Global and Local Deformation Analysis of Mg-SiC Nanocomposites: Digital Image Correlation (DIC) and Representative Volume Element (RVE) Techniques

Abstract

:1. Introduction

2. Materials and Methods

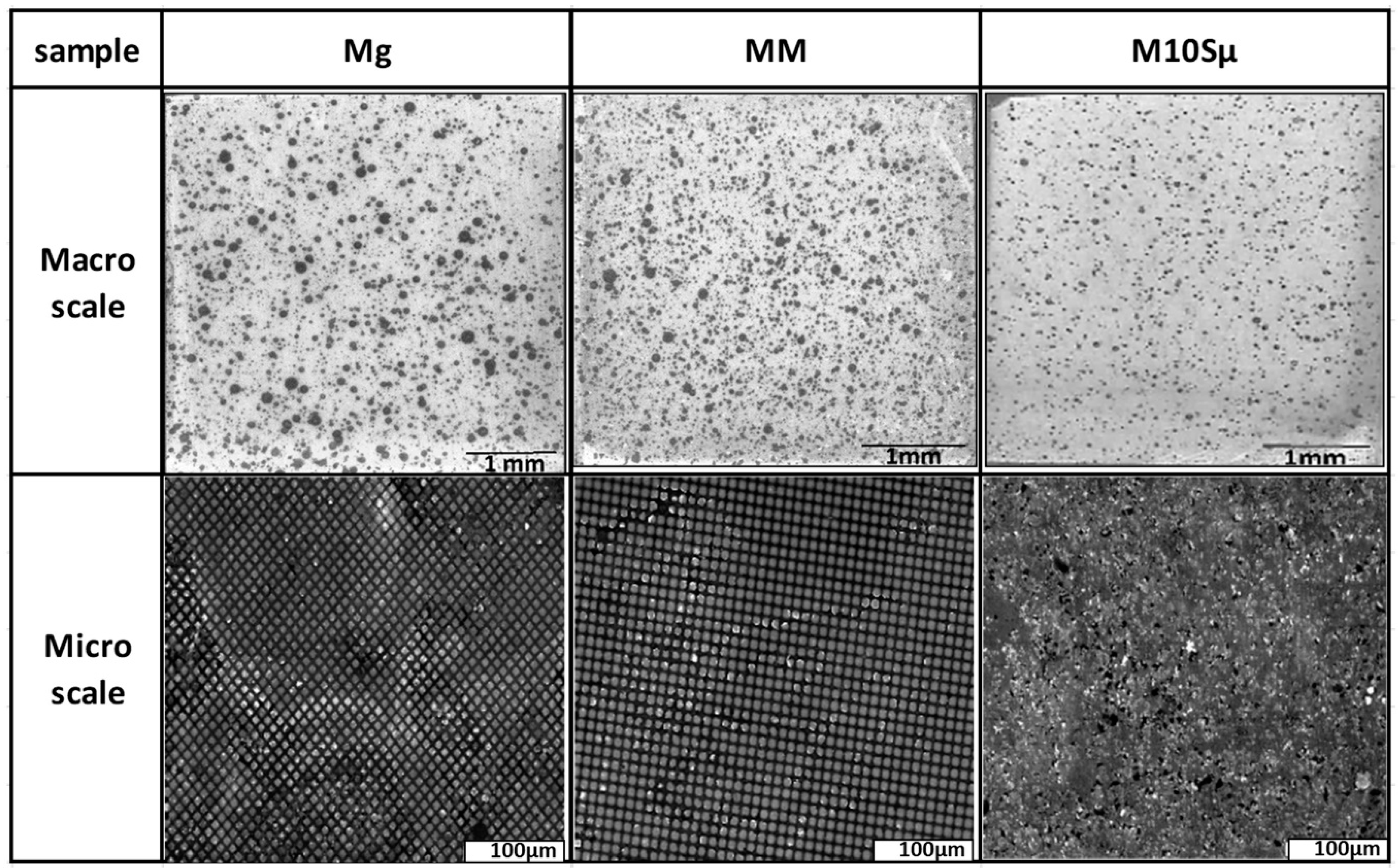

2.1. Material

2.2. Sample Preparation and Speckle Pattern for DIC

2.3. In Situ Compression Testing for Macro–Micro DIC Analysis

2.4. Numerical Modeling; RVE Generation

3. Results

3.1. Mechanical Responses to the Uniaxial Compressive Loading

