Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites

Abstract

:1. Introduction

2. Overview of Cellulosic Filler-Reinforced Plastic Composites

2.1. Overview

2.2. Industrially Important WPC

3. Issues of Composites and Scope of this Review

4. Acid-Modified Resins

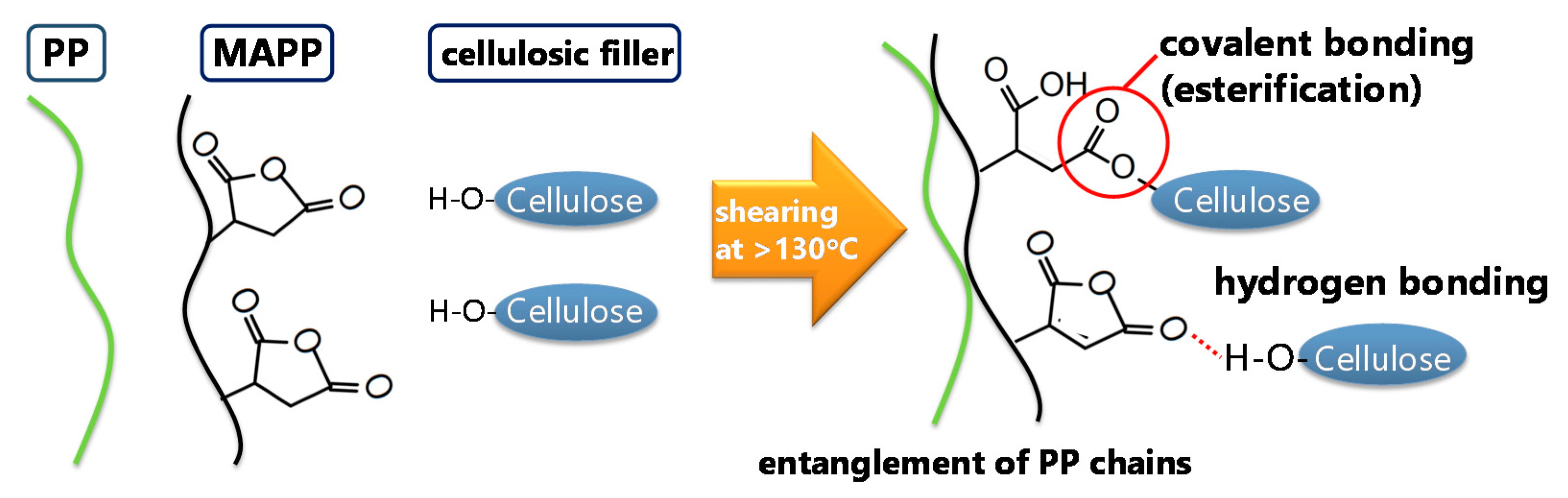

4.1. General Understanding

4.2. Difficulty in Estimating the Effect of an Acid-Modified Resin Compatibilizer

5. Recent Research on the Function of MAPP by Experiments on Various Scales

5.1. Analysis at a Molecular Level: Detection of Binding between Cellulosic Filler and Acid-Modified Resin by Spectroscopy

