Investigation of Mechanical Properties and Microstructure of Construction- and Demolition-Waste-Based Geopolymers

Abstract

:1. Introduction

2. Materials and Methods

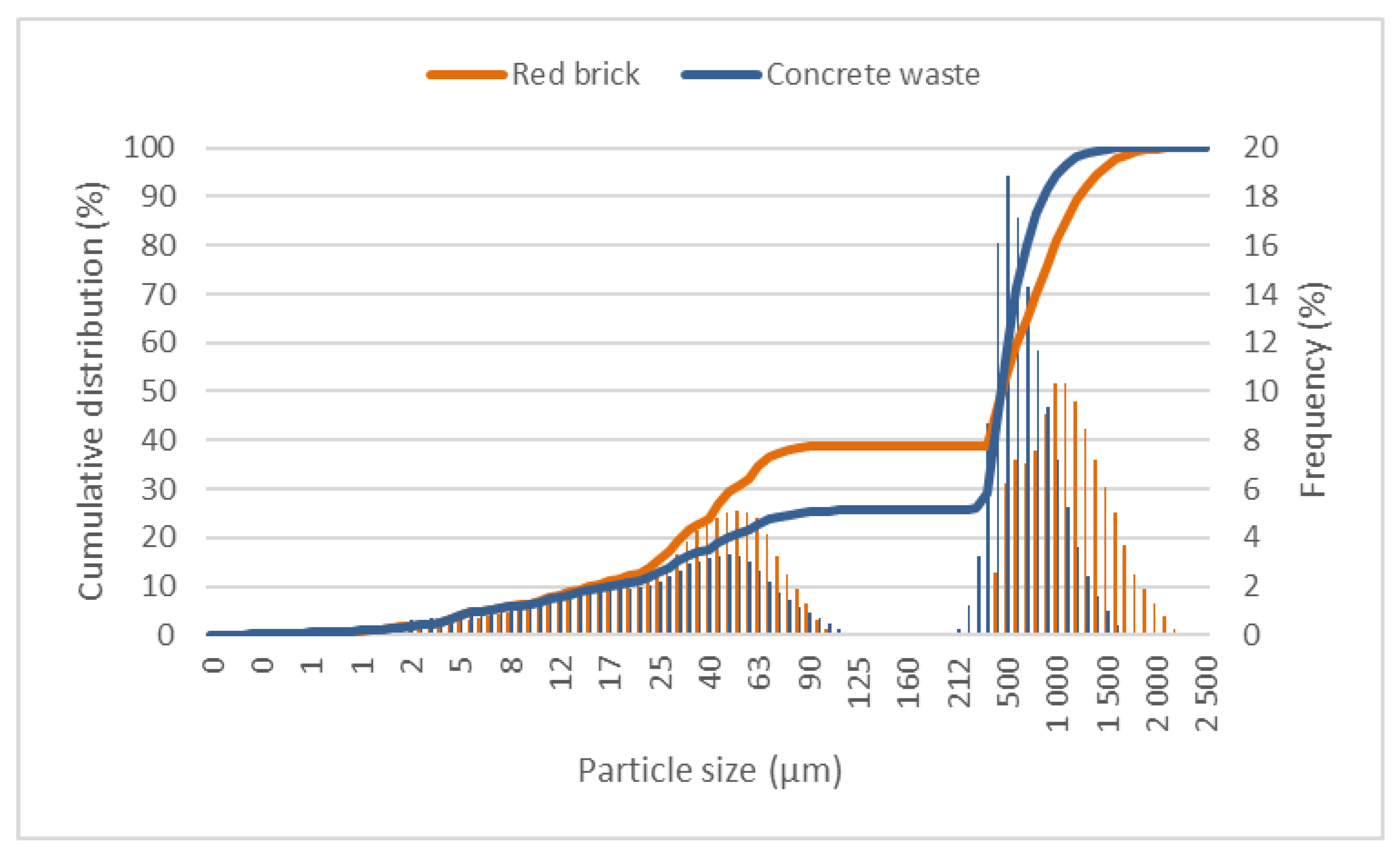

2.1. Materials

2.2. Samples Preparation

2.3. Methods

3. Results

3.1. Density

3.2. Mechanical Properties

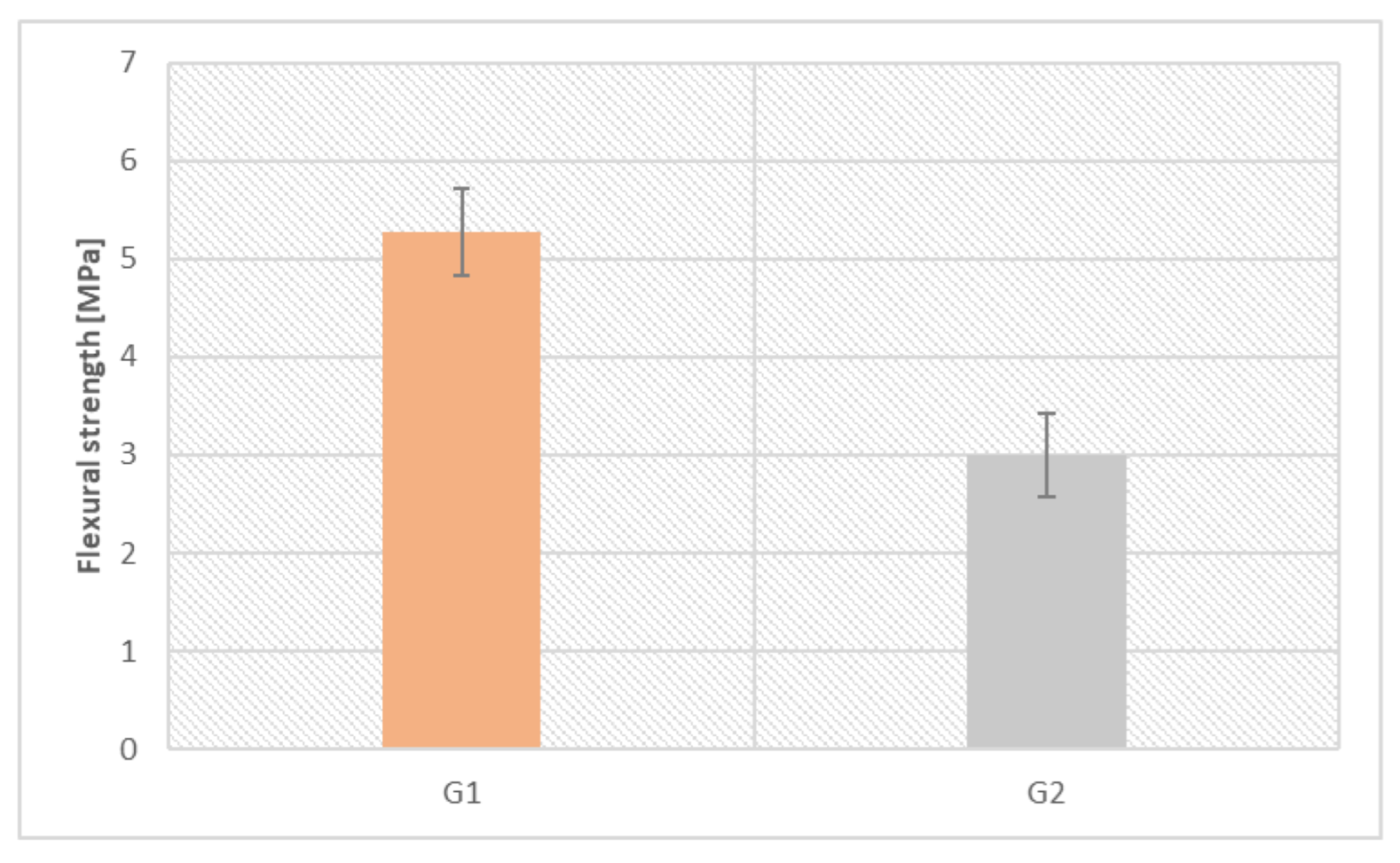

3.2.1. Flexural Strength

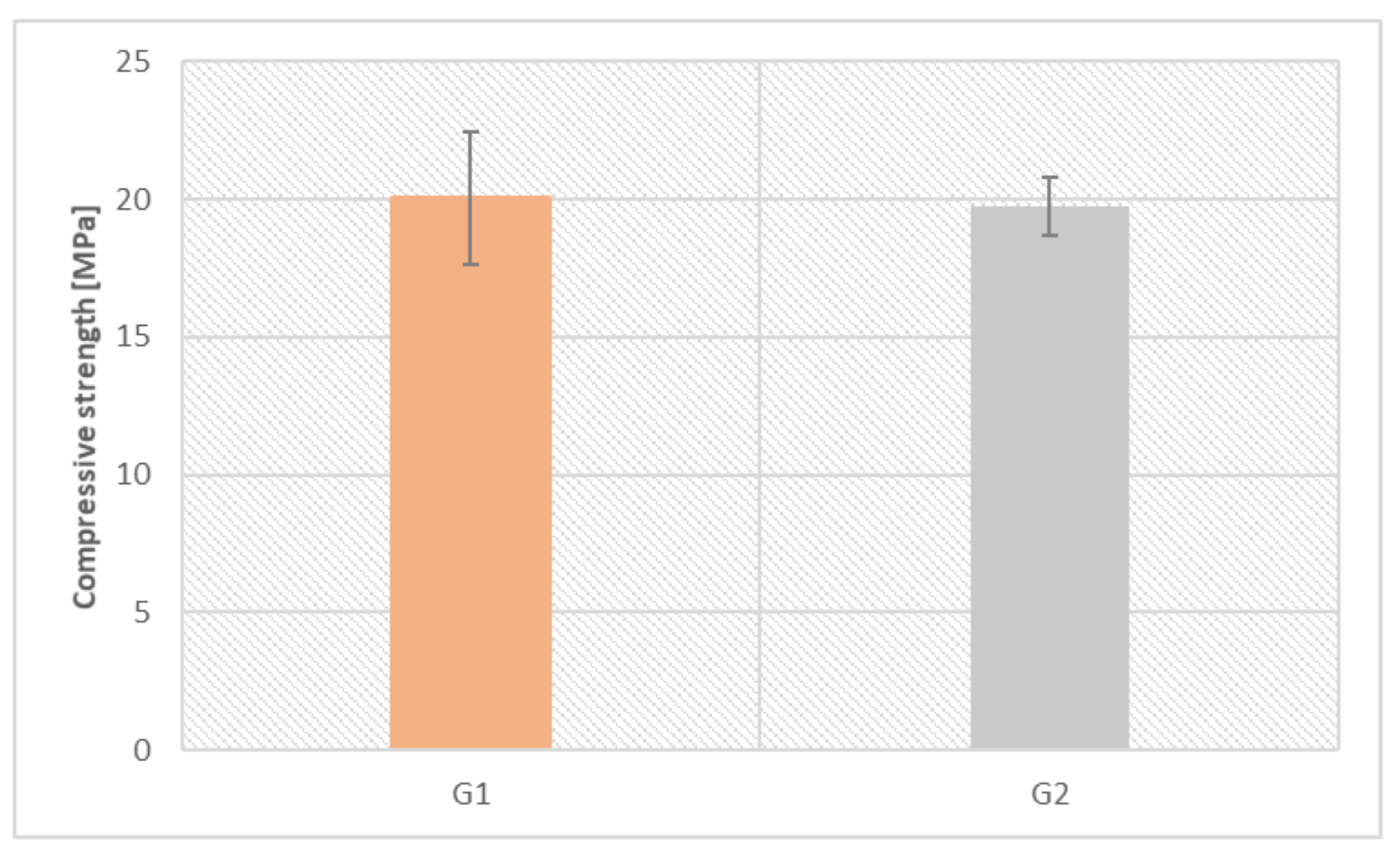

3.2.2. Compressive Strength

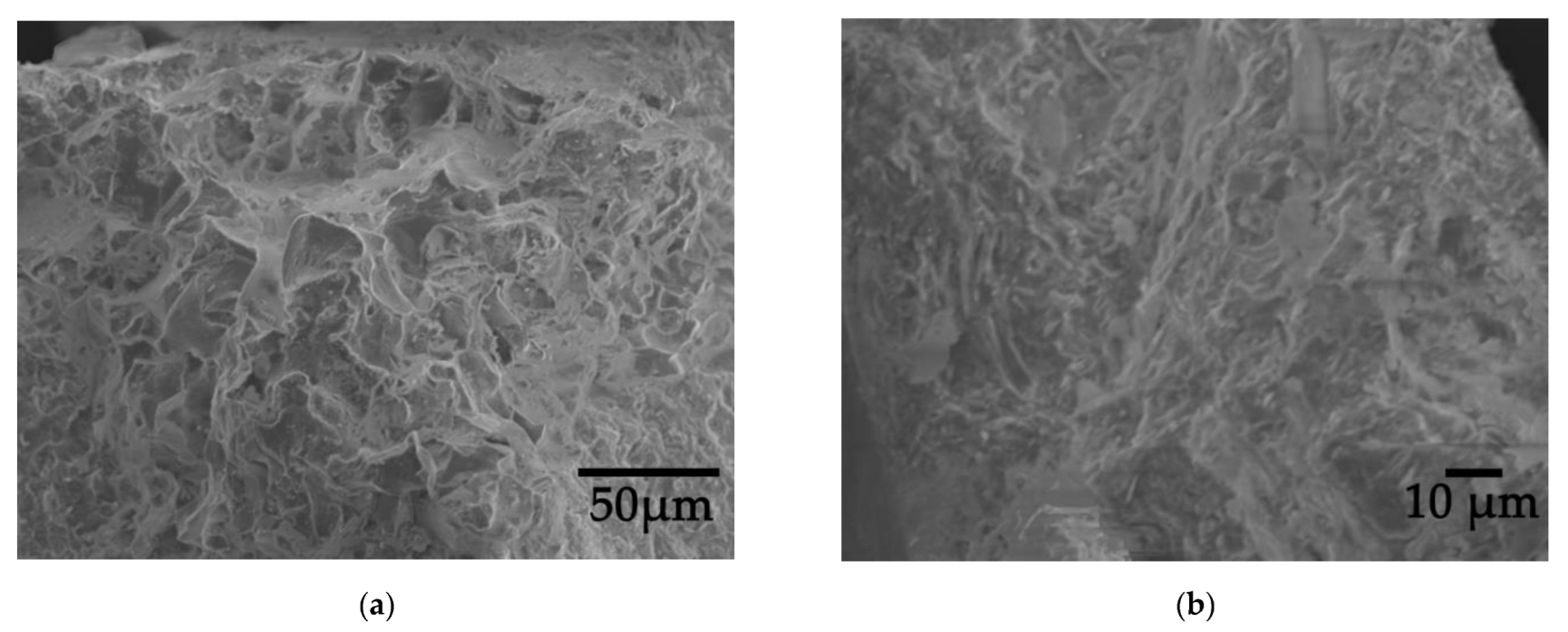

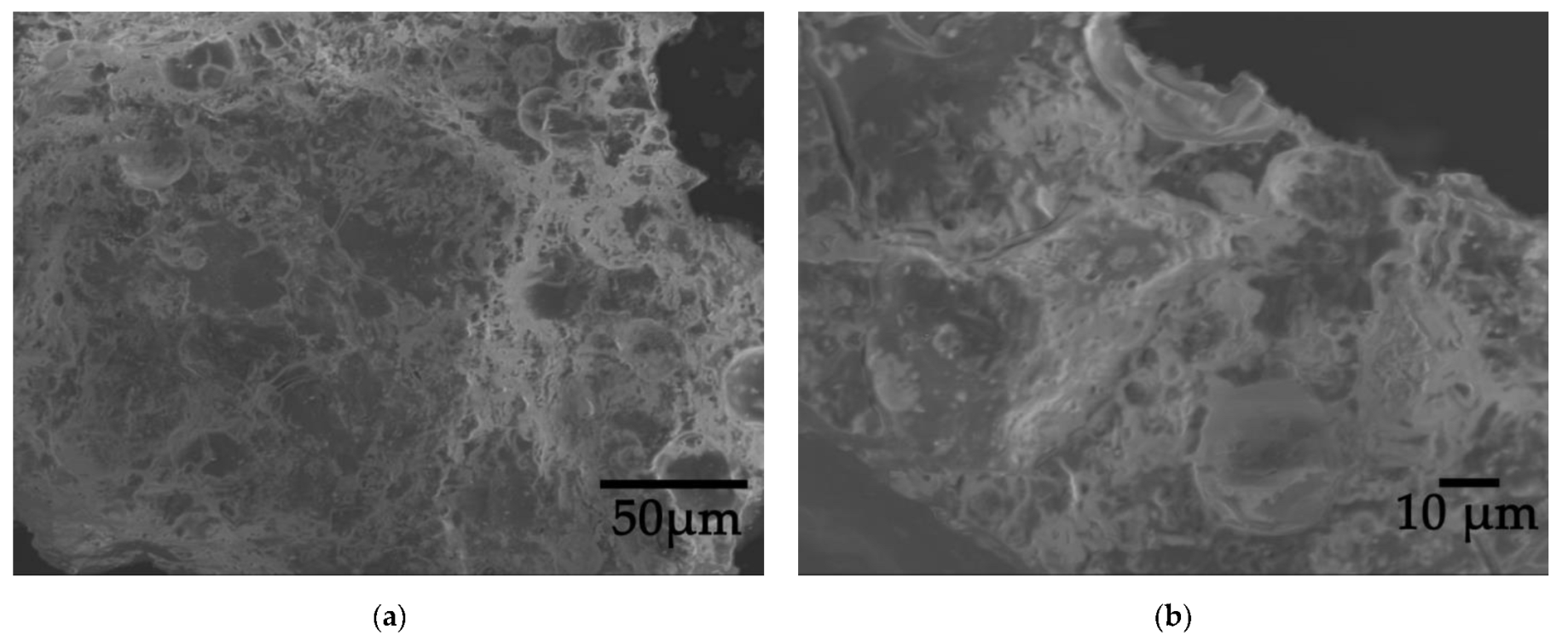

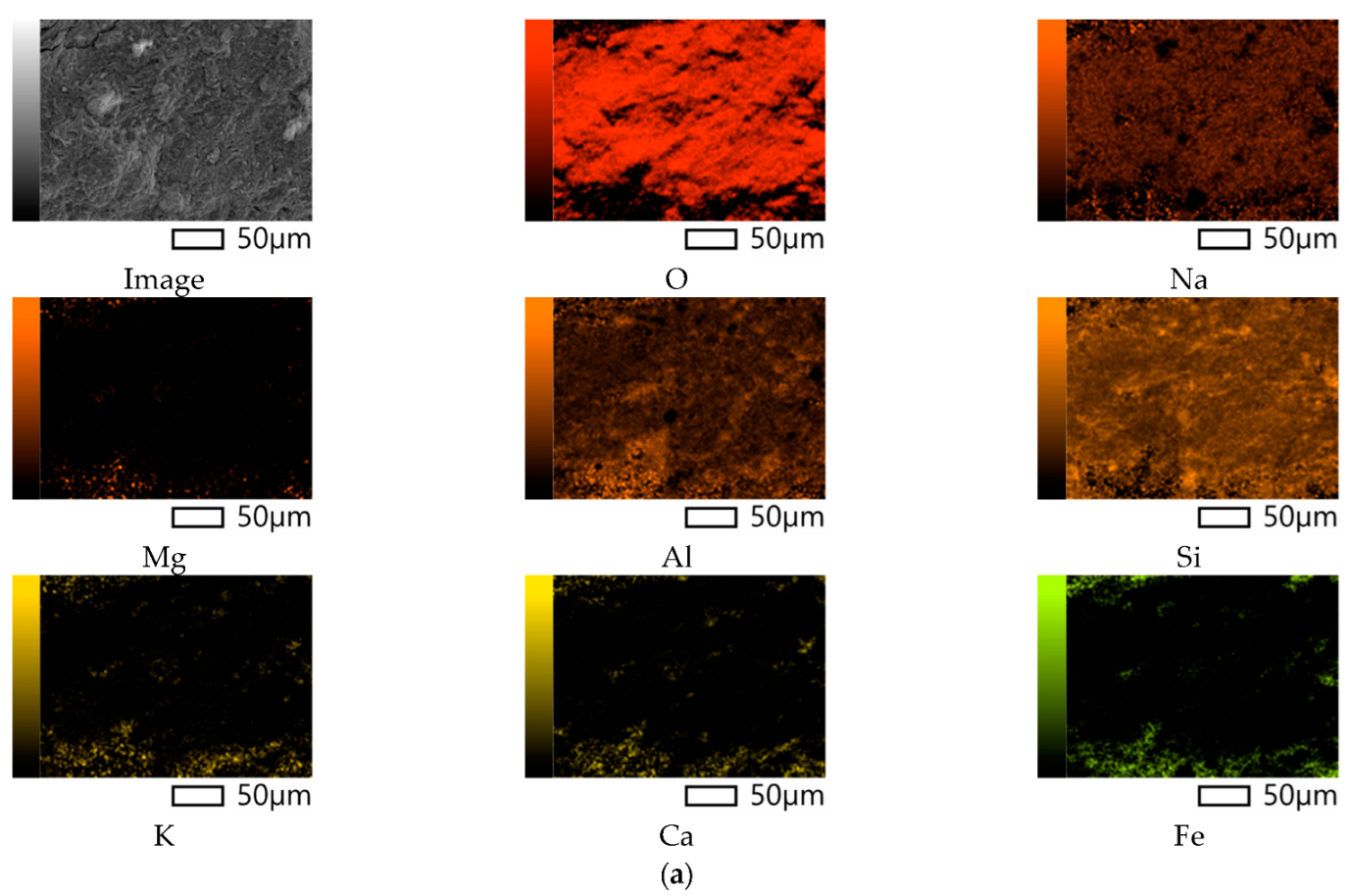

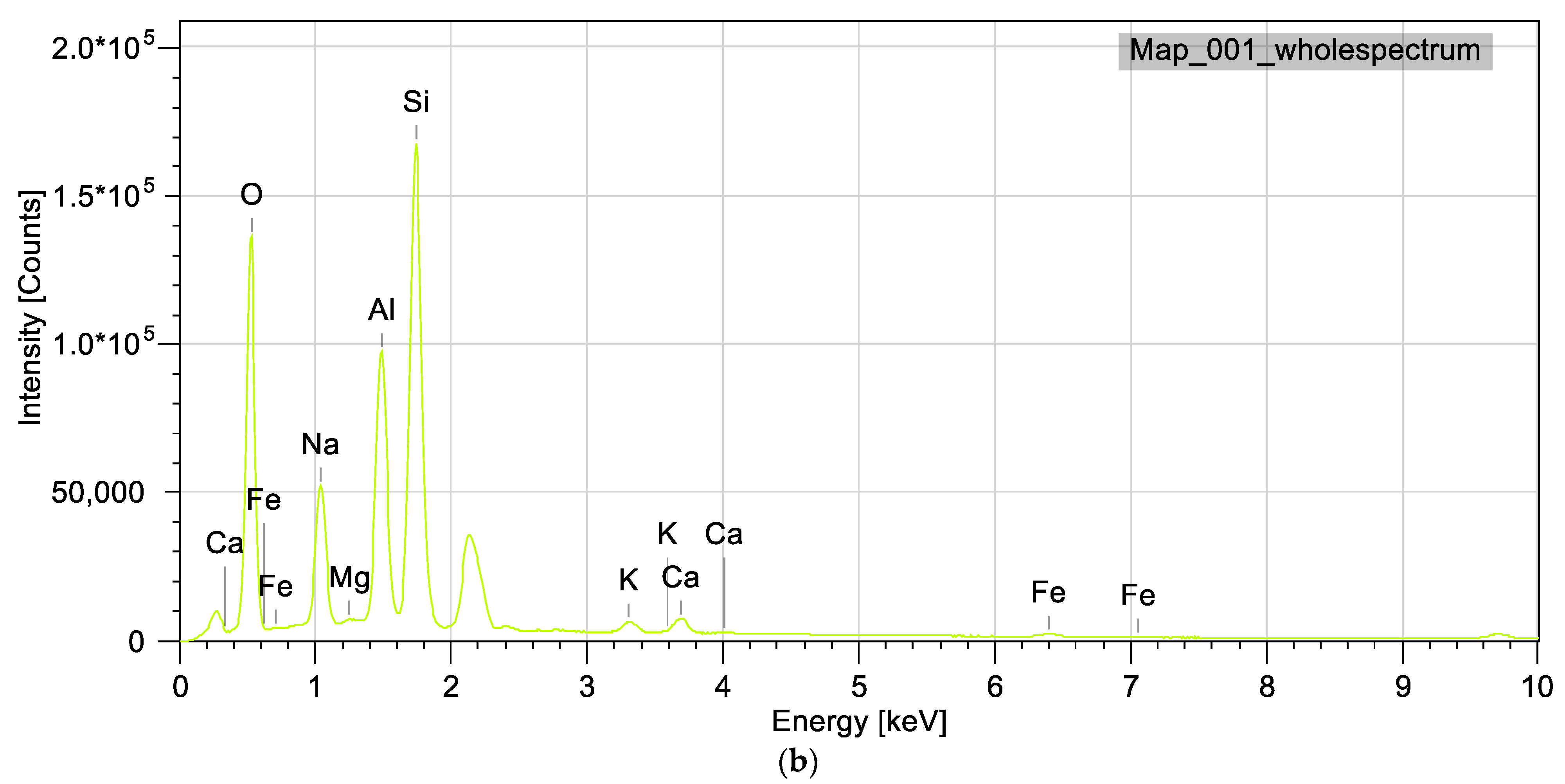

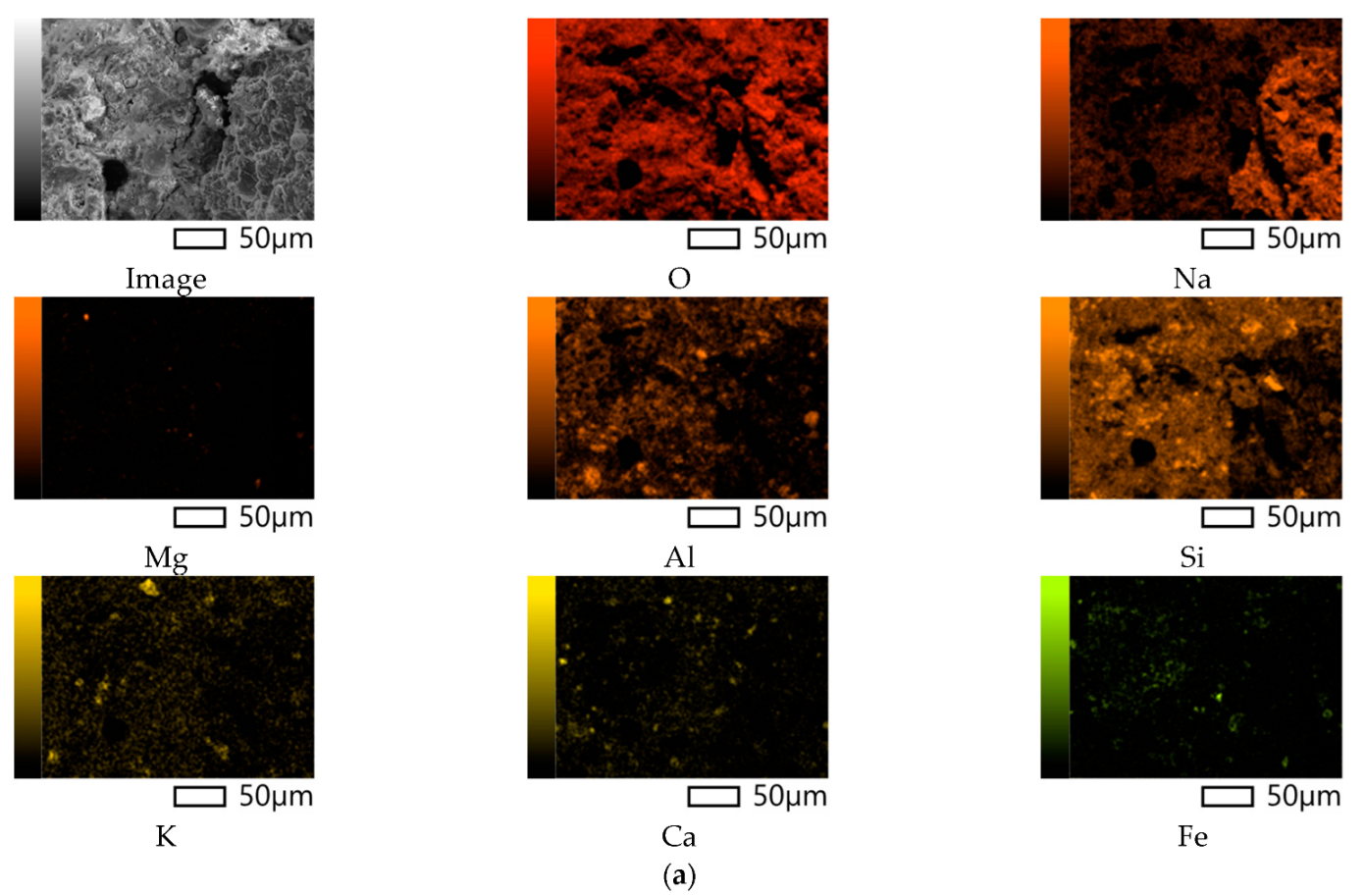

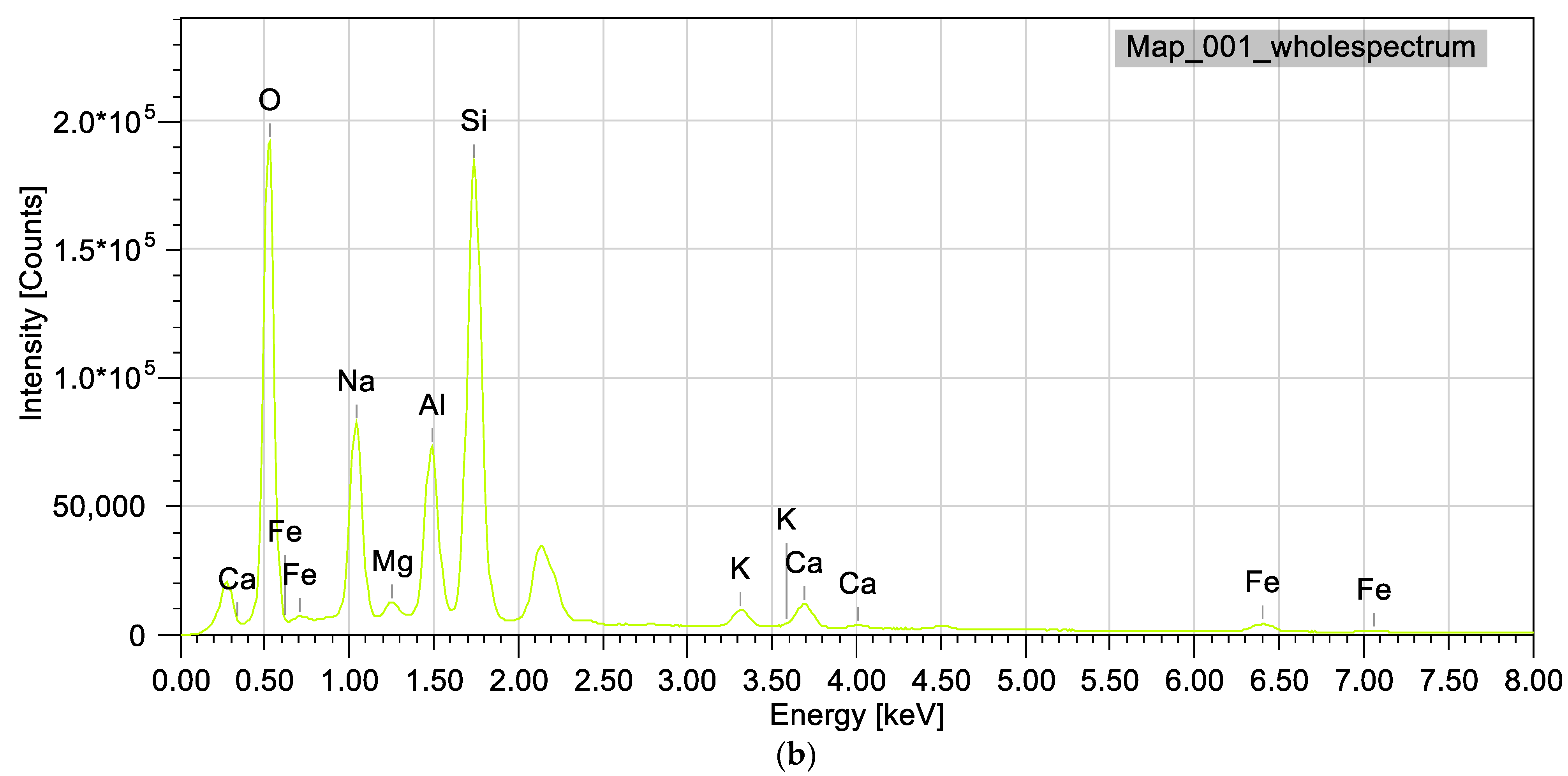

3.3. Microstructure Observations

4. Discussion

5. Conclusions

- The densities of the materials were 1.76 g/cm3 and 1.81 g/cm3. These values are typical for solid geopolymer materials.

