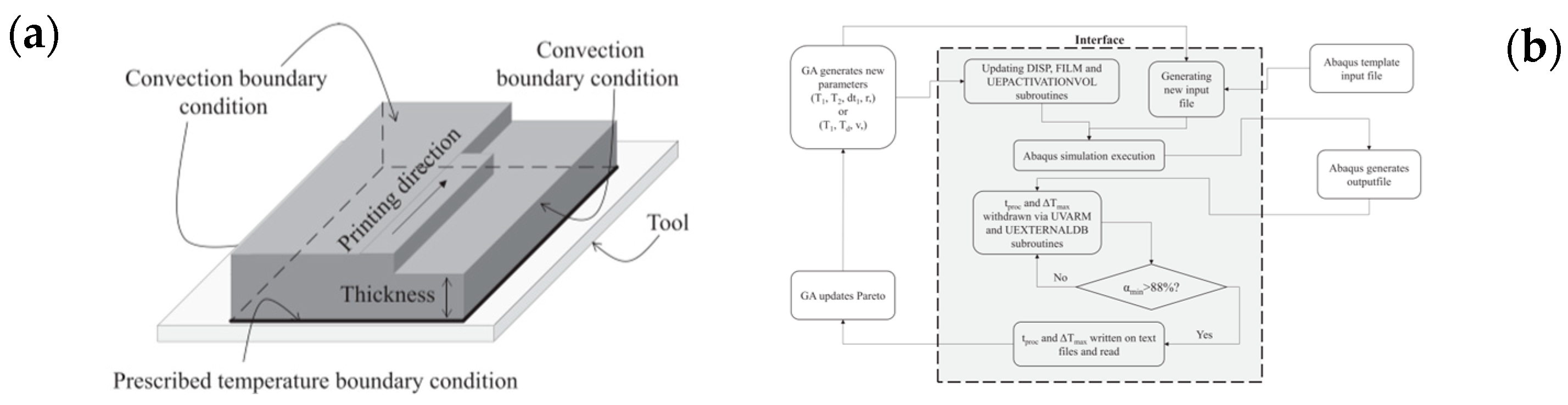

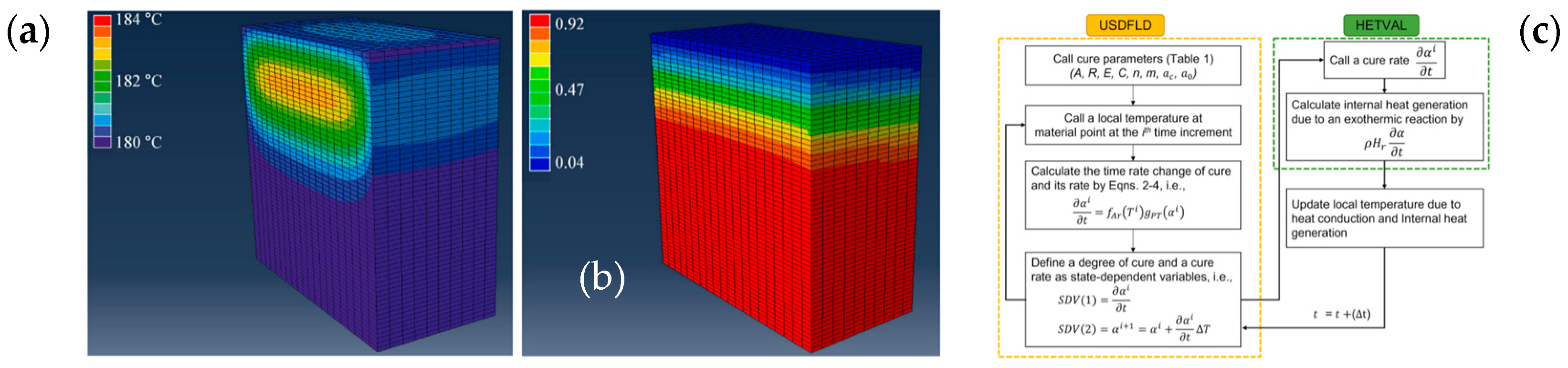

3.8. Solidification of 3D-Printed Thermoset Composites

3.9. Defect Simulations of Completed 3D-Printed Composites

3.10. Void Formation Simulation

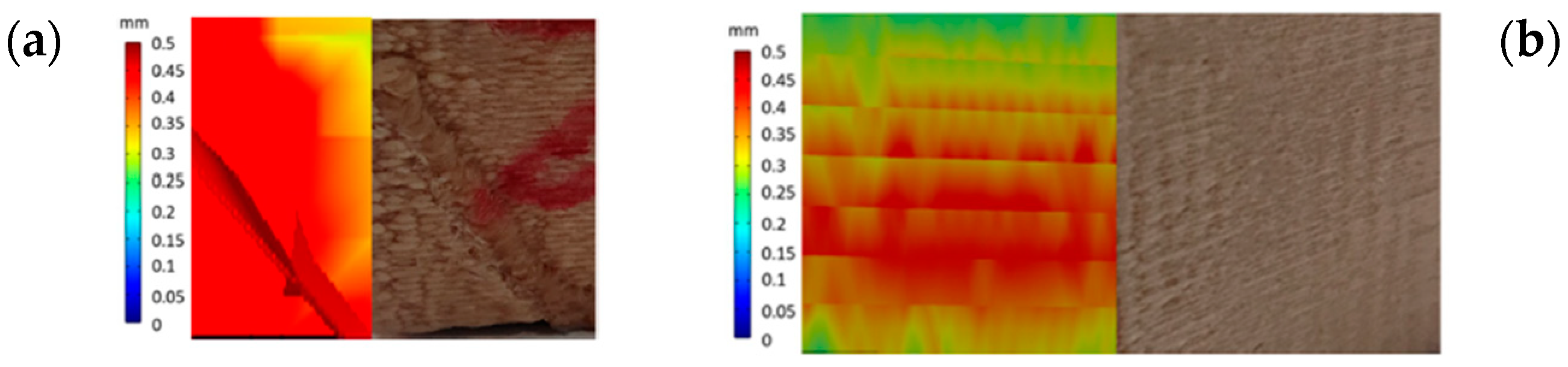

3.11. Surface Roughness Simulation

3.12. Post-Processing Simulation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Introduction and Basic Principles. In Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021; pp. 1–19. [Google Scholar] [CrossRef]

- Associates, W. Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2022. [Google Scholar]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 45,753,30A, 1 December 1977. [Google Scholar]

- Siemiński, P. Introduction to Fused Deposition Modeling. In Handbooks in Advanced Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 217–275. [Google Scholar] [CrossRef]

- Agarwal, R. Chapter 5—Additive manufacturing, Materials, technologies, and applications. In Additive Manufacturing: Advanced Materials and Design Techniques, 1st ed.; Pandey, P.M., Singh, N.K., Singh, Y., Eds.; CRC Press: Boca Raton, FL, USA, 2023; pp. 77–97. [Google Scholar]

- Yan, C.; Shi, Y.; Li, Z.; Wen, S.; Wei, Q. Selective Laser Sintering Additive Manufacturing Technology; Elsevier: New York, NY, USA, 2020. [Google Scholar] [CrossRef]

- The Evolution of SLS: New Technologies, Materials and Applications. Autonomous Manufacturing. 2021. Available online: https://amfg.ai/2020/01/21/the-evolution-of-sls-new-technologies-materials-and-applications/ (accessed on 12 January 2024).

- Prince, J.D. 3D Printing: An Industrial Revolution. J. Electron. Resour. Med. Libr. 2014, 11, 39–45. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive manufacturing: Current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 014001. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Martinez, D.W.; Espino, M.T.; Cascolan, H.M.; Crisostomo, J.L.; Dizon, J.R.C. A Comprehensive Review on the Application of 3D Printing in the Aerospace Industry. Key Eng. Mater. 2022, 913, 27–34. [Google Scholar] [CrossRef]

- Nichols, M.R. How does the automotive industry benefit from 3D metal printing? Met. Powder Rep. 2019, 74, 257–258. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Behera, A.; Menezes, P.L. Role of Composite Materials in Automotive Sector: Potential Applications. In Advances in Engine Tribology; Kumar, V., Agarwal, A.K., Jena, A., Upadhyay, R.K., Eds.; Springer: Singapore, 2022; pp. 193–217. [Google Scholar] [CrossRef]

