Abstract

The current review paper studies the most noteworthy points in the fabrication of inorganic, eco-benign geopolymer mortar stressing the valorisation of Waste of Glasses (WG) about its properties and applications. Only a few studies are so far accessible on the topic, and therefore, more advanced studies in this respect will be valuable to construction industries and the research scientist, too. Mostly, the centre of attention on its valorisation with WG points a finger to its attitude to embrace the “conversion of wastes into best” strategy. Up until now, their character is neither well understood nor as embraced as OPC mortars. That is why this article reviews its confined literature with an aim to comprehend the valorisation of WG incorporation with geopolymer mortar, and it also reviews studies on its properties and applications, establishing it as a forthcoming constructive, productive, cost-effective, and sustainable large-scale construction material. The recommendations of this paper will be helpful for potential researchers on the topic. However, there are some challenges, such as curing impediments, occasionally practical antagonises of use, a restrained chain of supply, and a precondition for a sharp-eyed command of mixing design for preparing it for use in roadways to replace OPC counterparts in industry. When fabricated by employing abundantly available precursors, activators, and WG up to the standard superior control of varied properties, chiefly strength, durability, and the low-carbon footprints of alkali activators, GP mortars supplemented with WG are ground-breaking approaches to part of the prospect toolbox of sustainable and reasonably inexpensive construction materials. Finally, the paper identifies research work challenges, endorsement of utilisation, and most essentially the features of its properties and pertinent discussions for this promising new kind of valorised construction material.

1. Introduction and Background

In 2006, The Flemish Public Environmental Agency (OVAM) initiated a project to boost the market for recycled composite aggregates. Premium recycled materials are frequently applied in substandard type applications owing to the vagueness about the facts of their technical presentations and the sometimes deficient regulations to stimulate their applications with higher added value [1]. The present review study aims to stimulate the use of waste glass (WG) incorporation in geopolymer concrete for construction. Accordingly, it requires its mechanical and durability attributes being verified. On the one hand, the utilisation of wastes in the construction industry irrelevant of fabricating technologies is very conspicuous for the diminution of solid wastes and their disposal management. What is more, the protection of restricted natural non-renewable resources is equally significant. Global warming—a colossal dilemma that leads to other problems such as climatic change and the degradation of natural resources, along with various plentiful wastes produced from a variety of origins filling the landfills responsible for health perils and atmospheric contamination on the sphere, altogether suggests for a “sustainable development” meaning “the equilibrium among the development of technologies and conservation of the environment at the same time”. On one side of the coin, burgeoning inhabitants on the earth require more homes and infrastructures. In order to adhere bricks and blocks as well as plastering work of structures, a demand for a huge amount of mortar emerged, which again turned to restricted natural deposits of natural sand and ordinary Portland cement (OPC) as a key binder. However, regrettably, the at-hand course of manufacture of OPC requires high-temperature and high energy. It is not merely expending non-renewable limited natural type resources of coal minerals toward attaining high temperature by converting them to ashes required for the calcination of rocks of limestones from nature as raw materials but then has been also found associated with global warming, such as the heating of earth—a gargantuan impasse the world is facing in the current millennium. OPC creation has contributed to the terrifying rise in the release of greenhouse gases (GHG), particularly, carbon dioxide, which is a primary type of GHG. It is not only expensive but also devours scant fossil fuels as well as requires intense thermal and electrical power. The creation of 1 ton of OPC swallows 1.7 tons of leading non-renewable confined resource materials [2,3]. This process emits CO2, drastically approximately 0.85 tons, into open-air [4,5,6,7,8,9], which accounts for 5 to 7% of the global carbon dioxide of anthropogenic sources [10,11,12,13,14,15]. On the other side of the coin, there are numerous different wastes such as Wastes of Glasses (WG), fly ash, rubber waste, solid wastes, etc. from a range of resources, resting in landfills and polluting air, soils, superficial and sub-superficial water on account of their non-biodegradable nature. Consequently, all of the above challenges have pushed concrete scientists as well as engineers to hunt for alternative construction material composites and binders, which should be in essence sustainable, durable, user as well as eco-benign, with low-carbon footprints and lower energy expenditure, and last but not least, reasonably lucrative. These days, geopolymer construction technology has broken the surface as a prospective replacement of conventional cement. Geopolymers include several ground-breaking, inorganic cementitious aluminosilicates with an amorphous 3D structure consisting of tetrahedral SiO4 as well as AlO4 linked to the common atoms of oxygen produced in the course of “geopolymerisation”; analogous to geo-synthesis of natural rocks, it is an exothermic reaction among alumina and silica-rich pozzolanic precursors [16]. The most commonly available solution for alkali hydroxide and alkali silicate (including NaOH, Na2CO3, and Na2SiO3) is the mixture of industrial by-products, fly ash (FA), ground granulated blast furnace slag (BFS), as well as clayey argillaceous, naturally occurring materials, for example with metakaolins (MK) [17,18], at room or ambient or max 100 °C temperatures at atmospheric pressure in alkaline condition [16,19]. Additionally, their outstanding characteristics viz.—appealing strength and durability; splendid mechanical attributes; radiant chemicals resistance; early strength in a short period; marvellous flexibility, extraordinary resistance against thermal as well as fire; resistance to aggressive freeze–thaw situations, and antagonistic nature of anticorrosion—overall have documented them as gifted green sustainable edifice materials that could be manufactured substantially having a ninefold smaller carbon footprint [16,20,21,22], and sixfold less energy than the modern OPC production method [16]. Beneficially, they could be manufactured at lower temperatures, aiming to avoid the degradation of limited non-renewable natural geological resources of rocks as well as minerals. In addition, they are competent in valorising plentiful, varied wastes in their making to manage the wastes disposal scientifically. Their structure is similar to those zeolites, but the regular long-range ordering is not found with them. Geopolymerisation includes the reactions during alkali activation that can be assessed as a complex series of transformations of the initial solid, resulting in a compacted structure coined as “Geopolymers” by inventor Joseph Davidovits [16].

The kinetic characteristics of their development occur in four phases: (i) the dissolution of amorphous aluminosilicate solid materials, i.e., activation in alkali-metal silicate solutions under high alkaline mediums; (ii) oligomer development (i.e., geopolymer precursors) through the polycondensation process between silicate solution and Al and Si of precursor phase of the gel formation by sharing the oxygen atoms in SiA-O-ASi and SiA-O-AAl bonds; (iii) part of the poly-silicates precursors and their restructuring form cross-link 3D alumino-silicates, the closed framework structure bonded to oxygen atoms; (iv) more solid particles that are not dissolved form reciprocal bonds through polymerisation that leads to the structure hardness and development of geopolymer structure [19,23]. The negative charges caused by tetrahedral aluminates from the active solution are balanced by the alkali cations [24,25]. They represent an innovative group of constructing materials: a synthetic alumina silicate group [18]. The fly ash and slag, which are remnants from coal-fired coal in thermal power stations and steel plants, are the promising precursors for the production of geopolymer building products not only because they are pozzolanic in Si and Al but because of their easy and untroubled access. This aids in managing their disposal and creates waste piles as landfills. This is why it can be very economical to produce fly ash and slag-based geopolymeric construction materials and to use them efficiently in the current time as a source material, or precursor, for geopolymers in its utilisation in civil engineering [26].

On the other side, at standard temperature and pressure, geopolymerised slag paste has the largest compressive strength [27]. The ECOBA Report for 2014 says that fly ash has covered 81% of the global total with 86 million tons a year. FA and BFS are overall rather studied and applied most due to their plentiful global presence [28,29,30,31,32,33]. At times, some other raw materials as precursors may encompass numerous wastes such as dissimilar WG rich in silica and alumina, proving their pozzolanic attitude. Recycled Glass (RG), a by-product, comprises crushed mixed colour bottles and other glass products acquired from municipal plus industrial wastes [34] enclosing sand-sized and some silt-sized particles. In addition, geopolymers are proficient in valorising a number of varied wastes from various resources, such as different WG viz., solar panel-WG, cullets of WG, TFT-LCD-WG, as well as modern WG of Electronic as well as Electric Equipment (EEE) i.e., recycled E-wastes from E-glasses, etc. [35,36,37].