- The mechanical properties of the composites obtained are reasonable and allow them to be applied in the construction industry. The compressive strength and flexural strength were 20.1 MPa and 5.3 MPa, respectively, for samples with metakaolin additive. Geopolymers containing fly ash achieved 19.7 MPa of compressive strength and 3.0 MPa of flexural strength. The values obtained for flexural strength are typical for geopolymers. The compressive strength is below the preliminary expectation but comparable to the data obtained from the literature.

- SEM analysis provides useful insights into the mineralogy and microstructure of the produced geopolymers. This research shows the coherent and solid structure of the material obtained. The results of the EDS analysis are typical for geopolymer concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EU Commission. Closing the Loop—An EU Action Plan for the Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions COM. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 23 March 2022).

- EU Commission. A New Circular Economy Action Plan. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions COM. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 23 March 2022).

- Korniejenko, K.; Kozub, B.; Bąk, A.; Balamurugan, P.; Uthayakumar, M.; Furtos, G. Tackling the Circular Economy Challenges—Composites Recycling: Used Tyres, Wind Turbine Blades, and Solar Panels. J. Compos. Sci. 2021, 5, 243. [Google Scholar] [CrossRef]

- Cerminara, G.; Cossu, R. 1.2—Waste Input to Landfills. In Solid Waste Landfilling, 1st ed.; Cossu, R., Stegmann, R., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2018; pp. 15–39. [Google Scholar]

