Using Graphene Nanoplatelets Nanofluid in a Closed-Loop Evacuated Tube Solar Collector—Energy and Exergy Analysis

Abstract

:1. Introduction

2. Analytical Methodology

2.1. Energy Efficiency

2.2. Exergy Efficiency

- The potential energy is negligible.

- The kinetic energy is negligible.

- The thermophysical properties of the nanofluids are constant.

- The work transfer from the system is a positive value.

- The flow rate is steady.

- The system is in steady-state conditions.

2.3. Pressure Drop

2.4. Pumping Power

2.5. Entropy Generation

2.6. Bejan Number

3. Experimental Procedures

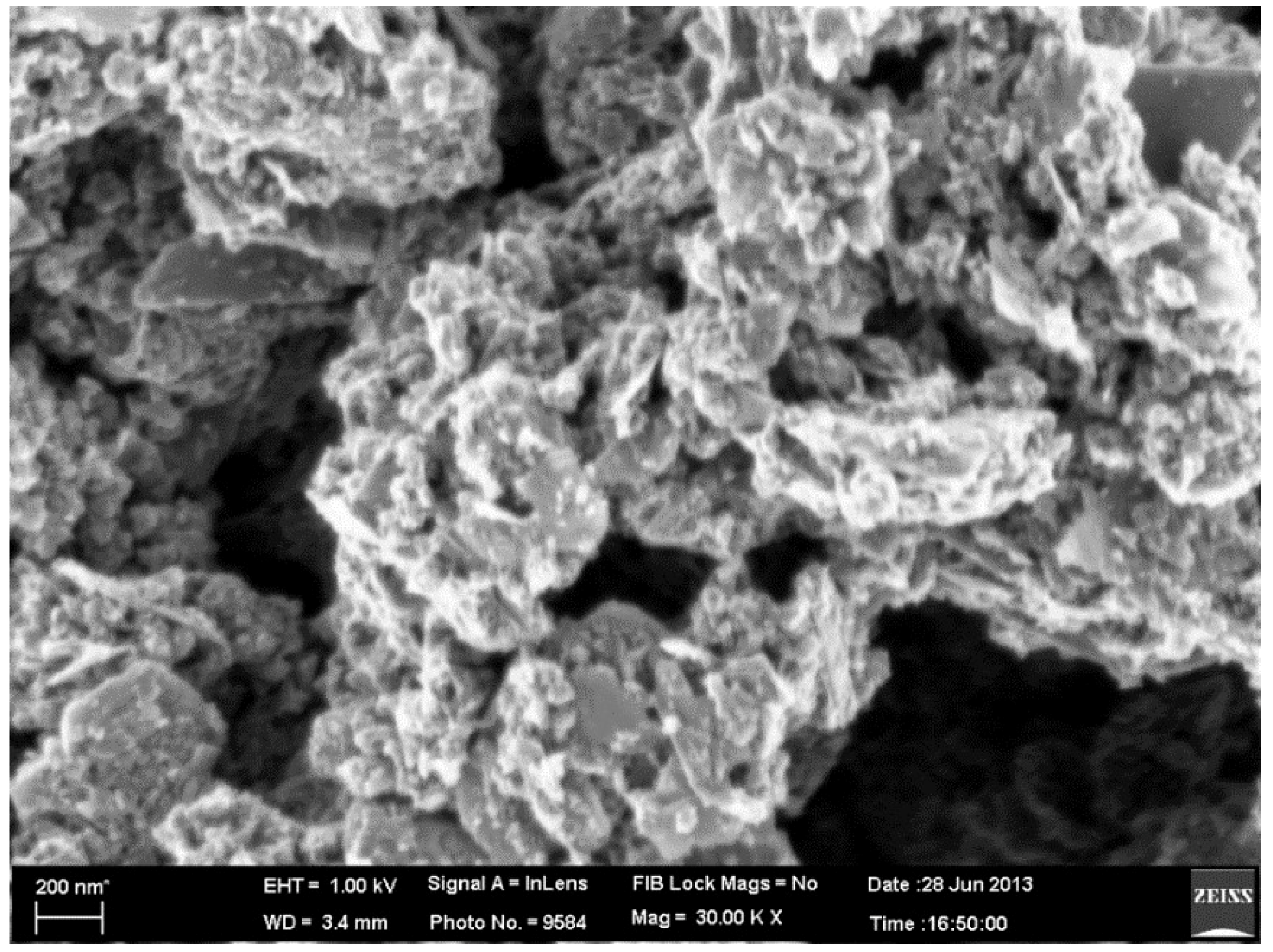

3.1. Material

3.2. Nanofluid Preparation and Stability

3.3. Experimental Setup

3.4. Testing Method

3.5. Uncertainties in Measurements

4. Results and Discussion

4.1. Efficiencies

4.2. Exergy Destruction and Entropy Generation

4.3. Pumping Power

5. Conclusions

- The outcome reveals the significant enhancement in the thermal efficiency of the setup using GNP nanofluid by 35.8% for 0.1 wt% nanoparticle concentration and volumetric flow rate at 1.5 L/min.

- The outcome reveals that by applying a GNP nanofluid in the setup, the exergetic efficiency was boosted about 20.5% in comparison with water under the same conditions.

- Pumping power increases when the concentration increases or the flow rate rises, which is not preferable. However, its impact is less noticeable compared with the rise of thermal efficiency and exergy.

- The entropy number decreases when increasing the nanofluid concentration and flow rate, which is desirable.

- The Bejan number has been observed to rise by adding nanoparticles to the base fluid.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Terminology

| A | absorbance area, m2 |

| Be | Bejan number |

| Cp | specific heat, J/kg K |

| exergy, W | |

| h | specific enthalpy, J/kg |

| k | thermal conductivity, W/m K |

| ṁ | mass flow rate, kg/s |

| Q | energy, W |

| Re | Reynolds number |

| S | received solar radiation to the plate, W/m2 |

| Ṡ | entropy rate, W/K |

| T | temperature, °C |

| wt% | weight percentage |

