Improvement of Mechanical, Thermal, and Physical Behaviors of Jute/Cotton Biocomposites Reinforced by Spent Tea Leaf Particles

Abstract

:1. Introduction

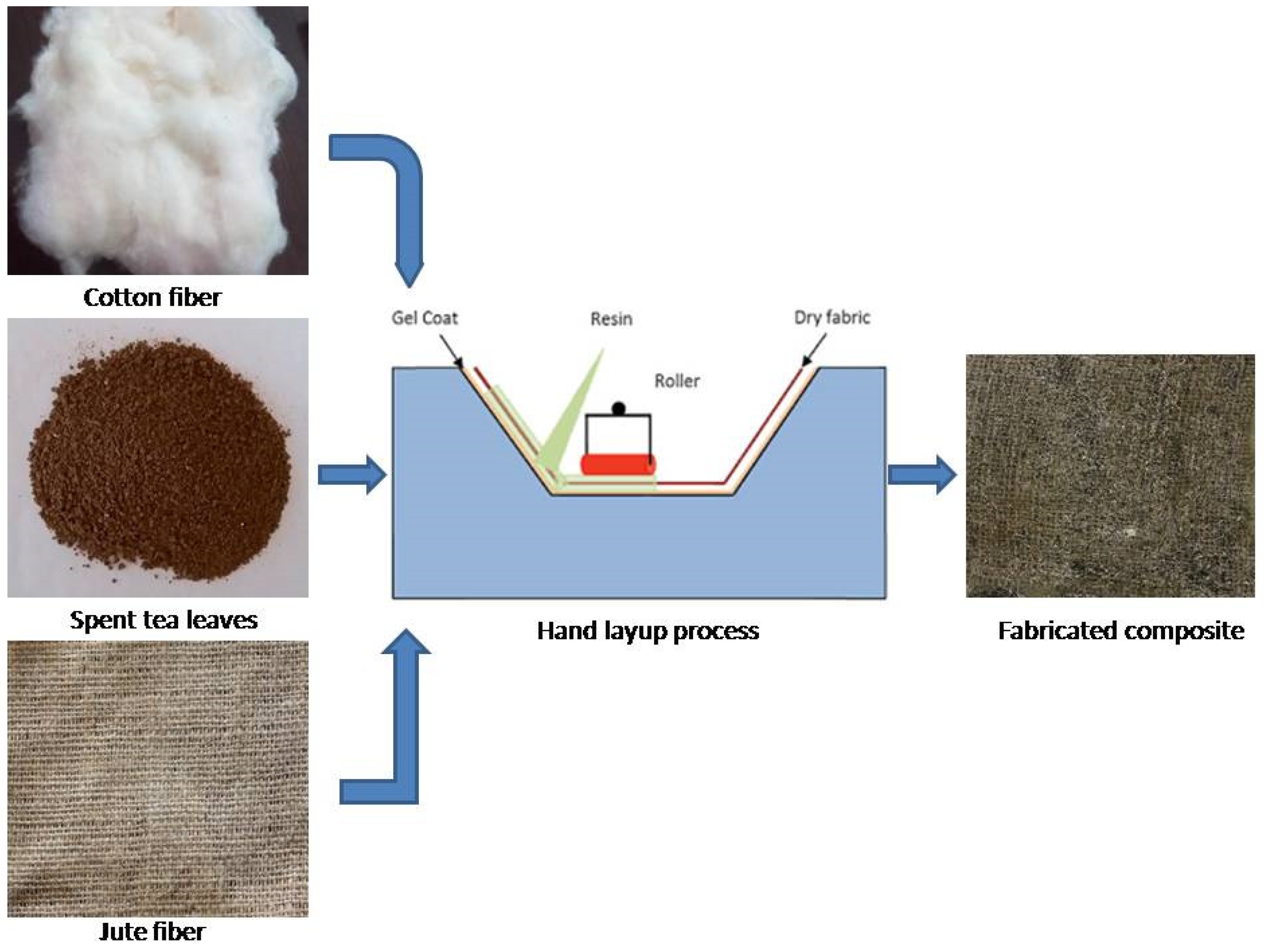

2. Materials and Methods

2.1. Materials

2.1.1. Spent Tea Leaves

2.1.2. Jute Fiber

2.1.3. Cotton Fiber

2.1.4. Epoxy Resin

2.1.5. Epoxy Hardener

2.2. Synthesis of Composite

2.3. Mechanical Studies

2.4. Characterization

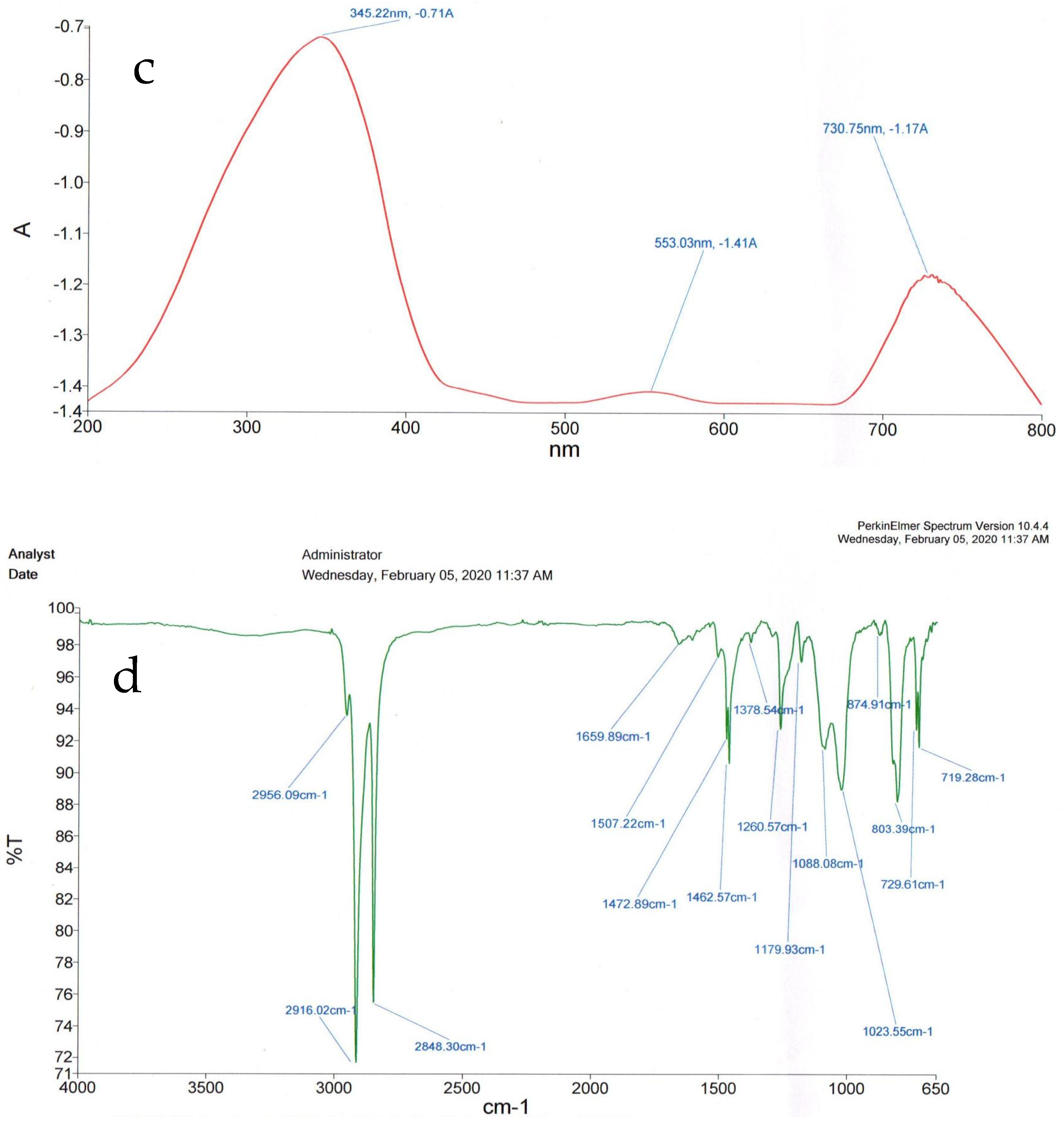

2.4.1. FTIR

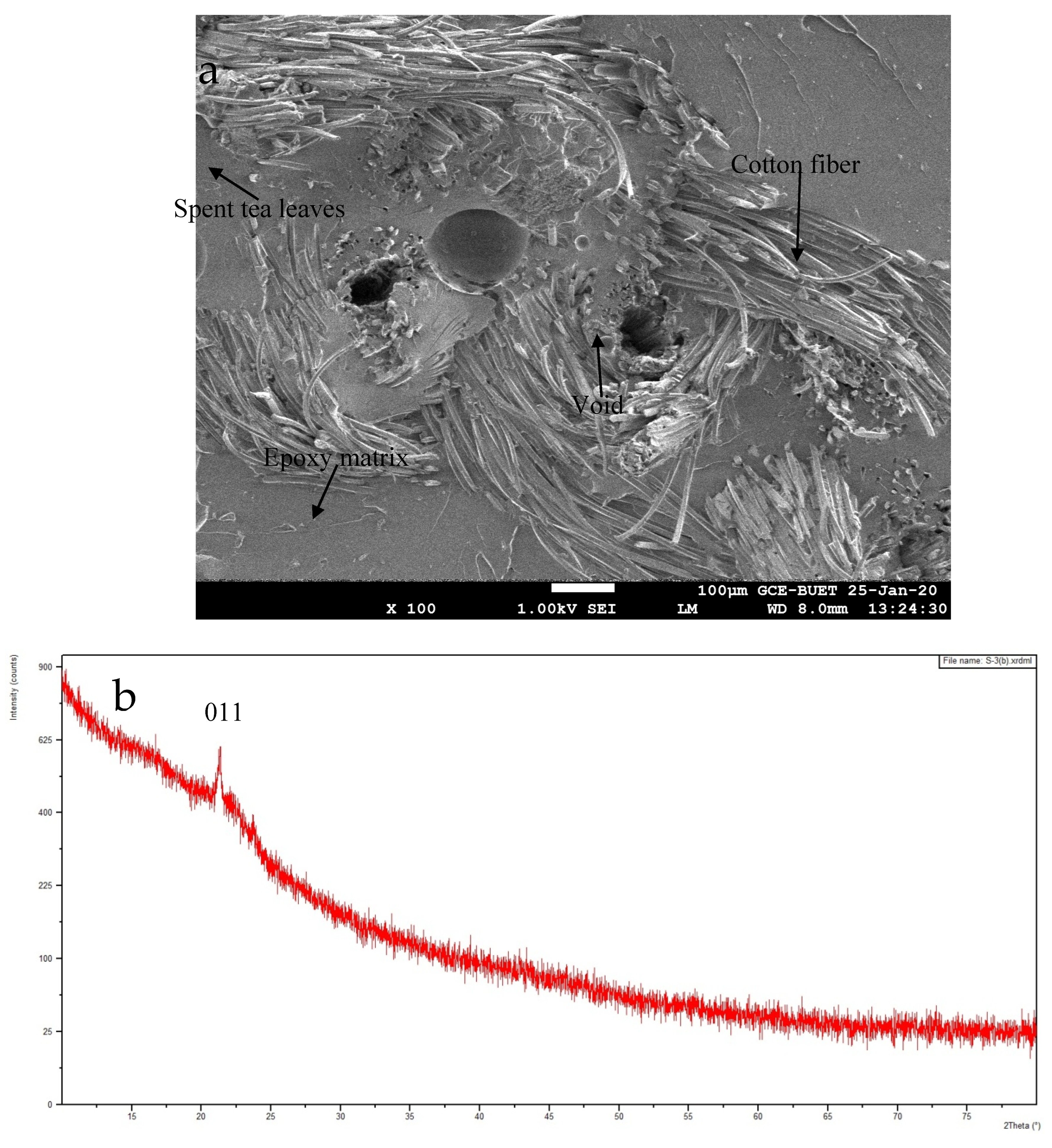

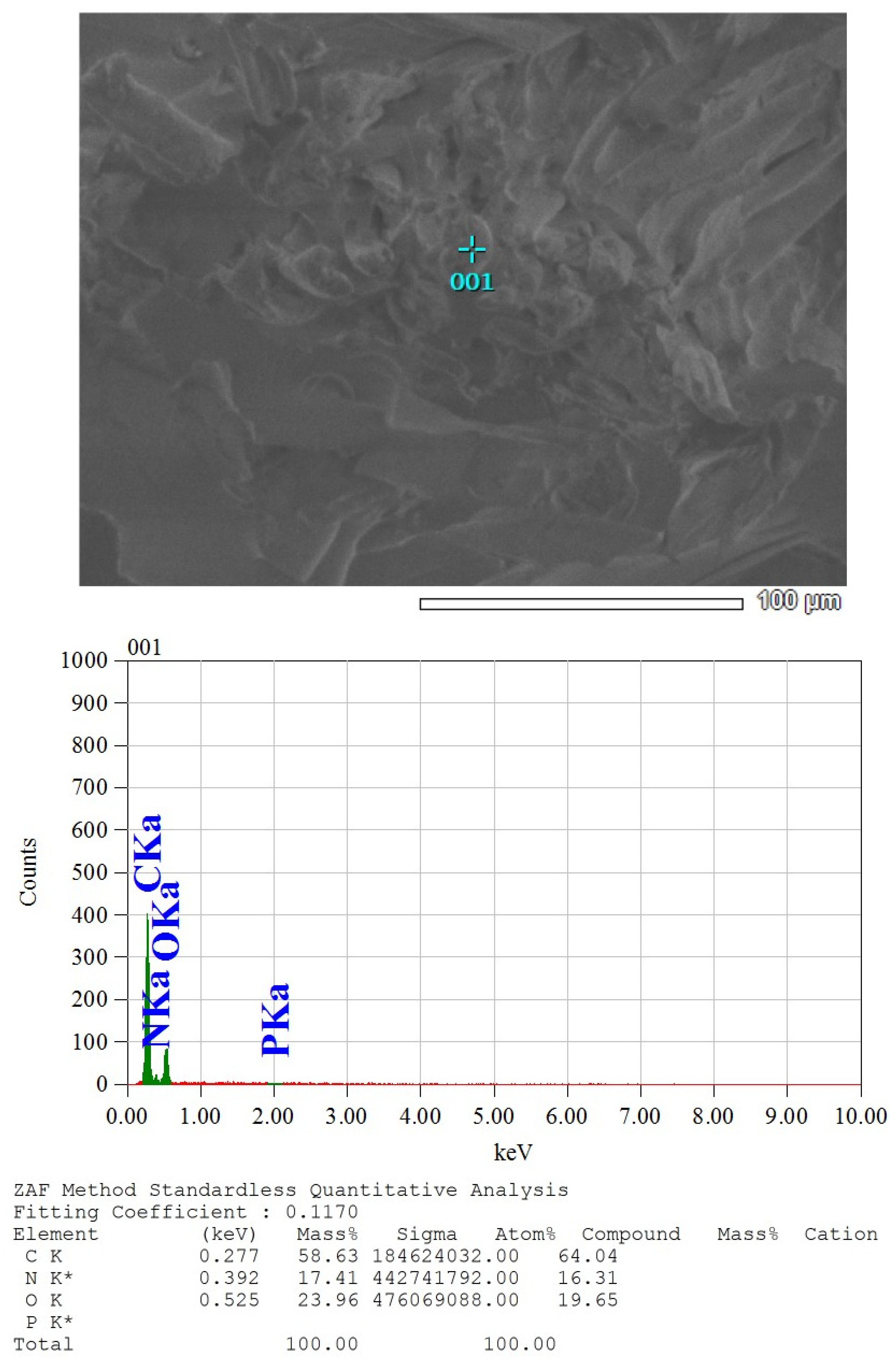