3.2. Deformation Behavior

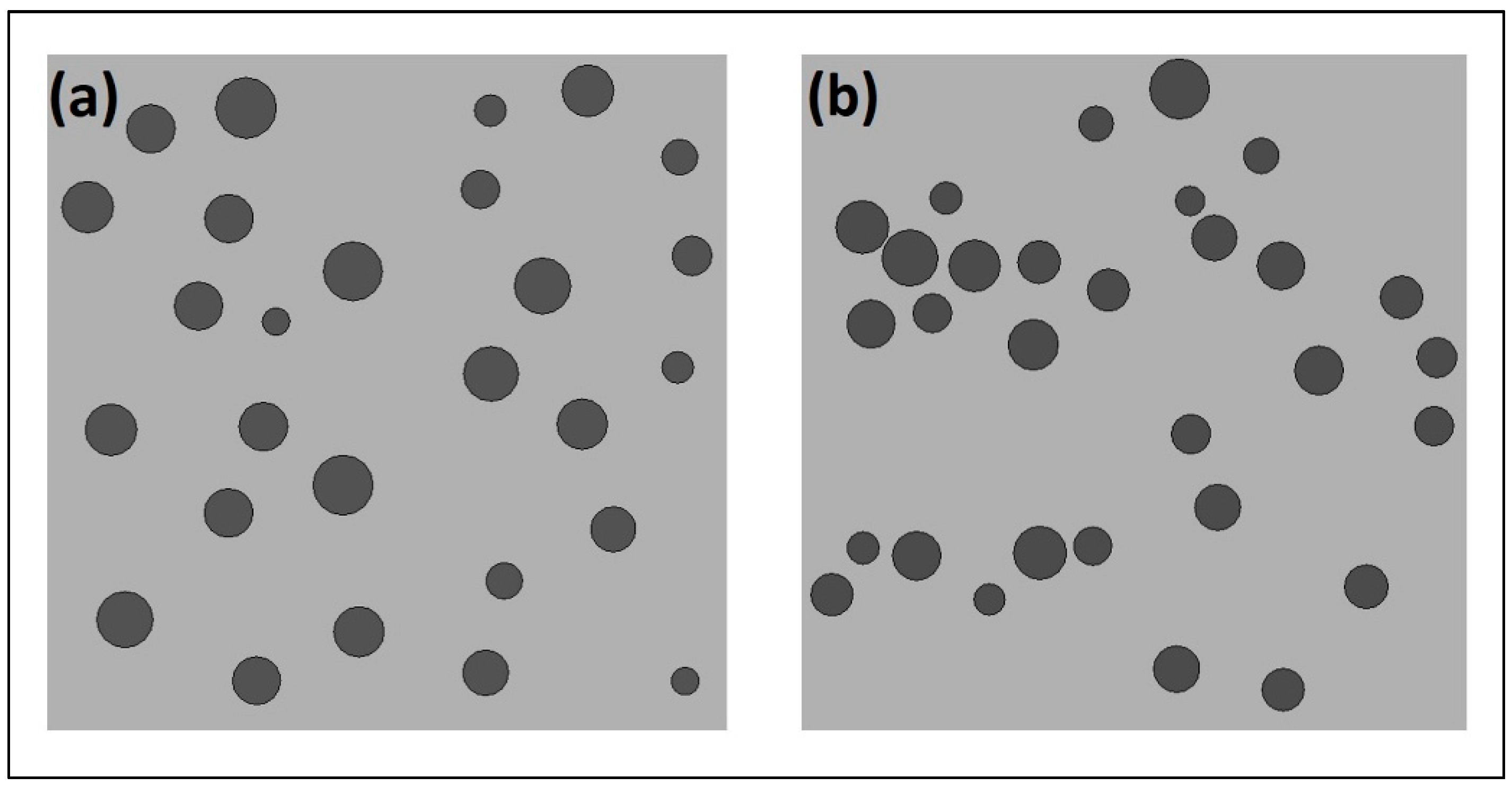

3.3. RVE Modeling Results for M10Sµ Sample

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matin, A.; Saniee, F.F.; Abedi, H.R. Microstructure and Mechanical Properties of Mg/SiC and AZ80/SiC Nano-Composites Fabricated through Stir Casting Method. Mater. Sci. Eng. A 2015, 625, 81–88. [Google Scholar] [CrossRef]

- Pollock, T.M. Weight Loss with Magnesium Alloys. Science 2010, 328, 986–987. [Google Scholar] [CrossRef]