1.1. Background

Glass is catalogued as an inert material in a normal environment and can be recycled through various methods devoid of influencing its chemical composition [38]. WG mounting up and disposal management is the issue of grand international apprehension. Even today, the current exercise is to abandon the bulk of the non-recyclable WG as land filling. Seeing that WG is a non-degradable material, the landfills are incapable of extending a way out for contamination of the environment. What is more, WG constantly crops up crises of disposal management, since its use is bountiful and across the board [39]. Subsequently, their valorisation and endeavours are very much indispensable to diminish the said gargantuan wastes to safeguard the environment. In 2014, Spain’s WG totalled 897,828 tonnes, while about 700,000 tons, i.e., 59 glass containers per head, were held specifically on the street and recycled in 2015 [38]. Almost 20,000 tonnes of WG residues were sent annually in the Netherlands in the form of powder and granules to landfills [38]. Australia also disposed of approximately 1.0 million tons of recycled glass (RG) in sites every year [40]. The United States produced and recycled 10,405,409 and 2,748,770 tons respectively in 2015 [41]. In 2014, the EU produced 18,500,000 tons and retrieved or recycled 15,820,000 tons [42]. WG corresponds to 95% of the whole weight of leftover fluorescent lamps as E-wastes [43,44] with a worldwide estimation of 1.5 billion units generation per year [45]. Iranian estimation for WG demonstrates about 740,000 tons per annum, of which less than 5% has undergone recycling [46]. WG estimations of more than 46 million tons yearly are lying at present in landfills, which may reach 77 million tons by the year 2025 [47]! WG amounting to about 12 million tons per annum comes from the U.S.A. alone, with merely 25% of it being recycled [18]. Likewise, China, with an annual generation of about 40 million tons of WG, has recycled just only 13% of it [48]. Statistics from domestic sources for the WG of Hong Kong in 2000 indicate roughly 44,000 along with 20,000 metric tons yearly from the commercial zone. Out of the overall annual figure of 64,000 metric tons, just 8000 metric tons of WG went to recycling or reuse; while the remaining was unloaded to land spaces [49]. Recycling glass containers can bring in an energy savings of about 27%, i.e., 3.3 GJ, besides an alleviation in GHG emissions of about 37%, i.e., 0.39 metric tons of carbon dioxide for every metric ton of glass [50]. Conversely, it gives the impression that every bit of WG is recycled and could be reprocessed in glass factories, but the chief problem starts with the disparities of quality and colour of the WG gathered. Some problems with mixed WG of different colours and origins is that the resulting uncontrolled colour and characteristics in the novel developed glass; in addition, it cannot be recycled and therefore has to be dumped into landfills [51].

On the other side, an amorphous type material containing its chemistry based essentially on SiO2—65% to 75%, CaO—6% to 12%, Na2O—12% to 15%, Al2O3—0.5 to 5%, and Fe2O3—0.1% to 3% is regarded as Urban Glass Waste (UGW) [52,53,54]. The recycling of UWG that encloses 90% of silica soda-lime glass in the glass industry is limited on account of predicaments pertaining to classifying its class and colour. As WG cullet is a by-product, only the grinding process is possible with low-energy raw material manufacturing for geopolymers. This consumption could be an alternative to the disposing outlets previously used for glass resurgence. The prime area is the making of fresh glass products; still, this manoeuvre is, for the most part, doable merely if the separate colours of glasses are recovered in isolation for the production of glass of matching colour [55]. All the same, the collected WG is more often than not of a mixed kind, and hence, it is not feasible to make bottles of an exact given colour. For that reason, the penchant route for the secondary utilisation of recycled WG is to develop water filtration media, abrasives, glass wool, etc. However, a value-added area to employ mixed WG is the construction sector [56,57,58,59,60]. The valorisation of WG enclosing geopolymer mortar-like composites is possible through enlarging its application to encourage their use in sustainable building construction in other industrial procedures and areas. What is more, apart from the transparency—the most recognised attribute of glass—it displays high resistance to attack of chemicals even though the mechanisms and level of corrosion might be a discrepancy [61]. It is remarkably solvable at alkaline pH values [62,63,64]. For illustration, the solubility of amorphous silica augments because of the production of silicate ions associated with a monomer in symmetry with the solid stage at 9 to 10.7 pH values. At pH values greater than 10.7, the amorphous silica dissolves to form a soluble silicate in the strong stage. Nonetheless, accelerated high temperatures also prop up the solubility of glass [62,65]. Consequently, the variety, chemical combination, and mixture member’s size of a particle of WG makes it reprocess extremely complex through the conventional process. Hence, 10–30% of WG is non-recyclable for the mentioned purposes, and alternative valorisation passages must be hunted. The utilisation of such varied wastes for fabricating geopolymer composites can convey a sanguine effect on the natural atmosphere, and the goals of energy saving, lessening carbon, and recycling of waste could also be attained. As a consequence, the sensibly practicable and smartest channel for WG dumping organisation via its reuse is its valorisation of building constituents in the form of ingredient or as an additional cementitious substance [66] irrespective of technologies of its fabrication embracing geopolymer mortar technology for the infrastructure plus construction industries. WG can be employed not only as an agent for the alkali activation in geopolymer concrete [67] but also as the raw material to prepare geopolymer mortars [68]. The predominant presence of SiO2 with more than 70% silica sand suggests its pozzolanic attitude, which directs to looking upon WG as a reactive ingredient in construction composite fabricating [69]. However, at this juncture, it should be noted that the mentioned higher silica presence leads to a comparatively low amount of alumina; for this reason, it is obligatory to correct the quantity percentage of its reactive contents by putting an indefinite mass of reactive alumina-rich materials to ensure the geopolymer production. In addition, the valorisation of different geopolymer composites is valuable to conserve the environment and natural resources that are non-renewable, save energy, and alleviate GHG emissions besides its methodical dumping organisation. The characteristic higher silica-rich glassy phase of WG has been found fit by so many researchers during their examinations for the practicability of using divergent harmless WG obtained from a variety of industries for the fabrication of inorganic polymers [70,71]. As per the expectation, WG demonstrates an inclination toward dissolution and contributes condensable groups of “Silanol, i.e., Si–OH” on account of its chemical volatility in alkaline medium, leading to silica-rich gel formation that affects the characteristics of the finishing product. Geopolymers are fit adequately to puff up the volume augment when undergoing thermal action between 600 and 800 °C [72], authorising for foamed geopolymeric composites via the alkali activation of WG cullets either in the presence or absence of admixture [73,74,75,76]. The fines of WG contain a higher quantity percentage of amorphous silica, and that is the core reason to use them as a precursor in geopolymer composites [77] and also employ them for the production of alkaline activators designed for geopolymers [78]. The high temperatures required for the curing treatment or dissolution of applications are necessary in order to achieve necessary mechanical attributes. At room temperature, the extent of silica dissolution from WG is petty. Very few previous studies are accessible that examine geopolymer mortar with the valorisation of WG. Some previous investigations have represented that the powder of WG has enough pozzolanic characteristics [79,80,81]. The powder of WG is well-known as rich in silica, and it can be activated by an alkaline medium to produce sodium silicate gel. To date, very few studies have investigated the geopolymerisation of WG or its powder or its mixes with slag, fly ash, etc.

Wang et al. [82] have reported the utilisation of sand of WG with 0%, 10%, and 20% in place of slag to manufacture geopolymer mortar by activation through NaOH plus Na-silicate solutions as an activator. The outcomes have displayed that the flow was augmented with the alkaline solution of 0.5%, 0.75%, and 1% concentration and also with the sand substitution with WG, while the compressive strength also enhanced. Torres-Carrasco et al. [52,71] have studied the likelihood of valorisation of WG in geopolymer slag mortar and employed NaOH and Na2SiO3 as well as glass mixed solution as activators to enhance the compressive strength of geopolymer mortar. Redden and Neithalath [28] investigated geopolymer mortars by employing mixes of WG powder with fly ash as raw materials and determined that geopolymer mortar valorising fly ash and WG in powder in equal ratio, having a NaOH concentration of −8 M as well as cured hydro-thermally at 75 °C and curing time of 48 h, exhibited the uppermost compressive strength: 35 MPa.

