Abstract

Deformation behavior of the composite “eggshell–polymer plomb” was examined under bending. Hen eggs were taken as a biological material for experiments. It was shown that a viscoelastic polymer coating does not change the type of deformation behavior of the composite, given that the eggshell continued to be brittle despite its mechanical characteristics varying widely for a brittle solid. Joint “polymer plomb–eggshell” never cracked under bending and hence exhibited a high cohesion strength under the stresses applied in these experiments. It seems that the composite “eggshell—polymer plomb” could substitute for the composite “tooth enamel–polymer plomb” under elaboration of novel restorative materials for dentistry, namely, for examination of their mechanical properties, including cohesive strength.

1. Introduction

Restorative procedures or treatments of deceased teeth in clinical dentistry necessitate that plomb or restorative material replaces some parts of tooth hard tissues that were degraded due to different pathologies, including trauma [1]. As a result of such procedures, treated teeth become alike to a composite structure, where soft and hard tissues are neighboring with synthetic materials of which the mechanical properties should not differ considerably from the properties of the surrounding teeth [2]. The search for novel restorative materials for dentistry is a complex problem consisting of many tasks, including materials science, biomedical, biomechanical, and ethics problems, which should be solved in close synergy [3].

One of these partial but important tasks is examination of the deformation behavior of “tooth hard tissue–plomb” composites, including estimation of the cohesive strength of the joining between them [2,3]. It is clearly understood that both restorative material and adhesive or glue should exhibit high biocompatibility with the human body. This is the main condition for a restorative material in the medical science of dentistry. The main factor that prevents the successful solving of this problem is the small volume of hard tissues in human teeth, which does not allow for standard mechanical testing of the joining “dentin/enamel–plomb” [4]. This is especially critical for human tooth enamel, which covers the crown of a tooth. Naturally, both the ethical and medical aspects of the problem, namely searching for experimental material for mechanical testing, are also very important.

Realistically, a researcher needs a considerable quantity of specimens for mechanical testing, such that their structural state makes statistical treatment of the findings possible. Unfortunately, this is practically impossible for majority of university laboratories, which, as a rule, have limited research budgets. Therefore, substitution of tooth hard tissues by a materials that have similar mechanical properties but is not as rare as human dentin and tooth enamel could open up prospects for solving this dental material science task, at least the initial stage of novel restorative material elaboration.

According to the chemical content and genesis, human tooth enamel is a mineral of biological genesis, or biomineral and hence, its mechanical properties should be similar to that of some rocks [5]. The shell of hen eggs is also a biomineral [6,7,8]. Its mechanical properties are similar to those of human dentin and tooth enamel when under the stress conditions of chewing normal human food [9,10]. An eggshell has two natural surfaces, of which the morphology is similar to the prism structure of the tooth enamel [5]. Hence, samples cut from an eggshell do not need additional preparation of the surface before mechanical testing necessary for the experimental procedure. The thickness of an eggshell is an almost constant value, and an eggshell is easily cut into plane samples for mechanical testing, for example, through the scheme of 3-point bending [11]. There are many legal supplies of hen eggs, including food markets, farms and city supermarkets. All of them come with the guarantee of the quality afforded by government institutions.

These features allow for carrying out mechanical testing of eggshell samples on the 3-point bending scheme without any engineering or ethical problems. Therefore, samples cut from hen eggshell and covered by a polymer plomb material, which has been glued on their convex surface, could be used for experimental study of the deformation behavior of “biomineral/tooth enamel–polymer plomb” composites, including the cohesive strength of the joining between them. Indeed, 3-point bending facilitates the effective examination of the mechanical properties of such composites. This narrowly applied task has some academic value because the deformation behavior of the composite “brittle material–viscous coating”, namely “eggshell—polymer plomb”, under bending is also interesting for composite science [12,13].

The aim of the present work is to carry out an experimental study of the deformation behavior of “eggshell–polymer plomb” composites under 3-point bending. Hen eggshells were used as an experimental material, cut into samples for 3-point bending, whereas some modern polymer plomb materials used in international clinical practice, including in Russia, were applied as polymer coatings.

