Insights into the Processing of Recycled Carbon Fibers via Injection Molding Compounding

Abstract

:1. Introduction

1.1. Recycling of Carbon Fibers and Fiber-Reinforced Plastics

1.2. Short Fiber Reinforced Thermoplastics

1.3. Recycling of Plastics

1.4. Aim

2. Experimental

2.1. Plastics Recycling

2.2. Carbon Fiber Recycling

2.2.1. Selection of Fibers

2.2.2. Sizing

2.2.3. Sliver Production

2.3. Production of Test Specimens

2.4. Characterization of Test Specimens

2.5. Summary of the Production Steps

- -

- A staple fiber hybrid sliver, containing recycled carbon fibers (product scraps) and recycled PA6 fibers, is created and analyzed. Since product scraps are used, no additional sizing is applied to the fibers, and no information about the previous sizing is available.

- -

- An IMC then produces recycling fiber-reinforced parts for evaluation. Virgin PA6 is mixed with recycled PA6 in various ratios. The sliver is added to the matrix via a direct feed module.

3. Results

3.1. Sliver Characterization

3.2. Preliminary Investigations of Fiber Content in Relation to the Process Settings

3.3. Fiber Content

3.4. Fiber Length

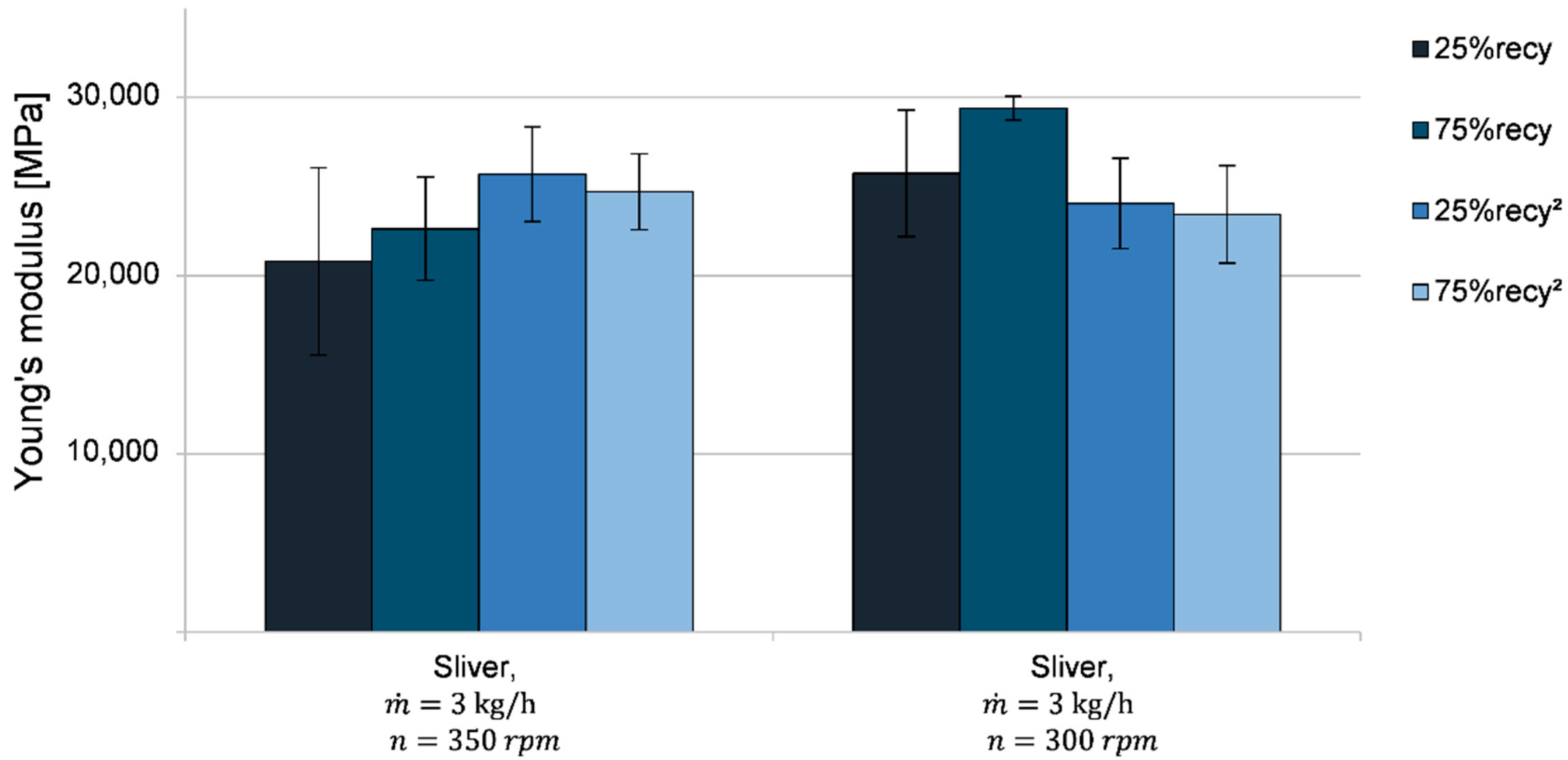

3.5. Mechanical Properties

4. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Meng, F.; Olivetti, E.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pickering, S.J.; Liu, Z.; Turner, T.; Wong, K. Applications for carbon fibre recovered from composites. Iop Conf. Ser. Mater. Sci. Eng. 2016, 139, 012005. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Pickering, S. Recycling technologies for thermoset composite materials—current status. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Schürmann, H. Konstruieren mit Faser-Kunststoff-Verbunden; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Truckenmüller, F. Direktverarbeitung von Endlosfasern auf Spritzgießmaschinen. Möglichkeiten und Grenzen. Dissertation, Universität Stuttgart, Stuttgart, Germany, 1996. [Google Scholar]

- Widmayer, S.; Fritz, H.-G.; Bonten, C. Spritzgießcompoundieren: Feuchte vereinzelt Naturfasern. Kunststoffe Munchen. 2012, 12, 71–74. [Google Scholar]

- Willems, F.; Bonten, C. Influence of processing on the fiber length degradation in fiber reinforced plastic parts. In Proceedings of the 34th International Conference of the Polymer Processing Society, Gratz, Austria, 14 December 2015; AIP Publishing: Melville, NY, USA, 2016; Volume 1779, p. 020003. [Google Scholar]

- Wellekötter, J.; Christian, B. Comparison of fiber-reinforced recycled polyamide in single stage and two stage injection molding. Polym. Compos. 2018, 40, 1731–1739. [Google Scholar] [CrossRef]

- Bonten, C. Plastics Technology—Introduction and Fundamentals; Hanser: Munich, Germany, 2019. [Google Scholar]

- Witten, E.; Kraus, T.; Kühnel, M. Composites-Marktbericht 2016. Available online: https://elib.dlr.de/106030/ (accessed on 15 September 2020).