- Chen, X.; Guo, Y.; Ding, S.; Zhang, H.; Xia, F.; Wang, J.; Zhou, M. Utilization of red mud in geopolymer-based pervious concrete with function of adsorption of heavy metal ions. J. Clean. Prod. 2019, 207, 789–800. [Google Scholar] [CrossRef]

- Eurostat Yearbook: The Statistical Guide to Europe; Office for the Official Publications of the European Communities: Luxembourg, 2019. Available online: https://ec.europa.eu/eurostat/documents/3217494/10095393/KS-HA-19-001-EN-N.pdf/d434affa-99cd-4ebf-a3e3-6d4a5f10bb07?t=1574339587000 (accessed on 20 May 2022).

- Wang, R.; Li, S. Talking about the Production and Disposing of Construction Waste from the View of Sustainable Development. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011; pp. 1–4. [Google Scholar]

- Avilés-Palacios, C.; Rodríguez-Olalla, A. The Sustainability of Waste Management Models in Circular Economies. Sustainability 2021, 13, 7105. [Google Scholar] [CrossRef]

- Dong, F.; Wang, Y.; Su, B.; Hua, Y.; Zhang, Y. The process of peak CO2 emissions in developed economies: A perspective of industrialization and urbanization. Resour. Conserv. Recycl. 2019, 141, 61–75. [Google Scholar] [CrossRef]

- Figiela, B.; Korniejenko, K. The possibility of using waste materials as raw materials for the production of geopolymers. Acta Innov. 2020, 36, 48–56. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of Geopolymer Cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 131–149. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Institut Geopolymere: Saint-Quentin, France, 2008. [Google Scholar]

- Xu, H.; Van Deventer, J. The geopolymerisation of aluminosilicate minerals. Int. J. Miner. Process. 2000, 593, 247–266. [Google Scholar] [CrossRef] [Green Version]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S.J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef]

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Tam, V.; Labrincha, J.; Ding, Y.; Brito, J. (Eds.) Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Aldemir, A.; Akduman, S.; Kocaer, O.; Aktepe, R.; Sahmaran, M.; Yildirim, G.; Almahmood, H.; Ashour, A. Shear behaviour of reinforced construction and demolition waste-based geopolymer concrete beams. J. Build. Eng. 2022, 47, 103861. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Vlachou, A.; Bartzas, G.; Galetakis, M. Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Adv. Powder Technol. 2015, 26, 368–376. [Google Scholar] [CrossRef] [Green Version]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- D’Angelo, G.; Fumo, M.; Merino, M.d.R.; Capasso, I.; Campanile, A.; Iucolano, F.; Caputo, D.; Liguori, B. Crushed Bricks: Demolition Waste as a Sustainable Raw Material for Geopolymers. Sustainability 2021, 13, 7572. [Google Scholar] [CrossRef]