2. Materials and Methods

During the experiments, we used the eggs of hens purchased from a retail outlet, which were described as having been distributed from a hen farm near Yekaterinburg. They were of C1 size and within the dates of guaranteed usage. The experimental biological material (hen eggs) was stored no more than two days in a home refrigerator under the conditions recommended by the manufacturer. Liquid biomass was extracted from an eggshell using the following procedure. Holes with a 2 mm diameter were drilled in the sharp and blunt ends of an egg. Warm water from a syringe was injected through the holes to dilute the biomass inside the egg. The diluted biomass was pumped from the egg using the syringe. Further, water at a temperature of 25 °C was used to wash the inside of the eggshell, which was then dried for a couple of days at room temperature.

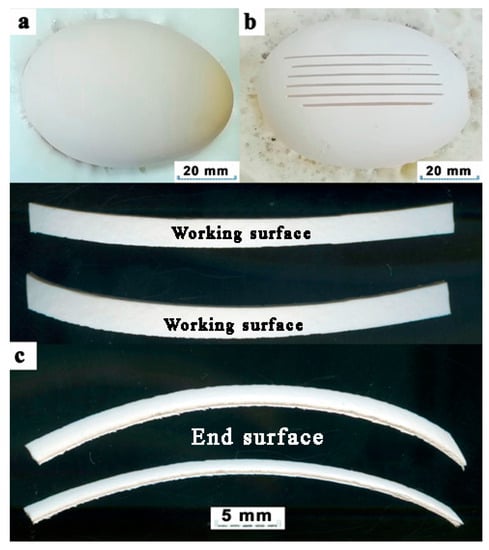

The fixing of an eggshell in the cutting off facility is a complicated engineering task because an eggshell has a brittle structure which additionally possesses a complicated shape. Therefore, an eggshell was fixed on the substrate through a construction polyurethane foam, which was further mounted on the cutting off facility (Figure 1a). This procedure guaranteed that the eggshell would never crack under cutting-off operation. The samples for mechanical testing were cut off with the help of a disc diamond saw (diameter, 45 mm; thickness, 0.5 mm) from the central area of the eggshell along its main axis (Figure 1b). The samples for bending are shown in Figure 1c. The sizes of the eggshell samples were controlled with the help of an instrumental optical microscope UIM-21 (measurement accuracy is 0.001 mm at a length of 200 mm). The average length of such samples varied from 40 mm to 50 mm. Their width and thickness were 3 mm and 0.3 mm, respectively.

Figure 1.

Preparation of samples from a hen eggshell: (a) the eggshell on the substrate; (b) the eggshell after the cut off procedure; (c) the eggshell samples for bending (working surface and end surface, respectively).

Preparation of composite “eggshell—polymer plomb material” samples for 3-point bending was carried out according to the procedure of tooth plumbing, recommended by some manufacturers and accepted by the Russian Federation Government for clinical applications. The technique includes the following four stages: (1) etching of the convex surface of a sample with a gel containing orthophosphoric acid (H3PO4); (2) application of a thin layer of the polymer adhesive or glue,, such as DX Bond Uni™ or Danova Bond™, on the etched convex surface of the sample; (3) gluing of the polymer plomb material to the convex surface with an adhesive, such as Boston Arkona™, Ceram 1™, Ceram 3M™, and DX Flow Composite™; (4) processing of the polymer plomb by the blue light laser that was the final stage of the sample preparation procedure. These operations with the eggshell samples aimed for 3-point bending were carried out by highly skilled dentists of the Urals State Medical University at Yekaterinburg.

We carried out mechanical testing under the scheme of 3-point bending on the Shimadzu™ AG-S 2kN testing machine (the rate of movement of the active traverse of the testing machine was 0.1 mm/min). Shimadzu’s device for the 3-point bending was used. The distance between the lower prisms was 10 mm and hence, the sample length was limited by 15–20 mm. Software Trapezium™ (Version 1.5.6), which was supplied with the Shimadzu™ testing machine, was applied for processing the data. Our earlier findings on the deformation behavior of the samples cut from hen eggshell under 3-point bending in the air and water are presented in [11].

A set of 10 samples for each operation was tested in the air at room temperature. The deformation behavior of the samples was analyzed via the means of their deformation (bending) curves. The effective elastic moduli were calculated from the inclination of the bending curve according to Trapezium™ software. The maximal deformation of the sample and ultimate bending strength were used as the mechanical characteristics of the samples in addition to the deformation curve. The working and end surfaces of the samples before and after mechanical testing were documented with the help of an optical microscope in the reflection mode. Examination of the sample images after bending, including the “polymer plomb—eggshell” joining, was used to estimate the cohesion between the eggshell and restorative materials.

