Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter

Abstract

:1. Introduction

1.1. Compounding of Phenolic Molding Compounds

1.2. At-Line Characterization Techniques

1.3. Differential Scanning Calorimetry

1.4. Aim and Scope of the Present Work

2. Materials and Methods

2.1. Materials

2.2. Twin-Screw Extruder Compounding

2.3. Manufacturing of Test Specimens

2.4. Characterization of Molding Compounds and Molded Test Specimen

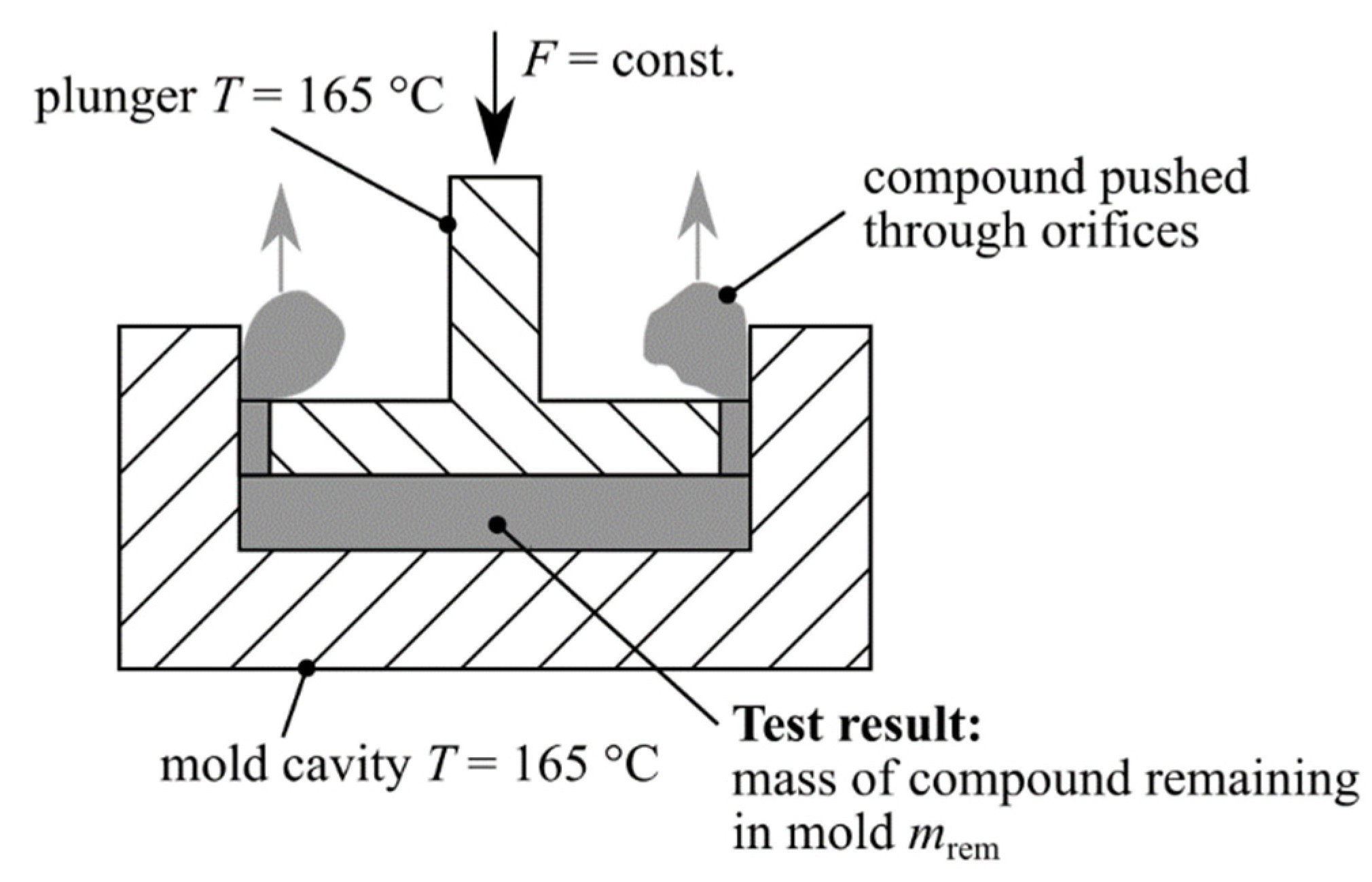

2.4.1. Orifice Flow Test

2.4.2. Differential Scanning Calorimetry

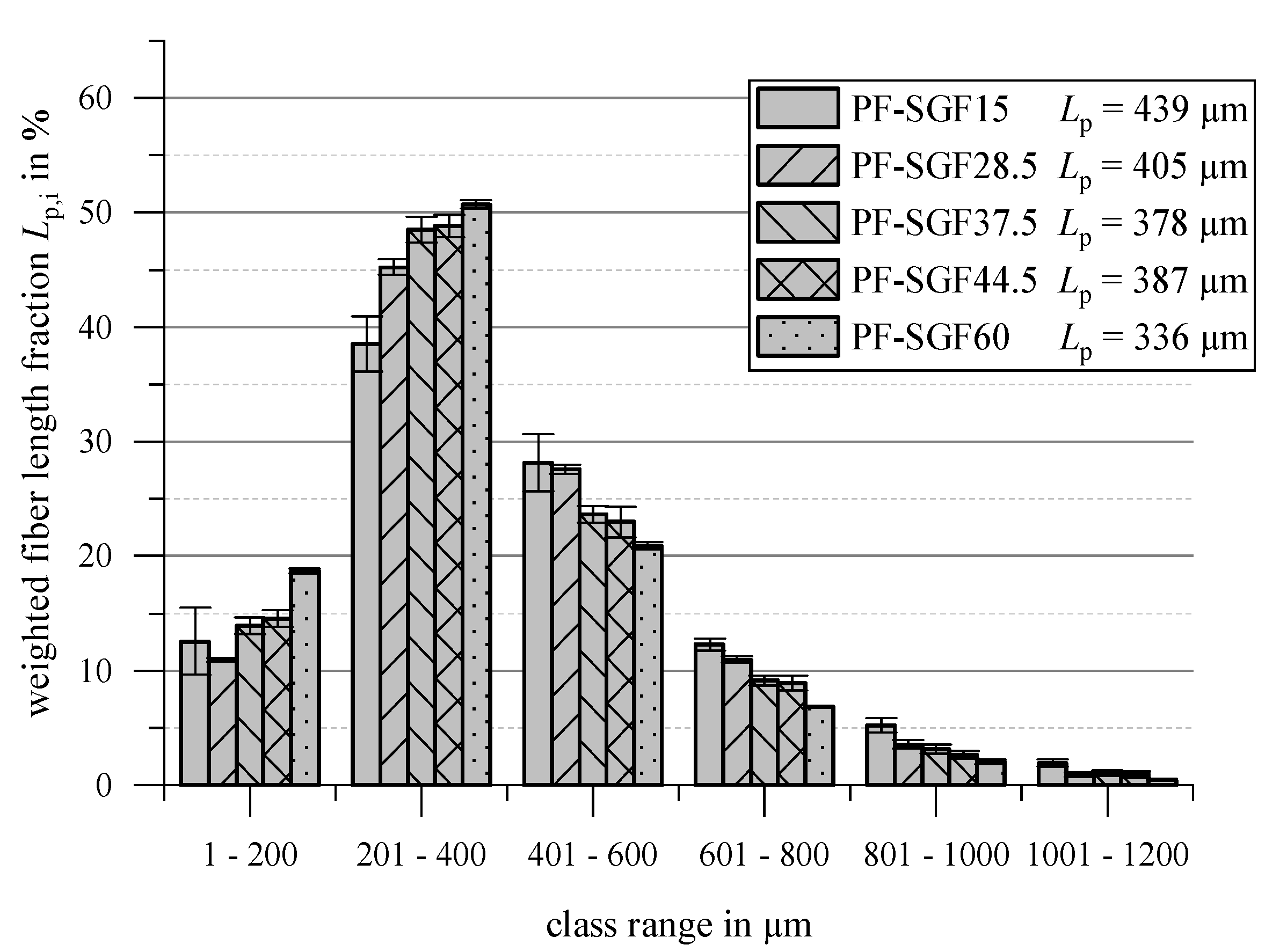

2.4.3. Fiber Length Measurement

2.4.4. Mechanical Characterization

3. Results

3.1. Compounding and Calorimetric Measurements

3.2. Fiber Length Measurement

3.3. Mechanical Testing

4. Discussion

4.1. Compounding and Calorimetric Measurements

4.2. Fiber Length Measurement

4.3. Mechanical Testing

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beran, T.; Hübel, J.; Maertens, R.; Reuter, S.; Gärtner, J.; Köhler, J.; Koch, T. Study of a polymer ejector design and manufacturing approach for a mobile air conditioning. Int. J. Refrig. 2021, 126, 35–44. [Google Scholar] [CrossRef]

