Performances Recovery of Flax Fiber Reinforced Composites after Salt-Fog Aging Test

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Water Uptake

- At first, during the wet stage, a gradual increase in the water uptake occurred, related to the direct proportionality between wetting time and absorbed water. For long exposure times (see the water uptake trend for the FW30 batch), a slight deviation from this linearity can be noticed. In particular, the maximum water uptake was 7.86% and 10.54% for the FW15 and FW30 batches, respectively. In fact, the curves do not show the clear stabilization of the weight increase, even for long exposure times in a salt spray chamber. This implies that, due to the inherently hydrophilic property of the fiber, the material has not completed its absorption process. Consequently, the natural fiber-reinforced laminate is still potentially sensitive to diffusion phenomena of water molecules. This expected finding can be related to the dramatic tendency to absorb water shown by NFRC materials [19,20];

- At the wet/dry stage transition, the trend in the water uptake curve exhibits an evident inversion point. In particular, the curves’ slope for both the investigated batches shows a clear weight reduction (i.e., related to a significant water uptake decrease) after a few days. In particular, the FW15 and FW30 batches exhibited water uptake reductions of 2.92% and 4.52% in the first 24 h of drying, respectively. A stabilization of the weight at an asymptotic constant value was only observed at long drying times. In particular, the batch FW30 showed residual water uptake of about 0.6% higher than that exposed for a shorter time to salt-fog (i.e., Mt ~1.86% and ~2.46% for FW15 and FW30 batches, respectively). This can be considered as quite predictable, because it is widely known that the weight gain of NFRCs exposed to humid or wet environmental conditions or immersed in aqueous solutions is strictly related to the immersion time [21,22].