- Gardiner, G. Closing the CFRP lifecycle loop. Recycled carbon fiber update. Compos. World 2014, 28–33. [Google Scholar]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050. Resour. Conserv. Recycl. 2017, 125, 264–272. [Google Scholar] [CrossRef]

- Pillain, B.; Loubet, P.; Pestalozzi, F.; Woidasky, J.; Erriguible, A.; Aymonier, C.; Sonnemann, G. Positioning supercritical solvolysis among innovative recycling and current waste management scenarios for carbon fiber reinforced plastics thanks to comparative life cycle assessment. J. Supercrit. Fluids 2019, 154, 104607. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef] [Green Version]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Manson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part. A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Naqvi, S.; Prabhakara, H.M.; Bramer, E.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Wong, K.; Rudd, C.; Pickering, S.; Sandinge, A. Composites recycling solutions for the aviation industry. Sci. China Ser. E Technol. Sci. 2017, 60, 1291–1300. [Google Scholar] [CrossRef]

- Hofmann, M.; Gulich, B. Verarbeitung von rezyklierten Carbonfasern für die Herstellung von Verbundbauteilen. Light. Des. 2013, 6, 20–23. [Google Scholar] [CrossRef]

- Jacob, A. Composites can be recycled. Reinf. Plast. 2011, 55, 45–46. [Google Scholar] [CrossRef]

- Hengstermann, M.; Raithel, N.; Abdkader, A.; Hasan, M.; Cherif, C. Development of new hybrid yarn construction from recycled carbon fibers for high performance composites. Part-I: Basic processing of hybrid carbon fiber/polyamide 6 yarn spinning from virgin carbon fiber staple fibers. Text. Res. J. 2015, 86, 1307–1317. [Google Scholar] [CrossRef] [Green Version]

- Longana, M.L.; Ong, N.; Yu, H.; Potter, K.D. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef] [Green Version]

- Reichert, O.; Ausheyks, L.; Baz, S.; Hehl, J.; Gresser, G.T. Innovative rC Staple Fiber Tapes - New Potentials for CF Recyclates in CFRP through Highly Oriented Carbon Staple Fiber Structures. Key Eng. Mater. 2019, 809, 509–514. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Osswald, T.A.; Menges, G. Materials Science of Polymers for Engineers, 3rd ed.; Hanser: München, Germany, 2012. [Google Scholar]

- Thomason, J. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part. A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Martens, H. Recyclingtechnik. Fachbuch für Lehre und Praxis; Spektrum: Heidelberg, Germany, 2011. [Google Scholar]

- Johannaber, F.; Michaeli, W. Handbuch Spritzgießen, 2nd ed.; Hanser: München, Germany, 2004. [Google Scholar]

- Maspoch, M.L.; Ferrando, H.E.; Velasco, J.I. Characterisation of filled and recycled PA6. Macromol. Symp. 2003, 194, 295–304. [Google Scholar] [CrossRef]

- Henning, F.; Moeller, E. Handbuch Leichtbau. Methoden, Werkstoffe, Fertigung; Hanser: München, Germany, 2011. [Google Scholar]