Pascual et al. [83] have added WG powder and metakaolin in making geopolymeric materials and acquired the optimum compressive strength of 30 MPa at 28 days intended for geopolymer mortar enclosing 8 wt % of metakaolin activated by an NaOH concentration of −5 M [28]. The production of geopolymers incorporating WG cullet is commonly made by mixes of metakaolin, fly ash (materials having higher in Si and Al content), which undergo activation by means of an alkali solution as activators such as sodium silicate i.e., water glass, and assessed the engineering attributes of cullet of WG–geopolymer mortars with dissimilar temperatures curing and synthesised with two kinds of alkali solutions employed at unlike concentrations along with an evaluation of durability characteristics considering the leakage of alkalis. The preceding studies have revealed that geopolymeric cementitious materials are advantageous as a potential engineering material, although the associated engineering materials’ properties are short of systematic incorporated and evaluation models.

Wang et al. [84] have valorised geopolymer slag–mortar with WG of LCD glass and utilised hyperbolic and linear functions to assemble prophecy models for the engineering attributes of the geopolymer slag mortar-like compressive strength, thermal conductivity, as well as ultrasonic pulse velocity (UPV), as an evaluation reference. Indubitably, investigations on the incorporation of WG with geopolymer slag or fly ash systems are not adequate, and merely, a few studies for their role as precursors are accessible. A study to verify how inherent variables such as the nature, alkaline activator concentration, and conditions of curing influence the microstructure as well as activation of glass for the products from the reaction was carried out by Carrasco and Puertas [38], who assessed the mechanical performance and microstructure behaviour of the mixtures formulated by blending WG–geopolymeric materials. Tashima et al. [85] examined the attributes and microstructure behaviour of fibre–WG activated through sodium or potassium-containing activators. In this case, compressive resistance of 77 MPa was obtained for fibre–WG valorised geopolymer mortars having activation through 10 M NaOH concentration and curing of three days at 65 °C temperature. Xiao et al. [86] determined the mechanical properties with respect to the kinetics and Si/Al ratio. The authors suggested that the WG mostly acted as an inert filler at early ages due to the slow reaction rate.

Pascual et al. [83] have employed 8% metakaolin (MK) to introduce alumina content and also to stabilise ions of alkali in the system and kept an eye on the enhancement of the compressive strength. Conversely, the compressive strength diminished on lowering the content of the MK by less than 3% by weight. Redden et al. [28] have accounted that geopolymer composites with MK activation through NaOH concentration enhanced compressive strength more than NaOH-activated fly ash-based geopolymer materials. The microstructural analysis of them exhibited sodium silicate gel as the key reaction product in alkali-activated geopolymers, whereas a mixture of silicate as well as alumina silicate of sodium, N-A-S-H gels, was seen in fly ash-based geopolymers. What is more, Torres-Carrasco et al. [52,71] explored the potential application of WG activated in slag-based geopolymer mortar and noted that employing hydroxides and silicates of sodium plus glass waste with activator solution augments the compressive strength.

1.2. Methodology

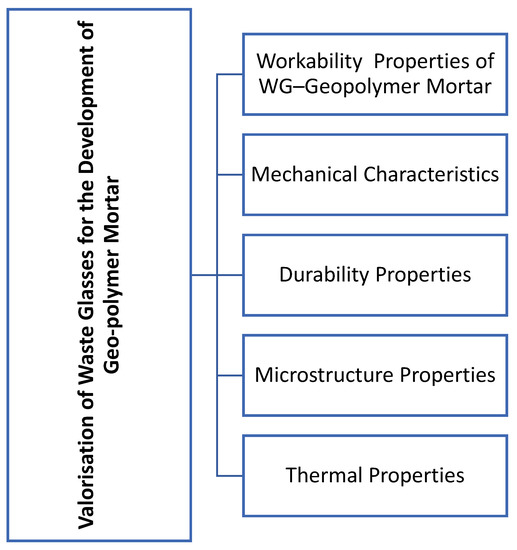

Web of Science, ScienceDirect, ResearchGate, SpringerLink, and other databases were used to find out more about novel geopolymer composites. The keywords “geopolymer, glass waste, and geopolymer mortar” were identified in the Scopus database. The goal of this study is to highlight the current research and application status in the domains of waste glass in geopolymers. For reference, the related references provided in the literature were also used. The structure of the manuscript is shown in Figure 1.

Figure 1.

The structure of a manuscript.

2. Properties of Fresh WG–Geopolymer Mortar

Workability Properties and Setting Time

Vafaei and Allahverdi [87] have accounted for the workability properties and setting time of WG–geopolymer mortar in their study on high-strength WG powder-based geopolymer binder. The results give an idea about the influence of calcium aluminate cements (CAC) type as well as the workability; the setting time properties of the WG–geopolymer mortar were obtained at the water to binder ratio of 0.5, having activator of MS = 1.5 with dry binder −10% by weight, i.e., Na2O, that demonstrated the optimum compressive resistance. Calcium aluminate cements (CACs), being alumina-rich materials, have the potential to be added to glass powder to compensate for the absence of reactive alumina in the initial raw mix composition. CACs are a form of special cement with alumina concentrations ranging from 38% to 80%, with a wide variety of mineral composition depending on the use and purity of the aluminium supply. Monocalcium aluminate (CA) is the primary reactive alumina phase in all CACs, with other calcium aluminates and less reactive phases serving as minor components. Regardless of their chemical and mineral makeup, all CACs can be employed as supplemental alumina sources for geopolymer synthesis. The authors have used different types of calcium aluminate cements CAC i.e., Fondu, Secar 71, and Secar 80. When the amount of CAC increases by 0 to 24%, the flow of the WG–geopolymer mortar through Fondu and Secar 71 increases (Fondu, Secar 80, and Secar 71 are calcium aluminate cement). However, the flow with Secar 80 decreased with the increased CAC replacement. The enhanced inflow was 13% and 10% for the WG–geopolymer mortars through Fondu and Secar 71, in that order, and the dwindling with the context of flow was 8% in case of the WG–geopolymer mortar with the Secar 80 as compared to the mortar devoid of any substitution. Recognising that alumina cements display a comparatively lower propensity to develop clusters in water-related suspensions [88], the substitution of WG powder by Fondu or Secar 71 with a definite surface area of about 3000 to 4000 cm2/g close together results in a decreased propensity for development, which in turn boosts the workability property of WG mortar for a 0.5 water to binder ratio. Due to the high-specific surface area, the pilot effect of Secar 80 on the workability of the said mortar could be significantly increased by leaving little free water for the mobilisation of particles in the mortar. The greater the amount of CACs in the mortar, the shorter the time required for the setting. For the mortar with Secar 80 in the binder, the impact is decreased. The mixture of 24% Secar 80 in the binder reduces the mortar setting period from 22 h to about 13 h, which decreases by approximately 41%. Nevertheless, Fondu is the most effective CAC in the process of settings escalation. A 24% replacement of WG by Fondu reduces the setting time by around 90%. The difference between the set and the pace effects of Fondu and the two other Secar cements is due to the differences in their CaO content. The development of the initial hydration product, which is generally swifter than the geopolymerisation process, is increased by calcium oxide [89]. The variations in shape and concentration of their aluminate phases may also have to do with the difference between the set, which stimulates the impacts of both Secar cements. The CaAl2O4 reactive alumina is the key part of Secar 71 rather than the less reactive phases such as CaAl4O7 and Al2O3, which are part of the CaAl2O4 phase in Secar 81. The trimmed-down setting time by the adding up of additional reactive alumina is owing to the swifter reaction rate of realisable accessible alumina as well as silica and enrichment in the polycondensation course, which is consequential in the development of more 3D structures of alumina silicate.

Another study on the use of WG in geopolymer mortar by Lu and Poon [90] has a flashlight on its workability. The study includes the influence of WG in the form of powder or cullet form on the workability of geopolymer mortar. Sans any shadow of a doubt, it was found that the escalating the substitution echelon of natural fine aggregate, i.e., natural sand by WG cullet, heightened the workability of the geopolymer mortar. They assigned the improvement of workability performance to the intrinsic smooth texture surface and trifling water absorption characteristic of glass. Apart from this, it may be due to the larger cullet particle size of WG compared to the river sand; a smaller quantity of paste was necessitated to coat the said cullet of WG that resulted in the more accessible paste to guarantee better fluidity.