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Aimar, A.; Palermo, A.; Innocenti, B. The Role of 3D Printing in Medical Applications: A State of the Art. J. Healthc. Eng. 2019, 2019, 5340616. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Saengchairat, N.; Tran, T.; Chua, C.K. A review: Additive manufacturing for active electronic components. Virtual Phys. Prototyp. 2017, 12, 31–46. [Google Scholar] [CrossRef]

- Inkwood Research. Global 3D Printing Market Growth_Global Opportunities. 2023. Available online: https://inkwoodresearch.com/reports/3d-printing-market/ (accessed on 12 January 2024).

- Statista. Global 3D Printing Industry Market Size. 2021. Available online: https://www.statista.com/statistics/315386/global-market-for-3d-printers/ (accessed on 12 January 2024).

- Report Linker. Additive Manufacturing Global Market Report 2023. 2023. Available online: https://www.globenewswire.com/news-release/2023/06/21/2692058/0/en/Additive-Manufacturing-Global-Market-Report-2023.html (accessed on 12 January 2024).

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short Fiber Reinforced Composites for Fused Deposition Modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Shofner, M.L.; Lozano, K.; Rodríguez-Macías, F.J.; Barrera, E.V. Nanofiber-Reinforced Polymers Prepared by Fused Deposition Modeling. J. Appl. Polym. Sci. 2003, 89, 3081–3090. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium filled polylactic acid (PLA) material for filament based 3D printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef]

- Ryder, M.A.; Lados, D.A.; Iannacchione, G.S.; Peterson, A.M. Fabrication and properties of novel polymer-metal composites using fused deposition modeling. Compos. Sci. Technol. 2018, 158, 43–50. [Google Scholar] [CrossRef]

- Kalsoom, U.; Nesterenko, P.N.; Paull, B. Recent developments in 3D printable composite materials. RSC Adv. 2016, 6, 60355–60371. [Google Scholar] [CrossRef]

- Singh, R.; Bedi, P.; Fraternali, F.; Ahuja, I. Effect of single particle size, double particle size and triple particle size Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM. Compos. B Eng. 2016, 106, 20–27. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T.-W. Interfacial bonding strength of short carbon fiber/acrylonitrile-butadiene-styrene composites fabricated by fused deposition modeling. Compos. B Eng. 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Fidan, I. Processing and Characterization of 3D-Printed Polymer Matrix Composites Reinforced with Discontinuous Fibers; University of Texas at Austin: Austin, TX, USA, 2019. [Google Scholar]

