Triboelectric Nanogenerators Based on Nanostructured Layers of Zinc Oxide Deposited on Carbon Fabric

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef] [PubMed]

- Seung, W.; Gupta, M.K.; Lee, K.Y.; Shin, K.-S.; Lee, J.-H.; Kim, T.Y.; Kim, S.; Lin, J.; Kim, J.H.; Kim, S.-W. Nanopatterned Textile-Based Wearable Triboelectric Nanogenerator. ACS Nano 2015, 9, 3501–3509. [Google Scholar] [CrossRef] [PubMed]

- Lim, Y.P.; Koay, J.S.C.; Zhao, J.T.; Huang, S.; Goh, B.T.; Aw, K.C.; Chen, B.; Haw, C.Y.; Gan, W.C. Modulating ZnO Growth Structures for Maximum Power Output of Hybrid Piezo/Triboelectric Nanogenerator. Adv. Funct. Mater. 2022, 32, 2206750. [Google Scholar] [CrossRef]

- Baro, B.; Khimhun, S.; Das, U.; Bayan, S. ZnO Based Triboelectric Nanogenerator on Textile Platform for Wearable Sweat Sensing Application. Nano Energy 2023, 108, 108212. [Google Scholar] [CrossRef]

- Yi, J.; Dong, K.; Shen, S.; Jiang, Y.; Peng, X.; Ye, C.; Wang, Z.L. Fully Fabric-Based Triboelectric Nanogenerators as Self-Powered Human–Machine Interactive Keyboards. Nano-Micro Lett. 2021, 13, 103. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Lee, P.S. Progress on Wearable Triboelectric Nanogenerators in Shapes of Fiber, Yarn, and Textile. Sci. Technol. Adv. Mater. 2019, 20, 837–857. [Google Scholar] [CrossRef] [PubMed]

- Walden, R.; Aazem, I.; Babu, A.; Pillai, S.C. Textile Triboelectric Nanogenerators (T-TENGs) for Wearable Energy Harvesting Devices. Chem. Eng. J. 2023, 451, 138741. [Google Scholar] [CrossRef]

- Huang, P.; Wen, D.-L.; Qiu, Y.; Yang, M.-H.; Tu, C.; Zhong, H.-S.; Zhang, X.-S. Textile-Based Triboelectric Nanogenerators for Wearable Self-Powered Microsystems. Micromachines 2021, 12, 158. [Google Scholar] [CrossRef]

- Jung, S.; Lee, J.; Hyeon, T.; Lee, M.; Kim, D.-H. Fabric-Based Integrated Energy Devices for Wearable Activity Monitors. Adv. Mater. 2014, 26, 6329–6334. [Google Scholar] [CrossRef]

- Abbas, Q.; Javed, M.S.; Ahmad, A.; Siyal, S.H.; Asim, I.; Luque, R.; Albaqami, M.D.; Tighezza, A.M. ZnO Nano-Flowers Assembled on Carbon Fiber Textile for High-Performance Supercapacitor’s Electrode. Coatings 2021, 11, 1337. [Google Scholar] [CrossRef]

- Xie, F.; Hu, W.; Ning, D.; Zhuo, L.; Deng, J.; Lu, Z. ZnO Nanowires Decoration on Carbon Fiber Via Hydrothermal Synthesis for Paper-Based Friction Materials with Improved Friction and Wear Properties. Ceram. Int. 2018, 44, 4204–4210. [Google Scholar] [CrossRef]

- Du, Y.; Fu, C.; Gao, Y.; Liu, L.; Liu, Y.; Xing, L.; Zhao, F. Carbon Fibers/ZnO Nanowires Hybrid Nanogenerator Based on an Insulating Interface Barrier. RSC Adv. 2017, 7, 21452–21458. [Google Scholar] [CrossRef]

- Fei, J.; Luo, D.; Huang, J.; Zhang, C.; Duan, X.; Zhang, L. Growth of Aligned ZnO Nanorods on Carbon Fabric and its Composite for Superior Mechanical and Tribological Performance. Surf. Coat. Technol. 2018, 344, 433–440. [Google Scholar] [CrossRef]