- Youssef, N.; Rabenantoandro, A.Z.; Dakhli, Z. Reuse of waste bricks: A new generation of geopolymer bricks. SN Appl. Sci. 2019, 1, 1252. [Google Scholar] [CrossRef] [Green Version]

- Korniejenko, K.; Halyag, N.P.; Mucsi, G. Fly ash as a raw material for geopolymerisation—Chemical composition and physical properties. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012002. [Google Scholar] [CrossRef]

- Ziejewska, C.; Marczyk, J.; Korniejenko, K.; Bednarz, S.; Sroczyk, P.; Łach, M.; Mikuła, J.; Figiela, B.; Szechyńska-Hebda, M.; Hebda, M. 3D Printing of Concrete-Geopolymer Hybrids. Materials 2022, 15, 2819. [Google Scholar] [CrossRef]

- Walter, J.; Uthayakumar, M.; Balamurugan, P.; Mierzwiński, D. The Variable Frequency Conductivity of Geopolymers during the Long Agieng Period. Materials 2021, 14, 5648. [Google Scholar] [CrossRef]

- Łach, M.; Korniejenko, K.; Hebdowska-Krupa, M.; Mikuła, J. The Effect of Additives on the Properties of Metakaolin and Fly Ash Based Geopolymers. MATEC Web Conf. 2018, 163, 06005. [Google Scholar] [CrossRef]

- Burduhos Nergis, D.D.; Vizureanu, P.; Sandu, A.V.; Burduhos Nergis, D.P.; Bejinariu, C. XRD and TG-DTA Study of New Phosphate-Based Geopolymers with Coal Ash or Metakaolin as Aluminosilicate Source and Mine Tailings Addition. Materials 2022, 15, 202. [Google Scholar] [CrossRef]

- Sitarz, M.; Figiela, B.; Łach, M.; Korniejenko, K.; Mróz, K.; Castro-Gomes, J.; Hager, I. Mechanical Response of Geopolymer Foams to Heating—Managing Coal Gangue in Fire-Resistant Materials Technology. Energies 2022, 15, 3363. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kejzlar, P.; Louda, P. The Influence of the Material Structure on the Mechanical Properties of Geopolymer Composites Reinforced with Short Fibers Obtained with Additive Technologies. Int. J. Mol. Sci. 2022, 23, 2023. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 12390-3:2019-07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 12390-5:2019-08; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- Marczyk, J.; Ziejewska, C.; Gądek, S.; Korniejenko, K.; Łach, M.; Góra, M.; Kurek, I.; Doğan-Sağlamtimur, N.; Hebda, M.; Szechyńska-Hebda, M. Hybrid Materials Based on Fly Ash, Metakaolin, and Cement for 3D Printing. Materials 2021, 14, 6874. [Google Scholar] [CrossRef] [PubMed]

- Kozub, B.; Bazan, P.; Gailitis, R.; Korniejenko, K.; Mierzwiński, D. Foamed Geopolymer Composites with the Addition of Glass Wool Waste. Materials 2021, 14, 4978. [Google Scholar] [CrossRef] [PubMed]

- Figiela, B.; Šimonová, H.; Korniejenko, K. State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers. Rev. Adv. Mater. Sci. 2022, 61, 67. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef]

- Wang, X.; Yang, W.; Liu, H.; Zhu, P.; Zong, N.; Feng, J. Strength and Microstructural Analysis of Geopolymer Prepared with Recycled Geopolymer Powder. J. Wuhan Univ. Technol. Mater. Sci. 2021, 36, 439–445. [Google Scholar] [CrossRef]

- Huo, W.; Zhu, Z.; Chen, W.; Zhang, J.; Kang, Z.; Pu, S.; Wan, Y. Effect of synthesis parameters on the development of unconfined compressive strength of recycled waste concrete powder-based geopolymers. Constr. Build. Mater. 2021, 292, 123264. [Google Scholar] [CrossRef]

- Das, S.K.; Shrivastava, S. Influence of molarity and alkali mixture ratio on ambient temperature cured waste cement concrete based geopolymer mortar. Constr. Build. Mater. 2021, 301, 124380. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Delgado-Plana, P.; Cabezas-Rodríguez, R.; Mejía de Gutiérrez, R.; Eliche-Quesada, D.; Pérez-Villarejo, L.; Galán-Arboledas, R.J.; Bueno, S. Alkaline activation of high-crystalline low-Al2O3 Construction and Demolition Wastes to obtain geopolymers. J. Clean. Prod. 2022, 330, 129770. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Nabiałek, M.; Sandu, A.V.; Szmidla, J.; Jurczyńska, A.; Razak, R.A.; Aziz, I.H.A.; Jamil, N.H.; et al. Assessment of the Suitability of Ceramic Waste in Geopolymer Composites: An Appraisal. Materials 2021, 14, 3279. [Google Scholar] [CrossRef] [PubMed]

- Plawecka, K.; Figiela, B.; Grela, A.; Buczkowska, K.E. Geopolymers based on plasma incineration waste as a material for circular economy. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 175470. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Z.; Liu, C.; Deng, X.; Hui, D.; Deng, S. Research progress on mechanical properties of geopolymer recycled aggregate concrete. Rev. Adv. Mater. Sci. 2021, 60, 158–172. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Kvočka, D.; Lešek, A.; Knez, F.; Ducman, V.; Panizza, M.; Tsoutis, C.; Bernardi, A. Life Cycle Assessment of Prefabricated Geopolymeric Façade Cladding Panels Made from Large Fractions of Recycled Construction and Demolition Waste. Materials 2020, 13, 3931. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Duan, Z.; Li, S. Geopolymers made of recycled brick and concrete powder—A critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Şahmaran, M. Optimized application of ternary brick, ceramic and concrete wastes in sustainable high strength geopolymers. J. Clean. Prod. 2022, 338, 130650. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Recycling of concrete, ceramic, and masonry waste via alkaline activation: Obtaining and characterization of hybrid cements. J. Build. Eng. 2022, 46, 103698. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Ramírez-Benavides, S.; Mejía de Gutiérrez, R.; Orobio, A. Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact. Materials 2021, 14, 1275. [Google Scholar] [CrossRef]

