Prediction of the Bond Strength of Externally Bonded FRP Sheets Applied to Concrete via Grooves Technique Using Artificial Neural Networks

Abstract

1. Introduction

2. Dataset Development

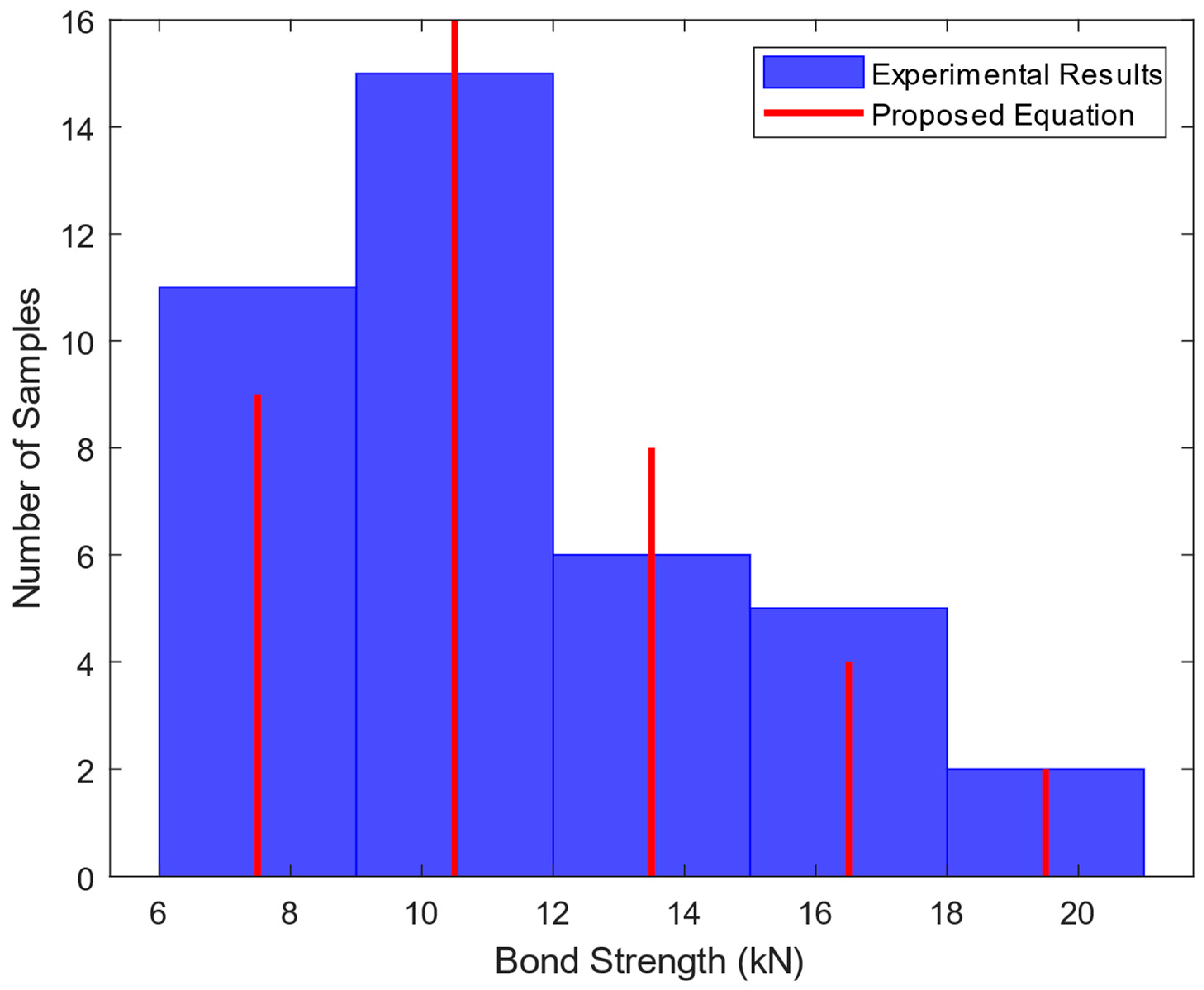

3. Projected Mathematical Equation

4. Artificial Neural Networks

4.1. Normalization of Dataset

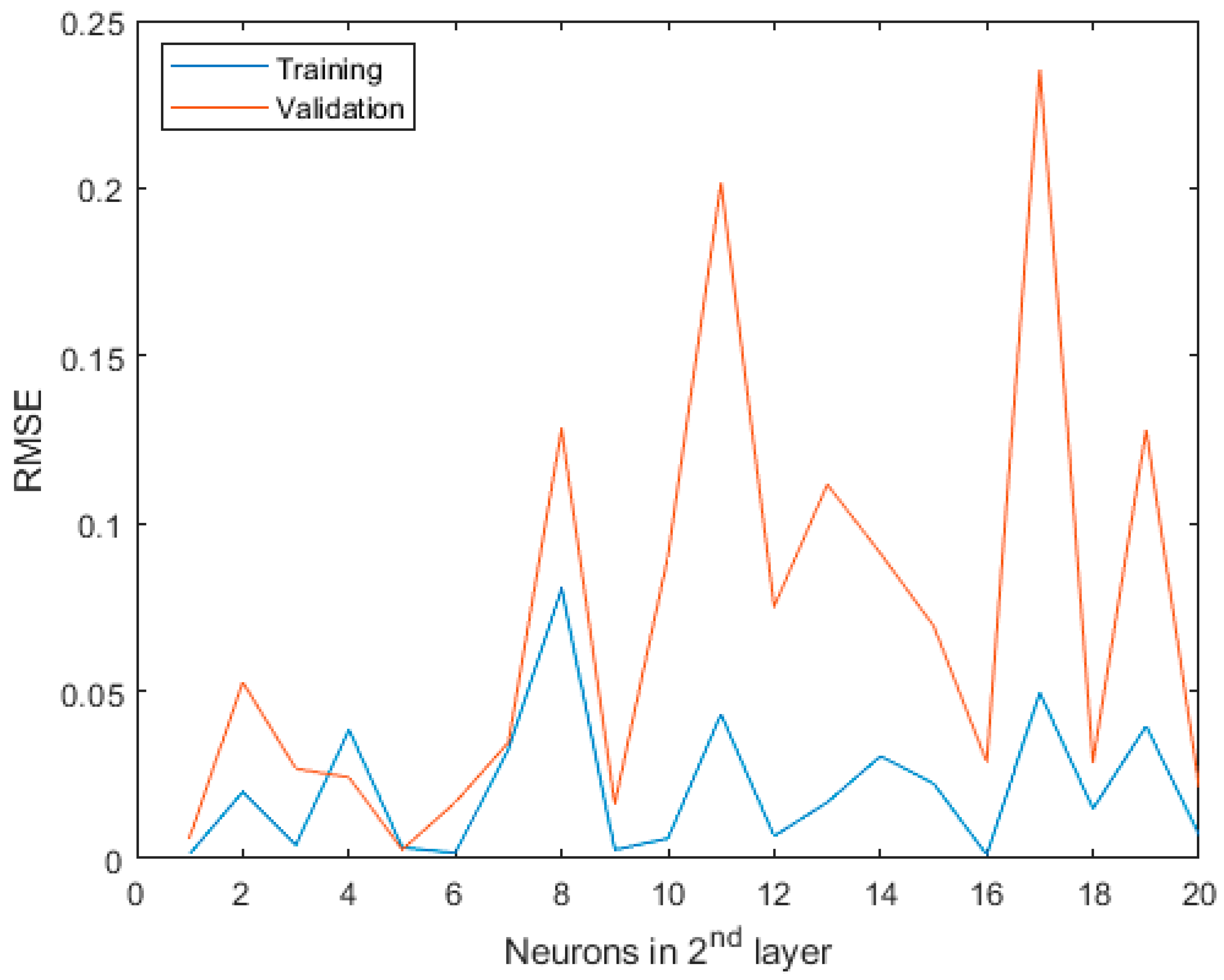

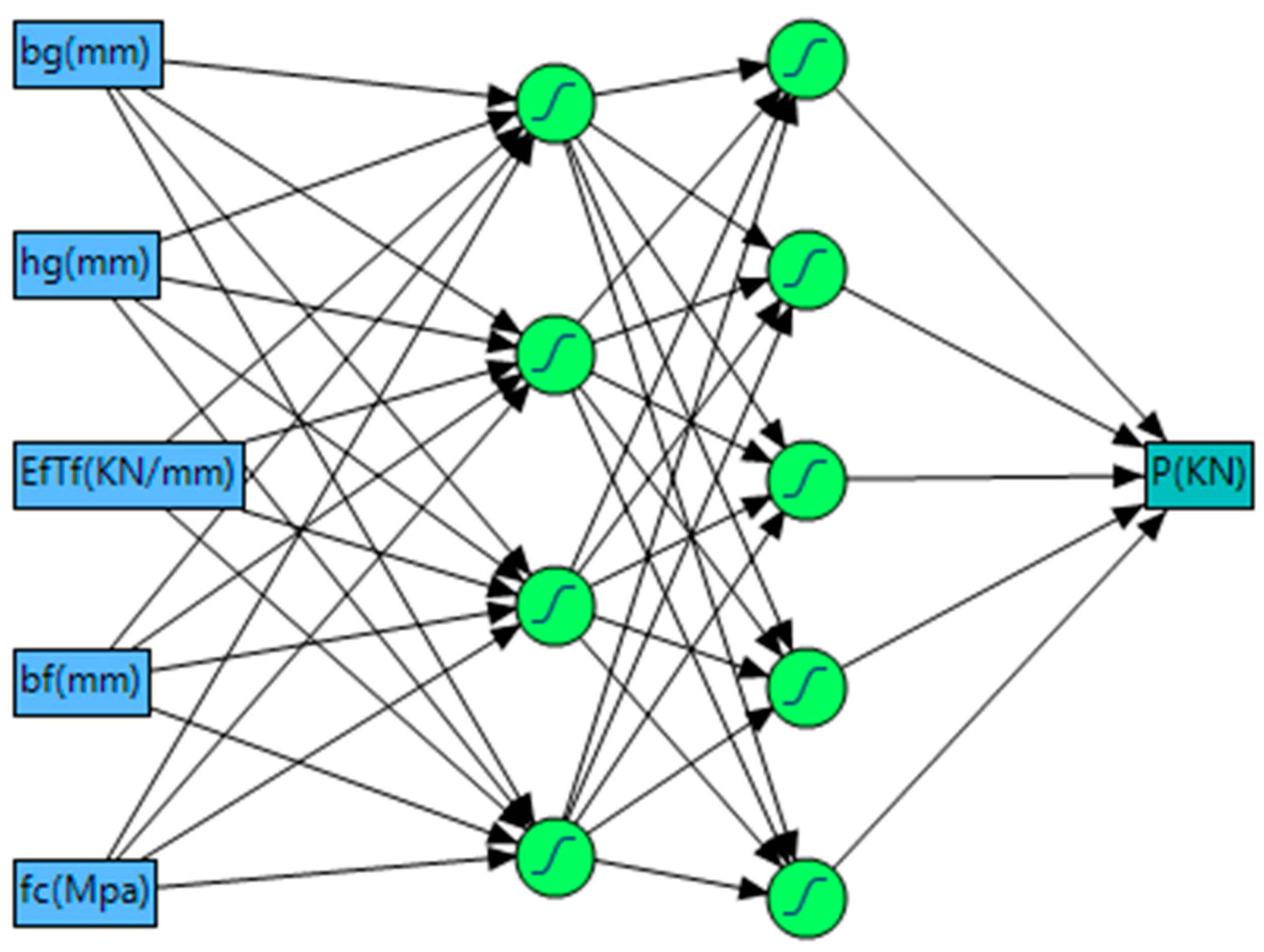

4.2. Structure of ANN Model

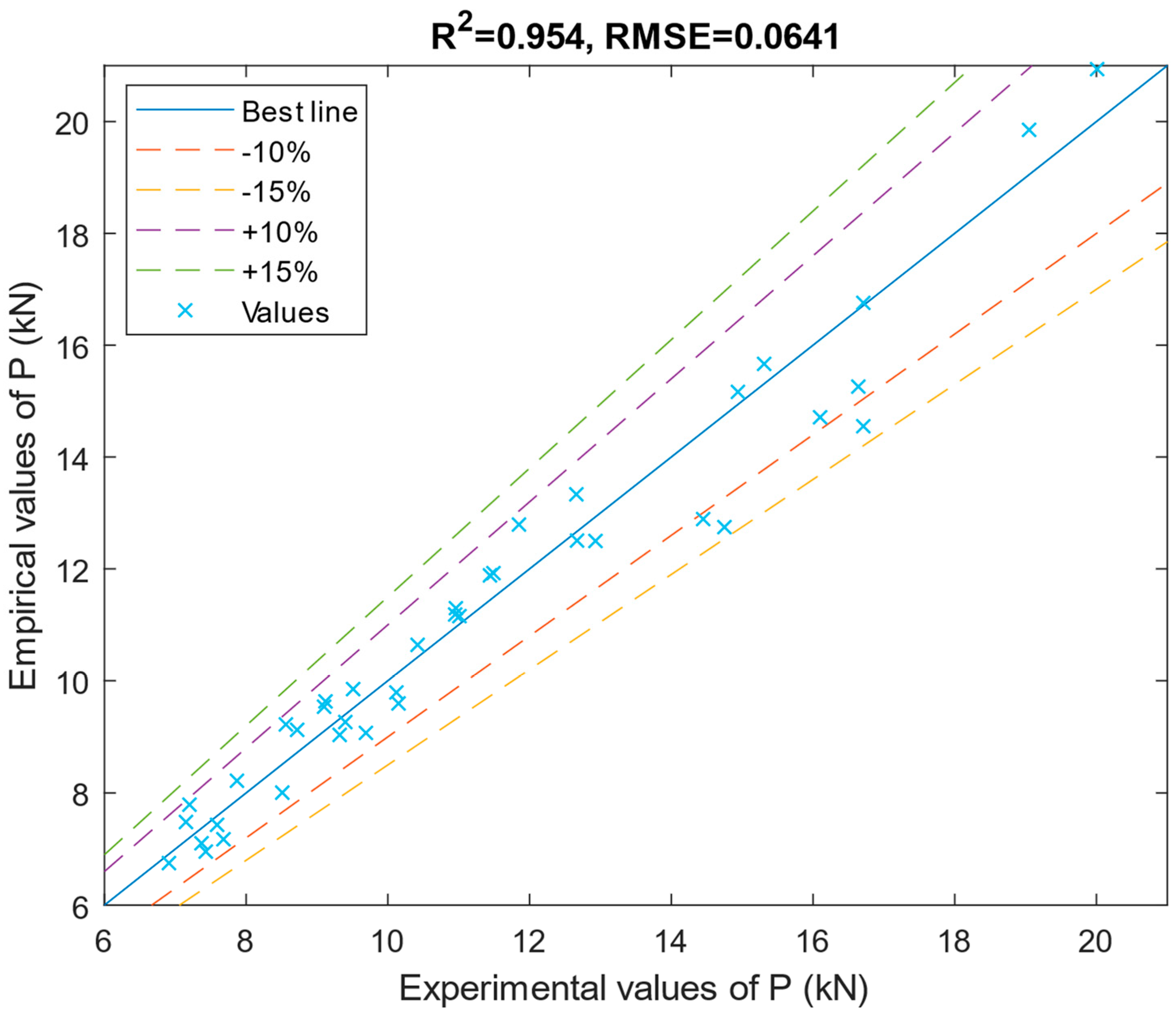

4.3. Performance of ANN Model

5. Statistical Comparison

6. Parametric Study Employing ANN Equation

7. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dolati, S.S.K.; Malla, P.; Ortiz, J.D.; Mehrabi, A.; Nanni, A. Identifying NDT methods for damage detection in concrete elements reinforced or strengthened with FRP. Eng. Struct. 2023, 287, 116155. [Google Scholar] [CrossRef]

- Castillo, E.; Griffith, M.; Ingham, J. Straight FRP anchors exhibiting fiber rupture failure mode. Compos. Struct. 2019, 207, 612–624. [Google Scholar] [CrossRef]

- Moghaddas, A.; Mostofinejad, D.; Ilia, E. Empirical FRP-concrete effective bond length model for externally bonded reinforcement on the grooves. Compos. Part B Eng. 2019, 172, 323–338. [Google Scholar] [CrossRef]

- Zhou, H.; Attard, T.L.; Dhiradhamvit, K.; Wang, Y.; Erdman, D. Crashworthiness characteristics of a carbon fiber reinforced dual-phase epoxy–polyurea hybrid matrix composite. Compos. Part B Eng. 2015, 71, 17–27. [Google Scholar] [CrossRef]

- Attard, T.L.; Zhou, H. Damage absorption of high-impact structural systems using time-reaction of hybridized epoxy-polyurea interfaces. Athens J. Technol. Eng. 2016, 3, 71–88. [Google Scholar] [CrossRef]

- Lu, X.Z.; Ye, L.P.; Teng, J.G.; Jiang, J.J. Meso-scale finite element model for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 564–575. [Google Scholar] [CrossRef]

- Seracino, R.; Raizal Saifulnaz, M.R.; Oehlers, D.J. Generic debonding resistance of EB and NSM plate-to-concrete joints. J. Compos. Constr. 2007, 11, 62–70. [Google Scholar] [CrossRef]

- Sayed Ahmed, E.Y.; Bakay, R.; Shrive, N.G. Bond strength of FRP laminates to concrete: State-of-the-art review. Electron. J. Struct. Eng. 2009, 9, 45–61. [Google Scholar] [CrossRef]

- Pan, J.; Wu, Y.F. Analytical modeling of bond behavior between FRP plate and concrete. Compos. Part B Eng. 2014, 61, 17–25. [Google Scholar] [CrossRef]

- Vahedian, A.; Shrestha, R.; Crews, K. Effective bond length and bond behaviour of FRP externally bonded to timber. Constr. Build. Mater. 2017, 151, 742–754. [Google Scholar] [CrossRef]

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2017.