Nevertheless, the amplified scale in the flow value owing to the substitution of river sand by WG cullets was insignificant. In addition, neither bleeding nor segregation had taken place when river sand was substituted entirely, i.e., 100% replacement, by cullets of WG.

Consequently, in the context of workability, the application of WG in geopolymer materials is practically devoid of the deterioration of constancy and homogeneity. To improve the workability of geopolymer mortar enclosing 100% cullets of WG, dissimilar a:b ratios were taken into consideration to obtain the sought-after flow. The flow values were efficiently boosted as the a to b ratio reduced. The enhancement in terms of workability is on account of the availability of surplus paste in the geopolymer mortar.

Moreover, a smaller quantity of cullet of WG could slim down the hindrance impact owing to the edged and angular nature. The procedure of production of geopolymer mortar takes into consideration the grain shapes of the cullets of WG. Additionally, when the fly ash was substituted by the powder of WG in geopolymer mortar, a flow value reduction was reported that was related to the coarser part size and uneven shape of WG particles, which could lessen the mortar mobility. Analogous upshots were monitored in the past study [91].

For this reason, the substitution of fly ash by a powder of WG caused a fall in the performance of workability. Nevertheless, it was monitored that the substitution of GGBS through 30% by weight of the powder of WG had merely a petite impact on flow value. It might be owing to the akin morphology as well as the WG particle’s structure with GGBS. On these grounds, the collective application of cullets of WG as aggregates and powder of WG as a precursor in geopolymer mortar appears to be eye-catching concerning the workability attribute.

3. Mechanical Characteristics

A study by Pacheco-Torgal et al. [92] achieved a compressive strength of 39.6 MPa at 28 days for Tungsten Mining Wastes (TMW) incorporating geopolymer mortar. It is well-known that the escalation of reactive silica proportion to the mortar enhances the eventual shrinkage [93]. Mortars incorporating WG plus fine aggregates are found to be more robust than fresh geopolymer gel at the age of seven days.

3.1. Compressive Strength

Vafaei and Allahverdi [87] found the compressive strength growth of geopolymer mortars compared to Na2O activator content and WG powder replacement quantities by various CACs. The alkali content of the activator solution and the powder replacement of WG by CACs have an important impact on the geopolymer strength resistance growth. For mixes containing Fondu, Secar 71 and Secar 80, which showed the best compression strength values of 48.87 and 51 MPa, the best possible Na2O contents and substitution echelon were found to be 10% and 24%, respectively. The results show that an increase in mechanical strength is tracked by increasing Na2O concentrations from 8 to 10%. This is the crucial role played by the alkali medium in the kinetics of geopolymerisation. At high alkaline levels, the silica and aluminium dissolution rate from precursors escalates and pilots to more N–A–S–H gel and therefore higher geopolymer strength [94]. Na+ also played a role in the production of geopolymer molecular structure as a charging balance ion, besides the dissolution function [95]. With Na2O percentages accelerated further than 10 to 12%, the compressive strength started to decline because of the excessive hydroxide ion outcomes in rapid aluminium-silicate precipitation gels leading to geopolymer development of lower strength. The high content of CAC always leads to a high compressive strength irrelevant of the alkaline content and the CAC type. The development of boosted quantities of reaction products (hydrated sodium alumino-silicate gel; N-A-S-H), resulting in the enhanced mechanical performance of the geopolymer binders, is provided with an adequate amount of reactive SiO2 and Al2O3 in the geopolymer mixture composition [96]. CaO fusion may also be monitored by replacing powder from WG with CACs. By providing hydrated products such as CASH gel together with a 3D geopolymer structure, the presence of CaO in the gel increases its strength [97]. What is more, the discrepancies of compressive strength increase because of the adding up of diverse kinds of CACs concerning the dose of additive and alkali quantity. Every single one of the three kinds of CACs offers a significant optimistic impact in strength enrichment; however, this influence is more palpable in the case of Secar 71, with a significant increase of strength, even at the smallest echelon of 8%. The elevated strengths monitored by Secar 71 are determined by the high level of accessibility of reactionary alumina, which has led to the growth of the geopolymerisation reaction kinetics, resulting in the development of a more interconnected molecular structure and hence a dense and elevated strength alumino-silicate gel. Redden et al. [28] have conducted a survey on the microstructure, strength, as well as humidity stability of powdered geopolymer binders from WG to examine the compressive strengths of geopolymer mortar containing WG powder, triggered by NaOH. The compressive strengths of mortar are produced using WG powder or fly ash, alone or combined with the same amounts, i.e., 50:50 of the two materials, according to the weight. There have been two distinct concentrations of 4 M and 8 M NaOH, together with two distinct curing temperatures, 50 °C and 75 °C. The approved curing period at this temperature was 48 and 72 h, since the samples cured for 24 h in 50 °C did not develop significant strength. In addition to 75 °C, the curing temperature caused remarkable sample cracking for the WG powder mortars over 72 h, and thus, the duration of curing was restricted to 24 and 48 h at that temperature. The changes in the compressive strengths of NaOH-activated mortar were a function of the WG powder content for different NaOH concentrations, cure temperatures, and cure duration. A WG powder addition increases the compressive strength of the activated mortar in general with exception of only 8 M NaOH activated mixes that are exposed to 75 °C for 48 h, which show a maximum compressive strength for the 50% fly ash and WG powder mixture. There is a momentous augment in compressive strength as the alkali concentration is escalated, which indicates that high levels of alkali lead to the growth of increased reaction rates from fly ash activation, i.e., the sodium aluminium silicate gel (N-A-S-H) [98]. When the WG powder with NaOH has activated, the compressive strength improves, while when the NaOH concentration is being accelerated from 4 to 8 M, the impact of mixtures incorporating fly ash may not be as crucial to WG powder activation as an increase in activator concentration beyond a certain level. This is because the alumina in the WG powder from N-A-S-H gel is very small and, accordingly, the reaction output is primarily a sodium silicate gel. Then, it is determined by electron micrograms and by the spectroscopy of EDX and FTIR. On the escalation of NaOH concentrations and reactive silica from WG powder accessibility, additional sodium silicate gel is created that is hardened by external heat supply, which results in some enhancement of strength. Nevertheless, the developed gel, for this case, is subordinate to the SiO2:Na2O ratio, i.e., the silica modulus, which is mechanically inferior to that of a high modulus gel [99]. Sodium silicate gels also show progressive shrinking and cracking quantities [100]. An increase in constant temperature results in increased compression strength for the fly ash-activated binders, i.e., 100% fly ash and 50% WG powder + 50% fly ash grouping, irrelevant of the curing duration. Contrarily, the highest compressive strengths are achieved for the WG powder mortar when heat is cured at a lower temperature or a short duration at a high temperature over a prolonged duration. It is quite eminent that heating and water loss stimulate polymerisation and that gel hardening takes place subsequently. It is plausible that the physically bound water on the surfaced sodium silicate gel groups of silanol, which accounts for a remarkable percentage of water in sodium silicate gels, might have been removed partly while the curing temperature and time are higher and last longer, causing the gel to shrink and crack and therefore lower strengths under alike states. When the mortar is activated with 4 M NaOH, an increase in cure period from 48 to 72 h at 50 °C or 24 to 48 h at 75 °C leads to a slight or no enhancement in strength, which means that the heat curing time at low alkali levels is not a significant factor at well-conceived temperatures. The acceleration of the duration of curing treatment of 8 M NaOH-activated mortars of 48 to 72 h at 50 °C gives a considerable strength gain, which is attributed to the collection effects of the increased alkaline level, resulting in a rapid reaction development and longer heat curing times, putting it ahead of the diffusion-controlled reaction of particularly activated mortars with fly ash. While the time to heat cure is increased from 24 to 48 h at 75 °C, for a 100% WG powder containing mortar, a loss of strength is tracked. Gel cracking and deterioration is conceivable as long as sodium silicate gel yields from the reaction.