| Subscripts | |

| i | inlet |

| c | collector |

| o | outlet |

| in | input |

| out | output |

| u | useful |

| a | ambient |

| p | nanoparticle |

| nf | nanofluid |

| bf | base fluid |

| gen | generation |

| dest | destruction |

| Greek symbols | |

| η | efficiency (%) |

| Δ | difference |

| ρ | density, kg/m3 |

| φ | nanoparticle volume fraction, vol.% |

| μ | viscosity, mPa.s |

References

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.; Gkinis, G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew. Energy 2016, 94, 213–222. [Google Scholar] [CrossRef]

- Kasaeian, A.; Eshghi, A.T.; Sameti, M. A review on the applications of nanofluids in solar energy systems. Renew. Sustain. Energy Rev. 2015, 43, 584–598. [Google Scholar] [CrossRef]

- Gangacharyulu, D. Preparation and Characterization of Nanofluids and Some Investigation in Biological Applications. Ph.D. Thesis, Thapar University, Patiala, India, 2010. [Google Scholar]

- Said, Z.; Sajid, M.; Saidur, R.; Kamalisarvestani, M.; Rahim, N. Radiative properties of nanofluids. Int. Commun. Heat Mass Transf. 2013, 46, 74–84. [Google Scholar] [CrossRef]

- Saidur, R.; Meng, T.; Said, Z.; Hasanuzzaman, M.; Kamyar, A. Evaluation of the effect of nanofluid-based absorbers on direct solar collector. Int. J. Heat Mass Transf. 2012, 55, 5899–5907. [Google Scholar] [CrossRef]

- Colangelo, G.; Favale, E.; de Risi, A.; Laforgia, D. A new solution for reduced sedimentation flat panel solar thermal collector using nanofluids. Appl. Energy 2013, 111, 80–93. [Google Scholar] [CrossRef]

- Otanicar, T.P.; Phelan, P.E.; Prasher, R.S.; Rosengarten, G.; Taylor, R.A. Nanofluid-based direct absorption solar collector. J. Renew. Sustain. Energy 2010, 2, 033102. [Google Scholar] [CrossRef] [Green Version]

- Iranmanesh, S.; Mehrali, M.; Sadeghinezhad, E.; Ang, B.C.; Ong, H.C.; Esmaeilzadeh, A. Evaluation of viscosity and thermal conductivity of graphene nanoplatelets nanofluids through a combined experimental–statistical approach using respond surface methodology method. Int. Commun. Heat Mass Transf. 2016, 79, 74–80. [Google Scholar] [CrossRef]