- Mohammadizadeh, M.; Gupta, A.; Fidan, I. Mechanical benchmarking of additively manufactured continuous and short carbon fiber reinforced nylon. J. Compos. Mater. 2021, 55, 3629–3638. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused deposition modeling of ABS-barium titanate composites: A simple route towards tailored dielectric devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [PubMed]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Dhavalikar, P.; Lan, Z.; Kar, R.; Salhadar, K. Biomedical Applications of Additive Manufacturing. In Biomaterials Science, 4th ed.; Wagner, W.R., Sakiyama-Elbert, S.E., Yaszemski, M.J., Eds.; Academic Press: New York, NY, USA, 2020; pp. 623–639. [Google Scholar]

- Penumakala, P.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2020, 37, 509–514. [Google Scholar] [CrossRef]

- Yin, J.; Lu, C.; Fu, J.; Huang, Y.; Zheng, Y. Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion. Mater. Des. 2018, 150, 104–112. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Tse, L.Y.L.; Kapila, S.; Barton, K. Contoured 3D Printing of Fiber Reinforced Polymers; University of Texas at Austin: Austin, TX, USA, 2016. [Google Scholar]

- Blanco, I. The use of composite materials in 3D printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Pervaiz, S.; Qureshi, T.A.; Kashwani, G.; Kannan, S. 3D Printing of Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: A Status Review. Materials 2021, 14, 4520. [Google Scholar] [CrossRef]

- Tyller, K. Method and Apparatus for Continuous Composite Three-Dimensional Printing. US20140061974A1, 24 August 2013. [Google Scholar]

- Pandelidi, C.; Bateman, S.; Piegert, S.; Hoehner, R.; Kelbassa, I.; Brandt, M. The technology of continuous fibre-reinforced polymers: A review on extrusion additive manufacturing methods. Int. J. Adv. Manuf. Technol. 2021, 113, 3057–3077. [Google Scholar] [CrossRef]

- Tamez, M.B.A.; Taha, I. A review of additive manufacturing technologies and markets for thermosetting resins and their potential for carbon fiber integration. Addit. Manuf. 2021, 37, 101748. [Google Scholar] [CrossRef]

- Continuous Composites. CF3D®. Available online: https://www.continuouscomposites.com/technology (accessed on 12 January 2024).

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Consolidation of continuous fibre reinforced composites in additive processes: A review. Addit. Manuf. 2021, 48, 102458. [Google Scholar] [CrossRef]

- Beyene, S.D.; Ayalew, B.; Pilla, S. Nonlinear Model Predictive Control of UV-Induced Thick Composite Manufacturing Process; University of Texas at Austin: Austin, TX, USA, 2019. [Google Scholar]

- Lewicki, J.P.; Rodriguez, J.N.; Zhu, C.; Worsley, M.A.; Wu, A.S.; Kanarska, Y.; Horn, J.D.; Duoss, E.B.; Ortega, J.M.; Elmer, W.; et al. 3D-Printing of Meso-structurally Ordered Carbon Fiber/Polymer Composites with Unprecedented Orthotropic Physical Properties. Sci. Rep. 2017, 7, 43401. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Duoss, E.B.; Worsley, M.A.; Lewicki, J.P. 3D printing of high performance cyanate ester thermoset polymers. J. Mater. Chem. A Mater. 2018, 6, 853–858. [Google Scholar] [CrossRef]

- Mahshid, R.; Isfahani, M.N.; Heidari-Rarani, M.; Mirkhalaf, M. Recent advances in development of additively manufactured thermosets and fiber reinforced thermosetting composites: Technologies, materials, and mechanical properties. Compos. Part. A Appl. Sci. Manuf. 2023, 171, 107584. [Google Scholar] [CrossRef]

- Thakur, A.; Dong, X. Printing with 3D continuous carbon fiber multifunctional composites via UV-assisted coextrusion deposition. Manuf. Lett. 2020, 24, 1–5. [Google Scholar] [CrossRef]

- Islam, Z.; Rahman, A.; Gibbon, L.; Hall, E.; Ulven, C.; Scala, J. Mechanical Characterization and Production of Complex Shapes Using Continuous Carbon Fiber Reinforced Thermoset Resin Based 3d Printing. SSRN 2023. [Google Scholar] [CrossRef]

- Xiao, H.; He, Q.; Duan, Y.; Wang, J.; Qi, Y.; Ming, Y.; Zhang, C.; Zhu, Y. Low-temperature 3D printing and curing process of continuous fiber-reinforced thermosetting polymer composites. Polym. Compos. 2023, 44, 2322–2330. [Google Scholar] [CrossRef]

- Robertson, I.D.; Yourdkhani, M.; Centellas, P.J.; Aw, J.E.; Ivanoff, D.G.; Goli, E.; Lloyd, E.M.; Dean, L.M.; Sottos, N.R.; Geubelle, P.H.; et al. Rapid energy-efficient manufacturing of polymers and composites via frontal polymerization. Nature 2018, 557, 223–227. [Google Scholar] [CrossRef]

- He, X.; Ding, Y.; Lei, Z.; Welch, S.; Zhang, W.; Dunn, M.; Yu, K. 3D printing of continuous fiber-reinforced thermoset composites. Addit. Manuf. 2021, 40, 101921. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, T.; Jiang, Q.; He, L.; Bismarck, A.; Hu, Q. Recent progress of 3D printed continuous fiber reinforced polymer composites based on fused deposition modeling: A review. J. Mater. Sci. 2021, 56, 12999–13022. [Google Scholar] [CrossRef]

- Markforged. Continuous Carbon Fiber—High Strength 3D Printing Material. Available online: https://markforged.com/materials/continuous-fibers (accessed on 18 January 2024).