Hajimohammadi et al. [101] have described that previous to portraying the chemistry of the binding gel, it is imperative to be acquainted with a mechanical attribute of the resulting mortars include the sand as well as WG aggregates. There is a growth of compressive strength in the three groups. There is a very identical density of both glass and control groups and a little higher density of the sand group, i.e., around 100 kg/m3 than the rest of the two systems. Subsequent to seven days, the glass and the sand groups having aggregates exhibit improved primary strength as compared to the control group. The WG and sand aggregates are stiff in comparison with the newly formed geopolymer gel. That is the core reason to demonstrate better strength by both WG and sand mortars than the control specimen in the early phases. On the 14th and 28th days, the comparable strength was observed in both control and sand group; however, on the 56th day, there was inferior strength detected for the sand group compared to that of a control group. On the 56th day, the strength of the glass group was significantly increased, which made it similar to the strength of the control group. The strength of sand and WG particles was prevailing after the first seven days. The strength of the paste and the bonding strength between aggregates as well as the paste preside over the overall strength of the structures as the amount of the response increases over time and takes the main role in strength development. There is a probable hindrance in the geopolymerisation process in the glass group in comparison with the sand and control groups. To weigh up the viability of manufacturing geopolymers with glass, parameter studies were made to assess the impact and the importance of some factors on the compressive resistance strength echelons of mixes. The factors such as the curing time period, the fineness of WG, temperature for curing, and the nature along with the concentration of the alkaline activator have been investigated.

Cyr et al. [25] have kept an eye on the influence of fineness of WG. The fineness of WG has a noticeable impact on the mechanical attribute of geopolymer mortars; i.e., the superior the fineness, the more advanced the compressive resistance of mortar. After grading, crushing, and sieving the washed glass waste material, the authors have produced different finesses of glass, indicating Fx (x = 1, 2, 3). Glass fineness has a significant impact on the mechanical performance of geopolymer mortars: the higher the fineness, the higher the compressive strength of the mortar. Regardless of the heating temperature, the WG mortars with the fineness F3 were optimal in strength, in-kind, and in the concentration of alkali solution. Fineness F1 is directed at low compressive strengths methodically.

Nevertheless, an augment of 50% in the context of the compressive resistance was attained when employing F3 in place of F2. Consequently, the porosity single-handedly could not elucidate the discrepancies of strength. The environment alkalinity, as well as temperatures utilised, appeared to be deficient in attacking F1 particles profoundly and developing products of a binding attitude.

In accordance with Abood Al-Saadi et al. [102], the geopolymer based on white glass (W-N5) attains following one day of curing at 60 °C an excellent compressive strength of 23.8 MPa; the reduction in the curing temperature of 20 °C later than the first day confirms a petite drop of compressive strengths; however, the values remain about 20 MPa. The replacement of the white glass with 25% red mud (WR25-N5) verifies a definite fall in terms of compressive strength as compared to the compressive strength evaluated on W-N5 mortars, i.e., 20% to 35% in correlation with the curing time. Regarding the impact of the augment of early curing time at 60 °C, from 1 to 3 days, the enhance in curing time at 60 °C does not puts forth an imperative effect on the compressive strength values of W-N5 and WR25-N5 mortars; i.e., the values stands roughly at 20 MPa for W-N5 and about 15 MPa for WR25-N5. The obtained values of compressive strength for the sample with red mud (WR25-N5) are smaller in comparison with those acquired for the mortar based merely on white WG powder [W-N5], even when the curing time at 60 °C accelerates from one to three days. The referred low values are described by the replacement of reactive WG powder with red mud. This waste encloses crystalline compounds and has an inferior reactivity versus alkali solution in comparison with WG powder. Analogous outcomes were attained in the preceding investigations carried out on different kinds of WG [103]. On account of the diminished impact exercised by the augment of curing time at 60 °C, from 1 to 3 days, on the values of compressive strength of the investigated compositions, the effects of the contents of cullets and powder of WG on the compressive resistance of geopolymer mortar were evaluated merely on samples cured for one day at 60 °C. The strength development for the geopolymer mortar was measured through a 60-day curing period. The compressive strength was boosted with curing age irrespective of the substitution echelon of cullets of WG. The strength enhancement at an early age is found to augment even at a later age. The compressive strength would likely be accelerated ahead subsequent to curing for 60 days. Nevertheless, the compressive resistance has gradually dwindled, except for the cullets of WG, which increased. It is attributed to the smooth surface of the cullets of WG, which was a consequence of the more inferior bond strength among the glass as well as the matrix [104]. Xiao et al. [105] evaluated glass powder-based geopolymer stabilised road bases containing recycled waste glass aggregate.

Furthermore, the microcracks in cullets of WG that propagated during the crushing of glass also may lead to a decline in the compressive resistance [106]. On the other hand, the impact of powder of WG on the compressive resistance of geopolymer mortar was also studied by the same researchers. They researched the effect of the use of WG powder as a precursor on the compressive resistance of geopolymer mortar with an a:b ratio of 2.0 (M2.0). The research used 30% WG powder to replace fly ash and GGBS and the resistance growth for geopolymer mortar.

Nevertheless, with boosted time, M2.0 that was manufactured sans any powder of WG performed superior to those composites enclosing WG powder, signalling obviously that the application of WG powder as a partly precursor substitution considerably decreased the strength of geopolymer mortar. This was owing to the low reactivity of the WG powder because it has a gross particle size. Furthermore, Torres et al. [107] discovered that glass has a low activation capacity compared to GGBS with the alkaline solution. However, the compressive strength values of geopolymer mortar made with WG powder are still higher than 15 MPa and can accomplish the strength requirement for non-load-bearing partition wall blocks.

3.2. Flexural Strength

Following Abood Al-Saadi et al. [102], the development tendency of flexural strength is dissimilar from a compressive resistance. The flexural behaviour was enhanced with an augment of cullet of WG content up to 50% and then declined when the content escalated ahead. The NFA was composed of comparatively spherical shape particles when the WG cullet demonstrated the angular type shape and a greater aspect ratio as compared to NFA. Such a disparity would result in an increase in flexural resistance of the WG cullet mix. The speculation of WG fibres (with a high aspect ratio) was continuous with the optimistic effect of improving the flexural or bending strength of cement [108]. Nevertheless, while the WG cullet substituted most of the NFA, the deteriorating impact of WG cullet owing to the smooth surface as well as the presence of microcracks would act to control the flexural resistance significantly. A decline in flexural performance was monitored in this case.

3.3. Impact of Aggregate to Binder (A:B) Ratio on the Compressive Strength

The geopolymer mortar compressive strength grew with a variety of a:b ratios. It is obvious that independent of curing ages, the a:b ratio had a small impact on the compressive strength. This trend was incompatible with the OPC system. The reduced a:b ratio should generally be directly related to an increase in strength caused by the increased OPC content. Nonetheless, the increased binding content of geopolymer mortar did not contribute to the growth of strength. The justification was most likely the more significant shrinkage owing to the elevated binder content [109]. Several researchers [110,111,112,113,114] have pointed out that geopolymer mortar experiences noticeably greater drying shrinkage performance than OPC mortar. Due to the elevated shrinking, the growth of microcracks would lead to poor compressing strength while the geopolymer material was cured under dry conditions [113]. For that reason, the lower a:b ratio (greater binder content) did not improve the compressive strength. The effective w:b ratio of geopolymer mortar was also improved with reduced a:b ratios since smaller quantities of water were necessary for coating the aggregates. Consequently, there was no consequence of the impact of a:b ratio on the compressive strength. The compressive strength of the 100% WG cullet mortar was around 30 MPa at 60 days. The advanced implementation of WG powder in this type of geopolymer mortar was supported by higher strength.