5.1.1. Increasing the Sensitivity of Spectroscopy

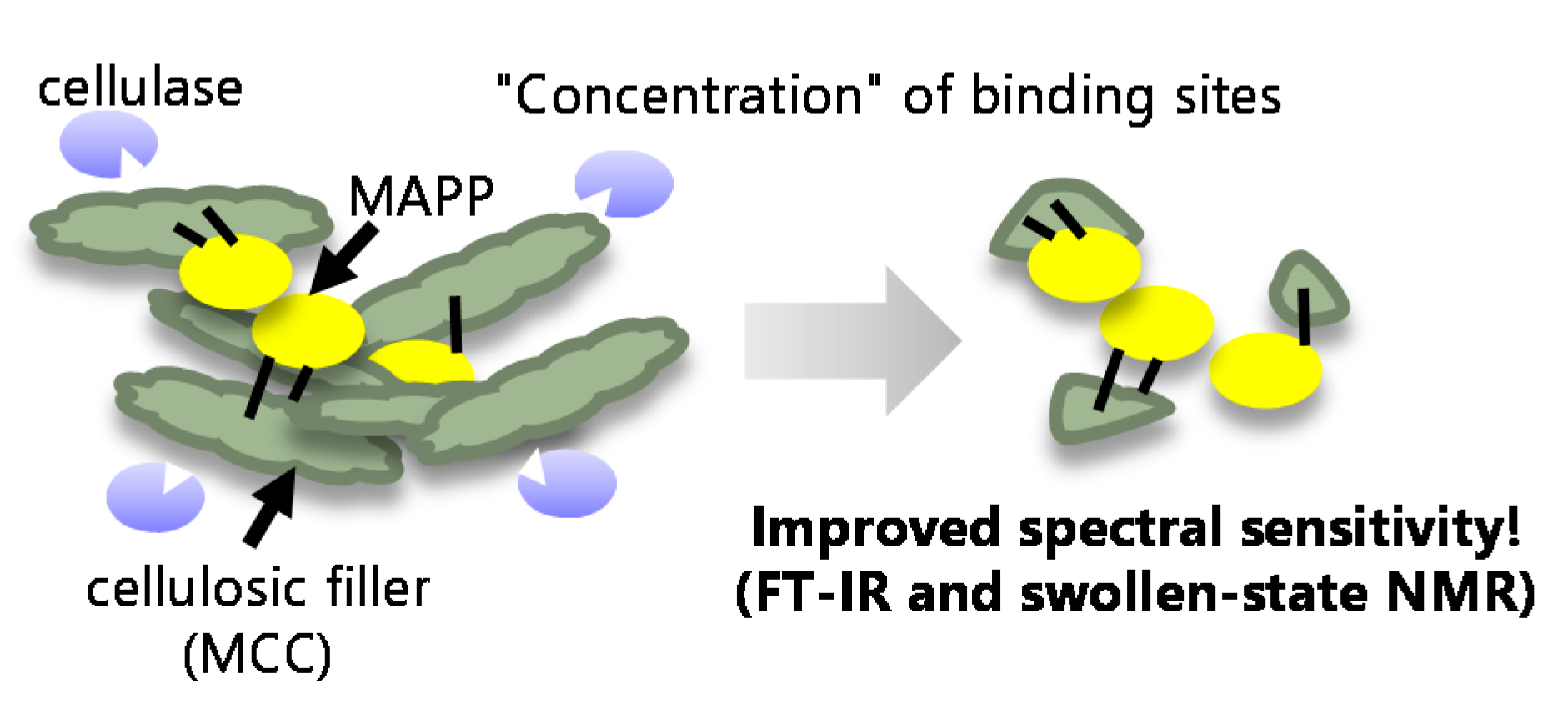

5.1.2. Preparation of Composites and Concentration of Binding Sites by Enzymatic Degradation

5.1.3. FTIR Spectroscopy of Samples with Concentrated Binding Sites

5.1.4. Swollen-state NMR Spectroscopy of Samples with Concentrated Binding Sites

5.1.5. Possibility of Developing Spectroscopy Specialized for the Interface of Composite Materials

5.2. Nanoscopic Analysis: Evaluation of the Wettability of Acid-modified Resin on the Filler Surface and Localization in Composites