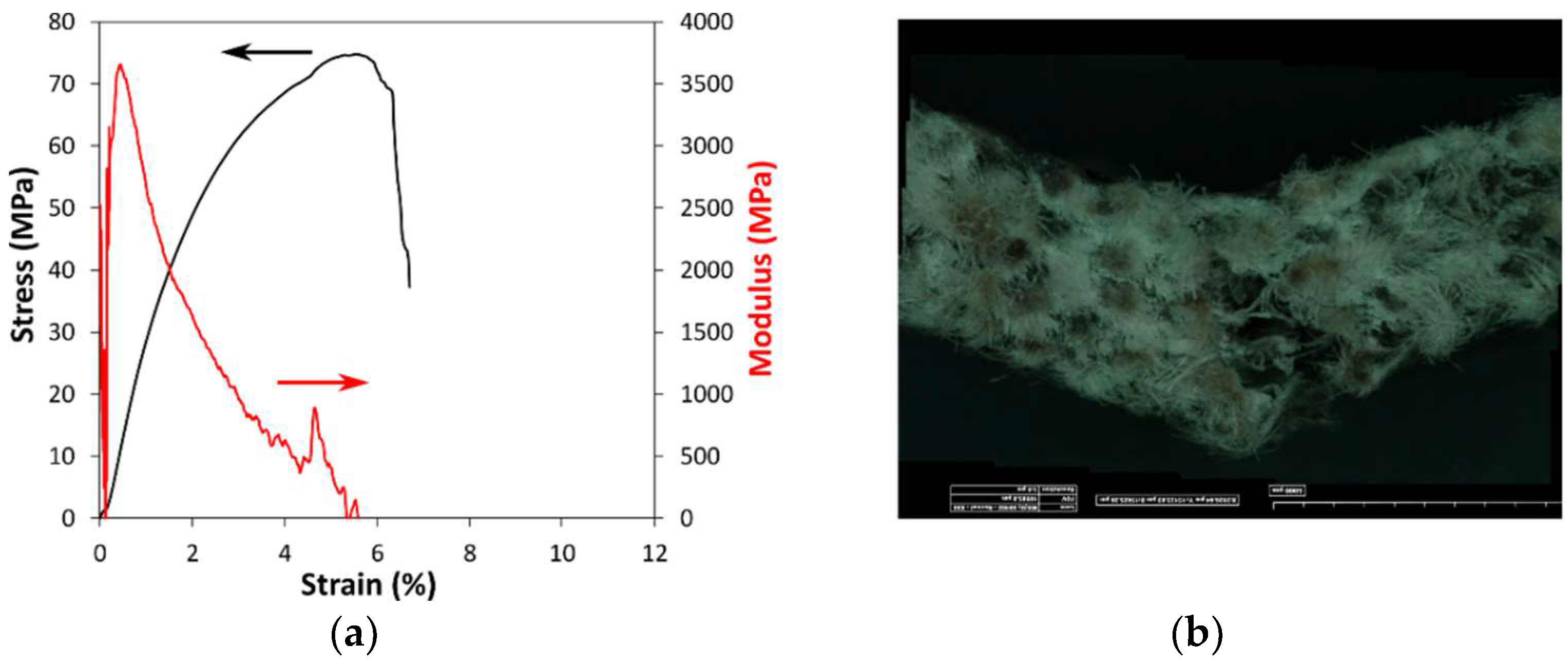

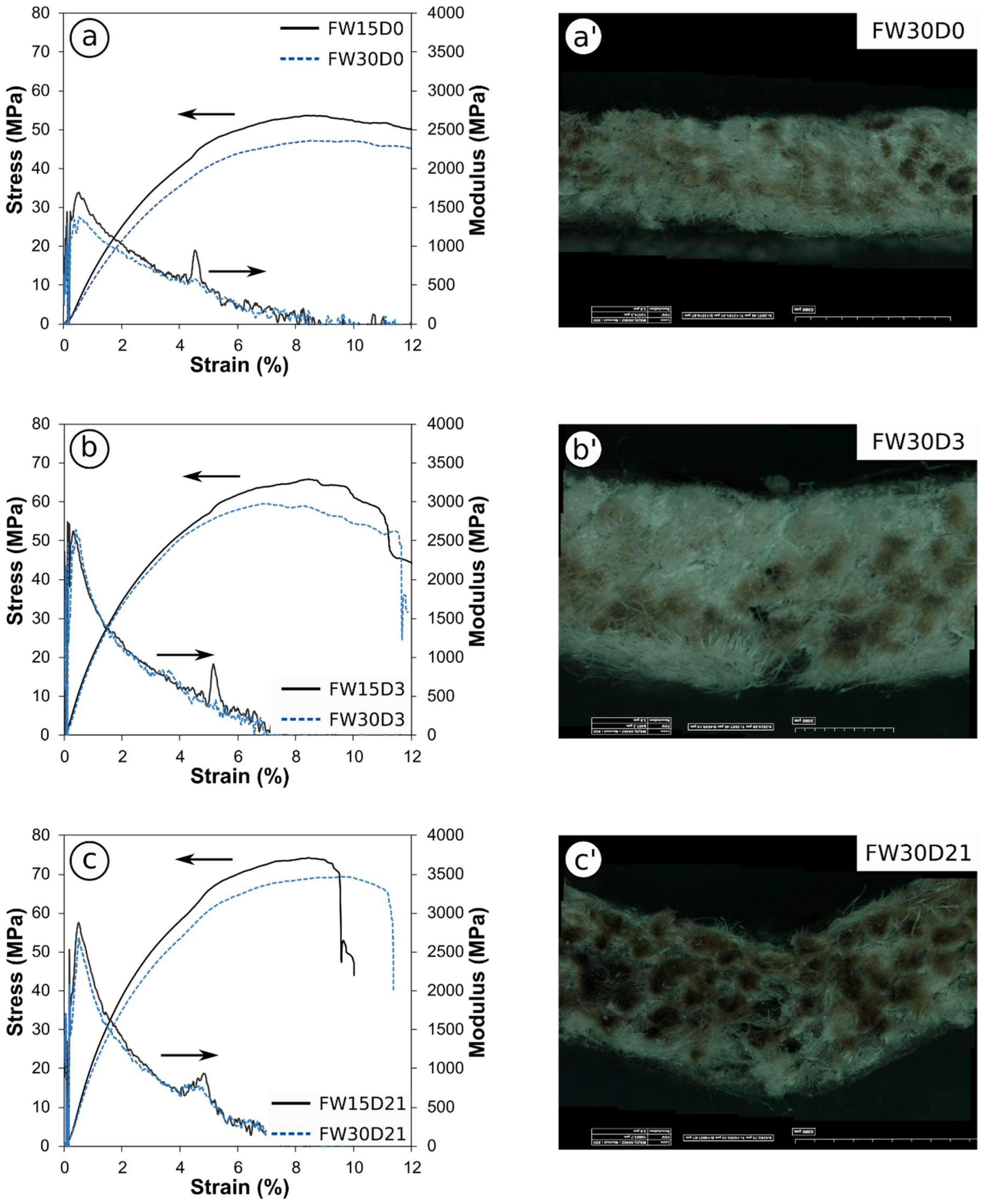

3.2. Quasi-Static Mechanical Tests

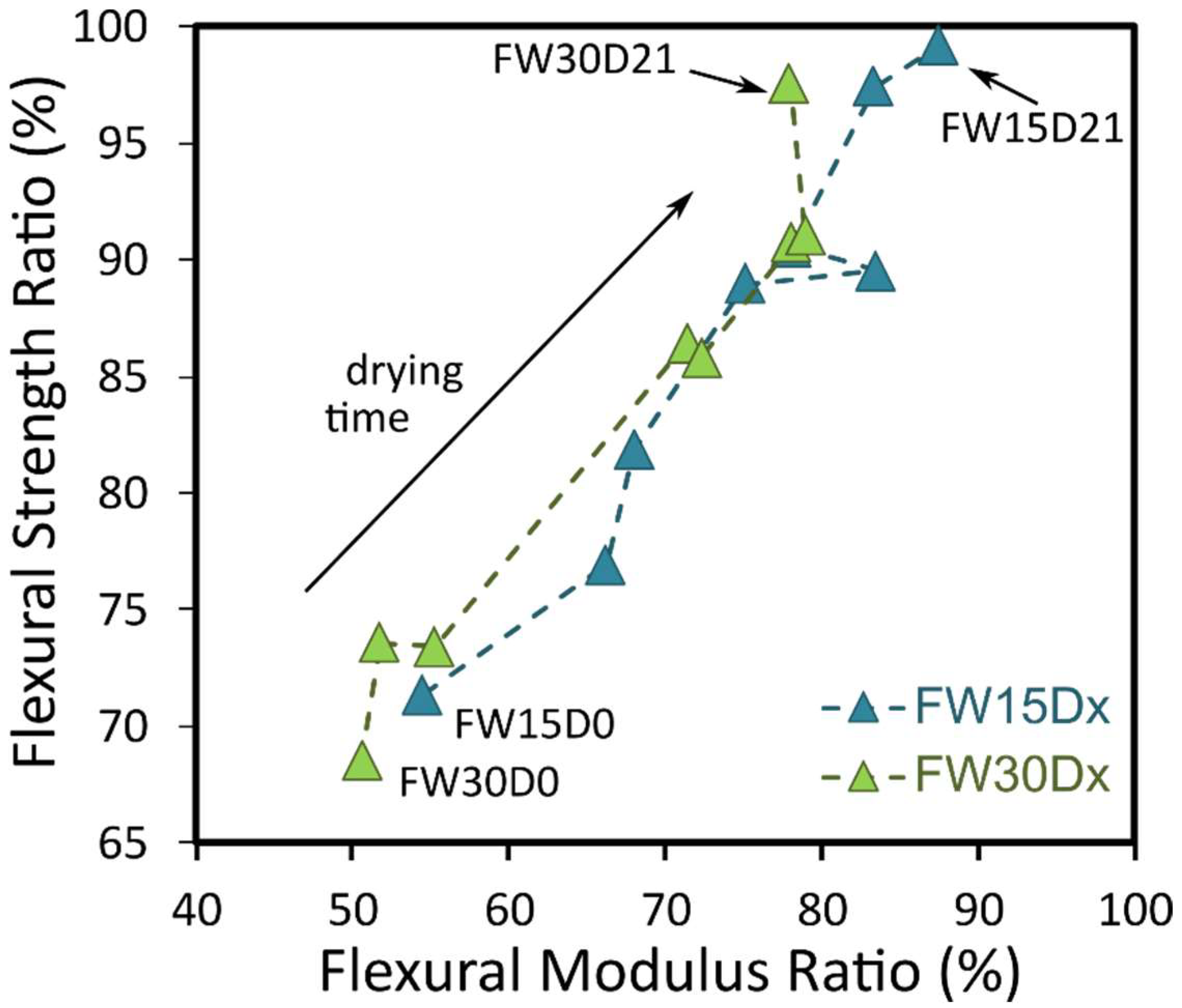

3.3. Toughness Map

4. Conclusions

- The degradation mechanisms that take place during the wet stage affect both the strength and stiffness of flax fiber-reinforced composites in different ways. In particular, after 30 days of salt-fog exposure, FW30 laminates showed decays in strength and stiffness of 31% and 49%, respectively;

- The performance reductions are recovered during the dry stage. Unlike stiffness, the composite laminate is able to recover almost completely its initial flexural strength. In particular, the FW30D21 batch exhibited recovery values of 98% and 78% in terms of strength and stiffness, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2019, 34, 238–284. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites. Int. J. Polym. Sci. 2015, 2015, 16–18. [Google Scholar] [CrossRef]

