Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites

Abstract

1. Introduction

2. Materials and Methods

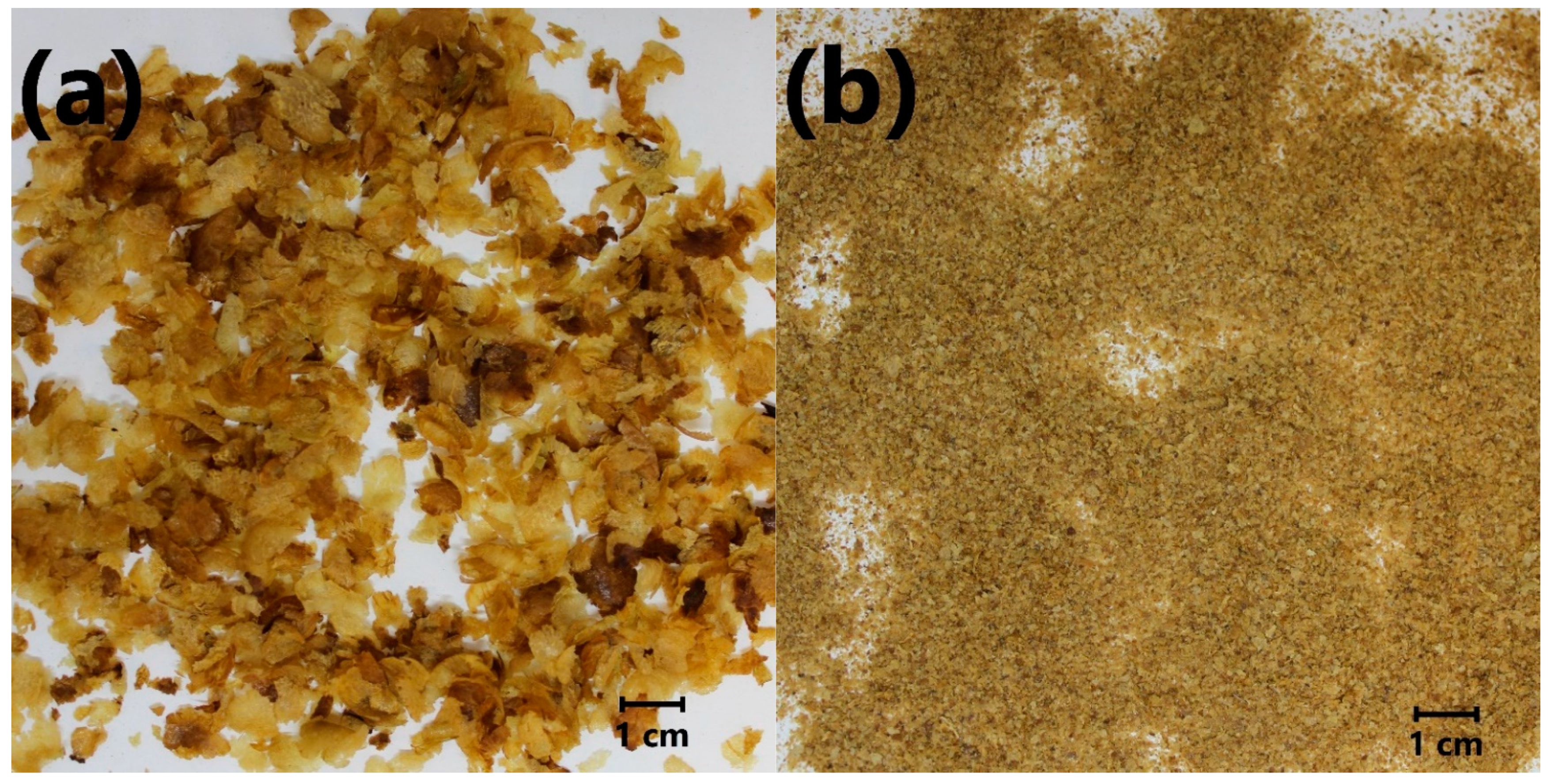

2.1. Materials

2.2. Preparation of Polymer Composites

2.3. Characterization Techniques

3. Results and Discussion

3.1. Melt Flow Index of Prepared Composites

3.2. Physico-Mechanical Performance of Prepared Composites

3.3. Thermal Properties of Prepared Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food Wastage: Key Facts and Figures. Available online: http://www.fao.org/news/story/en/item/196402/icode/ (accessed on 31 December 2020).