4. Durability Property

In comparison with pure paste, mortars are notorious for having low shrinkage on account of the addition of aggregates [114]. It is also well-known that the increase in the aggregate dimensions increases mortar drying shrinkage. This results in a significant decline of the shrinking from the control group to the sand group, and it is ahead of the shrinking from the sand into the glass group with finer glass particles, which monitored attitude. The glass group shows exceptionally small declines at 7 and 14 days, but at 21 days, the decline is suddenly four times higher. The core reason behind it is the fineness pozzolanic nature of the glass, and it will ultimately be involved in the reaction of geopolymerisation kinetics. The amount of silica dissolution in WG is recognised as insignificant at ambient temperature [53]. In addition, it is important to improve the eventual shrinkage by increasing the percentage of reactive silica to mortar. Increasing the degree of WG response in the matrix changes the reacted percentage of the WG from one unit to the other. It shows a considerably higher degree of decline over a lengthy period of time. Nevertheless, the ultimate shrinking is the smallest of the three systems in the glass group. The compressive strength of the binding matrix was studied within the three geopolymer groups. When the strength of the aggregates is close to the binding matrix strength, aggregates can increase the paste’s strength [115]. Mortars with WG plus sand are stronger than the newly made geopolymer gel at 7 days. Nevertheless, the geopolymer gel achieves increased strength over time comparable to the sand group (which is slightly higher in 56 days in reaction). The strength of the glass group at 14 and 28 days was less than the control and the sand group, but this group gained remarkable strength over a long period. Subsequent to 56 days of reaction, the glass group strength is similar to the control group strength. This reading suggests that the WG aggregate surface will play a part in the reaction, given that the paste ages over time, and therefore, the glass groups have a denser and stronger gel.

5. Microstructure Properties

The WG powder’s microstructural observations include geopolymer mortar that displays SEM images as the control and geopolymer mortar amalgamating 24% CAC compared to the MS activator = 1.5 10% Na2O, which is hydrothermally healed at 95 °C with 20 h. The microstructure created mainly introduces a glass phase structure with the geopolymer matrix (fully react to WG powder particles) and WG powder particles, partially or non-reacted. Regarding chemical and mineral raw material chemistry, any alteration in the geopolymer structure’s morphology and porosity can be monitored. When the addition of all three types of CACs resulted in a more compact microstructure with a lesser number of finer non-reacted particles, geopolymer without added CAC (a and b) is noticeable with an exceptionally cracked microstructure.

Nevertheless, a decreased pore gel microstructure, with less non-reacted particles, is shown by a geopolymer sample with Secar 71, on account of the increase in reactive alumina content accelerating geopolymerisation. The difference in the morphology of the interface transition zone (ITZ) microstructures between the aggregate and various WG powders containing CAC geopolymer paste was studied as well. SEM studies on the microstructure of ITZ showed that the morphology of ITZ changed with different types of CAC admixtures in raw materials. There is a clear interfacial region between the aggregate and geopolymer paste for control mortar due to the existence of void micro-areas and microcracks, while the amplification in response results due to adding CAC admixtures leads to the ITZ densification. The amalgamation of admixtures of CACs into WG powders, especially Secar 71 and the quantity of reactive aluminas as the result of the mixture chemical process, is significantly increased in the development of a microstructure with a much denser dimension [87].

6. Thermal Properties

The residual compressive strength of the geopolymer mortar and its residual strength index (RSI), subjected to 800 °C, was studied. The residual compressive strengths of the WG cullet mortar were slightly lower than those without the WG cullet mortar. The residual strength is tending to be constant with the WG cullet echelon increase. Such attitudes indicate that the possible melting of the geopolymer mortar by the WG cullet at greater temperatures has not caused a harsh deterioration in strength for the geopolymer mortar. Contrarily, the values of RSI had a propensity to escalate, since the WG cullet content was accelerated in the mortars, suggesting that the incorporation of WG cullet could reduce the loss in strength owing to the higher temperature exposure. The advantageous impact was most likely assigned to the low thermal incompetence among the geopolymer paste matrix and the WG cullet. Following the preceding studies [116], the geopolymer composites demonstrated thermal shrinkages subsequent to higher temperature. Accordingly, NFA’s substituting with WG cullet reduced the difference in thermal expansion between the geopolymer paste and the WG aggregates. Additionally, the change from b-form to a-form at 573 °C in the NFA quartz was identified with a volume amendment associated with the damage caused by the interface of the aggregate binders, thus encouraging the loss of strength. Perceptibly, also partly liable for a strength deterioration following exposure to greater temperatures was the varied thermal expansion of the gel matrix and aggregates [117,118]. The pore structure characteristics were evaluated using MIP before and after greater temperature exposure to authenticate the justification. The pore size of the mortars following the elevated temperature exposure period was greatly superior to the mortars that were not subjected to the higher temperature, which signals that the porosity was hugely boosted subsequent to higher temperature exposure. The increase is in agreement with a harsh loss of strength for geopolymer mortars subsequent to exposure to 800 °C. Nevertheless, the presence of WG cullets in geopolymer mortars was capable of efficiently reducing the increase in porosity. In comparison with the NFA mortar following exposure to 800 °C, the WG cullet incorporating mortars had a very small pore volume. The porosity value also instinctively shows the same drift. Regarding the pore size distributions of geopolymer mortars with or without exposure to 800 °C, after exposure to the high temperature, the pores of the geopolymer mortar have been significantly coarsened. Nevertheless, the effect on coarse was reduced when WG concrete was replaced by NFA, especially in the form of the rounded pores, which would decrease the amount of coarsened bulky pores after higher temperature exposures by adding the WG cullet. It is supposed that the reduction of coarse pores was attributed to the less significant thermal incompetence among the geopolymer paste matrix and the WG cullet. The RSIs produced with and without the WG cullet of the geopolymer mortar was more than 50%. In all geopolymer samples, visual tests showed a lack of visible cracking and spalling. In comparison, previous studies [119,120] found that OPC composites’ RSIs were approximately 20%. This discrepancy indicates that the WG–geopolymer mortar had better temperature resistance than OPC mortars. Zuda and Cerny [121] achieved similar upshots, which found that the thermo-mechanical behaviour of the composite geopolymer in general was superior to the OPC composites. The increase in the mechanical attributability of geopolymer mortar after exposure to a higher temperature may be because the crystallisation of akermanite in the alumino-silicate material at 800 °C was aimed at developing a ceramic connection with much higher thermal stability [122]. What is more, in geopolymer mortar, no calcium hydroxide was discovered, which also supplied improved greater efficiency at high temperatures. The geopolymer mortar’s resistant compression and RSI values were similarly manufactured with dissimilar a:b ratios, which showed that the a:b ratio only has a minor effect on geopolymer mortar fire resistance. Two pessimistic effects due to the high temperature can be ascribed to the factors: one being the decomposition of reaction yield and the other being the heat incompetence between the matrix and the WG cullet [123]. Therefore, the latter effect could be predominant with higher a:b ratio composites because of the higher aggregate content, whereas the resistance to higher temperature exposure was most probably regulated with the previous effect, due to the increased binder content, for the small a:b ratio composites. The increases indicate that the incorporation of WG powder into the geopolymer mortar efficiently enhanced the resistance to a higher temperature. The greater values of RSI in WG powder-amalgamated geopolymer mortar may be described by a phenomenon analogous to those monitored in WG powder-integrated OPC mortar [124]; i.e., the change from solid to fluid beyond the melting point of unreacted WG powder was useful to fill open pores and high temperature-induced microcracks. On the other hand, the fine WG powder is used to intensify the synthesising advancement in the production of ceramic yields, depending upon the mixing attributes [125,126]. When subjected to high temperatures, the geopolymer mortar created a much better ceramic bond due to the akermanite crystallisation [122]. Consequently, the vitreous phase of a melted WG powder is thought to encourage crystallisation that delivers higher resistance at temperatures. However, this speculation still requires detailed study. The geopolymer-derived material of WG can be used as partition wall blocks because it not only provides a viable implementation of WG in non-OPC material but also strengthens the excellent mechanical features and fire resistance. Nevertheless, further research is required to shed more light on the effects of valorisation of WG as a geopolymeric material, for instance, the ASR jeopardy of WG aggregates in geopolymer material with higher alkali concentrations, the effect of WG on drying shrinking, and carbonation as well as the efflorescence properties of geopolymer composites.