5.2.1. Nanoscopic Analysis Viewpoint

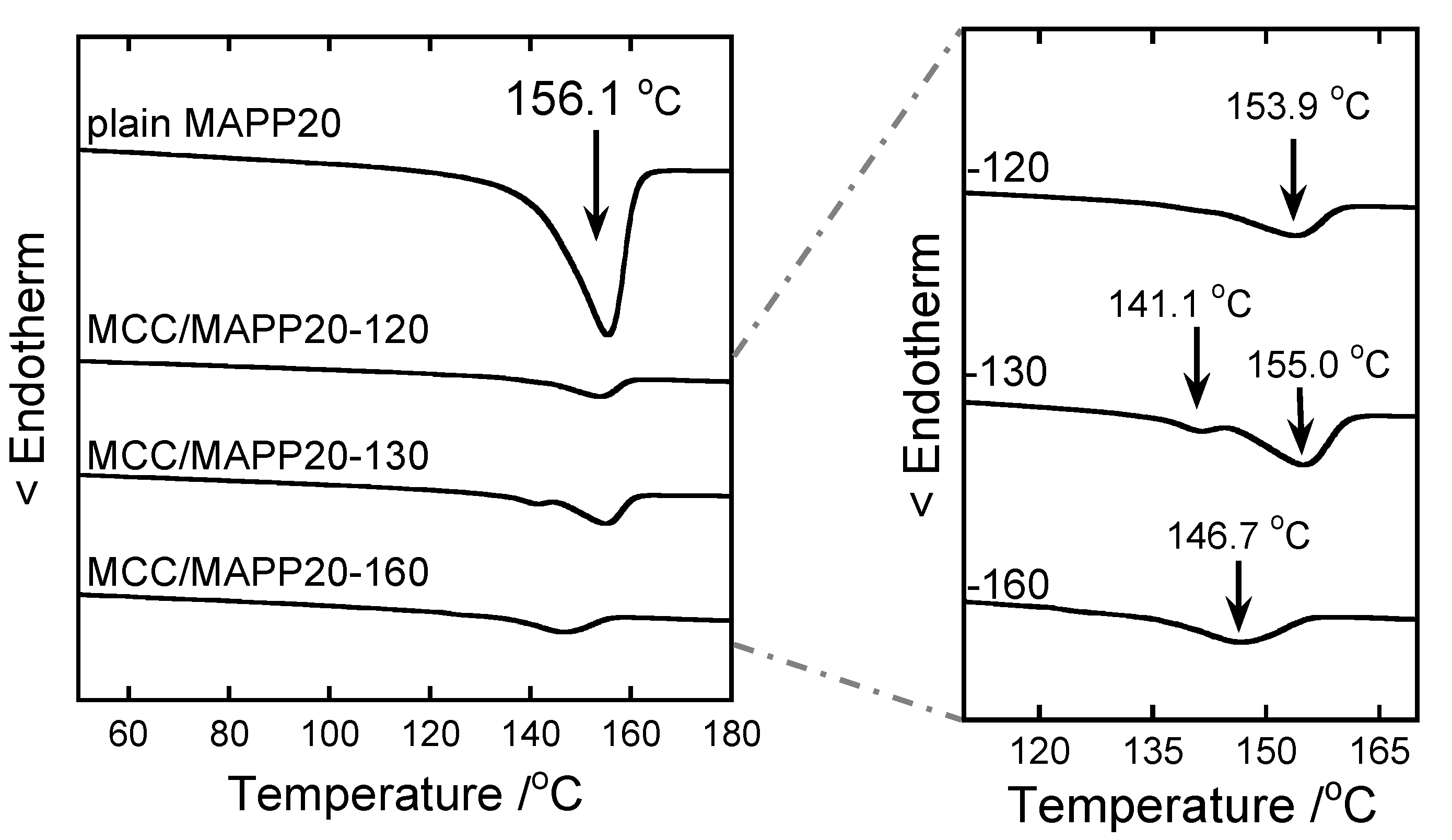

5.2.2. Crystallization Studies by Thermal Analysis

5.2.3. Intercomparison of Compatibilizer Wettability by Thermal Analysis

5.2.4. Nanoscopic Localization of Compatibilizer

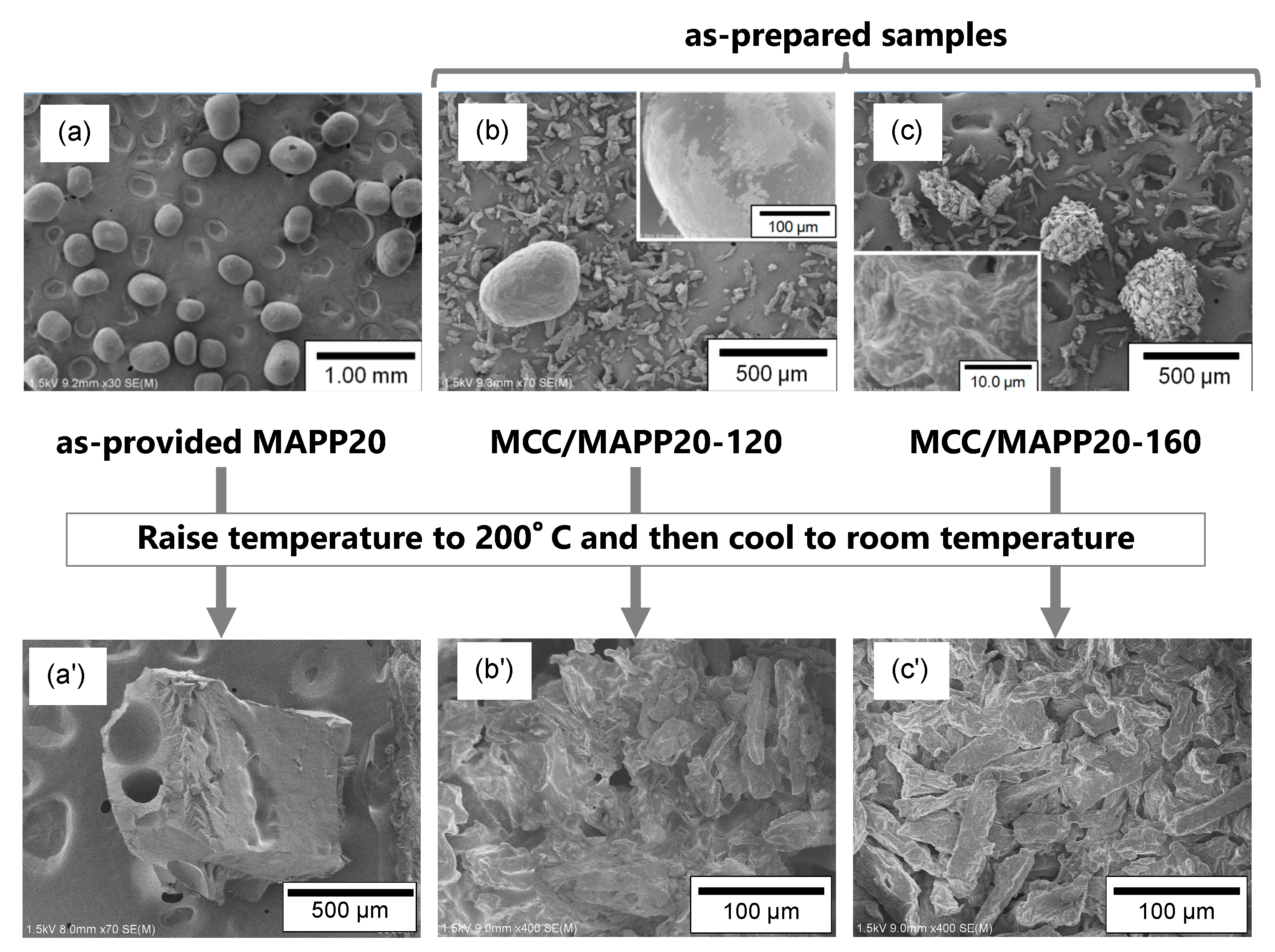

5.2.5. Achievement and Applicability of Nanoscopic Evaluation

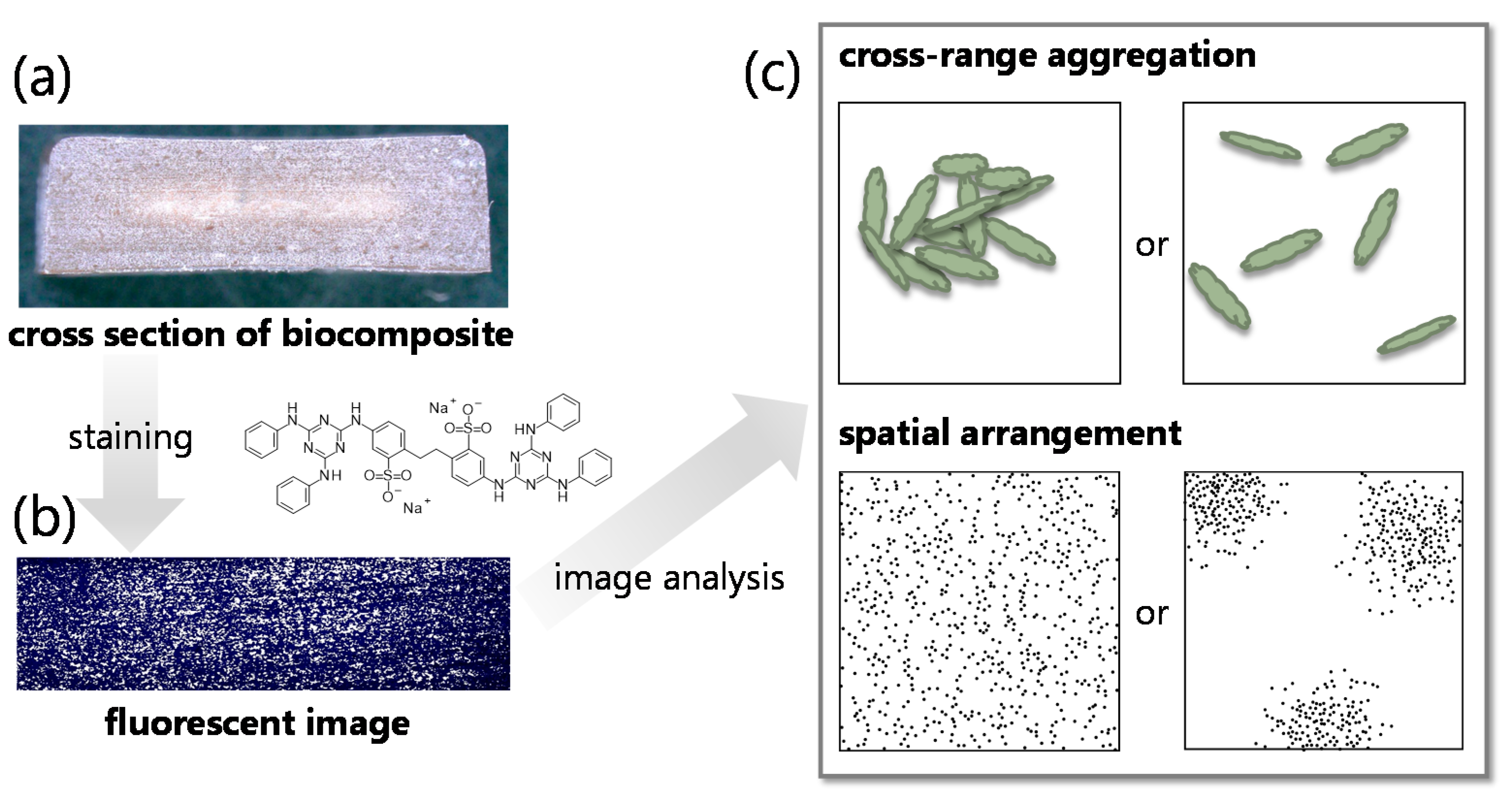

5.3. Filler Dispersibility Evaluation by Micron-Scale Imaging Analysis

5.3.1. Extraction of Fillers from Images and Utilization of Fluorescent Staining

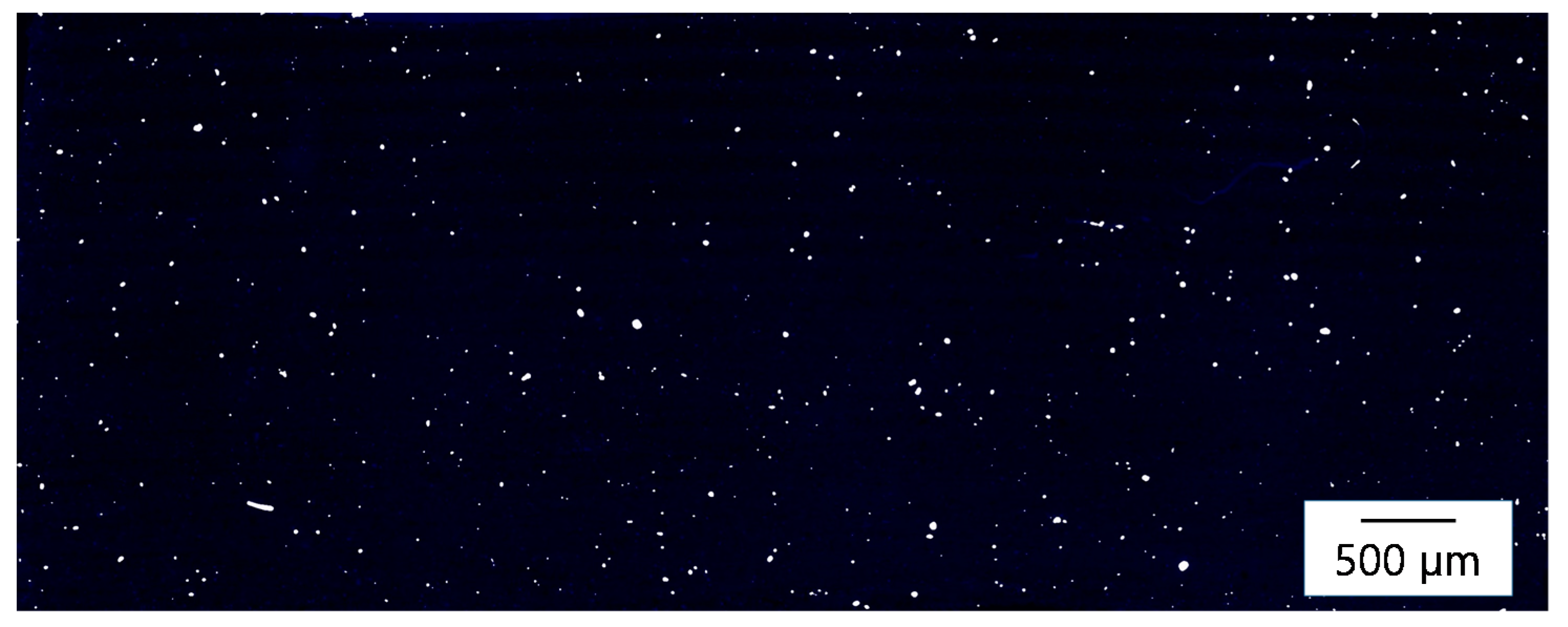

5.3.2. Acquisition of Fluorescence Images and Analysis

5.3.3. Correlation between Image Analysis Data and Physical Properties

5.3.4. Application of the Fluorescence Method to CNF Composites

5.3.5. Prospects for Image Analysis by Fluorescent Staining

6. Challenges and Perspectives

- Issues for WPC: In order to further promote the use of WPC for automotive components, improved impact resistance is required. Currently, there are no realistic measures to enhance the impact resistance of common WPC based on PP, but the fracture phenomenon should be clarified. For this purpose, analysis of the morphology by the fluorescent labeling of impact fracture surfaces would provide intuitive data. The behavior can also be discussed with the data showing the degree of interfacial adhesion.