- Wang, J.; Weng, B.; Larson, P.; Liu, Y. Synthesis of ZnO Nanoarrays on Carbon Fibers Using Combined Atomic Layer Deposition and Hydrothermal Methods. Mater. Res. Express 2018, 5, 065029. [Google Scholar] [CrossRef]

- Tapily, K.; Gu, D.; Baumgart, H.; Rigo, M.; Seo, J. Raman Spectroscopy of ZnO Thin Films by Atomic Layer Deposition. ECS Trans. 2010, 33, 117–123. [Google Scholar] [CrossRef]

- Torchynska, T.; El Filali, B.; Jaramillo Gomez, J.A.; Polupan, G.; Ramírez García, J.L.; Shcherbyna, L. Raman Scattering, Emission, and Deep Defect Evolution in ZnO:In Thin Films. J. Vac. Sci. Technol. A 2020, 38, 063409. [Google Scholar] [CrossRef]

- Konan, F.K.; Hartiti, B.; Batan, A.; Aka, B. X-ray Diffraction, XPS, and Raman Spectroscopy of Coated ZnO:Al (1–7 at%) Nanoparticles. Surf. Sci. Nanotechnol. 2019, 17, 163–168. [Google Scholar] [CrossRef]

- El Filali, B.; Torchynska, T.V.; Díaz Cano, A.I.; Morales Rodriguez, M. Revista Structural and Raman Scattering Studies of ZnO Cu Nanocrystals Grown by Spray Pyrolysis. Mex. Ing. Quím. 2015, 14, 781–788. [Google Scholar]

- Nowak, E.; Szybowicz, M.; Stachowiak, A.; Koczorowski, W.; Schulz, D.; Paprocki, K.; Fabisiak, K.; Los, S. A Comprehensive Study of Structural and Optical Properties of ZnO Bulk Crystals and Polycrystalline Films Grown by Sol-Gel Method. Appl. Phys. A 2020, 126, 552. [Google Scholar] [CrossRef]

- Gültekin, D.; Akbulut, H. Raman Studies of ZnO Products Synthesized by Solution Based Methods. Acta Phys. Pol. A 2016, 129, 803–805. [Google Scholar] [CrossRef]

- Li, T.; Zou, J.; Xing, F.; Zhang, M.; Cao, X.; Wang, N.; Wang, Z.L. From Dual-Mode Triboelectric Nanogenerator to Smart Tactile Sensor: A Multiplexing Design. ACS Nano 2017, 11, 3950–3956. [Google Scholar] [CrossRef] [PubMed]

- Bai, Z.; Xu, Y.; Li, J.; Zhu, J.; Gao, C.; Zhang, Y.; Wang, J.; Guo, J. An Eco-Friendly Porous Nanocomposite Fabric-Based Triboelectric Nanogenerator for Efficient Energy Harvesting and Motion Sensing. ACS Appl. Mater. Interfaces 2020, 12, 42880–42890. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, Y.; Wang, Z.L. Triboelectric Nanogenerators as Flexible Power Sources. npj Flex Electron. 2017, 1, 10. [Google Scholar] [CrossRef]

- Kaur, D.; Bharti, A.; Sharma, T.; Madhu, C. The Future of Opto-Electronics: Device Architecture, Novel Materials, and Applications. Int. J. Opt. 2021, 2021, 9950202. [Google Scholar] [CrossRef]

- Koyano, M.; QuocBao, P.; thi ThanhBinh, L.; HongHa, L.; NgocLong, N.; Katayama, S. Photoluminescence and Raman Spectra of ZnO Thin Films by Charged Liquid Cluster Beam Technique. Phys. Stat. Sol. (a) 2002, 193, 125–131. [Google Scholar] [CrossRef]

- Rudolph, W.W.; Brooker, M.H.; Tremaine, P.R. Raman Spectroscopy of Aqueous ZnSO4 Solutions under Hydrothermal Conditions: Solubility, Hydrolysis, and Sulfate Ion Pairing. J. Solut. Chem. 1999, 28, 621–630. [Google Scholar] [CrossRef]

- Pan, M.; Yuan, C.; Liang, X.; Zou, J.; Zhang, Y.; Bowen, C. Triboelectric and Piezoelectric Nanogenerators for Future Soft Robots and Machines. iScience 2020, 23, 101682. [Google Scholar] [CrossRef]