- Ball, C. Phenolic molding compounds in automotive powertrain applications. In Proceedings of the 17th Annual Automotive Conference & Exhibition, Novi, MI, USA, 6–8 September 2017. [Google Scholar]

- Jauernick, M.; Pohnert, D.; Kujawski, W.; Otte, R. Hybrid lightweight cylinder crankcase: Challenges and feasibility. MTZ Worldw. 2019, 80, 70–75. [Google Scholar] [CrossRef]

- Schindele, K.; Sorg, T.; Hentschel, T.; Liebertseder, J. Lightweight camshaft module made of high-strength fiber-reinforced plastic. MTZ Worldw. 2020, 81, 26–31. [Google Scholar] [CrossRef]

- Langheck, A.; Reuter, S.; Saburow, O.; Maertens, R.; Wittemann, F.; Berg, L.F.; Doppelbauer, M. Evaluation of an integral injection molded housing for high power density synchronous machines with concentrated single-tooth winding. In Proceedings of the 2018 8th International Electric Drives Production Conference (EDPC), Schweinfurt, Germany, 4–5 December 2018; pp. 187–192. [Google Scholar] [CrossRef]

- Koizumi, K.; Charles, T.; Keyser, H.D. Phenolic molding compounds. In Phenolic Resins: A Century of Progress; Pilato, L.A., Ed.; Springer: Berlin, Germany, 2010; pp. 383–437. ISBN 978-3-642-04713-8. [Google Scholar]

- Wan, J.; Wang, S.; Li, C.; Zhou, D.; Chen, J.; Liu, Z.; Yu, L.; Fan, H.; Li, B.-G. Effect of molecular weight and molecular weight distribution on cure reaction of novolac with hexamethylenetetramine and properties of related composites. Thermochim. Acta 2012, 530, 32–41. [Google Scholar] [CrossRef]

- Chaiwan, P.; Pumchusak, J. The synergistic effects of multi-filler addition on the mechanical and thermo-mechanical properties of phenolic resins. MSF 2018, 940, 23–27. [Google Scholar] [CrossRef]

- Šahinović, A.; Mušič, B. Improvement of the mechanical properties of thermosetting-binding-system-based composites by means of kneading procedure modification and composite formulation. Processes 2020, 8, 625. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Hallouch, M. Compounding of thermosets in continuous kneaders. Adv. Polym. Technol. 1986, 6, 237–249. [Google Scholar] [CrossRef]

- Methe, D.; Gehde, M. Analysis of the flow-curing behavior of chemically foamable phenolic molding compounds in the extrusion process. J. Plast. Technol. 2020, 5, 227–254. [Google Scholar] [CrossRef]