- Simulation of mechanical properties: It is desirable to consider how to theoretically create materials with higher performance. In this way, we can break through the limitations of empirical and experimental approaches. Therefore, it is expected that the parameters of interfacial adhesion and filler dispersibility will be incorporated into the structural analysis such as the finite element method (FEM). These parameters are not limited to dummy variables but can be continuous explanatory ones.

- Providing explanatory variables for process informatics: The concept can also be used for so-called process informatics [85], which is an effort in data science. Some of the explanatory variables can be shared with FEM. Objective variables include formability, weatherability, and product life.

- Extension to other materials: The primary experimental point for the multiscale analysis discussed in this review paper was the enrichment of binding sites between the filler and MAPP by removing cellulose by enzymatic hydrolysis. On the other hand, components can be selectively extracted from non-cellulosic composites as long as a solvent is available. In addition, the swollen-state NMR has a wide range of applications and the ordinary DSC can classify the performance of the acid-modified resin compatibilizers. By applying organic or physicochemical techniques to the multiscale analysis, useful information may thus be obtained for plastic composites reinforced with glass or carbon fibers, and for material systems such as adhesion, lamination, and surface modification.

7. Concluding Remarks

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Felix, J.M.; Gatenholm, P. Formation of Entanglements at Brushlike Interfaces in Cellulose–Polymer Composites. J. Appl. Polym. Sci. 1993, 50, 699–708. [Google Scholar] [CrossRef]

- Niwa, S.; Saito, Y.; Ito, M.; Ogoe, S.; Ito, H.; Sunaga, Y.; Aoki, K.; Endo, T.; Teramoto, Y. Direct Spectroscopic Detection of Binding Formation by Kneading of Biomass Filler and Acid-Modified Resin. Polymer 2017, 125, 161–171. [Google Scholar] [CrossRef]

- Lee, K.Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the Use of Nanocellulose as Reinforcement in Polymer Matrix Composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Oksman, K.; Aitomäki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.; Hooshmand, S. Review of the Recent Developments in Cellulose Nanocomposite Processing. Compos. Part A Appl. Sci. Manuf. 2016, 83, 2–18. [Google Scholar] [CrossRef] [Green Version]

- Chakrabarty, A.; Teramoto, Y. Recent Advances in Nanocellulose Composites with Polymers: A Guide for Choosing Partners and How to Incorporate Them. Polymers 2018, 10, 517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferreira, F.V.; Trindade, G.N.; Lona, L.M.F.; Bernardes, J.S.; Gouveia, R.F. LDPE-Based Composites Reinforced with Surface Modified Cellulose Fibres: 3D Morphological and Morphometrical Analyses to Understand the Improved Mechanical Performance. Eur. Polym. J. 2019, 117, 105–113. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A Review on New Bio-Based Constituents for Natural Fiber-Polymer Composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Nabi Saheb, D.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Yang, T.H.; Leu, S.Y.; Yang, T.H.; Lo, S.F. Optimized Material Composition to Improve the Physical and Mechanical Properties of Extruded Wood-Plastic Composites (WPCs). Constr. Build. Mater. 2012, 29, 120–127. [Google Scholar] [CrossRef]

- Sunaga, Y.; Ogoe, S.; Aoki, K.; Ito, H.; Teramoto, Y. Profitable Mass-Production of Acid-Modified Recovered Resins for Value-Added Mechanical Recycling as a Compatibilizer for Composites. ACS Sustain. Chem. Eng. 2018, 6, 12110–12118. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural Fiber Eco-Composites. Polym. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, A. History of Wood Plastics. Wood Ind. 2012, 67, 466–469. (In Japanese) [Google Scholar]

- Kikuchi, T. WPRC (Wood Plastic Recycled Composite) Market Trends. J. Transl. Crit. Care Med. 2016, 52, 26–27. (In Japanese) [Google Scholar]

- Bledzki, A.K.; Faruk, O.; Sperber, V.E. Cars from Bio-Fibres. Macromol. Mater. Eng. 2006, 291, 449–457. [Google Scholar] [CrossRef]

- Bledzki, A.; Gassan, J. Composites Reinforced with Cellulose Based Fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A Review on Interface Modification and Characterization of Natural Fiber Reinforced Plastic Composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Móczó, J.; Pukánszky, B. Polymer Micro and Nanocomposites: Structure, Interactions, Properties. J. Ind. Eng. Chem. 2008, 14, 535–563. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Surface Modifications of Natural Fibers and Performance of the Resulting Biocomposites: An Overview. J. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical Modification of Hemp, Sisal, Jute, and Kapok Fibers by Alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane Coupling Agents Used for Natural Fiber/Polymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Stark, N.M.; Rowlands, R.E. Effects of Wood Fiber Characteristics on Mechanical Properties of Wood/Polypropylene Composites. Wood Fiber Sci. 2003, 35, 167–174. [Google Scholar]