- Shen, M.J.; Ying, W.F.; Wang, X.J.; Zhang, M.F.; Wu, K. Development of High Performance Magnesium Matrix Nanocomposites Using Nano-SiC Particulates as Reinforcement. J. Mater. Eng. Perform. 2015, 24, 3798–3807. [Google Scholar] [CrossRef]

- Rahmani, K.; Majzoobi, G.H.; Sadooghi, A.; Kashfi, M. Mechanical and Physical Characterization of Mg-TiO2 and Mg-ZrO2 Nanocomposites Produced by Hot-Pressing. Mater. Chem. Phys. 2020, 246, 122844. [Google Scholar] [CrossRef]

- Mahdy, A.A. Fabrication and Characterizations of Mg/SiC Composite via Compo-Casting Technique. J. Am. Sci. 2014, 10. Available online: https://api.semanticscholar.org/CorpusID:199385967 (accessed on 14 December 2023).

- Ramakrishnan, N. An Analytical Study on Strengthening of Particulate Reinforced Metal Matrix Composites. Acta Mater. 1996, 44, 69–77. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically Alloyed Nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Benjamin, J.S. Mechanical Alloying. Sci. Am. 1976, 234, 40–49. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Velasco, F.; Robert, M.H.; Torralba, J.M. Effect of Mechanical Alloying on the Morphology, Microstructure and Properties of Aluminium Matrix Composite Powders. Mater. Sci. Eng. A 2003, 342, 131–143. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, X.J.; Wu, Y.W.; Hu, X.S.; Wu, K.; Gan, W.M. Effect of Particle Size on Microstructure and Mechanical Properties of SiCp/AZ91 Magnesium Matrix Composite. Mater. Sci. Eng. A 2012, 543, 158–163. [Google Scholar] [CrossRef]

- Penther, D.; Ghasemi, A.; Riedel, R.; Fleck, C.; Kamrani, S. Effect of SiC Nanoparticles on Manufacturing Process, Microstructure and Hardness of Mg-SiC Nanocomposites Produced by Mechanical Milling and Hot Extrusion. Mater. Sci. Eng. A 2018, 738, 264–272. [Google Scholar] [CrossRef]

- Tekumalla, S.; Bibhanshu, N.; Shabadi, R.; Suwas, S.; Ha, T.M.H.; Gupta, M. Evolution of Texture and Asymmetry and Its Impact on the Fatigue Behaviour of an In-Situ Magnesium Nanocomposite. Mater. Sci. Eng. A 2018, 727, 61–69. [Google Scholar] [CrossRef]

- Habibi, M.K.; Hamouda, A.M.S.; Gupta, M. Enhancing Tensile and Compressive Strength of Magnesium Using Ball Milled Al+ CNT Reinforcement. Compos. Sci. Technol. 2012, 72, 290–298. [Google Scholar] [CrossRef]

- Tun, K.S.; Gupta, M. Compressive Deformation Behavior of Mg and Mg/(Y2O3+ Ni) Nanocomposites. Mater. Sci. Eng. A 2010, 527, 5550–5556. [Google Scholar] [CrossRef]

- Canal, L.P.; González, C.; Molina-Aldareguía, J.M.; Segurado, J.; LLorca, J. Application of Digital Image Correlation at the Microscale in Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1630–1638. [Google Scholar] [CrossRef]

- Kaya, A.C.; Fleck, C. Deformation Behavior of Open-Cell Stainless Steel Foams. Mater. Sci. Eng. A 2014, 615, 447–456. [Google Scholar] [CrossRef]

- Schüler, P.; Fischer, S.F.; Bührig-Polaczek, A.; Fleck, C. Deformation and Failure Behaviour of Open Cell Al Foams under Quasistatic and Impact Loading. Mater. Sci. Eng. A 2013, 587, 250–261. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Lunt, D.; Robson, J.D.; Da Fonseca, J.Q. How Magnesium Accommodates Local Deformation Incompatibility: A High-Resolution Digital Image Correlation Study. Acta Mater. 2017, 133, 367–379. [Google Scholar] [CrossRef]

- Kammers, A.D.; Daly, S. Digital Image Correlation under Scanning Electron Microscopy: Methodology and Validation. Exp. Mech. 2013, 53, 1743–1761. [Google Scholar] [CrossRef]