- Zeng, J.; Zhao, J.; Li, C.; Qi, Y.; Liu, G.; Fu, X.; Zhou, H.; Zhang, C. Triboelectric Nanogenerators as Active Tactile Stimulators for Multifunctional Sensing and Artificial Synapses. Sensors 2022, 22, 975. [Google Scholar] [CrossRef]

- Supraja, P.; Kumar, R.R.; Mishra, S.; Haranath, D.; Sankar, P.R.; Prakash, K.; Jayarambabu, N.; Rao, T.V.; Kumar, K.U. A Simple and Low-cost Triboelectric Nanogenerator Based on Two Dimensional ZnO Nanosheets and its Application in Portable Electronics. Sens. Actuators A Phys. 2022, 335, 113368. [Google Scholar] [CrossRef]

| Sample | Composition According to EDS, at. % | |||

|---|---|---|---|---|

| Zn | O | S | C | |

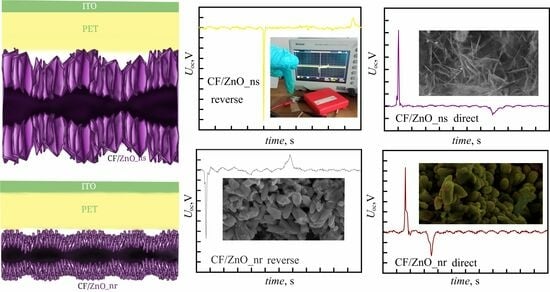

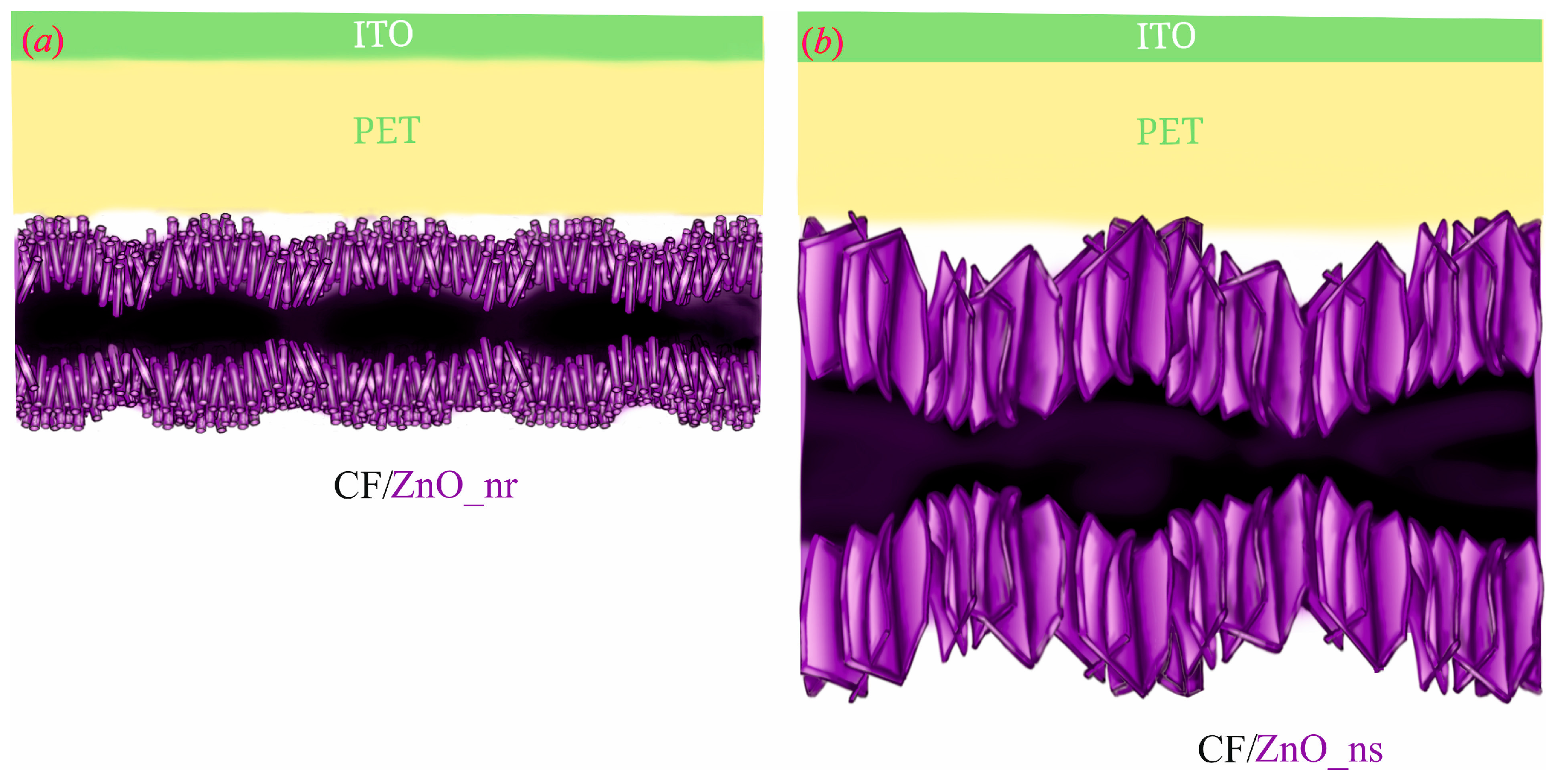

| CF/ZnO_nr (~1 µm thick ZnO nanorods obtained by the SILAR method on the surface of CF fibers pre-coated with ZnO seed layers) | 9 | 16 | 1 | 74 |

| CF/ZnO_ns (~20 µm thick ZnO nanosheets fabricated by the SILAR method on bare CF) | 27 | 46 | 8 | 19 |

| TENG | R, kΩ | J, μA/cm2 | Q, nC | U, mV | P, nW/cm2 |

|---|---|---|---|---|---|

| CF/ZnO_nr/PET/ITO | 270 | 1.07 | 3.26 | 432 | 461 |

| 620 | 0.87 | 1.93 | 808 | 699 | |

| 4800 | 0.47 | 1.15 | 3360 | 1568 | |

| CF/ZnO_ns/PET/ITO | 270 | 1.47 | 3.58 | 594 | 871 |

| 620 | 0.90 | 3.03 | 837 | 753 | |