3. Results

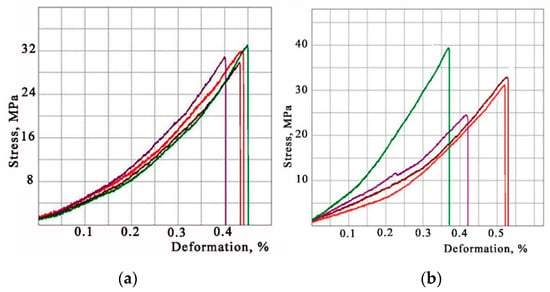

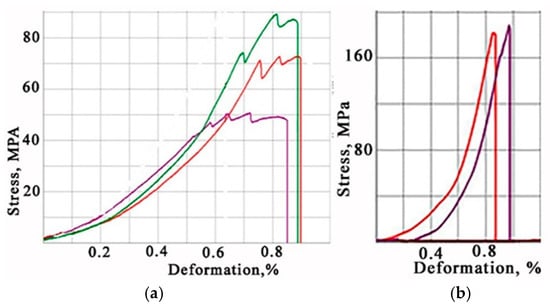

The results of mechanical testing of the “eggshell—polymer plomb” composite samples under 3-point bending at room temperature are presented in Figure 2, Figure 3, Figure 4 and Figure 5 and Table 1. It is clear that the samples from all sets exhibited brittle deformation behavior because their deformation prior to the failure was less than 1%. The shape of the engineering deformation curves also agreed with the brittle character of the deformation behavior of these composites, insomuch as it was close to linear dependence in the middle and final stages of the loading. The inclination of the engineering curves from linear dependence at the initial stage of the loading is caused by complicated geometry of the eggshell and hence, by the complicated shape of the samples. Indeed, this is an expected behavior for a brittle material even when a viscous coating covers it.

Figure 2.

Deformation curves of the samples cut from hen eggshell under 3-point bending (each one is colored differently): (a) initial state; (b) after etching.

Figure 3.

Three-point bending deformation curves of the samples cut from hen eggshell and covered by the adhesive: (a) «DX Bond Uni™»; (b) «Danova Bond™».

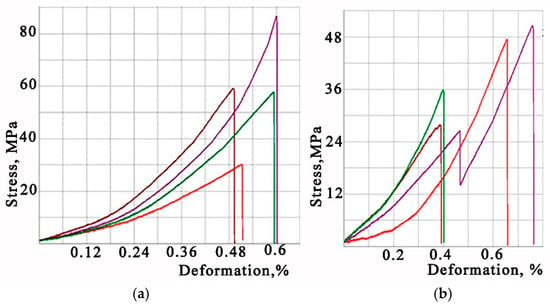

Figure 4.

Three-point bending deformation curves of the samples cut from hen eggshell and covered by the polymer plomb: (a) «Boston Arkona™»; (b) «Ceram 1™».

Figure 5.

Three-point bending deformation curves of the samples cut from hen eggshell and covered by the polymer plomb: (a) «Ceram 3M™»; (b) «DX Flow Composite™».

Table 1.

Mechanical properties of hen eggshell with polymer plomb materials under bending.

All eggshell samples without treatment of the surfaces taken from Set 1 exhibited the same deformation behavior under 3-point bending. Their deformation curves laid closely one to another (Figure 2a), while their mechanical properties (Table 1) were the same as described in ref. [11]. The curves were close to linear dependence at the middle and final stages, while deformation prior to the failure was about 0.5% at the ultimate strength of 30 MPa. Thus, they confirm the conclusion that eggshell samples demonstrate brittle deformation behavior under 3-point bending at room temperature.

Processing of the samples by orthophosphoric acid (Set 2) caused the appearance of some differences in deformation curves; however, this did not change their deformation behavior which was still brittle (Figure 2b and Table 1). For example, the total deformation of some samples from Set 2 could differ by more than in 0.1%. In addition, some samples exhibited higher elastic moduli than the majority of samples from Set 2. However, the engineering curves of the majority of samples from Set 2 were similar to those of Set 1. The differences in the mechanical properties of these samples may be caused by the etching of defects appearing on their surfaces under the cut off procedure. The small quantity of such defected samples points to the high quality of the sample preparation technique.