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Blinová, L.; Sirotiak, M.; Bartošová, A.; Soldán, M. Review: Utilization of Waste From Coffee Production. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2017, 25, 91–101. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Adams, M.R.; Dougan, J. Waste Products. In Coffee; Clarke, R.J., Macrae, R., Eds.; Springer: Dordrecht, The Netherlands, 1987; pp. 257–291. [Google Scholar] [CrossRef]

- Bharat Helkar, P.; Sahoo, A. Review: Food Industry By-Products used as a Functional Food Ingredients. Int. J. Waste Resour. 2016, 6, 1000248. [Google Scholar] [CrossRef]

- Leal, H.A.; Babetto, A.S.; Bonse, B.C. Properties of lignocellulosic composites of coffee husk filled polypropylene. AIP Conf. Proc. 2020, 2205, 020072. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of Bio-Based Products on Waste Management. Sustainability 2020, 12, 2088. [Google Scholar] [CrossRef]

- Mazur, K.; Jakubowska, P.; Romańska, P.; Kuciel, S. Green high density polyethylene (HDPE) reinforced with basalt fiber and agricultural fillers for technical applications. Compos. Part B Eng. 2020, 202, 108399. [Google Scholar] [CrossRef]

- Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials 2020, 13, 2595. [Google Scholar] [CrossRef]

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.S.; Song, H.; Kim, K.H.; Kwon, E.E.; Jeon, Y.J. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef]

- Sanchez-Vazquez, S.A.; Hailes, H.C.; Evans, J.R.G. Hydrophobic Polymers from Food Waste: Resources and Synthesis. Polym. Rev. 2013, 53, 627–694. [Google Scholar] [CrossRef]

- Jaisan, C.; Punbusayakul, N. Development of Coffee Pulp Extract-Incorporated Chitosan Film and Its Antimicrobial and Antioxidant Activities. KKU Res. J. 2016, 21, 140–149. [Google Scholar] [CrossRef]

- Mirón-Mérida, V.A.; Yáñez-Fernández, J.; Montañez-Barragán, B.; Barragán Huerta, B.E. Valorization of coffee parchment waste (Coffea arabica) as a source of caffeine and phenolic compounds in antifungal gellan gum films. LWT–Food Sci. Technol. 2019, 101, 167–174. [Google Scholar] [CrossRef]

- Garcia-Serna, E.; Martinez-Saez, N.; Mesias, M.; Morales, F.J.; del Castillo, M.D. Use of Coffee Silverskin and Stevia to Improve the Formulation of Biscuits. Pol. J. Food Nutr. Sci. 2014, 64, 243–251. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Review on utilization and composition of coffee silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Conde, T.; Mussatto, S.I. Isolation of polyphenols from spent coffee grounds and silverskin by mild hydrothermal pretreatment. Prep. Biochem. Biotechnol. 2015, 46, 406–409. [Google Scholar] [CrossRef] [PubMed]

- Moraczewski, K.; Stepczyńska, M.; Malinowski, R.; Karasiewicz, T.; Jagodziński, B.; Rytlewski, P. The Effect of Accelerated Aging on Polylactide Containing Plant Extracts. Polymers 2019, 11, 575. [Google Scholar] [CrossRef]

- Ochoa, D.; Rojas-Vargas, J.; Costa, Y. Characterization of NaOH-Treated Colombian Silverskin Coffee Fiber as a Composite Reinforcement. BioResources 2017, 12, 8803–8812. [Google Scholar]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-Polyethylene-Based Composites Reinforced with Alkali and Palmitoyl Chloride-Treated Coffee Silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of Green Particulate Composites from PLA and PBS Matrix and Wastes Deriving from the Coffee Production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crop. Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Hejna, A. Potential applications of by-products from the coffee industry inpolymer technology—Current state and perspectives. Waste Manag. 2021, 121, 296–330. [Google Scholar] [CrossRef] [PubMed]

- Behrouzian, F.; Amini, A.M.; Alghooneh, A.; Razavi, S.M.A. Characterization of dietary fiber from coffee silverskin: An optimization study using response surface methodology. Bioact. Carbohydr. Diet. Fibre 2016, 8, 58–64. [Google Scholar] [CrossRef]

- Costa, A.S.G.; Alves, R.C.; Vinha, A.F.; Costa, E.; Costa, C.S.G.; Nunes, M.A.; Almeida, A.A.; Santos-Silva, A.; Oliveira, M.B.P.P. Nutritional, chemical and antioxidant/pro-oxidant profiles of silverskin, a coffee roasting by-product. Food Chem. 2018, 267, 28–35. [Google Scholar] [CrossRef]