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H.; Bagheri Saed, A. Improving mechanical properties of continuous fiber-reinforced thermoplastic composites produced by FDM 3D printer. J. Reinf. Plast. Compos. 2019, 38, 99–116. [Google Scholar] [CrossRef]

- Bettini, P.; Alitta, G.; Sala, G.; Di Landro, L. Fused Deposition Technique for Continuous Fiber Reinforced Thermoplastic. J. Mater. Eng. Perform. 2017, 26, 843–848. [Google Scholar] [CrossRef]

- Mori, K.I.; Maeno, T.; Nakagawa, Y. Dieless forming of carbon fibre reinforced plastic parts using 3D printer. Procedia Eng. 2014, 81, 1595–1600. [Google Scholar] [CrossRef]

- Araya-Calvo, M.; López-Gómez, I.; Chamberlain-Simon, N.; León-Salazar, J.L.; Guillén-Girón, T.; Corrales-Cordero, J.S.; Sánchez-Brenes, O. Evaluation of compressive and flexural properties of continuous fiber fabrication additive manufacturing technology. Addit. Manuf. 2018, 22, 157–164. [Google Scholar] [CrossRef]

- Luo, M.; Tian, X.; Shang, J.; Zhu, W.; Li, D.; Qin, Y. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 130–138. [Google Scholar] [CrossRef]

- Brooks, H.; Molony, S. Design and evaluation of additively manufactured parts with three dimensional continuous fibre reinforcement. Mater. Des. 2016, 90, 276–283. [Google Scholar] [CrossRef]

- Heitkamp, T.; Kuschmitz, S.; Girnth, S.; Marx, J.-D.; Klawitter, G.; Waldt, N.; Vietor, T. Stress-adapted fiber orientation along the principal stress directions for continuous fiber-reinforced material extrusion. Progress. Addit. Manuf. 2023, 8, 541–559. [Google Scholar] [CrossRef]

- Yeong, W.Y.; Goh, G.D. 3D Printing of Carbon Fiber Composite: The Future of Composite Industry? Matter 2020, 2, 1361–1363. [Google Scholar] [CrossRef]

- Stamopoulos, A.G.; Glinz, J.; Senck, S. Assessment of the effects of the addition of continuous fiber filaments in PA 6/short fiber 3D-printed components using interrupted in-situ x-ray CT tensile testing. Eng. Fail. Anal. 2024, 159, 108121. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Zhang, P.; Liu, Q.; Zhuang, Y.; Feng, Z.; Wang, F.; Wang, X. Layer thickness and path width setting in 3D printing of pre-impregnated continuous carbon, glass fibers and their hybrid composites. Addit. Manuf. 2024, 83, 104054. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Jayaprakash, S.; Kolari, K.; Kuva, J.; Kukko, K.; Partanen, J. The role of printing parameters on the short beam strength of 3D-printed continuous carbon fibre reinforced epoxy-PETG composites. Compos. Struct. 2024, 337, 118034. [Google Scholar] [CrossRef]

- Baechle-Clayton, M.; Loos, E.; Taheri, M.; Taheri, H. Failures and Flaws in Fused Deposition Modeling (FDM) Additively Manufactured Polymers and Composites. J. Compos. Sci. 2022, 6, 202. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H.; Bagheri Saed, A. An innovative design approach in three-dimensional printing of continuous fiber–reinforced thermoplastic composites via fused deposition modeling process: In-melt simultaneous impregnation. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2020, 234, 243–259. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Venezia, C.; Badini, C. Experimental Characterization and Modeling of 3D Printed Continuous Carbon Fibers Composites with Different Fiber Orientation Produced by FFF Process. Polymers 2022, 14, 426. [Google Scholar] [CrossRef]

- Croom, B.P.; Abbott, A.; Kemp, J.W.; Rueschhoff, L.; Smieska, L.; Woll, A.; Stoupin, S.; Koerner, H. Mechanics of nozzle clogging during direct ink writing of fiber-reinforced composites. Addit. Manuf. 2021, 37, 101701. [Google Scholar] [CrossRef]

- Muftu, S. Introduction. In Finite Element Method; Academic Press: Cambridge, MA, USA, 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method Volume 1: The Basis; Wiley: Hoboken, NJ, USA, 2000; Volume 1. [Google Scholar]

- Li, S.; Sitnikova, E. Representative volume elements and unit cells. In Representative Volume Elements and Unit Cells: Concepts, Theory, Applications and Implementation; Woodhead Publishing: Sawston, UK, 2020; pp. 67–77. [Google Scholar] [CrossRef]

- Shafighfard, T.; Cender, T.A.; Demir, E. Additive manufacturing of compliance optimized variable stiffness composites through short fiber alignment along curvilinear paths. Addit. Manuf. 2021, 37, 101728. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Wang, T.; Ramopoulos, V.; Neumaier, D.; Hofele, J.; Walter, M.; Jelonnek, J. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures. Compos. B Eng. 2020, 182, 107612. [Google Scholar] [CrossRef]

- Chen, Y.; Klingler, A.; Fu, K.; Ye, L. 3D printing and modelling of continuous carbon fibre reinforced composite grids with enhanced shear modulus. Eng. Struct. 2023, 286, 116165. [Google Scholar] [CrossRef]