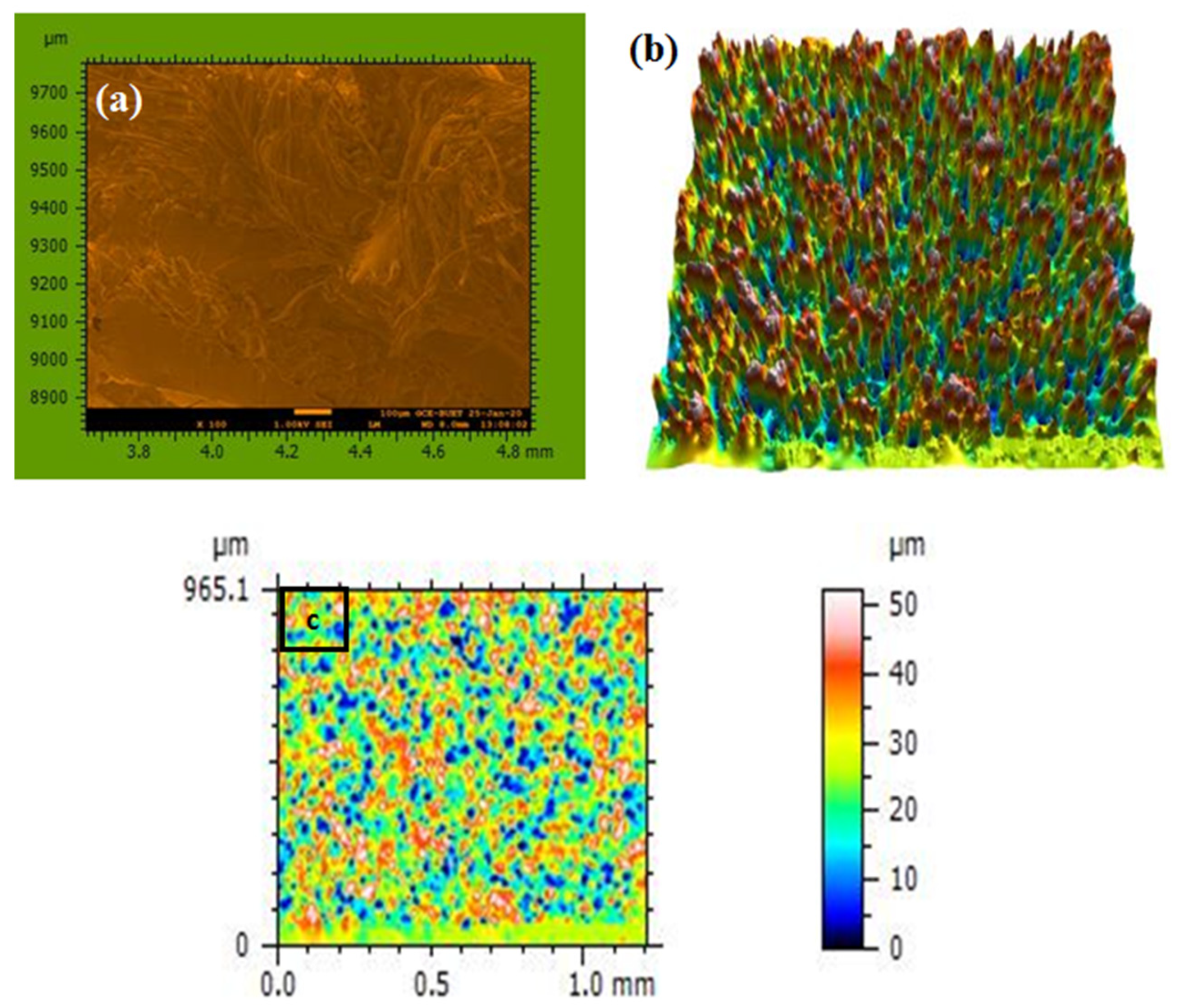

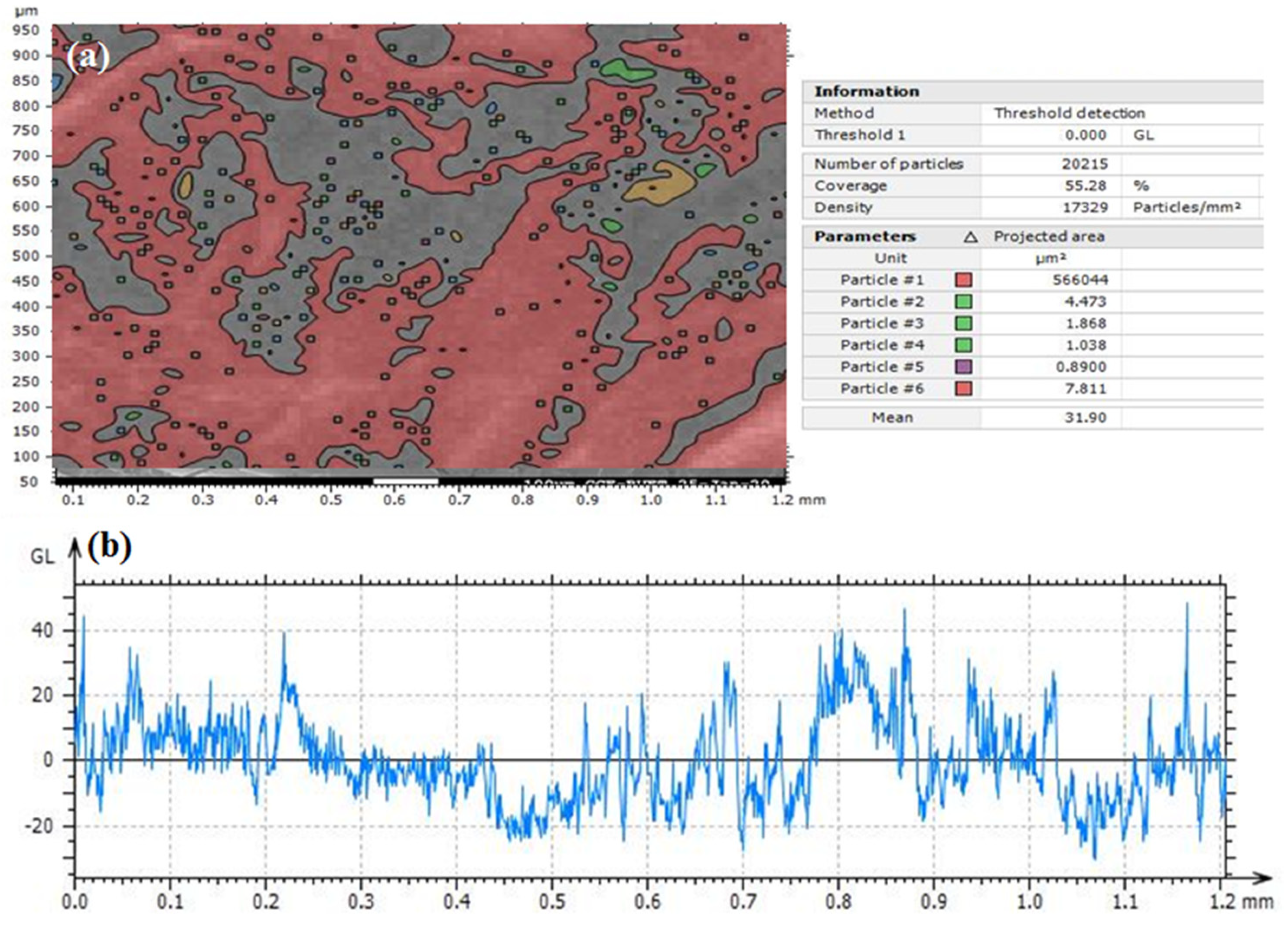

2.4.2. SEM

2.4.3. XRD

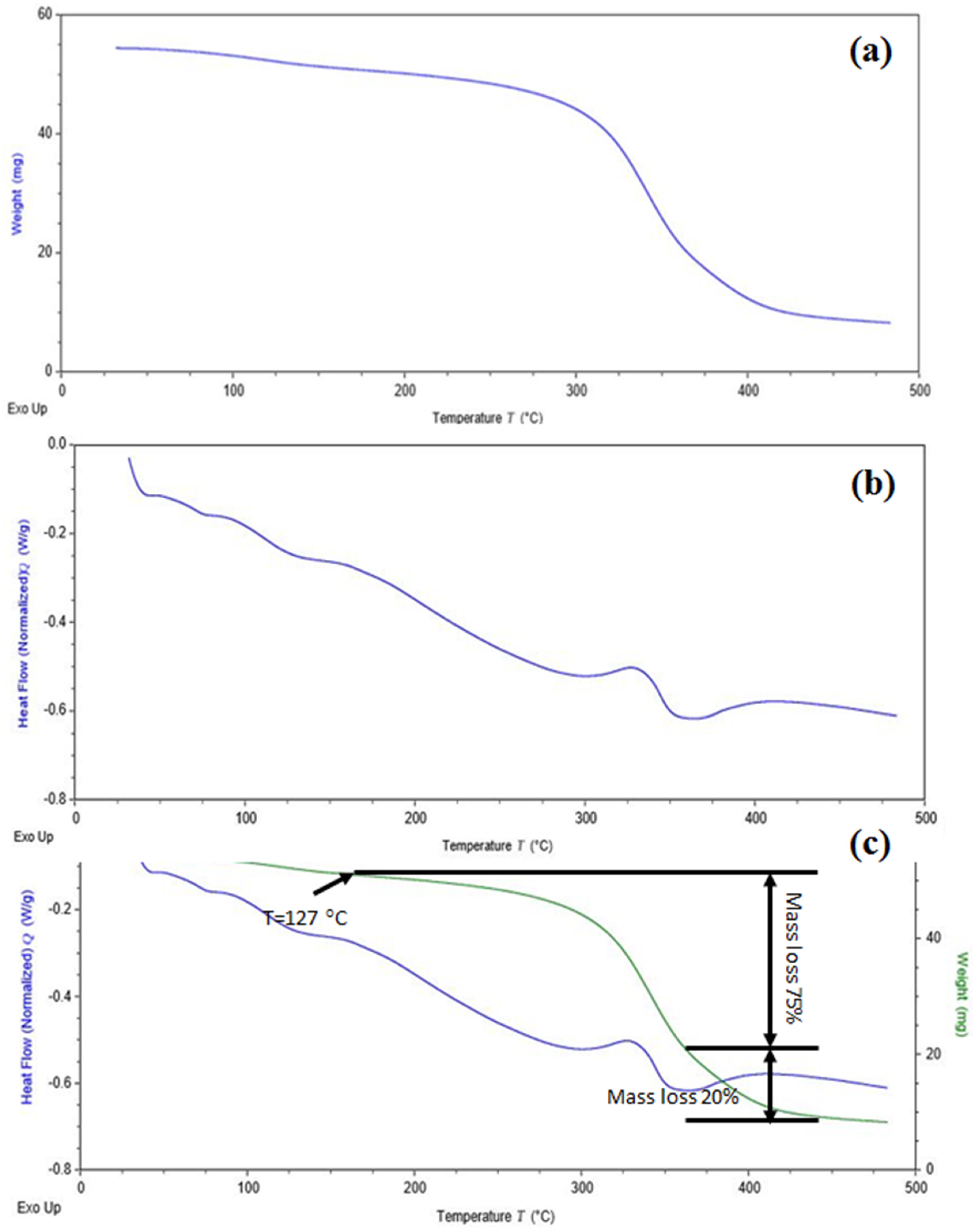

2.4.4. Thermal Analysis

3. Results and Discussion

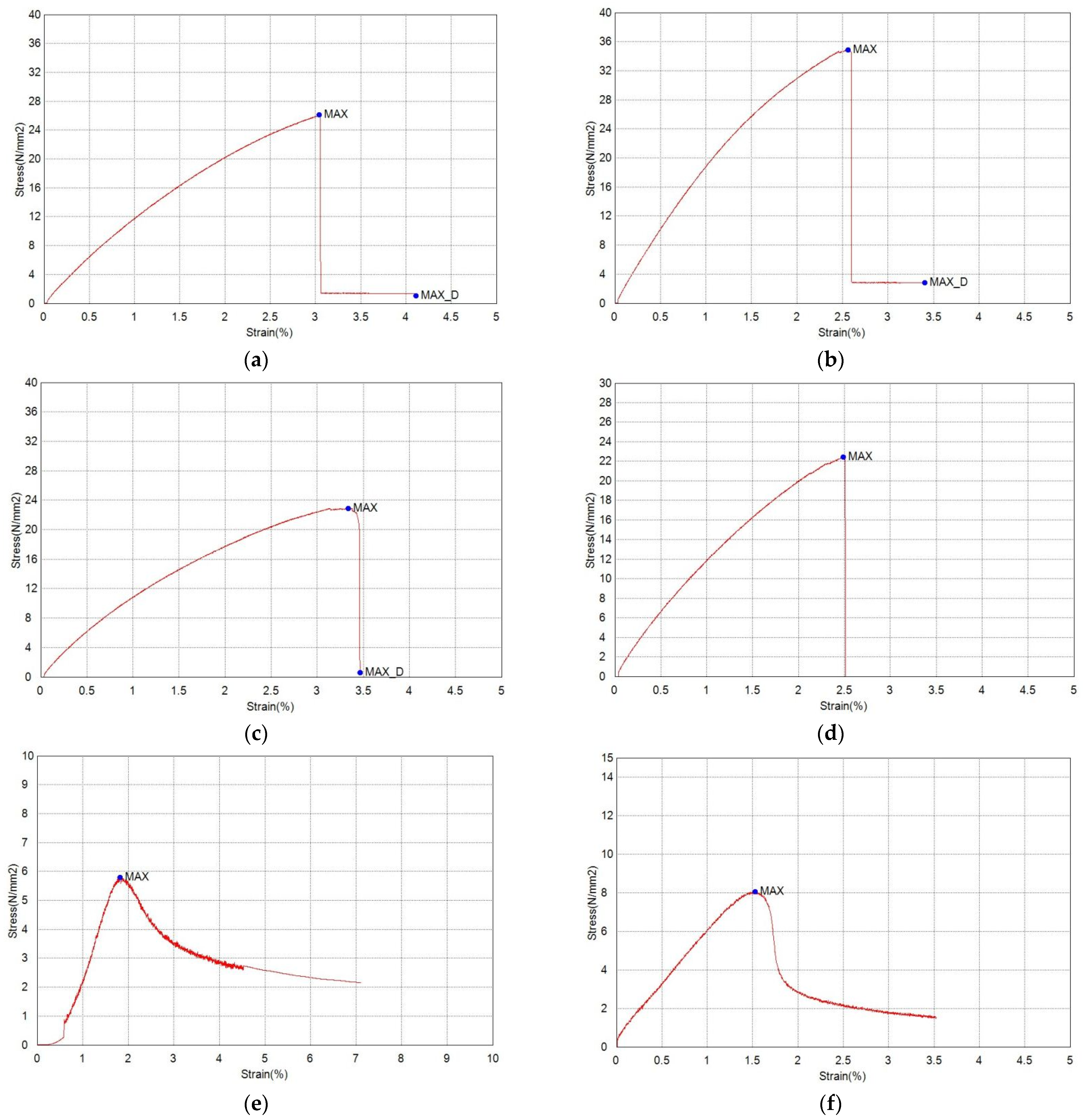

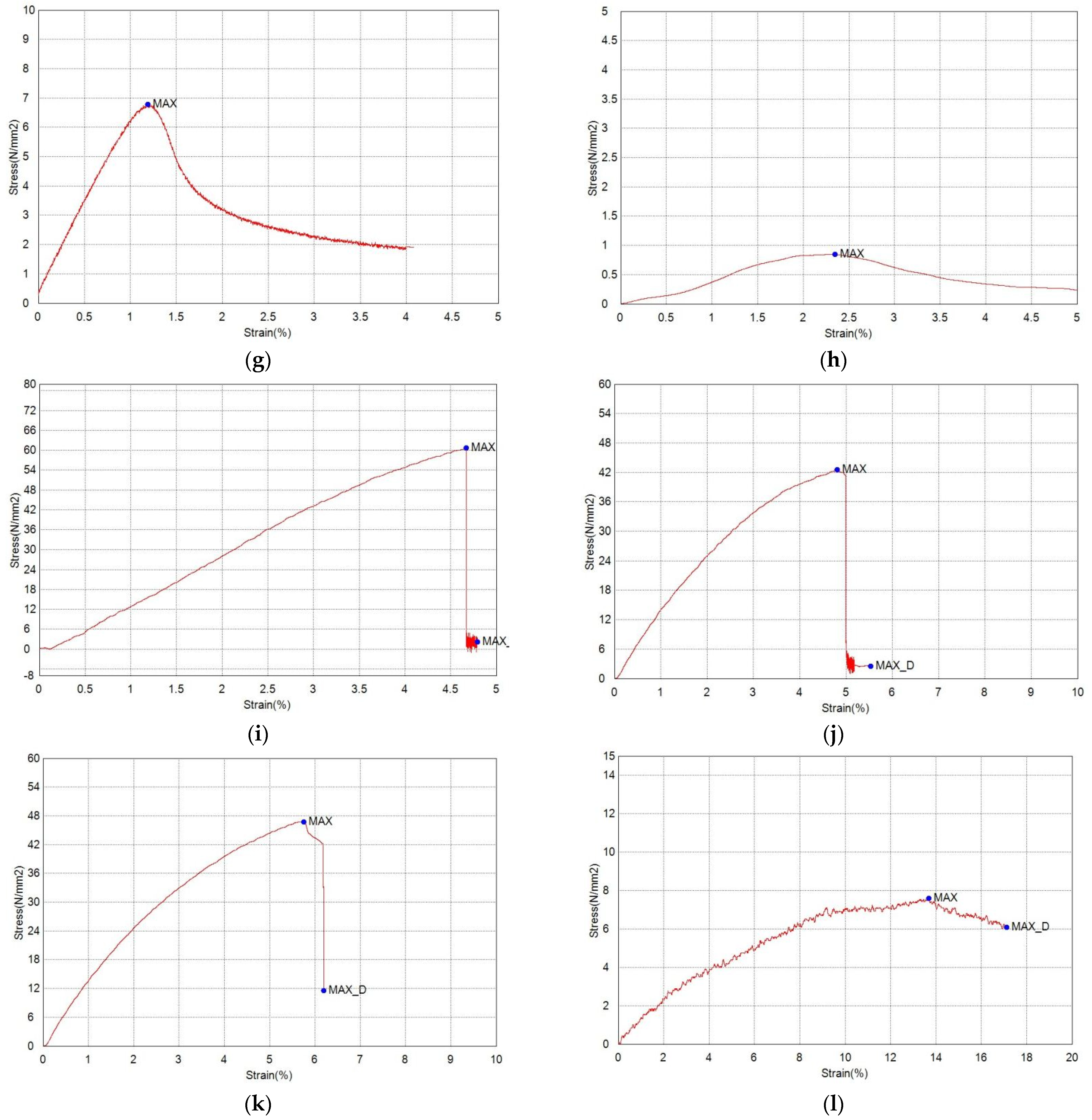

3.1. Mechanical Properties of JCPC Spent Tea Leaves Composites

3.2. Characterization of JCJC Spent Tea Leaf Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rangasamy, G.; Mani, S.; Kolandavelu, S.K.S.; Alsoufi, M.S.; Ibrahim, A.M.M.; Muthusamy, S.; Panchal, H.; Sadasivuni, K.K.; Elsheikh, A.H. An