- Salemane, M.G.; Luyt, A.S. Thermal and Mechanical Properties of Polypropylene-Wood Powder Composites. J. Appl. Polym. Sci. 2006, 100, 4173–4180. [Google Scholar] [CrossRef]

- Kim, J.K.; Pal, K. Recent Advances in the Processing of Wood-Plastic Composites; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Iwamoto, S.; Yamamoto, S.; Lee, S.H.; Endo, T. Solid-State Shear Pulverization as Effective Treatment for Dispersing Lignocellulose Nanofibers in Polypropylene Composites. Cellulose 2014, 21, 1573–1580. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Milling-Induced Esterification between Cellulose and Maleated Polypropylene. J. Appl. Polym. Sci. 2004, 91, 1703–1709. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Effect of Maleated Polypropylene on the Performance of Polypropylene/Cellulose Composite. Polym. Compos. 2005, 26, 448–453. [Google Scholar] [CrossRef]

- Maleic Anhydride; Trivedi, B. (Ed.) Springer Science & Business Media: New York, NY, USA, 2013; Originally published by Plenum Press (New York, NY, USA) in 1982. [Google Scholar]

- Zhang, M.; Colby, R.H.; Milner, S.T.; Chung, T.C.M.; Huang, T.; Degroot, W. Synthesis and Characterization of Maleic Anhydride Grafted Polypropylene with a Well-Defined Molecular Structure. Macromolecules 2013, 46, 4313–4323. [Google Scholar] [CrossRef]

- Niwa, S.; Ogawa, T.; Ogoe, S.; Teramoto, Y. Wetting and Localization of Compatibilizers in Biocomposites: A Nanoscale Evaluation and Effects on Physical Properties. Polymer 2019, 185, 121963. [Google Scholar] [CrossRef]

- Kishi, H.; Yoshioka, M.; Yamanoi, A.; Shiraishi, N. Composites of Wood and Polypropylens I. Mokuzai Gakkaishi 1988, 34, 133–139. [Google Scholar]

- Felix, J.M.; Gatenholm, P. Nature of Adhesion in Composites of Modified Cellulose Fibers and Polypropylene. J. Appl. Polym. Sci. 1991, 42, 609–620. [Google Scholar] [CrossRef]

- Li, Q.; Matuana, L.M. Surface of Cellulosic Materials Modified with Functionalized Polyethylene Coupling Agents. J. Appl. Polym. Sci. 2003, 88, 278–286. [Google Scholar] [CrossRef]

- Park, B.D.; Wi, S.G.; Lee, K.H.; Singh, A.P.; Yoon, T.H.; Kim, Y.S. X-Ray Photoelectron Spectroscopy of Rice Husk Surface Modified with Maleated Polypropylene and Silane. Biomass Bioenergy 2004, 27, 353–363. [Google Scholar] [CrossRef]

- Matsuda, H.; Ueda, M.; Murakami, K. Preparation and Utilization of Esterified Woods Bearing Carboxyl Groups. II. Esterification of Wood with Dicarboxylic Acid Anhydrides in the Absence of Solvent. Mokuzai Gakkaishi 1984, 30, 1003–1010. [Google Scholar]

- Hristov, V.; Vasileva, S. Dynamic Mechanical and Thermal Properties of Modified Poly(Propylene) Wood Fiber Composites. Macromol. Mater. Eng. 2003, 288, 798–806. [Google Scholar] [CrossRef]

- Miyauchi, K.; Saito, K. Direct Analysis of Graft Structure of Maleic Anhydride Grafted Polypropylene by Nuclear Magnetic Resonance Spectroscopy. Bunseki Kagaku 2006, 55, 547–554. [Google Scholar] [CrossRef] [Green Version]

- Maiti, P.; Nam, P.H.; Okamoto, M.; Hasegawa, N.; Usuki, A. Influence of Crystallization on Intercalation, Morphology, and Mechanical Properties of Polypropylene/Clay Nanocomposites. Macromolecules 2002, 35, 2042–2049. [Google Scholar] [CrossRef]

- Ogawa, T.; Ogoe, S.; Asoh, T.; Uyama, H.; Teramoto, Y. Fluorescent Labeling and Image Analysis of Cellulosic Fillers in Biocomposites: Effect of Added Compatibilizer and Correlation with Physical Properties. Compos. Sci. Technol. 2020, 198, 108277. [Google Scholar] [CrossRef]

- Rude, E.; Laborie, M.P.G. Carbon-13 Cross-Polarization Magic-Angle-Spinning Nuclear Magnetic Resonance Investigation of the Interactions between Maleic Anhydride Grafted Polypropylene and Wood Polymers. Appl. Spectrosc. 2008, 62, 563–568. [Google Scholar] [CrossRef] [PubMed]

- de Miguel, Y.R.; Bampos, N.; Nalin de Silva, K.M.; Sanders, J.K.M.; Richards, S.A. Gel Phase MAS 1H NMR as a Probe for Supramolecular Interactions at the Solid–Liquid Interface. Chem. Commun. 1998, 2267–2268. [Google Scholar] [CrossRef]

- Kim, H.; Ralph, J.; Akiyama, T. Solution-State 2D NMR of Ball-Milled Plant Cell Wall Gels in DMSO-d6. BioEnergy Res. 2008, 1, 56–66. [Google Scholar] [CrossRef]

- Kim, H.; Ralph, J. Solution-State 2D NMR of Ball-Milled Plant Cell Wall Gels in DMSO-D6/Pyridine-D5. Org. Biomol. Chem. 2010, 8, 576–591. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Ralph, J. A Gel-State 2D-NMR Method for Plant Cell Wall Profiling and Analysis: A Model Study with the Amorphous Cellulose and Xylan from Ball-Milled Cotton Linters. RSC Adv. 2014, 4, 7549–7560. [Google Scholar] [CrossRef]