- Bait, O.; Si-Ameur, M. Enhanced heat and mass transfer in solar stills using nanofluids: A review. Sol. Energy 2018, 170, 694–722. [Google Scholar] [CrossRef]

- Sadeghinezhad, E.; Mehrali, M.; Rosen, M.A.; Akhiani, A.R.; Latibari, S.T.; Mehrali, M.; Metselaar, H.S.C. Experimental investigation of the effect of graphene nanofluids on heat pipe thermal performance. Appl. Therm. Eng. 2016, 100, 775–787. [Google Scholar] [CrossRef] [Green Version]

- Esmaeilzadeh, A.; Silakhori, M.; Nik Ghazali, N.N.; Metselaar, H.S.C.; Bin Mamat, A.; Naghavi Sanjani, M.S.; Iranmanesh, S. Thermal Performance and Numerical Simulation of the 1-Pyrene Carboxylic-Acid Functionalized Graphene Nanofluids in a Sintered Wick Heat Pipe. Energies 2020, 13, 6542. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Graphene family nanofluids: A critical review and future research directions. Energy Convers. Manag. 2019, 196, 1222–1256. [Google Scholar] [CrossRef]

- Khosravi, R.; Rabiei, S.; Khaki, M.; Safaei, M.R.; Goodarzi, M. Entropy generation of graphene–platinum hybrid nanofluid flow through a wavy cylindrical microchannel solar receiver by using neural networks. J. Therm. Anal. Calorim. 2021, 145, 1949–1967. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Tlili, I.; Tian, Z.; Bakouri, M.; Safaei, M.R.; Goodarzi, M. Thermal Evaluation of Graphene Nanoplatelets Nanofluid in a Fast-Responding HP with the Potential Use in Solar Systems in Smart Cities. Appl. Sci. 2019, 9, 2101. [Google Scholar] [CrossRef] [Green Version]

- Goodarzi, M.; Kherbeet, A.S.; Afrand, M.; Sadeghinezhad, E.; Mehrali, M.; Zahedi, P.; Wongwises, S.; Dahari, M. Investigation of heat transfer performance and friction factor of a counter-flow double-pipe heat exchanger using nitrogen-doped, graphene-based nanofluids. Int. Commun. Heat Mass Transf. 2016, 76, 16–23. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y.; Reay, D. A review on graphene based nanofluids: Preparation, characterization and applications. J. Mol. Liq. 2019, 279, 444–484. [Google Scholar] [CrossRef]

- Sadeghinezhad, E.; Mehrali, M.; Saidur, R.; Mehrali, M.; Latibari, S.T.; Akhiani, A.R.; Metselaar, H.S.C. A comprehensive review on graphene nanofluids: Recent research, development and applications. Energy Convers. Manag. 2016, 111, 466–487. [Google Scholar] [CrossRef]

- Borode, A.; Ahmed, N.; Olubambi, P. A review of solar collectors using carbon-based nanofluids. J. Clean. Prod. 2019, 241, 118311. [Google Scholar] [CrossRef]

- Mansour, M.K. Thermal analysis of novel minichannel-based solar flat-plate collector. Energy 2013, 60, 333–343. [Google Scholar] [CrossRef]

- Al-Tahaineh, H.; Damseh, R. Exergy Analysis of A Single-Ended Glass Direct Flow Evacuated Tube Solar Collector. Int. J. Adv. Res. Eng. Technol. (IJARET) 2013, 4, 1–9. [Google Scholar]

- Ismail, K.; Abogderah, M. Performance of a heat pipe solar collector. J. Sol. Energy Eng. 1998, 120, 51–59. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Hu, R.-L.; Lu, L.; Zhao, F.; Xiao, H.-S. Thermal performance of an open thermosyphon using nanofluid for evacuated tubular high temperature air solar collector. Energy Convers. Manag. 2013, 73, 135–143. [Google Scholar] [CrossRef]

- Pandey, A.K. Exergy Analysis and Exergoeconomic Evaluation of Renewable Energy Conversion Systems. 2014. Available online: http://hdl.handle.net/10603/16319 (accessed on 22 July 2021).