The inflicting of polymer the adhesive layer induced an increase in the deformation prior of the failure and a decrease in the elastic modulus of the samples from Set 3 and Set 4 (Figure 3a,b; Table 1). Etching of the surface by H3PO4 and the presence of a thin layer of the polymer adhesive on the surface (Set 2 and Set 3, respectively) did not cause any change in the ultimate stress of the samples (Figure 2b and Figure 3a, Table 1). On the other hand, a thick polymer adhesive layer on the surface of samples (Set 4) led to a considerable rise in ultimate stress under bending (Figure 3b, Table 1). It seems that this was an expected response of the “brittle material—viscous coating” composite. Despite this difference, the type of mechanical response of the samples covered by different adhesives was the same, i.e., brittle.

The thick non-flowing cuboidal polymer plombs (Boston Arkona™ and «Ceram 1™) on the surface of the eggshell samples from Set 5 and Set 6, which were used in the clinical practice at Yekaterinburg, induced an increase in the ultimate stress by 1.5–2 times. On the contrary, the elastic moduli and deformation prior to the failure of these samples reached the levels of the eggshell samples from Set 1, while the deformation prior to the failure decreased in comparison with the samples covered by adhesives (Set 3 and Set 4) (Figure 4a,b, Table 1). The deformation curves of the samples from these sets do not coincide one to another, as observed in Figure 2a; however, their type could be also considered as brittle. This feature may be explained by differences in the geometry of plombs on the samples due to their manual formation.

The behavior of the deformation curves of samples from Set 7 differs from that of the composite samples from Set 5 and Set 6. In the deformation curves of these samples, there is a yield plateau (Figure 5a, Table 1). The length of the yield areas on the curves was about 0.2%, while their deformation prior to the failure was about 0.8%. Therefore, the length of the brittle area can be estimated as 0.6%, comparable with the total deformation prior to the failure of the samples from Set 5 and Set 6. The yield plateau in the bending curves of this non-flowing polymer plomb material («Ceram 3M™») could happen due to the incomplete hardening of the polymer plomb material under the blue light laser processing. This circumstance could also induce the appearance of “teeth” on the yield plateau. The elastic modulus of the samples of Set 7 is similar to moduli of the samples with other non-flowing plombs (Set 5 and Set 6); however, their ultimate stress is 1.5–2 times higher. Despite the yield plateau, the deformation behavior of the samples from Set 7 may be also estimated to be brittle because the deformation prior to the failure was less than 1%.

The deformation curves of the samples of Set 8 are shown in Figure 5b. Their working surfaces were covered by liquid-flowing polymer plomb material («DX Flow Composite™») between the lower prisms of Shimadzu bending device (Figure 5b). Their deformation prior to the failure was about 0.8%, while the elastic modulus was considerably higher than of the other composite samples (Table 1). This trend reflects on the ultimate stress, which was 2–3 times higher than for the samples of other sets. Despite these differences, the deformation behavior of the samples from Set 8 was estimated to be brittle because their total deformation under bending was less than 1%.