extensive analysis of mechanical, thermal and physical properties of jute fiber composites with different fiber orientations. Case Stud. Therm. Eng. 2021, 28, 101612. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.-D. Introduction to Composite Materials; InTech: London, UK, 2020. [Google Scholar]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Karim, N.; Sarker, F.; Afroj, S.; Zhang, M.; Potluri, P.; Novoselov, K.S. Sustainable and Multifunctional Composites of Graphene-Based Natural Jute Fibers. Adv. Sustain. Syst. 2021, 5, 2000228. [Google Scholar] [CrossRef]

- Islam, M.H.; Islam, M.R.; Dulal, M.; Afroj, S.; Karim, N. The effect of surface treatments and graphene-based modifications on mechanical properties of natural jute fibre reinforced composites: A review. Iscience 2022, 25, 103597. [Google Scholar] [CrossRef]

- Ashik, K.P.; Sharma, R.S. A Review on Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites. J. Miner. Mater. Charact. Eng. 2015, 3, 420–426. [Google Scholar] [CrossRef]

- Khan, M.A.; Rahaman, M.S.; Al-Jubayer, A.; Islam, J. Modification of jute fibers by radiation-induced graft copolymerization and their applications. In Cellulose-Based Graft Copolymers: Structure and Chemistry; Thakur, V.K., Ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 209–235. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Bavan, D.S.; Kumar, G.C.M. Potential use of natural fiber composite materials in India. J. Reinf. Plast. Compos. 2010, 29, 3600–3613. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.; Sapuan, S.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Rajini, N.; Ismail, S.O.; Ayrilmis, N.; Mohammad, F.; Al-Lohedan, H.A.; Tawfeek, A.M.; Issa, Z.A.; Aldhayan, D.M. Assessment on hybrid jute/coir fibers reinforced polyester composite with hybrid fillers under different environmental conditions. Constr. Build. Mater. 2021, 301, 124117. [Google Scholar] [CrossRef]

- Thamer, S.A. Development and Characterisation of Cotton and Cotton fabric Reinforced Geopolymer Composites. Ph.D. Thesis, Curtin University, Perth, Australia, 2015. [Google Scholar]