| 4800 | 0.50 | 1.23 | 3600 | 1800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrushenko, S.I.; Fijalkowski, M.; Kopach, V.R.; Shepotko, Y.M.; Adach, K.; Dukarov, S.V.; Sukhov, V.M.; Fedonenko, A.; Khrypunova, A.L.; Klochko, N.P. Triboelectric Nanogenerators Based on Nanostructured Layers of Zinc Oxide Deposited on Carbon Fabric. J. Compos. Sci. 2023, 7, 496. https://doi.org/10.3390/jcs7120496

Petrushenko SI, Fijalkowski M, Kopach VR, Shepotko YM, Adach K, Dukarov SV, Sukhov VM, Fedonenko A, Khrypunova AL, Klochko NP. Triboelectric Nanogenerators Based on Nanostructured Layers of Zinc Oxide Deposited on Carbon Fabric. Journal of Composites Science. 2023; 7(12):496. https://doi.org/10.3390/jcs7120496

Chicago/Turabian StylePetrushenko, Sergey I., Mateusz Fijalkowski, Volodymyr R. Kopach, Yevhenii M. Shepotko, Kinga Adach, Sergei V. Dukarov, Volodymyr M. Sukhov, Alina Fedonenko, Alina L. Khrypunova, and Natalia P. Klochko. 2023. "Triboelectric Nanogenerators Based on Nanostructured Layers of Zinc Oxide Deposited on Carbon Fabric" Journal of Composites Science 7, no. 12: 496. https://doi.org/10.3390/jcs7120496

APA StylePetrushenko, S. I., Fijalkowski, M., Kopach, V. R., Shepotko, Y. M., Adach, K., Dukarov, S. V., Sukhov, V. M., Fedonenko, A., Khrypunova, A. L., & Klochko, N. P. (2023). Triboelectric Nanogenerators Based on Nanostructured Layers of Zinc Oxide Deposited on Carbon Fabric. Journal of Composites Science, 7(12), 496. https://doi.org/10.3390/jcs7120496