- Chen, Y.; Ye, L. Topological design for 3D-printing of carbon fibre reinforced composite structural parts. Compos. Sci. Technol. 2021, 204, 108644. [Google Scholar] [CrossRef]

- Qian, S.; Liu, H.; Wang, Y.; Mei, D. Structural optimization of 3D printed SiC scaffold with gradient pore size distribution as catalyst support for methanol steam reforming. Fuel 2023, 341, 127612. [Google Scholar] [CrossRef]

- Date, A.W. (Ed.) Introduction. In Introduction to Computational Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2005; pp. 1–16. [Google Scholar] [CrossRef]

- Hu, H.H. Chapter 10—Computational Fluid Dynamics. In Fluid Mechanics, 5th ed.; Kundu, P.K., Cohen, I.M., Dowling, D.R., Eds.; Academic Press: Boston, MA, USA, 2012; pp. 421–472. [Google Scholar] [CrossRef]

- Xu, X.; Ren, H.; Chen, S.; Luo, X.; Zhao, F.; Xiong, Y. Review on melt flow simulations for thermoplastics and their fiber reinforced composites in fused deposition modeling. J. Manuf. Process. 2023, 92, 272–286. [Google Scholar] [CrossRef]

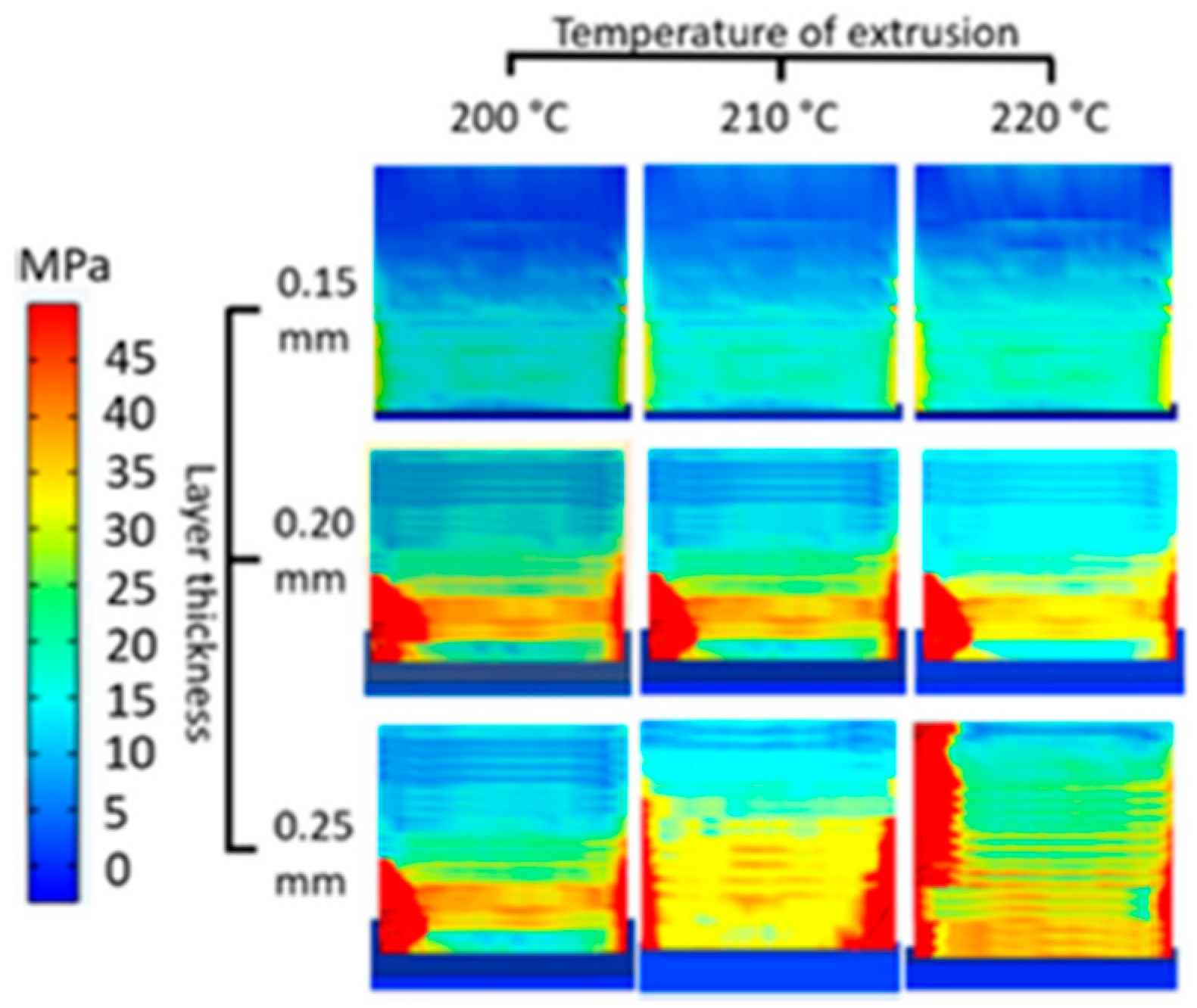

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Shi, X.Z.; Huang, M.; Zhao, Z.F.; Shen, C.Y. Nonlinear fitting technology of 7-parameter Cross-WLF viscosity model. Adv. Mater. Res. 2011, 189–193, 2103–2106. [Google Scholar] [CrossRef]

- Yang, D.; Wu, K.; Wan, L.; Sheng, Y. A particle element approach for modelling the 3d printing process of fibre reinforced polymer composites. J. Manuf. Mater. Process. 2017, 1, 10. [Google Scholar] [CrossRef]