- Harzallah, O.; Benzina, H.; Drean, J.-Y. Physical and Mechanical Properties of Cotton Fibers: Single-fiber Failure. Text. Res. J. 2010, 80, 1093–1102. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, T. MIXTAs and phytohormones orchestrate cotton fiber development. Curr. Opin. Plant. Biol. 2021, 59, 101975. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Wang, X.; Gul, K.; Khuda, F.; Aly, Z.; Elseman, A. Microwave-assisted spent black tea leaves as cost-effective and powerful green adsorbent for the efficient removal of Eriochrome black T from aqueous solutions. Egypt. J. Basic Appl. Sci. 2018, 5, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Hu, Q.; Zhang, Y.; Mao, Y.; Memon, H.; Qiu, Y.; Wei, Y.; Liu, W. A Comparative Study on Interlaminar Properties of L-shaped Two-Dimensional (2D) and Three-Dimensional (3D) Woven Composites. Appl. Compos. Mater. 2019, 26, 723–744. [Google Scholar] [CrossRef]

- Larguech, S.; Triki, A.; Ramachandran, M.; Kallel, A. Dielectric Properties of Jute Fibers Reinforced Poly (lactic acid)/Poly (butylene succinate) Blend Matrix. J. Polym. Environ. 2020, 29, 1240–1256. [Google Scholar] [CrossRef]

- Dastan, T.; Safian, A.; Sheikhzadeh, M. The crashworthiness performance of integrally woven sandwich composite panels made using natural and glass fibers. J. Compos. Mater. 2021, 55, 1279–1292. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Selver, E.; Ucar, N.; Gulmez, T. Effect of stacking sequence on tensile, flexural and thermomechanical properties of hybrid flax/glass and jute/glass thermoset composites. J. Ind. Text. 2018, 48, 494–520. [Google Scholar] [CrossRef]

- Rahman, A.; Chowdhury, M.A.; Shuvho, M.B.A.; Hossain, N.; Fotouhi, M.; Ali, R. Fabrication and characterization of jute/cottonbio composites reinforced with eggshell particles. Polym. Bull. 2022, 1–27. [Google Scholar] [CrossRef]

- Sonesso, M.F.C. Obtenção e caracterização de nanocristais de celulose a partir de algodão cru e polpakraft. 2012. Available online: http://repositorio.ufsc.br/xmlui/handle/123456789/95543 (accessed on 12 April 2022).

- Chand, N.; Fahim, M. Tribology of Natural Fiber Polymer Composites; Elsevier BV: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Wang, P.; Shen, J.; Chen, T.; Li, Q.; Yue, X.; Wang, L. Fabrication of graphene nanoplatelets reinforced Mg matrix composites via powder thixoforging. . 2021. J. Magnes. Alloy 2021, in press. [Google Scholar] [CrossRef]

- Akçamlı, N.; Şenyurt, B.; Gökçe, H.; Ağaoğulları, D. Powder metallurgical fabrication of graphene reinforced near-eutectic Al-Si matrix composites: Microstructural, mechanical and electrochemical characterization. Eng. Sci. Technol. Int. J. 2021, 31, 101052. [Google Scholar] [CrossRef]

- Liu, F.; Deng, S.; Zhang, J. Mechanical properties of epoxy and its carbon fiber composites modified by nanoparticles. J. Nanomater. 2017, 2017, 8146248. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Zhang, Y.; Wu, R.; Yang, D.; Ma, Z. The utilization of active recycled powder from various construction wastes in preparing ductile fiber-reinforced cementitious composites: A case study. Case Stud. Constr. Mater. 2021, 15, e00650. [Google Scholar] [CrossRef]

- Pereira, A.L.; Banea, M.D.; Neto, J.S.S.; Cavalcanti, D.K.K. Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal. Polymers 2020, 12, 886. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Ramachandran, M.; Bansal, S.; Raichurkar, P. Experimental study of bamboo using banana and linen fibre reinforced polymeric composites. Perspect. Sci. 2016, 8, 313–316. [Google Scholar]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Neto, J.S.S.; Lima, R.A.A.; Cavalcanti, D.K.K.; Souza, J.P.B.; Aguiar, R.A.A.; Banea, M.D. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J. Appl. Polym. Sci. 2019, 136, 47154. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M. Sisal (Agave sisalana) fibre and its polymer-based composites: A review on current developments. J. Reinf. Plast. Compos. 2017, 36, 1759–1780. [Google Scholar] [CrossRef]

| Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Reference |

|---|---|---|---|

| Jute fiber | |||

| 393–773 | 26.5 | 1.5–1.8 | [10] |

| 400–800 | 10–30 | 1.5–1.8 | [11] |

| 393–773 | 13–26.5 | 1.16–1.5 | [12] |

| 393–773 | 19.0–26.5 | 1.16–1.8 | [13] |

| Cotton fiber | |||

| 287–597 | 5.5–12.6 | 9.7 | [14,15] |

| Elements | Content (%) |

|---|---|

| Cellulose | 64.4 |

| Hemicellulose | 12 |

| Lignin | 11.8 |

| Pectin | 0.2 |

| Water soluble | 1.1 |

| Water | 10 |

| Wax | 0.5 |

| Sample No | Layer | Spent Tea Leaves (gm) | Epoxy Resin (%) | Hardener (%) |

|---|---|---|---|---|

| S1 | J/C/J/C | 0 | 70 | 30 |

| S2 | J/C/J/C | 5 | 70 | 30 |

| S3 | J/C/J/C | 10 | 70 | 30 |

| S4 | J/C/J/C | 15 | 70 | 30 |

| Sample Name | Tensile Strength (MPa) | Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|