- Segurado, J.; González, C.; LLorca, J. A Numerical Investigation of the Effect of Particle Clustering on the Mechanical Properties of Composites. Acta Mater. 2003, 51, 2355–2369. [Google Scholar] [CrossRef]

- Ma, S.; Zhuang, X.; Wang, X. 3D Micromechanical Simulation of the Mechanical Behavior of an In-Situ Al3Ti/A356 Composite. Compos. Part B Eng. 2019, 176, 107115. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, X.; Chen, T.; Wang, X. Microstructure-Based Numerical Simulation of the Mechanical Properties and Fracture of a Ti-Al3Ti Core-Shell Structured Particulate Reinforced A356 Composite. Mater. Des. 2020, 191, 108685. [Google Scholar] [CrossRef]

- Zhang, J.F.; Andrae, H.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. An Enhanced Finite Element Model Considering Multi Strengthening and Damage Mechanisms in Particle Reinforced Metal Matrix Composites. Compos. Struct. 2019, 226, 111281. [Google Scholar] [CrossRef]

- Weng, L.; Fan, T.; Wen, M.; Shen, Y. Three-Dimensional Multi-Particle FE Model and Effects of Interface Damage, Particle Size and Morphology on Tensile Behavior of Particle Reinforced Composites. Compos. Struct. 2019, 209, 590–605. [Google Scholar] [CrossRef]

- Rana, A.K.; Paul, S.K.; Dey, P.P. Effect of Martensite Volume Fraction on Cyclic Plastic Deformation Behavior of Dual Phase Steel: Micromechanics Simulation Study. J. Mater. Res. Technol. 2019, 8, 3705–3712. [Google Scholar] [CrossRef]

- Mehr, F.R.; Salavati, M.; Morgenthal, A.; Kamrani, S.; Fleck, C. Computational Analysis and Experimental Calibration of Cold Isostatic Compaction of Mg-SiC Nanocomposite Powders. Mater. Today Commun. 2021, 27, 102321. [Google Scholar] [CrossRef]

- Rahimi Mehr, F.; Kamrani, S.; Fleck, C.; Salavati, M. Optimal Performance of Mg-SiC Nanocomposite: Unraveling the Influence of Reinforcement Particle Size on Compaction and Densification in Materials Processed via Mechanical Milling and Cold Iso-Static Pressing. Appl. Sci. 2023, 13, 8909. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Duvall, F. Digital Image Correlation for Determination of Weld and Base Metal Constitutive Behavior. Weld. J. N. Y. 1999, 78, 355-s. [Google Scholar]

- Jin, H.; Lu, W.-Y.; Korellis, J. Micro-Scale Deformation Measurement Using the Digital Image Correlation Technique and Scanning Electron Microscope Imaging. J. Strain Anal. Eng. Des. 2008, 43, 719–728. [Google Scholar] [CrossRef]

- Yao, X.; Zheng, Y.F.; Quadir, M.Z.; Kong, C.; Liang, J.M.; Chen, Y.H.; Munroe, P.; Zhang, D.L. Grain Growth and Recrystallization Behaviors of an Ultrafine Grained Al-0.6 Wt% Mg-0.4 Wt% Si-5vol.% SiC Nanocomposite during Heat Treatment and Extrusion. J. Alloys Compd. 2018, 745, 519–524. [Google Scholar] [CrossRef]

- Wang, J.T.; Liu, J.Q.; Zhao, X. On Tension–Compression Yield Asymmetry in an Extruded Mg–3Al–1Zn Alloy. J. Alloys Compd. 2009, 478, 789–795. [Google Scholar]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Recrystallization Mechanisms and Microstructure Development in Emerging Metallic Materials: A Review. J. Sci. Adv. Mater. Devices 2019, 4, 19–33. [Google Scholar] [CrossRef]

- Xu, Y.; Gu, T.; Xian, J.; Giuliani, F.; Ben Britton, T.; Gourlay, C.M.; Dunne, F.P.E. Intermetallic Size and Morphology Effects on Creep Rate of Sn-3Ag-0.5Cu Solder. Int. J. Plast. 2021, 137, 102904. [Google Scholar] [CrossRef]

- Belyakov, A.; Wei, F.G.; Tsuzaki, K.; Kimura, Y.; Mishima, Y. Incomplete Recrystallization in Cold Worked Steel Containing TiC. Mater. Sci. Eng. A 2007, 471, 50–56. [Google Scholar] [CrossRef]