- Hopmann, C.; Michaeli, W. Einführung in die Kunststoffverarbeitung, 7th ed.; Hanser: München, Germany, 2015. [Google Scholar]

- Wolters, L. (Ed.) Kunststoff-Recycling; Hanser: München, Germany, 1997. [Google Scholar]

- Crespo, J.; Parres, F.; Peydro, M.; Navarro, R. Study of rheological, thermal, and mechanical behavior of reprocessed polyamide 6. Polym. Eng. Sci. 2012, 53, 679–688. [Google Scholar] [CrossRef] [Green Version]

- Su, K.-H.; Lin, J.-H.; Lin, C.-C. Influence of reprocessing on the mechanical properties and structure of polyamide 6. J. Mater. Process. Technol. 2007, 192–193, 532–538. [Google Scholar] [CrossRef]

- Formisano, B.; Göttermann, S.; Bonten, C. Recycling of cast polyamide waste on a twin-screw-extruder. In Proceedings of the 34th International Conference of the Polymer Processing Society, Lyon, France, 25–29 July 2016; AIP Publishing: Melville, NY, USA, 2016; Volume 140002. [Google Scholar]

- Moritzer, E.; Heiderich, G.; Hirsch, A. Fiber length reduction during injection molding. In Proceedings of the AIP Conference 2055, Dresden, Germany, 27–29 June 2017; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Cieslinski, M. Using a Sliding Plate Rheometer to Obtain Material Parameters for Simulating Long Fiber Orientation in Injection Molded Composites. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2015. [Google Scholar]

- Sarasua, J.R.; Remiro, P.M.; Pouyet, J. The mechanical behaviour of PEEK short fibre composites. J. Mater. Sci. 1995, 30, 3501–3508. [Google Scholar] [CrossRef]

| Type | Carbiso C60/90 Pyrolyzed and Cut Rovings | Carbiso CT60/90 Cut Rovings | ||

|---|---|---|---|---|

| Picture |  |  | ||

| Fiber Fineness | Sample: | 0.81 dtex | Sample: | 0.83 dtex |

| 10 kg batch: | 0.70 dtex | 10 kg batch: | 0.82 dtex | |

| Sizing Amount | Sample: | 0.0% | Sample: | 1.4% |

| 10 kg batch: | 0.0% | 10 kg batch: | 0.8% | |

| Tenacity | Sample: | 3140 MPa | Sample: | 3100 MPa |

| 10 kg batch: | 3620 MPa | 10 kg batch: | 3830 MPa | |

| Mean Fiber Length | Sample: | 46.5 mm | Sample: | 47.5 mm |

| 10 kg batch: | 101.0 mm | 10 kg batch: | 41.0 mm | |

| Sizing | Mass of PA6 in g | Mass of Carbon Fibers in g | Mass after Processing in g | Loss in % |

|---|---|---|---|---|

| Silastol CF1/CF2 | 222 | 235 | 331 | 28 |

| Stantex S 6256 PC | 222 | 235 | 349 | 24 |

| Roving Sections | 222 | 235 | 188 | 59 |

| Unsized | 222 | 235 | 0 | 100 |

| Type of Fiber | Mass throughput (kg/h) | Screw Speed (rpm) | Calculated Fiber Content (wt-%) |

|---|---|---|---|

| Reinforced Carbon Fiber | 4 | 160 | 30 |

| 4 | 100 | 25 | |

| 5 | 100 | 20 | |

| Recycled Staple Fiber Sliver | 3 | 200 | - |

| 3 | 300 | - | |

| 3 | 400 | - |

| Type of Fiber | Fiber Content (wt-%) | Averaged Fiber Length (mm) |

|---|---|---|

| Roving | 26 | 0.33 |

| Sliver | 27 | 0.20 |

| Sliver | 31 | 0.32 |

| Glass Fiber | 23 | 1.06 |

| Glass Fiber | 31 | 0.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wellekötter, J.; Resch, J.; Baz, S.; Gresser, G.T.; Bonten, C. Insights into the Processing of Recycled Carbon Fibers via Injection Molding Compounding. J. Compos. Sci. 2020, 4, 161. https://doi.org/10.3390/jcs4040161

Wellekötter J, Resch J, Baz S, Gresser GT, Bonten C. Insights into the Processing of Recycled Carbon Fibers via Injection Molding Compounding. Journal of Composites Science. 2020; 4(4):161. https://doi.org/10.3390/jcs4040161

Chicago/Turabian StyleWellekötter, Jochen, Julia Resch, Stephan Baz, Götz Theo Gresser, and Christian Bonten. 2020. "Insights into the Processing of Recycled Carbon Fibers via Injection Molding Compounding" Journal of Composites Science 4, no. 4: 161. https://doi.org/10.3390/jcs4040161

APA StyleWellekötter, J., Resch, J., Baz, S., Gresser, G. T., & Bonten, C. (2020). Insights into the Processing of Recycled Carbon Fibers via Injection Molding Compounding. Journal of Composites Science, 4(4), 161. https://doi.org/10.3390/jcs4040161