- Terrill, R.H.; Postlethwaite, T.A.; Chen, C.H.; Poon, C.D.; Terzis, A.; Chen, A.; Hutchison, J.E.; Clark, M.R.; Wignall, G.; Londono, J.D.; et al. Monolayers in Three Dimensions: NMR, SAXS, Thermal, and Electron Hopping Studies of Alkanethiol Stabilized Gold Clusters. J. Am. Chem. Soc. 1995, 117, 12537–12548. [Google Scholar] [CrossRef]

- Tang, B.Z.; Xu, H. Preparation, Alignment, and Optical Properties of Soluble Poly(Phenylacetylene)-Wrapped Carbon Nanotubes. Macromolecules 1999, 32, 2569–2576. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Fernando, S.; Allard, L.F.; Sun, Y.P. Solubilization of Single-Walled Carbon Nanotubes with Diamine-Terminated Oligomeric Poly(Ethylene Glycol) in Different Functionalization Reactions. Nano Lett. 2003, 3, 565–568. [Google Scholar] [CrossRef]

- Jiang, F.; Dallas, J.L.; Ahn, B.K.; Hsieh, Y.L. 1D and 2D NMR of Nanocellulose in Aqueous Colloidal Suspensions. Carbohydr. Polym. 2014, 110, 360–366. [Google Scholar] [CrossRef] [Green Version]

- Pukánszky, B.; Tüdös, F. Indirect Determination of Interphase Thickness from the Mechanical Properties of Particulate Filled Polymers. In Controlled Interphases in Composite Materials; Ishida, H., Ed.; Springer: Dordrecht, The Netherlands, 1990; pp. 691–700. [Google Scholar] [CrossRef]

- Nielsen, L.E. Mechanical Properties of Polymers and Composites; Marcel Dekker: New York, NY, USA, 1974. [Google Scholar]

- Nishio, Y. Material Functionalization of Cellulose and Related Polysaccharides via Diverse Microcompositions. Adv. Polym. Sci. 2006, 205, 97–151. [Google Scholar] [CrossRef]

- Nishio, Y.; Teramoto, Y.; Kusumi, R.; Sugimura, K.; Aranishi, Y. Blends and Graft Copolymers of Cellulosics: Toward the Design and Development of Advanced Films and Fibers; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Amash, A.; Zugenmaier, P. Study on Cellulose and Xylan Filled Polypropylene Composites. Polym. Bull. 1998, 40, 251–258. [Google Scholar] [CrossRef]

- Menczel, J.; Varga, J. Influence of Nucleating Agents on Crystallization of Polypropylene-I. Talc as a Nucleating Agent. J. Therm. Anal. 1983, 28, 161–174. [Google Scholar] [CrossRef]

- Fujiyama, M.; Wakino, T. Structures and Properties of Injection Moldings of Crystallization Nucleator-Added Polypropylenes. 1. Structure-Property Relationships. J. Appl. Polym. Sci. 1991, 42, 2739–2747. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, Y.; Zhang, X. Maleated Polypropylene as a Coupling Agent for Polypropylene-Waste Newspaper Flour Composites. J. Appl. Polym. Sci. 1999, 71, 333–337. [Google Scholar] [CrossRef]

- Son, S.J.; Lee, Y.M.; Im, S.S. Transcrystalline Morphology and Mechanical Properties in Polypropylene Composites Containing Cellulose Treated with Sodium Hydroxide and Cellulase. J. Mater. Sci. 2000, 35, 5767–5778. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K.; Tripathy, S.S. Influence of Fiber Treatment on the Performance of Sisal-Polypropylene Composites. J. Appl. Polym. Sci. 2004, 94, 1336–1345. [Google Scholar] [CrossRef]

- Huang, C.W.; Yang, T.C.; Hung, K.C.; Xu, J.W.; Wu, J.H. The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites. Polymers 2018, 10, 382. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turcsányi, B.; Pukánszky, B.; Tüdõs, F. Composition Dependence of Tensile Yield Stress in Filled Polymers. J. Mater. Sci. Lett. 1988, 7, 160–162. [Google Scholar] [CrossRef]

- Pukánszky, B.; Fekete, E.; Tüdós, F. Surface Tension and Mechanical Properties in Polyolefin Composites. Makromol. Chemie. Macromol. Symp. 1989, 28, 165–186. [Google Scholar] [CrossRef]

- Pukánszky, B.; Tüdös, F.; Jančař, J.; Kolařik, J. The Possible Mechanisms of Polymer-Filler Interaction in Polypropylene-CaCO3 Composites. J. Mater. Sci. Lett. 1989, 8, 1040–1042. [Google Scholar] [CrossRef]

- Pukánszky, B. Influence of Interface Interaction on the Ultimate Tensile Properties of Polymer Composites. Composites 1990, 21, 255–262. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S.; Pharr, G.M.; Xu, H. Evaluation of Interphase Properties in a Cellulose Fiber-Reinforced Polypropylene Composite by Nanoindentation and Finite Element Analysis. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1517–1524. [Google Scholar] [CrossRef]

- Han, G.S.; Saka, S.; Shiraishi, N. Composites of Wood and Polypropylenes V. Morphological Study of Composite by TEM-EDXA. Mokuzai Gakkaishi 1991, 37, 241–246. [Google Scholar]

- López Manchado, M.A.; Arroyo, M.; Biagiotti, J.; Kenny, J.M. Enhancement of Mechanical Properties and Interfacial Adhesion of PP/EPDM/Flax Fiber Composites Using Maleic Anhydride as a Compatibilizer. J. Appl. Polym. Sci. 2003, 90, 2170–2178. [Google Scholar] [CrossRef]