- Wu, Y.F.; Xu, X.S.; Sun, J.B.; Jiang, C. Analytical solution for the bond strength of externally bonded reinforcement. Compos. Struct. 2012, 94, 3232–3239. [Google Scholar] [CrossRef]

- Grace, C.; Yang, Y.; Sneed, L. Fracture mechanics approaches to debonding behavior of reinforced concrete members with externally-bonded fiber reinforced polymer laminates. ACI Spec. Publ. 2012, 286, 99–118. [Google Scholar]

- Karbhari, V.M.; Niu, H.; Sikorsky, C. Review and comparison of fracture mechanics based bond strength models for FRP-strengthened structures. J. Reinf. Plast. Compos. 2006, 25, 1757–1794. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Saatcioglu, M. Tensile behavior of FRP anchors in concrete. J. Compos. Constr. 2009, 13, 82–92. [Google Scholar] [CrossRef]

- Murad, Y. An experimental study on flexural strengthening of RC beams using CFRP sheets. Int. J. Eng. Technol. 2018, 7, 2075–2080. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Fang, C.; Gholampour, A. Influence of FRP anchor configuration on the behavior of FRP plates externally bonded on concrete members. Eng. Struct. 2017, 133, 133–150. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Haddad, R.; Al-Halboni, A. Bond-slip behaviour between self-compacting concrete and carbon fibre-reinforced polymer sheets. Mag. Concr. Res. 2015, 67, 89–103. [Google Scholar] [CrossRef]

- Haddad, R.; Al-Rousan, R.; Almasry, A. Bond-slip behavior between carbon fiber reinforced polymer sheets and heat-damaged concrete. Compos. Part B Eng. 2013, 45, 1049–1060. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Effect of using carbon nanotube modified epoxy on bond–slip behavior between concrete and FRP sheets. Constr. Build. Mater. 2016, 105, 511–518. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hajrasouliha, M.J. Effect of concrete strength and groove dimensions on performance of grooving method to postpone debonding of FRP sheets in strengthened concrete beams. IJST Trans. Civ. Eng. 2013, 37, 219–232. [Google Scholar]

- Mostofinejad, D.; Tabatabaei Kashani, A. Experimental study on effect of EBR and EBROG methods on debonding of FRP sheets used for shear strengthening of RC beams. Compos. Part B Eng. 2013, 45, 1704–1713. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Moghaddas, A. Bond efficiency of EBR and EBROG methods in different flexural failure mechanisms of FRP strengthened RC beams. Constr. Build. Mater. 2014, 54, 605–614. [Google Scholar] [CrossRef]

- Hosseini, A.; Mostofinejad, D.; Hajialilue Bonab, M. Displacement and strain field measurement in steel and RC beams using particle image velocimetry. J. Eng. Mech. 2014, 140, 04014086. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Mahmoudabadi, E. Grooving as alternative method of surface preparation to postpone debonding of FRP laminates in concrete beams. J. Compos. Constr. 2010, 14, 804–811. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Khozaei, K. Effect of GM patterns on ductility and debonding control of FRP sheets in RC strengthened beams. Constr. Build. Mater. 2015, 93, 110–120. [Google Scholar] [CrossRef]

- Moshiri, N.; Tajmir-Riahi, A.; Mostofinejad, D.; Czaderski, C.; Motavalli, M. Experimental and analytical study on CFRP strips-to-concrete bonded joints using EBROG method. Compos. Part B Eng. 2019, 158, 437–447. [Google Scholar] [CrossRef]

- Hosseini, A.; Mostofinejad, D.; Emami, M. Influence of bonding technique on bond behavior of CFRP-to-claybrick masonry joints: Experimental study using particle image velocimetry (PIV). Int. J. Adhes. Adhes. 2015, 59, 27–39. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Akhlaghi, A. Experimental investigation of the efficacy of EBROG method in seismic rehabilitation of deficient reinforced concrete beam–column joints using CFRP sheets. J. Compos. Constr. 2016, 21, 04016116. [Google Scholar] [CrossRef]