- Sun, X.; Sakai, M.; Yamada, Y. Three-dimensional simulation of a solid-liquid flow by the DEM-SPH method. J. Comput. Phys. 2013, 248, 147–176. [Google Scholar] [CrossRef]

- Monaghan, J.J. An Introduction to SPH. Comput. Phys. Commun. 1988, 48, 89–96. [Google Scholar] [CrossRef]

- Kanarska, Y.; Duoss, E.B.; Lewicki, J.P.; Rodriguez, J.N.; Wu, A. Fiber motion in highly confined flows of carbon fiber and non-Newtonian polymer. J. Nonnewton Fluid. Mech. 2019, 265, 41–52. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Wu, J.; An, X.; Yang, D. Fibre bridging and nozzle clogging in 3D printing of discontinuous carbon fibre-reinforced polymer composites: Coupled CFD-DEM modelling. Int. J. Adv. Manuf. Technol. 2021, 117, 3549–3562. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D.E. A fully coupled simulation of planar deposition flow and fiber orientation in polymer composites additive manufacturing. Materials 2021, 14, 2596. [Google Scholar] [CrossRef]

- Kermani, N.N.; Advani, S.G.; Férec, J. Orientation Predictions of Fibers Within 3D Printed Strand in Material Extrusion of Polymer Composites. Addit. Manuf. 2023, 77, 103781. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L. The Use of Tensors to Describe and Predict Fiber Orientation in Short Fiber Composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Carreau, P.J.; De Kee, D.C.R.; Chhabra, R.P. Rheology of Polymeric Systems. In Rheology of Polymeric Systems; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2021. [Google Scholar] [CrossRef]

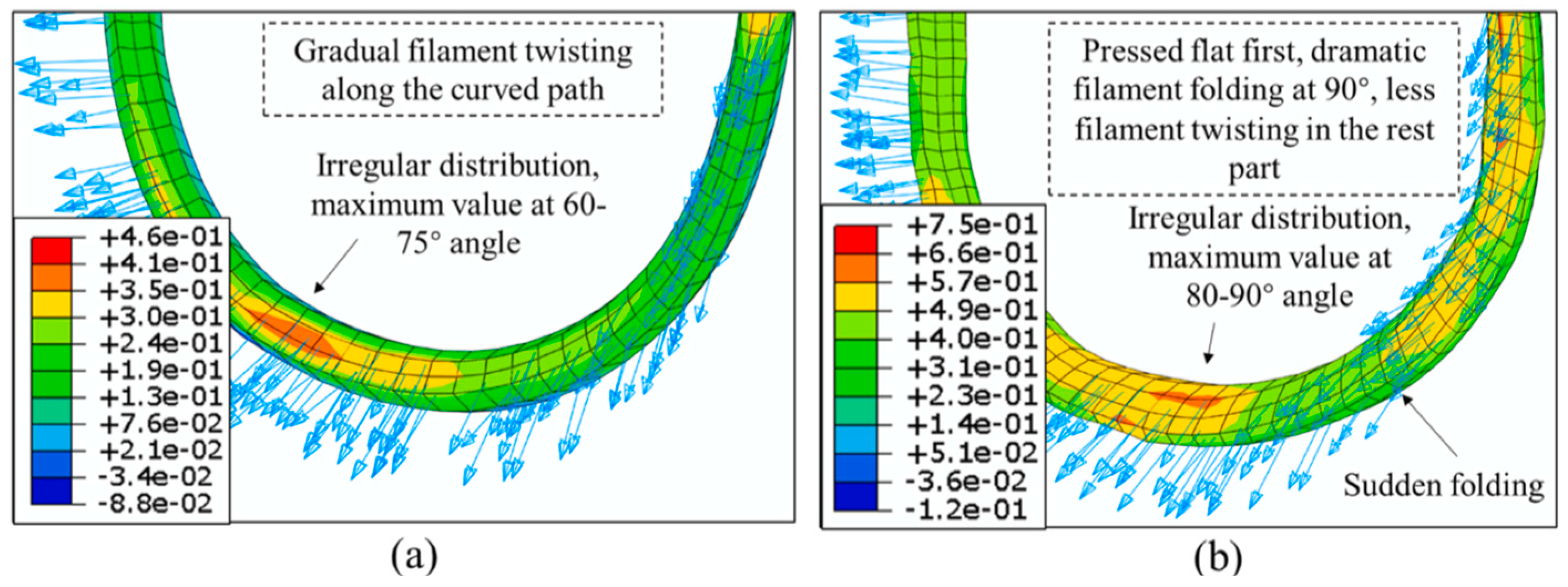

- Zhang, H.; Chen, J.; Yang, D. Fibre misalignment and breakage in 3D printing of continuous carbon fibre reinforced thermoplastic composites. Addit. Manuf. 2021, 38, 101775. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, H.; Wu, J.; Chen, J.; Yang, D. Improved fibre placement in filament-based 3D printing of continuous carbon fibre reinforced thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2023, 168, 107454. [Google Scholar] [CrossRef]