- Rudin, B.; Drummer, D. Heat conductive thermosets for the injection molding process. In Proceedings of the 2012 2nd International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–18 October 2012; IEEE: New York, NY, USA, 2012; pp. 1–4, ISBN 978-1-4673-3008-4. [Google Scholar]

- Tonogai, S.; Hasegawa, K.; Fukuda, A. The disk cure test—An evaluation method for flow and curing characteristics of thermosetting molding compounds. Polym. Eng. Sci. 1980, 20, 985–994. [Google Scholar] [CrossRef]

- Dreiblatt, A.; Canedo, E.L. Distribution of specific energy in twin-screw corotating extruders using one-dimensional process simulation. In ANTEC 2012; Society of Plastics Engineers: Danbury, CT, USA, 2012. [Google Scholar]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Vera-Sorroche, J.; Coates, P.D.; Harkin-Jones, E.; Howell, K.B.; Deng, J.; Li, K.; Price, M. Investigation of the process energy demand in polymer extrusion: A brief review and an experimental study. Appl. Energy 2014, 136, 726–737. [Google Scholar] [CrossRef]

- Inceoglu, F.; Ville, J.; Ghamri, N.; Pradel, J.L.; Durin, A.; Valette, R.; Vergnes, B. Correlation between processing conditions and fiber breakage during compounding of glass fiber-reinforced polyamide. Polym. Compos. 2011, 32, 1842–1850. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B.; Beaugrand, J. Evolution of lignocellulosic fibre lengths along the screw profile during twin screw compounding with polycaprolactone. Compos. Part A Appl. Sci. Manuf. 2014, 59, 30–36. [Google Scholar] [CrossRef]

- Stratiychuk-Dear, D.; Looney, K.; Oliver, P.; Blackburn, S.; Simmons, M. Investigating the impact of operating conditions on the extent of additive mixing during thermoplastic polymer extrusion. In AIP Conference Proceedings 1914, Proceedings of the Pps-32: The 32nd International Conference of The Polymer Processing Society—Conference Papers, Lyon, France, 25–29 July 2016; AIP Publishing: Melville, NY, USA, 2017; p. 150002. [Google Scholar]

- Englich, S. Strukturbildung bei der Verarbeitung von glasfasergefüllten Phenolformaldehydharzformmassen; Universitätsverlag Chemnitz: Chemnitz, Germany, 2015; ISBN 978-3-944640-61-7. [Google Scholar]

- ISO. 7808 Plastics: Thermosetting Moulding Materials—Determination of Transfer Flow; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- ASTM. D3123—09 Standard Test Method for Spiral Flow of Low-Pressure Thermosetting Molding Compounds; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. D569 Method for Measuring the Flow Properties of Thermoplastic Molding Materials, Withdrawn; ASTM: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM. D731−18 Standard Test Method for Molding Index of Thermosetting Molding Powder; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- DIN 53764. Test Method for Flow and Cure Properties of Pourable Thermosettings Using a Torque Rheometer and a Measuring Mixer (Withdrawn); DIN: Berlin, Germany, 1992. [Google Scholar]

- Osswald, T.A.; Rudolph, N. Polymer Rheology: Fundamentals and Applications; Hanser: Munich, Germany, 2014; ISBN 978-1-56990-523-4. [Google Scholar]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; ISBN 9780471769170. [Google Scholar]

- Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rojo, E.; Rodríguez, F. Kinetic study of a phenolic-novolac resin curing process by rheological and DSC analysis. Thermochim. Acta 2010, 498, 39–44. [Google Scholar] [CrossRef]

- Stark, W. Investigation of curing behaviour of melamine/phenolic (MP) thermosets. Polym. Test. 2010, 29, 723–728. [Google Scholar] [CrossRef]

- Scheffler, T. Werkstoffeinflüsse auf den Spritzgussprozess von hochgefüllten Phenol-Formaldehydharz-Formmassen; Universitätsverlag Chemnitz: Chemnitz, Germany, 2018; ISBN 3961000735. [Google Scholar]