7. Discussion

This paper reviews the valorisation of the applications of WG incorporation for the development of geopolymer mortar and discussed the previous studies on the workability, strength, thermal, and microstructural properties. This review included the possibility of employing WG in geopolymer as a precursor for alkaline cement. The review reveals that it is wholly possible to blend these wastes in construction and building materials, sans any further makeover beyond crushing to develop innovative geopolymer building materials. Glass can be ground easily to very fine particles that can replace fine sand in lightweight geopolymer foams. Over time, the surface of the glass particles reacts with the paste and forms stronger bonds with the geopolymer binder. These inimitable features make fine glass particles a suitable substitute to fine sand in geopolymer foam applications. In concrete, scrap glass serves as a rich supply of silica. As a result of the addition of fine WG to concrete, pozzolanic activity improves, hydration product production increases, and microstructures improve. Furthermore, the addition of fine WG powder promotes silica solubility in the geopolymer system, resulting in better geopolymeric reaction. Due to the slower reaction rate of WG, WG powder in geopolymer samples served mostly as an inert filler in the early stages. Both the sodium aluminate silicate (N-A-S-H) gel and the calcium aluminate silicate (C-A-S-H) gel formed were incorporated in the geopolymer gel, resulting in a denser and stronger geopolymer network with composite binding phases. The creation of new quartz phases may also contribute to the geopolymer’s strong mechanical characteristics. Table 1 shows the effect of waste glass on the properties of concrete

Table 1.

Effect of waste glass on compressive strength.

8. Conclusions

This article reviews the valorisation of the applications of WG for the development of geopolymer composites and discussed the previous studies on the strength, thermal, and durability properties along with the microstructural behaviour. The following findings have been reached:

- The possibilities of augmenting WG by substituting volumetric percentages of either precursor (such as fly ash) or aggregate (such as sand). The use of WG is extremely common. Not only is it feasible to produce geopolymer composites as a raw material, but it is also feasible to generate geopolymer composites as a finished product material.

- The addition of fine WG powder promotes silica solubility in the geopolymer system, resulting in better geopolymeric reaction. Due to the slower reaction rate of WG, WG powder in geopolymer samples served mostly as an inert filler in the early stages.

- When compared to control mortars, the geopolymer mortar demonstrated higher endurance in both acid solutions.

To sum up, the application of WG has been established as a valuable material in making geopolymers with excellent and acceptable attributes, which valorise it as an economical and sustainable construction material. This is a valuable step putting a step forward in the direction of its valorisation.

Author Contributions

Conceptualization, S.L. and I.L.; methodology, S.L.; validation, S.L. and I.L.; formal analysis, I.L.; investigation, S.L. and I.L.; resources, I.L.; writing—original draft preparation, S.L. and I.L.; writing—review and editing, I.L.; visualization, I.L. and S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vrijders, J.; Desmyter, J. Een Hoogwaardig Gebruik van Puingranulaten Stimuleren; OVAM: Mechelen, Belgium, 2008. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Hendriks, C.A.; Worrell, E.; De Jager, D.; Blok, K.; Riemer, P. Emission Reduction of Greenhouse Gases from the Cement Industry. In Proceedings of the Fourth International Conference on Greenhouse Gas Control Technologies, IEA GHG R&D Programme, Interlaken, Austria, 30 August–2 September 1998; pp. 939–944. [Google Scholar]

- Ke, X.; Bernal, S.A.; Ye, N.; Provis, J.L.; Yang, J. One-part geopolymers based on thermally treated red mud/NaOH blends. J. Am. Ceram. Soc. 2015, 98, 5–11. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. A Review on the Performance Evaluation of Autonomous Self-Healing Bacterial Concrete: Mechanisms, Strength, Durability, and Microstructural Properties. J. Compos. Sci. 2022, 6, 23. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Razak, R.A.; Vizureanu, P.; Sandu, A.V.; Matasaru, P.-D. A State-of-the-Art Review on Innovative Geopolymer Composites Designed for Water and Wastewater Treatment. Materials 2021, 14, 7456. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S. Rubberized Geopolymer Composites: Value-Added Applications. J. Compos. Sci. 2021, 5, 312. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Nabiałek, M.; Sandu, A.V.; Szmidla, J.; Jurczyńska, A.; Razak, R.A.; Aziz, I.H.A.; Jamil, N.H.; et al. Assessment of the Suitability of Ceramic Waste in Geopolymer Composites: An Appraisal. Materials 2021, 14, 3279. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Gupta, R. Durability Performance Evaluation of Rubberized Geopolymer Concrete. Sustainability 2021, 13, 5969. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. Review on Performance Evaluation of Autonomous Healing of Geopolymer Composites. Infrastructures 2021, 6, 94. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Savva, P.; Theodosiou, A.; Petrou, M.F.; Nicolaides, D. Light Transmitting Concrete: A Review. Buildings 2021, 11, 480. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Abdullah, M.M.A.B.; Hussin, K. Challenges and prospective trends of various industrial and solid wastes incorporated with sustainable green concrete. In Advances in Organic Farming; Woodhead Publishing: Sawston, UK, 2021; pp. 223–240. [Google Scholar]

- Luhar, S.; Dave, U. Investigations on mechanical properties of fly ash and slag based geopolymer concrete. Ind. Concr. J. 2016, 34–41. [Google Scholar]

- Luhar, S.; Rajamane, N.P.; Corbu, O.; Luhar, I. Impact of incorporation of volcanic ash on geopolymerization of eco-friendly geopolymer composites: A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 572, 012001. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Saint-Quentin: Aisne, France, 2015. [Google Scholar]

- Palacios, M.; Puertas, F. Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem. Concr. Res. 2007, 37, 691–702. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S.J. (Eds.) Geopolymers: Structures, Processing, Properties and Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Temuujin, J.V.; Van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash-and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Verdolotti, L.; Iannace, S.; Lavorgna, M.; Lamanna, R. Geopolymerization reaction to consolidate incoherent pozzolanic soil. J. Mater. Sci. 2008, 43, 865–873. [Google Scholar] [CrossRef]

- Liew, Y.M.; Kamarudin, H.; Al Bakri, A.M.; Bnhussain, M.; Luqman, M.; Nizar, I.K.; Heah, C.Y. Optimization of solids-to-liquid and alkali activator ratios of calcined kaolin geopolymeric powder. Constr. Build. Mater. 2012, 37, 440–451. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Chao, J.-Y. Manufacturing and Properties of Alkali-Activated Waste Glass Cement; National Cheng Kung University: Tainan, Taiwan, 2008. [Google Scholar]

- Redden, R.; Neithalath, N. Microstructure, strength, and moisture stability of alkali activated glass powder-based binders. Cem. Concr. Compos. 2014, 45, 46–56. [Google Scholar] [CrossRef]

- Escalante-Garcia, J.I.; Sharp, J. The chemical composition and microstructure of hydration products in blended cements. Cem. Concr. Compos. 2004, 26, 967–976. [Google Scholar] [CrossRef]

- Nguyen, K.; Ahn, N.; Le, T.A.; Lee, K. Theoretical and experimental study on mechanical properties and flexural strength of fly ash-geopolymer concrete. Constr. Build. Mater. 2016, 106, 65–77. [Google Scholar] [CrossRef]

- Yun, H.; Ek, D.; Ong, L.; Sanjayan, J.G.; Nazari, A. The effect of different Na2O and K2O ratios of alkali activator on compressive strength of fly ash based geopolymer. Constr. Build. Mater. 2016, 106, 500–511. [Google Scholar]

- Nazari, A.; Sanjayan, J. Synthesis of geopolymer from industrial wastes. J. Clean. Prod. 2015, 99, 297–304. [Google Scholar] [CrossRef]

- Sarathi, P.; Nath, P.; Kumar, P. Drying shrinkage of slag blended fly ash geopolymer concrete cured at room temperature. Proc. Eng. 2015, 125, 594–600. [Google Scholar]

- Wartman, J.; Grubb, D.; Nasim, A. Select engineering characteristics of crushed glass. J. Mater. Civ. Eng. 2004, 16, 526–539. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Lin, K.-L.; Shiu, H.-S.; Shie, J.-L.; Cheng, T.-W.; Hwang, C.-L. Effect of composition on characteristics of thin film transistor liquid crystal display (TFT-LCD) waste glass-metakaolin-based geopolymers. Constr. Build. Mater. 2012, 36, 501–507. [Google Scholar] [CrossRef]

- Hao, H.; Lin, K.-L.; Wang, D.; Chao, S.-J.; Shiu, H.-S.; Cheng, T.-W.; Hwang, C.-L. Utilization of solar panel waste glass for metakaolinite-based geopolymer synthesis. Environ. Prog. Sustain. Energy 2013, 32, 797–803. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Mamun, M.A.A.; Alyousef, R.; Ferdous, W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers 2021, 13, 2071. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Glass: Material-Specific Data. 2018. Available online: https://www.epa.gov/facts-and-figures-about-materialswaste-and-recycling/glass-material-specific-data (accessed on 14 December 2021).