- Li, Y.; Bushby, A.J.; Dunstan, D.J. The Hall–Petch Effect as a Manifestation of the General Size Effect. Proc. R. Soc. A 2016, 472, 20150890. [Google Scholar] [CrossRef]

- Huang, T.; Shuai, L.; Wakeel, A.; Wu, G.; Hansen, N.; Huang, X. Strengthening Mechanisms and Hall-Petch Stress of Ultrafine Grained Al-0.3% Cu. Acta Mater. 2018, 156, 369–378. [Google Scholar] [CrossRef]

- Jiang, S. Fracture Mechanism of Magnesium Alloys at Room Temperature. In Proceedings of the 2015 4th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering, Xi’an, China, 12–13 December 2015; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 1109–1114. [Google Scholar]

- Wan, W.; Xu, Y.; Yu, X.; Dunne, F.P.E. Microstructurally-Sensitive Fatigue Crack Nucleation in a Zircaloy-4 Alloy. J. Mech. Phys. Solids 2023, 180, 105417. [Google Scholar] [CrossRef]

- Luo, X.; Liu, J.; Zhang, L.; He, X.; Zhao, K.; An, L. Deformation and Failure Behavior of Heterogeneous Mg/SiC Nanocomposite under Compression. J. Magnes. Alloys 2021, 10, 3433–3446. [Google Scholar] [CrossRef]

- Somekawa, H.; Inoue, T.; Tsuzaki, K. Effect of Solute Atoms on Fracture Toughness in Dilute Magnesium Alloys. Philos. Mag. 2013, 93, 4582–4592. [Google Scholar] [CrossRef]

- Tang, Y.; Bringa, E.M.; Remington, B.A.; Meyers, M.A. Growth and Collapse of Nanovoids in Tantalum Monocrystals. Acta Mater. 2011, 59, 1354–1372. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of Grain Size on the Compressive Deformation of Wrought Mg–3Al–1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The Onset of Twinning in Metals: A Constitutive Description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Vásárhelyi, B.; Bobet, A. Modeling of Crack Initiation, Propagation and Coalescence in Uniaxial Compression. Rock Mech. Rock Engng 2000, 33, 119–139. [Google Scholar] [CrossRef]

- He, X.; Song, S.; Luo, X.; Liu, J.; An, L.; Bai, Y. Predicting Ductility of Mg/SiCp Nanocomposite under Multiaxial Loading Conditions Based on Unit Cell Modeling. Int. J. Mech. Sci. 2020, 184, 105831. [Google Scholar] [CrossRef]

- Goodier, J.N. Concentration of Stress around Spherical and Cylindrical Inclusions and Flaws. J. Appl. Mech. 1933, 1, 39–44. [Google Scholar] [CrossRef]

| Sample | Content | Milling Time (h) | Subsequent Process |

|---|---|---|---|

| Mg | Mg | 0 | CIP + sinter + extrusion |

| MM | Mg | 25 | CIP + sinter + extrusion |

| M10Sµ | Mg + 10% SiC (1 µm>) | 25 | CIP + sinter + extrusion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahimi Mehr, F.; Kamrani, S.; Fleck, C.; Salavati, M. Global and Local Deformation Analysis of Mg-SiC Nanocomposites: Digital Image Correlation (DIC) and Representative Volume Element (RVE) Techniques. J. Compos. Sci. 2024, 8, 1. https://doi.org/10.3390/jcs8010001

Rahimi Mehr F, Kamrani S, Fleck C, Salavati M. Global and Local Deformation Analysis of Mg-SiC Nanocomposites: Digital Image Correlation (DIC) and Representative Volume Element (RVE) Techniques. Journal of Composites Science. 2024; 8(1):1. https://doi.org/10.3390/jcs8010001

Chicago/Turabian StyleRahimi Mehr, Fatemeh, Sepideh Kamrani, Claudia Fleck, and Mohammad Salavati. 2024. "Global and Local Deformation Analysis of Mg-SiC Nanocomposites: Digital Image Correlation (DIC) and Representative Volume Element (RVE) Techniques" Journal of Composites Science 8, no. 1: 1. https://doi.org/10.3390/jcs8010001

APA StyleRahimi Mehr, F., Kamrani, S., Fleck, C., & Salavati, M. (2024). Global and Local Deformation Analysis of Mg-SiC Nanocomposites: Digital Image Correlation (DIC) and Representative Volume Element (RVE) Techniques. Journal of Composites Science, 8(1), 1. https://doi.org/10.3390/jcs8010001