- Gardziella, A.; Pilato, L.A.; Knop, A. Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology, 2nd ed.; Springer: Berlin, Germany, 2000; ISBN 3540655174. [Google Scholar]

- Ishida, H.; Rodriguez, Y. Curing kinetics of a new benzoxazine-based phenolic resin by differential scanning calorimetry. Polymer 1995, 36, 3151–3158. [Google Scholar] [CrossRef]

- Alonso, M.V.; Oliet, M.; Pérez, J.M.; Rodríguez, F.; Echeverría, J. Determination of curing kinetic parameters of lignin–phenol–formaldehyde resol resins by several dynamic differential scanning calorimetry methods. Thermochim. Acta 2004, 419, 161–167. [Google Scholar] [CrossRef]

- Park, B.-D.; Riedl, B.; Hsu, E.W.; Shields, J. Differential scanning calorimetry of phenol–formaldehyde resins cure-accelerated by carbonates. Polymer 1999, 40, 1689–1699. [Google Scholar] [CrossRef]

- De Medeiros, E.S.; Agnelli, J.A.M.; Joseph, K.; de Carvalho, L.H.; Mattoso, L.H.C. Curing behavior of a novolac-type phenolic resin analyzed by differential scanning calorimetry. J. Appl. Polym. Sci. 2003, 90, 1678–1682. [Google Scholar] [CrossRef]

- Sumitomo Bakelite Europe n.v. Technical Data Sheet X6952 Green. Available online: https://www.sbhpp.com/products-applications/catalog/item/vyncolit-x6952 (accessed on 8 April 2021).

- 3B Fibreglass. Technical Data Sheet Chopped Strands DS5163-13P. Available online: https://www.3b-fibreglass.com/sites/default/files/products-data-sheets/TDS-DS5163-13P.pdf (accessed on 8 April 2021).

- DIN EN ISO. 11357-5 Differential Scanning Calorimetry (DSC): Determination of Characteristic Reaction-Curve Temperatures and Times, Enthalpy of Reaction and Degree of Conversion (11357-5:2013); DIN: Berlin, Germany, 2014. [Google Scholar]

- Hartwich, M.R.; Höhn, N.; Mayr, H.; Sandau, K.; Stengler, R. FASEP ultra-automated analysis of fibre length distribution in glass-fibre-reinforced products. In Optical Measurement Systems for Industrial Inspection VI; Lehmann, P.H., Ed.; SPIE Europe Optical Metrology: Munich, Germany, 2009. [Google Scholar]

- Maertens, R.; Hees, A.; Schöttl, L.; Liebig, W.V.; Elsner, P.; Weidenmann, K.A. Fiber shortening during injection molding of glass fiber-reinforced phenolic molding compounds: Fiber length measurement method development and validation. Polym. Plast. Technol. Mater. 2021, 60, 872–885. [Google Scholar] [CrossRef]

- DIN EN ISO. 527 Plastic—Determination of Tensile Properties; DIN: Berlin, Germany, 2011. [Google Scholar]

- DIN EN ISO. 179-1 Plastics—Determination of Charpy Impact Properties; DIN: Berlin Germany, 2008. [Google Scholar]

- Kao, S.V.; Allison, G.R. Residence time distribution in a twin screw extruder. Polym. Eng. Sci. 1984, 24. [Google Scholar] [CrossRef]

- Rudolf, R. General overview of the compounding process: Tasks, selected applications, and process zones. In Co-Rotating Twin-Screw Extruders: Fundamentals; Kohlgrüber, K., Ed.; Hanser Publishers: Munich, Germany, 2020; ISBN 978-1-56990-748-1. [Google Scholar]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.-T. Experimental and Theoretical Studies on the Properties of Injection Moulded Glass Fibre Reinforced Mixed Plastics Composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 393–405. [Google Scholar] [CrossRef]