- Ersöz, M.A. Effects of different working fluid use on the energy and exergy performance for evacuated tube solar collector with thermosyphon heat pipe. Renew. Energy 2016, 96, 244–256. [Google Scholar] [CrossRef]

- Nguyen, M.; Ziemski, M.; Vink, S. Application of an exergy approach to understand energy demand of mine water management options. J. Clean. Prod. 2014, 84, 639–648. [Google Scholar] [CrossRef] [Green Version]

- Meibodi, S.S.; Kianifar, A.; Mahian, O.; Wongwises, S. Second law analysis of a nanofluid-based solar collector using experimental data. J. Therm. Anal. Calorim. 2016, 126, 617–625. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Sahin, A.Z.; Wongwises, S. Heat Transfer, Pressure Drop, and Entropy Generation in a Solar Collector Using SiO2/Water Nanofluids: Effects of Nanoparticle Size and pH. J. Heat Transf. 2015, 137, 061011. [Google Scholar] [CrossRef]

- Said, Z.; Saidur, R.; Rahim, N. Energy and exergy analysis of a flat plate solar collector using different sizes of Aluminium oxide based nanofluid. J. Clean. Prod. 2016, 133, 518–530. [Google Scholar] [CrossRef]

- Saidur, R.; BoroumandJazi, G.; Mekhlif, S.; Jameel, M. Exergy analysis of solar energy applications. Renew. Sustain. Energy Rev. 2012, 16, 350–356. [Google Scholar] [CrossRef]

- Mehrali, M.; Sadeghinezhad, E.; Rosen, M.A.; Akhiani, A.R.; Latibari, S.T.; Mehrali, M.; Metselaar, H.S.C. Heat transfer and entropy generation for laminar forced convection flow of graphene nanoplatelets nanofluids in a horizontal tube. Int. Commun. Heat Mass Transf. 2015, 66, 23–31. [Google Scholar] [CrossRef]

- Mehrali, M.; Sadeghinezhad, E.; Akhiani, A.R.; Latibari, S.T.; Metselaar, H.S.C.; Kherbeet, A.S.; Mehrali, M. Heat transfer and entropy generation analysis of hybrid graphene/Fe3O4 ferro-nanofluid flow under the influence of a magnetic field. Powder Technol. 2017, 308, 149–157. [Google Scholar] [CrossRef]

- Alous, S.; Kayfeci, M.; Uysal, A. Experimental investigations of using MWCNTs and graphene nanoplatelets water-based nanofluids as coolants in PVT systems. Appl. Therm. Eng. 2019, 162, 114265. [Google Scholar] [CrossRef]

- Alawi, O.A.; Mohamed Kamar, H.; Mallah, A.R.; Kazi, S.N.; Sidik, N.A.C. Thermal efficiency of a flat-plate solar collector filled with Pentaethylene Glycol-Treated Graphene Nanoplatelets: An experimental analysis. Sol. Energy 2019, 191, 360–370. [Google Scholar] [CrossRef]

- Bahiraei, M.; Mazaheri, N.; Moayedi, H. Entropy generation and exergy destruction for flow of a biologically functionalized graphene nanoplatelets nanofluid within tube enhanced with a novel rotary coaxial cross double-twisted tape. Int. Commun. Heat Mass Transf. 2020, 113, 104546. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Shirazi, S.F.S.; Amiri, A.; Alehashem, M.S.; Dahari, M.; Kazi, S.N. Experimental investigation of thermo-physical properties, convective heat transfer and pressure drop of functionalized graphene nanoplatelets aqueous nanofluid in a square heated pipe. Energy Convers. Manag. 2016, 114, 38–49. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Safaei, M.R. Diurnal thermal evaluation of an evacuated tube solar collector (ETSC) charged with graphene nanoplatelets-methanol nano-suspension. Renew. Energy 2019, 142, 364–372. [Google Scholar] [CrossRef]

- Iranmanesh, S.; Ong, H.C.; Ang, B.C.; Sadeghinezhad, E.; Esmaeilzadeh, A.; Mehrali, M. Thermal performance enhancement of an evacuated tube solar collector using graphene nanoplatelets nanofluid. J. Clean. Prod. 2017, 162, 121–129. [Google Scholar] [CrossRef]

- Tong, Y.; Kim, J.; Cho, H. Effects of thermal performance of enclosed-type evacuated U-tube solar collector with multi-walled carbon nanotube/water nanofluid. Renew. Energy 2015, 83, 463–473. [Google Scholar] [CrossRef]