| S1 | 22.43 | 2.48 | 9.02 |

| S2 | 26.14 | 4.11 | 6.36 |

| S3 | 34.89 | 3.40 | 10.26 |

| S4 | 25.64 | 3.47 | 7.04 |

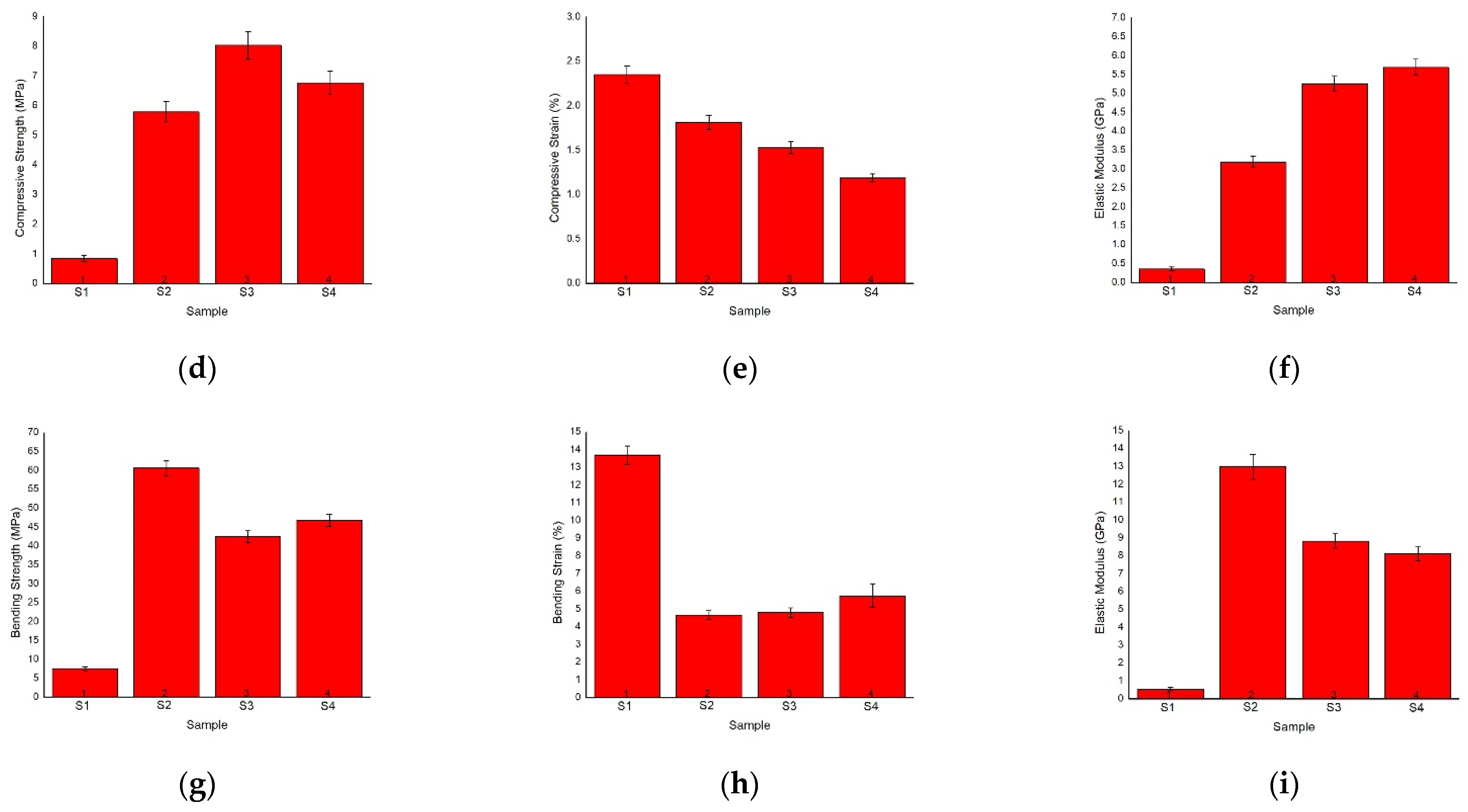

| Sample Name | Compression Strength (MPa) | Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|

| S1 | 0.84 | 2.35 | 0.36 |

| S2 | 5.79 | 1.81 | 3.19 |

| S3 | 8.03 | 1.53 | 5.26 |

| S4 | 6.77 | 1.19 | 5.69 |

| Sample Name | Bending Strength (MPa) | Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|

| S1 | 7.59 | 13.68 | 0.55 |

| S2 | 60.61 | 4.66 | 12.98 |

| S3 | 42.49 | 4.80 | 8.83 |

| S4 | 46.76 | 5.75 | 8.12 |

| Band | Functional Class | Assignment | Vibration Type |

|---|---|---|---|

| 2966 | Hydrogen | C-H | Stretching |

| 2916 | Methylene | C-H | Asymmetric stretching |

| 2646 | Aldehyde | C-H | Stretching |

| 1659 | Alkenyl | C=C | Stretching |

| 1507 | Aromatic ring | C=C-C | Stretching |

| 1472 | Methylene | C-H | Bend |

| 1462 | Methylene | C-H | Bend |

| 1378.54 | Gem-Dimethyl | –CH3 | Doublet |

| 1260.57 | Vinylidene | C-H | Bend |

| 1179.93 | Aromatic | C-H | In-plane bend |

| 1068.08 | Aromatic | C-H | In-plane bend |

| 1023.56 | Alkyl-substituted ether | C-O | Stretching |

| 874.91 | Peroxides | C-O-O- | Stretching |

| 803.39 | Alkene | C-H | Bend |

| 729.61 | Alkene | C-H | Bend |

| 719.26 | Aromatic | C-H | Bend |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, A.; Chowdhury, M.A.; Hossain, N.; Shuvho, M.B.A.; Kowser, M.A.; Rahman, M.R.; Chani, M.T.S.; Kuok, K.K.; Rahman, M.M. Improvement of Mechanical, Thermal, and Physical Behaviors of Jute/Cotton Biocomposites Reinforced by Spent Tea Leaf Particles. J. Compos. Sci. 2022, 6, 145. https://doi.org/10.3390/jcs6050145

Rahman A, Chowdhury MA, Hossain N, Shuvho MBA, Kowser MA, Rahman MR, Chani MTS, Kuok KK, Rahman MM. Improvement of Mechanical, Thermal, and Physical Behaviors of Jute/Cotton Biocomposites Reinforced by Spent Tea Leaf Particles. Journal of Composites Science. 2022; 6(5):145. https://doi.org/10.3390/jcs6050145

Chicago/Turabian StyleRahman, Atiqur, Mohammad Asaduzzaman Chowdhury, Nayem Hossain, Md. Bengir Ahmed Shuvho, Md. Arefin Kowser, Md. Rezaur Rahman, Muhammad Tariq Saeed Chani, Kuok King Kuok, and Mohammed M. Rahman. 2022. "Improvement of Mechanical, Thermal, and Physical Behaviors of Jute/Cotton Biocomposites Reinforced by Spent Tea Leaf Particles" Journal of Composites Science 6, no. 5: 145. https://doi.org/10.3390/jcs6050145

APA StyleRahman, A., Chowdhury, M. A., Hossain, N., Shuvho, M. B. A., Kowser, M. A., Rahman, M. R., Chani, M. T. S., Kuok, K. K., & Rahman, M. M. (2022). Improvement of Mechanical, Thermal, and Physical Behaviors of Jute/Cotton Biocomposites Reinforced by Spent Tea Leaf Particles. Journal of Composites Science, 6(5), 145. https://doi.org/10.3390/jcs6050145