- Adeli, H.; Yeh, C. Perceptron Learning in Engineering Design. Microcomput. Civ. Eng. 1989, 4, 247–256. [Google Scholar] [CrossRef]

- Dimiduk, D.M.; Holm, E.A.; Niezgoda, S.R. Perspectives on the impact of machine learning, deep learning, and artificial intelligence on materials, processes, and structures engineering. Integr. Mater. Manuf. Innov. 2018, 7, 157–172. [Google Scholar] [CrossRef]

- Dolbow, J.E.; Garikipati, K.; Park, H.S. Computational Mechanics Vision and Future Challenges Workshop Report; Technical Report; University of Michigan: Ann Arbor, MI, USA, 2019. [Google Scholar]

- Shakiba, M.; Parson, N.; Chen, X.G. Modeling the effects of cu content and deformation variables on the high-temperature flow behavior of dilute Al-Fe-Si alloys using an artificial naural network. Materials 2016, 9, 536. [Google Scholar] [CrossRef]

- Chojaczyk, A.A.; Teixeira, A.P.; Luìs, C.; Cardosa, J.B.; Soares, C.G. Review and application of artificial neural networks models in reliability analysis of steel structures. Struct. Saf. 2015, 52, 78–89. [Google Scholar] [CrossRef]

- Liu, G.R.; Xu, Y.G.; Wu, Z.P. Total solution for structural mechanics problems. Comput. Methods Appl. Mech. Eng. 2001, 191, 989–1012. [Google Scholar] [CrossRef]

- Waszczyszyn, Z.; Ziemianski, L. Neural networks in mechanics of structures and materials—New results and prospects of applications. Comput. Struct. 2001, 79, 2261–2276. [Google Scholar] [CrossRef]

- Tahir, Z.R.; Mandal, P. Artificial neural networks prediction of buckling load of thin cylindrical shells under axial compression. Eng. Struct. 2017, 152, 843–855. [Google Scholar] [CrossRef]

- Cheng, J.; Li, Q.S. Reliability analysis of structures using artificial neural network based genetic algorithms. Comput. Methods Appl. Mech. Eng. 2008, 197, 3742–3750. [Google Scholar] [CrossRef]

- Zhao, D.; Ren, D.; Zhao, K.; Pan, S.; Guo, X. Effect of welding parameters on tensile strength of ultrasonic spot welded joints of aluminum to steel—By experimentation and artificial neural network. J. Manuf. Process. 2017, 30, 63–74. [Google Scholar] [CrossRef]

- Mathew, J.; Parfitt, D.; Wilford, K.; Riddle, N.; Alamaniotis, M.; Chroneos, A.; Fitzpatrick, M.E. Reactor pressure vessel embrittlement: Insights from neural network modelling. J. Nucl. Mater. 2018, 502, 311–322. [Google Scholar] [CrossRef]

- Capuno, G.; Rimoli, J. Smart finite elements: A novel machine learning application. Comput. Methods Appl. Mech. Eng. 2019, 345, 363–381. [Google Scholar] [CrossRef]

- Lefik, M.; Boso, D.P.; Schrefler, B.A. Artificial neural networks in numerical modeling of composites. Comput. Methods Appl. Mech. Eng. 2009, 198, 1785–1804. [Google Scholar] [CrossRef]

- Chen, T.; Chen, H. Universal approximation to non-linear operators by neural networks with arbitrary activation functions and its application to dynamical systems. IEEE Trans. Neural Netw. 1995, 6, 911–917. [Google Scholar] [CrossRef] [PubMed]

- Ajmani, A.; Kamthania, D.; Hoda, M.N. A comparative study on constructive and non-constructive supervised learning algorithms for artificial neural networks. In Proceedings of the 2nd National Conference (INDIACom), New Delhi, India, 8–9 February 2008; Bharati Vidyapeeth’s Institute of Computer Applications and Management: New Delhi, India, 2008. [Google Scholar]

- Mandal, S.; Sivaprasad, P.V.; Venugopal, S.; Murthy, K.P.N. Artificial neural network modeling to evaluate and predict the deformation behavior of stainless-steel type AISI 304L during hot torsion. Appl. Soft Comput. 2009, 9, 237–244. [Google Scholar] [CrossRef]

- Chen, J.F.; Teng, J.G. Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Ueda, T.; Dai, J. Interface bond between FRP sheets and concrete substrates: Properties, numerical modeling and roles in member behaviour. Prog. Struct. Eng. Mater. 2005, 7, 27–43. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C.; Silva, M.A.G. Nonlinear numerical analysis of the debonding failure process of FRP-to-concrete interfaces. Compos. Part B Eng. 2013, 50, 210–223. [Google Scholar] [CrossRef]