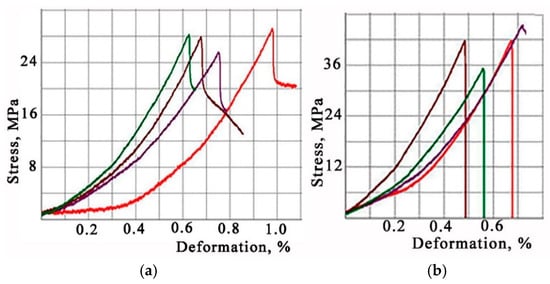

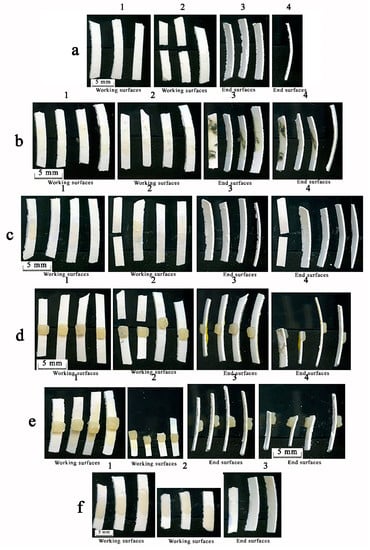

Metallographic examination of the samples after 3-point bending was carried out using light microscope under low magnification (×20). It was shown that the geometry of applied stress governs the trajectory of a dangerous crack (Figure 6), as it should be in a brittle isotropic solid [13]. The dangerous crack appeared under the loading prism in eggshell samples from Set 1 (Figure 6a). It is worth noting that the motion of a dangerous crack did not always lead to the failure of the samples. Sometimes, the sample did not take apart if the loading was plugged off as soon as a kink appeared on the deformation curve. The same effect on the eggshell samples was observed in [11].

Figure 6.

Samples cut from hen eggshell with the polymer plomb (1 initial state, working surface; 2 bending in the air, working surface; 3initial state, end surface; 4 bending in the air, end surface): (a) initial state; (b) etched state; (c) adhesive «Danova Bond™»; (d) polymer plomb «Ceram 1™»; (e) polymer plomb «Ceram 3M™»; (f) polymer plomb «DX Flow Composite™».

Etching of the samples (Set 2) did not influence the fracture behavior of the eggshell samples under 3-point bending. The dangerous crack in the etched samples was created under the loading prism; while its appearance did not mean simultaneous separation of the sample into two parts (Figure 6b). Inflicting the polymer adhesive layer on the eggshell samples (Set 3) did not change their fracture behavior, too. The dangerous crack appeared under the loading prism; however, this fact also did not imply the simultaneous failure of the sample (Figure 6c).

The fracture behavior of the eggshell samples covered by polymer plomb materials under bending differed from the above-described behavior of the samples of Sets 1–4 (Figure 6a–c). The dangerous crack appeared on the boundary line between the “polymer plomb—eggshell” joining and the eggshell (Figure 6d–f). At that, this feature of fracture did depend on neither the type of plomb nor length of polymer coating. Indeed, non-flowing plombs having the cuboid shape were seated in areas near the contact of the loading prism with the sample (Figure 6d,e), while liquid-flowing plombs covered the sample between the lower prisms (Figure 6f).

The dangerous crack in the sample with a non-flowing polymer plomb could be braked when the testing was stopped, whereas the dangerous crack never stopped in the samples with liquid-flowing plombs and therefore, such samples always failed under bending. This fact may be explained by the high ultimate strength of the samples covered by liquid-flowing plombs.

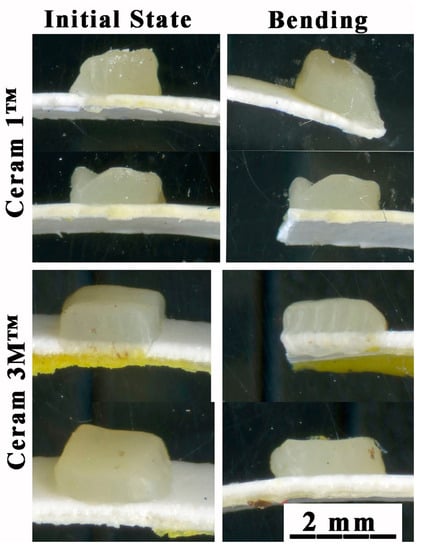

Metallographic examination of the tested samples also allowed for estimating the cohesive strength of the “polymer plomb—eggshell” joining. According to the geometry of the 3-point loading, the maximal level of shear stress should have occurred near the loading prism, where the polymer plomb was glued to the eggshell. Hence, this is the most dangerous place in the sample for the decohesion of the “polymer plomb—eggshell” joining. However, decohesion between the eggshell and polymer plombs was never observed in our experiments (Figure 6b–f). No visible cracks on the “polymer plomb—eggshell” boundary were detected in the samples with cuboidal plombs after bending (Figure 7).

Figure 7.

Samples cut from hen eggshell and supplied with polymer «Ceram 1™» and «Ceram 3M™» plombs.