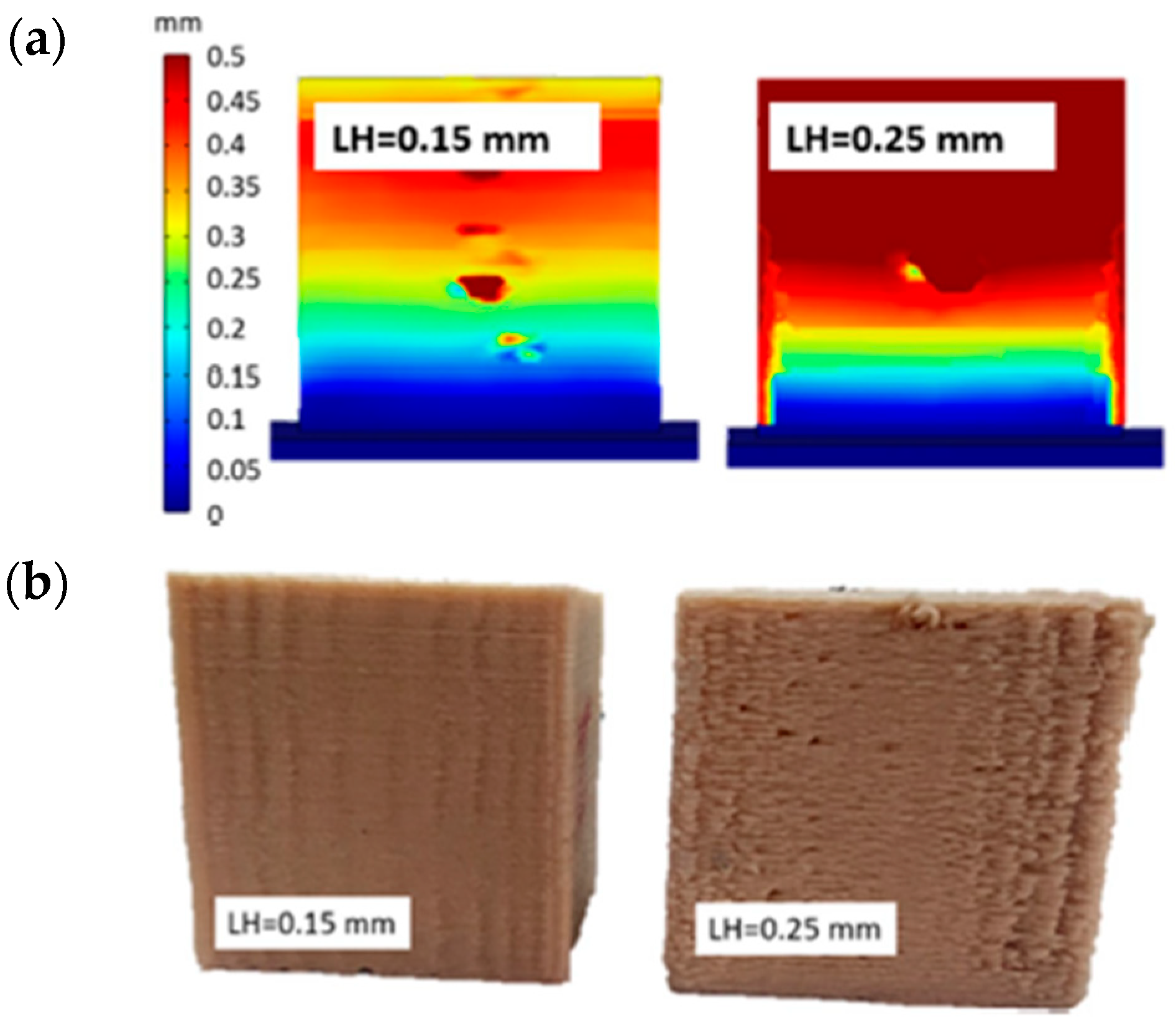

- Morvayová, A.; Contuzzi, N.; Casalino, G. Defects and residual stresses finite element prediction of FDM 3D printed wood/PLA biocomposite. Int. J. Adv. Manuf. Technol. 2023, 129, 2281–2293. [Google Scholar] [CrossRef]

- Ghnatios, C.; Fayazbakhsh, K. Warping estimation of continuous fiber-reinforced composites made by robotic 3D printing. Addit. Manuf. 2022, 55, 102796. [Google Scholar] [CrossRef]

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Assessment of the benefits of 3D printing of advanced thermosetting composites using process simulation and numerical optimisation. Addit. Manuf. 2023, 63, 103417. [Google Scholar] [CrossRef]

- Sharifi, A.M.; Kwon, D.J.; Shah, S.Z.H.; Lee, J. Modeling of frontal polymerization of carbon fiber and dicyclopentadiene woven composites with stochastic material uncertainty. Compos. Struct. 2023, 326, 117582. [Google Scholar] [CrossRef]

- Ross, S.M. Generating continuous random variables. In Simulation; Academic Press: Cambridge, MA, USA, 2023. [Google Scholar] [CrossRef]

- Fu, Y.T.; Li, J.; Li, Y.Q.; Fu, S.Y.; Guo, F.L. Full-process multi-scale morphological and mechanical analyses of 3D printed short carbon fiber reinforced polyetheretherketone composites. Compos. Sci. Technol. 2023, 236, 109999. [Google Scholar] [CrossRef]

- Gao, C.Y. FE Realization of a Thermo-Visco-Plastic Constitutive Model using VUMAT in ABAQUS/Explicit Program. In Computational Mechanics; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