- EI Hachem, Z.; Célino, A.; Challita, G.; Branchu, S.; Le Duigou, A.; Fréour, S. Dimensional variation and evolution of mechanical properties of wet aged composites reinforced with flax fibers. J. Compos. Mater. 2020, 55, 1131–1148. [Google Scholar] [CrossRef]

- Pisupati, A.; Bonnaud, L.; Deléglise-Lagardère, M.; Park, C.H. Influence of Environmental Conditions on the Mechanical Properties of Flax Fiber Reinforced Thermoset Composites. Appl. Compos. Mater. 2021, 28, 633–649. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Influence of sodium bicarbonate treatment on the aging resistance of natural fiber reinforced polymer composites under marine environment. Polym. Test. 2019, 80, 106100. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Dynamic Mechanical Behavior Analysis of Flax/Jute Fiber-Reinforced Composites under Salt-Fog Spray Environment. Polymers 2020, 12, 716. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Calabrese, L.; Di Bella, G.; Scalici, T.; Galtieri, G.; Valenza, A.; Proverbio, E. Effects of aging in salt spray conditions on flax and flax/basalt reinforced composites: Wettability and dynamic mechanical properties. Compos. Part B Eng. 2016, 93, 35–42. [Google Scholar] [CrossRef]

- Mejri, M.; Toubal, L.; Cuillière, J.C.; François, V. Hygrothermal aging effects on mechanical and fatigue behaviors of a short- natural-fiber-reinforced composite. Int. J. Fatigue 2018, 108, 96–108. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Hassan, A.; Khan, R.; Khan, N.; Aamir, M.; Pimenov, D.Y.; Giasin, K. Effect of Seawater Ageing on Fracture Toughness of Stitched Glass Fiber/Epoxy Laminates for Marine Applications. J. Mar. Sci. Eng. 2021, 9, 196. [Google Scholar] [CrossRef]

- Cadu, T.; Van Schoors, L.; Sicot, O.; Moscardelli, S.; Divet, L.; Fontaine, S. Cyclic hygrothermal ageing of flax fibers’ bundles and unidirectional flax/epoxy composite. Are bio-based reinforced composites so sensitive? Ind. Crops Prod. 2019, 141, 111730. [Google Scholar] [CrossRef]

- Van Schoors, L.; Cadu, T.; Moscardelli, S.; Divet, L.; Fontaine, S.; Sicot, O. Why cyclic hygrothermal ageing modifies the transverse mechanical properties of a unidirectional epoxy-flax fibres composite? Ind. Crops Prod. 2021, 164, 113341. [Google Scholar] [CrossRef]

- Ventura, H.; Claramunt, J.; Navarro, A.; Rodriguez-Perez, M.A.; Ardanuy, M. Effects of Wet/Dry-Cycling and Plasma Treatments on the Properties of Flax Nonwovens Intended for Composite Reinforcing. Materials 2016, 9, 93. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Piperopoulos, E.; Badagliacco, D.; Palamara, D.; Valenza, A.; Proverbio, E. In situ monitoring of moisture uptake of flax fiber reinforced composites under humid/dry conditions. J. Appl. Polym. Sci. 2021, 139, 51969. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Seawater ageing of flax/poly (lactic acid) biocomposites. Polym. Degrad. Stab. 2009, 94, 1151–1162. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Effect of water, seawater and alkaline solution ageing on mechanical properties of flax fabric/epoxy composites used for civil engineering applications. Constr. Build. Mater. 2015, 99, 118–127. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.M.; Bakar, A.A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2011, 46, 51–61. [Google Scholar] [CrossRef]

- Hristozov, D.; Wroblewski, L.; Sadeghian, P. Long-term tensile properties of natural fibre-reinforced polymer composites: Comparison of flax and glass fibres. Compos. Part B Eng. 2016, 95, 82–95. [Google Scholar] [CrossRef]

- Chegdani, F.; El Mansori, M.; Chebbi, A.-A. Cutting behavior of flax fibers as reinforcement of biocomposite structures involving multiscale hygrometric shear. Compos. Part B Eng. 2021, 211, 108660. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Öchsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2019, 38, 323–339. [Google Scholar] [CrossRef]