- Davidovits, J. Environmentally Driven Geopolymer Cement Applications. In Proceedings of the Geopolymer 2002 Conference, Melbourne, Australia, 28–29 October 2002. [Google Scholar]

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and Starch—Alternative Binders for Bio-Based Building Materials: A Review and Life-Cycle Assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, M.; Di Maio, F.; Cucurachi, S. Life cycle assessment of 3D printing geo-polymer concrete an ex-ante study. J. Ind. Ecol. 2020, 24, 116–127. [Google Scholar] [CrossRef] [Green Version]

- Kugler, F.; Aumüller, J.; Krcmar, W.; Teipel, U. Construction and Demolition Residuals as Raw Materials for the Production of Novel Geopolymer Building Materials. Crystals 2022, 12, 678. [Google Scholar] [CrossRef]

| Element [Mass%] | ||||||||

|---|---|---|---|---|---|---|---|---|

| O | Al | Si | Fe | K | Na | Mg | Ca | |

| Clay brick | balance | 7.11 | 30.6 | 6.2 | 1.7 | 0.8 | 0.7 | - |

| Concrete waste | balance | 1.9 | 11.8 | 2.0 | - | 0.3 | 0.5 | 41.8 |

| MK 1 | balance | 21.3 | 26.2 | 0.6 | 0.7 | - | 0.1 | 0.3 |

| FA 2 | balance | 16.8 | 22.7 | 4.6 | 2.2 | 1.6 | 1.1 | 2.2 |

| Material | Oxide Composition [%] | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | FexOy | Na2O | TiO2 | K2O | MgO | CaO | |

| MK | 53.0 | 41.6 | 1.3 | 0.8 | 0.7 | 0.7 | 0.4 | 0.3 |

| FA | 55.9 | 23.5 | 5.9 | 0.6 | 1.1 | 3.6 | 2.6 | 2.7 |

| Sample | Materials [mass%] | |||

|---|---|---|---|---|

| Metakaolin | Fly Ash | Clay Brick | Rubble | |

| G1 | 40 | - | 30 | 30 |

| G2 | - | 40 | 30 | 30 |

| Sample | Density [g/cm3] |

|---|---|

| G1 | 1.81 (±0.13) |

| G2 | 1.76 (±0.01) |

| Element [Mass%] | G1 | G2 |

|---|---|---|

| O | 48.21 ± 0.07 | 47.84 ± 0.08 |

| Na | 5.52 ± 0.03 | 10.04 ± 0.04 |

| Mg | 0.57 ± 0.01 | 0.76 ± 0.01 |

| Al | 10.29 ± 0.04 | 9.06 ± 0.04 |

| Si | 31.90 ± 0.07 | 24.42 ± 0.06 |

| K | 2.52 ± 0.03 | 1.89 ± 0.03 |

| Ca | 1.00 ± 0.02 | 6.00 ± 0.05 |

| Precursors | Activator | Compressive Strength after 7 Days [MPa] | Compressive Strength after 28 Days [MPa] | Flexural Strength [MPa] | Source |

|---|---|---|---|---|---|

| G1 | 10 M (NaOH + water + sodium silicate) | - | 20.1 (±2.4) | 5.3 (±0.4) | current research |

| G2 | 10 M (NaOH + water + sodium silicate) | - | 19.7 (±1.0) | 3.0 (±0.4) | current research |

| Brick (CDW) | 8 M, 10 M (NaOH + water + sodium silicate) | 49.5 | [20] | ||

| Tiles (CDW) | 8 M, 10 M (NaOH + water + sodium silicate) | 57.8 | |||

| Concrete (CDW) | 8 M, 10 M (NaOH + water + sodium silicate) | 13.0 | - | - | |

| NGC (tile, red clay brick, hollow brick, glass, concrete waste, slag, fly ash, and natural aggregate) | 8 M (NaOH + water + calcium hydroxide + sodium silicate) | - | 37.5 | 2.56 | [19] |

| NGC—R (tile, red clay brick, hollow brick, glass, concrete waste, slag, fly ash, and recycled aggregate) | 8 M (NaOH + water + calcium hydroxide + sodium silicate) | - | 36.6 | 2.37 | |

| 80% (hollow brick, red clay, roof tile), 10% glass, 10% concrete waste | NaOH + water | - | 11.0 | - | [21] |

| 80% (hollow brick, red clay, roof tile), 10% glass, 10% concrete waste | NaOH + water + calcium hydroxide | - | 17.9 | - | |

| 80% (hollow brick, red clay, roof tile), 10% glass, 10% concrete waste | NaOH + water + calcium hydroxide + sodium silicate | - | 36.0 | - | |

| Clay brick wastes | 10 M (NaOH + water + sodium silicate) | - | 5.34 (±0.66) | 2.85 (±0.73) | [22] |

| 50% waste bricks, 50% sand | 8 M (NaOH + water + sodium silicate) | 38.96 | 7.30 | [23] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Figiela, B.; Brudny, K.; Lin, W.-T.; Korniejenko, K. Investigation of Mechanical Properties and Microstructure of Construction- and Demolition-Waste-Based Geopolymers. J. Compos. Sci. 2022, 6, 191. https://doi.org/10.3390/jcs6070191

Figiela B, Brudny K, Lin W-T, Korniejenko K. Investigation of Mechanical Properties and Microstructure of Construction- and Demolition-Waste-Based Geopolymers. Journal of Composites Science. 2022; 6(7):191. https://doi.org/10.3390/jcs6070191

Chicago/Turabian StyleFigiela, Beata, Karolina Brudny, Wei-Ting Lin, and Kinga Korniejenko. 2022. "Investigation of Mechanical Properties and Microstructure of Construction- and Demolition-Waste-Based Geopolymers" Journal of Composites Science 6, no. 7: 191. https://doi.org/10.3390/jcs6070191

APA StyleFigiela, B., Brudny, K., Lin, W.-T., & Korniejenko, K. (2022). Investigation of Mechanical Properties and Microstructure of Construction- and Demolition-Waste-Based Geopolymers. Journal of Composites Science, 6(7), 191. https://doi.org/10.3390/jcs6070191