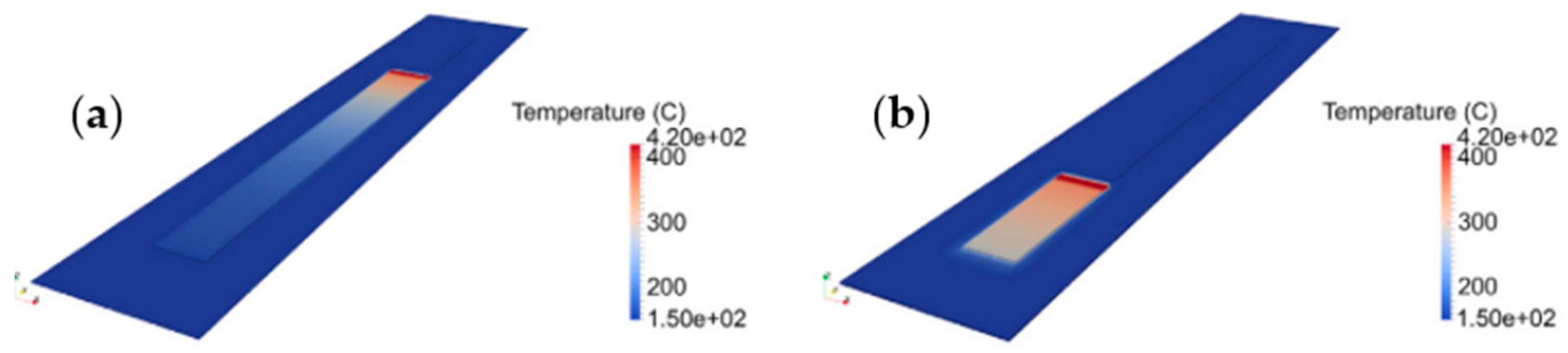

- Zhilyaev, I.; Grieder, S.; Küng, M.; Brauner, C.; Akermann, M.; Bosshard, J.; Inderkum, P.; Francisco, J.; Eichenhofer, M. Experimental and numerical analysis of the consolidation process for additive manufactured continuous carbon fiber-reinforced polyamide 12 composites. Front. Mater. 2022, 9, 1068261. [Google Scholar] [CrossRef]

- Nakamura, K.; Katayama, K.; Amano, T. Some aspects of nonisothermal crystallization of polymers. II. Consideration of the isokinetic condition. J. Appl. Polym. Sci. 1973, 17, 1031–1041. [Google Scholar] [CrossRef]

- Lorenz, N.; Gröger, B.; Müller-Pabel, M.; Gerritzen, J.; Müller, J.; Wang, A.; Fischer, K.; Gude, M.; Hopmann, C. Development and verification of a cure-dependent visco-thermo-elastic simulation model for predicting the process-induced surface waviness of continuous fiber reinforced thermosets. J. Compos. Mater. 2023, 57, 1105–1120. [Google Scholar] [CrossRef]

- Grieder, S.; Zhilyaev, I.; Küng, M.; Brauner, C.; Akermann, M.; Bosshard, J.; Inderkum, P.; Francisco, J.; Willemin, Y.; Eichenhofer, M. Consolidation of Additive Manufactured Continuous Carbon Fiber Reinforced Polyamide 12 Composites and the Development of Process-Related Numerical Simulation Methods. Polymers 2022, 14, 3429. [Google Scholar] [CrossRef]

| No. | Technological Parameters | Defects Induced in the Structure | Influenced Characteristic |

|---|---|---|---|

| 1. | Slicing Strategy | Voids Creation/Fiber Interruptions/Fiber Orientation | Mechanical Strength |

| 2. | Extrusion Temperature | Warping/Residual Stresses/Nozzle Clogging | Precision, Mechanical Strength |

| 3. | Nozzle Diameter | Fiber Volume Content/Fiber Orientation | Mechanical Strength |

| 4. | Printing-Bed Temperature | Delamination/Residual Stresses | Precision/Mechanical Strength/Surface Defects |

| 5. | Layer Height | Warping, Surface Defects, Voids, Delamination, Residual Stresses | Precision, Mechanical Strength |

| 6. | Printing Speed | Fiber Orientation/Void Formation | Mechanical Strength |

| No. | Process Phase | Subject | FE Approach | Application |

|---|---|---|---|---|

| 1. | Pre-Processing | Path Optimization | Topological Optimization, Fiber Direction Optimization | Trajectory Definition/Optimization |

| 2. | AM Process | Extrusion | Computational Fluid Dynamics | Melting Simulation |

| In-Nozzle Flow and Fiber Orientation | ||||

| Nozzle Clogging Simulation | ||||

| Deposition | Multi-Physics (Thermo-Mechanical) | First Layer Formation | ||

| Solidification | Multi-Physics (Thermo-Mechanical) | Residual Stresses | ||

| Dimensional Accuracy | ||||

| Curing Thermoset Composites | ||||

| 3. | Post-Processing | Defects and Post-processing Treatments | Multi-Physics (Thermo-Mechanical) | Internal Defects |

| Void Formation | ||||

| Surface Roughness |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zach, T.F.; Dudescu, M.C. The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process. J. Compos. Sci. 2024, 8, 146. https://doi.org/10.3390/jcs8040146

Zach TF, Dudescu MC. The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process. Journal of Composites Science. 2024; 8(4):146. https://doi.org/10.3390/jcs8040146

Chicago/Turabian StyleZach, Theodor Florian, and Mircea Cristian Dudescu. 2024. "The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process" Journal of Composites Science 8, no. 4: 146. https://doi.org/10.3390/jcs8040146

APA StyleZach, T. F., & Dudescu, M. C. (2024). The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process. Journal of Composites Science, 8(4), 146. https://doi.org/10.3390/jcs8040146