- Haghighatnia, T.; Abbasian, A.; Morshedian, J. Hemp fiber reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crops Prod. 2017, 108, 853–863. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. On the response of flax fiber reinforced composites under salt-fog/dry conditions: Reversible and irreversible performances degradation. Compos. Part B Eng. 2022, 230, 109535. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. Assessment of performance degradation of hybrid flax-glass fiber reinforced epoxy composites during a salt spray fog/dry aging cycle. Compos. Part B Eng. 2022, 238, 109897. [Google Scholar] [CrossRef]

- Sheinbaum, M.; Sheinbaum, L.; Weizman, O.; Dodiuk, H.; Kenig, S. Toughening and enhancing mechanical and thermal properties of adhesives and glass-fiber reinforced epoxy composites by brominated epoxy. Compos. Part B Eng. 2019, 165, 604–612. [Google Scholar] [CrossRef]

- Javanshour, F.; Prapavesis, A.; Pärnänen, T.; Orell, O.; Belone, M.L.; Layek, R.K.; Kanerva, M.; Kallio, P.; Van Vuure, A.W.; Sarlin, E. Modulating impact resistance of flax epoxy composites with thermoplastic interfacial toughening. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106628. [Google Scholar] [CrossRef]

| σ (MPa) | E (GPa) | εpeak (%) | ||||

|---|---|---|---|---|---|---|

| Avg | Std.dev. | Avg | Std.dev. | Avg | Std.dev | |

| FW0D0 | 74.5 | 4.4 | 3.4 | 0.2 | 5.3 | 0.2 |

| FW15D0 | 53.2 | 0.9 | 1.9 | 0.0 | 8.8 | 0.4 |

| FW15D0.25 | 57.3 | 6.4 | 2.3 | 0.2 | 8.9 | 0.2 |

| FW15D1 | 61.0 | 2.3 | 2.3 | 0.1 | 8.8 | 0.4 |

| FW15D2 | 66.3 | 4.6 | 2.6 | 0.2 | 8.8 | 0.4 |

| FW15D3 | 66.7 | 2.2 | 2.9 | 0.0 | 8.6 | 0.6 |

| FW15D7 | 67.5 | 4.4 | 2.7 | 0.3 | 8.2 | 0.4 |

| FW15D11 | 72.6 | 3.5 | 2.9 | 0.2 | 8.4 | 0.6 |

| FW15D21 | 73.9 | 3.9 | 3.0 | 0.2 | 8.0 | 0.7 |

| FW30D0 | 51.1 | 2.8 | 1.7 | 0.3 | 8.8 | 0.4 |

| FW30D0.25 | 54.8 | 0.8 | 1.8 | 0.2 | 8.8 | 0.6 |

| FW30D1 | 54.7 | 1.2 | 1.9 | 0.2 | 9.1 | 0.7 |

| FW30D2 | 64.4 | 5.7 | 2.4 | 0.3 | 9.2 | 0.8 |

| FW30D3 | 63.9 | 3.3 | 2.5 | 0.4 | 9.0 | 1.0 |

| FW30D7 | 67.6 | 4.1 | 2.7 | 0.4 | 9.2 | 0.7 |

| FW30D11 | 67.9 | 1.3 | 2.7 | 0.2 | 9.1 | 0.8 |

| FW30D21 | 72.7 | 2.2 | 2.7 | 0.2 | 9.0 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calabrese, L.; Fiore, V.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. Performances Recovery of Flax Fiber Reinforced Composites after Salt-Fog Aging Test. J. Compos. Sci. 2022, 6, 264. https://doi.org/10.3390/jcs6090264

Calabrese L, Fiore V, Miranda R, Badagliacco D, Sanfilippo C, Palamara D, Valenza A, Proverbio E. Performances Recovery of Flax Fiber Reinforced Composites after Salt-Fog Aging Test. Journal of Composites Science. 2022; 6(9):264. https://doi.org/10.3390/jcs6090264

Chicago/Turabian StyleCalabrese, Luigi, Vincenzo Fiore, Riccardo Miranda, Dionisio Badagliacco, Carmelo Sanfilippo, Davide Palamara, Antonino Valenza, and Edoardo Proverbio. 2022. "Performances Recovery of Flax Fiber Reinforced Composites after Salt-Fog Aging Test" Journal of Composites Science 6, no. 9: 264. https://doi.org/10.3390/jcs6090264

APA StyleCalabrese, L., Fiore, V., Miranda, R., Badagliacco, D., Sanfilippo, C., Palamara, D., Valenza, A., & Proverbio, E. (2022). Performances Recovery of Flax Fiber Reinforced Composites after Salt-Fog Aging Test. Journal of Composites Science, 6(9), 264. https://doi.org/10.3390/jcs6090264