- Rea, U.; McKrell, T.; Hu, L.-W.; Buongiorno, J. Laminar convective heat transfer and viscous pressure loss of alumina–water and zirconia–water nanofluids. Int. J. Heat Mass Transf. 2009, 52, 2042–2048. [Google Scholar] [CrossRef]

- Ijam, A.; Saidur, R.; Ganesan, P.; Golsheikh, A.M. Stability, thermo-physical properties, and electrical conductivity of graphene oxide-deionized water/ethylene glycol based nanofluid. Int. J. Heat Mass Transf. 2015, 87, 92–103. [Google Scholar] [CrossRef]

- Said, Z.; Sajid, M.; Alim, M.; Saidur, R.; Rahim, N. Experimental investigation of the thermophysical properties of Al2O3-nanofluid and its effect on a flat plate solar collector. Int. Commun. Heat Mass Transf. 2013, 48, 99–107. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Sahin, A.Z.; Wongwises, S. Performance analysis of a minichannel-based solar collector using different nanofluids. Energy Convers. Manag. 2014, 88, 129–138. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Sahin, A.Z.; Wongwises, S. Entropy generation during Al2O3/water nanofluid flow in a solar collector: Effects of tube roughness, nanoparticle size, and different thermophysical models. Int. J. Heat Mass Transf. 2014, 78, 64–75. [Google Scholar] [CrossRef]

| Item | Dimension |

|---|---|

| Inner tube diameter | 47 mm (0.047 m) |

| Outer tube diameter | 58 mm (0.058 m) |

| Length | 1800 mm (1.8 m) |

| Material | Borosilicate glass 3.3 |

| Absorbance area | 1.14 m2 |

| Absorbance coefficient | 0.93 |

| Transmittance | 0.89 |

| Solar tubes interval | 7.5 cm |

| Heat transfer coefficient | 2.360 W/(m2·K) |

| Thickness of the glass | 1.6 mm |

| Variable | Absolute Limits | Units |

|---|---|---|

| Required ambient conditions | ||

| Incidence angle modifier | 98% < normal incident value < 102% | |

| Total solar irradiance (normal to sun) | 790 (average) | W/m2 |

| Diffuse fraction | 20 | % |

| Wind speed, u | 2.2 < u < 4.5 | m/s |

| Maximum variation of key variable | ||

| Incident angle | ±2.5 | Degree (°) |

| Ambient temperature | ±1.5 | K |

| Inlet temperature | 1 | K |

| Volume flow rate | ±0.005 | GPM |

| Total solar irradiance (normal to the surface) | ±32 | W/m2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iranmanesh, S.; Silakhori, M.; Naghavi, M.S.; Ang, B.C.; Ong, H.C.; Esmaeilzadeh, A. Using Graphene Nanoplatelets Nanofluid in a Closed-Loop Evacuated Tube Solar Collector—Energy and Exergy Analysis. J. Compos. Sci. 2021, 5, 277. https://doi.org/10.3390/jcs5100277

Iranmanesh S, Silakhori M, Naghavi MS, Ang BC, Ong HC, Esmaeilzadeh A. Using Graphene Nanoplatelets Nanofluid in a Closed-Loop Evacuated Tube Solar Collector—Energy and Exergy Analysis. Journal of Composites Science. 2021; 5(10):277. https://doi.org/10.3390/jcs5100277

Chicago/Turabian StyleIranmanesh, Soudeh, Mahyar Silakhori, Mohammad S. Naghavi, Bee C. Ang, Hwai C. Ong, and Alireza Esmaeilzadeh. 2021. "Using Graphene Nanoplatelets Nanofluid in a Closed-Loop Evacuated Tube Solar Collector—Energy and Exergy Analysis" Journal of Composites Science 5, no. 10: 277. https://doi.org/10.3390/jcs5100277

APA StyleIranmanesh, S., Silakhori, M., Naghavi, M. S., Ang, B. C., Ong, H. C., & Esmaeilzadeh, A. (2021). Using Graphene Nanoplatelets Nanofluid in a Closed-Loop Evacuated Tube Solar Collector—Energy and Exergy Analysis. Journal of Composites Science, 5(10), 277. https://doi.org/10.3390/jcs5100277