- Oksman, K.; Clemons, C. Mechanical Properties and Morphology of Impact Modified Polypropylene–Wood Flour Composites. J. Appl. Polym. Sci. 1998, 67, 1503–1513. [Google Scholar] [CrossRef]

- Tanaka, H.; Hayashi, T.; Nishi, T. Digital Image Analysis of Droplet Patterns in Polymer Systems: Point Pattern. J. Appl. Phys. 1989, 65, 4480–4495. [Google Scholar] [CrossRef]

- Karásek, L.; Sumita, M. Characterization of Dispersion State of Filler and Polymer-Filler Interactions in Rubber-Carbon Black Composites. J. Mater. Sci. 1996, 31, 281–289. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.; Lin, Z.; Zhu, L.; Tannenbaum, A.; Bouix, S.; Wong, C.P. Automated Dispersion and Orientation Analysis for Carbon Nanotube Reinforced Polymer Composites. Nanotechnology 2012, 23, 435706. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Gao, Y.; Moon, K.S.; Yao, Y.; Tannenbaum, A.; Wong, C.P. Automatic Quantification of Filler Dispersion in Polymer Composites. Polymer 2012, 53, 1571–1580. [Google Scholar] [CrossRef]

- Peretz, R.; Mamane, H.; Sterenzon, E.; Gerchman, Y. Rapid Quantification of Cellulose Nanocrystals by Calcofluor White Fluorescence Staining. Cellulose 2019, 26, 971–977. [Google Scholar] [CrossRef]

- Goi, Y.; Fujisawa, S.; Saito, T.; Yamane, K.; Kuroda, K.; Isogai, A. Dual Functions of TEMPO-Oxidized Cellulose Nanofibers in Oil-in-Water Emulsions: A Pickering Emulsifier and a Unique Dispersion Stabilizer. Langmuir 2019, 35, 10920–10926. [Google Scholar] [CrossRef] [PubMed]

- Harper, D.P.; Wolcott, M.P. Chemical Imaging of Wood-Polypropylene Composites. Appl. Spectrosc. 2006, 60, 898–905. [Google Scholar] [CrossRef]

- Tsuchikawa, S.; Kobori, H. A Review of Recent Application of near Infrared Spectroscopy to Wood Science and Technology. J. Wood Sci. 2015, 61, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Zhong, J.; Li, Z.; Guan, W.; Lu, C. Cation-π Interaction Triggered-Fluorescence of Clay Fillers in Polymer Composites for Quantification of Three-Dimensional Macrodispersion. Anal. Chem. 2017, 89, 12472–12479. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Kang, M.; Lu, A.; Chen, L.; Song, L.; Sun, R. Visualization of Silica Dispersion States in Silicone Rubber by Fluorescent Labeling. J. Mater. Sci. 2018, 54, 5149–5159. [Google Scholar] [CrossRef]

- Lv, X.; Kang, M.; Chen, K.; Yuan, L.; Shen, S.; Sun, R.; Song, L. Preparation of Fluorescent Calcium Carbonate and Visualization of Its Dispersion States in Polypropylene. J. Compos. Mater. 2019, 54, 913–921. [Google Scholar] [CrossRef]

- Haigler, C.H.; Brown, R.M.; Benziman, M. Calcofluor White ST Alters the in Vivo Assembly of Cellulose Microfibrils. Science 1980, 210, 903–906. [Google Scholar] [CrossRef] [PubMed]

- Kazayawoko, M.; Balatinecz, J.J.; Matuana, L.M. Surface Modification and Adhesion Mechanisms in Woodfiber-Polypropylene Composites. J. Mater. Sci. 1999, 34, 6189–6199. [Google Scholar] [CrossRef]

- Cui, X.; Honda, T.; Asoh, T.A.; Uyama, H. Cellulose Modified by Citric Acid Reinforced Polypropylene Resin as Fillers. Carbohydr. Polym. 2020, 230, 115662. [Google Scholar] [CrossRef] [PubMed]

- Kaneko, H.; Funatsu, K. Chemometrics and Intelligent Laboratory Systems Nonlinear Regression Method with Variable Region Selection and Application to Soft Sensors. Chemom. Intell. Lab. Syst. 2013, 121, 26–32. [Google Scholar] [CrossRef]

| Sample Code | wMA (wt%) | Mn /104 | Mw /104 | Mw/Mn | MFR/g/10 min (10 kgf) a | |

|---|---|---|---|---|---|---|

| 180 °C | 230 °C | |||||

| MAPP04 | 0.4 | 5.9 | 43 | 7.4 | 0.2 | 1.5 |

| MAPP08 | 0.8 | 3.4 | 23 | 6.7 | 0.6 | 2.2 |

| MAPP12 | 1.2 | 3.0 | 1.7 | 5.6 | 5.8 | 140 |

| MAPP15 | 1.5 | 1.5 | 8.2 | 5.6 | 12 | 250 |

| MAPP20 | 2.0 | 1.4 | 7.4 | 5.2 | 50 | 630 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teramoto, Y. Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites. J. Compos. Sci. 2021, 5, 138. https://doi.org/10.3390/jcs5050138

Teramoto Y. Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites. Journal of Composites Science. 2021; 5(5):138. https://doi.org/10.3390/jcs5050138

Chicago/Turabian StyleTeramoto, Yoshikuni. 2021. "Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites" Journal of Composites Science 5, no. 5: 138. https://doi.org/10.3390/jcs5050138

APA StyleTeramoto, Y. (2021). Recent Advances in Multi-Scale Experimental Analysis to Assess the Role of Compatibilizers in Cellulosic Filler-Reinforced Plastic Composites. Journal of Composites Science, 5(5), 138. https://doi.org/10.3390/jcs5050138