4. Discussion

Mechanical testing showed that the deformation behavior of the samples cut from the shell of hen eggs and supplied with polymer coatings under bending was brittle in spite of the different properties of the coatings, because in all cases, the total deformation prior to the failure was less than 1% [14]. An additional argument for this conclusion is the behavior of the deformation curves for majority of the tested samples, which can be approximated as linear [15,16]. Some deviation of the engineering curves from the straight line at the initial stage of loading occurred due to the complicated shape of the samples and, as a result, a poor contact with the prisms of bending device. This result was expected because the eggshell is the mineral of biological genesis or the natural material with covalent chemical bonding [6,7,8], which can not exhibit any behavior other than brittleness [17]. It should be especially noted that the “eggshell—polymer plomb” composite possesses mechanical characteristics which can vary in wide limits but are always within the brittle behavior. This finding seems to be important because it was obtained on samples that possessed native surfaces and hence, the effect of a random factor, such as the sample preparation on experimental data, was minor.

The geometry of viscous polymer coating and its mechanical characteristics are the main factors that govern the mechanical properties of “eggshell—polymer plomb” composites under bending, although the deformation behavior of these composites does not change and continues to be brittle. The polymer plomb materials that are used in the modern dentistry are commonly viscoelastic solids, which are strengthened by the blue-light laser treatment of their surface at the final stage of dental treatment [3]. Sometimes, the viscoelastic nature of the polymer coating [18] can appear on the engineering curve (Figure 5a); however, this small ductility does not change the brittle character of the mechanical response of the “eggshell—polymer plomb” composite because its total plasticity is always less than 1%.

The cohesive strength of the “polymer plomb—eggshell” joining is quite high and homogeneous in all examined composites, since the joining never cracks under bending. Indeed, the surface of hen eggshell contains microrelief, including microscopic holes that guarantee the high adhesion of the biomineral substrate and polymer coating.

Our experiments showed that one of the procedures of the restorative treatment of damaged teeth, namely the montage of a plomb in a damaged tooth, could be successfully applied to the preparation of composite “eggshell—polymer plomb” samples for mechanical testing under 3-point bending. The high skills of the personnel inflicting the polymer plombs on the eggshell samples guarantee the similarity of the composite samples between themselves, and hence increase the quality of the experimental data obtained during mechanical testing. In addition, this procedure can be applied for teaching students from dentistry schools, because a mentor could check the quality of the montage of the polymer plombs on the eggshell samples both visually and with the help of mechanical testing. It is very important to highlight that such a choice of the model material cancels a lot of ethical problems and technical troubles related to the experiments on the tooth hard tissues.

Clearly, hen eggshells are not an equivalent substitution for the human tooth enamel [5]. However, they can be considered as the substitution of tooth hard tissues under elaboration and examination of novel plomb materials, at least at the initial stage of this process. The aforementioned experiments allow for examining the deformation behavior of this biomineral at different stages of the restorative procedure or the formation of “biomineral—polymer coating” composites. The main features of the behavior of modern dental restorative materials in contact with a biomineral are normally described without the use of composite samples based on tooth enamel. In addition, 3-point bending is a more appropriative loading scheme for routine mechanical testing of the “biomineral—polymer coating” composite in comparison with the uniaxial compression of small-size cuboid composite samples based on tooth enamel with a polymer plomb coating. This result could open an opportunity for accelerated elaboration of novel restorative materials for dentistry.

As it seems, the conclusion that viscous polymer coating does not change the brittle deformation behavior of natural inorganic material following covalent chemical bonding sounds like a negative prognosis for the application of “eggshell—polymer plomb” composites as structural materials. However, as a substitution of tooth hard tissues in damaged teeth, especially tooth enamel, such a composite has some prospects. Indeed, (1) human teeth work under average loading in the limits of one dozen MPas and (2) their deformations due to the chewing of normal human food comprise considerably less than 1% of compression. Therefore, the examined composites can work without any damage under these conditions, since a brittle material is actively damaged under loading close to the ultimate strength. It is also worth to be reminded that hen eggshells possess high biocompatibility with the human body. It is also very important that, in contrast with dental ceramics, the composite restauration of a damaged tooth can never be the cause for mechanical damages of surrounding teeth.

5. Conclusions

It was shown that viscous polymer coatings (for example, the modern polymer plombs used in dentistry) do not change the 3-point bending deformation behavior of samples cut from hen eggshells, which continue to be brittle despite their mechanical characteristics varying within wide limits. The “polymer plomb—eggshell” joining never cracks under bending, and hence exhibits high cohesion strength. It seems that “eggshell—polymer plomb” composites under bending could serve as substitutions for the “tooth enamel—polymer plomb” joining under elaboration and examination of novel restorative materials for dentistry, namely, for estimation of their mechanical properties including cohesive strength. In addition, it seems that hen eggshells have some prospects as the basis for novel restorative materials in dentistry.