- Yum, J.Y.F.; Chow, T.W.S. A Weight Initialization Method for Improving training Speed in Feedforward Neural Network. Neurocomputing 2000, 30, 219–323. [Google Scholar] [CrossRef]

- Horikawa, S.I.; Furuhashi, T.; Uchikawa, Y. On Fuzzy Modeling Using Fuzzy Neural Networks with the Back-Propagation Algorithm. IEEE Trans. Neural Netw. 1992, 3, 801–806. [Google Scholar] [CrossRef]

- Zou, J.; Han, Y.; So, S.-S. Overview of Artificial Neural Networks. In Artificial Neural Networks; Humana Press: Totowa, NJ, USA, 2008; Volume 458, pp. 14–22. [Google Scholar]

- LeCun, Y.A.; Bottou, L.; Orr, G.B.; Müller, K.R. Efficient Backprop. In Neural Networks: Tricks of the Trade; Springer: Berlin/Heidelberg, Germany, 2012; pp. 9–48. [Google Scholar]

| bg (mm) | hg (mm) | Eftf (kN/mm) | bf (mm) | fc (MPa) | P (kN) |

|---|---|---|---|---|---|

| 5 | 5 | 12.92 | 40 | 37.88 | 6.91 |

| 5 | 5 | 12.92 | 50 | 27.09 | 7.87 |

| 5 | 5 | 12.92 | 60 | 32.7 | 10.15 |

| 5 | 5 | 25.3 | 30 | 39.07 | 7.15 |

| 5 | 5 | 25.3 | 40 | 22.68 | 9.4 |

| 5 | 5 | 25.3 | 60 | 28.09 | 11.85 |

| 5 | 5 | 39.1 | 30 | 26.69 | 8.56 |

| 5 | 5 | 39.1 | 50 | 32.7 | 14.75 |

| 5 | 5 | 78.2 | 30 | 39.07 | 11.44 |

| 5 | 5 | 78.2 | 40 | 22.68 | 16.1 |

| 5 | 10 | 12.92 | 40 | 22.68 | 7.37 |

| 5 | 10 | 12.92 | 60 | 26.67 | 9.51 |

| 5 | 10 | 25.3 | 30 | 26.69 | 7.2 |

| 5 | 10 | 25.3 | 30 | 48.15 | 7.59 |

| 5 | 10 | 39.1 | 30 | 39.07 | 9.32 |

| 5 | 10 | 39.1 | 40 | 22.68 | 10.95 |

| 5 | 10 | 39.1 | 60 | 32.7 | 16.64 |

| 10 | 10 | 12.92 | 40 | 22.68 | 7.68 |

| 10 | 10 | 12.92 | 50 | 48.24 | 8.51 |

| 10 | 10 | 12.92 | 60 | 45.35 | 9.1 |

| 10 | 10 | 25.3 | 40 | 37.88 | 9.69 |

| 10 | 10 | 25.3 | 60 | 47.9 | 12.67 |

| 10 | 10 | 39.1 | 30 | 39.07 | 8.72 |

| 10 | 10 | 39.1 | 40 | 22.68 | 10.96 |

| 10 | 10 | 39.1 | 40 | 47.9 | 10.42 |

| 10 | 10 | 39.1 | 50 | 36.46 | 14.45 |

| 10 | 10 | 39.1 | 60 | 26.67 | 15.31 |

| 10 | 10 | 78.2 | 30 | 26.69 | 12.93 |

| 10 | 10 | 78.2 | 30 | 48.15 | 11.49 |

| 10 | 10 | 78.2 | 50 | 47.9 | 16.71 |

| 10 | 10 | 78.2 | 60 | 48.24 | 19.05 |

| 10 | 15 | 12.92 | 40 | 37.88 | 7.43 |

| 10 | 15 | 12.92 | 60 | 36.94 | 10.12 |

| 10 | 15 | 12.92 | 60 | 45.35 | 9.12 |

| 10 | 15 | 25.3 | 50 | 27.09 | 11.01 |

| 10 | 15 | 39.1 | 50 | 27.09 | 12.66 |

| 10 | 15 | 39.1 | 60 | 45.35 | 14.94 |

| 10 | 15 | 78.2 | 40 | 37.88 | 16.71 |

| 10 | 15 | 78.2 | 60 | 28.09 | 20.01 |

| bg (mm) | hg (mm) | Eftf (kN/mm) | bf (mm) | fc (MPa) | P (kN) | |

|---|---|---|---|---|---|---|

| Lowest | 5 | 5 | 12.92 | 30 | 22.68 | 6.91 |

| Highest | 10 | 15 | 78.2 | 60 | 48.24 | 20.01 |

| Mean | 7.89 | 9.87 | 37.54 | 45.79 | 34.76 | 11.46 |

| St. deviation | 2.51 | 3.43 | 23.57 | 11.65 | 9.14 | 3.54 |

| Coef. of variance | 0.32 | 0.35 | 0.63 | 0.25 | 0.26 | 0.31 |

| Quantities | Normalized Quantities |

|---|---|