- Goris, S.; Simon, S.; Montoya, C.; Bechara, A.; Candal, M.V.; Brands, D.; Yanev, A.; Osswald, T.A. Experimental study on fiber attrition of long glass fiber-reinforced thermoplastics under controlled conditions in a couette flow. In ANTEC 2017; Society of Plastics Engineers: Danbury, CT, USA, 2017; pp. 600–606. [Google Scholar]

- Meyer, R.; Almin, K.E.; Steenberg, B. Length reduction of fibres subject to breakage. Br. J. Appl. Phys. 1966, 17, 409–416. [Google Scholar] [CrossRef]

- Shon, K.; Liu, D.; White, J.L. Experimental studies and modeling of development of dispersion and fiber damage in continuous compounding. IPP 2005, 20, 322–331. [Google Scholar] [CrossRef]

- Sasayama, T.; Inagaki, M.; Sato, N. Direct simulation of glass fiber breakage in simple shear flow considering fiber-fiber interaction. Compos. Part A Appl. Sci. Manuf. 2019, 124. [Google Scholar] [CrossRef]

- Singh, R.; Chen, F.; Jones, F.R. Injection molding of glass fiber reinforced phenolic composites. 2: Study of the injection molding process. Polym. Compos. 1998, 19, 37–47. [Google Scholar] [CrossRef]

- Englich, S.; Scheffler, T.; Gehde, M. Specific mold filling characteristics of highly filled phenolic injection molding compounds. In ANTEC 2013; Society of Plastics Engineers: Danbury, CT, USA, 2013; pp. 2068–2071. [Google Scholar]

- Kobayashi, T.; Hamada, H. Basic study of thermosetting injection composites. In ANTEC 2015; Society of Plastics Engineers: Danbury, CT, USA, 2015; pp. 2873–2877. [Google Scholar]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part A Appl. Sci. Manuf. 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A.; Schipper, G.; Krikor, H. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: Part 3. Strength and strain at failure. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1075–1084. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. The Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 4. Impact properties. Compos. Part A Appl. Sci. Manuf. 1997, 28, 277–288. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 6. The properties of injection moulded long fibre PP at high fibre content. Compos. Part A Appl. Sci. Manuf. 2005, 36, 995–1003. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Unit | Value |

|---|---|---|

| Plasticizing unit temperature profile inlet—nozzle | °C | 60–70–80–90 |

| Mold temperature | °C | 185 |

| Screw speed | 1/min | 40 |

| Back pressure | bar | 30 |

| Injection speed | cm3/s | 100 |

| Switchover pressure at pressure sensor 2 | bar | 100 |

| Hold pressure stage 1 | bar for s | PF-SGF0: constant 300 bar for 30 s PF-SGF16.7 and PF-SGF28.5: constant 600 bar for 30 s All other formulations: constant 800 bar for 30 s |

| Hold pressure stage 2 | bar to bar in s | ramp from hold pressure stage 1 (300 bar, 600 bar or 800 bar) to 10 bar in 10 s |

| Cure time | s | 110 |

| Elapsed Time in Min | Step End Temperature in °C | Step |

|---|---|---|

| 0 | 25 | start |

| 60 | 150 | linear ramp |

| 120 | 150 | hold |

| 240 | 180 | linear ramp |

| 600 | 180 | hold |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maertens, R.; Liebig, W.V.; Elsner, P.; Weidenmann, K.A. Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter. J. Compos. Sci. 2021, 5, 127. https://doi.org/10.3390/jcs5050127

Maertens R, Liebig WV, Elsner P, Weidenmann KA. Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter. Journal of Composites Science. 2021; 5(5):127. https://doi.org/10.3390/jcs5050127

Chicago/Turabian StyleMaertens, Robert, Wilfried V. Liebig, Peter Elsner, and Kay A. Weidenmann. 2021. "Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter" Journal of Composites Science 5, no. 5: 127. https://doi.org/10.3390/jcs5050127

APA StyleMaertens, R., Liebig, W. V., Elsner, P., & Weidenmann, K. A. (2021). Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter. Journal of Composites Science, 5(5), 127. https://doi.org/10.3390/jcs5050127