Author Contributions

Conceptualization, P.P. and S.G.; methodology, P.P. and D.Z.; validation, P.P., D.Z. and M.M.; formal analysis, D.Z.; investigation, M.M.; writing—original draft preparation P.P. and D.Z.; writing—review and editing, S.G.; visualization, P.P. All authors have read and agreed to the published version of the manuscript.

Funding

The Russian Science Foundation supported this research (# 23-29-00253).

Data Availability Statement

All additional information relating this research, including conference presentations and related publications, is open on Peter Panfilov’s page (https://www.researchgate.net/profile/Peter-Panfilov-2/research).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heymann, H.O.; Swift, E.J.; Ritter, A.V. (Eds.) Sturdivant’s Art and Science of Operative Dentistry; Elsevier/Mosby: Amsterdam, The Netherlands, 2013; 756p. [Google Scholar]

- Besinis, A.; De Peralta, T.; Tredwin, C.J.; Handy, R.D. A review of nanomaterials in dentistry: Interactions with the oral microenvironment, clinical applications, hazards and benefits. ACS Nano 2015, 24, 2255–2289. [Google Scholar] [CrossRef] [PubMed]

- Cramer, N.B.; Stansbury, J.W.; Bowman, C.N. Recent advances and developments in composite dental restorative materials. J. Dent. Res. 2011, 90, 402–416. [Google Scholar] [CrossRef] [PubMed]

- Deb, S.; Chana, S. Biomaterials in Relation to Dentistry. Front. Oral Biol. 2015, 17, 1–12. [Google Scholar] [CrossRef] [PubMed]

- He, L.H.; Swain, M.V. Understanding the mechanical behavior of human enamel from its structural and compositional characteristics. J. Mech. Behav. Biomed. Mater. 2008, 1, 18–29. [Google Scholar] [CrossRef] [PubMed]

- Solomon, S.E. The eggshell: Strength, structure and function. Br. Poult. Sci. 2010, 51, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Hincke, M.T.; Nys, Y.; Gautron, J.; Mann, K.; Rodriguez-Navarro, A.B.; McKee, M.D. The eggshell: Structure, composition and mineralization? Front. Biosci. 2012, 17, 1266–1280. [Google Scholar] [CrossRef]

- Stefanello, C.; Santos, T.C.; Murakami, A.E.; Martins, E.N.; Carneiro, T.C. Productive performance, eggshell quality, and eggshell ultrastructure of laying hens fed diets supplemented with organic trace minerals. Poult. Sci. 2014, 93, 104–113. [Google Scholar] [CrossRef]

- Neumann, H.H.; De Salvo, N.A. Compression of teeth under, the load of chewing. J. Dent. Res. 1957, 36, 286–290. [Google Scholar] [CrossRef]

- Waters, N.E. Some mechanical and physical properties of teeth. Symp. Soc. Exp. Biol. 1980, 34, 99–135. [Google Scholar]

- Mezhenov, M.; Zheludkov, D.; Kabanova, A.V.; Zaytsev, D.; Panfilov, P. Deformation Behavior of Chicken Eggshell. AIP Conf. Proc. 2022, 2509, 020131. [Google Scholar] [CrossRef]

- Leinfelder, K.F.; Bayne, S.C.; Swift, E.J. Packable composites: Overview and technical considerations. J. Esthet. Dent. 1999, 11, 234–258. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–85. [Google Scholar] [CrossRef] [PubMed]

- Knott, J.F. Fundamentals of Fracture Mechanics; Butterworths: London, UK, 1973. [Google Scholar]

- Argon, A.S. Strengthening Mechanisms in Crystal Plasticity; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Kachanov, M.; Sevostianov, I. Micromechanics of Materials, with Applications, Solid Mechanics and Its Applications 249; Springer Nature: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Gandhi, C.; Ashby, M.F. Fracture-mechanisms maps for materials, which cleave: F.c.c.; b.c.c. and h.c.p. metals and ceramics. Acta Metall. 1979, 27, 1565–1602. [Google Scholar] [CrossRef]

- Argon, A.S. The Physics of Deformation and Fracture of Polymers; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).