- European Statistics. Generation of Waste by Waste Category, Hazardousness and NACE. Rev. 2 Activity. 2014. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 14 December 2021).

- Lee, C.-H.; Popuri, S.R.; Peng, Y.-H.; Fang, S.-S.; Lin, K.-L.; Fan, K.-S.; Chang, T.-C. Overview on industrial recycling technologies and management strategies of end-of-life fluorescent lamps in Taiwan and other developed countries. J. Mater. Cycles Waste Manag. 2014, 17, 312–323. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Potential application of E-wastes in construction industry: A review. Constr. Build. Mater. 2019, 203, 222–240. [Google Scholar] [CrossRef]

- Wagner, T.P. Compact fluorescent lights and the impact of convenience and knowledge on household recycling rates. Waste Manag. 2011, 31, 1300–1306. [Google Scholar] [CrossRef] [PubMed]

- Asian Productivity Organization. Solid Waste Management: Issues and Challenges in Asia; Environmental Management Centre: Mumbai, India, 2007. [Google Scholar]

- Escalante-García, J.I. Overview of potential of urban waste glass as a cementitious material in alternative chemically activated binders. J. Chin. Ceram. Soc. 2015, 43, 1441–1448. [Google Scholar]

- Ke, G.; Bai, J. A review on the reuse of waste glasses in the cement concrete. J. Univ. South China 2010, 24, 96–102. [Google Scholar]

- Chen, G.; Lee, H.; Young, K.L.; Yue, P.L.; Wong, A.; Tao, T.; Choi, K.K. Glass recycling in cement production—An innovative approach. Waste Manag. 2002, 22, 747–753. [Google Scholar] [CrossRef]

- Vossberg, C.; Mason-Jones, K.; Cohen, B. An energetic life cycle assessment of C&D waste and container glass recycling in Cape Town, South Africa. Resour. Conserv. Recycl. 2014, 88, 39–49. [Google Scholar]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Palomo, J.G.; Puertas, F. Sodium silicate solutions from dissolution of glass wastes. Statistical analysis. Mater. Constr. 2014, 64, 314. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M.; Varga, C.; Torres, J.J.; Moreno, E.; Palomo, J.G.; Puertas, F.; Torres-Carrasco, M.; Varga, C.; Torres, J.J.; et al. Re-use of urban and industrial glass waste to prepare alkaline cements. In Proceedings of the 4th International Conference on Engineering for Waste and Biomass Valorization, Porto, Portugal, 10–13 September 2012. [Google Scholar]

- Torres-Carrasco, M.; Puertas, F.; Blanco-Varela, M.T. Preparación de cementos alcalinos a partir de residuos vítreos, Solubilidad de residuos vítreos en medios fuertemente básicos. XII Congr. Nac. De Mater. 2012, 35, 113–117. [Google Scholar]

- Idir, R. Me’canismes D’action des Fines et des Granulats de Verre sur la re´Action Alcali-Silice et la Re´Action Pouzzolanique. Ph.D. Thesis, Universite´ de Toulouse and Universite´ de Sherbrooke, Sherbrooke, QC, Canada, 2009. [Google Scholar]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Pozzolanic properties of fine and coarse color-mixed glass cullet. Cem. Concr. Compos. 2011, 33, 19–29. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of Fine Glass as ASR Inhibitor in Glass Aggregate Mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Role of the nature of reaction products in the antagonistic behaviours of fine glass powders and coarse glass aggregates used in concrete. Mater Struct. 2011, 46, 233–243. [Google Scholar] [CrossRef]

- Fernández Navarro, J.M.; Vidrio, E.I. Boletin de la Sociedad Española de Cerámica y Vidrio; Consejo Superior de Investigaciones Científicas, Sociedad Española de Cerámica y Vidrio: Madrid, Spain, 2003. [Google Scholar]

- Paul, A. Chemical durability of glasses; a thermodynamic approach. J. Mater. Sci. 1977, 12, 2246–2268. [Google Scholar] [CrossRef]

- El-Shamy, T.M.; Panteno, C.G. Descomposition of silicates glasses in alkaline solutions. Nature 1977, 266, 704–706. [Google Scholar] [CrossRef]

- El-Shamy, T.M.; Lewis, J.; Douglas, R.W. The dependence on the pH of the descomposition of glasses by aqueous solutions. Glass Technol. 1972, 13, 81–87. [Google Scholar]

- Goto, K. States of Silica in Aqueous Solution. II. Solubility of Amorphous Silica. Nippon. Kagaku Zassi 1955, 76, 1364–1366. [Google Scholar] [CrossRef][Green Version]

- Shi, C.; Zheng, K. A review on the use of waste glasses in the production of cement and concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Cleaner Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Swamy, R.N. The Alkali-Silica Reaction in Concrete; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Kourti, I.; Devaraj, A.R.; Bustos, A.G.; Deegan, D.; Boccaccini, A.R.; Cheeseman, C.R. Geopolymer sprepared from DC plasma treated air pollution control(APC) residues glass: Properties and characterization of the binderphase. J. Hazard. Mater. 2011, 196, 86–92. [Google Scholar] [CrossRef]

- Puertas, F.; Torres, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Badanoiu, A.; Al-Saadi, T.H.A.; Stoleriu, S.; Voicu, G. Preparation and characterization of foamed geopolymers from waste glass and red mud. Constr. Build. Mater. 2015, 84, 284–293. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Allouche, E.N. Impact of alkali silica reaction on fly ash based geopolymer concrete. J. Mater. Civ. Eng. 2012, 25, 131–139. [Google Scholar] [CrossRef]

- Lu, D.; Liu, Y.; Zheng, Y.; Xu, Z.; Shen, X. Alkali-aggregate reactivity of typical siliceious glass and carbonate rocks in alkali-activated fly ash based geopolymers. In Proceedings of the Medical Imaging 2001: Physics of Medical Imaging; International Society for Optics and Photonics: Bellingham, WA, USA; Volume 8793, p. 879313.

- Pouhet, R.; Cyr, M. Alkaliesilica reaction in metakaolin-based geopolymer mortar. Mater. Struct. 2015, 48, 571–583. [Google Scholar] [CrossRef]

- Williamson, T.; Juenger, M.C. The role of activating solution concentration on alkali silica reaction in alkali-activated fly ash concrete. Cement Concr. Res. 2016, 83, 124–130. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. Durability of geopolymer mortar based on wasteglass powder and calcium aluminate cement in acid solutions. J. Mater. Civ. Eng. 2017, 29, 04017196. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Geopolymer binders from metakaolin using sodium waterglass from waste glass and rice husk ash as alternative activators: A comparative study. Constr. Build. Mater. 2016, 114, 276–289. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Schwarz, N.; Neithalath, N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem. Concr. Res. 2008, 38, 429–436. [Google Scholar] [CrossRef]

- Wang, W.C.; Chen, B.T.; Wang, H.Y.; Chou, H.C. A study of the engineering properties of alkali-activated waste glass material (AAWGM). Constr. Build. Mater. 2016, 112, 962–969. [Google Scholar] [CrossRef]

- Ana Balaguer Pascual, M.T.T.; Tagnit-Hamou, A. Waste glass powder-based alkali- activated mortar. In Proceedings of the NTCC2014: International Conference on Non-Traditional Cement and Concrete, Brno, Czech Republic, 16–19 June 2014. [Google Scholar]