- Toschi, T.G.; Cardenia, V.; Bonaga, G.; Mandrioli, M.; Rodriguez-Estrada, M.T. Coffee Silverskin: Characterization, Possible Uses, and Safety Aspects. J. Agric. Food Chem. 2014, 62, 10836–10844. [Google Scholar] [CrossRef]

- Napolitano, A.; Fogliano, V.; Tafuri, A.; Ritieni, A. Natural occurrence of ochratoxin A and antioxidant activities of green and roasted coffees and corresponding byproducts. J. Agric. Food Chem. 2007, 55, 10499–10504. [Google Scholar] [CrossRef]

- Ateş, G.; Elmacı, Y. Physical, chemical and sensory characteristics of fiber-enriched cakes prepared with coffee silverskin as wheat flour substitution. Food Meas. 2019, 13, 755–763. [Google Scholar] [CrossRef]

- Janissen, B.; Huynh, T. Chemical composition and value-adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between processing parameters and deg-radation of different polylactide grades during twin-screw extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef] [PubMed]

- Mirabella, F.M.; Bafna, A. Determination of the crystallinity of polyethylene/?-olefin copolymers by thermal analysis: Relationship of the heat of fusion of 100% polyethylene crystal and the density. J. Polym. Sci. Pol. Phys. 2002, 40, 1637–1643. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Isocyanate as a compatibilizing agent on the properties of highly crystalline cellulose/polypropylene composites. J. Mater. Sci. 2005, 40, 3607–3614. [Google Scholar] [CrossRef]

- Kloziński, A.; Barczewski, M. Comparison of off-line, on-line and in-line measuring techniques used for determining the rheological characteristics of polyethylene composites with calcium carbonate. Polimery 2019, 64, 83–92. [Google Scholar] [CrossRef]

- Hejna, A.; Formela, K.; Saeb, M.R. Processing, mechanical and thermal behavior assessments of polycaprolactone/agricultural wastes biocomposites. Ind. Crop. Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- D’Antò, V.; Muraglie, S.; Castellano, B.; Candida, E.; Sfondrini, M.F.; Scribante, A.; Grippaudo, C. Influence of Dental Composite Viscosity in Attachment Reproduction: An Experimental in Vitro Study. Materials 2019, 12, 4001. [Google Scholar] [CrossRef]

- Aranguren, M.I.; Mora, E.; DeGroot, J.V.; Macosko, C.W. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 1992, 36, 1165–1182. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Kosmela, P.; Barczewski, M.; Hejna, A. Mechanical, Thermal and Rheological Properties of Polyethylene-Based Composites Filled with Micrometric Aluminum Powder. Materials 2020, 13, 1242. [Google Scholar] [CrossRef]

- Gent, M.R.; Menendez, M.; Toraño, J.; Diego, I. Recycling of plastic waste by density separation: Prospects for optimization. Waste Manag. Res. 2009, 27, 175–187. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2018, 002199831877215. [Google Scholar] [CrossRef]

- Keskisaari, A.; Butylina, S.; Kärki, T. Use of construction and demolition wastes as mineral fillers in hybrid wood-polymer composites. J. Appl. Polym. Sci. 2016, 133, 43412. [Google Scholar] [CrossRef]

- Salasinska, K.; Polka, M.; Gloc, M.; Ryszkowska, J. Natural fiber composites: The effect of the kind and content of filler on the dimensional and fire stability of polyolefin-based composites. Polimery 2016, 61, 255–265. [Google Scholar] [CrossRef]

- Birt, E.A.; Smith, R.A. A review of NDE methods for porosity measurement in fibre-reinforced polymer composites. Insight Non-Destr. Test. Cond. Monit. 2004, 46, 681–686. [Google Scholar] [CrossRef]

- Michalska-Pożoga, I.; Rydzkowski, T. The effect of extrusion conditions for a screw-disk plasticizing system on the mechanical properties of wood-polymer composites (WPC). Polimery 2016, 61, 202–212. [Google Scholar] [CrossRef]

- Chan, C.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Processing and characterisation of polyhydroxyalkanoate (PHA)-based wood plastic composites: Effect of non-reactive additives. Appita J. 2016, 69, 352–360. [Google Scholar]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Barczewski, M.; Szostak, M.; Nowak, D.; Piasecki, A. Effect of wood flour addition and modification of its surface on the properties of rotationally molded polypropylene composites. Polimery 2018, 63, 772–784. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Khoja, S. Brittleness and toughness of polymers and other materials. Mater. Lett. 2015, 159, 478–480. [Google Scholar] [CrossRef]