| Compression stress of concrete: |

| Groups | Count | Sum | Average | |||

|---|---|---|---|---|---|---|

| Testing capacity (kN) | 39 | 438.77 | 11.250 | |||

| mathematical equation Capacity (kN) | 39 | 442.45 | 11.345 | |||

| Source of Variation | Sum of squares (SS) | Degrees of freedom (df) | Mean squares (MS) | F | p-value | Fcri |

| Between groups | 0.17 | 1 | 0.17 | 0.0142 | 0.905 | 3.967 |

| Within Groups | 930.49 | 76 | 12.24 | |||

| Total | 930.66 | 77 | ||||

| Groups | Count | Sum | Average | |||

|---|---|---|---|---|---|---|

| Testing capacity (kN) | 39 | 442.45 | 11.34 | |||

| ANN model (kN) | 39 | 441.79 | 11.33 | |||

| Source of Variation | Sum of squares (SS) | Degrees of freedom (df) | Mean squares (MS) | F | p-value | Fcri |

| Between groups | 0.0056 | 1 | 0.0056 | 0.0005 | 0.983 | 3.967 |

| Within Groups | 870.9646 | 76 | 11.4601 | |||

| Total | 870.9701 | 77 | ||||

| Parameter | Constant Value | Investigated Counts |

|---|---|---|

| Groove’s width (mm) | 7.89 | 5, 5.5, 6, 6.5, 7, 7.5, 8, 8.5, 9, 9.5, 10, 10.5, 11, 11.5, 12, 12.5, 13, 13.5, 14, 14.5, 15 |

| Groove’s depth (mm) | 9.87 | 5, 5.25, 5.5, 5.75, 6, 6.25, 6.5, 6.75, 7, 7.25, 7.5, 7.75, 8, 8.25, 8.5, 8.75, 9, 9.25, 9.5, 9.75, 10, 10.25, 10.5, 10.75, 11, 11.25, 11.5, 11.75, 12, 12.25, 12.5, 12.75, 13, 13.25, 13.5, 13.75, 14, 14.25, 14.5, 14.75, 15, 15.25, 15.5, 15.75, 16, 16.25, 16.5, 16.75, 17, 17.25, 17.5, 17.75, 18, 18.25, 18.5, 18.75, 19, 19.25, 19.5, 19.75, 20 |

| Tensile stiffness per width (kN/mm) | 37.54 | 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100 |

| FRP sheet width(mm) | 45.79 | 20, 22, 24, 26, 28, 30, 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60, 62, 64, 66, 68, 70 |

| Concrete compressive strength (MPa) | 34.76 | 20, 22, 25, 27, 30, 32, 35, 37, 40, 42, 45, 47, 50, 52, 55, 57, 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salmi, A. Prediction of the Bond Strength of Externally Bonded FRP Sheets Applied to Concrete via Grooves Technique Using Artificial Neural Networks. J. Compos. Sci. 2024, 8, 30. https://doi.org/10.3390/jcs8010030

Salmi A. Prediction of the Bond Strength of Externally Bonded FRP Sheets Applied to Concrete via Grooves Technique Using Artificial Neural Networks. Journal of Composites Science. 2024; 8(1):30. https://doi.org/10.3390/jcs8010030

Chicago/Turabian StyleSalmi, Abdelatif. 2024. "Prediction of the Bond Strength of Externally Bonded FRP Sheets Applied to Concrete via Grooves Technique Using Artificial Neural Networks" Journal of Composites Science 8, no. 1: 30. https://doi.org/10.3390/jcs8010030

APA StyleSalmi, A. (2024). Prediction of the Bond Strength of Externally Bonded FRP Sheets Applied to Concrete via Grooves Technique Using Artificial Neural Networks. Journal of Composites Science, 8(1), 30. https://doi.org/10.3390/jcs8010030