- Abdalla, M.; Dean, D.; Adibempe, D.; Nyairo, E.; Robinson, P.; Thompson, G. The effect of interfacial chemistry on molecular mobility and morphology of multiwalled carbon nanotubes epoxy nanocomposite. Polymer 2007, 48, 5662–5670. [Google Scholar] [CrossRef]

- Kubát, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W. Thermal and Dielectric Properties of the Aluminum Particle Reinforced Linear Low-Density Polyethylene Composites. Polym. Eng. Sci. 2011, 51, 917–924. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P. Insights into Compatibilization of Poly(ε-caprolactone)-based Biocomposites with Diisocyanates as Modifiers of Cellulose Fillers. Mindanao J. Sci. Technol. 2020, 18, 221–241. [Google Scholar]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Inhibition of Polymer Photodegradation by Incorporation of Coffee Silverskin. Proceedings 2020, 4, 7219. [Google Scholar] [CrossRef]

| Parameter | Sample | |||||

|---|---|---|---|---|---|---|

| PE | PE/1ŁK | PE/2ŁK | PE/5ŁK | PE/10ŁK | PE/20ŁK | |

| E’ at 25 °C, MPa | 1637 | 1686 | 1882 | 1967 | 1998 | 2121 |

| E’ at −120 °C, MPa | 4372 | 4206 | 4565 | 4662 | 4783 | 5086 |

| C factor | 1.000 | 0.934 | 0.908 | 0.888 | 0.896 | 0.898 |

| Brittleness, 1010 %·Pa | 0.0080 | 0.3231 | 0.3580 | 0.4572 | 0.6466 | 1.0589 |

| E” at 25 °C, MPa | 103.6 | 99.8 | 108.9 | 114.2 | 115.3 | 120.6 |

| tan δ at 25 °C | 0.0633 | 0.0592 | 0.0581 | 0.0577 | 0.0579 | 0.0570 |

| A factor at 25 °C | - | −0.0586 | −0.0696 | −0.0566 | −0.0179 | 0.0507 |

| Tg, °C | −111.0 | −111.8 | −112.2 | −113.1 | −113.4 | −113.9 |

| tan δ at Tg | 0.0495 | 0.0486 | 0.0479 | 0.0465 | 0.0444 | 0.0424 |

| Cv, % | 0 | 1.50 | 2.88 | 5.32 | 8.96 | 12.74 |

| XCv | 0 | 1.50 | 1.44 | 1.06 | 0.90 | 0.64 |

| Sample | Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Tc, °C | ΔHc, J/g | Tm, °C | ΔHm, J/g | Xcr, % | ΔT, °C | OIT, min | |

| PE | 112.8 | −190.0 | 134.1 | 187.4 | 63.83 | 21.3 | 20.0 |

| PE/1ŁK | 113.1 | −192.8 | 133.2 | 190.5 | 65.54 | 20.1 | 54.8 |

| PE/2ŁK | 113.0 | −191.7 | 134.1 | 188.9 | 65.65 | 21.1 | 83.9 |

| PE/5ŁK | 113.3 | −189.4 | 133.3 | 186.5 | 66.87 | 20.0 | 131.9 |

| PE/10ŁK | 113.4 | −178.1 | 133.0 | 174.5 | 66.04 | 19.6 | 139.5 |

| PE/20ŁK | 112.5 | −159.2 | 132.6 | 156.4 | 66.59 | 20.1 | 140.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. J. Compos. Sci. 2021, 5, 44. https://doi.org/10.3390/jcs5020044

Hejna A, Barczewski M, Kosmela P, Mysiukiewicz O, Kuzmin A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. Journal of Composites Science. 2021; 5(2):44. https://doi.org/10.3390/jcs5020044

Chicago/Turabian StyleHejna, Aleksander, Mateusz Barczewski, Paulina Kosmela, Olga Mysiukiewicz, and Anton Kuzmin. 2021. "Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites" Journal of Composites Science 5, no. 2: 44. https://doi.org/10.3390/jcs5020044

APA StyleHejna, A., Barczewski, M., Kosmela, P., Mysiukiewicz, O., & Kuzmin, A. (2021). Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. Journal of Composites Science, 5(2), 44. https://doi.org/10.3390/jcs5020044